Standard LDO Regulators

Standard Variable Output

LDO Regulators with Shutdown Switch

BA00DD0WCP-V5,BA00DD0WHFP,

BA00CC0WT,BA00CC0WCP-V5,BA00CC0WFP

●Description

The BA00DD0/CC0 series are low-saturation regulators available for outputs up to 2A/1A. The output voltage can be

arbitrarily configured using the external resistance. These series of LDO regulators are offered in a broad packaging lineup.

This IC has a built-in over-current protection circuit that prevents the destruction of the IC due to output short circuits and a

thermal shutdown circuit that protects the IC from thermal damage due to overloading.

●Features

1) Maximum output current: 2A (BA00DD0 series), 1A(BA00CC0 series)

2) ±1% high-precision output voltage (BA00DD0)

3) Low saturation with PNP output

4) Built-in over-current protection circuit that prevents the destruction of the IC due to output short circuits

5) Built-in thermal shutdown circuit for protecting the IC from thermal damage due to overloading

6) Built-in over- voltage protection circuit that prevents the destruction of the IC due to power supply surges

7) TO220FP andHRP5 packaging (BA00DD0), and TO220FP and TO252 packaging (BA00CC0)

●Applications

Usable in DSP power supplies for DVDs and CDs, FPDs, televisions, personal computers or any other consumer device

●Line up

1A BA00CC0 Series

Part Number Package

BA00CC0WT TO220FP-5

BA00CC0WCP-V5 TO220CP-V5

BA00CC0WFP TO252-5

2A BA00DD0 Series

Part Number Package

BA00DD0WCP-V5 TO220CP-V5

BA00DD0WHFP HRP5

No.11023ECT01

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

1/9

2011.03 - Rev.C

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

Technical Note

●ABSOLUTE MAXIMUM RATINGS(Ta=25℃)

Parameter Symbol Limits Unit

Input Power Supply Voltage*1 Vcc -0.3 ~ +35 V

2300(HRP5)

Power Dissipation Pd

mW 1300(TO252-5)

2000(TO220FP-5)

Operating Temperature Range Topr -40 ~ +125 ℃

Ambient Storage Temperature Tstg -55 ~ +150 ℃

Junction Temperature Tjmax +150 ℃

Output Control Terminal Voltage VCTL -0.3 ~ +Vcc V

Voltage Applied to the Tip*3 Vcc peak +50 V

*1 Must not exceed Pd

*2 HRP5 : In cases in which Ta≥25℃ when a 70mm×70mm×1.6mm glass epoxy board is used, the power is reduced by 18.4 mW/℃.

TO252-5 : In cases in which Ta≥25℃ when a 70mm×70mm×1.6mm glass epoxy board is used, the power is reduced by 10.4 mW/℃.

TO252FP-5 : No heat sink. When Ta≥25℃, the power is reduced by 16 mW/℃.

*3 Applied voltage: 200msec or less (tr≥1msec)

50V

tr≧1msec

35V

0V

MAX200msec

(Voltage Supply more than 35V)

●Recommended Operating Range (Ta=25℃)

Parameter Symbol Min. Max. Unit

Input PowerSupply Voltage

Output Current

BA00CC0□□

BA00DD0□□ 3.0 25.0

BA00CC0□□

BA00DD0□□ - 2

Vcc

Io

4.0 25.0

- 1

V

A

Output Control Terminal Voltage VCTL 0 Vcc V

●Electrical Characteristics(ABRIDGED)

BA00CC0□□ Series (unless specified otherwise, Ta=25℃, Vcc=10V, VCTL=5V, Io=500mA, R1=2.2kΩ, R2=6.8kΩ)

Parameter Symbol Min. Typ. Max. Unit Conditions

C-terminal Voltage Vc 1.200 1.225 1.250 V Io=50mA

Circuit Current at the Time of Shutdown Isd - 0 10 µA VCTL=0V

Minimum I/O Voltage Difference ΔVd - 0.3 0.5 V Vcc= 0.95×Vo

Output Current Capacity Io 1.0 - - A

Input Stability Reg.I - 20 100 mV Vcc= 6V→25 V

Load Stability Reg.L - 50 150 mV Io=5mA→1A

Output Voltage Temperature Coefficient* TCVO - ±0.02 - %/℃ Io=5mA ,Tj=0~125℃

*Design guarantee (100% shipping inspection not performed)

BA00DD0□□ Series (unless specified otherwise, Ta=25℃, Vcc=8V, VCTL=3V, Io=500mA, R1=15kΩ, R2=44kΩ)

Parameter Symbol Min. Typ. Max. Unit Conditions

C-terminal Voltage VADJ 1.257 1.270 1.283 V Io=100mA

Circuit Current at the Time of Shutdown Isd - 0 10 µA VCTL=0V

Minimum I/O Voltage Difference ΔVd - 0.45 0.7 V Vcc= 0.95×Vo, Io=2A

Output Current Capacity Io 2.0 - - A

Input Stability Reg.I - 15 35 mV Vcc= 5.7V→25 V, Io=200mA

Load Stability Reg.L - 50 100 mV Io=0mA→2A

Output Voltage Temperature Coefficient* TCVO - ±0.02 - %/℃ Io=5mA ,Tj=0~125℃

*Design guarantee (100% shipping inspection not performed)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

2/9

2011.03 - Rev.C

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

]

]

]

]

]

]

]

]

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

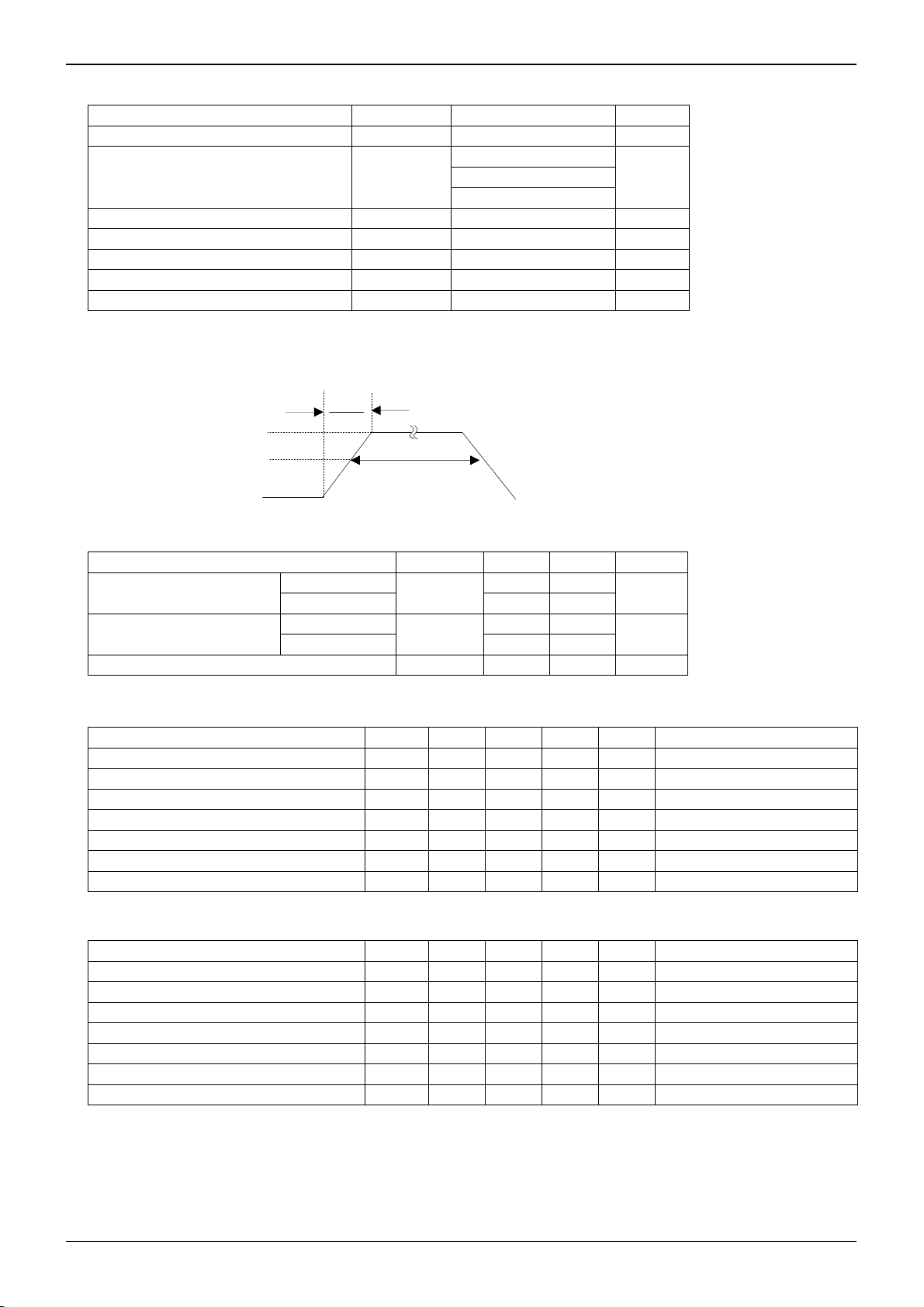

●Reference Data BA00CC0□□(3.3V preset voltage)

(Unless specified otherwise, Vcc=10V, VOUT=3.3V preset, VCTL=3V, Io=0mA, R1=2.2kΩ, and R2=6.8kΩ)

3.0

4.0

4.0

2.5

3.0

2.0

3.0

Technical Note

1.5

1.0

CIRCUIT CURRENT:ICC[mA]

0.5

0.0

02468101214161820

SUPPLY VOLTAGE:VC C[V]

2.0

1.0

OUTPUT VOLTAGE:VOUT[V

0.0

0 2 4 6 8 10 12 14 16 18 20

SUPPLY VOLT AGE:VCC[ V]

2.0

1.0

OUTPUT VOLTAGE:VOUT[V

0.0

0 2 4 6 8 10 12 14 16 18 20

SUPPLY VOLT AGE:VCC[ V]

Fig.3 Input Stability Fig.1 Circuit current Fig.2 Input Stability

3.5

3.0

2.5

2.0

1.5

1.0

OUTPUT VOLTAGE:VOUT[V

0.5

0.0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

OUTPU T C URR ENT:Io[mA]

Fig.4 Load Stability

600

500

Vd[V]

Δ

400

300

200

DROPOUT VOLTAGE:

100

0

0 100 200 300 400 500 600 700 800 900 1000

OUTPUT CURRENT:Io[mA]

Fig.5 Input/Output Voltage Difference

80

70

60

50

40

30

20

RIPPLE REJECTION:R.R[dB

10

0

10 1000 100000

Fig.6 Ripple Rejection Characteristics

Io-ΔVd Characteristics(Vcc=2.95V)

4.5

4.0

3.5

3.0

OUTPUT VOLTAGE:VOUT[V

2.5

2.0

-40 -20 0 20 40 60 80 100 120

AMBIENT TEMPER ATU RE:Ta[℃]

Fig.7 Output Voltage

Temperature Characteristics

8

7

6

5

4

3

2

OUTPUT VOLTAGE:VOUT[V

1

0

0 2 4 6 8 1012141618202224

CONTROL VOLTAGE:VCTL[V]

Fig.10 CTL Voltage vs. Output Voltage

200

150

100

50

CIRCUIT CURRENT:Icc[mA]

0

0 100 200 300 400 500 600 700 800 900 1000

OUTPUT CURRENT:Io[mA]

1000

900

800

700

600

500

400

300

200

CONTROL CURRENT:ICTL[μA]

100

0

0 2 4 6 8 1012 1416 1820

Fig.8 Circuit Current by load Level Fig.9 CTL Voltage vs. CTL Current

(I

4

4

3

3

2

2

1

OUTPUT VOLTAGE:VOUT[V

1

0

0 5 10 15 20 25 30 35 40

OUT=0mA→1A)

SUPPLY VOLT AGE:Vcc[V]

4

4

3

3

2

2

1

OUTPUT VOLTAGE:VOUT[V

1

0

130 140 150 160 170 180 190

Fig.11 Overvoltage Operating

Characteristics (Io=200mA)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

3/9

(Io=500mA)

FREQU ENC Y:f[Hz]

100k 10k 1k 100

(Io=100mA)

CON TROL VOLT AGE:VC TL[V]

AMBIEN T TEMPER ATURE:T a[℃]

Fig.12 Thermal Shutdown

Circuit Characteristics

2011.03 - Rev.C

1000k

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

]

]

]

]

]

]

]

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

Technical Note

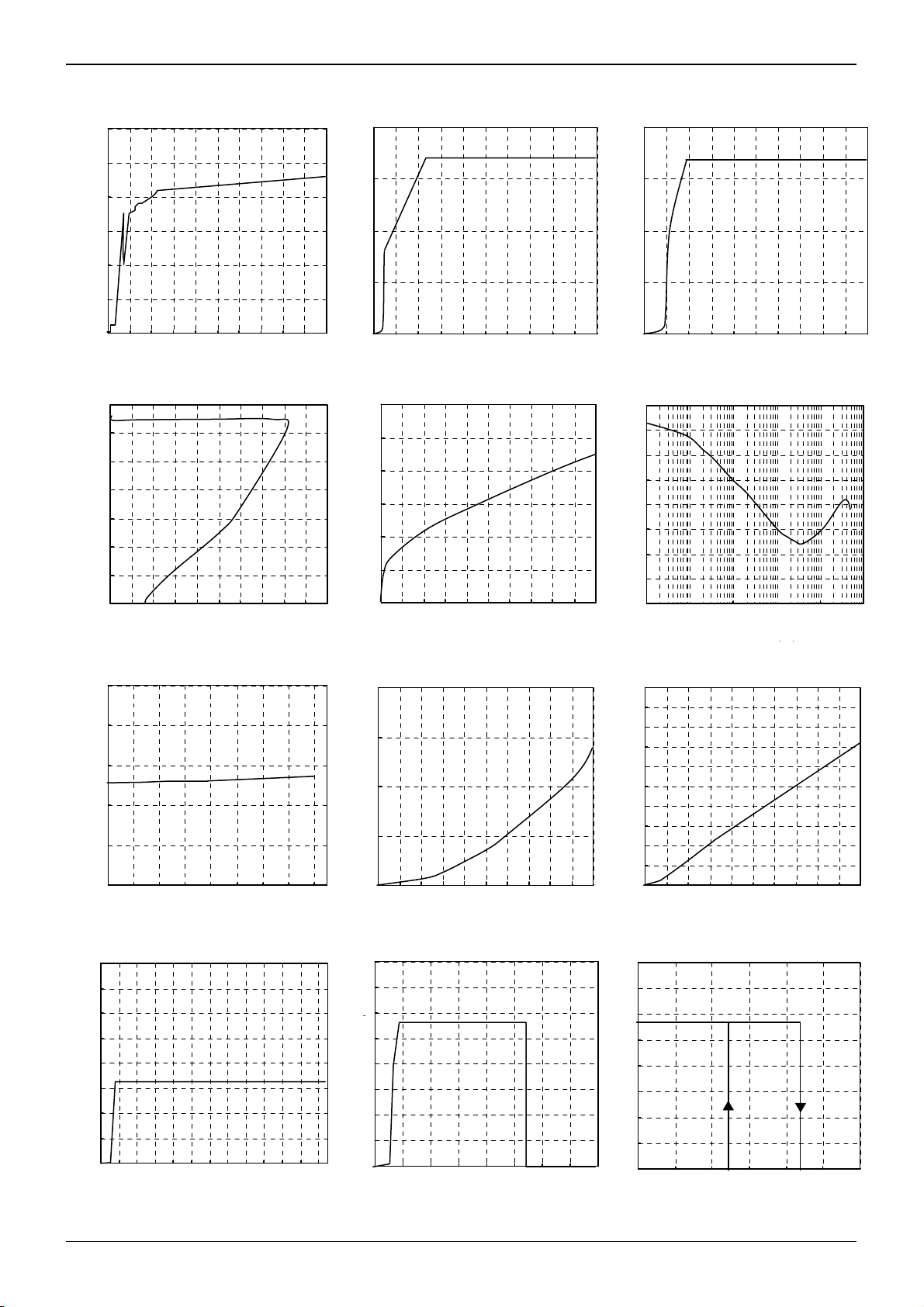

●Reference Data BA00DD0□□(5.0V preset voltage)

(Unless specified otherwise, Vcc=8V, V

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

CIRCUIT CURRENT:ICC[mA]

1.0

0.5

0.0

024681012141618202224

SUPPLY VOLTAGE:VC C[V]

8

8

7

7

6

6

5

5

4

4

3

3

2

OUTPUT VOLTAGE:VOUT[V]

2

1

1

0

OUTPUT CURRENT:IOUT[A ]

Fig.16 Load Stability

5.2

5.1

5.0

4.9

OUTPUT VOLTAGE:VOUT[V

4.8

-40 -20 0 20 40 60 80 100

8

7

6

5

4

3

2

OUTPUT VOLTAGE:VOUT[V

1

0

0 2 4 6 8 1012141618202224

AMBIENT TEMPER ATU RE:Ta[℃]

Fig.19 Output Voltage

Temperature Characteristics

CONTROL VOLTAGE:VCTL[V]

Fig.10 CTL Voltage vs. Output Voltage

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

OUT=5V preset, VCTL=3V, Io=0mA, R1=15kΩ, and R2=44kΩ)

8

7

6

5

4

3

2

OUTPUT VOLTAGE:VOUT[V

1

0

0 2 4 6 8 10 12 14 16 18 20 22 24

SUPPLY VOLT AGE:VCC[V]

8

7

6

5

4

3

2

OUTPUT VOLTAGE:VOUT[V

1

0

0 2 4 6 8 10 12 14 16 18 20 22 24

SUPPLY VOLT AGE:VCC[V]

Fig.15 Input Stability Fig.13 Circuit Current Fig.14 Input Stability

(Io=2A)

800

700

600

500

400

300

200

DROPOUT VOLTAGE:VDRP[V]

100

0

0.5 1.0 1.5 2.0 1.0 2.0 3.0 4.0 4.8

OUTPUT CURRENT:IOUT[A ]

Fig.17 Input/Output Voltage Difference

Iout-ΔVd Characteristics(Vcc=4.75V)

200

180

160

140

120

100

80

60

CIRCUIT CURRENT:[mA]

40

20

0

0.5 1.0 1.5 2.0

OUTPUT CURRENT:IOUT[A]

60

55

50

45

40

35

30

25

20

15

RIPPLE REJECTION:R.R[dB

10

5

0

10 1000 100000

100

FREQU ENC Y:f[Hz]

1k

10k

Fig.18 Ripple Rejection Characteristics

(Iout=100mA)

800

700

600

500

400

300

200

CONTROL CURRENT:ICTL[μA]

100

0

0 2 4 6 8 1012141618202224

CONTROL VOLTAGE:VCTL[V]

Fig.20 Circuit Current by load Level Fig.21 CTL Voltage vs. CTL Current

(I

4

8

4

7

6

3

3

5

4

2

2

3

2

1

OUTPUT VOLTAGE:VOUT[V

1

0

0 5 10 15 20 25 30 35 40

SUPPLY VOLT AGE:Vcc[V]

Fig.11 Overvoltage Operating

Characteristics(Io=200mA)

4/9

OUT=0mA→2A)

8

6

4

2

OUTPUT VOLTAGE:VOUT[V

0

130 140 150 160 170 18 0 190

AMBIEN T TEMPER ATU RE:Ta[℃]

Fig.12 Thermal Shutdown

Circuit Characteristics

2011.03 - Rev.C

100k

1000k

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

cc

μ

)

cc

(

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

Technical Note

●Block Diagrams

[BA00CC0WFP]

[BA00DD0WHFP]

V

0.33μF

2

Vref

3

Driver

N.C.(TO252-5)

GND(HRP5)

TOP VIEW

FIN

1 2 3 4 5

TO252-5 HRP5

1 2 3 4 5

OVP

1 5

CTL

TSD

Fin

OCP

GND

Fig.25

PINNo. Symbol Function

1 CTL Output voltage ON/OFF control

2 VCC Power supply voltage input

3 N.C./GND Unconnected terminal/GND*

4 OUT Voltage output

5 C Output voltage regulation terminal

FIN

GND GND

*TO252-5 is N.C., and HRP5 is GND

C(ADJ)

R1

VOUT

4

+

22μF

R2

[BA00CC0WT] [BA00CC0CP-V5] [BA00DD0WCP-V5]

0.33

V

F

Vref

2

Driver

TOP VIEW

TOP VIEW

1 2 3 4 5 1 2 3 4 5

TO220FP-5 TO220FP-5(V5)

OVP

1 5

CTL

TSD

3

GND

OCP

C(ADJ

R1

R2

Fig.26

PINNo. Symbol Function

1 CTL Output voltage ON/OFF control

2 VCC Power supply voltage input

3 GND GND

4 OUT Voltage output

5 ADJ Output voltage regulation terminal

2 3 4 5

1

TO220CP-V5

●Input / Output Equivalent Circuit Diagrams

< BA00CC0WT/BA00CC0WFP >

CTL

25kΩ

25kΩ

10 kΩ

Vcc

VOUT

C

5.5 kΩ

10kΩ

Fig.27

Vcc

Vcc

VOUT

ADJ

500Ω

< BA00DD0WFP >

CTL

Vcc

39kΩ

Ω

2k

31kΩ

Fig.28

●Output Voltage Configuration Method

Please connect resistors R

1 and R2 (which determines the output voltage) as shown in Fig.29.

Please be aware that the offset due to the current that flows from the ADJ terminal becomes large when resistors with large

values are used. The use of resistors with R1=2kΩ to 15 kΩ is recommended.

2

Vo = Vc (V

ADJ) × 1 +

R

1

R

BA□□CC0□□ Vc : 1.225 (Typ.)

BA□□DD0□□

ADJ : 1.270 (Typ.)

V

C

V

OUT

ADJ)

(V

Vc

R2

ADJ

R

)

1

4

VOUT

+

22μF

Fig.29

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

5/9

2011.03 - Rev.C

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

)

)

)

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

Technical Note

●Thermal Design

HRP5 To225FP-5 TO252-5

10

Board size : 70×70×1.6 ㎜3 (board contains a thermal)

Board front copper foil area : 10.5×10.5 ㎜

9

①2-layer board (back surface copper foil area :15×15 ㎜

②2-layer board (back surface copper foil area :70×70 ㎜2)

8

③4-layer board (back surface copper foil area :70×70 ㎜2)

③7.3W

7

6

5

②5.5W

4

Power Dissipation:Pd(W

3

2

①2.3W

1

0

0 25 50 75 100 125 150

Ambient temperature:Ta(℃)

2

2

)

25

(1) When using a maximum heat sick : θj-c=6.25(℃/W)

(2) When us ing an IC alone : θj-c=62.5(℃/W)

20

(1)20.0

15

10

Power Dissipation:Pd(W

5

(2)2.0

0

0 25 50 75 100 125 150

Ambient temperature:Ta(℃)

2.0

Mounted on a Rohm standard board

Board size : 70×70×1.6 ㎜

Copper foil area :7×7 ㎜

TO252-5θja=96.2(℃/W)

1.6

1.30

1.2

0.8

Power Dissipation:Pd(W

0.4

0.0

0 25 5 0 75 100 125 150

Ambie nt te mpe rature :Ta(℃ )

Fig.30 Fig.31 Fig.32

When using at temperatures over Ta=25℃, please refer to the heat reducing characteristics shown in Fig.30 through 32.

The IC characteristics are closely related to the temperature at which the IC is used, so it is necessary to operate the IC at

temperatures less than the maximum junction temperature Tj

MAX.

Fig.31 shows the acceptable loss and heat reducing characteristics of the TO220FP package The portion shown by the

diagonal line is the acceptable loss range that can be used with the IC alone. Even when the ambient temperature Ta is a

normal temperature (25℃), the chip (junction) temperature Tj may be quite high so please operate the IC at temperatures

less than the acceptable loss Pd.

The calculation method for power consumption Pc(W) is as follows :

Pc = (Vcc-Vo)×Io+Vcc×Icca

Vcc:

Input voltage

Vo:

Output voltage

Io:

Load current

Icca:

Circuit current

Acceptable loss Pd≦Pc

Solving this for load current IO in order to operate within the acceptable loss,

Io≦

(Please refer to Figs.8 and 20 for Icca.)

It is then possible to find the maximum load current Io

Pd – Vcc×Icca

Vcc-Vo

MAX with respect to the applied voltage Vcc at the time of thermal design.

Calculation Example

Example 1) When Ta=85℃, Vcc=8.3V, Vo=3.3V, BA33DD0WT

Io≦ With the IC alone : θja=62.5℃/W → -16mW/℃

Io≦200mA (Icca : 2mA) 25℃=2000mW → 85℃=1040mW

1.04-8.3×Icca

5

Please refer to the above information and keep thermal designs within the scope of acceptable loss for all operating

temperature ranges. The power consumption Pc of the IC when there is a short circuit (short between Vo and GND) is :

Pc=Vcc×(Icca+Ishort)

Ishort : Short circuit current

●Terminal Vicinity Settings and Cautions

・Vcc Terminal

Please attach a capacitor (greater than 0.33μF) between the Vcc and GND.

The capacitance values differ depending on the application, so please chose a capacitor with sufficient margin and verify

the operation on an actual board.

・CTL Terminal

The CTL terminal is turned ON at 2.0V and higher and OFF at 0.8V and lower within the operating power supply voltage range.

The power supply and the CTL terminal may be started up and shut down in any order without problems.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6/9

2011.03 - Rev.C

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

(

G

G

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

Technical Note

●Vo Terminal

Please attach an anti-oscillation capacitor between VOUT and GND. The capacitance of the capacitor may significantly

change due to factors such as temperature changes, which may cause oscillations. Please use a tantalum capacitor or

aluminum electrolytic capacitor with favorable characteristics and small external series resistance (ESR) even at low

temperatures. The output oscillates regardless of whether the ESR is large or small. Please use the IC within the stable

operating region while referring to the ESR characteristics reference data shown in Figs.33 through 35. In cases where there

are sudden load fluctuations, the a large capacitor is recommended.

EFFECTIVE SERIES RESISTANCE:ESR [Ω]

0.1

100

10

Unstable operating region

Stable operating region

1

Unstable operating region

100

1

10

OUTPUT CURRENT:lo(mA)

1000

OUTPUT CURRENT:lo(mA)

IC

OUT

22μF

C(ADJ)

100

10

1

0.1

0

EFFECTIVE SERIES RESISTANCE:ESR [Ω]

Fig.33:Output equivalent circuit Fig.34:Io vs. ESR characteristics Fig.35: Io vs. ESR characteristics

Unstable operating region

Stable operating region

Unstable operating region

200

400

1000

800

600

(BA□□CC0) (BA□□DD0)

●Other

1) Protection Circuits

Overcurrent Protection Circuit

A built-in overcurrent protection circuit corresponding to the current capacity prevents the destruction of the IC when there

are load shorts. This protection circuit is a “7”-shaped current control circuit that is designed such that the current is

restricted and does not latch even when a large current momentarily flows through the system with a high-capacitance

capacitor. However, while this protection circuit is effective for the prevention of destruction due to unexpected accidents, it

is not suitable for continuous operation or transient use. Please be aware when creating thermal designs that the overcurrent

protection circuit has negative current capacity characteristics with regard to temperature (Refer to Figs.4 and 16).

Thermal Shutdown Circuit (Thermal Protection)

This system has a built-in temperature protection circuit for the purpose of protecting the IC from thermal damage. As

shown above, this must be used within the range of acceptable loss, but if the acceptable loss happens to be continuously

exceeded, the chip temperature Tj increases, causing the temperature protection circuit to operate.

When the thermal shutdown circuit operates, the operation of the circuit is suspended. The circuit resumes operation

immediately after the chip temperature Tj decreases, so the output repeats the ON and OFF states (Please refer to

Figs.12 and 24 for the temperatures at which the temperature protection circuit operates).

There are cases in which the IC is destroyed due to thermal runaway when it is left in the overloaded state. Be sure to

avoid leaving the IC in the overloaded state.

Reverse Current

In order to prevent the destruction of the IC when a reverse current flows through the IC, it is recommended that a diode

be placed between the Vcc and Vo and a pathway be created so that the current can escape (Refer to Fig.36).

2) This IC is bipolar IC that has a P-board (substrate) and P+ isolation layer

between each devise, as shown in Fig.37. A P-N junction is formed between

Reverse current

this P-layer and the N-layer of each device, and the P-N junction operates as a

parasitic diode when the electric potential relationship is GND> Terminal A,

GND> Terminal B, while it operates as a parasitic transistor when the electric

potential relationship is Terminal B GND> Terminal A. Parasitic devices are

Vcc

CTL

OUT

GND

intrinsic to the IC. The operation of parasitic devices induces mutual

interference between circuits, causing malfunctions and eventually the

destruction of the IC itself. It is necessary to be careful not to use the IC in ways

that would cause parasitic elements to operate. For example, applying a

voltage that is lower than the GND (P-board) to the input terminal.

NPN)

B

E

(Pin A)

Resistor

(Pin B)

(Pin B)

Transistor

O

P+

GND

N

P+

N

P

N

P+

P

Parasitic element

GND

N

ig. 37: Example of the basic structure of a bipolar IC

(Pin A)

P+

N

F

Parasitic element

or transistor

N

P

N

P

GND

Fig. 36:Bypass diode

C

B

E

ND

Parasitic element

or transistor

Parasitic element

ND

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

7/9

2011.03 - Rev.C

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

●Ordering part number

B A 0 0 C C 0 W H F P - T R

Part No. Output voltage

00:Variable

HRP5

9.395±0.125

(MAX 9.745 include BURR)

8.82 ± 0.1

(6.5)

8.0±0.13 1.017±0.2

1.2575

1.72

0.08±0.05

TO252-5

5.5±0.2 1.5±0.2

6.5±0.2

5.1

123 54

0.5

FIN

+0.2

-

0.1

0.8

TO220CP-V5

10.0

+0.4

0.2

-

15.2

12.0± 0.2

8.0± 0.2

4.92± 0.2

0.82± 0.1

1.0± 0.2

0.92

+0.3

-

0.1

54321

0.73±0.1

0.08 S

C0.5

1.27

φ3.2± 0.1

1.7781.444

(7.49)

2.3±0.2

1.905±0.1

S

0.5±0.1

1.5

0.5±0.1

1.0±0.2

4.5±0.1

+0.2

2.8

-

0.1

0.42± 0.1

(2.85)

4.12

Series

CC0 : 1A

DD0 : 2A

10.54±0.13

0.835±0.2

1.523±0.15

+5.5°

4.5°

−4.5°

+0.1

0.27

−0.05

(Unit : mm)

9.5±0.5

2.5

(Unit : mm)

13.60

16.92

(1.0)

1.58

(Unit : mm)

Shutdown

switch

W : Includes

switch

Package

HFP :HRP5

FP :TO252

CP :TO220CP

T :TO220FP

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2000pcs

TR

The direction is the 1pin of product is at the upper right when you hold

( )

reel on the left hand and you pull out the tape on the right hand

Reel

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2000pcs

E2

The direction is the 1pin of product is at the lower left when you hold

( )

reel on the left hand and you pull out the tape on the right hand

Reel

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

500pcs

E2

The direction is the 1pin of product is at the lower left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Technical Note

Packaging and forming specification

TR: Embossed tape and reel

(HRP5)

E2: Embossed tape and reel

(TO252-5,TO220CP)

None : Container Tube

V5 :Foaming(V5 only)

Direction of feed

Direction of feed

Direction of feed

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

8/9

2011.03 - Rev.C

BA00DD0WCP-V5,BA00DD0WHFP,BA00DD0WT,

BA00CC0WT,BA00CC0WT-V5,BA00CC0WCP-V5,BA00CC0WFP

TO220FP-5

−0.2

+0.4

17.0

13.5Min.

+0.3

10.0

−0.1

+0.3

7.0

1.8±0.28.0±0.2

12.0±0.2

0.7

−0.1

φ

3.2±0.1

1.2

0.8

+0.3

4.5

−0.1

+0.2

2.8

−0.1

<Tape and Reel information>

Quantity

Direction of feed

TubeContainer

500pcs

Direction of products is fixed in a container tube

Technical Note

1.778

23451

0.5±0.1

2.85

(Unit : mm)

Order quantity needs to be multiple of the minimum quantity.

∗

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

9/9

2011.03 - Rev.C

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...