Page 1

¸HMC8015

Power Analyzer

User Manual

*5800532402*

5800532402

User Manual

Version 01

Test & Measurement

Page 2

General Information Regarding the CE Marking

General Information Regarding the CE Marking

General Information Regarding the CE Marking

All ROHDE & SCHWARZ measuring instruments comply

with the regulations of the EMC directive. The ROHDE &

SCHWARZ conformity evaluation is based on applicable

professional and product standards. In cases where

multiple limit values can be used, ROHDE & SCHWARZ

will apply the stricter standard of the two. With regard to

interference emission, the limit values for businesses and

commercial operations including the small business sector

are applied (Class 1B). For the susceptibility to interference

emissions, the applicable limit values for the industrial sector are used. The signal and data cables that must be connected to the device during operation will necessarily affect

the compliance with the acceptance limits to some extent.

However, the cables used for this purpose will vary, depending on the application. For operation of the device, the following information and conditions should therefore be observed

with regard to interference emission and susceptibility:

1. Data Cables

All connections between measuring instruments or their

interfaces and external devices (printers, computers, etc.)

must always be implemented with adequately shielded

cables. Unless the user manual species a shorter maximum

cable length, the data cable (input/output, signal/control) may

not exceed a total length of 3 m, and may not be located

outdoors. If the device interface allows the connection of

more than one cable, only one may be connected at a time.

Data cables in general should always be double-shielded

cable. For the IEEE bus cable, the double-shielded cable

HZ72 is recommended and can be ordered from ROHDE &

SCHWARZ.

2. Signal Cables

Signal cables used for signal transmission between the

measurement point and the measuring device should generally be kept as short as possible. Unless a shorter maximum

cable length is specied, the signal cables (input/output,

signal/control) may not exceed a total length of 1 m, and may

not be located outdoors. All signal cables must be shielded

(RG58/U coaxial cable). Care must be taken to achieve a

proper ground connection. For signal generators, doubleshielded coaxial cables (RG223/U, RG214/U) must always be

used.

General Information

3. Impact on the Equipment

In the presence of strong high-frequency electric or

magnetic elds, unwanted signal components may enter

the equipment, despite careful setup of the connected

cables and lines. With ROHDE & SCHWARZ measuring

instruments, this will neither be destructive nor lead to the

shutdown of the equipment. As a result of such external

conditions, the displayed values and readings may show

minor deviations with respect to the applicable instrument

specications in individual cases.

Regarding the

CE Marking

2

2

Page 3

Content

General Information Regarding the CE Marking .... 2

1 Important Information ...................4

1.1 Symbols ...................................4

1.2 Unpacking ..................................4

1.3 Instrument Setup ............................4

1.4 Safet y .....................................4

1.5 Intended Use ...............................4

1.6 Ambient Conditions ..........................5

1.7 Warranty and Repair ..........................5

1.8 Maintenance ................................5

1.9 CAT II ......................................6

1.10 Supply Voltage ..............................6

1.11 Limit Values .................................6

1.12 Batteries and Accumulators/Cells ...............6

1.13 Product Disposal .............................7

2 Instrument Controls and Indicators .........8

3 Options/Upgrade Vouchers ............... 9

4 Connecting a Device under Test .......... 10

4.1 Connecting a Device under Test via Adapter ......10

4.2 Connecting a Device under Test Directly .........11

4.3 Sensor Menu ...............................12

5 Setting Parameters ..................... 13

5.1 Using the Instrument for the First Time ..........13

5.2 Screen Display Description ...................13

5.3 Multifunction Softkeys .......................14

5.4 Conguring the Operating Mode from a List of

Measuring Parameter Options (“Cells”) ..........14

5.5 Readout Display ............................14

5.6 Selecting the Measuring Range ................15

6 Instrument Functions ................... 16

6.1 Measurement Parameters ....................16

6.2 Display Modes (VIEW Menu) ..................16

6.3 Crest Factor ................................19

6.4 Energy Counter (Integrator Values) .............19

6.5 Invert Function .............................20

6.6 Acquisition Mode ...........................20

6.7 Peak Hold .................................21

6.8 Limits .....................................21

6.9 Analog / Digital Inputs and Outputs .............21

7 Data Logging .........................23

8 Documenting, Saving and Retrieving ....... 25

8.1 Device Settings .............................25

9 General Settings ....................... 26

9.1 Updates (Instrument Firmware) ................26

9.2 Interface Setup .............................26

9.3 General Settings (Misc). ......................26

10 Remot Operation ......................28

10.1 USB VCP ..................................28

10.2 USB TMC .................................28

10.3 Ethernet ...................................30

10.4 IEEE 488.2 / GPIB ...........................32

11 Technical Data ........................33

12 Appendix ............................34

12.1 List of gures ..............................34

12. 2 Glos sar y ..................................34

Content

Content

3

3

Page 4

Important Information

Important Information

1 Important

Information

1.1 Symbols

must follow the instructions and warnings contained in

this manual carefully. The enclosure, chassis and all

measuring terminals are connected to protective ground

lead. The device complies with protection class II.

Disabling or separating the intended safety ground

connection, either inside or outside the device, is not

permitted!

(1) (2) (3) (4)

(5) (6) (7)

Symbol 1: CAUTION: General hazard –

Observe product documentation

Symbol 2: Danger of electric shock

Symbol 3: Earth (ground)

Symbol 4: Protective conductor terminal

Symbol 5: ON (supply voltage)

Symbol 6: OFF (supply voltage)

Symbol 7: Ground terminal

1.2 Un packing

When unpacking, check the package contents for completeness (measuring instrument, power cord, product CD,

any optional accessories). After you have nished unpacking, check the equipment for any visible shipping-related

damage or other mechanical problems. For any damage

occured during transport and shipping, contact the carrier

and supplier immediately. Do not use the equipment if it is

damaged.

1.3 Instrument Setup

As shown in the picture below, the instrument may be

set up at a slight angle by using small extension legs that

unfold from its feet. Ensure that the extension legs are

completely unfolded to ensure secure footing.

Fig. 1.1: Operating positions.

Position the instrument so the power switch is not obstructed at any time.

1.4 Safety

This instrument is designed in accordance with EN

61010-1 (VDE 0411 Part 1), Safety Requirements for

Electrical Equipment for Measurement, Control and

Laboratory Use, and left the factory in perfect condition. It

thus also meets the requirements of European Standard

EN 61010-1 and the international standard IEC 61010-1. To

maintain this condition and ensure safe operation, the user

All exposed metal parts have been tested against the AC

power leads with a test voltage of 2200 VDC. The instru-

ment complies with overvoltage category CAT II (600V). To

ensure safe operation, the instrument may only be operated from a properly grounded power outlet. Plug in the

power cord before connecting any signal circuits. Never

use the product if the power cable is damaged. Check the

power cable on a regular basis to ensure that it is in proper

operating condition. Take appropriate safety measures and

carefully lay the power cable to ensure that the cable will

not be damaged and that no one can be hurt by, for example, tripping over the cable or suffering an electric shock.

Any time there is reason to believe that safe operation is

no longer possible, the instrument must be taken out of

service and secured against inadvertent use.

Safe operation is not possible:

❙ If the instrument shows visible damage

❙ If the instrument is no longer working

❙ Following long-term storage under unfavorable conditions

(e.g. outdoors or in damp rooms)

❙ After severe transport stress (e.g. in packaging that does

not meet the minimum conditions for shipping by post,

rail or truck)

Prior to switching on the product, always ensure that the

nominal voltage set on the product matches the nominal

voltage of the mains supply. If a different voltage is to be

set, the mains fuse of the product may have to be changed

accordingly.

1.5 Intended Use

This instrument is only intended to be used by persons

who are familiar with the risks associated with measuring

electrical quantities. The instrument may only be operated with a properly grounded power outlet. Never use a

“cheater plug” or other means to defeat or disconnect the

protective ground lead. The power plug must be connected before any signal circuits are connected. The product may be operated only under the operating conditions

and in the positions specied by the manufacturer, without

the product's ventilation being obstructed. If the manufac-

turer's specications are not observed, this can result in

electric shock, re and/or serious personal injury or death.

Applicable local or national safety regulations and rules for

the prevention of accidents must be observed in all work

performed.

4

4

Page 5

Important Information

Important Information

The instrument is intended for use in the following areas:

❙ Industrial

❙ Residential

❙ Business and commercial

❙ Small business

The measuring device is to be used only with authentic ROHDE &

SCHWARZ test accessories, signal cables and power cords. Never

use power cords with insufcient ratings. Before starting each

measurement, the signal cables should be checked for damage and

replaced if necessary. Damaged or worn components may damage

the equipment or cause injury.

The instrument may only be used indoors. Before each

measurement, check the instrument for proper operation

using a known signal source or sample.

To disconnect from the power supply, the rear uncooled IEC plug

must be removed.

1.6 Ambient Conditions

The permissible operating temperature is +5 °C to +40 °C

(connector contamination level 2). The maximum permissible relative humidity (non-condensing) is 80 %. During

storage or transport, the permissible temperature range

is –25 °C to +60 °C. If condensation has formed during

transport or storage, the equipment should be allowed to

acclimatize to ambient levels for about two hours before

use. The instrument is intended for use in clean, dry areas.

It may not be operated in dusty or damp conditions, an

explosion hazard area, or in the vicinity of aggressive

chemicals. The instrument can be positioned as needed,

but sufcient air circulation must always be ensured. For

prolonged operation, a horizontal or slightly angled operating position (extension legs) is preferable.

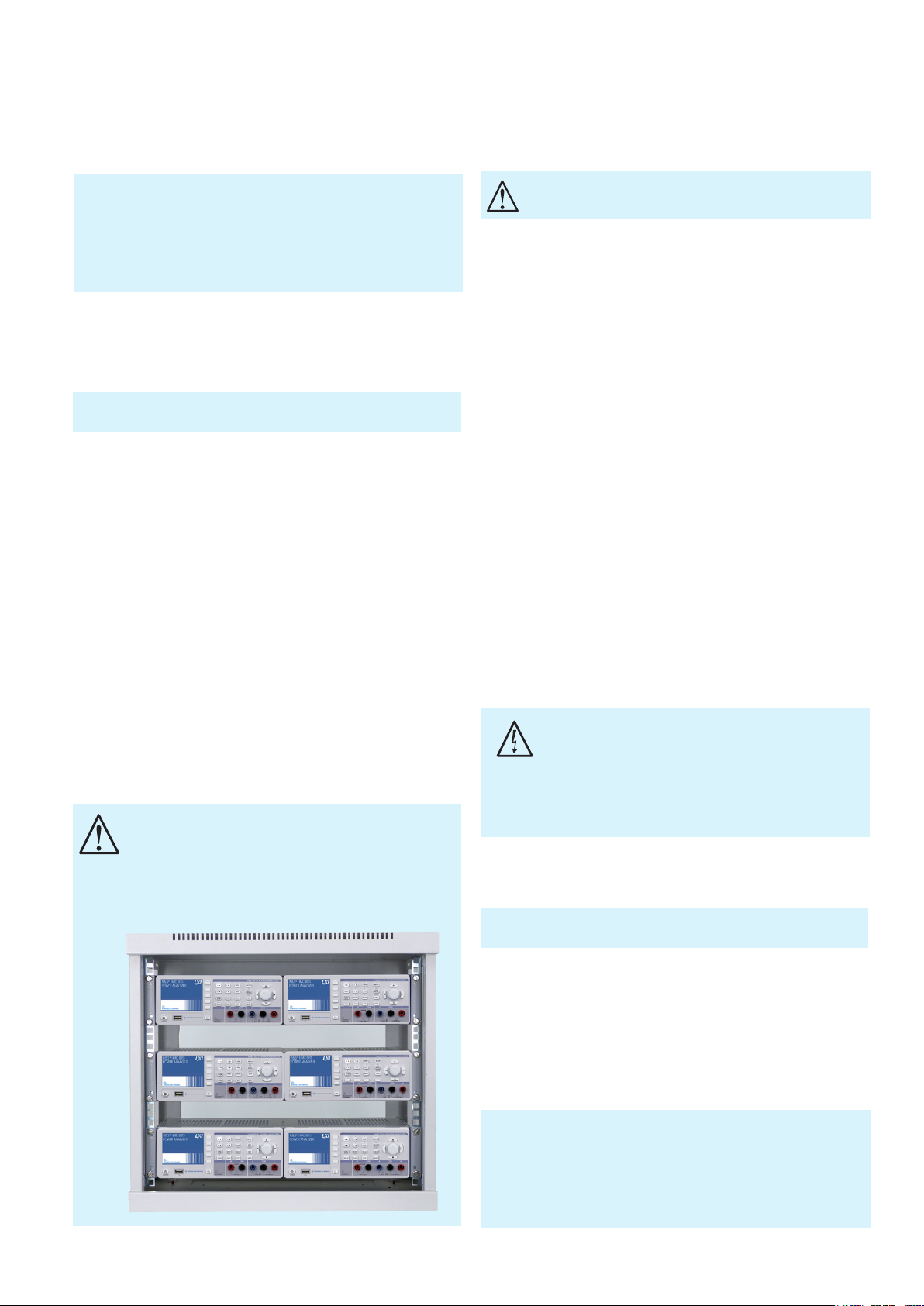

When installing one or more R&S®HMC8015 units in a 19inch rack, make sure that there is enough space around

its periphery to ensure sufcient cooling (see gure).

Recommended minimum clearance: 1 height unit (HU)

The instrument may be operated at an altitude of up to

2000 m. The specications and tolerances apply after

a warm-up time of at least 60 minutes, at an ambient

temperature of 23 °C (± 2 °C). All values stated without

tolerances are typical values for an average unit.

The ventilation openings must not be

covered!

1.7 Warranty and Repair

ROHDE & SCHWARZ equipment is subject to strict quality

control. Before leaving the production line, each device

is subjected to a 10-hour “burn-in test”. This is followed

by an extensive functional test and quality inspection, in

which all operating modes and compliance with speci-

cations are checked. These tests are carried out using

equipment that is calibrated traceable to national standards. The statutory warranty provisions of the country in

which the ROHDE & SCHWARZ product was purchased

are applicable. In the event of any complaints, please

contact the dealer from whom you purchased the ROHDE

& SCHWARZ product.

All adjustments, parts replacements, maintenance and

repairs must be carried out by authorized ROHDE &

SCHWARZ specialists. Only original parts may be used

for replacing safety-relevant parts (e.g. mains switches,

mains transformers, fuses). After each replacement of

safety-relevant parts, a safety check (visual inspection, PG

conductor test, insulation resistance test, leakage current

measurement, functional testing) must be performed. This

helps ensure the continued safety of the product.

The product may only be opened by authorized,

specially trained personnel. Before any work is

performed on the product or before the product is

opened, it must be disconnected from the supply

voltage. Otherwise, personnel will be exposed to the

risk of an electric shock.

1.8 Maintenance

The outside of the instrument should be cleaned regularly with a

soft, lint-free dust cloth.

The display may only be cleaned with water or a suitable glass cleaner (not with alcohol or solvents), followed

by wiping with a clean, dry, lint-free cloth. Never allow

cleaning liquid to enter into the equipment. Other cleaning

products may dissolve the labels or mar the plastic surface

and painted or varnished surfaces.

Before cleaning the instrument, make sure that it is turned off

and disconnected from any power supply (e.g. AC power grid or

battery).

No part of the equipment should be cleaned with chemical solvents such as alcohol, acetone or paint thinners!

5

5

Page 6

Important Information

Important Information

1.9 CAT II

This instrument is intended for measurements on circuits that are or are not connected directly to the normal

(low-voltage) AC power grid. The device complies with

measurement category CAT II; the input voltage must not

exceed 600 V

in a CAT II application.

RMS

The following information relates exclusively to user

safety. Other aspects, e.g. the maximum permissible

input voltage, are specied in the technical data sheets

and must also be observed. Indirect measurements on

the power grid may be performed by means of appropriate transducers (e.g. current probes) that meet or exceed

the requirements of the protection class applicable to the

measurement task. When measuring, the transducer’s

measurement category – as specied by the manufacturer

– must be observed.

Measurement categories

The measurement categories relate to transients superimposed on the AC line voltage. Transients are short, very

fast (steep) voltage and current changes that may occur

either periodically or non-periodically. The amplitude of

possible transients increases as the distance to the source

of the low-voltage network decreases.

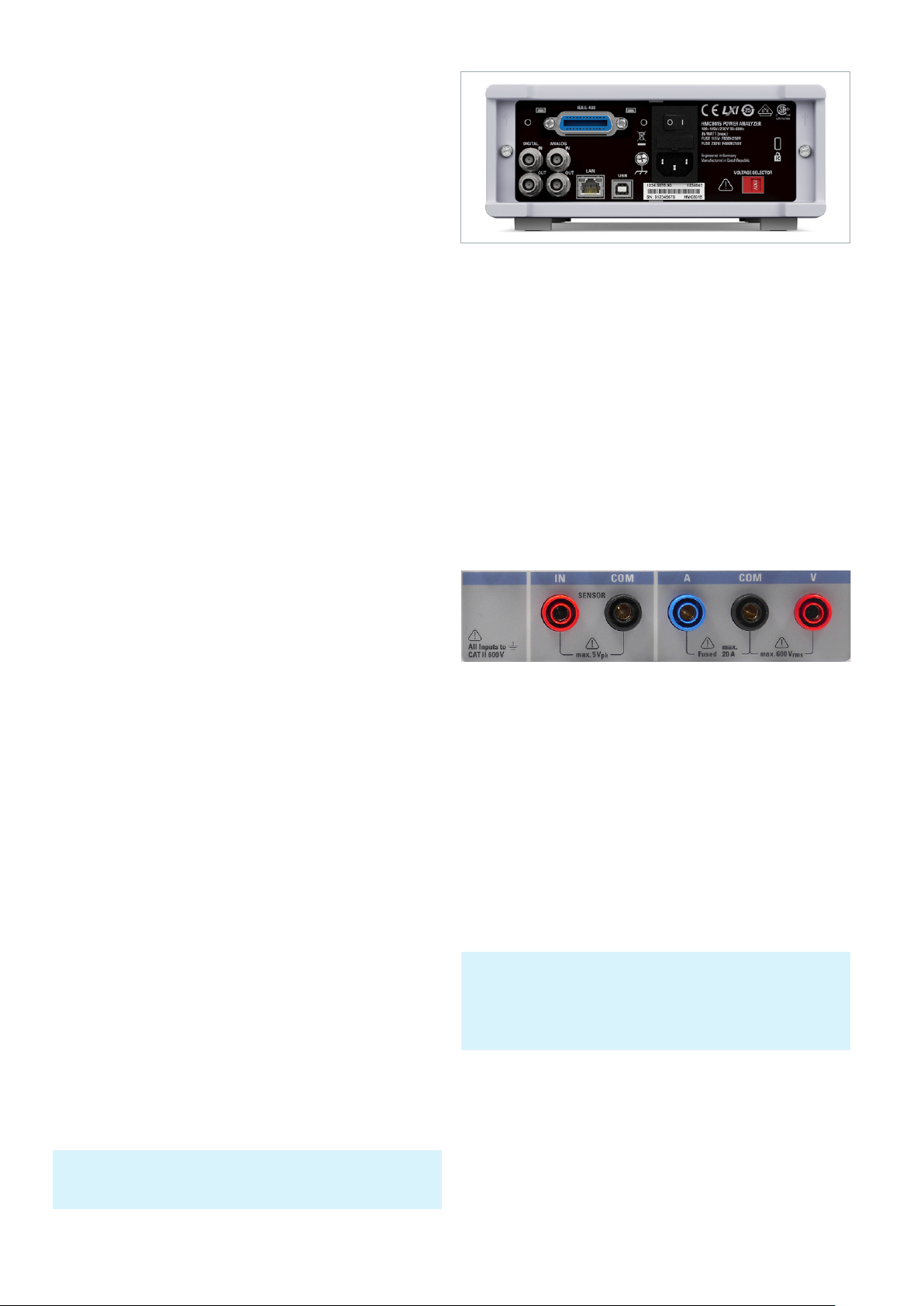

Fig. 1.2: Rear panel with supply voltage selector and connections.

The measuring circuit is equipped with a current overow

fuse against excess current that cannot be serviced or

replaced by the user.

1.11 Limit Values

The R&S HMC8015 is equipped with an overload protection circuit. The overload protection circuit is used to

prevent damage to the unit, and to protect against possible

electrical shock. The limit values of the unit must not be

exceeded. The front panel of the R&S HMC8015 species

the protection limit values in order to ensure safe operation of the unit. These protection limits must be strictly

observed:

❙ Measurement category IV: Measurements at the

source of the low-voltage network (e.g. on electricity

meters).

❙ Measurement category III: Measurements in a building

network (e.g. distribution panels, circuit breakers,

permanently installed electrical outlets, stationary

motors, etc.).

❙ Measurement category II: Measurements on circuits

directly connected to the low-voltage power grid (e.g.

household appliances, power tools, etc.)

❙ 0 (Devices with no measurement category rating): Other

circuits that are not directly connected to the power grid.

1.10 Supply Voltage

Before turning on this device, please check that the available supply voltage (115 V or 230 V ±10 %, 50 Hz to 60 Hz)

matches the specications on the supply voltage selector

switch of the device. If this is not the case, the supply volt-

age must be adjusted using the switch. The mains voltage

selector switch is located on the rear panel of the unit.

The unit has a main power fuse, which is located on

the rear panel of the unit for uncooled IEC connectors.

Depending on the supply voltage setting, a fuse of the correct type must be installed.

❙ At the 115 V setting: F630L250V

❙ At the 230 V setting: F400L250V

If the equipment must be left unattended for a long period of

time, it must be switched off at the power switch for safety

reasons.

Fig. 1.3: Connections on the front panel.

Voltage input: 600 V

RMS

Current input: 20 A

Max. voltage

between COM and IN: 5 V

Peak

Connection to power supply:

115 V / 230 V, selectable with the voltage selector on

the rear panel of the unit

Frequency: 50 -60 Hz

Power consumption: 35 W maximum, 15 W typical

1.12 Batteries and Accumulators/Cells

If the information regarding batteries and accumulators/cells

is ignored or not sufciently observed, this may lead to explosion, re and serious personal injury or death. The handling of

batteries and accumulators based on alkaline electrolytes must

conform to EN 62133.

1. Cells must not be taken apart, opened or crushed.

2. Cells or batteries must not be exposed to heat or re.

Storage in direct sunlight must be avoided. Keep cells

and batteries clean and dry. Clean soiled connectors

using a dry, clean cloth.

6

6

Page 7

3. Cells or batteries must not be short-circuited. Cells or

batteries must not be stored loose in a box or drawer

where they can short-circuit each other, or where they

can be short-circuited by other conductive materials.

Cells and batteries must not be removed from their

original packaging until they are ready to be used.

4. Keep cells and batteries out of the reach of children. If

a cell or battery has been swallowed, seek immediate

medical care.

5. Cells and batteries must not be subjected to any mechanical impacts that are stronger than permitted.

6. If a cell develops a leak, the uid must not come into

contact with the skin or eyes. If contact occurs, wash

the affected area with plenty of water and seek medical

aid.

7. Cells or batteries that are not properly replaced or

charged pose a risk of explosion. To ensure that the

product remains safe to use, always replace cells or

batteries with the matching type.

Important Information

Important Information

8. Cells and batteries must be recycled and kept separate from regular household waste. Accumulators or

batteries that contain either lead, mercury or cadmium

are hazardous waste. Observe the national regulations

regarding waste disposal and recycling.

1.13 Product Disposal

Fig. 1.4: Product labeling in accordance

with EN 50419.

The German Electrical and Electronic Equipment Act (ElektroG) implements the following EC directives:

❙ 2002/96/EC (WEEE) for electrical and electronic

equipment waste and

❙ 2002/95/EC on the Restriction of Use of Hazardous

Substances in electrical and electronic equipment (RoHS

directive)

At the end of the lifecycle of this product, it may not be

disposed of with normal household waste. Moreover,

disposal via the municipal collection points for electrical

equipment waste is also not permissible. Rohde & Schwarz

GmbH & Co. KG fully assumes the manufacturer’s obligations to take back and dispose as set forth by the ElektroG,

to ensure environmentally sound disposal or recycling of

the materials used.

Please contact your local service representative in order to

dispose of the product.

7

7

Page 8

Instrument Controls and Indicators

Instrument Controls and Indicators

2 Instrument Con-

trols and Indicators

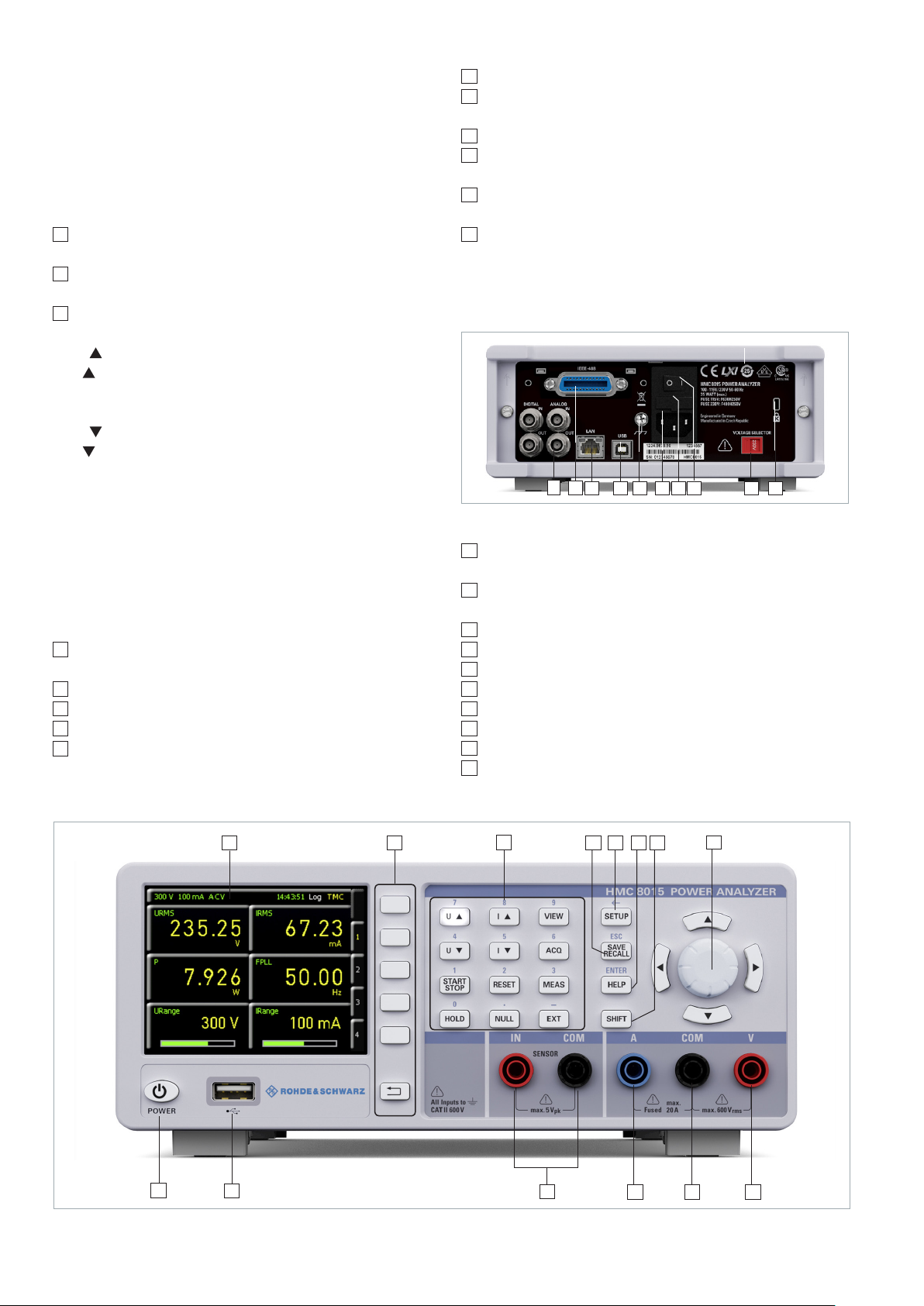

¸HMC8015 front panel

1

Display – 3.5" TFT color display with QVGA resolution

(320 pixels x 240 pixels)

2

Interactive softkeys – Direct access to all relevant func-

tions

3

Function Keys – Operates as a numeric keypad using

SHIFT function

U – Increases voltage range manually

I – Increases current range manually

VIEW – Switches between graphical and numeric dis-

play

U – Decreases voltage range manually

I – Decreases current range manually

ACQ – Data acquisition menu for recording data

START / STOP – Starts/stops the energy counter

RESET – Resets peak values / energy counter

MEAS – Logging function / energy counter / limit val-

ues

HOLD – Stops the update of measurement values

NULL – Sets the current display values as zero refer-

ence values

EXT – Sensor menu and additional functions

4

SAVE/RECALL – Saves and recalls/uploads device set-

tings

5

SETUP – Gives access to general device settings

6

HELP – Integrated help screen

7

SHIFT – Activates the numeric keypad

8

Universal rotary control knob with arrow keys – Sets

the parameters cells (editing keys)

V jack – Input for voltage measurement

9

COM jack – Shared measuring input for voltage and

10

current measurement

A jack – Input for current measurement

11

IN/COM jacks – Sensor input for external shunts or cur-

12

rent probes

USB port – USB host port for USB ash drives when

13

saving parameters

POWER – ON/OFF for standby mode

14

¸HMC8015 rear panel

15

Fig. 2.2: ¸HMC8015 rear panel.

15

Digital / Analog IN/OUT – Digital / analog inputs and

19181716

20 21 2422

23

outputs for Pass/Fail sorting and limit values

16

IEEE-488 (GPIB) interface (optional) – Installation avail-

able at factory only

17

Ethernet (LAN) interface

18

USB interface

19

Ground terminal

20

Uncooled IEC plug

21

Fuse

22

Power switch

Supply voltage selector switch (115V or 230V)

23

24

Kensington lock

1

14

Fig. 2.1: ¸HMC8015 front panel.

8

8

13

2

3

12

4

5 6 7

11

8

10

9

Page 9

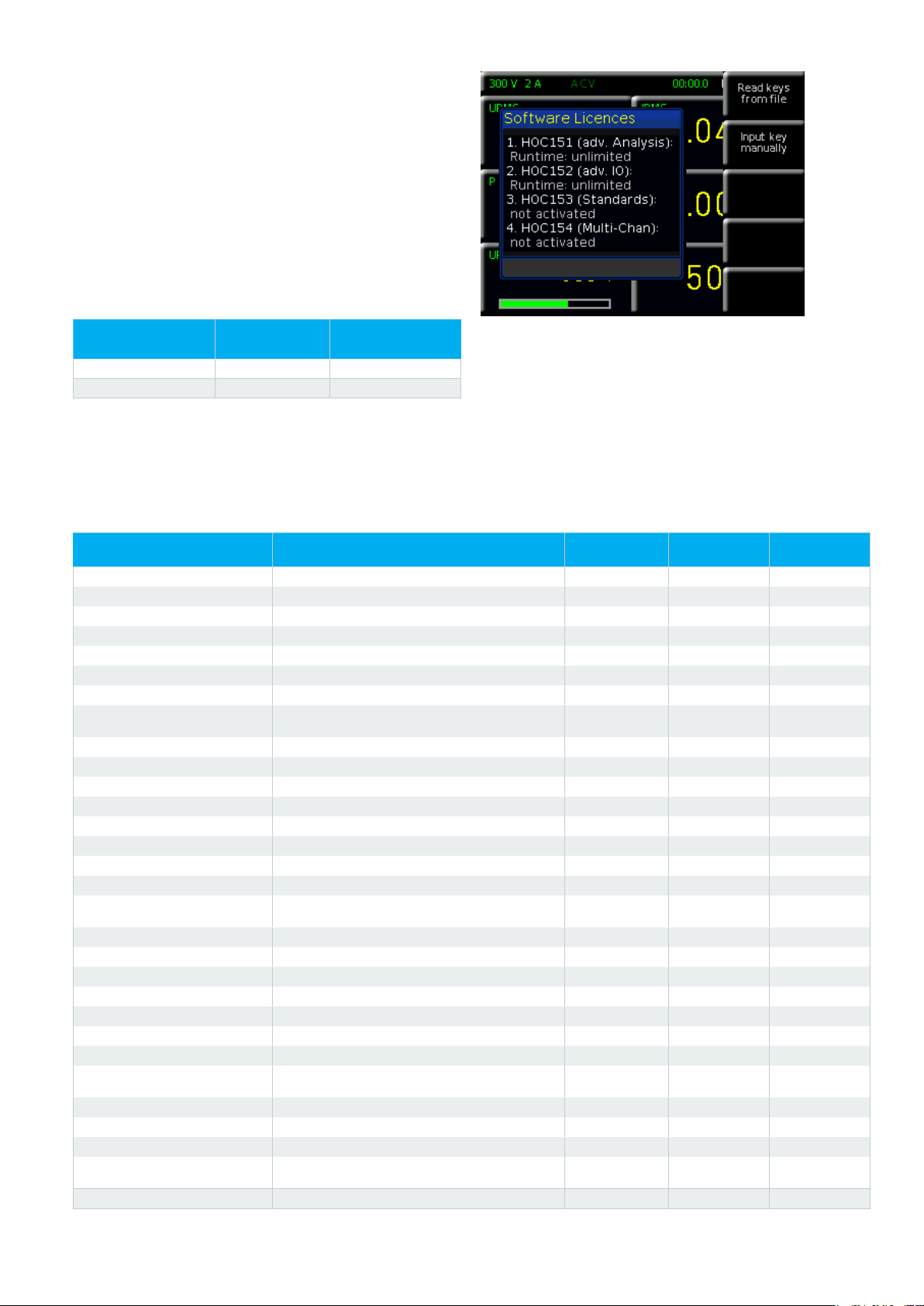

3 Options/Upgrade

Vouchers

The R&S®HMC8015 has available options that increase the

application scope of the instrument. Options and upgrade

vouchers can be combined. The following options (or upgrade vouchers) are available for the R&S®HMC8015 power

analyzer:

Options/Upgrade Vouchers

Options/Upgrade Vouchers

Description ¸HMC8 015

Advanced Analysis ¸HOC151 ¸HVC151

Advanced IO ¸HOC152 ¸HVC152

Table 3.1: Overview of ¸HMC8015 options/upgrade vouchers

options

1)

¸HMC8 015

upgrade vouchers

Fig. 3.1: Upgrade menu.

2)

The R&S®HOC151 Advanced Analysis option or

R&S®HOC152 Advanced IO function can both be purchased from the factory with an R&S®HMC8015. In contrast, the R&S®HV151 Advanced Analysis upgrade voucher

1) Only when ordered in combination with a ¸HMC8015 base unit

2) Subsequent activation of ¸HMC8015 options via upgrade voucher

Function Description

P Active power (W) ●

S Apparent power (VA) ●

Q Reactive power (var) ●

PF Power factor lambda (λ) ●

PHI Phase shift (φ) ●

FU Frequency value for the voltage (Hz) ●

FI Frequency value for the current (Hz) ●

FPLL

URMS True root mean square (RMS) voltage (U

UAVG Average voltage ●

IRMS True root mean square (RMS) current (I

IAVG Average current ●

UTHD Total harmonic distortion U ●

ITHD Total harmonic distortion I ●

WHM, WHP, WH, AHM, AHP, AH Energy counter (integrator values) ●

Logging Data recording (comma-separated values CSV) ●

USB, Ethernet

(GPIB optional – HMC8015- G)

UPPeak Maximum voltage (U

UMPeak Minimum voltage (U

IPPeak Maximum current (I

IMPeak Minimum current (I

PPPeak Maximum power (P

PMPeak Minimum power (P

HARMONICS mode Bar graph of 50 harmonics ●

WAVEFORM mode

TRENDCHART mode Current or voltage displayed as signal prole ●

INRUSH mode Triggered display of a signal prole (single shot) ●

Sensor input Input jack for current probe / external shunt ●

DIN / AIN

Limit value / PASS-FAIL Displays limit values ●

Table 3.2: Feature overview: options/upgrade vouchers

Frequency and phase locked loop recording frequency (Hz)

Remote interfaces ●

) ●

+pk

) ●

–pk

) ●

+pk

) ●

–pk

) ●

+pk

) ●

–pk

Displays the waveform (for one cycle of voltage, current or power data)

Digital / analog inputs and outputs (Bayonet Neill –

Concelman BNC)

or R&S®HV152 Advanced IO upgrade voucher enable a

subsequent upgrade via a license key. The installed options or upgrade vouchers can be looked up under “Device

R&S®HMC8015

) ●

RMS

) ●

RMS

base unit

●

¸HOC151

¸HVC151

●

¸HOC152

¸HVC152

●

9

9

Page 10

Options/Upgrade Vouchers

Options/Upgrade Vouchers

Information” in the SETUP menu. Table 3.2 shows an overview of the most important optional features. For com-

plete specications, please visit the ROHDE & SCHWARZ

homepage.

To generate a license key, go to http://voucherrs.hameg.

com and enter the voucher code. The license key (SERI-

ALNUMBER.hlk) is an ASCII le and can be opened using

a le editor. The key is listed in the le in plain text. Enable

the option in the instrument by either reading the key in

automatically or entering it manually. The fastest and easiest method is to read the key in automatically from a USB

ash drive. To do this, save the license le to a USB ash

drive and then insert the ash drive into the USB port on

the instrument front panel. Press the SETUP button and

then softkey LICENSE to open the menu for reading in

options and upgrade vouchers. Press softkey READ KEYS

FROM FILE to open the File Manager. Use the rotary con-

trol knob to select the license le, then press softkey LOAD

to load the key. The license key is loaded and the option is

available after the instrument has been restarted.

Alternatively, the license key can be entered manually. To

do this, press softkey INPUT KEY MANUALLY. This opens

an input window where the license key can be typed in

manually. Once the key has been entered, conrm by

pressing softkey ACCEPT. Restart the instrument to enable

the option.

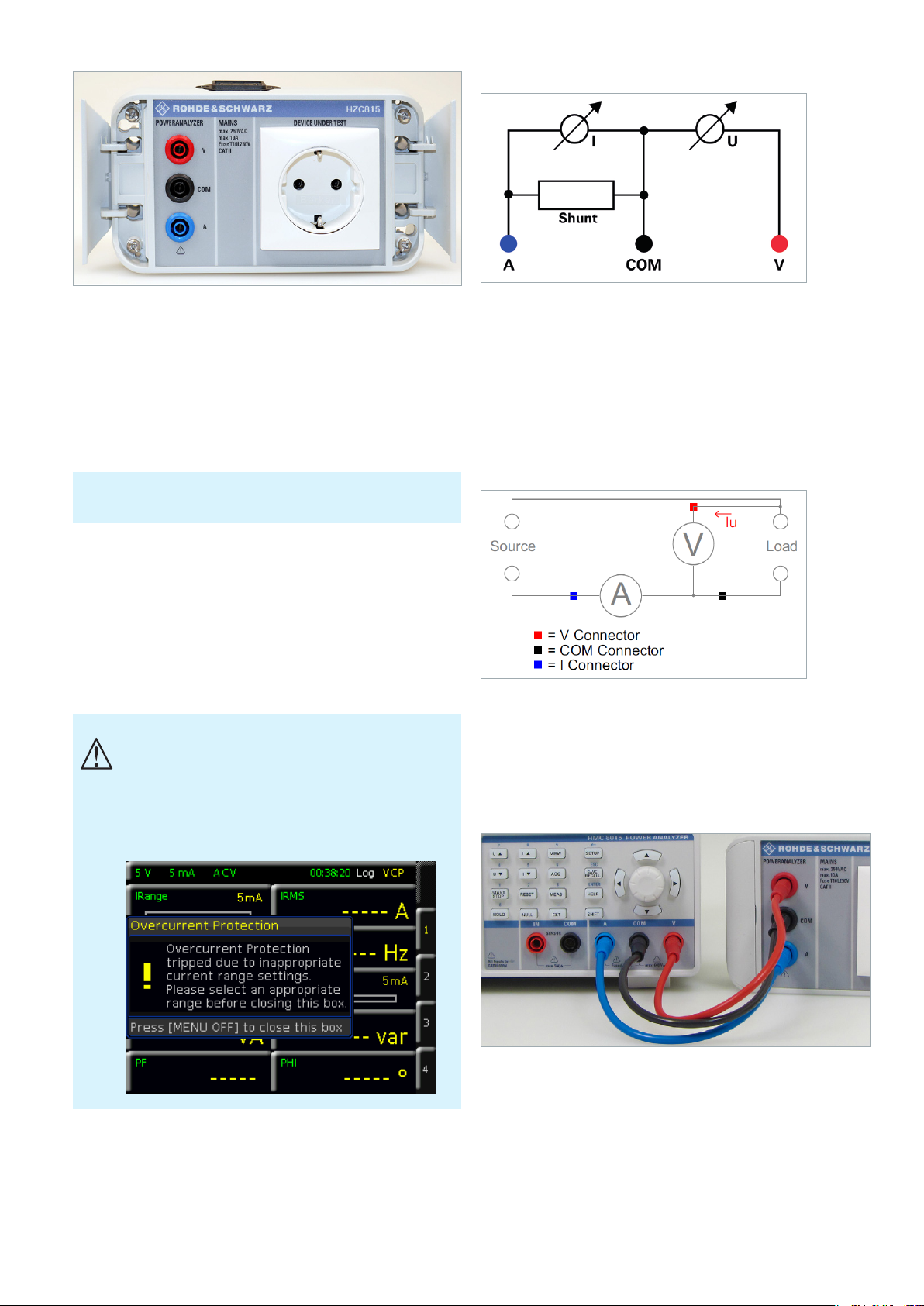

4 Connecting a

Device under Test

4.1 Connecting a Device under Test via Adapter

Fig. 4.1: Connecting HZC815 DE version to ¸HMC8015.

A device under test (DUT) can easily and securely be

connected to the ¸HMC8015 using the optional

HZC815 socket adapter. In this case, the cables enclosed

with the HZC815 (length = 25 cm) are connected to the

¸HMC8015 socket on the front panel. The connection

of the socket adapter to the ¸HMC8015 front panel is

determined by the color of the HZC815 accessory cables.

The cables on the socket adapter represent an extension

of contacts for a standard AC outlet with grounded safety

sockets and are used for measuring a DUT. Power is supplied to the HZC815 socket adapter through the uncooled

IEC plug on the top of the adapter and a power cord.

Fig. 3.2: Manually entering the license key.

There are 3 different types of HZC815 available ex factory:

❙ HZC815-DE: DE version; EU socket adapter (230V)

❙ HZC815-UK: UK version; UK socket adapter (230V)

❙ HZC815-US: US version; US socket adapter (115V)

Fig. 4.2: HZC815 DE, UK and US version plug adapters.

The HZC815 standard AC grounded safety outlet system is

only approved for a 10 A continuous load. A load of 20 A would

destroy the adapter.

10

10

On the sides of the HZC815 adapter, special faceplates

hide mounting screws. The socket adapter can be permanently mounted with these mounting screws if so desired.

Page 11

4.2.1 Internal Jack Wiring

Options/Upgrade Vouchers

Options/Upgrade Vouchers

Fig. 4.3: HZC815 DE version plug adapter with mounting screws.

4.2 Connecting a Device under Test Directly

The ¸HMC8015 can measure voltages up to 600 V

and currents up to 20 A

. In these cases, a device under

RMS

RMS

test (DUT) can be directly connected to the power analyzer

using the 4 mm safety jacks on the front panel.

Before the start of each measurement, the signal cables to be used

must be checked for damage and wear.

Voltages are measured using the red V jack; currents are

measured using the blue A jack. The black COM jack acts

here as the shared measuring input for voltage and current

measurement.

If the maximum values for current and voltage are exceeded, the ¸HMC8015 power analyzer is automatically switched off.

If the safety warning “Overcurrent Protection” appears

on the screen, then more than 2 A were supplied in the

low current range. The unit switches itself off in order

to protect the internal shunt. In this case, switch to the

automatic range selection (AUTO) or a higher range (>

500 mA) manually.

Fig. 4.4: Internal wiring of A, V and COM jacks.

The 4 mm A, V and COM safety jacks on the front panel

are not electrically isolated and separate from each other,

and therefore offer several methods for measuring a DUT:

❙ Voltage-based measurement

❙ Current-based measurement

❙ Measurements via external shunt / current probe

4.2.2 Voltage-Based Measurement

Fig. 4.5: Voltage-based measurement.

Voltage-based measurement is typically used with high

currents, since the voltage drop at the shunt increases as

the current increases. The voltage U is correctly measured

at the load.

Fig. 4.6: Voltage-based measurement, wiring example.

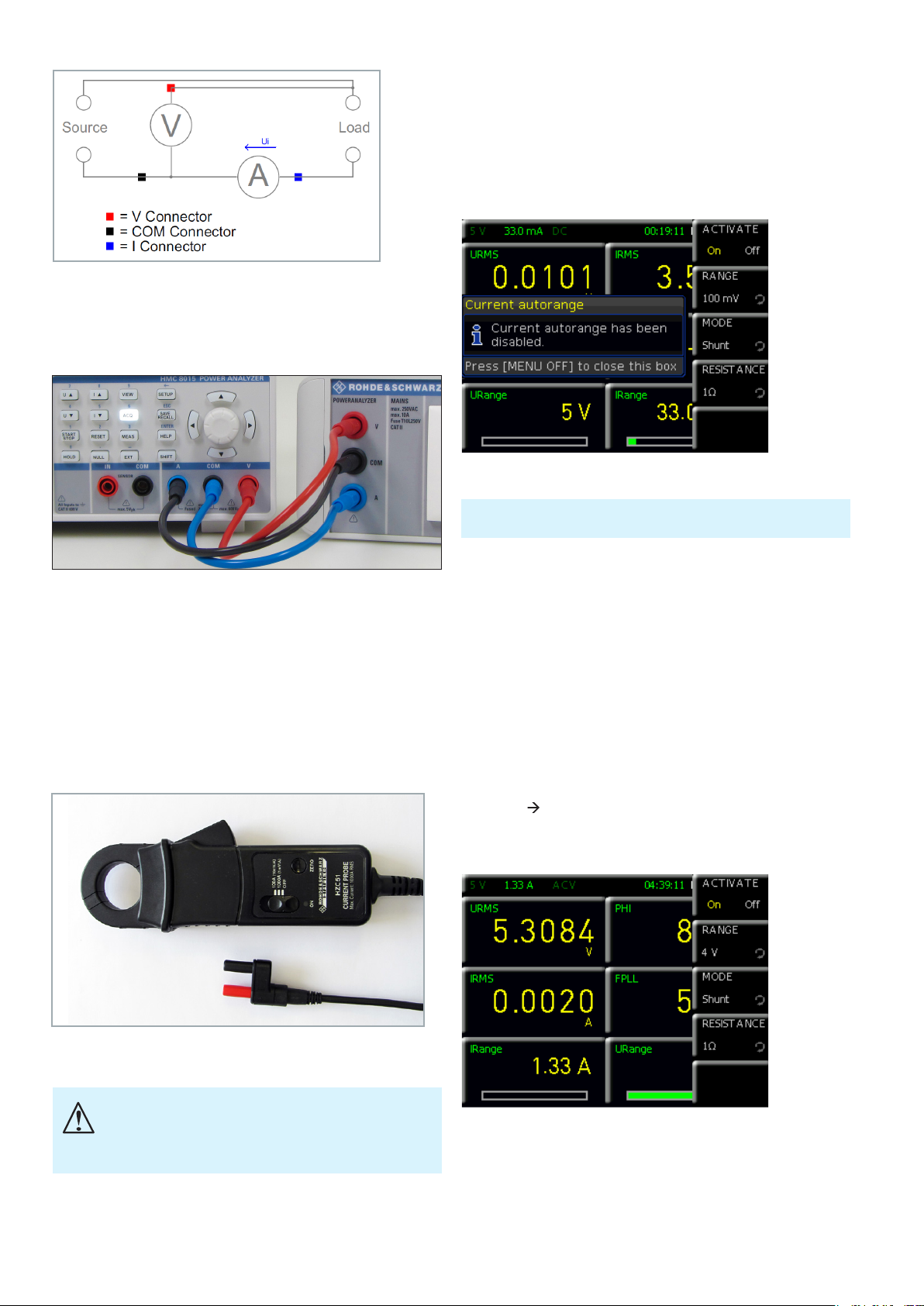

4.2.3 Current-Based Measurement

Current-based measurement is preferred with low currents

and high voltages, because it prevents current owing

through the voltage measuring jack from going through

the shunt, which would falsify the reading. With this measurement type, the current reading must be inverted (IN-

11

11

Page 12

Options/Upgrade Vouchers

Options/Upgrade Vouchers

Fig. 4.7: Current-based measurement.

VERT) using the ACQ menu and softkey menu CURRENT.

In addition, the I and COM cables need to be reversed (see

Fig. 4.8).

4.3 Sensor Menu

The Sensor conguration menu is opened via the EXT

menu and the softkey menu SENSOR. Press softkey

ACTIVATE to activate (ON) or deactivate (OFF) the sensor

measurement. When the sensor measurement is activated

(ON), the automatic current measurement (AUTO) is deactivated (if it was activated previously).

Fig. 4.10: Sensor menu.

Fig. 4.8: Current-based measurement, wiring example.

4.2.4 Measurements with an External Shunt or

Clamp-on Current Probe

The 4 mm safety jacks IN and COM are used for making

measurements with an external shunt or clamp-on current

probe. Safety plugs connect the shunt or clamp-on probe

directly to the jacks. Accessories such as HZC50 or HZC51

can be used for the clamp-on probe.

The softkey ACTIVATE activates the sensor inputs IN and COM

on the instrument front panel (hardware switch).

Use the softkey RANGE and the rotary control knob to

select the maximum measuring range for the measured

voltage. The available settings are 100mV, 1V and 4V. As

a rule, the 100mV range is appropriate for measurements

on shunts, while 1V and 4V are used for measurements

with a current probe. This setting is referenced to the peak

value.

Example for shunt:

Set RESISTANCE to 1Ω.

Set RANGE to 4V.

Convert as follows:

1V = 1A 4V divided by CF3 = 1.33A.

Use the cell conguration to display this power range as

IRANGE on the screen.

Fig. 4.9: HZC51 Clamp-on current probe.

The connection of a clamp-on probe through a BNC adapter

is not allowed, since depending on the polarity of the volt-

age, the measuring voltage may be present across the BNC

plug coupling.

12

12

Fig. 4.11: Example of a sensor.

Use softkey MODE and the rotary control knob to select

the sensor mode. The available modes are SHUNT (to

connect an external shunt) and CLAMP (to connect a

current probe, e.g. HZC50 / HZC51). The Sensor menu

Page 13

changes dynamically to match the selected sensor mode.

In sensor mode SHUNT, softkey RESISTANCE is used to

enter the value of the externally connected shunt in ohms.

Select the value using the rotary control knob or press the

SHIFT button to input the value numerically. If you entered

the value numerically, press the appropriate unit on the

softkey menu to conrm the value. Once the shunt value

is entered, all measured values (current, power and values

derived from these) can be calculated correctly and displayed. Manual calculations are no longer necessary. The

data from the external shunt is converted to the correct

measured values internally.

Setting Parameters

Setting Parameters

5 Setting Parameters

5.1 Using the Instrument for the First Time

Pay particular attention to the safety instructions indicated

above when using the instrument for the rst time!

After connecting the uncooled IEC power cable and

operating the power switch on the rear panel, the unit can

be switched on by pressing the POWER button on the

front panel. A help screen appears automatically. If you do

not want to see the help screen, it can be hidden with the

HIDE function. With the HIDE FOREVER softkey, the help

screen feature will be disabled and no longer automatically

displayed after restarting. After doing this, the help function can only be opened using the HELP button.

Whenever the power analyzer is switched on, it is in the

same mode as when it was last shut down. All device

settings are stored in nonvolatile memory (NVM) and

retrieved when restarting.

Fig. 4.12: Sensor mode.

In sensor mode CLAMP, softkey RATIO and the rotary con-

trol knob are used to dene a conversion factor. This factor

denes how many millivolts the sensor transmits when

a current of 1A is applied. Once the factor is entered, all

measured values (current, power and values derived from

these) can be calculated correctly and displayed. Manual

calculations are no longer necessary. Available factors are

1mV/A, 10mV/A and a user-dened value (USER). The

conversion factors 1mV/A and 10mV/A are appropriate for

the current probes HZO50 and HZO51, for example. If you

are using a current probe from a different manufacturer,

use the rotary control knob to select the factor or use the

SHIFT button to input the factor numerically.

5.2 Screen Display Description

1 2 3 4 6

7

8

9

1

Voltage measuring range

2

Current measuring range

3

Operating mode

4

Time displayed as function of the operating mode

5

Logging enabled (yellow) / disabled (white)

6

Type of interface: GPIB / TMC / VCP / LAN

7

Cell function

8

Measuring parameter cell with reading

9

Measuring range and modulation shown as bar

5

graphs (URange / IRange function)

10

Softkey menu 1 to 4 used to congure the meas-

uring parameter cell / display toggles between six and

10 measurement values

10

Fig. 5.1: Screen display description.

13

13

Page 14

Setting Parameters

Setting Parameters

Fig. 5.2: Help function.

5.3 Multifunction Softkeys

The menu eld that appears on the screen can be manipulated using the softkeys on the right side of the screen.

After a menu is activated by using the function keys on the

front panel, control and conguration of the menu functions is done by using the softkeys. If a device function is

not available within a specic setting (e.g. if an option or

upgrade voucher is not installed), then the corresponding

softkey is disabled and the caption is grayed out. Close a

menu or jump back one menu level using the softkey

at the very bottom. In addition, the Quick Menu and the

softkeys 1 to 4 can be used to congure the display of the

measuring parameter cells. If the softkey of the already

active conguration page is pressed again, it is possible

to toggle between a display of six and 10 parameter cells.

Each cell can be fully customized. Up to four conguration

menus are available.

5.4 ConguringtheOperatingModefromaListof

Measuring Parameter Options (“Cells”)

The individual functions and operating modes of the

power meter can be selected using the buttons on the

front panel. To select a device function, the corresponding

function key is pressed. The white LED inside the key is lit

as an indication that the function is active. The editing of

a cell is activated by pressing on the rotary control knob

or one of the arrow keys. The rst cell on the top left is

highlighted in blue. The relevant parameter cell can then

be selected using the rotary control knob or the arrow

keys. Once a parameter cell is selected, the parameter list

can be opened by pressing the rotary control knob again.

When a measuring parameter has been selected, it can be

conrmed by pressing the rotary control knob, or after 20

seconds without input, the unit will automatically return to

the previous screen (see Section 9.3.5 Key Fallback Time).

5.5 Readout Display

The R&S®HMC8015 power analyzer has a TFT color display. The screen is divided into two sections. The rst section is the status bar, in which the currently active modules

and interface information are displayed. Table 3.2 presents

a general overview of the power meter’s split screen with

all possible function displays and their descriptions.

Fig. 5.4: Readout display with six active cells.

The eld of cells is variable and dependent on the operating mode. In NUMERIC mode (set by default), typical

numeric measurement values, such as power, voltage, current etc., are displayed. By contrast, in HARMONICS mode

(HVC151 option required), the harmonics of the signals are

displayed as bar graphs. Each mode has its own menu

structures, which can be congured by using the softkeys.

By default, the display consists of either six or 10 cells with

four different conguration pages.

Fig. 5.3: Selecting the measurement function.

14

14

Fig. 5.5: Readout display with 10 active cells.

With the HOLD function, the current measurement results

are paused and shown on the display. Therefore when

the HOLD button is pressed (button is lit), the particular

measurement values are frozen on the display. The data

recording is then running in the background. If the HOLD

button is pressed again (LED turned off), the function is

deactivated.

Page 15

Setting Parameters

Setting Parameters

Using the NULL button, the current readings are taken as

reference values and any deviation from them is shown

on the display. If the NULL function is activated, the LED

inside the button is lit. To deactivate the NULL function,

press the button again (LED turned off).

If the device shows only dashes “---” on the display, the

¸HMC8015 could not determine a valid frequency. This can

occur, for example, when the AC function was selected and the

signal amplitude is too small or when the measuring range has

been set too high.

5.6 Selecting the Measuring Range

The individual functions and operating modes of the

R&S®HMC8015 unit can be selected using the buttons on

the front panel. Basic functions, such as voltage or current

measuring range, can be selected through the corresponding function keys. Using the U, I, U and I keys, the

measuring range can be increased or decreased manually.

U or I switches to the next higher, U or I to the

next lower voltage or current measuring range.

In automatic range selection mode, this leads to a switch

to the next higher range if the signal readings exceed

120% of the current measuring range. The unit switches

to the next lower range if 0.6s have elapsed since the last

range change and the RMS reading is within 95% of the

next smaller measuring range.

Moreover, by using the ACQ menu, the automatic measuring range selection (AUTORANGE) for current or voltage

can be activated (ON) or deactivated (OFF) in the VOLTAGE

or CURRENT softkey menu. The manual range selection is

automatically disabled when using AUTORANGE.

In the case of manual range selection, if the applied value is too

large, the display will show the message “OL” (overload).

Fig. 5.6: Example of measuring range display.

Push long the U , I , U and I keys to activate the automatic

measurement range mode.

Using the URANGE or IRANGE measurement parameters,

the modulation of the selected measuring range can be

graphically displayed (bar graph) on the screen. If the measuring range is manually adjusted with the U, I, U

and I keys, the bar graph is changed accordingly. A red

measuring range bar indicates that the measuring range of

the incoming signal is too small.

Fig. 5.7: Selecting the measurement function.

If, at crest factor 3, the instrument is in a current measuring

range less than 200 mA and automatic current range selection

is activated, then the data acquisition hardware automatically

switches to the highest current measuring range for any large

overcurrent (e.g. 2 A).

15

15

Page 16

Instrument Functions

Instrument Functions

6 Instrument

Functions

6.1 Measurement Parameters

Fig. 6.1: R&S®HMC8015 readout display.

In NUMERIC mode, the instrument screen provides an

overview of the measurement values. The numeric values

displayed on the instrument screen are instantaneous val-

Fig. 6.2: Option / upgrade voucher info box.

ues that are constantly updated. If an instrument function

is grayed out in the menu, the purchase of an option/upgrade voucher is required in order to unlock this feature. If

the softkey of the grayed-out function is pressed, then an

info box appears on the screen with the required option/

upgrade voucher (see Chapter 3).

6.2 Display Modes (VIEW Menu)

R&S®HMC8015 base unit

P Active power (W)

S Apparent power (VA)

Q Reactive power (var)

PF Power factor lambda (λ)

PHI Phase shift (φ)

FU Frequency value for the voltage (Hz)

FI Frequency value for the current (Hz)

FPLL Frequency and phase locked loop recording frequency (Hz)

URMS True root mean square (RMS) voltage (U

UAVG Average voltage

IRMS True root mean square (RMS) current (I

IAVG Average current

UTHD Total harmonic distortion U

ITHD Total harmonic distortion I

Wh+ Positive watt hours

Wh– Negative watt hours

Wh Sum of positive and negative watt hours

Ah+ Positive ampere hours

Ah– Negative ampere hours

Ah Sum of positive and negative ampere hours

R&S®HMC8015 base unit + HOC151 option /HVC151 voucher

UPPeak Maximum voltage (U

UMPeak Minimum voltage (U

IPPeak Maximum current (I

IMPeak Minimum current (I

PPPeak Maximum power (P

PMPeak Minimum power (P

R&S®HMC8015 base unit + HOC152 option /HVC152 voucher

DIN Digital input value (digital IN)

AIN Analog input value (analog IN)

Limit N Limit display

Table 6.1: Overview of measurement functions

–pk

–pk

+pk

+pk

–pk

+pk

)

)

)

)

)

)

RMS

RMS

)

)

Fig. 6.3: VIEW menu.

The R&S®HMC8015 power analyzer includes ve different display modes for the display of measurement results;

these can be enabled by activating options/upgrade

vouchers. The display modes can be selected using the

VIEW menu. The following display modes are available:

❙ Numeric mode: (default display)

Numeric display, toggles between six and ten

measurement parameters presented as cells with four

different conguration pages; this provides a quick

overview of the individual, congurable measurement

value cells.

❙ Harmonics mode:

Bar graph of the rst 50 harmonics; this represents the

density of voltage / current as a percentage, absolute

value or as a list. HARMONICS mode is only available in

conjunction with the HOC151 option or the HVC151

upgrade voucher.

❙ Waveform mode:

Displays the waveform (for one cycle of voltage, current

or power data). WAVEFORM mode is only available in

conjunction with the HOC151 option or the HVC151

upgrade voucher.

16

16

Page 17

Instrument Functions

Instrument Functions

❙ Trendchart mode:

Current or voltage displayed as a signal prole (similar to

the roll mode in an oscilloscope). TRENDCHART mode is

only available in conjunction with the HOC151 option or

the HVC151 upgrade voucher.

❙ Inrush mode:

Triggered display of a signal prole (single shot); INRUSH

mode is only available in conjunction with the HOC151

option or the HVC151 upgrade voucher.

6.2.1 Harmonics Mode

Fig. 6.4: Logarithmic readout display in Harmonics mode.

FFT is used to calculate the RMS value and phase angle of

the harmonics. This includes a calculation of the rst 50

harmonics (100kHz max.). Instead of the total RMS value,

the display shows the voltage level or the current level of

the individual harmonics selected using the cursor. The

cursor, which appears in the form of a small triangle under

the indicator bar, is moved using the rotary control knob.

The voltage levels (softkey SOURCE U – Quick Menu U)

are displayed as blue bars and the current levels (softkey

SOURCE I – Quick Menu I) as blue bars. Using SCALING

(Quick Menu A or %), it is possible to select a scaling factor for the signal in the Y-axis with reference to the fundamental (ABS or %). The measurement diagram is displayed

logarithmically on the screen so that even the smallest

signal details are visible.

key NUMBER (Quick Menu #) and the rotary control knob

can be used to display the number of harmonics included

in the FFT calculation. The softkey SUBSET (Quick Menu E

or O) can be used to dene what harmonics are to be used

in the calculation (EVEN, ODD or all). The voltage U or

current I or both can be selected as the source for the FFT

calculation (softkey SOURCE).

The FFT is calculated continuously. Settings made using softkeys

affect only the display of values on the screen.

Pressing the bottommost softkey closes the HARMONICS menu and opens a Quick Menu while the mode

remains active. This permits convenient control of the

harmonics settings via the Quick Menu. Pressing the VIEW

button and then selecting display mode NUMERIC closes

Harmonics mode and returns to the default display mode.

6.2.2 Waveform Mode

The WAVEFORM display mode can be used to display

the voltage, current and power simultaneously as a trace

on the screen (hardware-based triggering). Exactly one

signal period is displayed in the measurement diagram and

automatically scaled to the measuring range nal value.

Softkeys U, I and P are used to display or hide the traces

for voltage (blue), current (red) and power (green). In addition, softkey R (Readouts) can be used to display statistical

values, including U

RMS

, I

, FPLL (= trigger frequency)

RMS

and P (power).

Fig. 6.5: Tabular display in Harmonics mode.

The softkey VIEW SELECT (Quick Menu B or T) can be

used to switch the harmonics display between a bar graph

(BAR) or a table (TAB). Unlike the bar graph, the tabular

display includes both the magnitude and phase. The soft-

Fig. 6.6: Quick Menu in Waveform mode.

Pressing the bottommost softkey closes the WAVEFORM menu and opens a Quick Menu while the mode

remains active. This permits convenient control of the settings via the Quick Menu. Pressing the VIEW button and

then selecting display mode NUMERIC closes Waveform

mode and returns to the default display mode.

6.2.3 Trendchart Mode

TRENDCHART display mode is used to view two selected

values over time. Softkeys SRC 1 (Source 1 – Quick Menu

1) and SRC 2 (Source 2 – Quick Menu 2) are used to select

the values (sources). The following measurement functions

are available as sources:

17

17

Page 18

Instrument Functions

Instrument Functions

Fig. 6.7: Trendchart mode. Fig. 6.8: Inrush mode.

Acquisition of the trend is restarted any time the measurement function is changed. The trace scaling is set

automatically on the screen and cannot be changed. The

softkey TIME BASE can be used to select the temporal

resolution per scale division. The available values are 1s/

Div, 10s/Div, 1m/Div or 10m/Div. The existing trace data

is deleted any time the temporal resolution is changed.

The softkey CLEAR deletes the trace data from the screen

and starts a new acquisition. VISIBLE is used to activate

Source 1 and Source 2 (yellow) or to deactivate them

(white).

Function Description

P Active power (W)

S Apparent power (VA)

Q Reactive power (var)

PF Power factor lambda (λ)

PHI Phase shift (φ)

FU Frequency value for the voltage (Hz)

FI Frequency value for the current (Hz)

FPLL

URMS True root mean square (RMS) voltage (U

UAVG Average voltage

IRMS True root mean square (RMS) current (I

IAVG Average current

UTHD Total harmonic distortion U

ITHD Total harmonic distortion I

DIN Digital input value (digital IN)

AIN Analog input value (analog IN)

Table 6.2: Overview of SOURCE measurement functions in Trendchart mode

Frequency and phase locked loop recording frequency (Hz)

)

RMS

)

RMS

Pressing the bottommost softkey closes the TRENDCHART menu and opens a Quick Menu while the mode

remains active. This permits convenient control of the settings via the Quick Menu. Pressing the VIEW button and

then selecting display mode NUMERIC closes Trendchart

mode and returns to the default display mode.

6.2.4 Inrush Mode

INRUSH display mode uses an internal hardware buffer to

trigger acquisition of a rare event and to output it to the

display (similar to the single shot function found on oscilloscopes). This might be used to acquire inrush currents

on loads, for example. After an event occurs, the current

and voltage trends are acquired. The trend display starts at

the right-hand side of the screen. The softkeys VOLTAGE

(Quick Menu U) and CURRENT (Quick Menu I) are used to

activate (ON) and deactivate (OFF) the voltage and current

traces, respectively. Under SETTINGS, the trigger is set

to one of these two values, or it can be selected manually. A threshold (softkey LEVEL) can also be set, as well

as the offset between the rising and falling edges (softkey

SLOPE). At the full sampling rate, the acquisition runs for

16ms (softkey ACQ. TIME). The sampling rate can also be

varied to permit acquisition of signal sequences of over a

minute (see Table 6.3).

Sampling rate Acquisition time

500.00 ksample 16ms

250.00 ksample 32ms

125.00 ksample 65ms

62.50 ksample 130ms

31.25 ksample 260ms

15.63 ksample 520ms

7.81 ksample 1s

3.91 ksample 2s

1.95 ksample 4 s

976.56 sample 8s

488.28 sample 16s

244.14 sample 33s

122.07 sample 67s

Table 6.3: Overview of sampling rates

The trace display does not update dynamically. Instead, it

must be updated manually by pressing softkey ACTIVATE

(ON) (Quick Menu A). The trace is updated each time the

button is pressed (single shot). The Inrush display cannot

be zoomed. A maximum of 8000 measurement values

each for current and voltage can be acquired.

Pressing the bottommost softkey closes the INRUSH

menu and opens a Quick Menu while the mode remains

active. This permits convenient control of the settings

via the Quick Menu. Pressing the VIEW button and then

selecting display mode NUMERIC closes Inrush mode and

returns to the default display mode.

18

18

Page 19

Instrument Functions

Instrument Functions

6.3 Crest Factor

The crest factor (also known as peak factor) describes the

factor by which a signal’s amplitude (peak value) is greater

than the rms-calculated effective value. This is important

for the measurement of pulse-shaped sizes. For pure si-

nusoidal wave types, the following ratio applies: √2=1.414.

The accuracy of the calculated effective value remains

the same as long as the peak value stays within the peak

range. A crest factor of 1.8 or higher indicates a strong

distortion from the waveform. To evaluate the waveform

distortion of non-linear electric loads, the Waveform or

TRENDCHART mode can be used.

Example:

If a battery is charged with 4AH and discharged with

3AH, the display will show AHP = 4, AH– = –3 and the

total AH = 1 (i.e. 4 + (–3) = 1).

The Integrator menu can be opened by pressing the softkey INTEGRATOR in the MEAS menu. The relevant integrator mode is then selected using the softkey MODE and the

rotary control knob.

6.4.1 Manual Integrator Mode (Default)

Fig. 6.9: Sample conguration for crest factor 6.

From the ACQ menu, the crest factor can be varied between 3 and 6 by using the softkey CREST FACT in the

VOLTAGE or the CURRENT softkey menu. When changing

the crest factor, the measuring range is adjusted automatically. A crest factor of 5 or higher is used e.g. for sinusoidal

waveforms with spikes (see example in Fig. 6.4) and is

also required for standby measurements according to IEC

62018.

6.4 Energy Counter (Integrator Values)

The power analyzer makes it possible to display integrator values (WHP, WHM, AHP, AHM) on the screen. These

values are also activated via the measuring parameter cell.

In this way, the energy use of electronic devices under test

(DUT) can be recorded where power consumption is not

constant. WHP / AHP represent the power / current in the

positive direction and WHM / AHM in the negative direction. WH / AH correspond to the sum of the watt-hour/

ampere-hour positive and negative portions, respectively.

Fig. 6.11: MANUAL integrator menu.

The manual integrator mode is pre-selected by default.

Using the START softkey, or directly using the START/

STOP button on the front panel of the instrument, the

energy counter can be started as soon as it has been

activated (ON) using the ACTIVATE softkey. Pressing either

the softkey START or the START/STOP button on the front

panel once more will stop the energy counter. The RESET

softkey or the RESET button on the front panel will reset

the integrator values.

6.4.2 Span Integrator Mode

A start time (START TIME) and an integration time span

(DURATION) can be set using the SPAN integrator mode.

Once the energy counter has been activated (ON) via the

ACTIVATE softkey, the counter will automatically start at

the preset start time and then automatically stop after the

integration time span (DURATION) has elapsed. The time

span for the integration can be set using the rotary control

knob or, by using the SET TO CURR. softkey, the current

system time can be applied and adjusted accordingly.

Fig. 6.10: Readout display with integrator output values. Fig. 6.12: Span integration mode selection menu.

19

19

Page 20

Instrument Functions

Instrument Functions

Initiating the start separately by using the START/STOP

button on the front panel is not required. The RESET

button on the front panel will reset the integrator values.

The maximum duration for running the energy counter is 96

hours (DURATION).

Fig. 6.13: Setting the integration duration.

Fig. 6.14: Inversion.

blue A jack. In order to record and display the current correctly with this type of wiring, the current direction must

be inverted in the ACQ menu using the CURRENT softkey

menu and the INVERT softkey. When the INVERT function is activated, it is displayed as a green box around the

measuring range displayed in the status bar.

6.4.3 Duration Integrator Mode

The DURATION integrator mode denes how long the

energy counter is active. Using the START softkey, or

directly using the START/STOP button on the front panel of

the instrument, the energy counter can be started as soon

as it has been activated (ON) using the ACTIVATE softkey.

After the integration time (DURATION) has elapsed, the

energy counter is automatically stopped. The time display

in the status bar is replaced with the integration time. The

time span for the integration can be set using the rotary

control knob or, by using the SET TO CURR. softkey, the

current system time can be applied and adjusted accordingly. If the integration time is expired, a new integrator

measurement can only be started via START button, if the

integrator values were reset with RESET softkey.

6.4.4 External Integrator Mode

(only with the HOC152 option/HVC152 voucher)

Using the external integrator mode (EXTERN), the energy

counter can be started and stopped by an external pulse

at the digital inputs on the rear panel. Once activated

(ON) using the ACTIVATE softkey, the energy counter is

automatically started by a “high” signal and automatically

stopped by a “low” signal. Initiating the start / stop separately by using the START/STOP button on the front panel

is not required.

6.5 Invert Function

The power analyzer also records the sign of the measured current with AC, for the correct calculation of the

exact input or output of power and energy, for example.

Depending on the external wiring (e.g. with the HZC815

adapter) the voltage or the current is measured inverted.

For current-based measurements, the wires going to the

jacks A and COM on the front panel must be swapped

(see Section 4.2.3). When using the HZC815 measuring

adapter, the blue cable must therefore be inserted into the

black COM jack, and the black cable is inserted into the

6.6 Acquisition Mode

Fig. 6.15: Selecting the data acquisition mode.

The acquisition of current and voltage is performed simultaneously and so can be compared with a two-channel

oscilloscope (16 bit). The sampling frequency is 500

ksample/s. The values displayed on the screen are updated

10 times per second. In the ACQ menu, the data acquisition mode can be selected by using the MODE softkey

menu, followed by the MODE softkey. The following settings can be selected:

❙ AUTO: Automatic selection of the data acquisition mode

(default); automatic detection of an incoming signal.

❙ DC: For measuring pure DC loads; in contrast to the AC

mode, there is no synchronization with the signal period,

instead synchronization is over a certain period of time

(error is displayed if AC signal is applied).

❙ AC: Average value of a voltage / current period

(synchronization with the signal period).

❙ EXTERN: Specifying a signal period via the external BNC

connector DIGITAL IN (only available in conjunction with

option HOC152 / upgrade voucher HVC152); e.g. used

with a fuzzy signal which must be ltered externally.

20

20

Page 21

Instrument Functions

Instrument Functions

6.6.1 Frequency Filter

The power analyzer R&S®HMC8015 features the following

lter settings which can be adjusted in the ACQ menu using the softkey menu MODE (for AUTO and AC only):

❙ Frequencylter:

Reliable acquisition of the zero crossings for the precise

determination of the signal period.

❙ Digitallter:

Automatic, adaptive averaging of the lter setting for

several periods to increase accuracy; ideal for highly

uctuating values (values become more stable).

❙ BWL:

Classic low-pass lter (1 kHz) as bandwidth limit (BWL), in

order to produce a clean, HF-adjusted signal.

Fig. 6.16: Filters arranged as a chain.

6.6.2 Frequency Source

Use the phase locked loop source frequency synchronization (PLL SRC) softkey to set the reference variable for the

fundamental frequency (VOLTAGE/CURRENT). The fundamental frequency of each period is the reference for the

measured harmonics of the reading. Voltage (VOLTAGE) is

selected as the reference variable by default. The CURRENT setting makes sense for signals with a very small or

an irregular current trace. Using the EXTERN function, the

frequency can be set via the digital input located on the

rear panel (only available in conjunction with the HOC152

option or the HVC152 upgrade voucher).

Function Description

P Active power (W)

S Apparent power (VA)

Q Reactive power (var)

PF Power factor lambda (λ)

PHI Phase shift (φ)

FU Frequency value for the voltage (Hz)

FI Frequency value for the current (Hz)

FPLL

URMS True root mean square (RMS) voltage (U

UAVG Average voltage

IRMS True root mean square (RMS) current (I

IAVG Average current

UTHD Total harmonic distortion U

ITHD Total harmonic distortion I

Table 6.4: Overview of LIMIT measurement functions

Frequency and phase locked loop recording frequency (Hz)

)

RMS

)

RMS

dene maximum and minimum limit values. Similar to the

measuring range modulation, a bar is used to display the

limit values. This two-part bar indicates the modulation of

the limit from –100% (minimum modulation) to +100%

(maximum modulation). It is also possible to link the limit

function with the ANALOG OUT or DIGITAL OUT (EXT

menu). See Section 6.9.

6.7 Peak Hold

The PEAK HOLD displays maximum peak values, ensuring

a stable readout display for loads. The sampling frequency

is 500 ksample/s. The PEAK HOLD function is activated

(ON) or deactivated (OFF) in the ACQ menu by selecting

softkey menu PEAK HOLD and softkey ACTIVATE.

If “OL” (Overload) appears on the display, the peak values must be

reset on the display using softkey RESET

6.8 Limits

In the MEAS menu, the softkey menu LIMIT can be used

to dene up to six limit values. Once up to six limit values (LIM1 to LIM6) are selected in the cell conguration,

they can be activated (ON) or deactivated (OFF) using the

softkey ACTIVATE. The softkey SOURCE and the rotary

control knob can be used to select the measurement function for the source. Table 6.4 shows the possible measurement functions. The softkeys HIGH and LOW are used to

If the measuring instrument displays only dashes “-----” on the

display, either the limit function is not activated or an error oc-

curred (e.g. limit value LOW ≥ limit value HIGH).

Fig. 6.17: LIMIT menu.

6.9 Analog / Digital Inputs and Outputs

On the R&S®HMC8015 rear panel, there are four BNC

connectors that can be used as analog or digital inputs

and outputs (Digital / Analog IN/OUT). The connectors are

available for limit values and Pass/Fail sorting, for example.

Fig. 6.18: BNC connectors Digital / Analog IN/OUT.

21

21

Page 22

Instrument Functions

Instrument Functions

6.9.1 Analog IN

The ANALOG IN can be activated (ON) or deactivated

(OFF) in the EXT menu by selecting softkey menu ANALOG IN and softkey ACTIVATE. In addition, the AIN

function in the cell conguration can be used to display

the measured value of the analog input signal on the

screen.

Fig. 6.19: ANALOG OUT menu.

6.9.2 Analog OUT

The ANALOG OUT can be activated (ON) or deactivated

(OFF) in the EXT menu by selecting softkey menu ANALOG OUT and softkey ACTIVATE. The external mode is

selected by using softkey MODE and the rotary control

knob. The following modes can be selected:

❙ Voltage:

Minimum modulation at the output corresponds to 0V

and maximum modulation corresponds to the measuring

range.

❙ Current:

Minimum modulation at the output corresponds to 0V

and maximum modulation corresponds to the measuring

range.

❙ Power:

Minimum modulation at the output corresponds to 0W

and maximum modulation corresponds to the maximum

current and voltage measuring ranges.

❙ Limit:

The limit module is connected to the analog output. The

output modulation is represented as a percentage %.

–100% corresponds to minimum modulation at the

output (≙ –5V) and +100% corresponds to maximum

modulation (≙ +5V). The limit value (LIM1 to LIM6) is

selected using softkey LIMIT NO and the rotary control

knob.

❙ Frequency:

The power analyzer measures the frequency at the

DIGITAL IN.

❙ PWM:

The power analyzer measures the relationship between

High and Low.

❙ State:

The power analyzer measures the High and Low levels.

Fig. 6.20: DIGITAL IN menu.

The softkey INVERT is used to invert the signal applied at

DIGITAL IN. This makes sense in STATE mode, for example.

6.9.4 Digital OUT

The DIGITAL OUT can be activated (ON) or deactivated

(OFF) in the EXT menu by selecting softkey menu DIGITAL

OUT and softkey ACTIVATE. The external mode is selected

by using softkey MODE and the rotary control knob. The

following modes can be selected:

❙ Limit:

The limit module is connected to the digital output. The

High level at the output corresponds to logical True and

the Low level corresponds to False.

❙ FPLL:

The output is controlled by an FPGA and always outputs

the frequency of the selected source.

6.9.3 Digital IN

The DIGITAL IN can be activated (ON) or deactivated (OFF)

in the EXT menu by selecting softkey menu DIGITAL IN

and softkey ACTIVATE. In addition, the DIN function in the

cell conguration can be used to display the measured

value of the digital input signal on the screen. The different modes can be selected using softkey MODE and the

rotary control knob:

22

22

Page 23

7 Data Logging

Data Logging

Data Logging

function should start. Using the DURATION softkey menu,

the recording duration for the readings is dened.

The maximum logging duration is 96 hours (DURATION).

Using the MEAS button and the LOGGING softkey menu,

the data acquisition can be started and various settings

can be selected. Using the ACTIVATE softkey, data acquisition and storage can be activated (ON) or deactivated

(OFF). Using the STORAGE softkey menu, the type of stor-

age device can be selected (Internal / USB ash drive), as

well as the le name (File Name) and the le format (CSV

/ TXT). Using the LOG PAGE softkey, the active measuring parameter cells menu (Quick Menu 1 to 4 on the main

screen) can be selected. If LOG PAGE 1 is selected, only

the readings from the rst measuring parameter cell menu

(Quick Menu 1 on the main screen) are recorded. If LOG

PAGE 2 is selected, only the readings from the second

measuring parameter cell menu (Quick Menu 2 on the

main screen) are recorded, and so on.

Using the INTERVAL softkey and the rotary control knob,

a measuring interval can be set. The measuring interval is

the time between readings. If, for example, the INTERVAL

function is set to 5, then a reading is taken every 5 s. The

MODE softkey menu offers various logging modes. Select

the UNLIMITED function if you intend to make an innitely

long data record. The limiting factor here is the size of the

internal memory (512 kbyte max.) or that of the connected

USB ash drive (4 Gbyte max., FAT/FAT32 formatting). If

the COUNT function is active, the number of recorded

events can be set with the COUNT softkey and the rotary

control knob. If, for example, an interval of 5 s and a count

of 5 are set, then 5 readings will be recorded at intervals

of 5 s. If the DURATION function is activated, the recording duration for the readings can be adjusted with the DURATION softkey and the rotary control knob. If the SPAN

function is activated, a logging time span can be dened.

Use the softkey menu START to dene when the logging

External USB hard drives (or USB extensions) are not supported.

Only USB ash drives with FAT/FAT32 formatting (4Gbyte max.)

are recognized by the R&S®HMC8015.

Using the SPAN function, a start time (START TIME) and

a logging time span (DURATION) can be set. Once the

logging function has been activated (ON) via the ACTIVATE

softkey, the data acquisition will automatically start at the

preset start time and then automatically stop after the logging time span (DURATION) has elapsed. The time span

for the logging can be set using the rotary control knob

or, by using the SET TO CURR. TIME softkey, the current

system time can be applied and adjusted accordingly.

The log function is active if the color of the LOG display in the

status bar has changed to green, or inactive if it is white.

Fig. 7.2: Setting the integration duration.

Using the CSV softkey menu, the structure of the CSV le

can be congured. This is used to dene the decimal separa-

tor (DEC.SEP.) as well as the line separator (FIELD DELIM.).

Data saved in a CSV le can be opened with Microsoft

Excel, for example, and displayed as graphical charts (see

example in Fig. 7.1).

Gaps in the logging may occur under the following circumstances:

❙ High load caused by SCPI commands over the interface

❙ Use of a “slow” USB ash drive

❙ Sector in le system is sized too large

Fig. 7.1: Graphical log le analysis in Excel.

23

23

Page 24

Data Logging

Data Logging

7.1.1 Example of Data Format in a Log File

#Device;HMC8015

#Device Name;PM

#Format;LOG

#Date;2000 -01-01

#Version;00.021-02.430-03.730

#Serial No.;012345678

#Mode;Count

#Logging Interval[s];1.000

#Specied Logging Count;1800

#Specied Logging Time[s];-----

#Start Time;04:49:33

#Stop Time;04:49:37

#Actual Count;4

URMS[V];IRMS[A];P[W];FU[Hz];EMPTY;EMPTY;S[VA];Q[var

];LAMBDA[];UTHD[%];Timestamp

231. 27E+00;45.0E-03;6.63E+00;50.0E+00;nan;nan;10.38 E+

00;7.98E+00;639E-03;2E+00;04:49:33:000

231.38E+00;45.0E-03;6.64E+00;50.0E+00;nan;nan;10.38E

+00;7.98E+00;639E-03;2E+00;04:49:34:000

231.35E+00;45.0E-03;6.63E+00;50.0E+00;nan;nan;10.38E

+00;7.98E+00;639E-03;2E+00;04:49:35:000

231.38E+0 0;44.9E- 03;6.63E+00;50.0E+00;nan;nan;10.38E

+00;7.99E+00;639E-03;2E+00;04:49:36:000

the time stamp can be adjusted by rst selecting the time

stamp values and then clicking the right mouse button for

“Format Cells”. Then, using the “User Dened” function,

the formatting can be congured manually with the key-

board in the “type” section as follows:

hh:mm:ss,000

After conrming with the OK button, the user-dened

custom formatting is saved, and the time stamp values are

displayed in the selected format. By doing this, even the

smallest millisecond values can be read easily.

Fig. 7.4: Excel Import Wizard (Text Import Wizard).

If the CSV le contains “NaN” (not a number), then either the corresponding measuring parameter cell was empty (EMPTY), or the

reading could not be displayed due to the chosen settings.

7.1.2 Data Formatting in Excel/Import Wizard

If a CSV log le is opened with Excel, the measurement

data is displayed correctly. However, we recommend that

you change the formatting of the time stamp (Timestamp)

manually. After opening the CSV le, the formatting of

It is also possible to use the Import Wizard in Excel. After

starting Excel, rst select the relevant CSV le by clicking

on the tab “Data” > “From Text”. After selecting the le

and conrming with the “Import” button, the Import Wiz-

ard is started. This Text Import Wizard can also be used

to format the CSV le as needed. For example, the “Start

import on line” function can be congured in a way that

only the readings are imported without the header (e.g. 18,

see Fig. 7.4).

Fig. 7.3: User-dened customization of time stamp formatting in Excel.

24

24

Page 25

8 Documenting,

Saving and

Retrieving

Documenting,Saving and Retrieving

Documenting,Saving and Retrieving

8.2 Screenshots

The most important method of storing data for documentation purposes is the screenshot. A screenshot is an

image le that shows the current screen contents at the

moment it is captured to a le. However, screenshots can

only be saved to a USB ash drive. When a USB ash drive

is connected, directories can also be changed, created or

deleted. The choice of the target directory is conrmed

with ACCEPT.

The R&S®HMC8015 power analyzer allows the user to save

all screen displays and user settings. Internal memory is

used to store device settings. This type of data can also

be saved to any USB ash drive connected to the unit.