LD-603 Series

LED displays

Flat displays

LD-603 Series

The LD-603 series were designed in response to the

need for large, flat displays. These are two-chip, flat

displays with high luminance.

!

Features

1) 6.8×13.8mm planar emission from two chips

connected in series.

2) High luminance, uniform planar emission

3) Thin outer casing, multiple units can be coupled

together.

4) Four colors are available : red, orange, yellow and

green.

!!!!

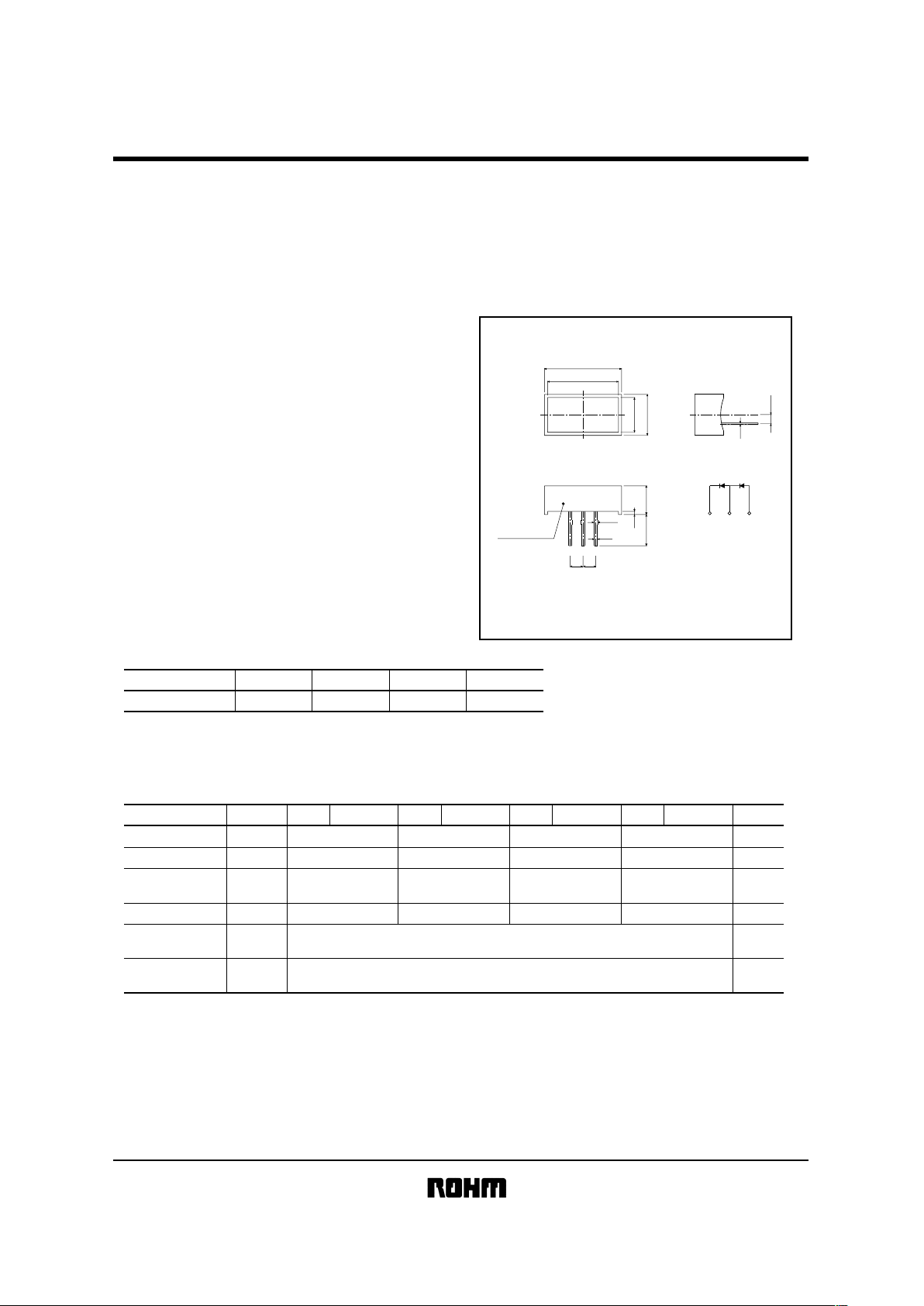

External Dimensions

(Units : mm)

Tolerances are ±0.3 unless otherwise noted :

(1.8)

0.3

0.6

(0.7)

(2.5)

(2.5)

6.7±0.5 5.6±0.2

0.6

15.0

13.8±0.2

6.8±0.2

8.0

Cathode mark

Pin No.1 2 3

Pin No.1 2 3

!!!!

Selection guide

Red

LD-603VR

Orange

LD-603DU ∗

Yellow

LD-603YY ∗

Green

LD-603MG

Emitting color

Type

∗ Order-based production.

!!!!

Absolute maximum ratings

(Ta=25°C)

Parameter

Symbol

Red

Unit

LD-603VR Orange LD-603DU

Yellow LD-603YY Green LD-603MG

mW

mA

mA

V

˚C

˚C

P

D

I

F

I

FP

V

R

Topr

Tstg

Power dissipation

Forward current

Peak forward

current

Reverse voltage

Operating

temperature

Storage

temperature

120

20

60

∗

60

∗

60

∗

60

∗

3

120

20

3

120

20

3

150

25

3

−25∼+75

−30∼+85

∗

Pulse width 1ms duty 1 / 5

LD-603 Series

LED displays

!!!!

Electrical and optical characteristics

(Ta=25°C)

Parameter Symbol

Red Orange Yellow Green

UnitConditions

Min. Typ. Max. Min. Typ. Max.

5.6 V

µA

nm

nm

4.05.64.0

650

40

10

610

40

10

−

−−

−

−

−

−

−

−−

−

−

−−

Min. Typ. Max.

5.64.2

585

40

10

−

−−

−

−

−−

Min. Typ. Max.

5.64.2

563

40

10

−

−−

−

−

−−

I

F

=

10mA

V

R

=

3V

I

F

=

10mA

I

F

=

10mA

V

F

I

R

λ

P

∆λ

Forward voltage

Reverse current

Peak wavelength

Spectral line half

width

Electrical and optical are guaranteed values per element.

!!!!

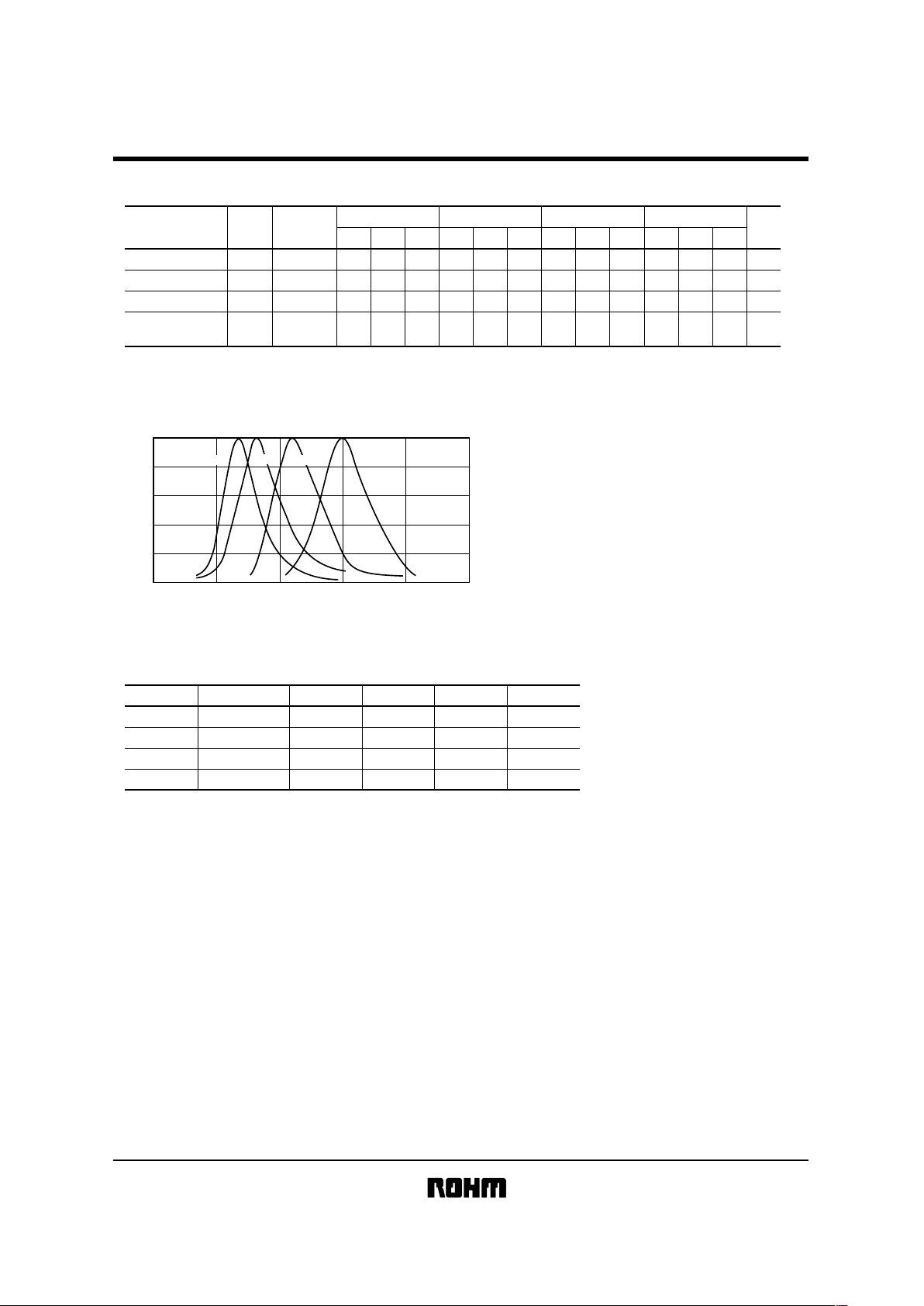

Luminous intensity vs. wavelength

1.0

0.8

0.6

0.4

0.2

0

500 550 600 650 700 750

Axial Luminous Intensity

Wavelength : λ

P

(

nm)

Green Yellow

Orange

Red

!!!!

Luminous intensity

Color

Orange

Yellow

Green

Type

LD-603VR

LD-603DU

LD-603YY

LD-603MG

Red

Min.

2.2

1.4

2.2

2.2

Typ.

6.3

4.0

6.3

6.3

Max.

−

−

−

−

Unit

mcd

mcd

mcd

mcd

Note 1: Measured at IF = 10mA

Note 2: Current passes through 2 elements.

!!!!

Operation notes

When forming leads, the bend should be at least 2 mm from the base of the package. Solder after forming the leads, and

ensure that the inside of the LED is not subjected to mechanical stress while it is hot.

Loading...

Loading...