090FS

Serial-in / Parallel-out Driver Series

Serial / Parallel

2-input Drivers

BU2098F, BU2090F, BU2090FS

No.11051EBT04

●Description

Serial-in-parallel-out driver is a open drain output driver. It incorporates a built-in shift register and a latch circuit to turn on a

maximum of 12 LED by a 2-line interface, linked to a microcontroller.

A open drain output provides maximum of 25mA current.

●Features

1) LED can be driven directly. (Output current 25mA)

2) 8/12 Bit parallel output

3) This product can be operated on low voltage.

4) Compatible with I

2

C BUS. (BU2098)

●Use

For AV equipment such as, audio stereo sets, videos and TV sets, PCs, control microcontroller mounted equipment.

●Line up

Parameter BU2098F BU2090F BU2090FS Unit

Output current 25 25 mA

Output line 8 12 lines

Package SOP16 SOP16 SSOP-A16 -

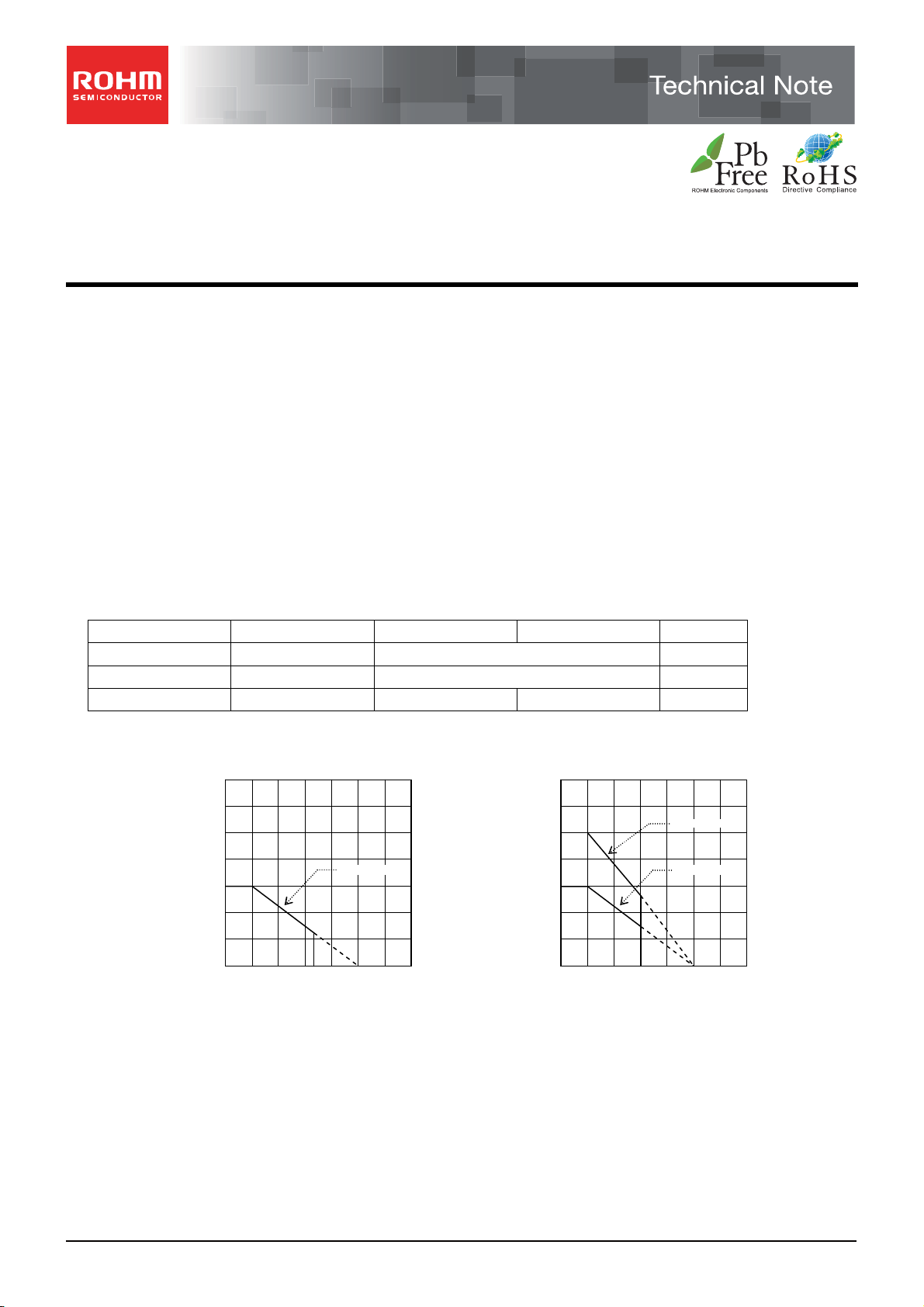

●Thermal derating curve

700

600

500

400

300

200

Power dissipation Pd [mW]

100

0

25 50

85℃

75 100

BU2098F

125 150

175

700

600

BU2

BU2090F

125 150

175

500

400

300

200

Power dissipation Pd [mW]

100

0

25 50

75 100

Ambient temperature Ta [℃]

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

1/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

●Electrical characteristics

BU2098F (unless otherwise noted, VDD=5V, Vss=0V, Ta=25℃)

Parameter Symbol Min. Typ. Max. Unit Condition

Input High-level voltage VIH 0.7×VDD - - V

Technical Note

Input Low-level voltage VIL - - 0.3×VDD V

Output Low-level voltage VOL - - 0.4 V IOUT=10mA

Input Low-level current IIL - 2.0 μA VIN=0

Input High-level current IIH - - -2.0 μA VIN=VDD

Output leakage current IOZ - - ±5.0 μA

Static dissipation current IDD - - 2.0 μA

Output=High impedance

OUT=VDD

V

BU2090F/BU2090FS (unless otherwise noted, V

DD=5V, VSS=0V, Ta=25℃)

Parameter Symbol Min. Typ. Max. Unit Condition

Input High-level voltage VIH

Input Low-level voltage VIL

Output Low-level voltage VOL

3.5 - - V V

2.5 - - V VDD=3V

- - 1.5 V V

- - 0.4 V VDD=3V

- - 2.0 V V

- - 1.0 V VDD=3V,IOL=5mA

DD=5V

DD=5V

DD=5V,IOL=20mA

“H” output disable current IOZH - - 10 μA VO=25V

“L” output disable current IOZL - -5.0 μA VO=0V

Static dissipation current IDD

- - 5.0 μA VDD=5V

3.0 μA VDD=3V

●Operating conditions (Ta=25℃, VSS=0V)

Parameter Symbol

BU2098F BU2090F/BU2090FS

Limits

Unit

Power Supply Voltage VDD +2.7 to 5.5 V

Output Voltage Vo 0 to +15 0 to +25 V

●Absolute maximum ratings

BU2098F, BU2090F,BU2090FS

Parameter Symbol

BU2098F BU2090F BU2090FS

Limits

Unit

Power supply voltage VDD -0.5 to +7.0 -0.3 to +7.0V V

Power dissipation1 Pd1 300 *1 300 *1 500 *2

Power dissipation2 Pd2 - 500 *3 650 *4

mW

Operating temperature range Topr -40 to +85 ℃

Storage temperature range Tstg -55 to +125 ℃

Output voltage Vo VSS to +18.0 VSS-0.3 to +25V V

Input voltage VIN -0.5 to VDD+0.5 VSS-0.3 to VDD+0.3V V

Allowable loss of single unit

* Reduced by 3mW/℃ over 25℃. (BU2098F)

1

*

Reduced by 3mW/℃ over 25℃.

2

*

Reduced by 5mW/℃ over 25℃.

3

*

Reduced by 5.0mW for each increase in Ta of 1℃ over 25℃.(When mounted on a board 70mm×70mm×1.6mm Glass-epoxy PCB)

4

*

Reduced by 6.5mW for each increase in Ta of 1℃ over 25℃.(When mounted on a board 70mm×70mm×1.6mm Glass-epoxy PCB)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

2/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

●Pin descriptions

BU2098F

PIN No. Pin Name I/O Function

1 A0 I

3 A2 I

4 Q0

5 Q1

6 Q2

O Open drain output

7 Q3

8 VSS - GND

9 Q4

10 Q5

11 Q6

O Open drain output

12 Q7

13 N.C. - Non connected

14 SCL I

15 SDA I/O

16 VDD -

BU2090F/BU2090FS

PIN No. Pin Name I/O Function

1 VSS - GND

2 DATA I Serial data input

3 CLOCK I

4 Q0

5 Q1

6 Q2

7 Q3

8 Q4

9 Q5

10 Q6

O

11 Q7

12 Q8

13 Q9

14 Q10

15 Q11

16 VDD -

Technical Note

Address input, internally pull-up 2 A1 I

Serial clock input

Serial data input/output

Power supply

Data shift clock input (rising edge trigger)

The shift data is transferred to the output when the input data logic

level is high during the falling transition of the clock pulse.

Parallel data output (Nch Open Drain FET)

Latch data L H

Output FET ON OFF

Power supply

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

3/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

A

A

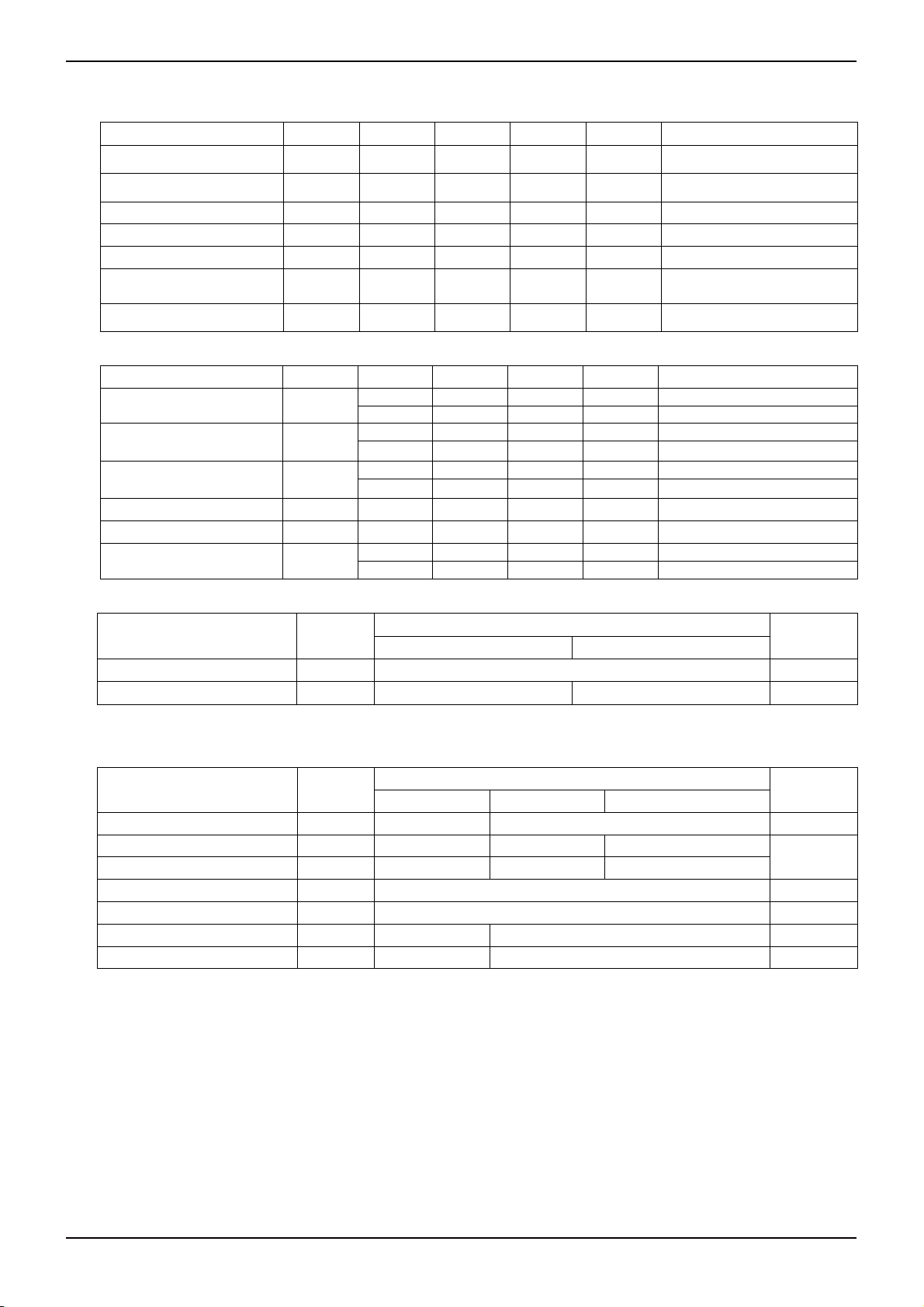

●Block diagram

BU2098F

Power-On Reset

SD

SCL

A0

A1

A2

I2C BUS

Controller

BU2090F/BU2090FS

CLOCK

Controller

DAT

●Interfaces

BU2090F/BU2090FS BU2090F/BU2090FS BU2098F

DATA, CLOCK Q0~Q11 Q0~Q7

V

V

DD

DD

IN

GND (V

)

SS

GND (V

)

SS

BU2098F BU2098F BU2098F

A0~A2 SDA SCL

V

V

DD

VDD

DD

IN

GND (V

)

GND (VSS)

SS

GND (V

SS

Technical Note

Shift

8bit

Register

Shift

12bit

Register

OUT

GND (VSS)

V

DD

IN

GND (V

)

)

GND (VSS)

SS

GND (V

)

SS

L

a

t

c

h

L

a

t

c

h

IN

GND (V

Write

Buffer

Write

Buffer

GND (VSS)

)

SS

Q0~Q11

OUT

V

DD

GND (V

Q0~Q7

)

SS

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

4/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

Technical Note

【BU2098F】

●AC characteristics (Unless otherwise noted, VDD=5V, VSS=0V, Ta=25℃)

2

Parameter Symbol

Fast mode I

Min. Max. Min. Max.

C BUS Standard mode I2C BUS

Unit

SCL clock frequency fSCL 0 400 0 100 kHz

Bus free time between start-stop condition tBUS 1.3 - 4.7 - μs

Hold time start condition tHD:STA 0.6 - 4.0 - μs

Low period of the SCL clock tLOW 1.3 - 4.7 - μs

High period of the SCL clock tHIGH 0.6 - 4.0 - μs

Set up time Re-start condition tSU:STA 0.6 - 4.7 - μs

Data hold time tHD:DAT 0 0.9 0 - μs

Data set up time tSU:DAT 100 - 250 - ns

Rise time of SDA and SCL tR 20+0.1Cb 300 - 1000 ns

Fall time of SDA and SCL tF 20+0.1Cb 300 - 300 ns

Set up time stop condition tSU:STO 0.6 - 4.0 - μs

Capacitive load for SDA line and SCL line Cb - 400 - 400 pF

●Timing chart

SDA

SCL

tBUS

tHD:STA

tLOW

tr

P

S

tHD:STA

tHD:DAT

tf

tSU:DAT

tSU:STA

Sr

tSU:STO

P

Fig.1 SDA, SCL timing chart

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

5/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

A

Technical Note

●Function

○Start condition

The start condition is a “HIGH” to “LOW” transition of the SDA line while SCL is “HIGH”.

○Stop condition

The stop condition is a “LOW” to “HIGH” transition of the SDA line while SCL is “HIGH”.

SD

SCL

S

Star t

condition

P

Stop

condition

Fig.2 Start / Stop condition

○Acknowledge

The master (μp) puts a resistive “HIGH” level on the SDA line during the acknowledge clock pulse. The peripheral (audio

processor) that acknowledge has to pull-down (“LOW”) the SDA line during the acknowledge clock pulse, so that the SDA

line is stable “LOW” during this clock pulse.

The slave which has been addressed has to generate an acknowledgement after the reception of each byte, otherwise the

SDA line remains at the “HIGH” level during the ninth clock pulse time. In this case the master transmitter can generate the

STOP information in order to abort the transfer.

SCL

(from master)

1

clock for acknowledge

9 8

SDA

(from master)

SDA

(from slave)

S

not confirm

confirm

ACK signal

Fig.3 Acknowledge

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

Technical Note

○Write DATA

Send the stave address from master following the start condition (S). This address consists of 7 bits. The left 1 bit (the foot

bit) is fixed “0”. The stop condition (P) is needed to finish the data transferred. But the re-send starting condition (Sr)

enables to transfer the data without STOP (P).

slave address R/W ACK

S

slave address R/W ACK

S

“0” (Write)

“0” (Write)

DATA

DATA

ACK

ACK Sr

P

slave address

R/W ACK

“0” (Write)

DATA

ACK P

Fig.4 DATA transmit

○Data format

The format is following.

S A6 A5 A4 A3 A2 A1 A0 R/W ACK D6 D5 D4 D3 D2 D1 D0 D7 ACK P

SLAVE ADDRESS WRITE DATA

Table 1 for WRITE format

A0~A2 Each bit can be defined by the input levels of pins A0~A3.

Slave address

A3~A6 These 4 bits are fixed.

R/W “0”

Write Data D0~D7

A6 A5 A4 A3 A2 A1 A0 Slave address

0 1 1 1 0 0 0 38H

0 1 1 1 0 0 1 39H

0 1 1 1 0 1 0 3AH

0 1 1 1 0 1 1 3BH

0 1 1 1 1 0 0 3CH

0 1 1 1 1 0 1 3DH

0 1 1 1 1 1 0 3EH

0 1 1 1 1 1 1 3FH

Fixed for BU2098F

Write “1” to D0 makes Q0 pin High-impedance. And write “0” makes Q0 pin

LOW. D[1:7] and Q[1:7] are same as D0 and Q0.

Table 2 for (A2, A1, A0) to SLAVE ADDRESS

Defined by external pin A0~A2

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

7/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

○Data transmission timing

SDA

S A6 A5 A4 A3 A2 A1 A0 R/W ACK D6 D5 D4 D3 D2 D1 D0 D7 ACK P

Slave address Write data

Latch pulse

Output (Q7~Q0)

Output the write data to Q7~Q0 at the same time.

Fig.5 Timing chart for WRITE

Command sample for driving LEDs. These are all off. (terminal A0~A2 is open)

Power Supply ON

LEDs all-ON with power supply ON

SDA

S 0 1 1 1 1 1 1 0 ACK 1 1 1 1 1 1 1 1 ACK P

Slave address Write data

LEDs are all-off by this command.

・RESET CONDITION

After reset, Q0~Q7 pins are ON. (LEDs are all ON.)

・RISING TIME OF POWER SUPPLY

V

DD must rise within 10ms. If the rise time would exceed 10ms, it is afraid not to reset the BU2098F.

VDD

GND

t≦10ms

Fig.6 Rising time of power supply

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

8/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

【BU2090F/BU2090FS】

●AC characteristics (unless otherwise noted, VDD=5V, VSS=0V, Ta=25℃)

Parameter Symbol

Minimum clock frequency tw

Data shift set up time tSU

Data shift hold time tH

Data latch set up time tLSUH

Data latch hold time tLHH

Data latch ”L”

set up time

Data latch ”L”

hold time

LSUL

t

t

LHL

Min. Typ. Max.

500 - - ns V

1000 - - ns VDD=3V

200 - - ns V

300 - - ns VDD=3V

200 - - ns V

400 - - ns VDD=3V

50 - - ns V

100 - - ns VDD=3V

250 - - ns V

500 - - ns VDD=3V

200 - - ns V

400 - - ns VDD=3V

250 - - ns V

500 - - ns VDD=3V

Limit

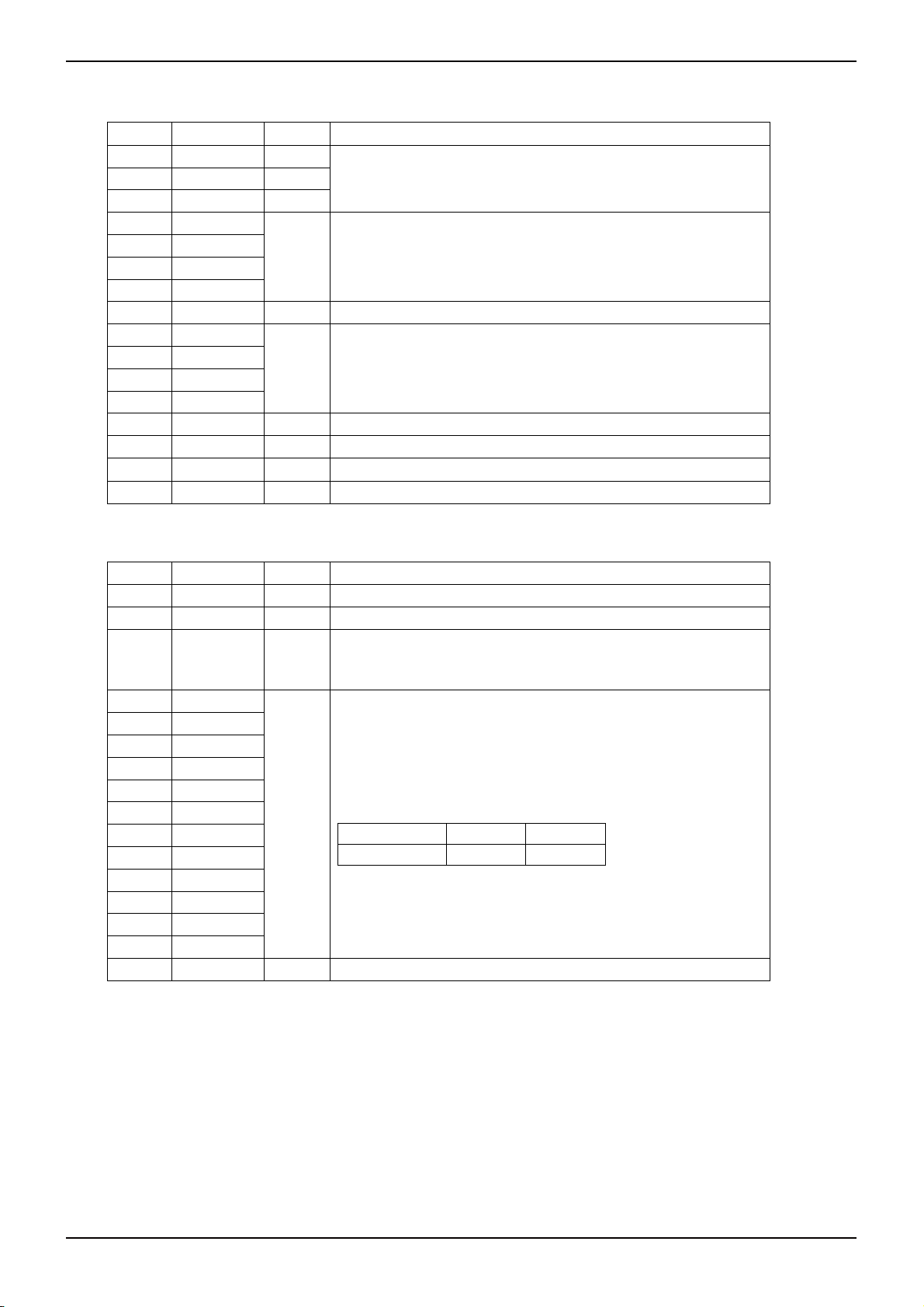

●Switching time test circuit

Pulse

Gen.

VDD

Q0

CLOCK

Pulse

Gen.

DATA

Q11

Technical Note

Unit Condition

DD=5V

DD=5V

DD=5V

DD=5V

DD=5V

DD=5V

DD=5V

±25V

RL 10kΩ

±25V

RL 10kΩ

●Switching time test waveforms

90%

CLOCK

10% 10% 10% 10%

90%

DATA

tW tW

90%

tHtSU

90%

10% 10%

GND (Vss)

Fig.7

Fig.8

DD

90%

tLSUH tLHHtLSUL tLHL

90%

90%

V

GND (Vss)

VDD

GND (Vss)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

9/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

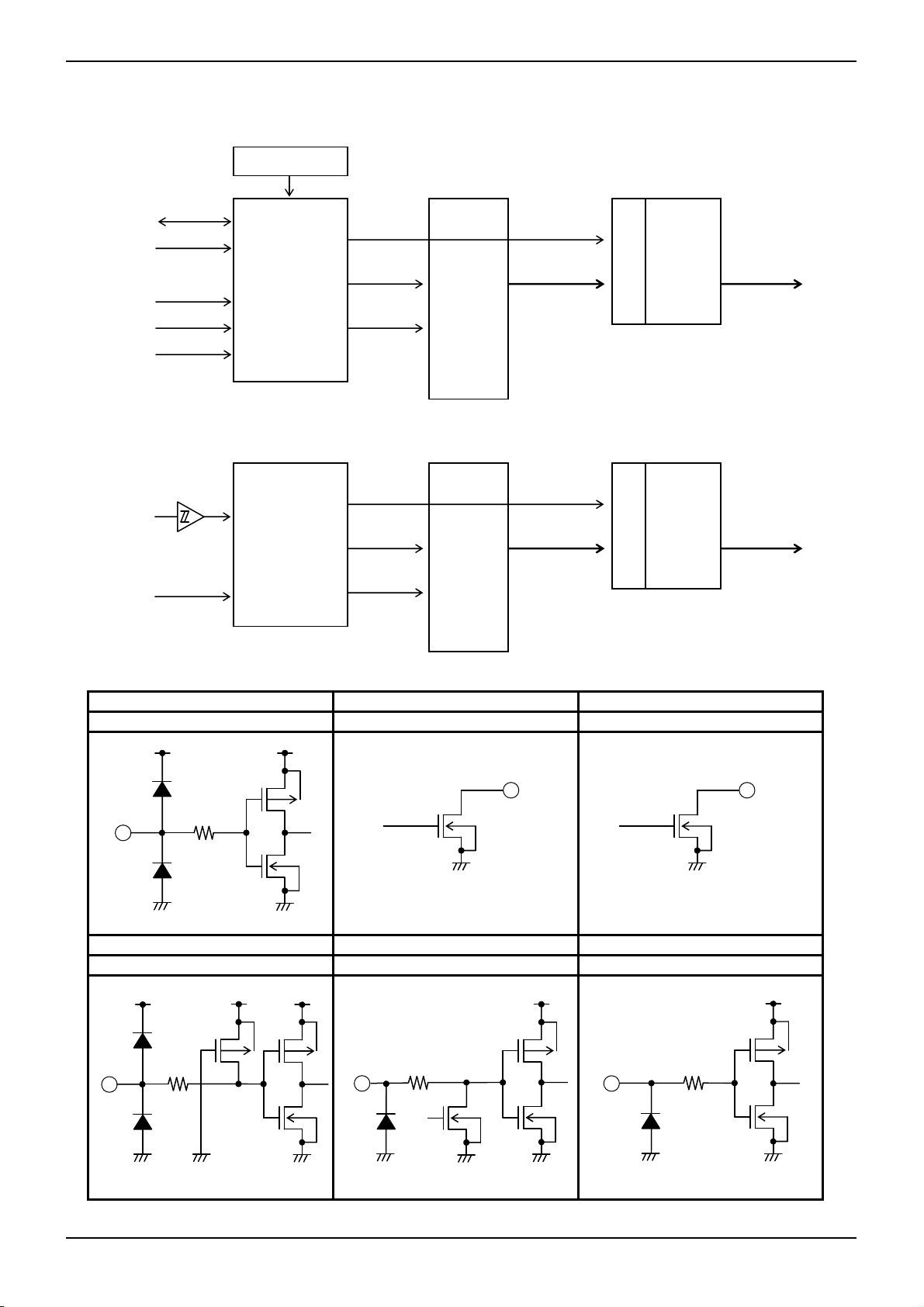

●Timing chart

【BU2098F】

Slave address

Device code

SCL

Start condition Stop condition

SDA

V

CC

Q7

Q6

1 2 3 4 5 6 7

A6 A5 A4A3

Q5

Q4

Q3

Q2

Q1

Q0

【BU2090F/BU2090FS】

CLOCK

DATA

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Q11

Q10

Q9

Q8

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

Technical Note

External terminal

8

9 12345678 9

A2 A1 A0RW

Note) Diagram shows a status where a pull-up resistor is connected to output.

ACK

D7

D6

D5

D4 D3 D2 D1 D0 ACK

Note1) Indicates undefined output.

Note2) Output terminal is provided with a pull-up resistor.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

10/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

●Notes for use

1. Absolute maximum ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can

break down the devices, thus making impossible to identify breaking mode, such as a short circuit or an open circuit. If any

over rated values will expect to exceed the absolute maximum ratings, consider adding circuit protection devices, such as

fuses.

2. Connecting the power supply connector backward

Connecting of the power supply in reverse polarity can damage IC. Take precautions when connecting the power supply

lines. An external direction diode can be added.

3. Power supply lines

Design PCB layout pattern to provide low impedance GND and supply lines. To obtain a low noise ground and supply line,

separate the ground section and supply lines of the digital and analog blocks. Furthermore, for all power supply terminals

to ICs, connect a capacitor between the power supply and the GND terminal. When applying electrolytic capacitors in the

circuit, not that capacitance characteristic values are reduced at low temperatures.

4. GND voltage

The potential of GND pin must be minimum potential in all operating conditions.

5. Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating conditions.

6. Inter-pin shorts and mounting errors

Use caution when positioning the IC for mounting on printed circuit boards. The IC may be damaged if there is any

connection error or if pins are shorted together.

7. Actions in strong electromagnetic field

Use caution when using the IC in the presence of a strong electromagnetic field as doing so may cause the IC to

malfunction.

8. Testing on application boards

When testing the IC on an application board, connecting a capacitor to a pin with low impedance subjects the IC to stress.

Always discharge capacitors after each process or step. Always turn the IC's power supply off before connecting it to or

removing it from a jig or fixture during the inspection process. Ground the IC during assembly steps as an antistatic

measure. Use similar precaution when transporting or storing the IC.

9. Ground Wiring Pattern

When using both small signal and large current GND patterns, it is recommended to isolate the two ground patterns,

placing a single ground point at the ground potential of application so that the pattern wiring resistance and voltage

variations caused by large currents do not cause variations in the small signal ground voltage. Be careful not to change the

GND wiring pattern of any external components, either.

10. Unused input terminals

Connect all unused input terminals to VDD or VSS in order to prevent excessive current or oscillation.

Insertion of a resistor (100kΩ approx.) is also recommended.

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

11/12

2011.12 - Rev.B

BU2098F, BU2090F, BU2090FS

●Ordering part number

B U 2 0 9 0 F S - E 2

Technical Note

Part No. Part No.

SOP16

(MAX 10.35 include BURR)

16

4.4± 0.2

6.2± 0.3

1

1.5± 0.1

1.27

0.11

0.4± 0.1

SSOP-A16

(MAX 6.95 include BURR)

15

6.2± 0.3

4.4± 0.2

2

10± 0.2

6.6± 0.2

13

453

1216 14

2098

2090

11

10

61

Package

F : SOP16

FS : SSOP-A16

Packaging and forming specification

E2: Embossed tape and reel

<Tape and Reel information>

Embossed carrier tapeTape

9

0.3MIN

8

0.15± 0.1

0.1

(Unit : mm)

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Direction of feed

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

<Tape and Reel information>

9

0.3MIN

87

0.15± 0.1

Quantity

Direction

of feed

Embossed carrier tapeTape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

1.5± 0.1

0.11

0.8

0.36± 0.1

0.1

(Unit : mm)

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

12/12

2011.12 - Rev.B

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...