Rohde & Schwarz FSP40 1164.4391.40, FSP30 1164.4391.30, FSP13 1164.4391.13, FSP7 1164.4391.07, FSP3 1164.4391.03 User Manual

...Page 1

Test and Measurement

Division

Operating Manual

SPECTRUM ANALYZER

R&S

1164.4391.03

R&S

1164.4391.07

R&S

1164.4391.13

R&S

1164.4391.30/.39

R&S

1164.4391.40

Volume 2

This Operating Manual consists of 2 volumes

FSP3

FSP7

FSP13

FSP30

FSP40

Printed in the Federal

Republic of Germany

1164.4556.12-01- II-1

Page 2

Dear Customer,

throughout this operating manual, the abbrev iation FSP is used for your Spectrum Analyz er R&S FSP.

R&S is a registered trademar k of Rohde & Schwarz Gm bH & Co. KG

Trade names are trademar k s of the owners

1164.4556.12-01- II-2

Page 3

FSP Tabbed Divider Overview

Tabbed Divider Overview

Volume 1

Data Sheet

Safety Instructions

Certificate of Quality

EU Certificate of Conformity

List of R&S Representatives

Manuals for Spectrum Analyzer FSP

Tabbed Divider

1 Chapter 1: Putting into Operation

2 Chapter 2: Getting Started

3 Chapter 3: Operation

4 Chapter 4: Functional Description

10 Chapter 10: Index

Volume 2

Data Sheet

Safety Instructions

Manuals for Spectrum Analyzer FSP

Tabbed Divider

5 Chapter 5: Remote Control – Basics

6 Chapter 6: Remote Control – Commands

7 Chapter 7: Remote Control – Program Examples

8 Chapter 8: Maintenance and Hardware Interfaces

9 Chapter 9: Error Messages

10 Chapter 10: Index

1164.4556.12 RE E-1

Page 4

Page 5

Safety Instructions

This unit has been designed and tested in accordance with the EC Certificate of Conformity and has left the

manufacturer’s plant in a condition fully complying with safety standards.

To maintain this condition and to ensure safe operation, the user must observe all instructions and warnings

given in this operating manual.

Safety-related symbols used on equipment and documentation from R&S:

Observe

operating

instructions

Weight

indication for

units >18 kg

PE terminal Ground

1. The unit may be used only in the operating conditions and positions specified by the manufacturer. Unless otherwise agreed, the following

applies to R&S products:

IP degree of protection 2X, pollution severity 2

overvoltage category 2, only for indoor use, altitude max. 2000 m.

The unit may be operated only from supply networks fused with max. 16 A.

Unless specified otherwise in the data sheet, a

tolerance of ±10% shall apply to the nominal

voltage and of ±5% to the nominal frequency.

2. For measurements in circuits with voltages V

> 30 V, suitable measures should be taken to

avoid any hazards.

(using, for example, appropriate measuring

equipment, fusing, current limiting, electrical

separation, insulation).

3. If the unit is to be permanently wired, the PE

terminal of the unit must first be connected to

the PE conductor on site before any other c onnections are made. Installation and cabling of

the unit to be performed only by qualified technical personnel.

4. For permanently installed units without built-in

fuses, circuit breakers or similar protective devices, the supply circuit must be fused such as

to provide suitable protection for the users and

equipment.

5. Prior to switching on the unit, it must be ensured

that the nominal voltage set on the unit matches

the nominal voltage of the AC supply network.

If a different voltage is to be set, the power fuse

of the unit may have to be changed accordingly.

6. Units of protection class I with disconnectible

AC supply cable and appliance connector may

be operated only from a power socket with

earthing contact and with the PE conductor connected.

terminal

Danger!

Shock hazard

Warning!

Hot surfaces

Ground

7. It is not permissible to interrupt the PE conductor intentionally, neither in the incoming cable

nor on the unit itself as this may cause the unit

to become electrically hazardous.

Any extension lines or multiple socket outlets

used must be checked for compliance with relevant safety standards at regular intervals.

8. If the unit has no power switch for disconnection

from the AC supply, the plug of the connecting

cable is regarded as the disconnecting device.

In such cases it must be ensured that the power

plug is easily reachable and accessible at all

rms

times (length of connecting cable approx. 2 m).

Functional or electronic switches are not suitable for providing disconnection from the AC

supply.

If units without power switches are integrated in

racks or systems, a disconnecting device must

be provided at system level.

9. Applicable local or national safety regulations

and rules for the prevention of accidents must

be observed in all work performed.

Prior to performing any work on the unit or

opening the unit, the latter must be disconnected from the supply network.

Any adjustments, replacements of parts, maintenance or repair may be carried out only by

authorized R&S technical personnel.

Only original parts may be used for replacing

parts relevant to safety (eg power switches,

power transformers, fuses). A safety test must

be performed after each replacement of parts

relevant to safety.

(visual inspection, PE conductor test, insulationresistance, leakage-current measurement, functional test).

continued overleaf

Attention!

Electrostatic

sensitive devices require

special care

095.1000 Sheet 17

Page 6

Safety Instructions

10. Ensure that the connections with information

technology equipment comply with IEC950 /

EN60950.

11. Lithium batteries must not be exposed to high

temperatures or fire.

Keep batteries away from children.

If the battery is replaced improperly, there is

danger of explosion. Only replace the battery by

R&S type (see spare part list).

Lithium batteries are suitable for environmentally-friendly disposal or specialized recycling.

Dispose them into appropriate containers, only.

Do not short-circuit the battery.

12. Equipment returned or sent in for repair must be

packed in the original packing or in packing with

electrostatic and mechanical protection.

Electrostatics via the connectors may dam-

13.

age the equipment. For the safe handling and

operation of the equipment, appropriate

measures against electrostatics should be implemented.

14. The outside of the instrument is suitably

cleaned using a soft, lint-free dustcloth. Never

use solvents such as thinners, acetone and

similar things, as they may damage the f ront

panel labeling or plastic parts.

15. Any additional safety instructions given in this

manual are also to be observed.

095.1000 Sheet 18

Page 7

FSP Manuals

Contents of Manuals for Spectrum Analyzer FSP

Operating Manual FSP

The operating manual describes the following models and options of spectrum analyzer FSP:

• FSP3 9 kHz to 3 GHz

• FSP7 9 kHz to 7 GHz

• FSP13 9 kHz to 13.6 GHz

• FSP30 9 kHz to 30 GHz

• FSP40 9 kHz to 40 GHz

• Option FSP B3 audio demodulator

• Option FSP-B4 OCXO - reference oscillator

• Option FSP-B9 tracking generator

• Option FSP-B10 external generator control

• Option FSP-B15 pulse calibrator

• Option FSP-B16 LAN interface

• Option FSP-B25 electronic attenuator

• Option FSP-B28 trigger port

This operating manual contains information about the technical data of the instrument, the setup

functions and about how to put the instrument into operation. It inf orms about the operating c oncept

and controls as well as about the operation of the FSP via the menus and via remote control. T ypical

measurement tas ks for the FSP are explained using the f unctions of f er ed by the menus and a selection of program examples.

Additionally the operating manual includes information about maintenance of the instrument and

about error detection listing the error messages which may be output by the instrument. It is subdivided into 9 chapters:

Chapter 1 describes the control elements and connectors on the front and rear panel as well

as all procedures required for putting the FSP into operation and integration into a

test system.

Chapter 2 gives an introduction to typical measurement tasks of the FSP which are ex-

plained step by step.

Chapter 3 describes the operating principles, the struc ture of the graphical interf ace and of-

fers a menu overview.

Chapter 4 forms a reference f or manual control of the FSP and contains a detailed descr ip-

tion of all instrument f unctions and their applic ation. The c hapter also lists the remote control command corresponding to each instrument function.

Chapter 5 describes the basics for programming the FSP, command processing and the

status reporting system.

Chapter 6 lists all the remote-control commands defined for the instrument.

Chapter 7 contains program examples for a number of typical applications of the FSP.

Chapter 8 describes preventive maintenance and the characteris tics of the instrument’s in-

terfaces.

Chapter 8 gives a list of error messages that the FSP may generate.

Chapter 9 contains a list of error messages.

Chapter 10 contains an index for the operating manual.

1164.4556.12 0.1 E-1

Page 8

Manuals FSP

Service Manual - Instrument

The service manual - instrument informs on how to check compliance with rated spec ifications, on

instrument function, repair, troubleshooting and f ault elimination. It contains all information r equired

for the maintenance of FSP by exchanging modules.

1164.4556.12 0.2 E-1

Page 9

FSP Contents - Remote Control - Basics

Contents - Chapter 5 "Remote Cont rol - "Basics"

5 Remote Control - Basics..................................................................................... 5.1

Introduction...................................................................................................................................... 5.1

Getting Started................................................................................................................................. 5.2

Starting Remote Control Operation ...............................................................................................5.3

Display Contents during Remote Control ................................................................................5.3

Remote Control via IEC/IEEE Bus........................................................................................... 5.4

Setting the Device Address...........................................................................................5.4

Return to Manual Operation..........................................................................................5.4

Remote Control via RS-232-Interface ..................................................................................... 5.5

Setting the Transmission Parameters........................................................................... 5.5

Return to Manual Operation..........................................................................................5.5

Limitations .....................................................................................................................5.5

Remote Control in a Network (RSIB Interface)........................................................................ 5.6

Setting the Device Address...........................................................................................5.6

Return to Manual Operation..........................................................................................5.6

Messages..........................................................................................................................................5.7

IEC/IEEE-Bus Interface Messages..........................................................................................5.7

Device Messages (Commands and Device Responses) ........................................................ 5.8

Structure and Syntax of the Device Messages............................................................................. 5.9

SCPI Introduction.....................................................................................................................5.9

Structure of a Command .........................................................................................................5.9

Structure of a Command Line................................................................................................5.12

Responses to Queries...........................................................................................................5.12

Parameters............................................................................................................................5.13

Overview of Syntax Elements................................................................................................5.14

Instrument Model and Command Processing ............................................................................5.15

Input Unit ...............................................................................................................................5.15

Command Recognition.......................................................................................................... 5.16

Instrument Data Base and Instrument Hardware.................................................................. 5.16

Output Unit.............................................................................................................................5.17

Command Sequence and Command Synchronization..........................................................5.17

Status Reporting System..............................................................................................................5.18

Structure of an SCPI Status Register.................................................................................... 5.18

Overview of the Status Registers ..........................................................................................5.20

Description of the Status Registers .......................................................................................5.21

Status Byte (STB) and Service Request Enable Register (SRE)................................ 5.21

IST Flag and Parallel Poll Enable Register (PPE)....................................................... 5.22

Event-Status Register (ESR) and Event-Status-Enable Register (ESE)..................... 5.22

STATus:OPERation Register...................................................................................... 5.23

STATus:QUEStionable Register .................................................................................5.24

STATus:QUEStionable:ACPLimit Register.................................................................5.25

STATus:QUEStionable:FREQuency Register.............................................................5.26

STATus:QUEStionable:LIMit<1|2> Register ...............................................................5.27

STATus:QUEStionable:LMARgin<1|2> Register ........................................................5.28

STATus:QUEStionable:POWer Register .................................................................... 5.29

1164.4556.12 I-5.1 E-1

Page 10

Contents - Remote Control - Basics FS P

STATus:QUEStionable:SYNC Register ......................................................................5.30

Application of the Status Reporting Systems......................................................................... 5.31

Service Request, Making Use of the Hierarchy Structure...........................................5.31

Serial Poll ....................................................................................................................5.31

Parallel Poll..................................................................................................................5.32

Query by Means of Commands................................................................................... 5.32

Error-Queue Query...................................................................................................... 5.32

Resetting Values of the Status Reporting System.................................................................5.33

1142.8142.12 I-5.2 E-2

Page 11

FSP Introduction

5 Remote Control - Basics

In this chapter you'll find:

• instructions on how to put the FSP into operation via remote control,

• a general introduction to remote control of programm able instruments . This includes the description

of the command structure and s yntax according to the SCPI standard, the description of com mand

execution and of the status registers,

• diagrams and tables describing the status registers used in the FSP.

In chapter 6, all remote control functions are described in detail. The subsystems are listed by

alphabetical order according to SCPI. All commands and their parameters are listed by alphabetical

order in the command list at the end of chapter 6.

Program examples for the FSP can be found in chapter 7.

The remote control interfaces and their interface functions are described in Chapter 8.

Introduction

The instrument is equipped with an IEC-bus interface accor ding to standard IEC 625.1/IEEE 488.2 and

a RS-232 interface. The connectors are located at the rear of the instrument and per mit to connect a

controller for remote control. In addition, the instrument can be remotely controlled in a local area

network (LAN interface) if option B16 is installed.

The instrument supports the SCPI:version 1997.0 (Standard Commands for Programmable

Instruments). T he SCPI standard is based on standard IEEE 488.2 and aims at the standardization of

device-specific commands, error handling and the status registers (see Section "SCPI Introduction").

The tutorial "Automatic Measurem ent Control – A tutor ial on SCPI and IEEE 488.2" f r om John M. Pieper

(R&S order number 0002.3536.00) offers detailed inform ation on concepts and definitions of SCPI. For

remote control in a network, information will be found in the relevant section, "Remote Control in a

Network (RSIB Interface)".

This section assumes basic k nowledge of IEC/IEEE bus pr ogram m ing and operation of the controller . A

description of the interface commands can be obtained from the relevant manuals.

The requirements of the SCPI standard placed on comm and syntax, error handling and conf iguration of

the status registers are explained in detail in the following sections. Tables provide a fast overview of the

bit assignment in the status regis ters. The tables are s upplemented by a compr ehensive description of

the status registers.

The program examples for IEC-bus programming are all written in VISUAL BASIC.

1164.4556.12 5.1 E-1

Page 12

Getting Started FSP

Getting Started

The short and simple operating sequence given below permits fast putting into operation of the

instrument and setting of its basic functions. As a prerequisite, the IEC/IEEE-bus address, which is

factory-set to 20, must not have been changed.

1. Connect instrument and controller using IEC/IEEE-bus cable.

2. Write and start the following program on the controller:

CALL IBFIND("DEV1", analyzer%) 'Open port to the instrument

CALL IBPAD(analyzer%, 20) 'Inform controller about instrument address

CALL IBWRT(analyzer%, '*RST;*CLS') ''Reset instrument

CALL IBWRT(analyzer%, 'FREQ:CENT 100MHz') ' Set center frequency to 100 MHz

CALL IBWRT(analyzer%, 'FREQ:SPAN 10MHz') ' Set span to 10 MHz

CALL IBWRT(analyzer%, 'DISP:TRAC:Y:RLEV -10dBm')

' Set reference level to -10 dBm

The instrument now performs a sweep in the frequency range of 95 MHz to 105 MHz .

3. To return to manual control, press the LOCAL key at the front panel

1164.4556.12 5.2 E-1

Page 13

FSP Starting Remote Control Operation

Starting Remote Control Operation

On power-on, the instrument is always in the manual operating state ("LOCAL" state) and can be

operated via the front panel.

It is switched to remote control ("REMOTE" state)

IEC/IEEE-bus as soon as it receives an addressed command from a controller.

if it is controlled in a network (R SIB interface), as soon as it receives a command

from a controller.

RS-232 as soon as it receives the command "@REM" from a controller.

During remote control, operation via the f ront panel is disabled. The instrum ent remains in the remote

state until it is reset to the manual state via the f ront panel or via remote control interfac es. Switching

from manual operation to remote control and vice versa does not affect the remaining instrument

settings.

Display Contents during Remote Control

During remote control, only the LOCAL softkey appears, with which it is possible to return to manual

operation.

In addition, the display of diagrams and results can be blanked out with the command

"SYSTem:DISPlay:UPDate OFF" (default in remote control) to obtain optim um performance during

remote control operation.

During program execution it is recommended to activate the display of results by means of

"SYSTem:DISPlay:UPDate ON" so that it is pos sible to follow the changes in the devic e settings and

the recorded measurement curves on the screen.

Note: If the instrument is exclusively operated in remote contr ol, it is recommended to switch on

the power-save mode (POWER SAVE). In this mode, the required display is completely

switched off after a preset time.

1164.4556.12 5.3 E-1

Page 14

Starting Remote Control Operation FSP

Remote Control via IEC/IEEE Bus

Setting the Device Address

In order to operate the instrument via the IEC-bus, it must be addressed using the s et IEC/IEEE bus

address. The IEC/IEEE bus address of the instrument is factory-set to 20. It can be changed manually in

the SETUP - GENERAL SETUP menu or via IEC bus. Addresses 0 to 30 are permissible.

Manually:

Ø Call SETUP - GENERAL SETUP menu

Ø Enter desired address in table GPIB-ADDRESS

Ø Terminate input using the ENTER key

Via IEC/IEEE bus:

CALL IBFIND("DEV1", analyzer%) 'Open port to the instrument

CALL IBPAD(analyzer%, 20) 'Inform controller about old address

CALL IBWRT(analyzer%, "SYST:COMM:GPIB:ADDR 18") 'Set instrument to new address

CALL IBPAD(analyzer%, 18) 'Inform controller about new address

Return to Manual Operation

Return to manual operation is possible via the front panel or the IEC/IEEE bus.

Manually: Ø Press the LOCAL softkey or the PRESET key

Notes:–Before the transition, command processing must be completed

as otherwise transition to remote control is performed

immediately.

– The keys can be disabled by the univer sal command LLO (see

Chapter 8, IEC/IEEE-Bus Interface – Interface Messages) in

order to prevent unintentional transition. In this case, transition to

manual mode is only possible via the IEC/IEEE bus.

– The keys can be enabled again by deactivating the REN line of

the IEC/IEEE bus (see Chapter 8, IEC/IEEE-Bus Interface – Bus

Lines).

Via IEC bus: ...

CALL IBLOC(analyzer%) 'Set instrument to manual operation

...

1164.4556.12 5.4 E-1

Page 15

FSP Starting Remote Control Operation

Remote Control via RS-232-Interface

Setting the Transmission Parameters

To enable an error-free and correct data transmission, the parameters of the unit and the controller

should have the same setting.

Parameters can be m anually changed in menu SETUP-GENERAL SETUP in table COM PORT or via

remote control using the command SYSTem:COMMunicate:SERial:... .

The transmission parameters of the COM interface are factory-set to the following values:

baudrate = 9600, data bits = 8, stop bits = 1, parity = NONE and owner = INSTRUMENT.

For remote control operation, the interface should be allocated to the operating system (owner = OS) s o

that the control characters including @ can be recognized by the interface.

Manually: Setting the COM interface

Ø Call SETUP-GENERAL SETUP menu

Ø Select desired baudrate, bits, stopbit, parity in table COM PORT.

Ø Set owner to OS in table COM PORT.

Ø Terminate input using the ENTER key.

Return to Manual Operation

Return to manual operation is possible via the front panel or via RS-232 interface.

Manually: Ø Press the LOCAL softkey or the PRESET key.

Notes:

– Before the transition, command processing must be completed as

otherwise transition to remote control is performed immediately

– The keys can be enabled again by sending the contr ol string "@LOC" via

RS-232 (see Chapter 8, S-232-C Interface - Control Commands).

Via RS-232: ...

v24puts(port,"@LOC"); Set instrument to manual operation..

...

Limitations

The following limitations apply if the unit is remote-controlled via the RS-232-C interface:

− No interface messages, only control strings (see interface description in Chapter 8, RS-232-C

Interface – Control Commands).

− Only the Common Com mands *OPC? can be used for c ommand synchronization, *W AI and *OPC

are not available.

− Block data cannot be transmitted.

1164.4556.12 5.5 E-1

Page 16

Starting Remote Control Operation FSP

Remote Control in a Network (RSIB Interface)

Setting the Device Address

For control of the instrument in a network, it must be accessed using the preselected IP address.

The IP address of the instrument (device address) is defined in the network configuration.

Setting the IP address:

Ø Call SETUP - GENERAL SETUP – CONFIGURE NETWORK menu.

Ø Select "Protocols" tab.

Ø Set IP address for TCP/IP protocol under "Properties" (see section on option FSP-B16).

Return to Manual Operation

Return to manual operation can be made manually via the front panel or remotely via the RSIB

interface.

Manually: Ø Press LOCAL softkey or PRESET key.

Note:

– Make sure that the execution of c ommands is completed prior to switc hover

since otherwise the instrument will switch back to remote control

immediately.

Via RSIB interface: ...

CALL RSDLLibloc(analyzer%, ibsta%, iberr%, ibcntl&)'Set

device to manual control

...

1164.4556.12 5.6 E-1

Page 17

FSP Messages

Messages

The messages tr ansferred via the data lines of the IEC bus (see Chapter 8, IEC/IEEE-Bus Interface)

can be divided into two groups:

– interface messages and

– device messages.

IEC/IEEE-Bus Interface Messages

Interface messages are transf erred on the data lines of the IEC bus, the "AT N" contr ol line being active.

They are used for communication between controller and instrument and can only be sent by a

controller which has the IEC/IEEE bus control. Interface commands can be subdivided into

– universal commands and

– addressed commands.

Universal commands act on all devices connected to the IEC/IEEE bus without previous addressing,

addressed comm ands only act on devices previously addressed as listeners. The interf ace messages

relevant to the instrument are listed in Chapter 8, IEC/IEEE-Bus Interface – Interface Functions.

1164.4556.12 5.7 E-1

Page 18

Messages FSP

Device Messages (Commands and Device Responses)

Device messages are transferred on the data lines of the IEC bus, the "ATN" control line not being

active. ASCII code is used.

A distinction is made according to the direction in which they are sent on the IEC/IEEE bus:

– Commands are messages the controller sends to the instrument. They operate the device

functions and request informations.

The commands are subdivided according to two criteria::

1. According to the effect they have on the instrument:

Setting commands cause instrument settings such as reset of the

instrument or setting the center frequency.

Queries cause data to be provided for output on the IEC/IEEE

bus, e.g. for identification of the device or polling the

marker.

2. According to their definition in standard IEEE 488.2:

Common Commands are exactly defined as to their function and

notation in standard IEEE 488.2. They refer to

functions such as m anagement of the st andar-dized

status registers, reset and selftest.

Device-specific

commands refer to functions depending on the features of the

instrument such as fr equency setting. A majority of

these commands has also been standar dized by the

SCPI committee (cf. Section "SCPI Introduction")).

– Device responses are messages the instrument sends to the controller after a query. They can

contain measurement results, instrument settings and information on the

instrument status (cf. Section "Responses to Queries").

Structure and syntax of the device messages are described in the following Section.

1164.4556.12 5.8 E-1

Page 19

FSP Structure and Syntax of the Device Messages

Structure and Syntax of the Device Messages

SCPI Introduction

SCPI (Standard Commands for Programmable Instruments) describes a standard command set for

programming instrum ents, irrespective of the type of instrument or manuf acturer. The goal of the SCPI

consortium is to standar dize the device-specif ic com mands to a large extent. For this purpose, a m odel

was developed which defines the same functions inside a device or for different devices. Command

systems were generated which are assigned to these func tions. T hus it is possible to addres s the sam e

functions with identical commands. The command systems are of a hierarchical structure.

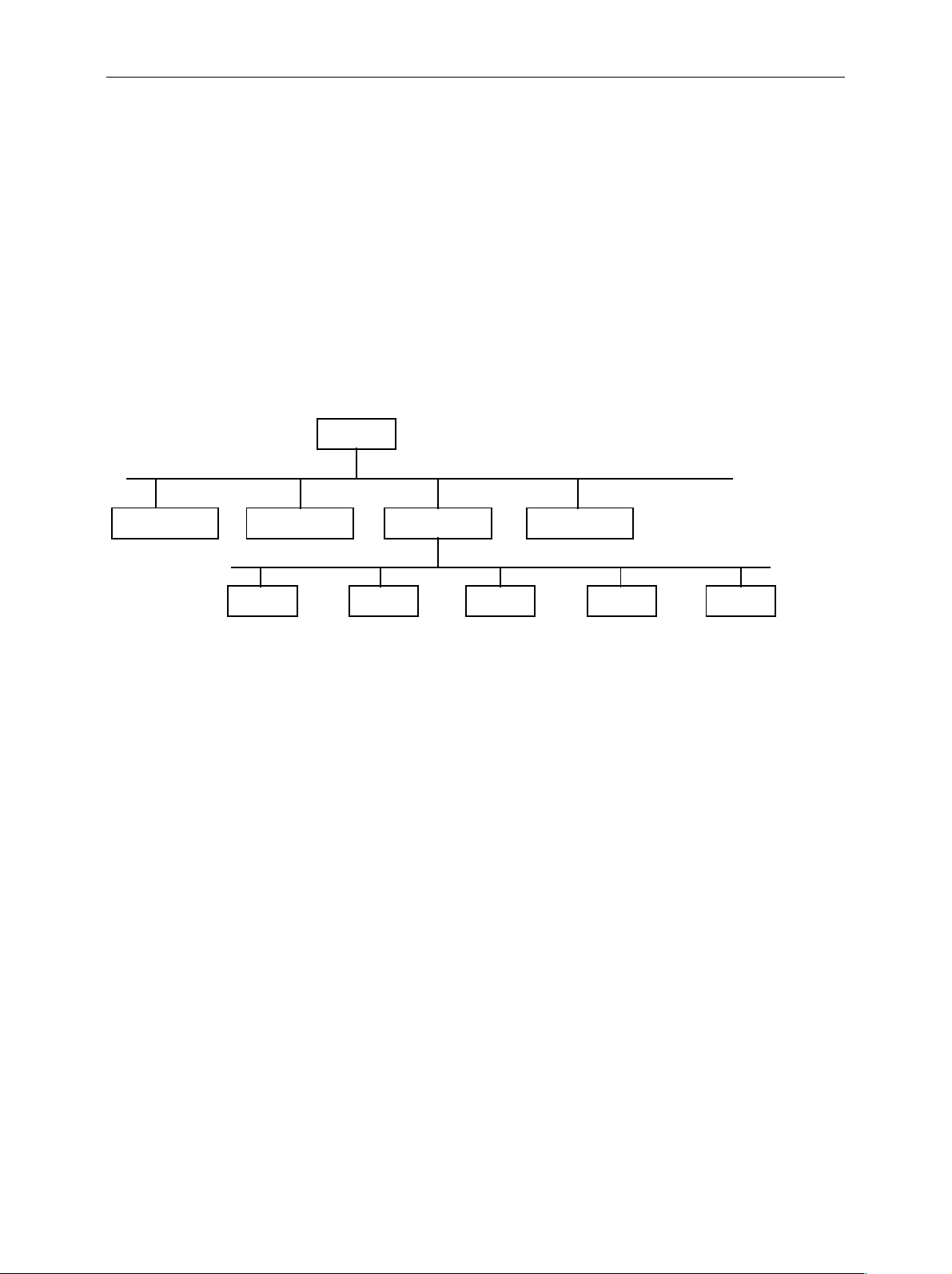

Fig. 5-1 illustrates this tree str ucture using a section of comm and system SENSe, which controls the

device-specific settings, that do not refer to the signal characteristics of the measurement signal.

SCPI is based on standard IEEE 488.2, i.e. it uses the sam e syntactic basic elements as well as the

common com m ands def ined in this standard. Part of the syntax of the device responses is defined with

greater restrictions than in standard IEEE 488.2 (see Section "Responses to Queries").

Structure of a Command

The comm ands c onsist of a so-c alled header and, in m ost cases , one or m ore par am eters. Header and

parameter are separated by a "white space" (ASCII code 0 to 9, 11 to 32 decimal, e.g. blank). The

headers may consist of several key words. Queries are f o rmed by directly appending a question mark to

the header.

Note: The commands used in the following examples are not in ever y case implemented in the

instrument.

Common commands Common commands consist of a header preceded by an asterisk "*"

and one or several parameters, if any.

Examples: *RST RESET, resets the device

*ESE 253 EVENT STATUS ENABLE, sets the bits of

the event status enable register

*ESR? EVENT STATUS QUERY, queries the

contents of the event status register.

1164.4556.12 5.9 E-1

Page 20

Structure and Syntax of the Device Messages FSP

Device-specific commands

Hierarchy: Device-specific commands are of hierarchical structure (see

Fig. 5-1). The different levels are represented by combined headers.

Headers of the highest level (root level) have only one key word. T his

key word denotes a complete command system.

Example: SENSe This key word denotes the com mand system

SENSe.

For commands of lower levels, the complete path has to be specified,

starting on the left with the highest level, the individual key words being

separated by a colon ":".

Example: SENSe:FREQuency:SPAN 10MHZ

This command lies in the third level of the SENSe system. It set the

frequency span.

SENSe

BANDwidth FUNCtion

STARt

Fig. 5-1 Tree structure the SCPI command systems using the SENSe system by way of example

Some key words occur in several levels within one command system. Their

effect depends on the struc ture of the command, that is to say, at which

position in the header of a command they are inserted.

Example: SOURce:FM:POLarity NORMal

FREQuency

STOP

This command contains key word POLarity in the third

command level. It defines the polarity between modulator and

modulation signal.

SOURce:FM:EXTernal:POLarity NORMal

This command contains key word POLarity in the fourth

command level. It defines the polarity between modulation

voltage and the resulting direction of the m odulation only for the

external signal source indicated.

CENTer

DETector

SPAN OFFSet

1164.4556.12 5.10 E-1

Page 21

FSP Structure and Syntax of the Device Messages

Optional key words: Some comm and s ystems per mit certain key words to be optionally inserted

into the header or omitted. These key words are marked by square

brackets in the descr iption. The full command length m ust be recognized

by the instrument for reasons of compatibility with the SCPI standard.

Some commands are considerably shortened by these optional key words.

Example: [SENSe]:BANDwidth[:RESolution]:AUTO

This command couples the resolution bandwidth of the

instrument to other parameters. The following command has

the same effect:

BANDwidth:AUTO

Note: An optional key word must not be omitted if its effect is specified

in detail by a numeric suffix.

Long and short form: T he key words feature a long form and a s hort form. Either the short form

or the long form can be entered, other abbreviations are not permissible.

Beispiel: STATus:QUEStionable:ENABle 1= STAT:QUES:ENAB 1

Note: The short form is marked by upper- case letters, the long form

corresponds to the complete word. Upper-c ase and lower-case

notation only serve the above purpose, the instrument itself

does not make any difference between upper-c ase and lowercase letters.

Parameter: T he parameter must be separated from the header by a "white space". If

several parameters are specif ied in a command, they are separated by a

comma ",". A f ew queries perm it the param eter s MINim um , MAXim um and

DEFault to be entered. For a description of the types of param eter, ref er to

Section "Parameters".

Example: SENSe:FREQuency:STOP? MAXimum Response: 3.5E9

This query requests the maximal value for the stop frequency.

Numeric suffix: If a device features several functions or features of the same kind, e.g.

inputs, the desired function can be selec ted by a suffix added to the command. Entries without suffix are interpreted like entries with the suffix 1.

Example:. SYSTem:COMMunicate:SERial2:BAUD 9600

This command sets the baudrate of a second serial interface.

1164.4556.12 5.11 E-1

Page 22

Structure and Syntax of the Device Messages FSP

Structure of a Command Line

A command line m ay consist of one or several com mands. It is term inated by a <New Line>, a <New

Line> with EOI or an EOI together with the last data byte. The IEC/IEEE driver of the controller us ually

produces automatically an EOI together with the last data byte.

Several commands in a comm and line are separated by a semicolon ";". If the next com mand belongs

to a different command system, the semicolon is followed by a colon.

Example:

CALL IBWRT(analyzer%,"SENSe:FREQuency:CENTer 100MHz;:INPut:ATTenuation 10")

This comm and line contains two com mands. T he first one is part of the SENSe c omm and

system and is used to determine the center frequency of the instrum ent. The second one is

part of the INPut command system and sets the input signal attenuation.

If the successive com mands belong to the sam e system, having one or several levels in common, the

command line can be abbr eviated. For that purpose, the second command af ter the semicolon starts

with the level that lies below the common levels (s ee also Fig. 5-1). The colon f ollowing the semicolon

must be omitted in this case.

Example:

CALL IBWRT

CALL IBWRT(analyzer%, "SENSe:FREQuency:STARt 1E6;STOP 1E9")

However, a new command line always begins with the complete path.

Example: CALL IBWRT(analyzer, "SENSe:FREQuency:STARt 1E6")

(analyzer%, "SENSe:FREQuency:STARt 1E6;:SENSe:FREQuency:STOP 1E9")

This comm and line is represented in its f ull length and contains two comm ands separated

from each other by the semicolon. Both commands are part of the SENSe command

system, subsystem FREQuency, i.e. they have two common levels.

When abbreviating the com mand line, the second command begins with the level below

SENSe:FREQuency. The colon after the semicolon is omitted.

The abbreviated form of the command line reads as follows:

CALL IBWRT(analyzer%, "SENSe:FREQuency:STOP 1E9")

Responses to Queries

A query is defined for each setting com mand unless explicitly specified otherwise. It is f or med by adding

a question mark to the associated setting c ommand. According to SCPI, the res ponses to queries are

partly subject to stricter rules than in standard IEEE 488.2.

1 The requested parameter is transmitted without header.

Example: INPut:COUPling? Response: DC

2. Maxim um values, minimu m values and all further quantities, which are r equested via a special text

parameter are returned as numerical values.

Example: SENSe:FREQuency:STOP? MAX Response: 3.5E9

3. Numerical values are output without a unit. Physical quantities are referred to the basic units or to the

units set using the Unit command.

Example: SENSe:FREQuency:CENTer? Response: 1E6 for 1 MHz

4. Truth values <Boolean values> are returned as 0 (for OFF) and 1 (for ON).

Example: SENSe:BANDwidth:AUTO? Response: 1 for ON

5. Text (character data) is returned in a short form (see also Section 3.5.5).

Example: SYSTem:COMMunicate:SERial:CONTrol:RTS? Response(for standard): STAN

1164.4556.12 5.12 E-1

Page 23

FSP Structure and Syntax of the Device Messages

Parameters

Most commands require a parameter to be specified. The parameters must be separated from the

header by a "white space". Permissible parameters are numerical values, Boolean parameters, text,

character strings and block data. The type of parameter required for the r espective command and the

permissible range of values are specified in the command description

Numerical values Numerical values can be entered in any form, i.e. with sign, decimal point and

exponent. Values exceeding the resolution of the instrument are rounded up or

down. The mantissa m ay compr ise up to 255 c har acter s , the ex ponent must lie

inside the value range -32000 to 32000. The exponent is introduced by an "E"

or "e". Entry of the exponent alone is not permissible. In the cas e of physical

quantities, the unit can be entered. Permiss ible unit prefixes are G (giga), MA

(mega), MOHM and MHZ are also permissible), K (kilo), M (m illi), U (micro)

and N (nano). It the unit is missing, the basic unit is used.

Example:

SENSe:FREQuency:STOP 1.5GHz = SENSe:FREQuency:STOP 1.5E9

Special numerical The texts MINimum, MAXimum, DEFault, UP and DOWN are interpreted as

valuesspecial numerical values.

In the case of a query, the numerical value is provided.

Example: Setting command: SENSe:FREQuency:STOP MAXimum

Query: SENSe:FREQuency:STOP? Response: 3.5E9

MIN/MAX MINimum and MAXimum denote the minimum and maximum value.

DEF DEFault denotes a preset value which has been stored in the EPROM. T his

value conforms to the default setting, as it is called by the *RST command

UP/DOWN UP, DOWN increas es or reduces the numerical value by one step. The step

width can be specified via an allocated step com mand (see annex C, List of

Commands) for each parameter which can be set via UP, DOWN.

INF/NINF INFinity, Negative INFinity (NINF) Negative INFinity (NINF) represent the

numerical values -9.9E37 or 9.9E37, respectively. INF and NINF are only sent

as device reponses.

NAN Not A Number (NAN) represents the value 9.91E37. NAN is only sent as

device response. This value is not defined. Possible c auses are the division of

zero by zero, the subtraction of infinite from infinite and the repr esentation of

missing values.

Boolean Parameters Boolean parameters represent two states. The ON state (logically true) is

represented by ON or a numerical value unequal to 0. T he OF F state (logically

untrue) is represented by OFF or the numerical value 0. 0 or 1 is provided in a

query.

Example: Setting command: DISPlay:WINDow:STATe ON

Query: DISPlay:WINDow:STATe? Response: 1

1164.4556.12 5.13 E-1

Page 24

Structure and Syntax of the Device Messages FSP

Text Text parameters observe the syntactic rules for key words, i.e. they can be

entered using a short or long form. Like any parameter, they have to be

separated from the header by a white space. In the case of a query, the short

form of the text is provided.

Example: Setting command: INPut:COUPling GROund

Query: INPut:COUPling? Response GRO

Strings Strings must always be entered in quotation marks (' or ").

Example: SYSTem:LANGuage "SCPI" or

SYSTem:LANGuage 'SCPI'

Block data Block data are a transmission format which is suitable for the transmission of

large amounts of data. A command using a block data parameter has the

following structure:

Example: HEADer:HEADer #45168xxxxxxxx

ASCII character # introduces the data block. The next number indicates how

many of the following digits describe the length of the data block. In the example

the 4 following digits indicate the length to be 5168 bytes. The data bytes follow.

During the transmission of these data bytes all End or other control signs are

ignored until all bytes are transmitted.

Overview of Syntax Elements

The following survey offers an overview of the syntax elements.

The colon separates the key words of a command.

:

In a command line the colon after the separating semicolon marks the uppermost comm and

level.

The semicolon separates two comm ands of a command line. It does not alter the path.

;

The comma separates sev eral param eters of a command.

,

The question mark forms a query.

?

The asterix marks a com mon comm an d.

*

Quotation marks introduce a string and termi nate it.

"

The double dagger ( #) introduces block data

#

A "white space (ASCII-Code 0 to 9, 11 to 32 decimal, e.g.blank) separates header and parameter.

1164.4556.12 5.14 E-1

Page 25

FSP Status Reporting System

Instrument Model and Command Processing

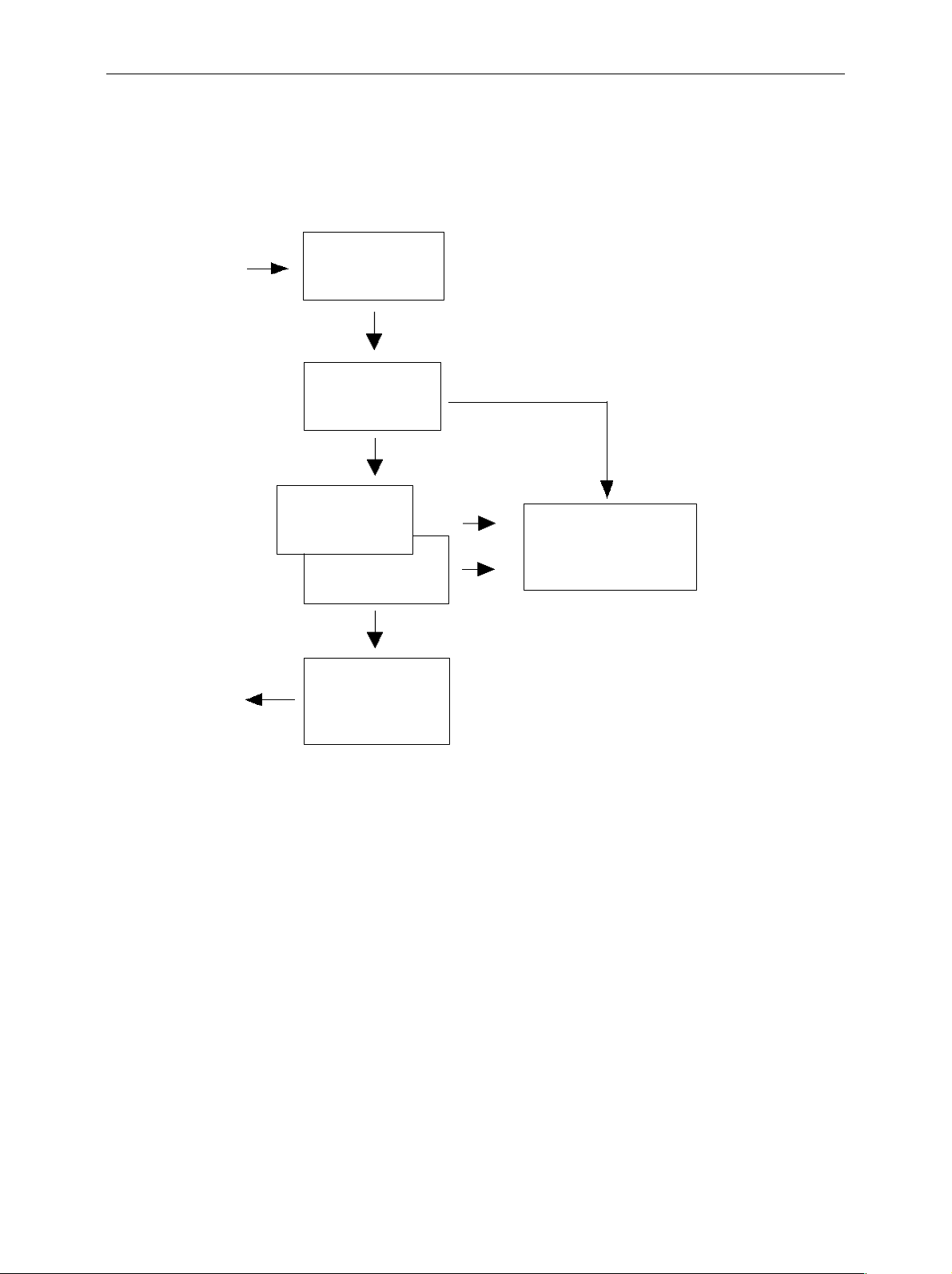

The instrument model shown in Fig. 5-2 has been made viewed f rom the standpoint of the s ervicing of

IEC-bus commands . The individual components work independently of each other and sim ultaneously.

They communicate by means of so-called "messages".

Input unit with

IEC Bus

input puffer

Command

recognition

Data set

Status reporting-

system

Instrument

hardware

Output unit with

IEC Bus

Fig. 5-2 Instrument model in the case of remote control by means of the IEC bus

output buf f er

Input Unit

The input unit receives com mands character by character from the IEC bus and collects them in the

input buffer. The input unit sends a message to the command recognition as s oon as the input buf f er is

full or as soon as it rece ives a delimiter, <PROGRAM MESSAGE T ERMINATOR>, as defined in IEEE

488.2, or the interface message DCL.

If the input buffer is full, the IEC-bus traf fic is stopped and the data rec eived up to then are processed.

Subsequently the IEC-bus traffic is continued. If, however, the buf fer is not yet full when receiving the

delimiter, the input unit can already receive the next command during command recognition and

execution. The receipt of a DCL clears the input buffer and immediately initiates a message to the

command recognition.

1164.4556.12 5.15 E-1

Page 26

Status Reporting System FSP

Command Recognition

The comm and recognition analyses the data received from the input unit. It proceeds in the order in

which it receives the data. Only a DCL is serviced with priority, a GET (Group Execute T rigger), e.g., is

only executed after the comm ands received before as well. Eac h recognized comm and is im mediately

transferred to the instrument data base but without being executed there at once.

Syntactical errors in the command are recognized in the command recognition and supplied to the

status reporting system. The res t of a comm and line after a syntax error is analysed further if poss ible

and serviced.

If the command recognition recognizes a delimiter (<PROGRAM MESSAGE SEPARATOR> or

<PROGRAM MESSAGE TERMINATOR>) or a DCL, it requests the instrument data bas e to set the

commands in the ins trum ent hardware as well now. Subsequently it is imm ediately prepared to process

commands again. This means for the command servicing that further commands can already be

serviced while the hardware is still being set ("overlapping execution").

Instrument Data Base and Instrument Hardware

Here the expression "instrument hardware" denotes the part of the instrument fulfilling the actual

instrument function - signal generation, measurement etc. The controller is not included.

The instrument data base is a detailed reproduction of the instrument hardware in the software.

IEC-bus setting comm ands lead to an alteration in the data set. The data base managem ent enters the

new values (e.g. frequency) into the data base, however, only passes them on to the hardware when

requested by the command recognition.

The data are only checked for their c ompatibility among each other and with the instrum ent hardware

immediately before they are transmitted to the instrument hardware. If the detection is made that an

execution is not possible, an "execution error" is signalled to the status reporting system. The alter ation

of the data base are cancelled, the instrument hardware is not reset.

IEC-bus queries induce the data base management to send the desired data to the output unit.

Status Reporting System

The status reporting system c ollects information on the instrum ent state and makes it available to the

output unit on request. The exact structure and function are described in Section 3.8

1164.4556.12 5.16 E-1

Page 27

FSP Status Reporting System

Output Unit

The output unit collects the information requested by the controller, which it receives f rom the data bas e

management. It processes it according to the SCPI rules and makes it available in the output buffer.

If the instrument is address ed as a talk er without the output buff er containing data or awaiting data from

the data base management, the output unit sends error message "Query UNTERMINATED" to the

status reporting system. No data are sent on the IEC bus, the controller waits until it has reac hed its

time limit. This behaviour is specified by SCPI.

Command Sequence and Command Synchronization

What has been said above makes clear that all commands can potentially be carried out overlapping.

In order to prevent an overlapping execution of comm ands, one of commands *OPC, *OPC? or *WAI

must be used. All three commands cause a cer tain action only to be carried out after the hardware has

been set and has settled. By a suitable programming, the controller can be forced to wait for the

respective action to occur (cf. Table 5-1).

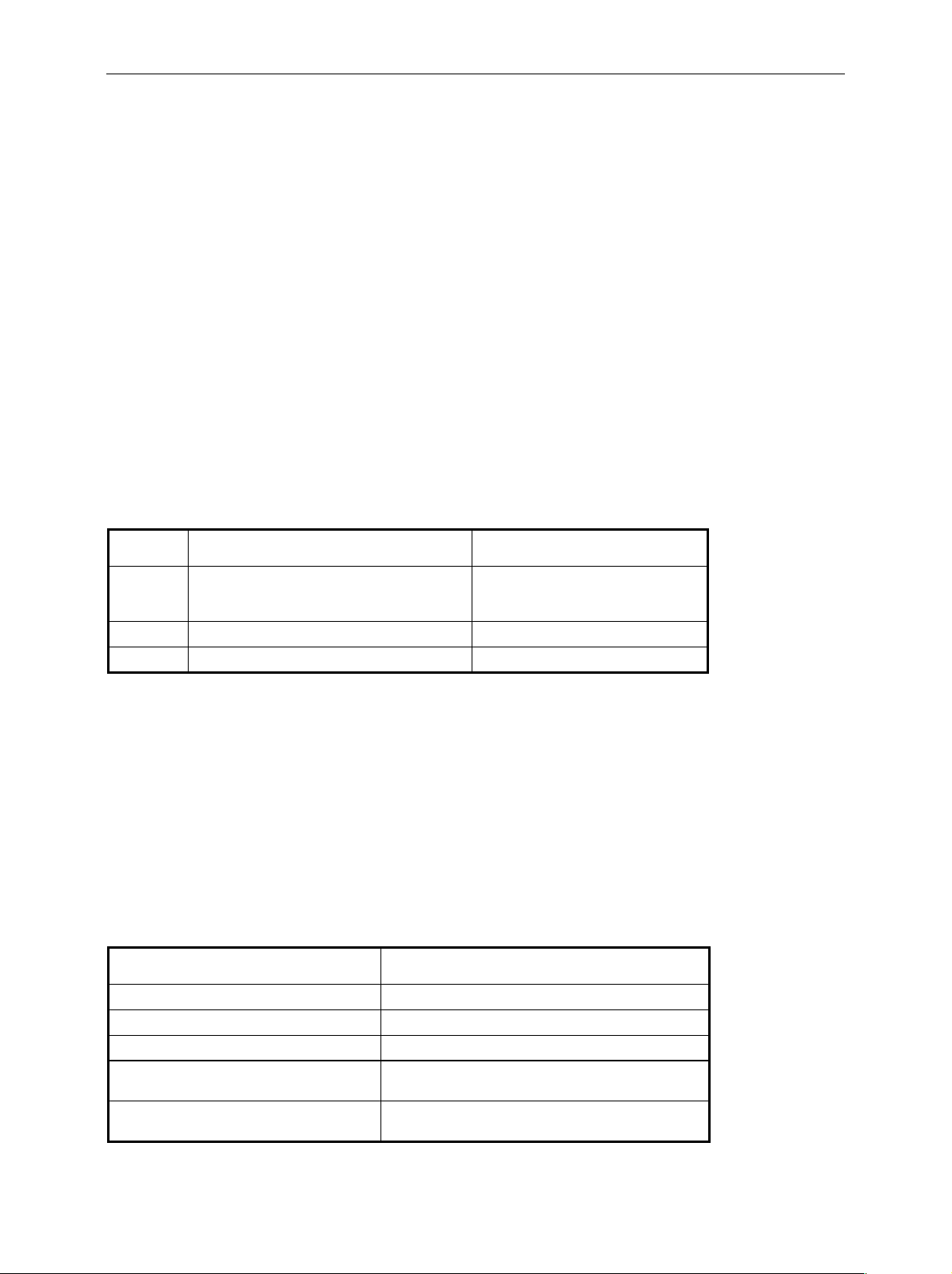

Table 5-1 Synchronisation using *OPC, *OPC? and *WAI

Command Action after the hardware has settled Programming the controller

*OPC Setting the opteration-complete bit in the ESR - Setting bit 0 in the ES E

*OPC? Writing a " 1" i nto the output buffer Addressing the instrument as a talker

*WAI Continuing the I E C-bus handshake Sending the next command

- Setting bit 5 in the SRE

- Waiting for service request (SRQ)

An example as to command synchronization can be found in Chapter "Program Examples".

For a couple of comm ands the s ynchronization to the end of comm and execution is m andatory in order

to obtain the desired result. The affected commands require either more than one measurement in

order to accomplish the desired instrument setting (eg autorange functions), or they require a longer

period of time for execution. If a new command is received during execution of the corresponding

function this may either lead to either to an aborted measurement or to invalid measurement data.

The following list includes the commands, for which a synchronization via *OPC, *OPC? or *W AI is

mandatory:

Table 5-1 Commands with mandatory synchronization (Overlapping Commands)

Command Purpose

INIT start measurem ent

INIT:CONM continue measurement

CALC:MARK:FUNC:ZOOM zoom frequency range around marker 1

CALC:STAT:SCAL:AUTO ONCE optimize level settings for signal s tatistic measurement

[SENS:]POW:ACH:PRES:RLEV optimize level sett i ngs for adjacent channel power

functions

measurements

1164.4556.12 5.17 E-1

Page 28

Status Reporting System FSP

D

Status Reporting System

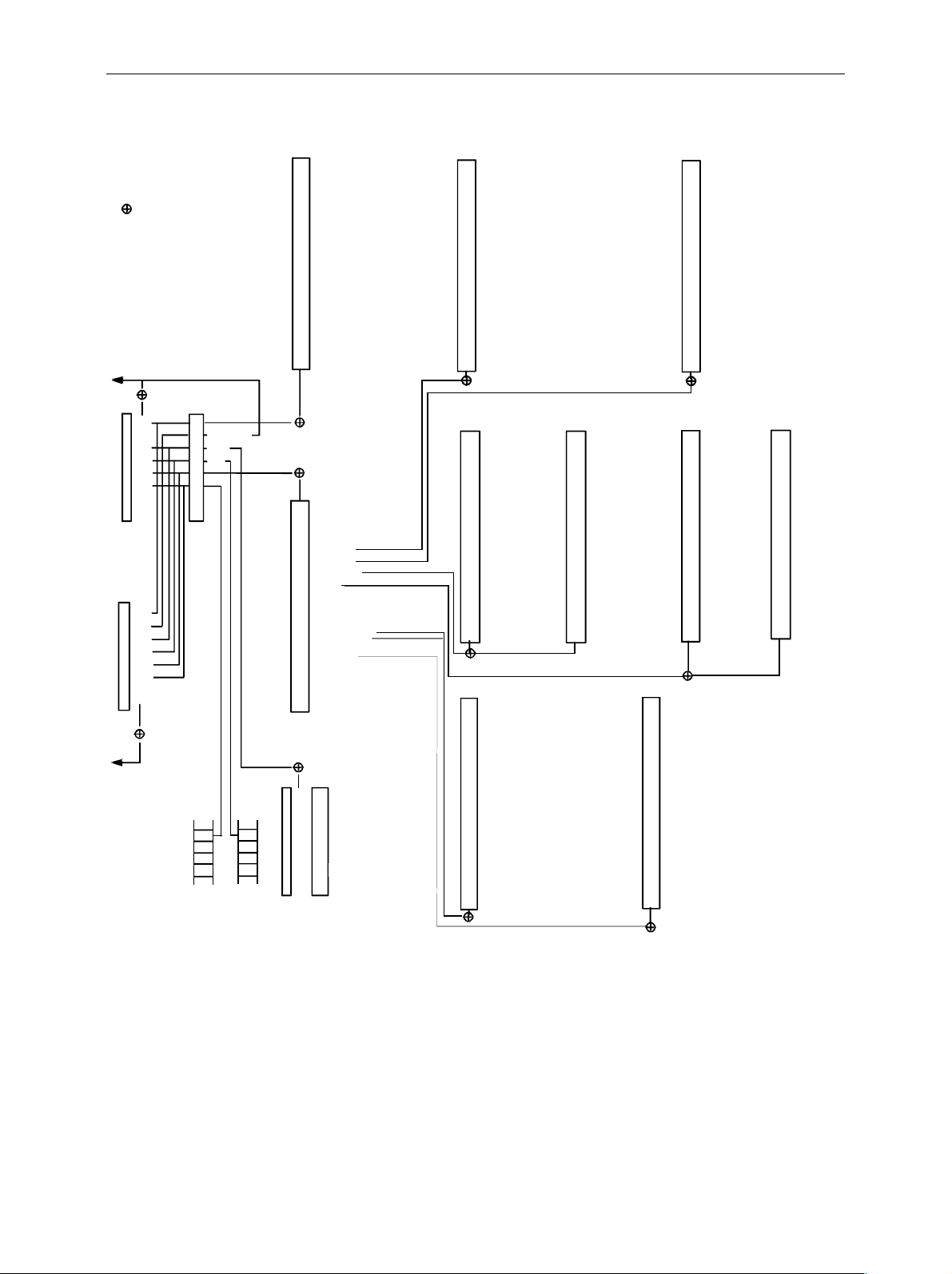

The status reporting system ( cf. Fig. 5-4) stores all information on the present operating state of the

instrument, e.g. that the instrument presently carries out a calibration and on errors which have

occurred. This inf ormation is stored in the status registers and in the error queue. T he status registers

and the error queue can be queried via IEC bus.

The information is of a hierarchic al structure. T he register status byte (STB) defined in IEEE 488.2 and

its associated mask regist er service r equest enable (SRE) for m the upper mos t level. The STB receives

its information f rom the standard event status register ( ESR) which is also defined in IEEE 488.2 with

the associated mask register standar d event status enable ( ESE) and r egis ters STATus:OPERation and

STATus:QUEStionable which are defined by SCPI and contain detailed information on the instrument.

The IST flag ("Individual ST atus") and the parallel poll enable regis ter (PPE) alloc ated to it are also part

of the status reporting system. T he IST flag, like the SRQ, com bines the entire instrument status in a

single bit. The PPE fulfills the same function for the IST flag as the SRE for the service request.

The output buffer contains the messages the instrum ent returns to the controller. It is not part of the

status reporting system but determines the value of the MAV bit in the STB and thus is represented in

Fig. 5-4.

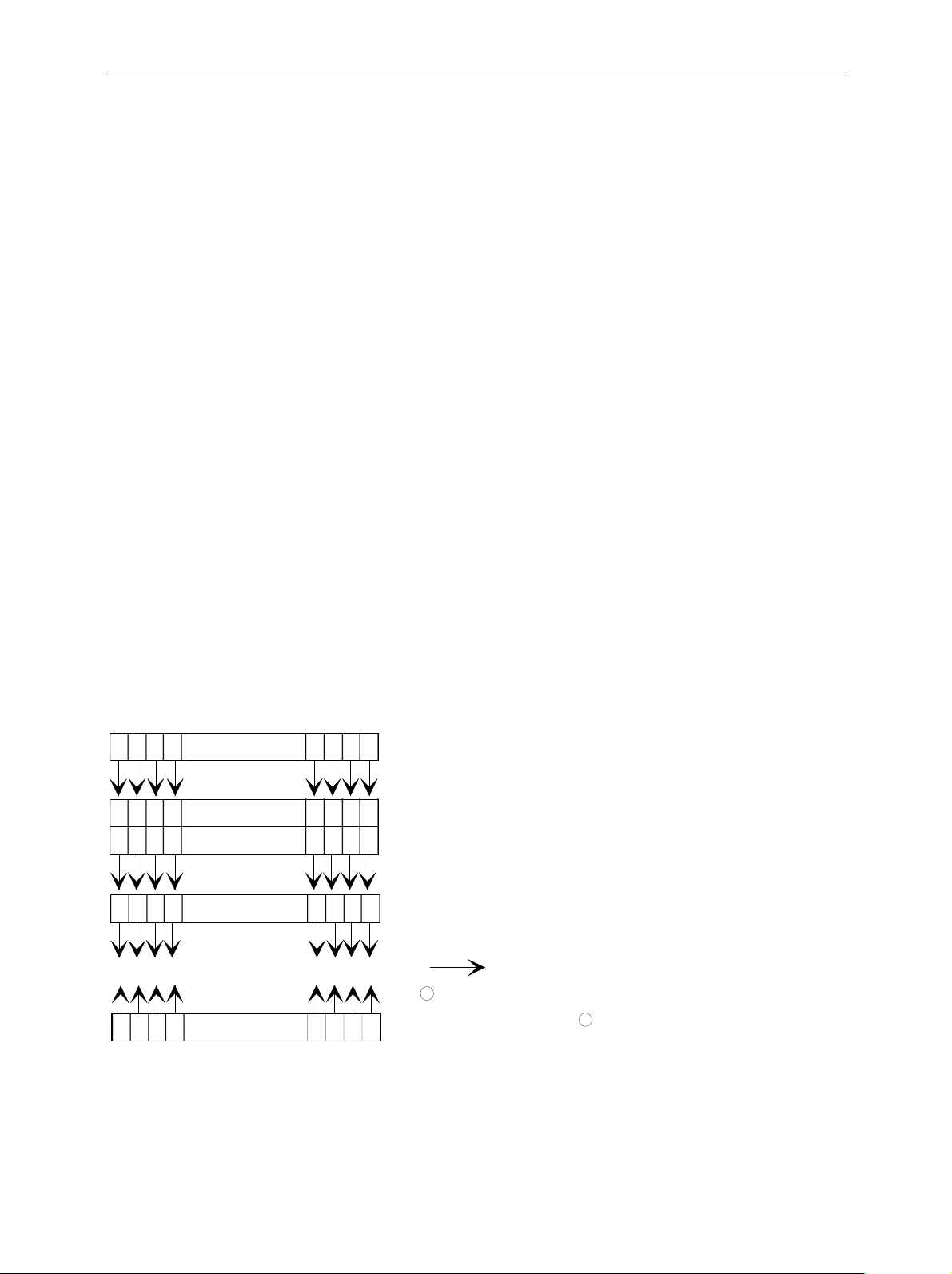

Structure of an SCPI Status Register

Each SCPI register consists of 5 parts which each have a width of 16 bits and have different func tions

(cf. Fig. 5-3). The individual bits are independent of each other, i.e. each hardware status is assigned a

bit number which is valid for all five parts. For example, bit 3 of the STATus:OPERation register is

assigned to the hardware status "wait for trigger" in all f ive parts . Bit 15 ( the most significant bit) is s et to

zero for all parts. Thus the contents of the register parts can be processed by the controller as pos itive

integer.

15 14 13 12 CONDition part 3 2 1 0

15 14 13 12 PTRansition part 3 2 1 0

15 14 13 12 NTRansition part 3 2 1 0

15 14 13 1 2 EVE Nt p art 3 2 1 0

to high er -order register

& & & & & & & & & & & & & & & &

15 14 13 12 ENABle part 3 2 1 0

Sum b it

+

& = logical AN

= logic al OR

+

of all bits

Fig. 5-3 The status-register model

1164.4556.12 5.18 E-1

Page 29

FSP Status Reporting System

CONDition part The CONDition part is directly written into by the hardware or the sum bit of

the next lower register. Its contents reflects the current ins trum ent status . T his

register part can only be read, but not written into or cleared. Its contents is

not affected by reading.

PTRansition part The Positive-TRansition part acts as an edge detector. When a bit of the

CONDition part is changed from 0 to 1, the associated PTR bit decides

whether the EVENt bit is set to 1.

PTR bit =1: the EVENt bit is set.

PTR bit =0: the EVENt bit is not set.

This part can be written into and read at will. Its contents is not af fected by

reading.

NTRansition part The Negative-TRansition part also acts as an edge detector . When a bit of the

CONDition part is changed from 1 to 0, the associated NTR bit decides

whether the EVENt bit is set to 1.

NTR-Bit = 1: the EVENt bit is set.

NTR-Bit = 0: the EVENt bit is not set.

This part can be written into and read at will. Its contents is not af fected by

reading.

With these two edge register parts the user can define which state transition of

the condition part (none, 0 to 1, 1 to 0 or both) is stored in the EVENt part.

EVENt part The EVENt part indicates whether an event has occurred since the last

reading, it is the "memory" of the condition part. It only indicates events

passed on by the edge filters. It is permanently updated by the instrument.

This part can only be read by the user. During reading, its contents is set to

zero. In linguistic usage this part is often equated with the entire register.

ENABle part The ENABle part determines whether the associated EVENt bit contr ibutes to

the sum bit (cf. below). Each bit of the EVENt part is ANDed with the

associated ENABle bit (symbol '&'). The r esults of all logic al operations of this

part are passed on to the sum bit via an OR function (symbol '+').

ENABle-Bit = 0: the associated EVENt bit does not contribute to the sum bit

ENABle-Bit = 1: if the associated EVENT bit is "1", the sum bit is s et to "1" as

well.

This part can be written into and read by the user at will. Its contents is not

affected by reading.

Sum bit As indicated above, the sum bit is obtained f rom the EVENt and ENABle part

for each register. The r esult is then entered into a bit of the CONDition part of

the higher-order register.

The instrument autom atic ally generates the sum bit f or each register . T hus an

event, e.g. a PLL that has not locked, can lead to a service request throughout

all levels of the hierarchy.

Note: The service request enable regis ter SRE defined in IEEE 488.2 can be taken as ENABle

part of the STB if the STB is structured according to SCPI. By analogy, the ESE can be

taken as the ENABle part of the ESR.

1164.4556.12 5.19 E-1

Page 30

Status Reporting System FSP

Overview of the Status Registers

not used

&=logic AND

=logic OR

of all bits

SRQ

15

14

13

12

11

10

Scan results available

9

HCOPy in progress

8

7

6

5

4

3

2

1

CALibrating

0

STATus:OPERation

not used

15

14

ALT2 LOWer FAIL (screen B)

13

ALT2 UPPer FAIL (screen B)

12

ALT1 LOWer FAIL (screen B)

11

ALT1 UPPer FAIL (screen B)

10

ADJ LOWer FAIL (screen B)

9

ADJ UPPer FAIL (screen B)

8

7

6

5

ALT2 LOWer FAIL (screen A)

4

ALT2 UPPer FAIL (screen A)

3

ALT1 LOWer FAIL (screen A)

2

ALT1 UPPer FAIL (screen A)

1

ADJ LOWer FAIL (screen A)

0

ADJ UPPer FAIL (screen A)

STATus:QUEStionable:ACPLimit

not used

15

14

13

12

11

10

9

8

7

6

5

4

3

CARRier overload (screen A)

2

No carrier (screen A)

1

SYNC not found (screen A)

0

BURSt not found (screen A)

STATus:QUEStionable:SYNC

-&-

-&-

-&-

-&-

-&-

SRE

-&-

-&-

-&-

-&-

-&-

-&-

PPE

ISTflag

7

RQS/MSS

6

5

ESB

4

MAV

3

2

1

0

ST B

Error/event

queue

bla

15

14

13

12

11

10

STATus:QUEStionable

-&-

-&-

-&-

-&-

-&-

-&-

-&-

Output

buffer

-&-

ESE ESR

not used

TRANsducer break

ACPLimit

SYNC

LMARgin

9

LIMit

8

CALibration (= UNCAL)

7

6

5

FREQuency

4

TEMPerature

POW er

3

2

1

0

Power o n

7

User Request

6

CommandError

5

Execution Error

4

Device Dependent Err or

3

Query Error

2

Request Control

1

0

Operation Complete

Screen A

not used not used

15

14

13

12

11

10

9

8

LMARgin 8 FAIL

7

LMARgin 7 FAIL

6

LMARgin 6 FAIL

5

LMARgin 5 FAIL

4

LMARgin 4 FAIL

3

LMARgin 3 FAIL

2

LMARgin 2 FAIL

1

LMARgin 1 FAIL

0

STATus:QUEStionabl e:LMARgin <1|2>

not used not used

15

14

13

12

11

10

LO UNLocked (screen B)

9

8

7

6

5

4

3

2

LO UNLocked (screen A)b

1

OVEN COLD

0

STATus:QUEStionabl e:FREQuency

Screen B

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Screen A Screen B

15

14

13

12

11

10

9

8

LIMit 8 FAIL

7

LIMit 7 FAIL

6

LIMit 6 FAIL

5

LIMit 5 FAIL

4

LIMit 4 FAIL

3

LIMit 3 FAIL

2

LIMit 2 FAIL

1

LIMit 1 FAIL

0

STATus:QUEStionable:LIMit<1|2>

IF_OVerload (screen B)

UNDerload

OVERload (screen B)

IF_OVerload (screen A)

UNDerload

OVERload (screen A)

STATus:QUEStionable:POWer

(screen B )

(screen A)

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Fig. 5-4 Overview of the status registers

1164.4556.12 5.20 E-1

Page 31

FSP Status Reporting System

Description of the Status Registers

Status Byte (STB) and Service Request Enable Register (SRE)

The STB is already defined in IEEE 488.2. It provides a rough overview of the instrument status by

collecting the pieces of inform ation of the lower registers. It can thus be com pared with the CONDition

part of an SCPI register and assum es the highest level within the SCPI hierarchy. A special f eature is

that bit 6 acts as the sum bit of the remaining bits of the status byte.

The STATUS BYTE is read out using the command "*STB?" or a serial poll.

The STB implies the SRE. It corresponds to the ENABle part of the SCPI registers as to its function.

Each bit of the STB is assigned a bit in the SRE. Bit 6 of the SRE is ignored. If a bit is set in the SRE

and the associated bit in the STB changes f rom 0 to 1, a Service Request (SRQ) is generated on the

IEC bus, which triggers an interrupt in the controller if this is appropriately configured and c an be f urther

processed there.

The SRE can be set using command "*SRE" and read using "*SRE?".

Table 5-2 Meaning of the bits in the status byte

Bit No. Meaning

2

3

4

5

6

Error Queue not empty

The bit is set when an entry is m ade i n the error queue.

If this bit is enabl ed by the SRE, each entry of the error queue generates a S ervi ce Request. Thus an error can

be recognized and specified in greater detail by polling the error queue. The poll provides an informative error

message. This proc edure i s to be recommended since i t considerably reduces the problem s involved with IECbus control.

QUEStionable status sum bit

The bit is set if an EVENt bit is set in the QUEStionable: status register and the associated ENABle bit is set

to 1.

A set bit indicates a questionable instrument status, which can be s pecified in greater detail by polling the

QUEStionable status regi ster.

MAV bit (message available)

The bit is set if a message is available in the output buffer which can be read.

This bit can be used to enable data to be automatically read from t he i nstrument to the controll er (cf. Chapter 7,

program examples).

ESB bit

Sum bit of the event s tatus register. It is set if one of the bits in the event status register is set and enabl ed in

the event status enable regis ter.

Setting of this bit i mplies an error or an event which can be specif i ed i n greater detail by polling the event status

register.

MSS bit (master status summary bit )

The bit is set if the i nstrument triggers a service request. This is the case i f one of the other bits of this regis ters

is set together with its mask bit in the servic e request enable register SRE.

7

OPERation status register sum bit

The bit is set if an EVENt bit is set in the OPERation-Stat us register and the associated ENABle bit is set to 1.

A set bit indicates that the instrument is j ust performing an action. The type of action can be determined by

polling the OPERation-stat us register.

1164.4556.12 5.21 E-1

Page 32

Status Reporting System FSP

IST Flag and Parallel Poll Enable Register (PPE)

By analogy with the SRQ, the IST flag combines the entire status information in a single bit. It can be

queried by means of a parallel poll (cf. Section 3.8.4.3) or using command "*IST?".

The parallel poll enable register (PPE) deter mines which bits of the STB contribute to the IST f lag. The

bits of the STB are ANDed with the corresponding bits of the PPE, with bit 6 being used as well in

contrast to the SRE. The Ist flag results from the ORing of all results. The PPE can be set using

commands "*PRE" and read using command "*PRE?".

Event-Status Register (ESR) and Event-Status-Enable Register (ESE)

The ESR is already defined in IEEE 488.2. It can be compared with the EVENt part of an SCPI r egister.

The event status register can be read out using command "*ESR?".

The ESE is the associated ENABle part. It can be s et us ing c ommand "*ESE" and r ead using command

"*ESE?".

Table 5-3 Meaning of the bits in the event status register

Bit No. Meaning

0

1 This bit is not used

2

3

4

5

6

Operation Complete

This bit is set on recei pt of the command *OPC exactly when all previous commands have been executed.

Query Error

This bit is set if ei ther the controller wants to read data from the instrument without having send a query, or if it

does not fetch requested data and sends new instructions to the ins trument instead. The cause i s often a query

which is faulty and hence cannot be executed.

Device-dependent Error

This bit is set if a devi ce-dependent error occurs. An error mes sage with a number between -300 and -399 or a

positive error number, which denotes t he error i n greater detail, is entered into the error queue (c f. Chapter 9,

Error Messages).

Execution Error

This bit is set if a received command is syntactically correct, however, cannot be perf ormed for other reasons.

An error message with a number bet ween -200 and -300, which denotes the error in greater detail, is entered

into the error queue (cf. Chapter 9, E rror Mes sages).

Command Error

This bit is set if a command which is undefined or syntactically incorrect is received. An error message with a

number between -100 and -200, which denotes the error in greater detail, is entered into the error queue (cf.

Chapter 9 "Error Messages").

User Request

This bit is set on pressing the LOCAL key.

7

Power On (supply voltage on)

This bit is set on switching on the instrument.

1164.4556.12 5.22 E-1

Page 33

FSP Status Reporting System

STATus:OPERation Register

In the CONDition part, this register contains information on which actions the instrument is being

executing or, in the EVENt part, inform ation on which ac tions the ins tr ument has executed s ince the las t

reading. It can be read using commands "STATus:OPERation:CONDition?" or "STATus

:OPERation[:EVENt]?".

Table 5-4 Meaning of the bits in the STATus.OPERation register

Bit No. Meaning

0

1 to 7 These bits are not used

8

9 to 14 These bit s are not used

15 This bit is always 0

CALibrating

This bit is set as l ong as the instrument is perf orming a calibration.

HardCOPy in progress

This bit is set while the instrument is printing a hardcopy.

1164.4556.12 5.23 E-1

Page 34

Status Reporting System FSP

STATus:QUEStionable Register

This register comprises information about indefinite states which may occur if the unit is operated

without meeting the specifications. It can be queried by commands STATus:QUEStionable:

CONDition? and STATus:QUEStionable[:EVENt]?.

Table 5-5 Meaning of bits in STATus:QUEStionable register

Bit No. Meaning

0 to 2 These bits are not used

3

4

5

6 to 7 These bits are not used

8

9

10

11

12

POWer

This bit is set if a questionable power occurs (cf. also section "STATus:QUEStionabl e:POWer Register")

TEMPerature

This bit is set if a questionable temperature occurs .

FREQuency

The bit is set if a frequenc y i s questionable (cf. sect i on " STATus:QUEStionable:FREQuenc y Regi ster")

CALibration

The bit is set if a measurement is performed uncalibrated (=^ label "UNCAL")

LIMit (device-specific )

This bit is set if a limit value is violated (see also section STATus :QUEStionable:LIMit Regist er)

LMARgin (device-specific)

This bit is set if a margin is violated (see also s ection STATus:QUESt i onabl e:LMARgin Register)

SYNC (device-dependent)

This bit is set if , in measurements or premeasurements in GSM MS mode, synchronization to midamble fails or

no burst is found.

This bit is also set i f, in premeasurements i n GSM MS mode, the result differs too strongly from the expected

value (see also "STATus:QUE Stionable:SYNC Register").

ACPLimit (device-specific)

This bit is set if a l i mit for the adjacent channel power m easurement is violated (see als o section

"STATus:QUEStionable: A CP Li mit Register")

13 to 14 These bits are not used

15 This bit is always 0.

1164.4556.12 5.24 E-1

Page 35

FSP Status Reporting System

STATus:QUEStionable:ACPLimit Register

This register comprises information about the observance of limits during adjacent power

measurements. It can be queried with commands 'STATus:QUEStionable:ACPLimit

:CONDition?' and 'STATus:QUEStionable:ACPLimit[:EVENt]?'

Table 5-6 Meaning of bits in STATus:QUEStionable:ACPLimit register

Bit No. Meaning

0

1

2

3

4

5

6 to 7 not used

8

9

ADJ UPPer FAIL(Screen A)

This bit is set if i n screen A. the limit is exceeded in the upper adjacent channel

ADJ LOWer FAIL (Screen A)

This bit is set if i n screen A the limit is exceeded in t he l ower adjacent channel.

ALT1 UPPer FAIL (Screen A)

This bit is set if i n screen A the limit is exceeded in t he upper 1st alternate channel.

ALT1 LOWer FAIL (Screen A)

This bit is set if i n screen A the limit is exceeded in t he l ower 1st al ternate channel.

ALT2 UPPer FAIL (Screen A)

This bit is set if i n screen A the limit is exceeded in t he upper 2nd al ternate channel.

ALT2 LOWer FAIL (Screen A)

This bit is set if i n screen A the limit is exceeded in t he l ower 2nd alternate channel.

ADJ UPPer FAIL (Screen B)

This bit is set if i n screen B the limit is exceeded in t he upper adj acent channel.

ADJ LOWer FAIL (Screen B)

This bit is set if in screen

B the limit is exceeded in the lower adjacent channel.

10

11

12

13

14 not used

15 This bit is always set to 0.

ALT1 UPPer FAIL (Screen B)

This bit is set if i n screen B the limit is exceeded in t he upper 1st alternate channel.

ALT1 LOWer FAIL (Screen B)

This bit is set if

ALT2 UPPer FAIL (Screen B)

This bit is set if i n screen B the limit is exceeded in t he upper 2nd al ternate channel.

ALT2 LOWer FAIL (Screen B)

This bit is set if i n screen B the limit is exceeded in t he l ower 2nd alternate channel.

in screen B the limi t i s exceeded in the lower 1st alternate channel.

1164.4556.12 5.25 E-1

Page 36

Status Reporting System FSP

STATus:QUEStionable:FREQuency Register

This register comprises information aboutthe reference and local oscillator.

It can be queried with commands STATus:QUEStionable:FREQuency:CONDition? and "STATus

:QUEStionable:FREQuency[:EVENt]?.

Table 5-7 Meaning of bits in STATus:QUEStionable:FREQuency register

Bit No. Meaning

0

1

2 to 8 not used

9

10 to 14 not used

15 This bit is always 0.

OVEN COLD

This bit is set if the reference os cillator has not yet attained its operating tem perat ure. 'OCXO' will then be

displayed.

LO UNLocked (Screen A)

This bit is set if the local oscillat or no longer locks. 'LOUNL will then be displayed.

LO UNLocked (Screen B)

This bit is set if the local oscillat or no longer locks.' LOUNL' will then be displayed.

1164.4556.12 5.26 E-1

Page 37

FSP Status Reporting System

STATus:QUEStionable:LIMit<1|2> Register

This register comprises information about the observance of limit lines in the corresponding

measurement window (LIMit 1 corr esponds to Screen A, LIMit 2 to Screen B). It can be queried with

commands STATus:QUEStionable:LIMit<1|2>:CONDition? and STATus:QUEStionable:

LIMit<1|2>[:EVENt]?.

Table 5-8 Meaning of bits in STATus:QUEStionable:LIMit<1|2> register

Bit No. Meaning

0

1

2

3

4

5

6

7

LIMit 1 FAIL

This bit is set if limit line 1 is violated.

LIMit 2 FAIL

This bit is set if limit line 2 is violated.

LIMit 3 FAIL

This bit is set if limit line 3 is violated.

LIMit 4 FAIL

This bit is set if limit line 4 is violated.

LIMit 5 FAIL

This bit is set if limit line 5 is violated.

LIMit 6 FAIL

This bit is set if limit line 6 is violated.

LIMit 7 FAIL

This bit is set if limit line 7 is violated.

LIMit 8 FAIL

This bit is set if limit line 8 is violated.

8 to 14 not used

15 This bit is always 0.

1164.4556.12 5.27 E-1

Page 38

Status Reporting System FSP

STATus:QUEStionable:LMARgin<1|2> Register

This register comprises information about the observance of limit margins in the corresponding

measurement window (LMARgin1 corresponds to Screen A, LMARgin2 corresponds to Screen B). It

can be queried with commands STATus:QUEStionable:LMARgin<1|2>:CONDition? and

"STATus :QUEStionable:LMARgin<1|2>[:EVENt]?.

Table 5-9 Meaning of bits in STATus:QUEStionable:LMARgin<1|2> register

Bit No. Meaning

0

1

2

3

4

5

6

7

LMARgin 1 FAIL

This bit is set if limit margin 1 is violated.

LMARgin 2 FAIL

This bit is set if limit margin 2 is violated.

LMARgin 3 FAIL

This bit is set if limit margin 3 is violated.

LMARgin 4 FAIL

This bit is set if limit margin 4 is violated.

LMARgin 5 FAIL

This bit is set if limit margin 5 is violated.

LMARgin 6 FAIL

This bit is set if limit margin 1 is violated.

LMARgin 7 FAIL

This bit is set if limit margin 7 is violated.

LMARgin 8 FAIL

This bit is set if limit margin 8 is violated.

8 to 14 not used

15 This bit is always 0.

1164.4556.12 5.28 E-1

Page 39

FSP Status Reporting System

STATus:QUEStionable:POWer Register

This register comprises all information about possible overloads of the unit.

It can be queried with commands STATus:QUEStionable:POWer:CONDition? and "STATus

:QUEStionable:POWer[:EVENt]?.

Table 5-10 Meaning of bits in STATus:QUEStionable:POWer register

Bit No. Meaning

0

1

2

3 to 7 not used

8

9

10

11 to 14 not used

15 This bit is always 0.

OVERload (Screen A)

This bit is set if the RF input is overloaded. 'OVLD' will then be displayed.

UNDerload (Screen A)

This bit is set if the RF input is underloaded. 'UNLD' will then be displayed.

IF_OVerload (Screen A)

This bit is set if the IF path is overloaded. 'IFOVL' will then be displayed.

OVERload (Screen B)

This bit is set if the RF input is overloaded. 'OVLD' will then be displayed.

UNDerload (Screen B)

This bit is set if the RF input is underloaded. 'UNLD' will then be displayed.

IF_OVerload (Screen B)

This bit is set if the IF path is overloaded. 'IFOVL' will then be displayed.

1164.4556.12 5.29 E-1

Page 40

Status Reporting System FSP

STATus:QUEStionable:SYNC Register

This register is used only with GSM MS mode. It contains inform ation about sync and bursts not found,

and about premeasurement results exceeding or falling short of expected values.

The bits can be queried with commands "STATus:QUEStionable:SYNC:CONDition?" and

"STATus:QUEStionable:SYNC[:EVENt]?".

Table 5-11 Meaning of bits in STATus:QUEstionable:SYNC register

Bit No. Meaning

0

1

2

3

4-14 Not used.

BURSt not found (screen A)

This bit is set if no burst is found in the measurements/premeasurement s for

phase/frequency error (PFE) or carrier power versus t i me (PVT) in GSM MS mode.

If a burst is found in t hese measurements/premeasurements, the bit i s reset.

SYNC not found (screen A)

This bit is set if the synchronization sequence (training sequence) of the midamble is not found in the

measurements/ premeasurements for phase/ frequency error (PFE) or carrier power versus time (PVT)

in GSM MS mode.

If the synchronization sequence (training sequence) of the midamble is found in these

measurements/ premeasurements, the bit is reset.

No carrier (screen A)

This bit is set if , in GSM MS mode, the level value determi ned i n the premeasurements for

carrier power versus time (PVT ) and spectrum due to modulati on i s too low.

The bit is reset at the beginning of the premeasurement

(see also Chapter 2, descript i on of the named premeasurement s).

Carrier overload (screen A)

This bit is set if , in GSM MS mode, the level value determi ned i n the premeasurements for

carrier versus time (P VT) and spectrum due to modul ation is too high.

The bit is reset at the beginning of the premeasurement

(see also Chapter 2, descript i on of the named premeasurement s).

15 This bit is always 0.