Page 1

A

Hi-performance Regulator IC Series for PCs

Termination Regulators

for DDR-SDRAMs

BD3539FVM,BD3539NUX

Description

BD3539FVM/NUX is a termination regulator compatible with JEDEC DDR1-SDRAM, DDR2-SDRAM, DDR3-SDRAM which

functions as a linear power supply incorporating an N-channel MOSFET and provides a sink/source current capability up to

1A respectively. A built-in high-speed OP-AMP specially designed offers an excellent transient response. Requires 3.3

volts (DDR2, DDR3) or 5.0 volts (DDR1, DDR2, DDR3) as a bias power supply to drive the N-channel MOSFET. Has an

independent reference voltage input pin (VDDQ) and an independent feedback pin (VTTS) to maintain the accuracy in

voltage required by JEDEC, and offers an excellent output voltage accuracy and load regulation. Also has a reference

power supply output pin (VREF) for DDR-SDRAM or a memory controller. When EN pin turns to “Low”, VTT output

becomes “Hi-Z” while VREF output is kept unchanged, compatible with “Self Refresh” state of DDR-SDRAM.

Features

1) Incorporates a push-pull power supply for termination (VTT)

2) Incorporates a reference voltage circuit (VREF)

3) Incorporates an enabler

4) Incorporates an under voltage lockout (UVLO)

5) Employs MSOP8 package : 2.9×4.0×0.9(mm) : BD3539FVM

6) Employs VSON008X2030 package : 2.0×3.0×0.6(mm) : BD3539NUX

7) Incorporates a thermal shutdown protector (TSD)

8) Operates with input voltage from 2.7 to 5.5 volts

9) Compatible with Dual Channel (DDR1, DDR2, DDR3)

10) Usable ceramic capacitor at output

Use

Power supply for DDR1- SDRAM (VCC=5V only)

Power supply for DDR2-SDRAM (VCC=3.3V or 5V)

Power supply for DDR3-SDRAM (VCC=3.3V or 5V)

●ABSOLUTE MAXIMUM RATINGS

Parameter Symbol

Input Voltage VCC 7

Enable Input Voltage VEN 7

Termination Input Voltage VTT_IN 7

VDDQ Reference Voltage VDDQ 7

Output Current ITT 1 A

Power Dissipation1 Pd1 387.4 *3 242.0 *4 mW

Power Dissipation2 Pd2 587.4 *4 515.0 *5 mW

Power Dissipation3 Pd3 - 877.2 *6 mW

Operating Temperature Range Topr -30~+100 ℃

Storage Temperature Range Tstg -55~+150 ℃

Maximum Junction Temperature Tjmax +150 ℃

*1 Should not exceed Pd.

*2 Instantaneous surge voltage, back electromotive force and voltage under less than 10% duty cycle.

*3 With Ta≧25℃ (With no heat sink) θja=322.6℃/W

*4 With Ta≧25℃ when mounting a 70mm×70mm×1.6mm glass-epoxy substrate, with no heat sinkθja=212.8℃/W

*5 With Ta≧25℃ (With no heat sink) θja=516.5℃/W

*6 With Ta≧25℃ when mounting a 70mm×70mm×1.6mm glass-epoxy substrate 1-layer board, θja=242.7℃/W

*7 With Ta≧25℃ when mounting a 70mm×70mm×1.6mm glass-epoxy substrate 4-layer board

(copper foil density: 5505mm

2

(copper foil area in each layer) ), θja=142.5℃/W

BD3539FVM BD3539NUX

Limit

*1*2

V

*1*2

V

*1*2

V

*1*2

V

No.09030EAT24

Unit

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

1/11

2009.10 - Rev.

Page 2

BD3539FVM,BD3539NUX

A

●Operating Conditions(Ta=25℃)

Parameter Symbol

Input Voltage VCC

Termination Input Voltage VTT_IN

VDDQ Reference Voltage VDDQ

Enable Input Voltage VEN

●Electrical Characteristics (Unless otherwise noted, Ta=25℃, VCC=3.3V, VEN=3V, VDDQ=1.5V, VTT_IN=1.5V)

Parameter Symbol

Standby Current IST - 0.5 1.0 mA VEN=0V

Bias Current ICC - 2 4 mA VEN=3V

[Enable]

High Level Enable Input Voltage VENHIGH 2.3 - 5.5 V

Low Level Enable Input Voltage VENLOW -0.3 - 0.8 V

Enable Pin Input Current IEN - 7 10 µA VEN=3V

[Termination]

Termination Output Voltage

(DDR3)

Termination Output Voltage

(DDR2)

Termination Output Voltage

(DDR1)

Source current ITT+ 1.0 - - A

VTT3

VTT2

VTT1

MIN TYP MAX

1/2×VDDQ

-15m

1/2×VDDQ

-30m

1/2×VDDQ

-30m

Limit

MIN MAX

2.7 5.5 V

1.0 5.5 V

1.0 2.75 V

-0.3 5.5 V

Limit

1/2×VDDQ

1/2×VDDQ

1/2×VDDQ

1/2×VDDQ

+15m

1/2×VDDQ

+30m

1/2×VDDQ

+30m

Unit

Unit Condition

ITT=-1.0A to 1.0A

V

Ta =0 ℃ to 100℃

VCC = 3.3V, VDDQ = 1.8V

VTT_IN = 1.8V

V

ITT=-1.0A to 1.0A

Ta =0 ℃ to 100℃

VCC = 5.0V, VDDQ = 2.5V

VTT_IN = 2.5V

V

ITT=-1.0A to 1.0A

Ta =0 ℃ to 100℃

Technical Note

Sink current ITT- - - -1.0 A

Load Regulation ⊿VTT - - 30 mV ITT=-1.0A to 1.0A

Upper Side ON Resistance HRON - 0.35 0.65 Ω

Lower Side ON Resistance LRON - 0.35 0.65 Ω

[VDDQ]

Input Impedance ZVDDQ 140 200 260 kΩ

[VREF]

Output Voltage VREF

[UVLO]

Threshold Voltage VUVLO 2.30 2.45 2.60 V VCC : sweep up

Hysteresis Voltage ⊿VUVLO 100 160 220 mV VCC : sweep down

1/2×VDDQ

-15m

1/2×VDDQ

1/2×VDDQ

+15m

IREF=-25mA to 25mA

V

Ta =0 ℃ to 100℃

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

2/11

2009.10 - Rev.

Page 3

BD3539FVM,BD3539NUX

A

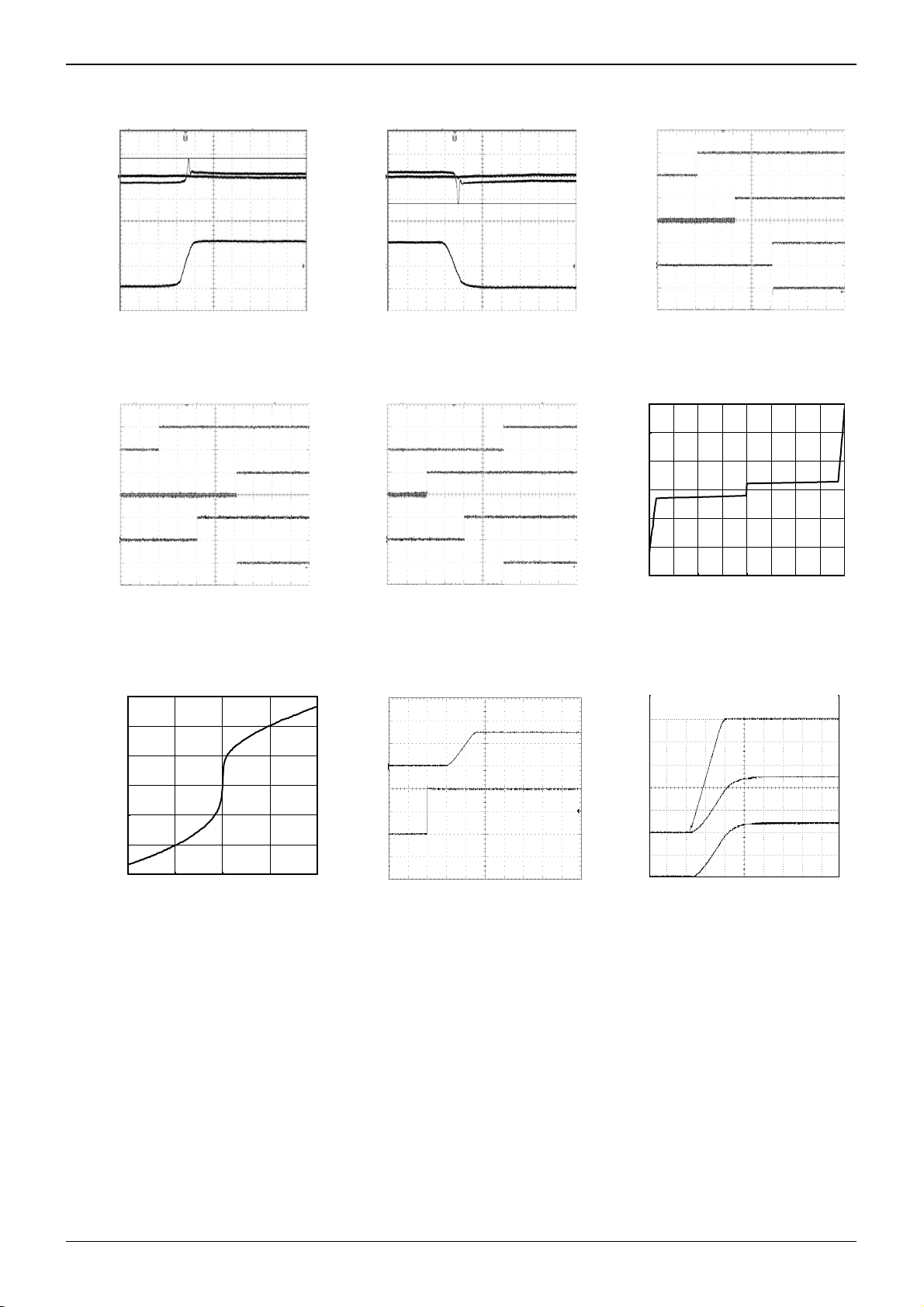

●Reference Data

VTT(50mV/div)

VREF(50mV/div)

sink

ITT(1A/div)

source

10µsec/Div

Fig.1 DDR3 (-1A→1A)

VCC

EN

VDDQ

VTT_IN

VTT

Fig.4 Input Sequence 2

2sec/Div

751.5

751.0

750.5

750.0

VREF [mV]

749.5

749.0

748.5

-20 -10 0 10 20

IREF[mA]

Fig.7 IREF-VREF (DDR3)

VCC

EN

VDDQ

VTT_IN

VTT

VTT

EN

VREF(50mV/div)

VTT(50mV/div)

sink

ITT(1A/div)

source

10µsec/Div

Fig.2 DDR3 (1A→-1A)

2sec/Div

Fig.5 Input Sequence 3

200µsec/Div

Fig.8 EN Soft Start

Technical Note

VCC

EN

VDDQ

VTT_IN

VTT

Fig.3 Input Sequence1

900

850

800

750

VTT [mV]

700

650

600

-2 -1.5 -1 -0.5 0 0.5 1 1.5 2

Fig.6 ITT-VTT (DDR3)

VDDQ

VREF

VTT

Fig.9 VDDQ Soft Start

ITT[A]

2sec/Div

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

3/11

2009.10 - Rev.

Page 4

BD3539FVM,BD3539NUX

A

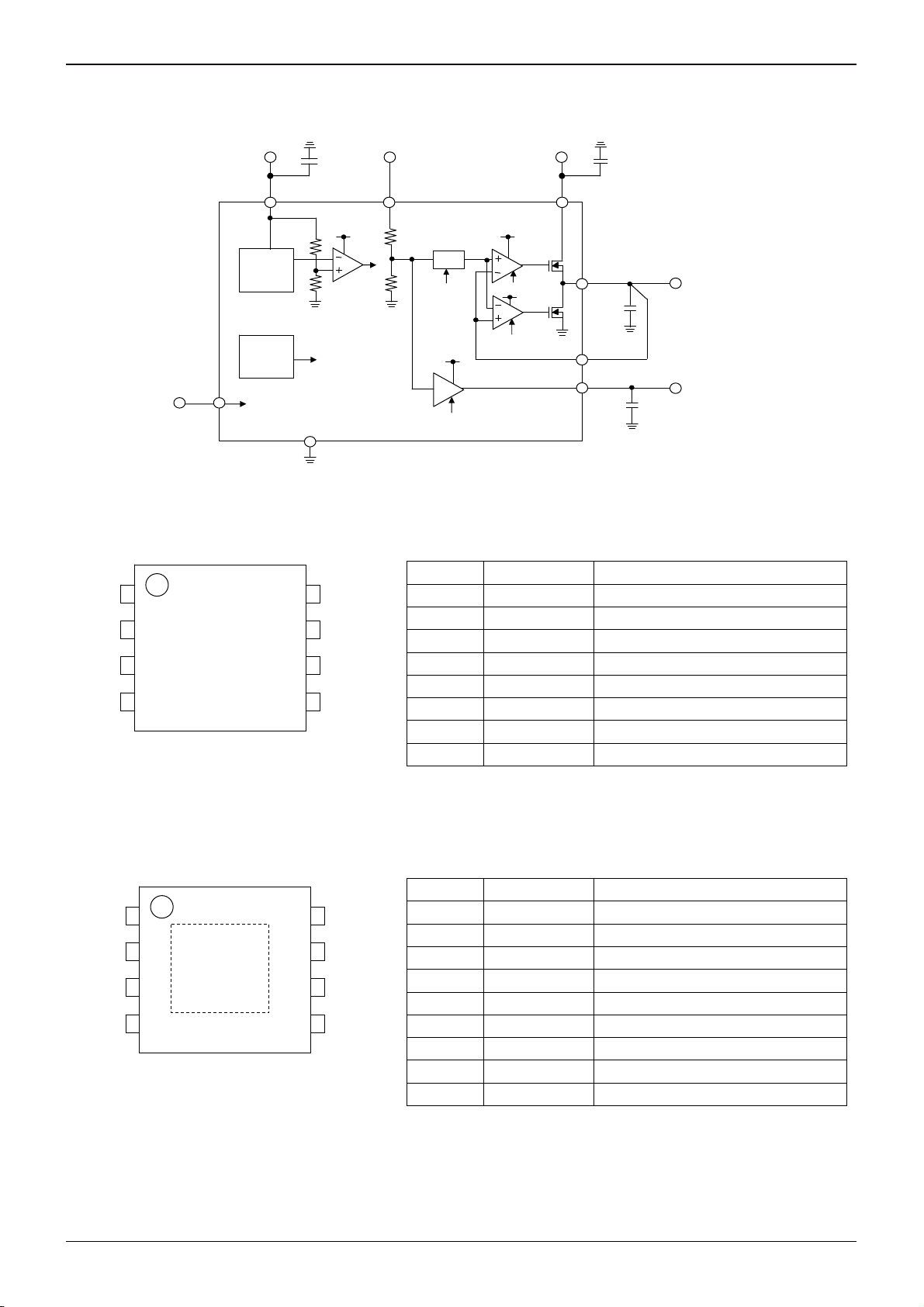

●Block Diagram

VCC

VCC

Reference

Block

VDDQ

C2 C3

VDDQ

VCC

UVLO

SOFT

TSD

EN

UVLO

2

Thermal

Protection

EN

TSD

1

VCC

UVLO

GND

Enable

EN

●PIN Configration ●PIN Function

○FVM

PIN No.

GND

1

EN

2

VTTS

3

4 5

VREF

8

7

6

VTT

VTT_IN

VCC

VDDQ

1 GND Ground Pin

2 EN Enable Input Pin

3 VTTS Detector Pin for Termination Voltage

4 VREF Reference Voltage Output Pin

5 VDDQ Reference Voltage Input Pin

6 VCC VCC Pin

7 VTT_IN Termination Input Pin

8 VTT Termination Output Pin

○NUX

PIN No.

VTT_IN

1

VCC

8

1 VTT_IN Termination Input Pin

2

VTT

GND

2

3

7

6

VDDQ

VREF

3 GND Ground Pin

4 EN Enable Input Pin

5 VTTS Detector Pin for Termination Voltage

4 5

EN

VTTS

6 VREF Reference Voltage Output Pin

7 VDDQ Reference Voltage Input Pin

8 VCC VCC Pin

Bottom FIN Substrate (Connected to GND)

Technical Note

VTT_IN

VTT_IN

756

VCC

TSD

EN

VCC

UVLO

TSD

EN

UVLO

PIN NAME PIN FUNCTION

PIN NAME PIN FUNCTION

VTT Termination Output Pin

VTT

8

3

VTTS

4

VREF

VTT

C4

½×

VDDQ

C1

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

4/11

2009.10 - Rev.

Page 5

BD3539FVM,BD3539NUX

A

●Description of operations

・VCC

In BD3539FVM/NUX, an independent power input pin is provided for an internal circuit operation of the IC. This is used

to drive the amplifier circuit of the IC, and its maximum current rating is 4mA. The power supply voltage is 2.7 to 5.5 volts.

It is recommended to connect a bypass capacitor of 1μF or so to VCC.

・VDDQ

Reference input pin for the output voltage that may be used to satisfy the JEDEC requirement for DDR3-SDRAM

(VREF=VTT = 1/2VDDQ) by dividing the voltage inside the IC with two 100kΩ voltage-divider resistors.

For BD3539FVM/NUX, care must be taken to an input noise to VDDQ pin because this IC also cuts such noise input into

half and provides it with the voltage output divided in half. Such noise may be reduced with an RC filter consisting of

such resistance and capacitance (220Ω and 2.2μF, for instance) that may not give significant effect to voltage dividing

inside the IC.

・VTT_IN

VTT_IN is a power supply input pin for VTT output. Voltage in the range between 1.0 and 5.5 volts may be supplied to

this VTT_IN terminal, but care must be taken to the current limitation due to on-resistance of the IC and the change in

allowable loss due to input/output voltage difference.

Generally, the following voltages are supplied:

・ DDR3 VTT_IN=1.5V

Higher impedance of the voltage input at VTT_IN may result in oscillation or degradation in ripple rejection, which must be

noted. To VTT_IN terminal, it is recommended to use a 10μF capacitor characterized with less change in capacitance.

But it may depend on the characteristics of the power supply input and the impedance of the pc board wiring, which must

be carefully checked before use.

・VREF

In BD3539FVM/NUX, a reference voltage output pin independent from VTT output is given to provide a reference input for

a memory controller and a DRAM. Even if EN pin turns to “Low” level, VREF output is kept unchanged, compatible with

“Self Refresh” state of DRAM. The maximum current capability of VREF is 10mA, and a suitable capacitor is needed to

stabilize the output voltage. It is recommended to use a combination of a 1.0 to 2.2μF ceramic capacitor characterized

with less change in capacitance. For an application where VREF current is low, a capacitor of lower capacitance may be

used. If VREF current is 1mA or less, it is possible to secure a phase margin with a ceramic capacitor of 1μF more or

less.

・VTTS

An independent pin provided to improve load regulation of VTT output. In case that longer wiring is needed to the load at

VTT output, connecting VTTS from the load side may improve the load regulation.

・VTT

A DDR memory termination output pin. BD3539FVM/NUX has a sink/source current capability of ±1.0A respectively.

The output voltage tracks the voltage divided in half at VDDQ pin. VTT output is turned to OFF when VCC UVLO or

thermal shutdown protector is activated with EN pin level turned to “Low”. Do not fail to connect a capacitor to VTT output

pin for a loop gain phase compensation and a reduction in output voltage variation in the event of sudden change in load.

Insufficient capacitance may cause an oscillation. High ESR (Equivalent Series Resistance) of the capacitor may result

in increase in output voltage variation in the event of sudden change in load. It is recommended to use a 10μF or so

ceramic capacitor, though it depends on ambient temperature and other conditions.

・EN

With an input of 2.3 volts or higher, the level at EN pin turns to “High” to provide VTT output. If the input is lowered to 0.8

volts or less, the level at EN pin turns to “Low” and VTT status turns to Hi-Z. But if VCC and VDDQ are established,

VREF output is maintained.

Technical Note

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

5/11

2009.10 - Rev.

Page 6

BD3539FVM,BD3539NUX

A

●Evaluation Board

BD3539FVM Evaluation Board Circuit

■■

VTT_IN

C5, C6

VCC

BD3539FVM Evaluation Board Application Components

■■

Part No Value Company Parts Name Part No Value Company Parts Name

U1 - ROHM BD3539FVM C4 - - -

R1 - - - C5 10µF KYOCERA CM21B106M06A

R4 220Ω ROHM MCR032200 C6 - - -

J1 0Ω - - C7 10µF KYOCERA CM21B106M06A

J2 0Ω - - C8 - - -

C1 - - - C9 2.2µF KYOCERA CM105B225K06A

C2 1µF KYOCERA CM105B105K06A C10 - - -

C3 1µF KYOCERA CM105B105K06A C11 - - -

BD3539FVM Evaluation Board Layout

■■

VCC

EN

SW1

2

7

VDDQ

5

J2 R4

C3,C4

Silk Screen TOP Layer

C9

6

1

C11

U1

BD3539FVM

EN

VTT_IN

VDDQ

VCC

GND

VTT

VTTS

VREF

8

3

4

C2

C7 C8 C10

VTTS

J1

R1

C1

Bottom Layer

Technical Note

GND

GND

VTT

VREF

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

6/11

2009.10 - Rev.

Page 7

BD3539FVM,BD3539NUX

A

●Example of layout pattern

[Example of board layout pattern] [Pin configuration]

Technical Note

Input capacitor Cin of VTT_IN should be placed close to VTT_IN pin as possible, and VTT output capacitor should also be

placed close to IC pin as possible. And, as for wiring pattern, pin above and GND pattern should be designed widely as

possible.

If connected to inner GND plane, several through hole should be used.

Because VTTS pin has comparatively high impedance, floating capacity should be minimum as possible, and design layout

at upper layer pattern. Please be careful in drawing.

Please take GND pattern space widely, and design layout to be able to increase radiation efficiency.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

7/11

2009.10 - Rev.

Page 8

BD3539FVM,BD3539NUX

A

P

iti

P

iti

Technical Note

●Note for Use

1.Absolute maximum ratings

For the present product, thoroughgoing quality control is carried out, but in the event that applied voltage, working

temperature range, and other absolute maximum rating are exceeded, the present product may be destroyed. Because

it is unable to identify the short mode, open mode, etc., if any special mode is assumed, which exceeds the absolute

maximum rating, physical safety measures are requested to be taken, such as fuses, etc.

2.GND potential

Bring the GND terminal potential to the minimum potential in any operating condition.

3.Thermal design

Consider allowable loss (Pd) under actual working condition and carry out thermal design with sufficient margin provided.

4.Terminal-to-terminal short-circuit and erroneous mounting

When the present IC is mounted to a printed circuit board, take utmost care to direction of IC and displacement. In the

event that the IC is mounted erroneously, IC may be destroyed. In the event of short-circuit caused by foreign matter that

enters in a clearance between outputs or output and power-GND, the IC may be destroyed.

5.Operation in strong electromagnetic field

The use of the present IC in the strong electromagnetic field may result in maloperation, to which care must be taken.

6.Built-in thermal shutdown protection circuit

The present IC incorporates a thermal shutdown protection circuit (TSD circuit). The working temperature is 175°C

(standard value) and has a -15°C (standard value) hysteresis width. When the IC chip temperature rises and the TSD

circuit operates, the output terminal is brought to the OFF state. The built-in thermal shutdown protection circuit (TSD

circuit) is first and foremost intended for interrupt IC from thermal runaway, and is not intended to protect and warrant the

IC. Consequently, never attempt to continuously use the IC after this circuit is activated or to use the circuit with the

activation of the circuit premised.

7.Capacitor across output and GND

In the event a large capacitor is connected across output and GND, when Vcc and VIN are short-circuited with 0V or GND

for some kind of reasons, current charged in the capacitor flows into the output and may destroy the IC. Use a capacitor

smaller than 1000 μF between output and GND.

8.Inspection by set substrate

In the event a capacitor is connected to a pin with low impedance at the time of inspection with a set substrate, there is a

fear of applying stress to the IC. Therefore, be sure to discharge electricity for every process. As electrostatic

measures, provide grounding in the assembly process, and take utmost care in transportation and storage. Furthermore,

when the set substrate is connected to a jig in the inspection process, be sure to turn OFF power supply to connect the jig

and be sure to turn OFF power supply to remove the jig.

9. Inputs to IC terminals

This device is a monolithic IC with P

+

isolation between P-substrate and each element as illustrated below. This P-layer

and the N-layer of each element form a PN junction which works as:

・a diode if the electric potentials at the terminals satisfy the following relationship; GND>Terminal A>Terminal B, or

・a parasitic transistor if the electric potentials at the terminals satisfy the following relationship; Terminal B>GND Terminal A.

The structure of the IC inevitably forms parasitic elements, the activation of which may cause interference among circuits,

and/or malfunctions contributing to breakdown. It is therefore requested to take care not to use the device in such

manner that the voltage lower than GND (at P-substrate) may be applied to the input terminal, which may result in

activation of parasitic elements.

Pin A

N

P+ P

P

Parasitic element

GND

Resistor Transistor (NPN)

B

C

E

N

GND

P

P+

P substrate

+

N N

P substrate

Pin A

aras

element

Pin B

N

c

Parasitic element

P+

N

GND

Pin B

B C

Other adjacent elements

E

GND

aras

element

c

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

8/11

2009.10 - Rev.

Page 9

BD3539FVM,BD3539NUX

A

10. GND wiring pattern

When both a small-signal GND and high current GND are present, single-point grounding (at the set standard point) is

recommended, in order to separate the small-signal and high current patterns, and to be sure the voltage change

stemming from the wiring resistance and high current does not cause any voltage change in the small-signal GND. In the

same way, care must be taken to avoid wiring pattern fluctuations in any connected external component GND.

11. Output capacitor, resistor (C1/block diagram)

Do not fail to connect a output capacitor to VREF output terminal for stabilization of output voltage. The capacitor

connected to VREF output terminal works as a loop gain phase compensator. Insufficient capacitance may cause an

oscillation. It is recommended to use a low temperature coefficient 1-10μF ceramic capacitor, though it depends on

ambient temperature and load conditions. It is therefore requested to carefully check under the actual temperature and

load conditions to be applied.

12. Output capacitor (C4)

Do not fail to connect a capacitor to VTT output pin for stabilization of output voltage. This output capacitor works as a

loop gain phase compensator and an output voltage variation reducer in the event of sudden change in load. Insufficient

capacitance may cause an oscillation. And if the equivalent series resistance (ESR) of this capacitor is high, the variation

in output voltage increases in the event of sudden change in load. It is recommended to use a 10μF or so ceramic

capacitor, though it depends on ambient temperature and load conditions. It is therefore requested to carefully check

under the actual temperature and load conditions to be applied.

13. Input capacitors setting (C2 and C3)

These input capacitors are used to reduce the output impedance of power supply to be connected to the input terminals

(VCC and VTT_IN). Increase in the power supply output impedance may result in oscillation or degradation in ripple

rejecting characteristics. It is recommended to use a low temperature coefficient 1μF (for VCC) and 10μF (for VTT_IN)

capacitor, but it depends on the characteristics of the power supply input, and the capacitance and impedance of the pc board

wiring pattern. It is therefore requested to carefully check under the actual temperature and load conditions to be applied.

14. Input terminals (VCC, VDDQ, VTT_IN and EN)

VCC, VDDQ, VTT_IN and EN terminals of this IC are made up independent one another. To VCC terminal, the UVLO

function is provided for malfunction protection. Irrespective of the input order of the inputs terminals, VTT output is

activated to provide the output voltage wheNUXLO and EN voltages reach the threshold voltage while VREF output is

activated wheNUXLO voltage reaches the threshold. If VDDQ and VTT_IN terminals have equal potential and common

impedance, any change in current at VTT_IN terminal may result in variation of VTT_IN voltage, which affects VDDQ

terminal and may cause variation in the output voltage. It is therefore required to perform wiring in such manner that

VDDQ and VTT_IN terminals may not have common impedance. If impossible, take appropriate corrective measures

including suitable CR filter to be inserted between VDDQ and VTT_IN terminals.

15. VTTS terminal

A terminal used to improve load regulation of VTT output. Connection with VTT terminal must be done not to have

common impedance with high current line, which may offer better load regulation of VTT output.

16. Operating range

Within the operating range, the operation and function of the circuits are generally guaranteed at an ambient temperature

within the range specified. The values specified for electrical characteristics may not be guaranteed, but drastic change

may not occur to such characteristics within the operating range.

17. Allowable loss Pd

For the allowable loss, the thermal derating characteristics are shown in the Exhibit, which should be used as a guide.

Any uses that exceed the allowable loss may result in degradation in the functions inherent to IC including a decrease in

current capability due to chip temperature increase. Use within the allowable loss.

18. The use in the strong electromagnetic field may sometimes cause malfunction, to which care must be taken.

In the event that load containing a large inductance component is connected to the output terminal, and generation of

back-EMF at the start-up and when output is turned OFF is assumed, it is requested to insert a protection diode.

19. In the event that load containing a large inductance component is

connected to the output terminal, and generation of back-EMF at the

start-up and when output is turned OF

to insert a protection diode.

20. We are certain that examples of applied circuit diagrams are recommendable,

but you are requested to thoroughly confirm the characteristics before using the IC.

In addition, when the IC is used with the external circuit changed, decide the IC with sufficient margin provided

while consideration is being given not only to static characteristics but also variations of external parts and our IC including

transient characteristics.

F is assumed, it is requested

(Example)

OUTPUT PIN

Technical Note

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

9/11

2009.10 - Rev.

Page 10

BD3539FVM,BD3539NUX

A

(

)

Technical Note

●Heat loss

Thermal design must be conducted with the operation under the conditions listed below (which are the guaranteed

temperature range requiring consideration on appropriate margins etc);

1: Ambient temperature Ta: 100℃ or lower

2:Chip junction temperature Tj: 150℃ or lower

The chip junction temperature Tj can be considered as follows:

①Calculation based on IC surface

temperature Tc, mounted on a board

Tj=Tc+θj-c×W

<Reference example>

θj-c:MSOP-8 46.0℃/W

PCB size:70×70×1.6mm

(Board copper foil area: :70×70mm

②Calculation based on ambient temperature Ta

Tj=Ta+θj-a×W

<Reference example>

θj-a:MSOP-8 212.8℃/W

322.6℃/W

θj-a:VSON008X2030 516.5℃/W

With no heat sink

242.7℃/W

1-layer board(copper foil area:70×70mm

2

4-layer board(copper foil area:70×70mm

)

142.5℃/W

PCB size: 70×70×1.6mm

With no heat sink

1-layer board(copper foil area :70×70mm

3

with thermal via

Because package with FIN is used at IC bottom side, package power changes considerably by copper foil area, which is

connected. Please radiate heat by taking enough area for board surface or using many through hole to inner layer pattern.

Most of heat loss in BD3539FVM/NUX occurs at the output N-channel FET. The power lost is determined by multiplying the

voltage between VIN and Vo by the output current. As this IC employs the power PKG, the thermal derating characteristics

significantly depends on the pc board conditions. When designing, care must be taken to the size of a pc board to be used.

Power consumption (W) = Input voltage (V

Example) Where V

Power consumption(W) = 1.5(V)-0.75(V) ×0.5(A)

=1.5V, VDDQ=1.5V, Io(Ave)= 0.5A

TT_IN

= 0.375(W)

)-Output voltage(VTT≒ VDDQ)×Io(Ave)

TT_IN

1

2

●Heat dissipation characteristics [Tc]

◎MSOP8

[W]

3.0

2.5

2.0

2.72W

1-layer board

θja=46.0℃/W

1.5

1.0

0.5

0

0 25 75 100 125 50

Ambient Temperature [Ta]

150

[℃]

●Heat dissipation characteristics [Ta]

◎MSOP8 ◎VSON008X2030

[mW]

600

500

400

(1) 587.4mW

(2) 387.4mW

(1) 1-layer board

θja=212.8℃/W

(2) with no heat sink

θja=322.6℃/W

300

[W]

1.0

0.75

0.5

(1) 877.2mW

(2) 515.0mW

(1) 4-layer board(copper foil area : 5505mm2)

Every layer has copper foil area,θja=142.5℃/W

(2) 1-layer board

θja=242.7℃/W

(3) With no heat sink

θja=516.5℃/W

200

Power Dissipation [Pd]

100

0

0 25 75 100 125 50

Ambient Temperature [Ta]

150

[℃]

Power Dissipation [Pd]

(3) 242.0mW

0.25

0

0 25 75 100 125 150 50

Ambient Temperature [Ta]

[℃]

2

)

2

)

2

)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

10/11

2009.10 - Rev.

Page 11

BD3539FVM,BD3539NUX

A

●Ordering part number

B D 3 5 3 9 F V M - T R

Technical Note

Part No. Part No.

MSOP8

4.0±0.2

0.9MAX

0.75±0.05

2.9±0.1

(MAX 3.25 include BURR)

8

2.8±0.1

1

0.475

0.65

0.08±0.05

VSON008X2030

0.6MAX

0.08 S

C0.25

0.3±0.1

0.25

6

2

3

2.0±0.1

1.5±0.1

3539

57

4

1PIN MARK

0.22

0.08 S

1PIN MARK

0.5

4

518

0.25

+0.05

−0.04

+0.03

0.02

+0.05

−0.04

3.0±0.1

−0.02

Package

FVM: MSOP8

Packaging and forming specification

TR: Embossed tape and reel

NUX: VSON008X2030

<Tape and Reel information>

+

6°

4°

−4°

0.6±0.2

0.29±0.15

+0.05

0.145

−0.03

S

Quantity

Direction

of feed

(Unit : mm)

<Tape and Reel information>

Quantity

S

(0.12)

1.4±0.1

(Unit : mm)

Direction

of feed

Embossed carrier tapeTape

3000pcs

TR

The direction is the 1pin of product is at the upper right when you hold

()

reel on the left hand and you pull out the tape on the right hand

1pin

Direction of feed

Reel

Order quantity needs to be multiple of the minimum quantity.

∗

Embossed carrier tapeTape

4000pcs

TR

The direction is the 1pin of product is at the upper right when you hold

()

reel on the left hand and you pull out the tape on the right hand

Direction of feed

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

11/ 11

2009.10 - Rev.

Page 12

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...