Page 1

PAD-T-M: 3574.3259.02/01.00/CI/1/EN

R&S®UPV-K7

Software for Hearing Aids Tests

Operating Manual

Version 2.0.0.20

Operating Manual

1401.9353.12 – 04

Page 2

© 2019 Rohde & Schwarz GmbH & Co. KG

Muehldorfstr. 15, 81671 Munich, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

E-mail: info@rohde-schwarz.com

Internet: http://www.rohde-schwarz.com

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1401.9353.12 | Version 04 | R&S®UPV-K7

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol , e.g. R&S®UPV-K7 is indicated as

R&S UPV-K7, or R&S®UPV is indicated as R&S UPV, etc.

Page 3

R&S UPV-K7 Contents

Operating Manual 1401.9353.12 - 04 3

Contents

1 Overview .............................................................................................. 6

2 Preparation and Start of the Application Software .......................... 7

2.1 Required Measuring Instruments and Accessories ................................................. 7

2.2 Installing the Software ................................................................................................ 9

2.3 Test Setup ..................................................................................................................... 9

2.4 Starting the Application Software ............................................................................10

3 Operating Concept............................................................................ 14

3.1 Options (General settings) ........................................................................................14

4 Calibration ......................................................................................... 19

4.1 Calibration Devices....................................................................................................19

4.2 Microphone Calibration .............................................................................................21

4.3 Calibration of Ear Simulator IEC 711 .......................................................................22

4.4 Entering correction values for Pistonphones .........................................................23

4.5 Calibration of Sound Source ....................................................................................23

4.6 Calibration of the International Speech Test Signal (ISTS) ...................................24

4.7 Calibration Value for Induction Coil.........................................................................25

5 Data Entry for Reporting .................................................................. 26

5.1 Operator ......................................................................................................................26

5.2 Test Object .................................................................................................................26

6 Measurements ................................................................................... 27

6.1 Functionality and Control of the Measurement Macros ........................................27

6.1.1 Zooming .......................................................................................................................28

6.1.2 Changing the Scale of the Graph ................................................................................28

6.1.3 Cursor ..........................................................................................................................28

6.1.4 Data Point Size ............................................................................................................29

6.1.5 Performing Additional Measurements..........................................................................29

6.1.6 Storing and Loading Curves ........................................................................................29

6.1.7 Storing Curves as Limit Curves ...................................................................................29

6.1.8 Entering a Comment ....................................................................................................29

6.1.9 Creating a Report.........................................................................................................30

6.1.10 Generating a Landscape Report ..................................................................................30

6.1.11 Closing the Measurement Window ..............................................................................30

Page 4

R&S UPV-K7 Contents

Operating Manual 1401.9353.12 - 04 4

6.2 Customizing Measurements .....................................................................................31

6.3 Notes on Individual Measurements .........................................................................33

6.3.1 Frequency Response Measurement............................................................................33

6.3.2 Multi-Curve Measurement ...........................................................................................37

6.3.3 Saturation Sound Pressure Level Measurement .........................................................40

6.3.4 Harmonic Distortion Measurement ..............................................................................41

6.3.5 Intermodulation Distortion Measurement .....................................................................44

6.3.6 Measurement of Dynamic Behaviour (AGC Settling) ..................................................47

6.3.7 Measurement of Input-Output Characteristics .............................................................49

6.3.8 Measurement of Equivalent Input Noise ......................................................................51

6.3.9 Battery Current Measurement .....................................................................................54

6.3.10 Speech Test according to IEC 60118-15 .....................................................................56

6.3.11 Routine for Reference Test Gain Setting .....................................................................62

6.3.12 Routine for Alignment of the Hearing Aid in the Magnetic Field ..................................64

6.3.13 Electric Input Sensitivity Measurement ........................................................................65

6.3.14 Create Report ..............................................................................................................67

6.3.15 Set Switcher .................................................................................................................68

6.3.16 Start Executable ...........................................................................................................69

7 Automatic Test Sequences .............................................................. 71

7.1 Creating and Editing a Sequence .............................................................................71

7.2 Opening an Existing Sequence ................................................................................72

7.3 Using a Sample Sequence ........................................................................................72

7.4 Running a Sequence .................................................................................................72

7.5 Running a Single Measurement within a Sequence...............................................73

7.6 Reporting on Sequence Results ..............................................................................73

8 Reporting, Storing, Loading and Deleting Results ........................ 74

8.1 Result Files .................................................................................................................74

8.2 Report Settings ..........................................................................................................74

8.3 Generating a Single Report ......................................................................................75

8.4 Generating a Sequence Report ................................................................................75

8.5 Configuring the Landscape Report..........................................................................76

8.6 Generating a Landscape Report ..............................................................................77

8.7 Selection Report ........................................................................................................77

8.8 Configuring the One-Page Report ............................................................................78

8.9 Generating a One-Page Report ................................................................................79

8.10 Preview Window.........................................................................................................81

8.11 Storing and Loading Curves .....................................................................................82

Page 5

R&S UPV-K7 Contents

Operating Manual 1401.9353.12 - 04 5

8.12 Deleting Results .........................................................................................................83

8.13 Automatic Backup and Restoration of the Results File.........................................83

9 Remote Control ................................................................................. 85

9.1 Preparations ...............................................................................................................85

9.2 String Buffers and Data Buffers ...............................................................................85

9.3 Sending a Remote Control Command .....................................................................87

9.4 Remote Controlled Settings .....................................................................................88

9.4.1 Selecting a device under test .......................................................................................88

9.4.2 Setting the supply voltage ............................................................................................89

9.4.3 Setting the environmental values for the reports .........................................................89

9.4.4 Measuring the supply current ......................................................................................89

9.4.5 Generating a report and storing it to a file ...................................................................90

9.5 Starting a Measurement ............................................................................................90

9.6 Continue and Done ....................................................................................................90

9.7 Reading the Results ..................................................................................................90

9.8 Status of the remotely started measurement function ..........................................91

10 Terminating the Application ............................................................ 92

11 Index .................................................................................................. 93

Page 6

R&S UPV-K7 Overview

Operating Manual 1401.9353.12 - 04 6

1 Overview

Tests of basic properties of hearing aids are specified in standards IEC 60118 and

ANSI S3.22. They comprise measurement of output sound pressure level, frequency

responses, output SPL over input SPL, harmonic distortion, battery current drain and

AGC settling.

Audio Analyzer R&S UPV with option R&S UPV-K7 provides a test system which,

together with the necessary acoustic accessories, allows measurements according to

IEC60118-0:1983, IEC60118-0:2015, IEC60118-1:1995, IEC60118-2:1983, IEC601186:1999, IEC60118-7:2005, IEC60118-9:1985 and ANSI S3.22-2003.

In addition to standard measurements it is possible to create own tests by customizing

the available parameters.

With additional option R&S UPV-K71, tests according to IEC60118-15 using speech

signal can be performed.

Automatic test sequences can be compiled from the available tests, and results are

compiled for subsequent creation of test reports.

1.1

Page 7

R&S UPV-K7 Preparation and Start of the Application Software

Required Measuring Instruments and Accessories

Operating Manual 1401.9353.12 - 04 7

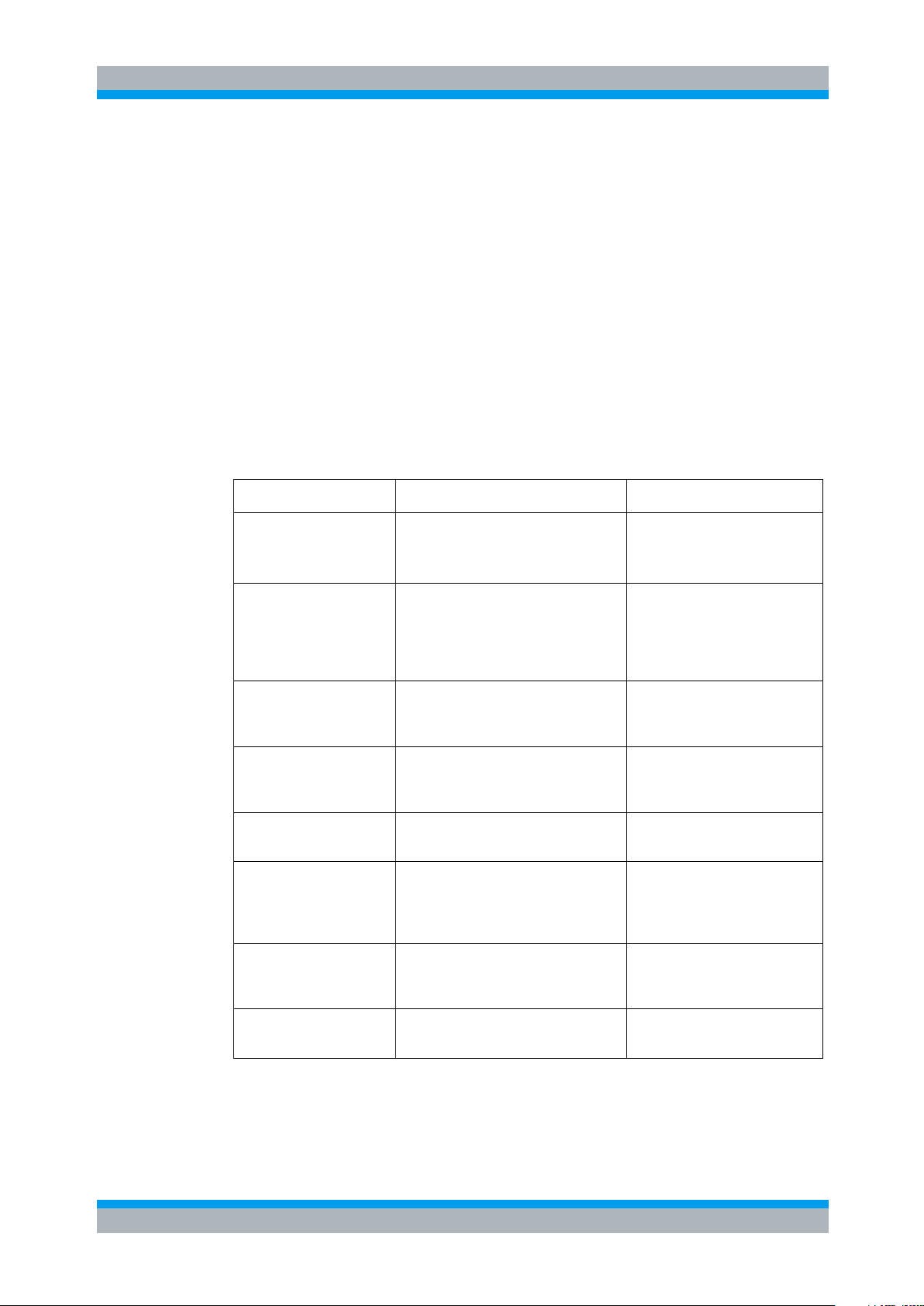

Device

Description

Type (examples)

Hearing aid test box

Anechoic box with built-in sound source

and induction loop, feed-throughs for

the most important connection lines

R&S UPL-B7 or Interacoustics

TBS25 or B&K 4232

Measurement microphone

¼” measurement microphone for

measurement of artificial mouth output

during calibration, to be inserted into

IEC 126 2cc coupler, and for

comparison measurement

B&K 4938 with B&K 2670 or

G.R.A.S. 40BP with G.R.A.S.

26AC

Low-noise measurement

microphone

½” measurement microphone with high

sensitivity and low self-noise for speech

tests according to IEC 60118-15.

G.R.A.S. 40AP with G.R.A.S.

26AC and right-angled adapter

RA0001

IEC 126 coupler

Acoustic coupler according to IEC 126

Part of R&S UPL-B7 (with internal

microphone or with ¼”

microphone with preamplifier)

IEC 126 coupler for ½“

microphone

Acoustic coupler according to IEC 126,

for use with ½” microphone

G.R.A.S. RA0038

IEC 711 ear simulator

(optional)

IEC 711 type occluded ear simulator

with adapters for calibration and

connection to the output of the DUT,

with 1/2” - preamplifier

B&K 4157 & 2669 or G.R.A.S.

RA0045

Acoustic calibrator

Sound level calibrator or pistonphone

for calibrating the measuring

microphones

B&K 4231 or G.R.A.S. 42AB

Microphone power supply

Power supply and preamplifier for the

measuring microphone

B&K 2829, 5935L or 2690A0S2

or G.R.A.S. 12AD or 12AA

2 Preparation and Start of the Application

Software

2.1 Required Measuring Instruments and Accessories

The Audio Analyzer R&S UPV with option R&S UPV-K7 is required for the

measurements.

Acoustic devices such as measurement couplers, a calibrator and other accessories

are required for the measurements. The following equipment from Brüel & Kjær or

G.R.A.S. may be used:

Table 2-1: Acoustic accessories for hearing aid tests

Page 8

R&S UPV-K7 Preparation and Start of the Application Software

Required Measuring Instruments and Accessories

Operating Manual 1401.9353.12 - 04 8

With the amplifier set to 0 dB, the microphone power supply B&K 2690A0S2 produces

too much noise for measuring idle noise and distortion. It is therefore advisable to set

a gain of 20 dB.

Theoretically the reference microphone for sound source calibration and comparison

measurement should be a free field type and the IEC 126 coupler should be used with

a pressure field type. However with a ¼” microphone the frequency response

difference is negligible up to at least 10 kHz.

When using a ½” pressure microphone as reference microphone, a good

approximation of a flat free field response is achieved if the microphone is place such

that the sound incidence is from 90 degrees relative to the microphone axis.

An external USB keyboard and a mouse must be connected to the R&S UPV.

R&S UPV-K7 does not support the use of headphones.

Do not connect headphones to the R&S UPV during hearing aid tests. High level

signals may be present at the headphone connector.

The audio analyzer must meet the following firmware requirements:

● R&S UPV firmware version 4.0.4 or higher

● License key R&S UPV-K7 installed

● For tests with speech-like signals according to IEC 60118-15, license key

R&S UPV-K71 must be installed in addition.

Page 9

R&S UPV-K7 Preparation and Start of the Application Software

Operating Manual 1401.9353.12 - 04 9

2.2 Installing the Software

Acoustical Test Box

START SINGLE CONT H COPY OUTPUT

STOP OFF

1 2 1 2

UNBAL OPTICAL

BAL

UNBAL OPTICAL

BAL

UPV AUDIO ANAL YZER DC ... 250 kHz

.

110 V RMS /160 V PK CAT I

CONTROL

DATA VARIATION

ANALOG

DIGITAL AUDIO OUTPUT

POWER

DIGITAL AUDIO INPUT

ON

REM

LOCALDOWN

SHUT-

WINDOW SETUP

SCREEN

WINDOW

SCAN

PAGE

WINBAR MODIFY HIDE CLOSE SAVE LOAD PRESETHELP

0

1 2 3

4 5 6

7 8

9

. -

+/

ESC

MENU

UNDO

.

ANALYZEROVLD OVLD

F 5 F 6

F 7 F 8 F 9 F 10 F 11 F 12

GENERATOR

USB

ghi jkl m no

# A a

pqrs tuv wxyz

abc d ef

*

...

Microphone

Power Supply

in

out

Loudspeaker Cable

Battery Adaptor Cable

Coupler Cable

Telecoil Cable

ANLG AUX OUT

Audio Analyzer

R&S UPV

The application program requires key K7 to be installed. The application program and

the key are installed in the factory in case a new R&S UPV is ordered together with this

option. If the option is ordered separately, the key as well as the installation manual is

part of the delivery.

For instructions on installation of the software and update of previous versions please

see the release notes.

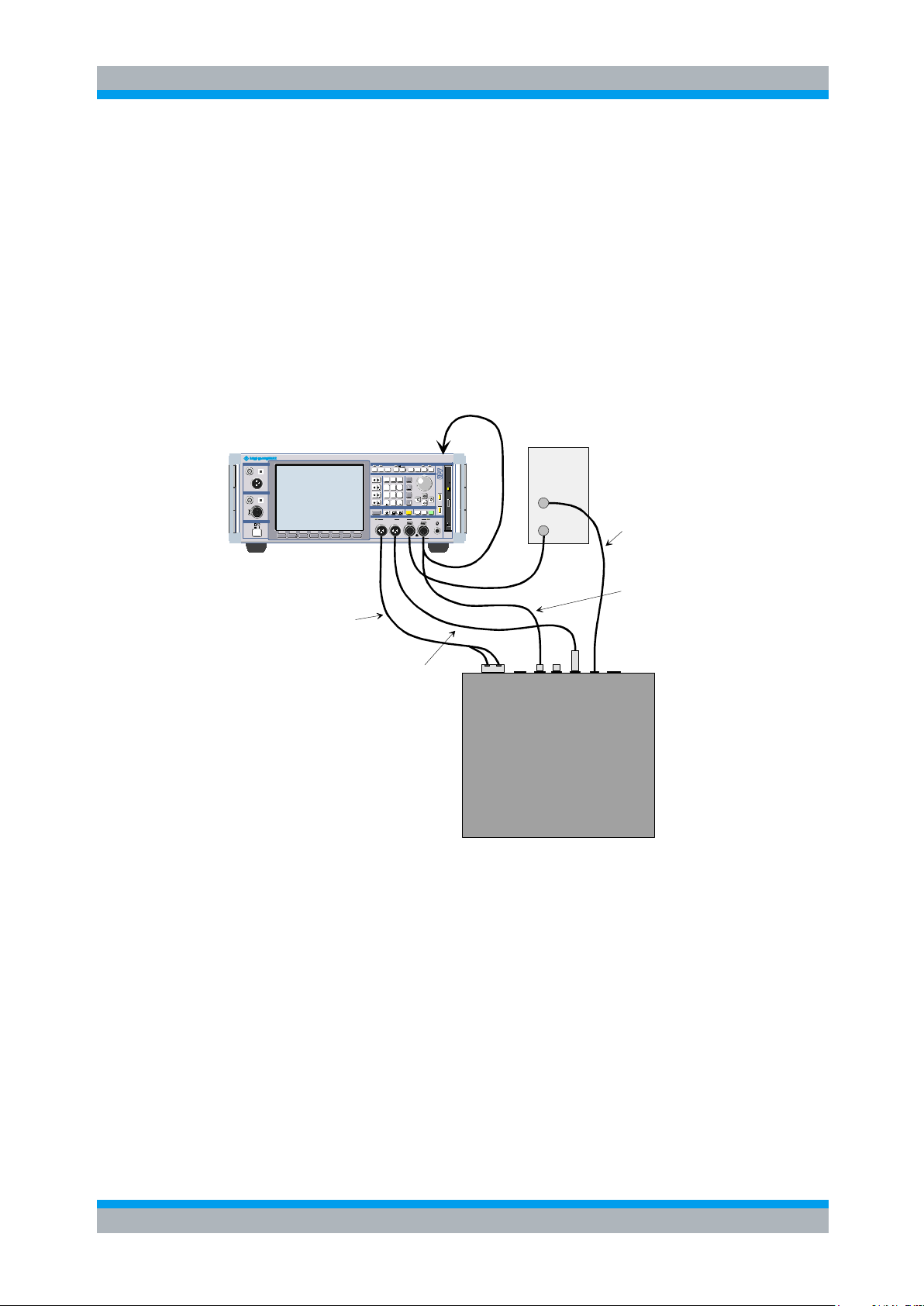

2.3 Test Setup

Installing the Software

Figure 2-1 Test setup and connection of external components

The following cables are required to connect speaker, induction loop and battery

voltage supply of the test box delivered with R&S UPL-B7 to the R&S UPV. The

microphone signal from the microphone power supply may be connected to the

analyzer input with a BNC cable and an R&S UP-Z1MF adapter. If a custom made

BNC to XLR cable is used, it should be made following the schematics of the R&S UPZ1MF adapter (see R&S UPV Manual, chapter “Configuring the Analog Analyzer”).

Page 10

R&S UPV-K7 Preparation and Start of the Application Software

Starting the Application Software

Operating Manual 1401.9353.12 - 04 10

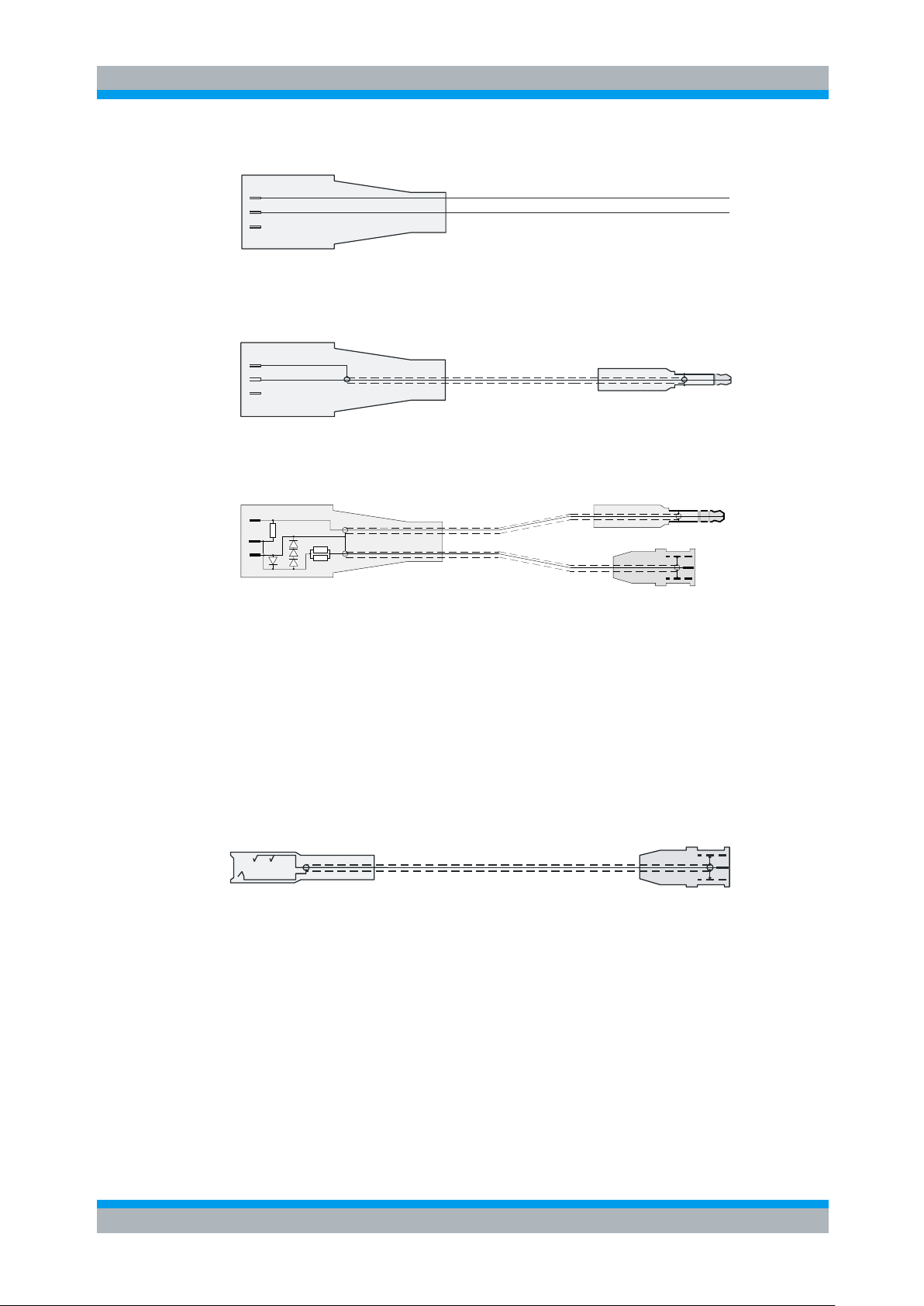

XLR female

3

2

1

open ends

Loudspeaker Cable

XLR female

3

2

1

6.3 mm mono jack male

Telecoil Cable

3

2

1

XLR male

D: 4 diodes: 1N4007 or similar (1A forward current)

R1: resistor 2 Ohm, 1%

R2: 2 resistors 1 Ohm, 1%

3.5 mm stereo jack male

BNC male

R1

R2

D

Battery Cable

6.3 mm stereo jack female BNC male

Figure 2-2 Connection cables for R&S UPL-B7 (Interacoustics TBS 25) test box

The cables shown in Figure 2-2 can be ordered as Accessory R&S UPV-Z7.

The cables of R&S UPL-B7 can be re-used for R&S UPV-K7. As the supply voltage is

now provided by the “ANLG AUX OUT” on the rear panel of the R&S UPV, the

following adapter is required in addition.

Figure 2-3 Adapter cable to connect the R&S UPL-B7 battery supply cable

to the “ANLG AUX OUT” of the R&S UPV

2.4 Starting the Application Software

After installation, the program can be started by double-clicking the Icon “UPV-K7

Hearing Aid Tests” or by clicking “R&S UPV Applications UPV-K7 Hearing Aid

Tests” in the “Programs” menu.

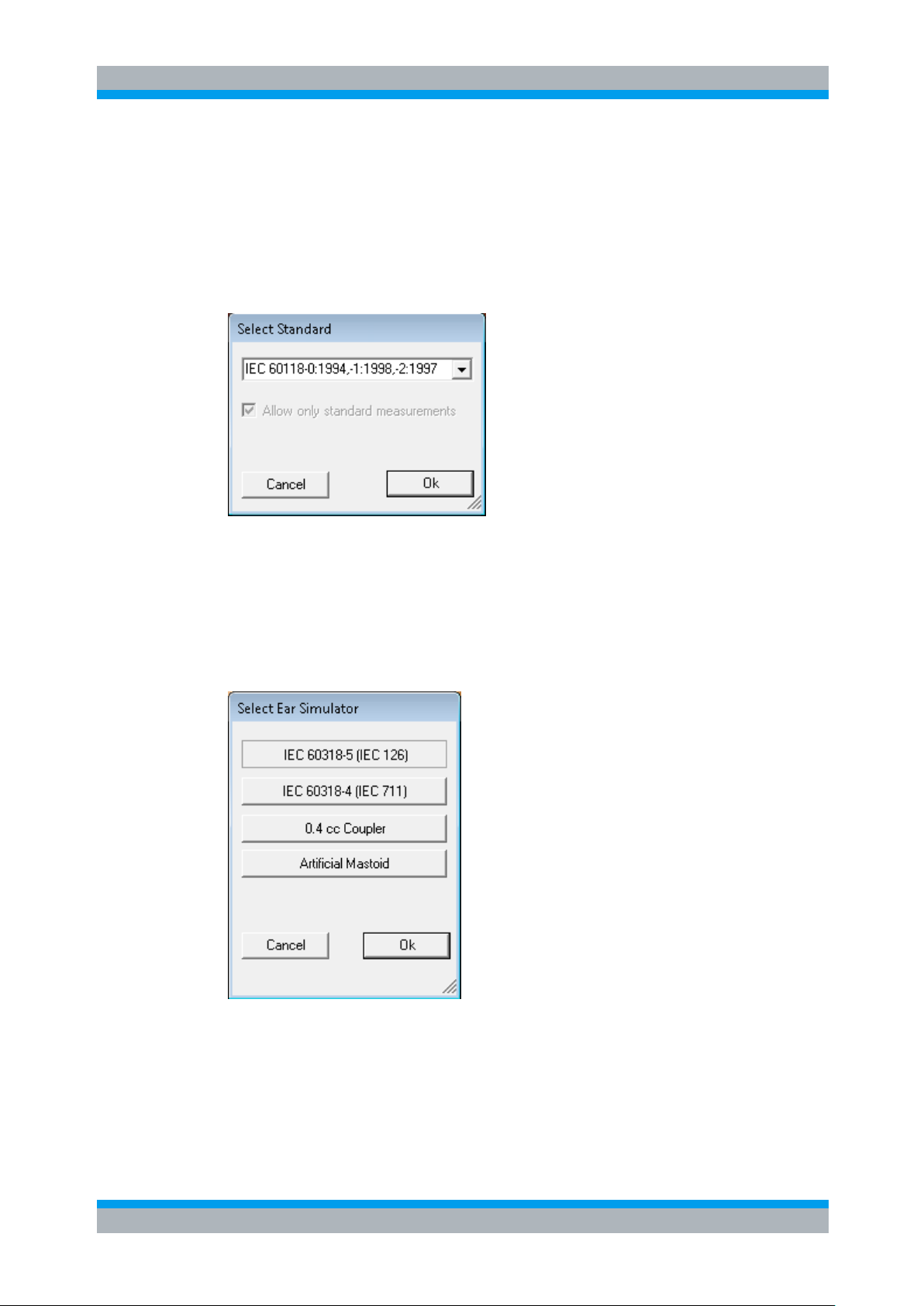

At the fist start of the program, selection windows appear for the standard according to

which the measurements should be made, and for the measurement coupler used.

Page 11

R&S UPV-K7 Preparation and Start of the Application Software

Starting the Application Software

Operating Manual 1401.9353.12 - 04 11

The entered selections are stored with the settings and automatically loaded at the

next start of the program.

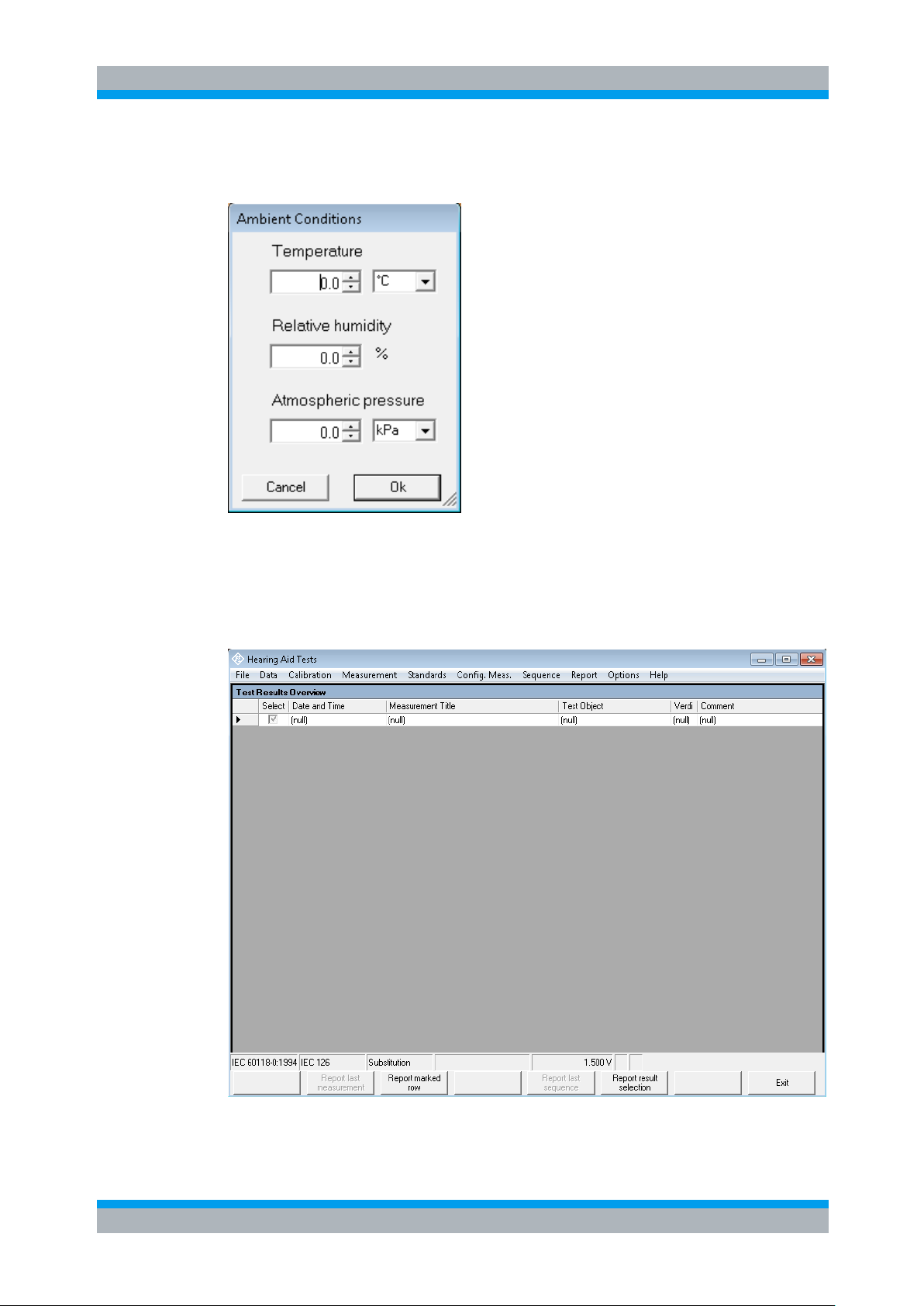

At each start of the program, the ambient conditions temperature, relative humidity and

atmospheric pressure are queried for protocol purpose. The entered values are not

stored in the settings, because the ambient conditions are supposed to change with

time. The query can be deselected and values can be changed any time in the

“Options” menu.

Figure 2-4 Query window for selection of applied standard

If “none” is selected in the standard selection window, all measurements appear in the

“Measurement” menu. If a standard is selected, all measurements appear in the

“Measurement” menu, but compliant measurements are checked in the menu. If “Allow

only standard measurements” is checked, non-compliant measurements are

suppressed in the Measurement menu.

Figure 2-5 Query window for selection of ear simulator

When the checkbox “Do not show this dialog again” is checked, the corresponding

selection window will not appear at the program start in future. However, the selection

is still available in the “Options” menu (see below).

Page 12

R&S UPV-K7 Preparation and Start of the Application Software

Starting the Application Software

Operating Manual 1401.9353.12 - 04 12

The next window to open is the input window for the ambient conditions temperature,

relative humidity and atmospheric pressure.

Figure 2-6 Query window for input of ambient conditions

The units can be switched between °C and °F and between kPa and mmHg,

respectively. After the last of the three selection windows has been closed, the main

window of the R&S UPV-K7 opens.

Figure 2-7 Main window after first start of the program

Page 13

R&S UPV-K7 Preparation and Start of the Application Software

Starting the Application Software

Operating Manual 1401.9353.12 - 04 13

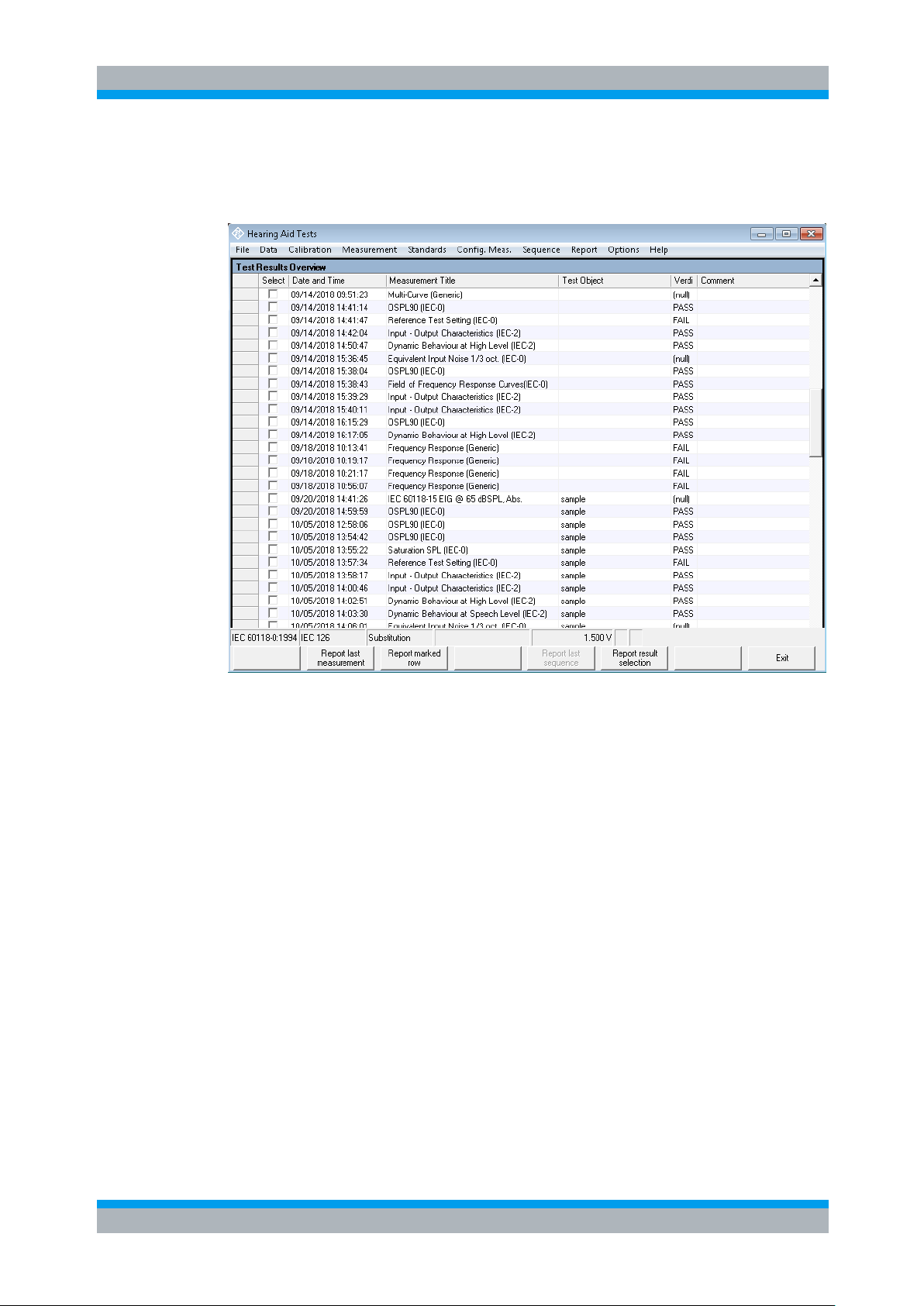

Initially, the data grid in the center of the screen which shows the result overview is

empty. The screenshot below shows an example after a number of measurements

have been made.

Figure 2-8 Main window with results

Page 14

R&S UPV-K7 Operating Concept

Operating Manual 1401.9353.12 - 04 14

3 Operating Concept

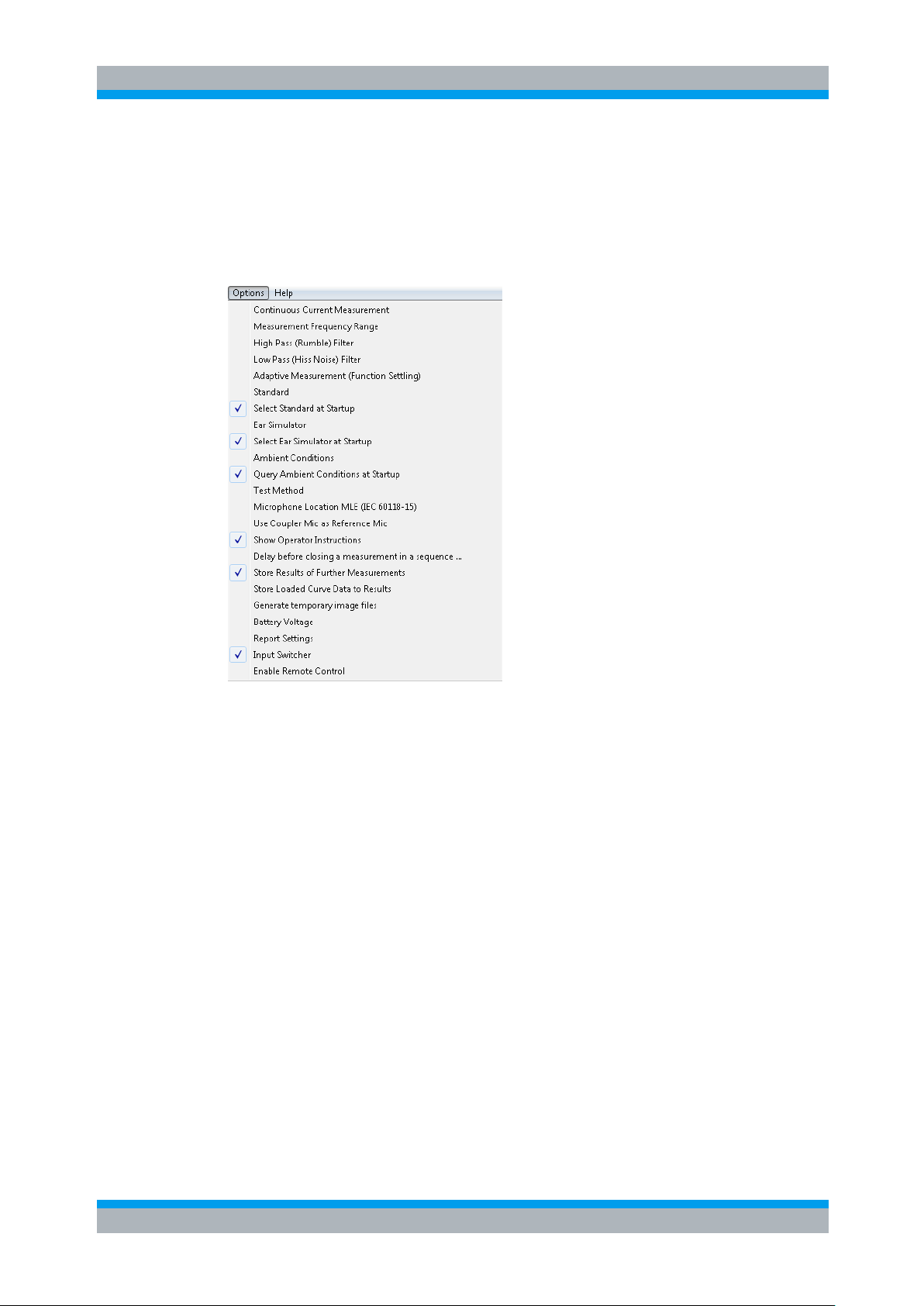

3.1 Options (General settings)

Options (General settings)

Figure 3-1 Options menu

The “Options” menu in the main window allows to change a set of general settings like

ear simulator, test method and battery voltage, which are valid for all or at least a

plurality of the tests.

“Continuous current measurement” allows to measure the supply current at

analyzer input 2. This option can only be selected with the substitution method. The

value of the shunt resistor for the current measurement can be entered in the

calibration menu. By default it is set to 2 Ω.

“Measurement frequency range” allows to enter the frequency range in which the

sound source is calibrated. In general this will be 100 Hz to 10 kHz which is the default.

“Number of points” specifies the number of (logarithmically spaced) frequencies

measured for the sound source equalization.

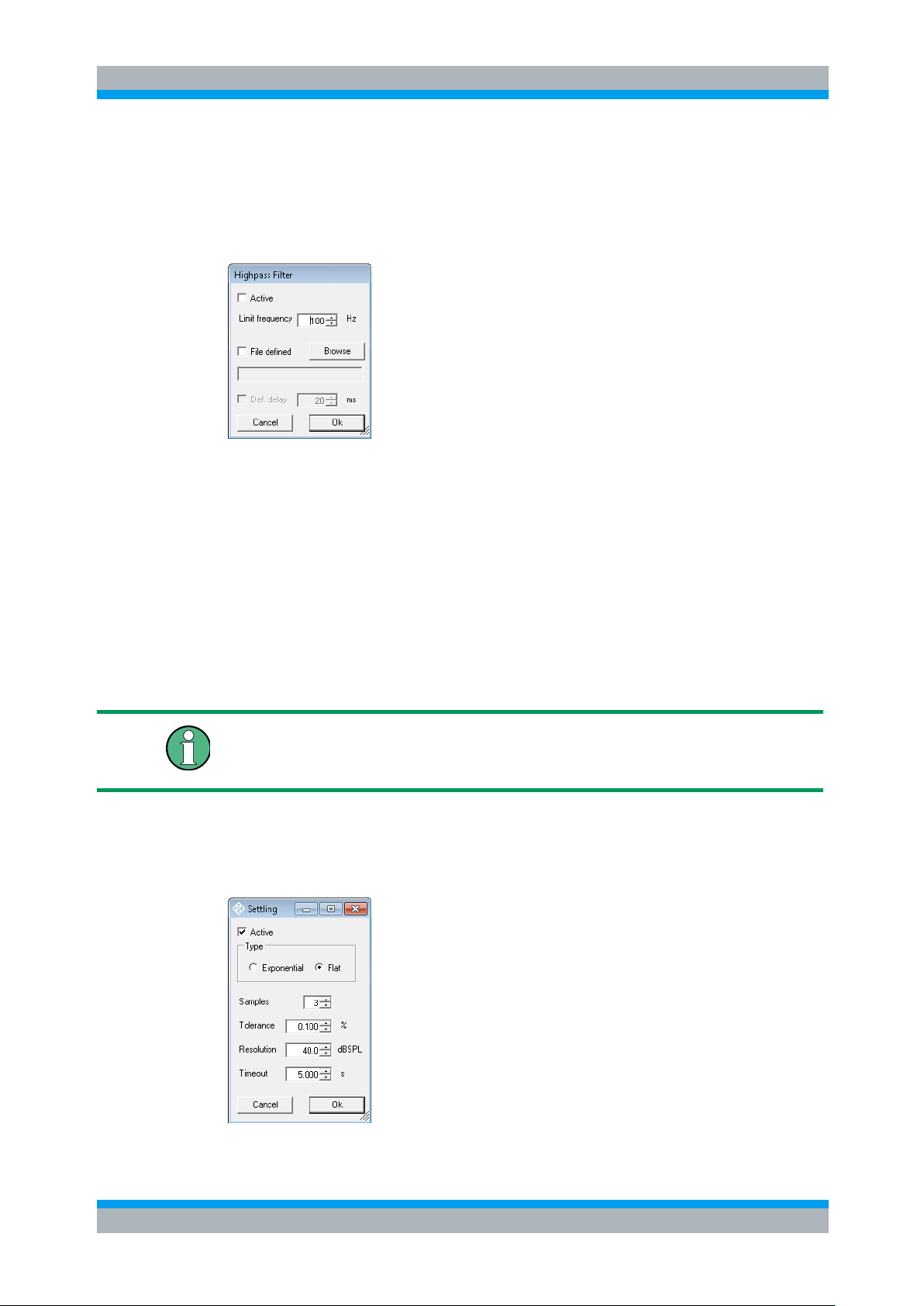

“High pass (rumble) filter” allows to set a high pass filter which is active in most

measurements except distortion measurements, battery current measurements and

noise measurements. The edge frequency of the high pass filter can be set, and the

filter can be activated and deactivated. The high pass filter is not applied to battery

current measurements.

Page 15

R&S UPV-K7 Operating Concept

Options (General settings)

Operating Manual 1401.9353.12 - 04 15

Filters slow down the measurement. Therefore they should only be used if necessary.

In particular a combination of selective measurement with high pass and / or low pass

filter is not recommended.

If “File defined” is deactivated, the edge frequency can be set in the “Limit frequency”

field. The R&S UPV firmware then calculates the filter coefficients and the delay to

account for the filter settling. If “File defined” is activated, a file with filter coefficients

can be loaded using the “Browse” button. A measurement delay for the filter settling

time can be set manually if the “Def. delay” checkbox is activated.

Figure 3-2 Input window for filter settings

“Low pass (hiss noise) filter” allows to set a low pass filter which is active in most

measurements except battery current measurements and noise measurements. The

edge frequency of the high pass filter can be set, and the filter can be activated and

deactivated. The low pass filter is not applied to battery current and distortion

measurements.

The settings in the “Lowpass Filter” window are according to those for the highpass

filter.

With noise measurements, the filters from the “Options” menu are only applied to the

gain measurement. The noise measurement has own parameters for the band limits of

the noise level measurement.

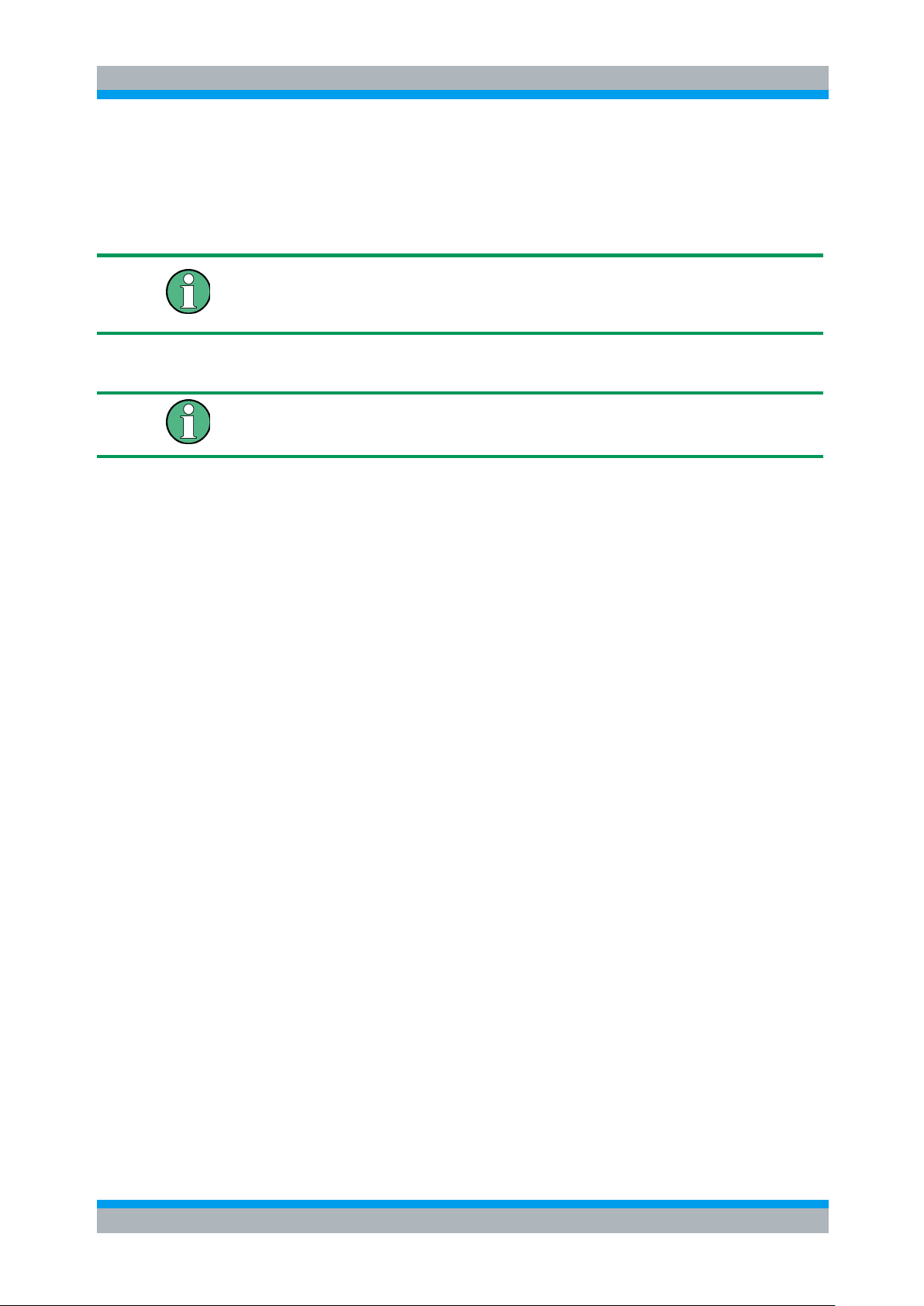

“Adaptive measurement (function settling)” causes gain and level measurements

to be repeated until the result has settled within a specified tolerance. This is helpful to

assure that an AGC which is present in the signal path has adapted to the applied

input signal of the hearing aid.

Figure 3-3 Input window for adaptive measurement

Page 16

R&S UPV-K7 Operating Concept

Options (General settings)

Operating Manual 1401.9353.12 - 04 16

The resolution value must be set high enough to take idle channel noise into account.

If it is set too low, especially measurements with high gain at low input levels may be

aborted due to invalid result values.

If the use of filters leads to slow measurements, the timeout value may have to be

increased.

With the “Flat” type, measurements are repeated until the last “Samples” number of

results are within the given “Tolerance” or the difference between two subsequent

measurement results is below the “Resolution” value. The “Resolution” can be used to

take into account the idle channel noise of hearing aid and measurement equipment.

With the “exponential” type of settling, differences between the earlier results may be

higher than specified, but the results must converge exponentially into the specified

values.

If the settling time of the hearing aid is known, measurement may be faster with settling

turned off. In this case the known settling time has to be entered as pre-delay in the

measurement parameters of each measurement.

Function settling is generally not applied to battery current measurements. For

harmonic distortion measurements the resolution is set fix to 0.01 % THD.

“Standard” allows to select one of the available standards. Measurements belonging

to this standard will be checked in the measurement menu. If “Allow only standard

measurements” is checked, it is not possible to start single measurements which do

not belong to the standard.

If “Select standard at startup” is checked, the selection window for the standard is

opened at each start of the program.

“Ear simulator” allows to select the type of ear simulator used. For details on the

handling of calibration data see section 4 Calibration below.

If “Select ear simulator at startup” is checked, the selection window for the ear

simulator is opened at each start of the program.

“Ambient conditions” allows to change the temperature, relative humidity and

atmospheric pressure values for the protocol.

“Query ambient conditions at startup” causes the input window for the ambient

condition to be opened at each start of the program.

Page 17

R&S UPV-K7 Operating Concept

Options (General settings)

Operating Manual 1401.9353.12 - 04 17

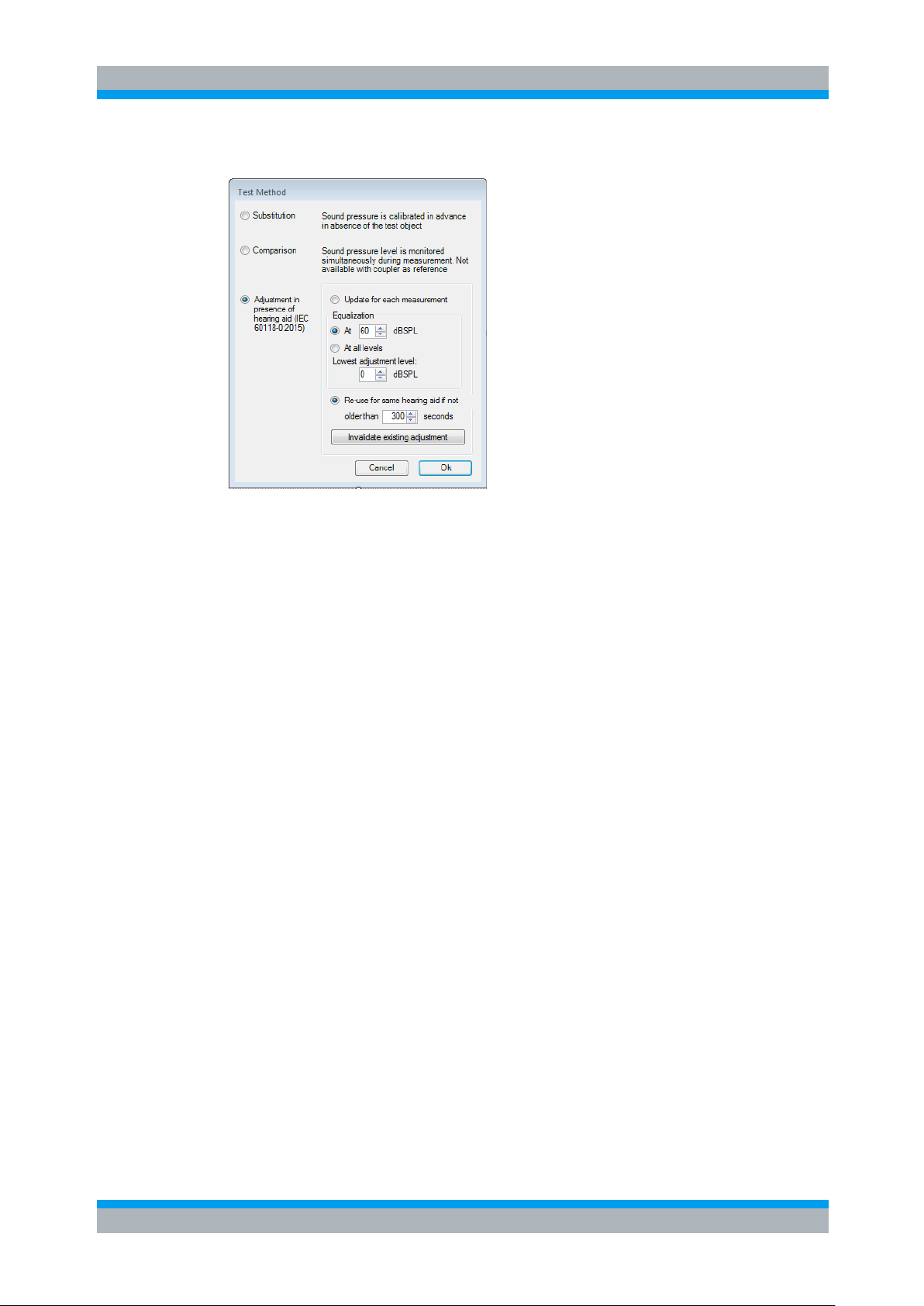

“Test method” allows to select the method for setting the input sound pressure.

Figure 3-4: Window for selection of the test method

With “Substitution”, the nominally set SPL at the input of the hearing aid is assumed to

be correct, due to the calibration of the sound source. With “Comparison”, the input

SPL is measured simultaneously with the output SPL by the reference microphone in a

two channel measurement, and results transfer measurements are corrected for the

deviation of the input SPL from the nominal value. “Comparison” cannot be selected

when the coupler microphone is used as reference microphone (see below). When the

continuous current measurement is active, an input switcher is required for the

“Comparison” method.

From IEC 60118-0:2015 it is required to adjust the input sound pressure level with the

hearing aid under test present. For sweep measurements the input sound pressure

level is measured with an extra sweep using the equalization and calibration value

obtained with the last source calibration. The deviation is subtracted as correction from

the existing values. There are options to do this for each input sound pressure level

value required in the measurement (“Subst. each”) or to do it once with a specified

default sound pressure level (“Subst. once”). As the measurement results from low

input levels can be noisy, especially when a ¼” measurement microphone is used, it is

possible to specify a minimum SPL. For all lower input levels, the sound pressure will

be adjusted with the minimum level instead. The values obtained can be re-used as

long as the same hearing aid is tested (i.e. the device under test is not changed in the

“Data” menu), or updated for each measurement. Single values are fine-adjusted in

this test mode with each measurement.

“Microphone Location MLE (IEC 60118-15)” allows to specify the location of the

hearing aid. The respective frequency correction (“location effect”) according

IEC 60118-8 is taken into account for speech tests according to IEC 60118-15.

● None: No location effect is taken into account

● BTE: Location effect for hearing aids worn behind the ear

● ITE: Location effect for hearing aids worn inside the concha

● ITC: Location effect for hearing aids inserted into the ear canal

● CIC: Location effect for hearing aids which are worn completely inside the ear

canal.

Page 18

R&S UPV-K7 Operating Concept

Options (General settings)

Operating Manual 1401.9353.12 - 04 18

“Use coupler mic as reference mic” allows to use the microphone of the IEC 126

coupler for sound source calibration. In this case the program applies the calibration

value of the coupler microphone for the sound source calibration, and the reference

microphone has to be connected to analyzer input 1 instead of analyzer input 2.

If “Show operator instructions” is checked, instructions to the operator are displayed

in a message box before the measurement starts. The operator may be prompted to

position the hearing aid in a defined way or to set the volume to a certain setting.

In Menu item “Delay before closing a measurement in a sequence” a time period

can be defined for which the result of a completed measurement is shown during

execution of a sequence, before the measurement window is closed and the next

measurement in the sequence is started.

“Store results of further measurements” allows to include results obtained with the

“Add measurement” softkey to the result database. All curves obtained this way will be

reported in the same graph. This allows e.g. to measure responses depending on

settings of the hearing aid, and to report them in a field of curves.

“Store Loaded Curve Data to results” includes curve data which is loaded with the

button “Load Curve” to the result database such that the loaded curves will appear in

the diagram of the respective report.

If “Generate temporary image files” is activated, each measurement stores a

screenshot of the result graph in an image file called “”. The file can be queried by a

remote control host after a remotely started testcase has finished. It is overwritten

when the next measurement finishes successfully.

“Battery voltage” allows to specify the supply voltage for the hearing aid. If a supply

voltage is specified in the parameters of a measurement, the general setting is

overridden. This allows to measure response curves for different supply voltages within

one sequence.

“Report settings” allows to define the type of information which should appear in the

reports. For details on reporting, see section 7 Automatic Test Sequences below.

“Input Switcher” enables the use of a UPZ12 switcher, e.g. to switch the second

analyzer input automatically between the output of a reference microphone measuring

the input sound pressure of a hearing aid, and a shunt resistor for continuous current

measurement.

If “Enable Remote Control” is active, remote controlled start of testcases and

configuration via SCPI commands is possible. For details see section 9.

Page 19

R&S UPV-K7 Calibration

Operating Manual 1401.9353.12 - 04 19

4 Calibration

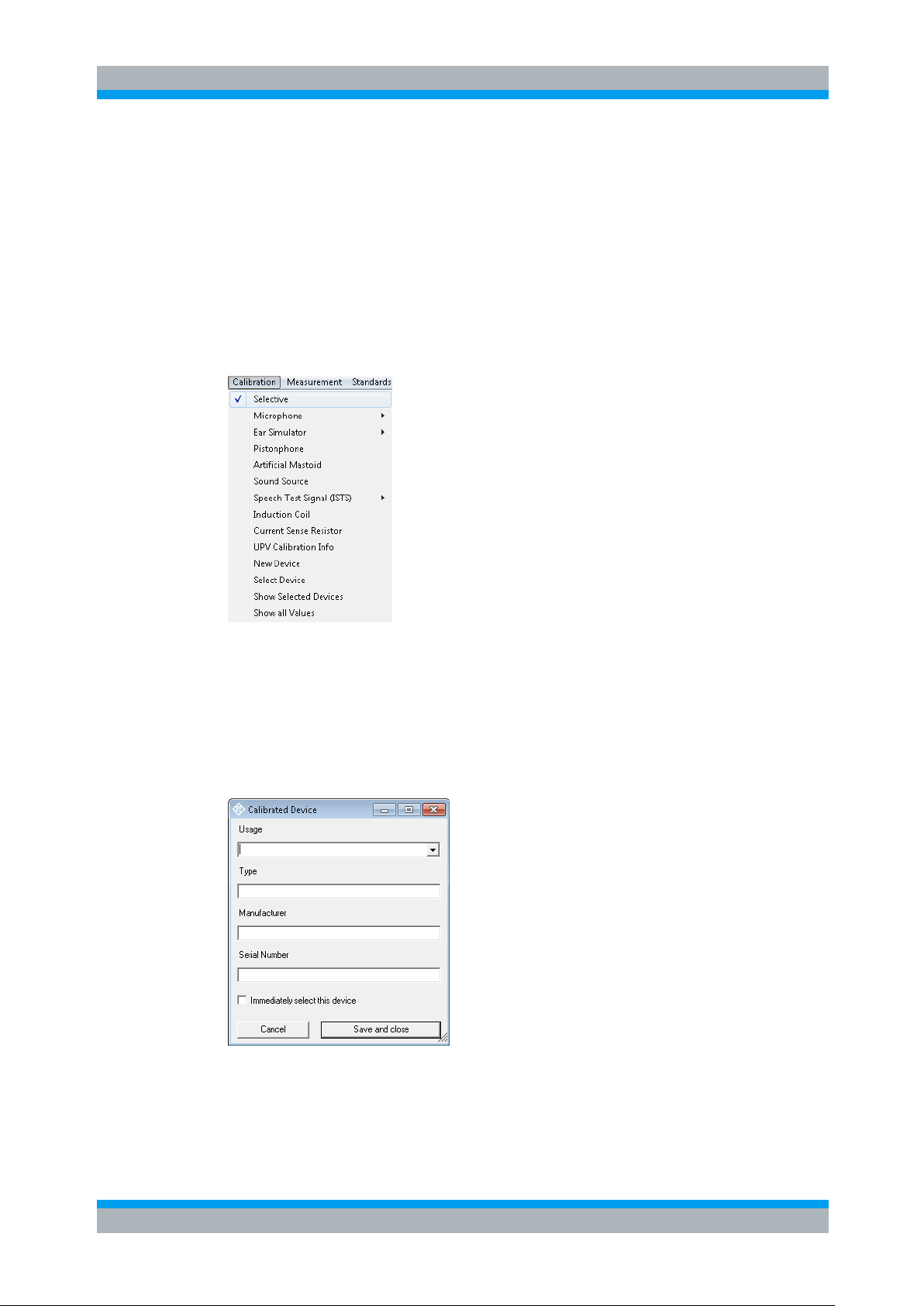

4.1 Calibration Devices

R&S UPV-K7 allows to simultaneously store calibration values for multiple individuals

of the same type. This allows to switch devices without the requirement for recalibration. However, regular re-calibration is recommended in order to assure the

correct function of the used devices.

Calibration Devices

Figure 4-1 Calibration menu

For every device to be calibrated, an entry must be created using “Calibration New

device” in the main menu. This menu item opens an entry window to specify the

calibrated device. A category of device must be chosen from the combo box on top.

Type, manufacturer and serial number are entered into the text boxes below. The

entries are confirmed by clicking on the “Save and close” button.

Figure 4-2 Input window for information about calibrated device

Page 20

R&S UPV-K7 Calibration

Calibration Devices

Operating Manual 1401.9353.12 - 04 20

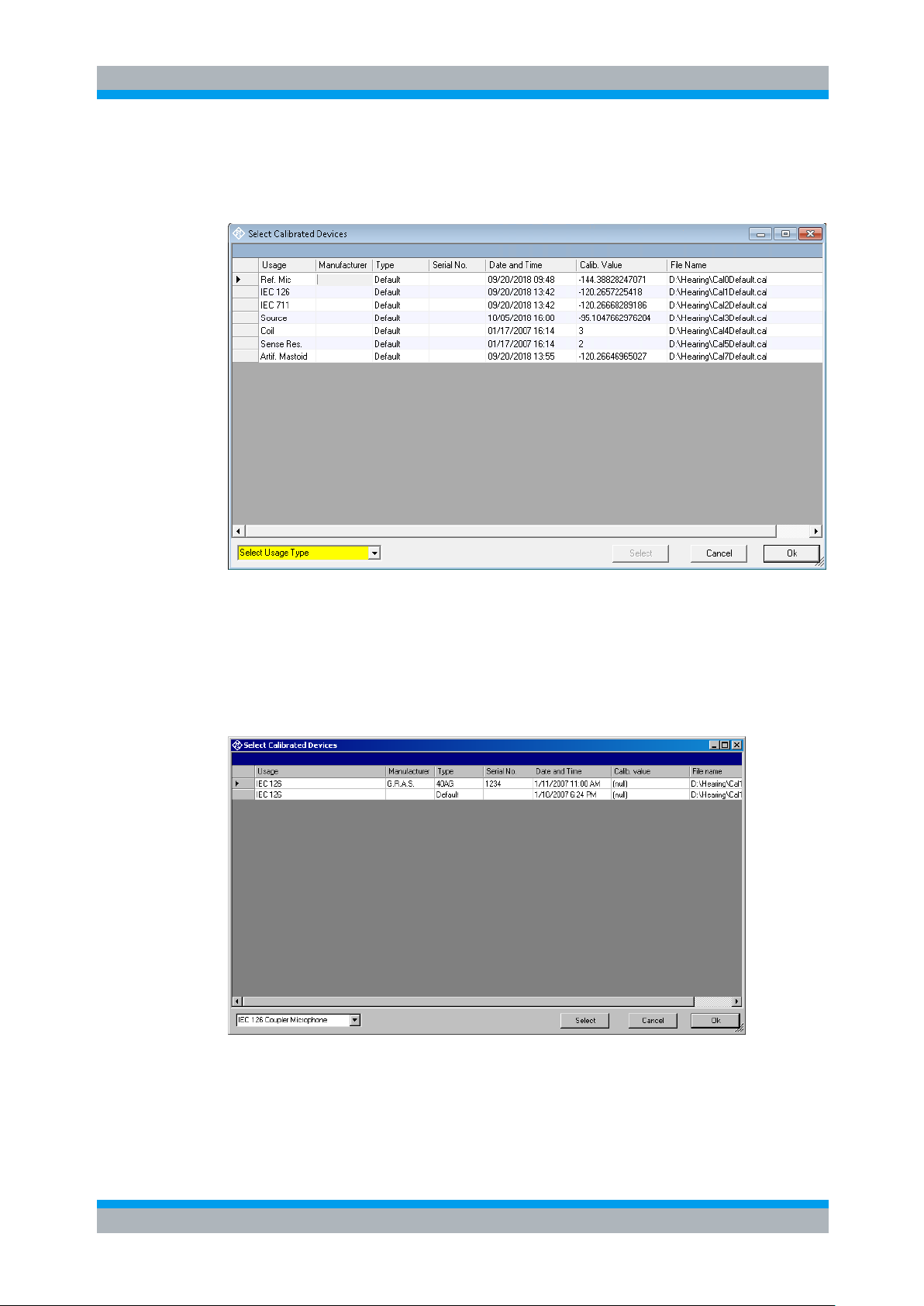

Before a device can be calibrated or used, it must be selected with “Calibration

Select device” in the main menu. Clicking on this item opens a window with a table of

all entered devices.

Figure 4-3 Window for selection of calibrated devices

In the combo box lower left, a category of devices must be selected. Subsequently the

table is reduced to available devices in this category. At first startup, there is only a

“Default” device for each category, but when more devices have been created with the

“New device” function, a choice will be available in this view. In this state a row in the

table can be marked with a mouse click on its left end. A mouse click on the button

“Select” selects this device for the associated usage.

Figure 4-4 Selection window for particular device type (here IEC 126 coupler)

Subsequently this procedure may be repeated for other categories. Finally all

selections are confirmed by clicking the “Ok” button.

Page 21

R&S UPV-K7 Calibration

Operating Manual 1401.9353.12 - 04 21

All calibration data are stored on the R&S UPV hard disk and are therefore

After inserting the microphone, wait about 10 s to allow for static pressure

equalization.

automatically available again after every restart. The calibration values for the

R&S UPV-K7 option are stored independently of other options.

All calibration routines below require as pre-requisite that a device for the respective

usage has been generated and selected.

To simplify the procedure for the case that it is not intended to use multiple devices of

the same category nor to include information about the used devices into a report,

there is a “Default” device selected for each device type or category after the first start

of the program.

4.2 Microphone Calibration

► Insert the measuring microphone fully into the adapter of the sound level

calibrator and switch on the calibrator.

Microphone Calibration

► Call the test routine with “Calibration Microphone 2 cc Coupler”,

“Calibration Microphone Reference” or “Calibration Microphone

0.4 cc Coupler” from the main menu, depending on the microphone.

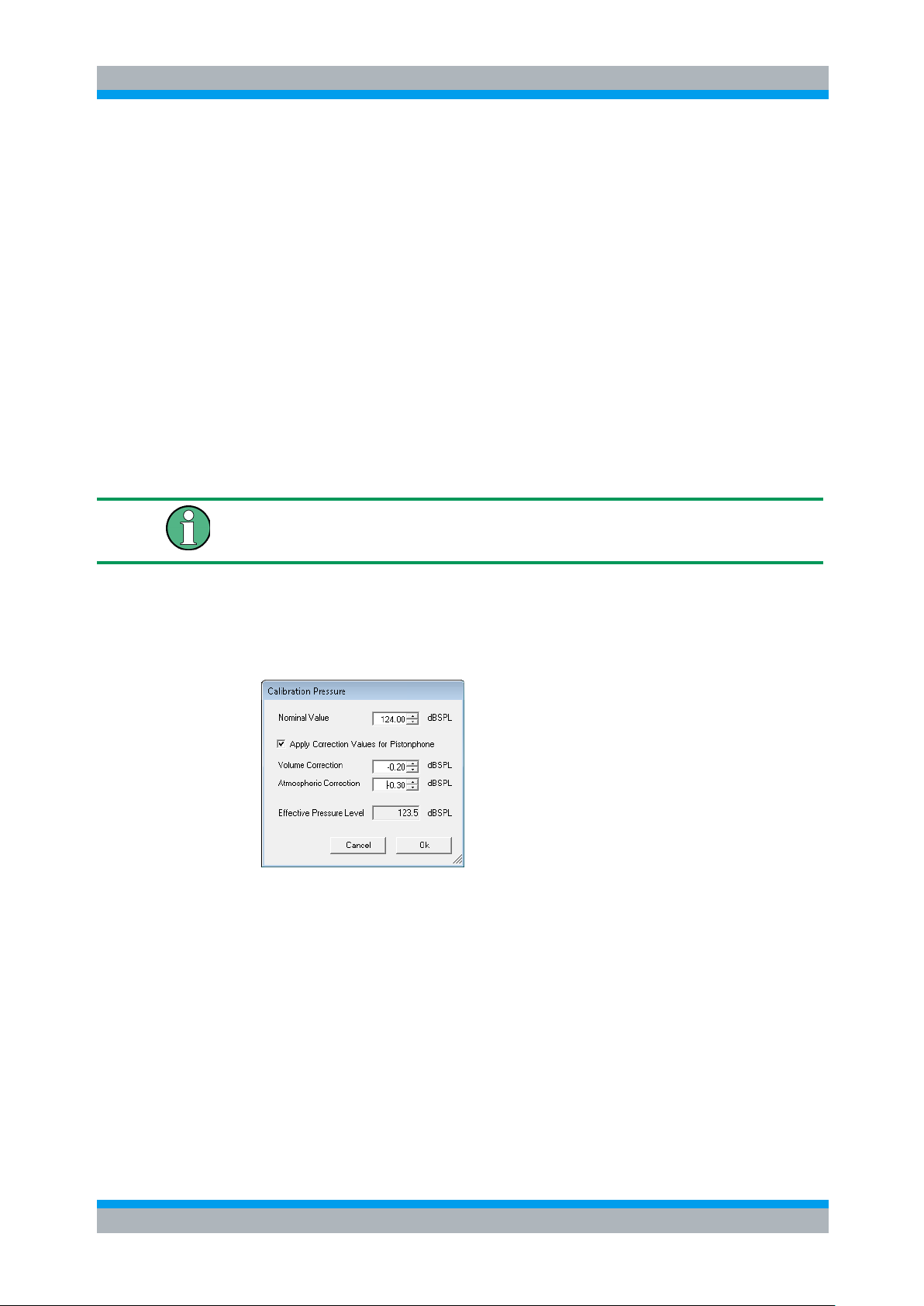

First the nominal SPL of the calibrator has to be entered:

Figure 4-5 Input window for calibration SPL

Checkbox “Apply Correction Values for Pistonphone” allows to specify volume

correction and atmospheric correction values which are added to the nominal

calibration value to calculate the effective pressure level at the microphone during

calibration. If this checkbox is checked, the default for the nominal calibration

value is 124 dBPL. If the calibration values are deactivated, the default is 93.98

dBSPL.

Page 22

R&S UPV-K7 Calibration

Calibration of Ear Simulator IEC 711

Operating Manual 1401.9353.12 - 04 22

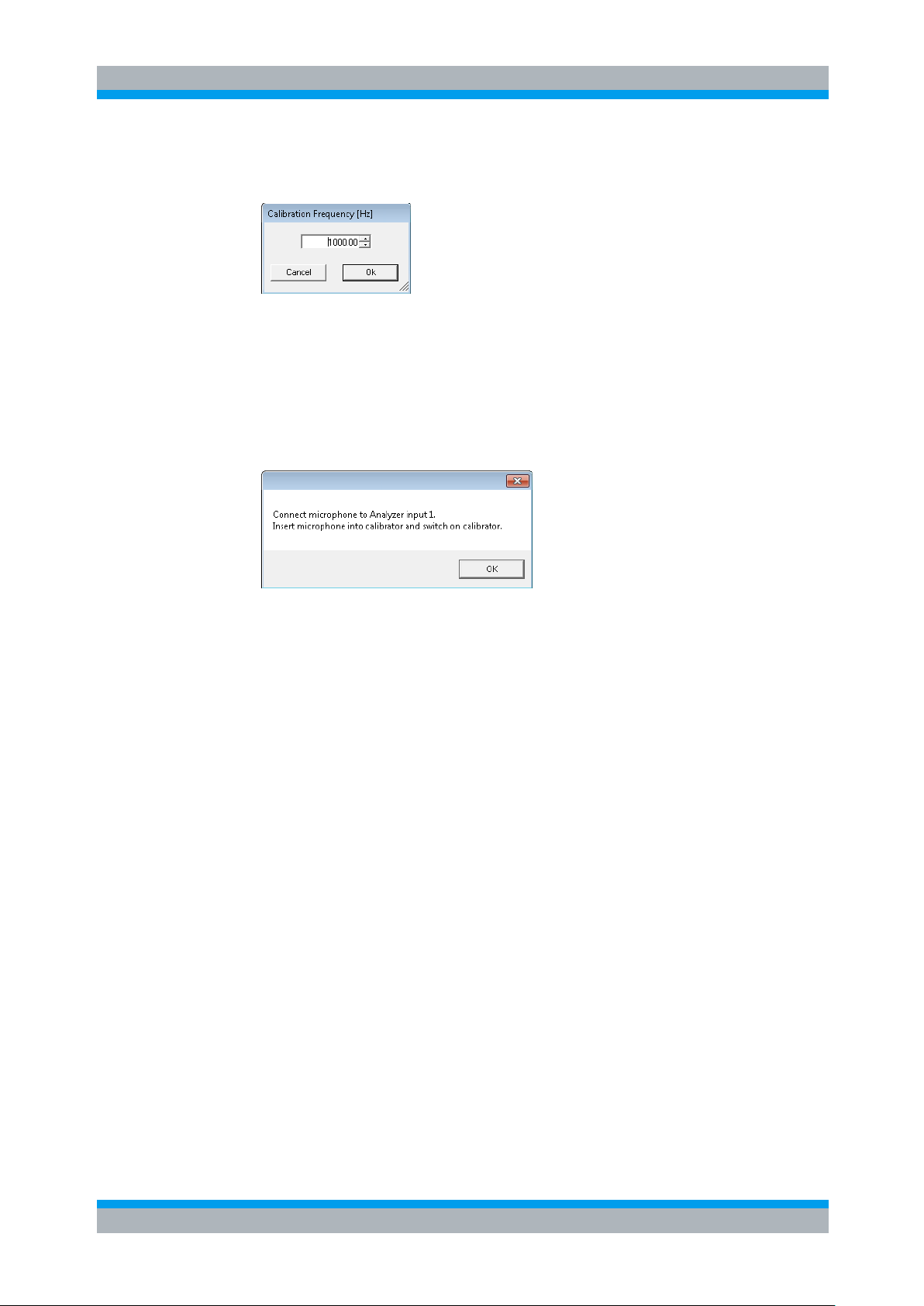

If selective calibration is activated in the calibration menu, the frequency of the

calibration signal has to be entered:

Figure 4-6 Input window for calibration frequency

If correction values for pistonphone are used, the default for the calibration

frequency is 250 Hz. Otherwise the default calibration frequency is 1000 Hz.

After these settings have been confirmed, instructions for connecting the

microphone are displayed, unless an input switcher is used. The reference

microphone must be connected to analyzer input 2, coupler microphones must be

connected to analyzer input 1.

Figure 4-7 Connection instructions of microphone calibration

Subsequently, the output voltage of the microphone is measured and the

sensitivity displayed with reference to 1 Pa. If a mere power supply without gain is

used, the displayed sensitivity must approximately match the value in the

calibration certificate of the microphone capsule (typical value for microphone

capsule 4134 of artificial ear 4185 is approx. 12 mV/Pa, display = 120 mV/Pa). If a

conditioning amplifier with 20 dB gain (recommended value) is used, the displayed

sensitivity must be about 10 times higher. If the voltage measured is below 3 mV

or instable, an error message is displayed. Possible error sources are, for

example, a switched-off microphone power supply or a disabled calibrator. In this

case, the program requests that the calibration is repeated. After switching on the

microphone power supply, wait approx. 20 s before starting the calibration again.

4.3 Calibration of Ear Simulator IEC 711

For calibration of the IEC 711 ear simulator, an adapter part must be screwed onto the

simulator which allows it to be inserted into the calibrator like a ½” microphone. The

calibration routine is started with “Calibration Ear Simulator IEC 711” and follows

the course described above.

Page 23

R&S UPV-K7 Calibration

Entering correction values for Pistonphones

Operating Manual 1401.9353.12 - 04 23

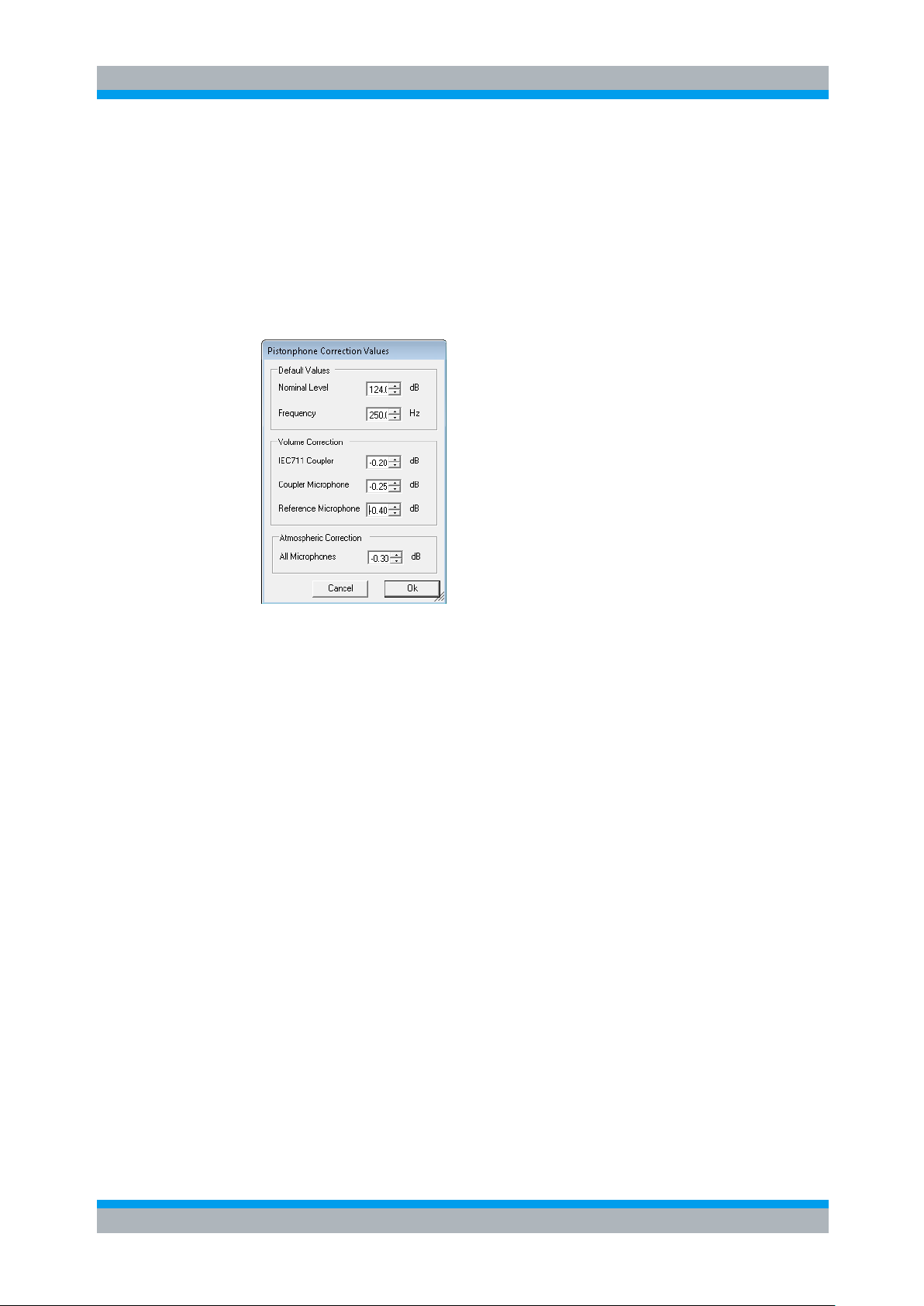

4.4 Entering correction values for Pistonphones

With the menu Item “Pistonphone” in the “Calibration” menu, volume and atmospheric

correction values can be viewed and edited. In addition the default nominal level and

calibration frequency for pistonphone use can be modified.

Volume correction values are specific to the different microphone or coupler types and

can therefore be entered separately. The atmospheric correction value is common to

all microphones and ear simulators.

Figure 4-8 Input window pistonphone correction values

4.5 Calibration of Sound Source

Before a hearing aid can be tested, the absolute sensitivity and frequency response of

the sound source have to be measured and corrected with the aid of a previously

calibrated reference microphone. If “Use coupler mic as reference mic” is activated in

the “Options” menu, the microphone of the IEC 126 coupler can be used for this

purpose. The frequency response of the microphone can be ignored in the test

frequency range (100 Hz to 10 kHz) (see also calibration certificate of microphone

capsule). If a separate reference microphone is used, this has to be calibrated

beforehand with “Calibration Microphone Reference”.

After starting the sound source calibration with “Calibration Sound Source”, the

calibration level can be defined. This allows to adapt the calibration to specific

measurement levels. It is also possible to store calibrations for different levels using

multiple calibration devices (see above).

The sound pressure generated at the point of the reference microphone is set to

exactly the specified level in an automatic measurement routine at 1 kHz. The

generator voltage required is stored in a file on the hard disk and used as a reference

for all subsequent settings with the same sound source. If the sound pressure cannot

be adjusted to the specified value, an error message is displayed with a request to

check the connection to the sound source and to repeat the measurement.

Page 24

R&S UPV-K7 Calibration

Calibration of the International Speech Test Signal (ISTS)

Operating Manual 1401.9353.12 - 04 24

The uncorrected frequency response of the sound source is measured and displayed.

Next, the frequency response is measured with the inverse frequency response

correction automatically selected in the generator (equalization). Residual errors

caused by nonlinearities of the speaker are measured and taken into account in the

final equalization file as fine correction.

To verify the results, the absolute sound pressure versus frequency is measured at the

specified sound pressure level. Correct calibration without interfering sound yields an

almost straight line.

4.6 Calibration of the International Speech Test Signal (ISTS)

This item is only available with option R&S UPV-K71 installed.

Figure 4-9 Submenu for ISTS calibration

The calibration function performs the following actions on the ISTS:

● Pre-filtering the speech signal with the inverse frequency response of the sound

source (valid sound source calibration is prerequisite)

● Level alignment of the filtered signal

● Analysis of the long-term average spectrum and percentile spectra at the

reference point and limit check in comparison to the requirements in IEC 60118-

15.

● Analysis of the speech signal at the reference point as input signal to the hearing

aid (according to IEC 60118-15). Raw results like 3rd octave spectra over time

and selected intervals in each 3rd octave for given percentiles are stored in files

for later use in the measurement function.

● Pre-filtering of the equalized signal according to the different microphone location

effects.

Standard speech levels are 65 dBSPL, 80 dBSPL and optionally 55 dBSPL.

Additionally calibration can also be performed at other levels if required. Especially for

low levels like 55 dBSPL, a low-noise microphone is required to get correct values for

the 30% percentile.

Page 25

R&S UPV-K7 Calibration

Calibration Value for Induction Coil

Operating Manual 1401.9353.12 - 04 25

Before starting the ISTS calibration routine, either a coupler microphone or a reference

microphone must be calibrated. If the coupler microphone is to be used for this

calibration function, select “Options Use coupler mic as reference mic”. The coupler

microphone must be connected to analyzer input 1. If a separate reference microphone

is to be used, “Options Use coupler mic as reference mic” must be unchecked. The

reference microphone must be connected to analyzer input 2.

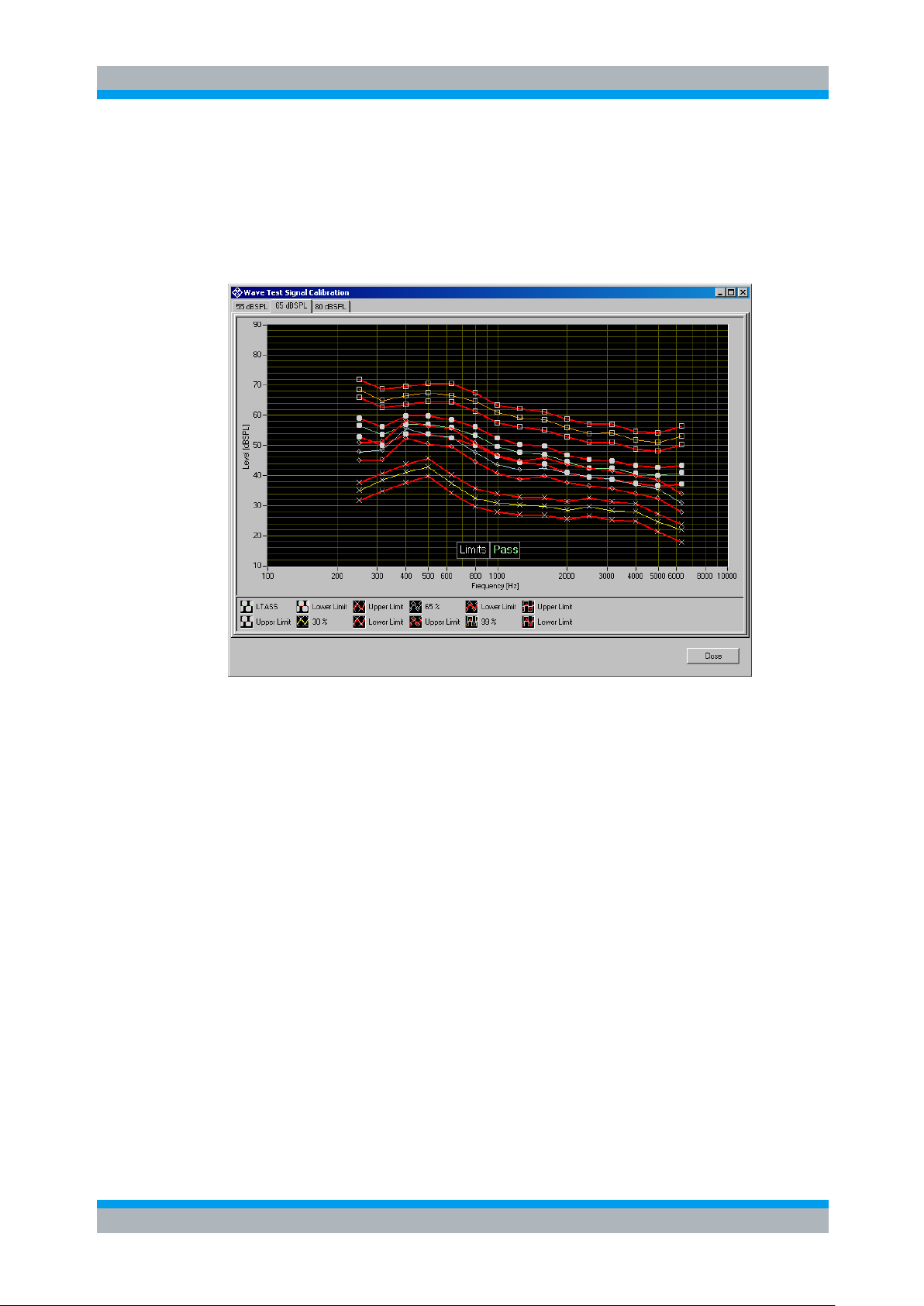

Figure 4-10 ISTS calibration result

For each calibrated speech level, the window contains a tab with a result graph. Each

result graph shows long-term average speech spectrum (LTASS) and percentile levels

for this speech level, together with limits calculated from the nominal levels given in

IEC 60118-15 for the ISTS at 65 dBSPL speech level ±3 dB.

The calibration is valid even if not all limits are passed. Particularly ad 55 dBSPL it

might be difficult to pass the limits for the 30% percentile.

4.7 Calibration Value for Induction Coil

The sensitivity H/I for the induction coil used for hearing aid tests with inductive input

can be entered under menu Item “Induction Coil” in the “Calibration” menu.

Refer to the data sheet of the test box for induction coil sensitivity and resistance.

Page 26

R&S UPV-K7 Data Entry for Reporting

Operating Manual 1401.9353.12 - 04 26

5 Data Entry for Reporting

5.1 Operator

Under “DataOperator” an operator’s name can be entered which is stored in

association with all calibration and measurement results. If “Operator” is activated in

the report settings, the name will appear in all reports about these measurements.

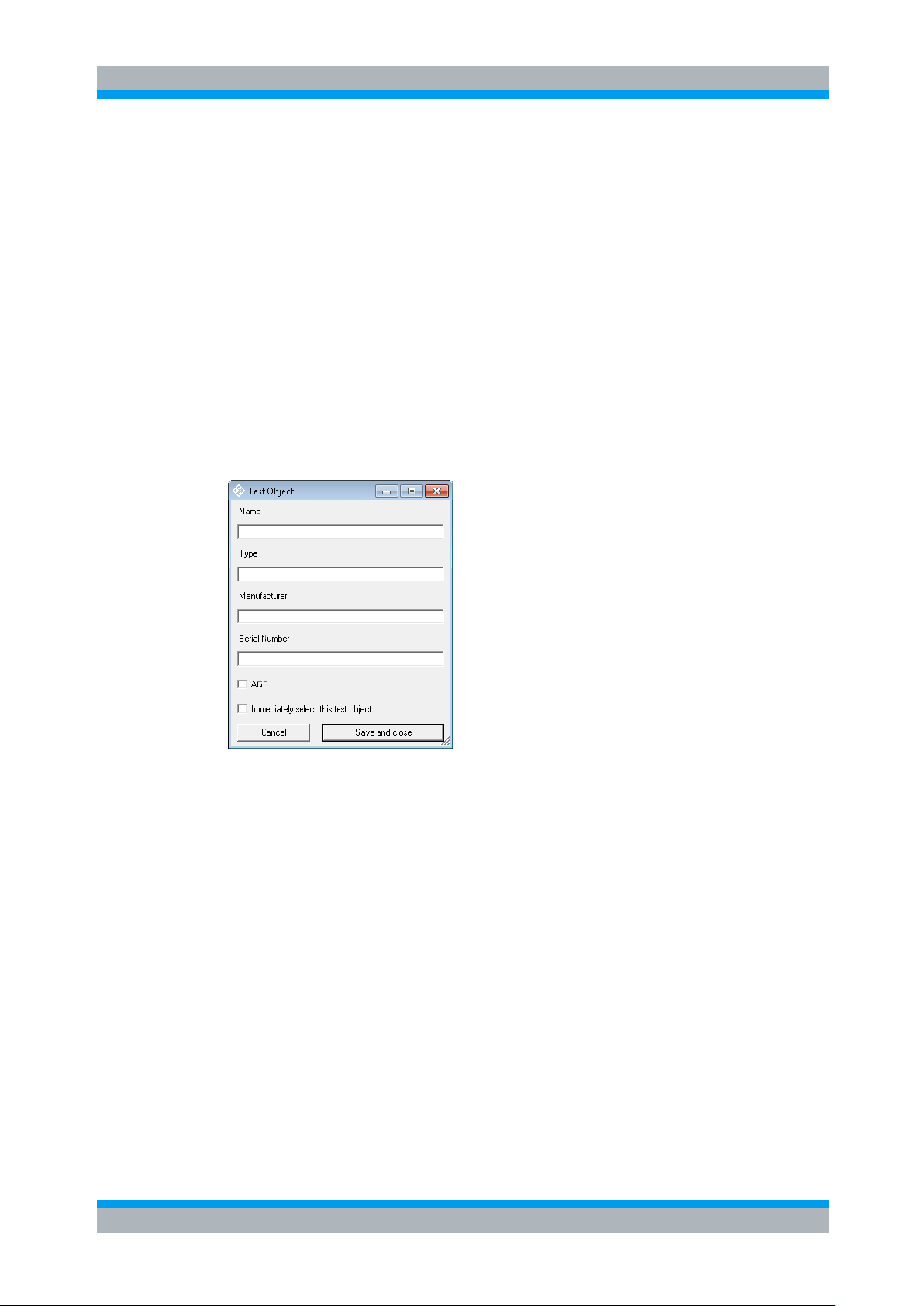

5.2 Test Object

Under “Data Test object New” a description of the device under test can be

entered.

Operator

Figure 5-1 Window for input of information about a test object

With “Data Test object Select” one of the entered test objects can be selected.

The data of this selected test object will be stored in association with all measurements

and appear on the associated reports if “DUT information” is activated in the report

settings.

Page 27

R&S UPV-K7 Measurements

Functionality and Control of the Measurement Macros

Operating Manual 1401.9353.12 - 04 27

6 Measurements

6.1 Functionality and Control of the Measurement Macros

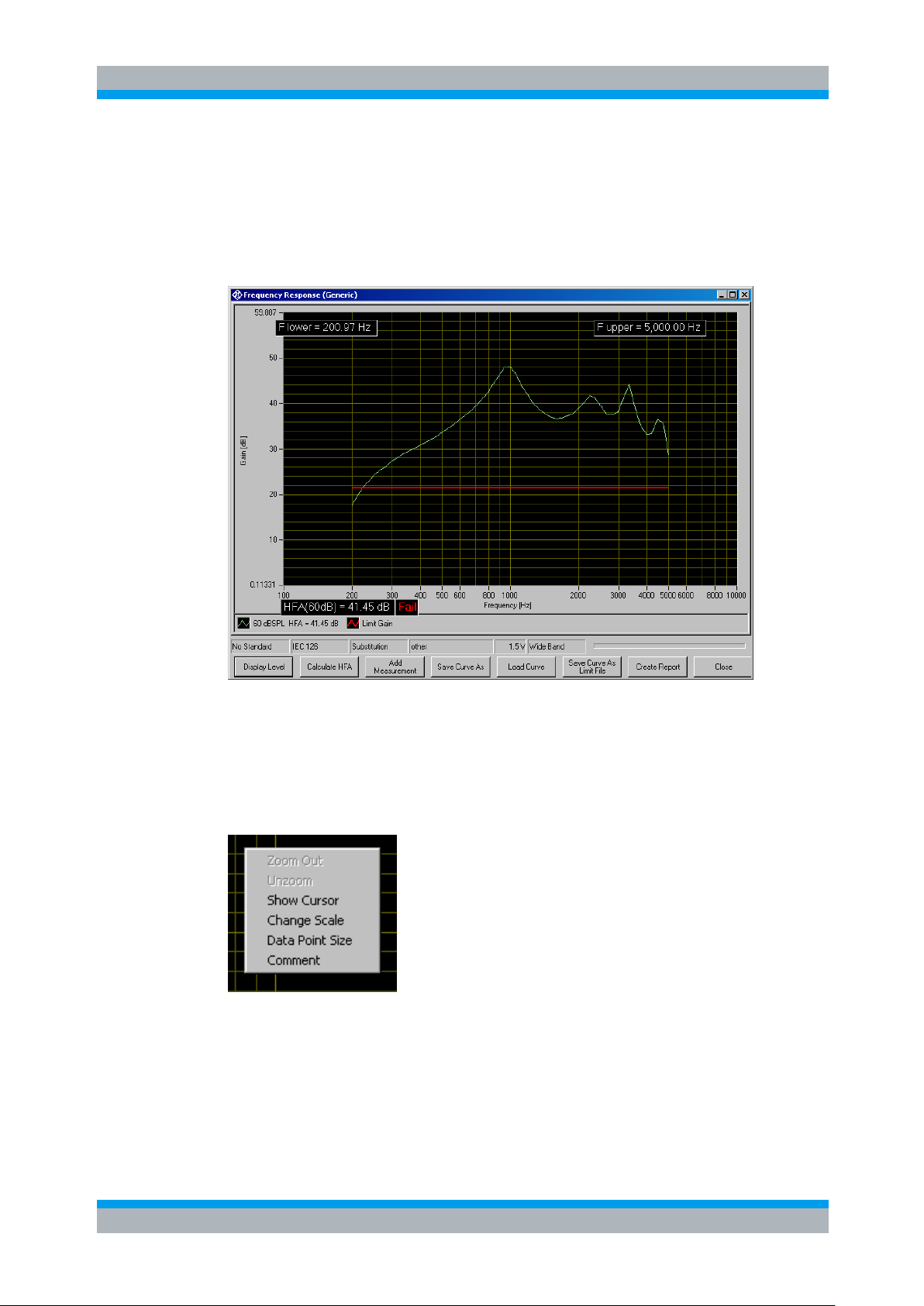

Figure 6-1 Example of a measurement window

When a measurement macro is started, e.g. from the “Measurement” menu, the

standardized measurement is immediately executed. With a single measurement, the

window of the measurement macro stays open after the measurement is terminated. At

that time, the following functionality is available:

Figure 6-2 Context menu of the graph window

Page 28

R&S UPV-K7 Measurements

Functionality and Control of the Measurement Macros

Operating Manual 1401.9353.12 - 04 28

6.1.1 Zooming

When the “Shift” key on the keyboard is pressed, the mouse cursor changes to the

zoom cursor. When the left mouse button is pressed, a rectangle can be marked in the

graph. As soon as the left mouse button is released, the graph is zoomed into the area

of the marked rectangle

“Zoom Out” in the graph context menu reverses the last zooming step. “Unzoom”

zooms completely out to the original scaling.

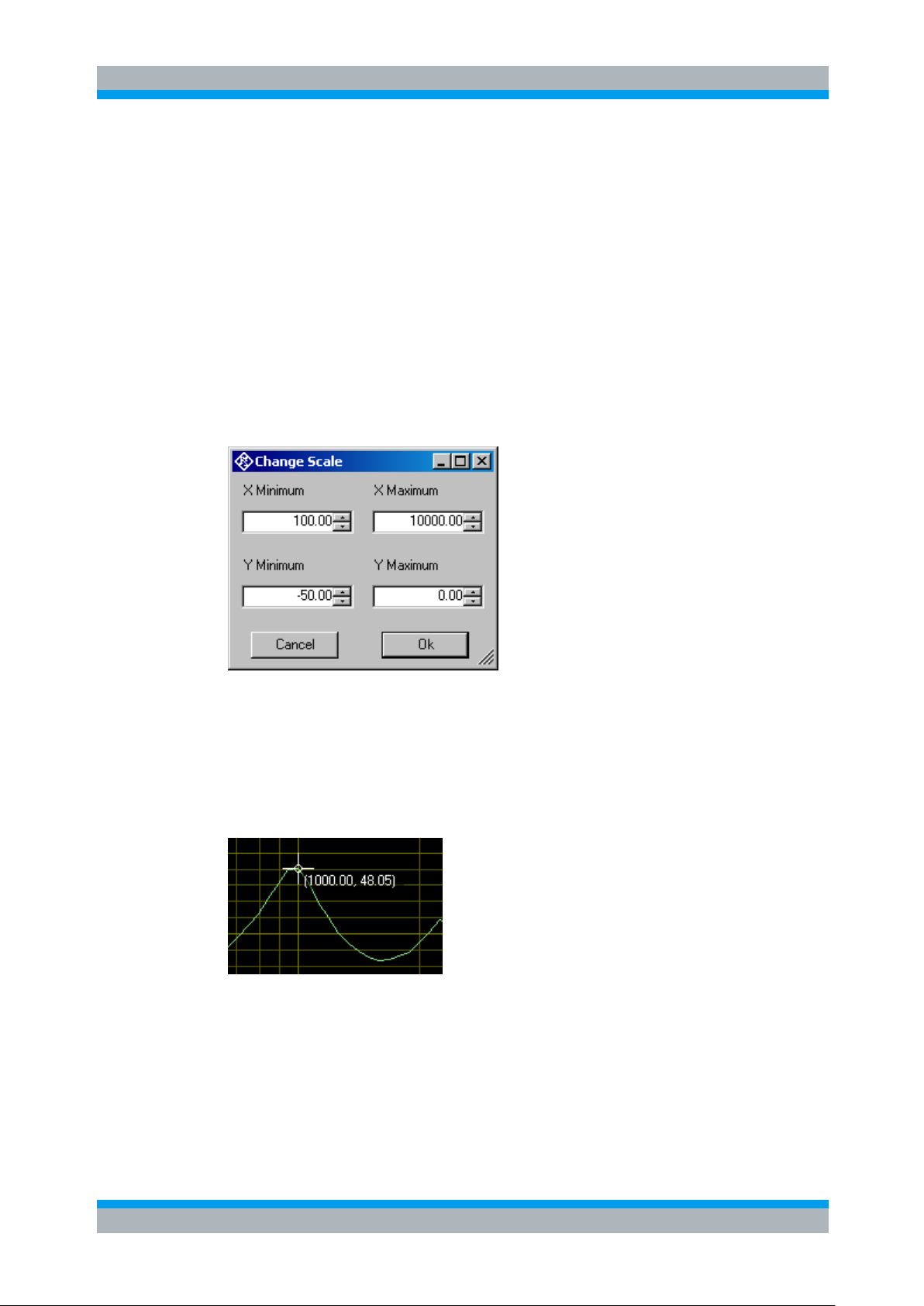

6.1.2 Changing the Scale of the Graph

“Change Scale” in the context menu opens a window in which the upper and lower

bounds of both axes can be entered by numbers.

Figure 6-3 Window for changing the scale of the graph

6.1.3 Cursor

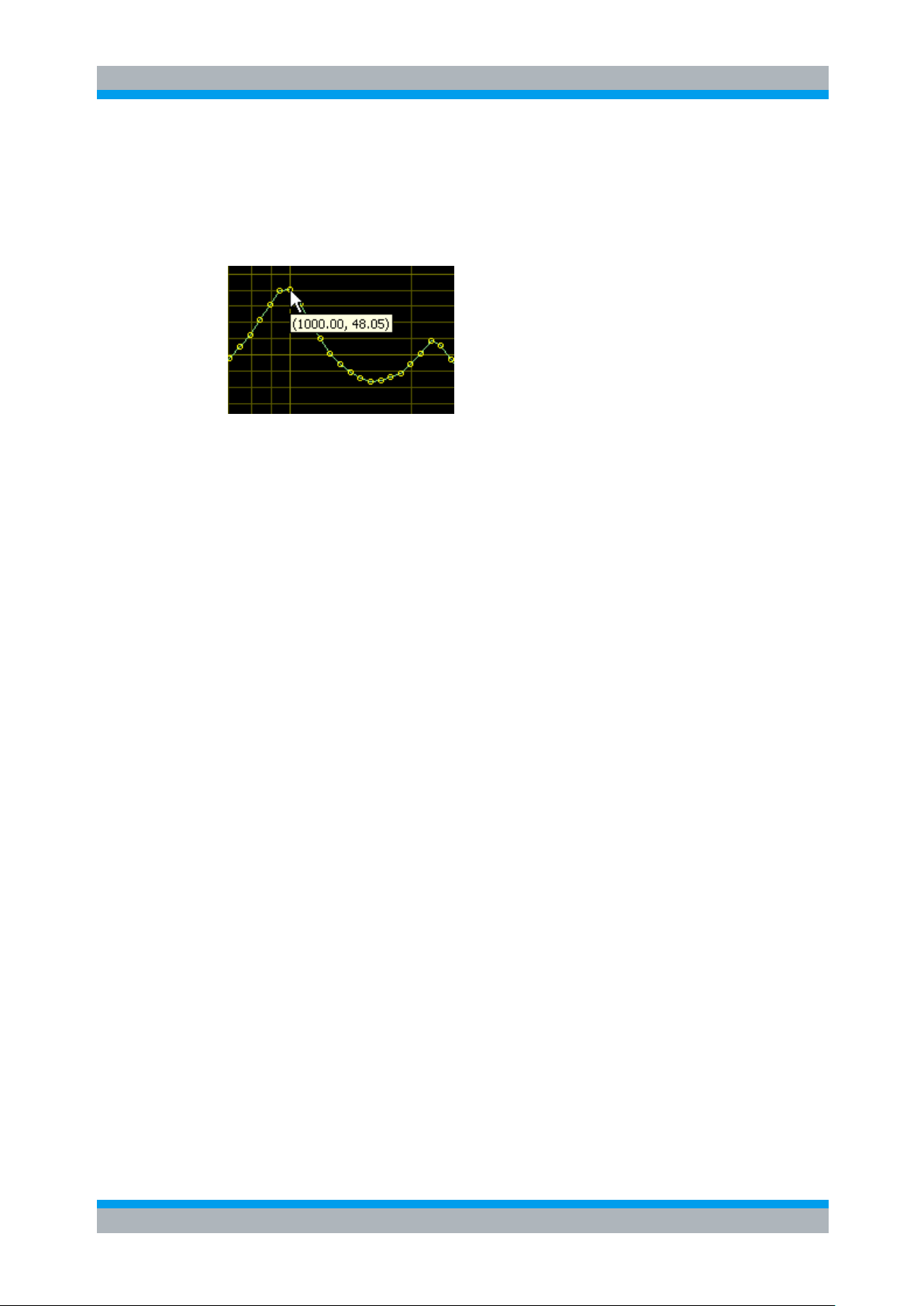

When the item “Show Cursor” is marked in the graph context menu, a cursor is

displayed which can be dragged along the graph with the mouse. X and Y values of

the data points below the cursor are displayed.

Figure 6-4 Cursor with data display

Page 29

R&S UPV-K7 Measurements

Functionality and Control of the Measurement Macros

Operating Manual 1401.9353.12 - 04 29

6.1.4 Data Point Size

“Data Point Size” in the graph context menu opens a window in which the size of

marks at the measured data points can be specified. Moving the mouse cursor over

one of the marks causes the associated X and Y values to be displayed.

Figure 6-5 Data points with data display

6.1.5 Performing Additional Measurements

The softkey “Add Measurement” triggers another measurement according to the

specification of the test. Loudness ratings and noise values are calculated and

displayed in the legend. However, limits are not checked. This function can e.g. be

used to compare different settings in a device under test.

If the item “Store results of further measurements” is activated in the “Options” menu,

graphs and result values obtained with this functionality are added to the results

database and will appear later in reports on this measurement. All curves obtained

within the same measurement will appear in the report in the same graph.

6.1.6 Storing and Loading Curves

All measured curves in the graph can be stored to an ASCII file, and stored curves can

be loaded back into the graph. The softkey “Store Curve” opens a window in which a

combo box offers choice between the legends of all measured curves in the graph. The

curve associated in which the selected entry is stored to the file at the specified

location.

6.1.7 Storing Curves as Limit Curves

With “Store As Limit Curve” a curve can be selected and stored into a R&S UPV format

limit file with a specified shift in Y axis direction. This functionality can be used to

generate limit curves from “golden” devices for evaluation purpose. Regarding the use

of such limit curves see section 6.2 Customizing Measurements below.

6.1.8 Entering a Comment

With the softkey “Enter Comment” or the item “Comment” in the graph context menu, a

comment can be entered and edited which will appear in the report about the

respective measurement.

Page 30

R&S UPV-K7 Measurements

Functionality and Control of the Measurement Macros

Operating Manual 1401.9353.12 - 04 30

6.1.9 Creating a Report

The softkey “Create Report” causes a report to be prepared. The report preview

window (see below) opens and shows the preview of the report. Buttons in the preview

window allow to print the report or to export it to PDF, WORD, EXCEL or Rich Text

format. For details see section 8.10 Preview Window below.

6.1.10 Generating a Landscape Report

Landscape reports are only available for frequency response graphs. They show the

result graph together with the measurement title and information about the tested

hearing aid and about the operator. The layout and scale is fixed and cannot be

configured.

A landscape report can be generated from the measurement window by right-clicking

into the result graph of a frequency response measurement and selecting “Create

Landscape Report” from the context menu.

6.1.11 Closing the Measurement Window

The softkey “Close” closes the measurement window. The control is returned to the

R&S UPV-K7 main window. All relevant data associated with the measurement is

imported to the results database. A new entry appears for the measurement as new

row on the bottom of the overview data grid in the main window.

Page 31

R&S UPV-K7 Measurements

Operating Manual 1401.9353.12 - 04 31

6.2 Customizing Measurements

The first item in the “Measurement” menu which is called “Settings” opens a sub-menu

with all available measurements in it. Clicking on a measurement in this sub-menu

opens a window which allows to change parameters of the selected measurement.

Customizing Measurements

Figure 6-6 Measurement setup window

The “Title” appears in the measurement menu and forms the heading of the report.

The “Description” can be chosen to be included into the report.

“Date” shows the date of the last change to this measurement definition.

“Operator instruction” is the text displayed before the start of each measurement,

provided that the item “Show operator instructions” is activated in the “Options” menu.

The entry in the field “Program File” designates the measurement type and must not be

changed.

The field “Setup Files” specifies the R&S UPV setups used by the measurement. The

specified file can be replaced by a user defined file but the number of setups is defined

by the measurement type. The customized setup file must be stored in folder

D:\Hearing. It is recommended to generate customized setups by copying existing

ones. Note that changes in the setup like changing the analysis function or generator

signal may cause malfunction of the measurement. Some parameters of the setup

might be overwritten by the macro during the measurement run.

The field “Template files” specifies limit template curves for the response curve. The

buttons “Add” or “Edit” produce the following input window:

Page 32

R&S UPV-K7 Measurements

Customizing Measurements

Operating Manual 1401.9353.12 - 04 32

Figure 6-7 Input window for limit template curve

The radio buttons allow to determine whether the given curve should be used as upper

limit, lower limit or for information only (no limit check). The field “File name” must

contain the path name of the file. To generate a new limit curve file, use the softkey

“Save as limit curve” of the respective measurement window or copy and edit an

existing limit file using a text editor.

All other available parameters of a measurement definition are shown in the

“Parameters” data grid. The rightmost column with the headline “Fixed” displays

whether the respective parameter can be changed by the operator or not. In “generic”

measurements all parameters may be changed. In measurements which follow

standards, only parameters which are not determined by the standard may be changed

by the operator. The “Edit” button opens an input window for the parameter in the line

specified in “Number”:

Figure 6-8 Input window for parameter value

Alternatively this input window can be opened by double-clicking on the row header of

the parameter to be edited.

“Name” appears in the report and explains the meaning of the parameter. “Type” is

determined by the measurement routine and cannot be changed. In the field “Value” a

value must be entered which conforms with the syntax rules of the selected data type.

The syntax is checked automatically when the text box is left. However there is no

check for the allowable range of the value. Entering inadequate values (e.g. too high

levels, negative frequencies) may cause malfunction of the measurement.

Page 33

R&S UPV-K7 Measurements

Operating Manual 1401.9353.12 - 04 33

Tables in section 6.3 list the available parameters for each measurement routine.

Some of the parameters are optional. They are marked with “Optional_i:” in the

explanation column, wherein i stands for a consecutive numbering. The following rules

apply for optional parameters:

● For each value of i, all or none of the parameters marked with “Optional_i” must

be present

● If optional parameters marked with “Optional_j” are present, all optional

parameters marked with “Optional_i” for values i < j must also be present.

6.3 Notes on Individual Measurements

6.3.1 Frequency Response Measurement

Notes on Individual Measurements

Figure 6-9 Display window of frequency response measurement

The softkey “Display Level” or “Display Gain”, respectively, allows to toggle between

gain and level in the Y axis of the graph. The button “Calculate HFA” allows to

calculate a high frequency average or special frequency average from one of the

displayed curves:

Page 34

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 34

Name

Type

Value

Explanation

battery voltage (V)

Double

0

Supply voltage provided at ANLG AUX OUT.

Overrides the general setting. “0 V “ means

“use voltage from general setting”.

lower frequency limit (Hz)

Double

200

Start frequency of sweep

upper frequency limit (Hz)

Double

5000

Stop frequency of sweep

number of frequencies

Integer

57

Number of sweep points

display result as gain

Boolean

True

„True“: Gain on Y axis, „False“: SPL on Y

axis

selective measurement

Boolean

false

„True“: Selective measurement with fast 3rd

octave filter

number of sweeps

Parameter count

1

Number of sweeps with level as parameter

sweep 1 level (dB)

Double

60

Sweep level for each sweep (dBSPL or dB re

1 mA/m)

Figure 6-10 Input window for HFA calculation

In the text box on the left side the HFA frequencies are entered in separate lines. In the

combo box top right, one of the existing curves is chosen. When the button “Calculate”

is clicked, the text box below shows the associated HFA value.

The following table lists all available parameters in the generic frequency response

measurement:

Table 6-1 Available parameters for frequency response measurements

Page 35

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 35

Name

Type

Value

Explanation

measurement delay (s)

Double

0.02

Pre-delay between sweep Step and

measurement trigger, allows for settling of the

DUT (e.g. AGC)

inductive

Boolean

false

“False”: Acoustic input, “True”: Inductive input

number of HFA frequencies

Parameter count

3

Number of frequencies averaged in the high

frequency average

HFA frequency 1 (Hz)

Double

1000

HFA frequency (Hz)

Double

1600

HFA frequency (Hz)

Double

2500

HFA upper limit (dB)

Double

30

Upper limit for limit check

HFA lower limit (dB)

Double

10

Lower limit for limit check

check limit for sweep no.

Byte 1 “0“ means: “don’t check”

calc. freq. range for swp. no

Byte 1 “0“ means: “don’t calculate”

level difference (dB)

Double

20

Level difference between HFA level and

frequency response limit points

check frequency range limits

Boolean

True

Determines whether the frequency range is

checked against the limits given below

max. lower frequency (Hz)

Double

500

min. upper frequency (Hz)

Double

3500

display curve maximum

Boolean

True

Stipulates whether the absolute curve

maximum should be determined

lower limit of max. (dB)

Double

0 upper limit of max. (dB)

Double

40 check max limits for swp. no

Byte 1 “0“ means: “don’t check”

calculate MASL for sweep

no.

Byte 0 Optional_1. Determines for which sweep the

MASL should be calculated. 0 means “no

calculation”.

check MASL limits

Boolean

False

Optional_1. Determines whether a limit check

should be performed on the MASL.

MASL lower limit (dB)

Double

0

Optional_1.

MASL upper limit (dB)

Double

100

Optional_1.

Page 36

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 36

Name

Type

Value

Explanation

electric input

Boolean

False

Optional_2. Set to “True”: The test signal is

fed on the electric input of the hearing aid.

The sweep levels are specified relative

to -54 dBV.

maximum voltage (V)

Double

1

Optional_2. Voltage limit for protection of the

electric input of the hearing aid.

If for example only an upper limit should be checked but not the corresponding lower

one, select the lower limit low enough to be always passed.

The following standard conformal tests are based on the frequency response

measurement routine:

Frequency Response @ 60 dBSPL (IEC-0)

Frequency Response (IEC-0:2015)

Field of Frequency Response Curves (IEC-0)

Frequency Response (ANSI)

Frequency Response (IEC-7)

Frequency Response Induction (ANSI)

Frequency Response Induction (IEC-1)

Frequency Response Induction (IEC-0:2015)

Full-On Frequency Response Induction (IEC-0:2015)

Full-On Gain 50 dB (IEC-0)

Full-On Gain 60 dB (IEC-0)

Full-On Gain (IEC-0:2015)

Full-On Gain (IEC-7)

Response Curve at Maximum Gain (IEC-1)

Full-On Gain (ANSI)

Output SPL at Maximum Gain, Induction (IEC-1)

OSPL90 (ANSI)

OSPL90 (IEC-7)

OSPL 90 (IEC-0)

OSPL 90 (IEC-0:2015)

Page 37

R&S UPV-K7 Measurements

Operating Manual 1401.9353.12 - 04 37

6.3.2 Multi-Curve Measurement

Name

Type

Value

Explanation

battery voltage (V)

Double

0

Supply voltage provided at ANLG AUX OUT.

Overrides the general setting. “0 V “ means

“use voltage from general setting”.

lower frequency limit (Hz)

Double

200

Start frequency of sweep

upper frequency limit (Hz)

Double

5000

Stop frequency of sweep

number of frequencies

Integer

57

Number of sweep points

Notes on Individual Measurements

Figure 6-11 Display window of multi-curve measurement

The multi-curve measurement is found in “Standards Utilities”. It is similar to

frequency response measurements and allows measurement and display of acoustic

and inductive frequency responses in one window. Unlike other measurements, the

multi-curve measurement does not automatically start a sweep when it opens. All

sweeps are started by the user using the “Add Measurement” button, even within

sequences. Therefore this window does not close automatically within a sequence but

has to be closed using the “Done” button.

The following table lists all available parameters available for configuration of the multicurve measurement:

Table 6-2 Available parameters for multi-curve measurement

Page 38

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 38

Name

Type

Value

Explanation

display result as gain

Boolean

False

„True“: Gain on Y axis, „False“: SPL on Y

axis

selective measurement

Boolean

True

„True“: Selective measurement with fast 3rd

octave filter

measurement predelay (s)

Double

0.02

Pre-delay between sweep Step and

measurement trigger, allows for settling of the

DUT (e.g. AGC)

number of HFA frequencies

Parameter count

3

Number of frequencies averaged in the high

frequency average

HFA frequency 1 (Hz)

Double

1000

HFA frequency (Hz)

Double

1600

HFA frequency (Hz)

Double

2500

HFA upper limit (dB)

Double

30

Upper limit for limit check

HFA lower limit (dB)

Double

10

Lower limit for limit check

determine maximum gain

Boolean

True

Stipulates whether the absolute curve

maximum should be determined

show operator instruction

Boolean

True

Determines whether the operator should be

prompted to switch the hearing aid between

microphone and telecoil mode

selective acoustic

measurement

Boolean

True

Optional_1: Activates selective measurement

for acoustic input only

selective induction

measurement

Boolean

True

Optional_1: Activates selective measurement

for induction input only

preset parameters

Boolean

False

Optional_2: Determines whether to use the

following two parameters or not

preset induction

Boolean

False

Optional_2: If “True”, each additional

measurement (Button “Add Measurement”

clicked) offers inductive measurement first

preset level (dB)

Double

60

Optional_2: Each additional measurement

(Button “Add Measurement” clicked) offers

the level value specified here first

lock parameters

Boolean

False

Optional_2: The settings of the previous two

parameters are forced. The user cannot

change them in the user interface.

curve text

String

Optional_2: Default for the curve name

offered when button “Add Measurement” is

clicked. This text is complemented with

numbering of the measured curves.

Page 39

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 39

When the “Add Measurement” button is clicked, an entry window for the level of the

next sweep opens.

The input to the hearing aid can be switched between acoustic and inductive signal.

For acoustic input the level is set in dBSPL. For inductive input the level can be

entered in mA/m or dB(mA/m). If there are already sweeps present in the graph, the

input window always opens with the settings done for the last sweep. In addition

buttons are provided for increasing or decreasing the level from the previous sweep by

1, 5 or 10 dB.

Figure 6-12 Entry window for sweep level in Multi-curve measurements

Page 40

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 40

Name

Type

Value

Explanation

battery voltage (V)

Double

1.5

Supply voltage provided at ANLG AUX OUT.

Overrides the general setting. “0 V “ means

“use voltage from general setting”.

lower frequency limit (Hz)

Double

200

Start frequency of sweep

upper frequency limit (Hz)

Double

8000

Stop frequency of sweep

number of frequencies

Integer

65

Number of sweep points

lowest input level (dB)

Double

60

Start level of sweep (dBSPL or dB re 1

mA/m)

highest input level (dB)

Double

90

Stop level of sweep (dBSPL or dB re 1

mA/m)

number of levels

Integer

31

Number of level steps in sweep

selective measurement

Boolean

false

„True“: Selective measurement with fast 3rd

octave filter

6.3.3 Saturation Sound Pressure Level Measurement

Figure 6-13 Display window of saturation sound pressure level measurement

The saturation sound pressure level measurement performs the specified number of

level sweeps and records the maximum level obtained in each sweep.

The following table lists all available parameters in the generic saturation sound

pressure level measurement:

Table 6-3 Available parameters for saturation SPL measurements

Page 41

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 41

Name

Type

Value

Explanation

measurement delay (s)

Double

0.02

Pre-delay between sweep Step and

measurement trigger, allows for settling of the

DUT (e.g. AGC)

inductive

Boolean

false

“False”: Acoustic input, “True”: Inductive input

display curve maximum

Boolean

True

Optional_1: Stipulates whether the absolute

curve maximum should be determined

lower limit of max. (dB)

Double

130

Optional_1

upper limit of max. (dB)

Double

150

Optional_1

check max limits

Boolean

true

Optional_1: Stipulates whether pass / fail

check takes place

The only standard conformal test based on the saturation SPL measurement routine is

Saturation SPL (IEC-0).

6.3.4 Harmonic Distortion Measurement

Figure 6-14 Curve display of harmonic distortion measurement

The softkey “Display dB” or “Display %”, respectively, allows to toggle between both Y

axis units. The softkey “Show Discrete Values” or “Show Curves”, respectively, allows

to toggle between curve display and result data table provided that discrete values or

curves, respectively, have been measured.

Page 42

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 42

Name

Type

Value

Explanation

battery voltage (V)

Double

0

Supply voltage provided at ANLG AUX OUT.

Overrides the general setting. “0 V “ means

“use voltage from general setting”.

lower frequency limit (Hz)

Double

200

Start frequency of sweep

upper frequency limit (Hz)

Double

5000

Stop frequency of sweep

number of frequencies

Integer

57

Number of sweep points

display result in dB

Boolean

false

“False”: Y axis and values in %, “True”: Y

axis and values in dB

number of sweeps

Parameter count

3

Number of sweeps with level as parameter

sweep 1 level (dB)

Double

60

(dBSPL or dB re 1 mA/m)

sweep 2 level (dB)

Double

80

(dBSPL or dB re 1 mA/m)

sweep 3 level (dB)

Double

100

(dBSPL or dB re 1 mA/m)

measurement delay (s)

Double

0.01

Pre-delay between sweep Step and

measurement trigger, allows for settling of the

DUT (e.g. AGC)

Figure 6-15 Data table display of harmonic distortion measurement

The following table lists all available parameters in the harmonic distortion

measurement:

Table 6-4 Available parameters for harmonic distortion measurements

Page 43

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 43

Name

Type

Value

Explanation

induction

Boolean

false

“False”: Acoustic input, “True”: Inductive input

show thd

Boolean

true

Stipulates whether the thd curve is displayed

show 2nd

Boolean

true

Stipulates whether curve of 2nd harmonic is

displayed

show 3rd

Boolean

true

Stipulates whether curve of 3rd harmonic is

displayed

show 4th

Boolean

false

Etc.

show 5th

Boolean

false show 6th

Boolean

false show 7th

Boolean

false show 8th

Boolean

false show 9th

Boolean

false

check limit for sweep no.

Byte 0 Stipulates whether limit curve is checked. “0”

means no limit check

number of discrete points

Parameter count

3

Number of discrete measured values

point 1 (Hz), (dB), limit %

String

500,

70, 1

Value triples specifying measurements and

upper limits for THD

point 2 (Hz), (dB), limit %

String

800,

70, 0.5

point 3 (Hz), (dB), limit %

String

1600,

65, 0.5

check limits

Boolean

true

Stipulates whether limits are checked in

discrete measurements

number of limits

Parameter count

3

Optional_1: Must be equal to the number of

discrete measured values. Allows to specify

the limits separately from frequency and

level.

THD upper limit 1 (%)

Double

1

Optional_1: upper THD limit for the first

discrete measurement point in %

THD upper limit 2 (%)

Double

0.5

Optional_1: upper THD limit for the second

discrete measurement point in %

THD upper limit 3 (%)

Double

0.5

Optional_1: upper THD limit for the third

discrete measurement point in %

Page 44

R&S UPV-K7 Measurements

Operating Manual 1401.9353.12 - 04 44

The following standard conformal tests are based on the harmonic distortion

measurement routine:

Harmonic Distortion (IEC-0)

Harmonic Distortion (IEC-0:2015)

Harmonic Distortion Induction (IEC-0:2015)

Harmonic Distortion (IEC-7)

Harmonic Distortion (ANSI)

6.3.5 Intermodulation Distortion Measurement

Notes on Individual Measurements

Figure 6-16 Curve display of intermodulation distortion measurement

The softkey “Display dB” or “Display %”, respectively, allows to toggle between both Y

axis units. The softkey “Show Discrete Values” or “Show Curves”, respectively, allows

to toggle between curve display and result data table provided that discrete values or

curves, respectively, have been measured.

Page 45

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 45

Name

Type

Value

Explanation

battery voltage (V)

Double

0

Supply voltage provided at ANLG AUX OUT.

Overrides the general setting. “0 V “ means

“use voltage from general setting”.

lower f2 frequency limit (Hz)

Double

350

Start frequency of sweep

upper f2 frequency limit (Hz)

Double

8000

Stop frequency of sweep

difference frequency (Hz)

Double

125

Frequency separation of test tone pair

number of frequencies

Integer

15

Number of sweep points

check with f2 off

Boolean

True

Plausibility check with upper test tone muted

shows noise level in the measurement

off difference (dB)

Double

10

Minimum difference between distortion result

an noise result measured with upper test tone

muted

display result in dB

Boolean

false

“False”: Y axis and values in %, “True”: Y axis

and values in dB

Figure 6-17 Data table display of intermodulation distortion measurement

The following table lists all available parameters in the intermodulation distortion

measurement:

Table 6-5 Available parameters for intermodulation distortion measurements

Page 46

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 46

Name

Type

Value

Explanation

number of sweeps

Parameter

count

1

Number of sweeps with level as parameter

sweep 1 f1, f2 level (dB)

Double

61

(dBSPL or dB re 1 mA/m) for each test tone

measurement delay (s)

Double

0.01

Pre-delay between sweep Step and

measurement trigger, allows for settling of the

DUT (e.g. AGC)

induction

Boolean

false

“False”: Acoustic input, “True”: Inductive input

check d2 limit for sweep no.

Byte 0 Stipulates against which of the sweeps the limit

curve is checked. “0” means no limit check

check d3 limit for sweep no.

Byte 0 Stipulates against which of the sweeps the limit

curve is checked. “0” means no limit check

number of discrete points

Parameter

count

3

Number of discrete measured values

point 1 f2 (Hz), Δf (Hz), (dB),

d2 limit (%), d3 limit (%)

String

500, 125,

61, 1, 1

Value quintuples specifying upper frequency,

frequency spacing, level of each tone, upper

limits for 2nd order and 3rd order distortion

products.

point 2 f2 (Hz), Δf (Hz), (dB),

d2 limit (%), d3 limit (%)

String

800, 125,

61, 0.5, 0.5

point 3 f2 (Hz), Δf (Hz), (dB),

d2 limit (%), d3 limit (%)

String

1600, 125,

61, 0.5, 0.5

check limits

Boolean

False

Stipulates whether limits are checked in

discrete measurements

number of limits

Parameter

count

3

Optional_1: Must be equal to the number of

discrete measured values. Allows to specify the

limits separately from frequency and level. If

limits are specified separately, only the first

three values out of each quintuple are

evaluated for each discrete measurement

point.

d2 limit 1 (%), d3 limit 1 (%)

Optional_1: upper distortion limits for the first

discrete measurement point in %

d2 limit 2 (%), d3 limit 2 (%)

Optional_1: upper distortion limits for the

second discrete measurement point in %

d2 limit 3 (%), d3 limit 3 (%)

Optional_1: upper distortion limits for the third

discrete measurement point in %

The following standard conformal tests are based on the intermodulation distortion

measurement routine:

Intermodulation Distortion (IEC-0)

Intermodulation Distortion (IEC-0:2015)

Page 47

R&S UPV-K7 Measurements

Notes on Individual Measurements

Operating Manual 1401.9353.12 - 04 47

6.3.6 Measurement of Dynamic Behaviour (AGC Settling)

Figure 6-18 Measurement window for dynamic behaviour

The dynamic behaviour measurement inputs a step-up and step-down burst of a

sinewave signal to the hearing aid. The output sound pressure level of the hearing aid