Page 1

Operation Manual

GuardShield

GuardShieldTM Safe 4

TM

Safe 4 PAC

Safety Light Curtain

Page 2

GuardShield Safe 4 Operation Manual

2

Page 3

Operation Manual GuardShield Safe 4

Please make sure you read and understand these requirements before you select and install

the GuardShield safety light curtain. GuardShield safety light curtains are point of operation

saf

eguarding devices. These safety light curtains are intended to be used to provide point of

op

eration safeguarding of personnel on a variety of machinery.

The GuardShield family of safety light curtains are general purpose presence sensing

devices which are designed to help protect personnel working on or near machinery.

The installation of the GuardShield safety light curtain must comply with all applicable

federal, state and local rules, regulations, and codes.

It is the responsibility of the employer to properly install, operate and maintain the product

as

well as the machinery on which the GuardShield presence sensing device is installed.

GuardShi

eld safety light curtains must be properly installed by qualified personnel.

GuardShi

eld safety light curtains are presence sensing devices and will not protect

personnel from heat, chemicals or flying parts. They are intended to signal a stop of

hazardous

machine motion when the sensing field is broken.

GuardShi

eld safety light curtains can only be used on machinery which can be stopped

anyw

here in it’s stroke or cycle.

GuardShi

eld safety light curtains should never be used on full revolution clutched

machinery.

The effectiveness of the GuardShield safety light curtains depend upon the integrity of the

machine control circuit. The machinery that the GuardShield presence sensing device is

ins

talled should have control circuitry that is fail safe in design.

All

stopping mechanisms for the machinery should be inspected regularly to provide proper

op

eration. The protected machinery must have a consistent reliable and repeatable stopping

time.

ATTENTION!Failure to read

and

follow these instructions can

lead

to misapplication or misuse

of

the GuardShield safety light

cu

rtains, resulting in personal

inju

ry and damage to equipment.

Conditions required for proper use of the

GuardShield Safety Light Curtain

3

Page 4

GuardShield Safe 4 Operation Manual

Content

1. Approvals and Conformity 4

2. Introduction 5

2.1. System design 5

2.2. Special features 5

3. Applications 5

3.1. Typical applications 5

3.2. Applications restrictions 6

3.3. Application conditions 6

3.3.1. Corner mirrors 6

4. Principles of operation 7

4.1. Mode of operation 7

4.2. Intelligent Laser Alignment System ILAS 7

4.3. LED indicators 7

4.4. Perimeter systems 7

4.5. Muting 7

5. Installation 8

5.1. Regulations and standards 8

5.1.1. IEC Safety distance to danger point 8

5.1.2. North American Safety distance formulas 8

5.1.3. Height of protective field 9

5.1.4. Response time – light curtain 9

5.1.5. Distance to reflective surfaces 10

5.1.6. Multiple light curtain arrangement 10

5.2. Mechanical installation 10

5.2.1. Mounting brackets 10

5.2.2. Intelligent Laser Alignment System ILAS 10

5.2.3. Adjustment Procedure without ILAS 12

5.2.4. Adjustment Procedure with ILAS 12

5.2.5. Remarks to ILAS 12

5.2.6. Testing the protection field 13

5.3. Electrical Installation 13

5.3.1. Connection diagram 13

5.3.2. Test input to transmitter 14

5.3.3. Power supply 14

5.3.4. Bringing into operation 14

5.3.5. Outputs 14

5.3.6. Trouble shooting 15

6. Interfacing to safety devices 15

7. Dimensional drawings 19

7.1. System with integrated controller 19

8. Selection of a safety light curtain 20

8.1. Check list 20

8.2. Selection table 20

8.3. Accessories / Components 21

9. Inspection and service 2

9.1. Cleaning 22

9.2. Inspections 22

9.3. Decommissioning 22

10. Product labels 22

11. Technical Data 2

1. Approvals and Conformity

TÜV Rheinland Product Safety GmbH, performed the

CE - type examination according to the machinery

directive EC/98/37, appendix VI and the respective

standards ICE 61496.

The CE - conformity declaration and the product

approval certification (TÜV) is available at your

nearest ROCKWELL AUTOMATION dealer or on the

home-page www.Rockwell Automation.com.

All ROCKWELL AUTOMATION products are

developed and manufactured following generally

accepted rules in industry and in compliance with a

total quality management system ISO 9001: 2000.

ATTENTION

GuardShield Safe 4 systems are only a safety

protection device if all instructions in this manual

and in the related documents are carefully followed

and fully complied with. In addition the installer

is responsible to comply with all local laws and

standards.

ATTENTION

Failure to follow all instructions in this manual and

related documents may lead to serious injury or

death. Rockwell Automation cannot be held liable

for any injury or death due to the negligence of the

purchaser or installer.

IMPORTANT

This instruction manual is part of the light curtain

GuardShield Safe 4. It must be kept accessible

during the whole life cycle for everybody who is in

charge of installation, operation, maintenance and

2

safety control.

3

4

Page 5

Operation Manual GuardShield Safe 4

Protection height

Intellig ent Laser Alig nment System ILAS

Intelligen t Laser Align ment System ILAS

Detection c apability

(resolution )

Operating range

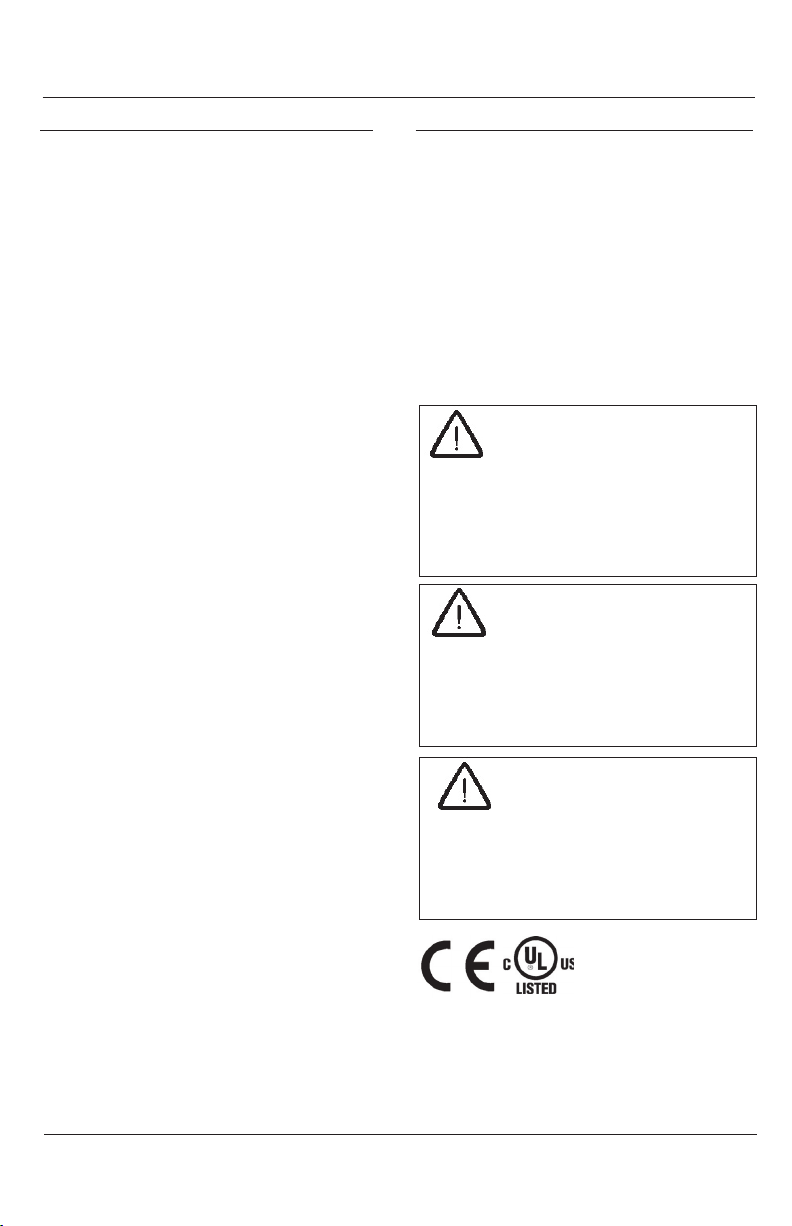

2. Introduction

GuardShield Safe 4 safety light curtains are active

optoelectronic protective equipment AOPE type 4

with object detection capability of 14 mm or 30 mm.

GuardShield Safe 4 has built-in fully redundant selfmonitoring circuitry and complies to annex VI of the

European Machinery Directive EC/98/37 and IEC

61496 as a safety component. GuardShield Safe 4 is

a control reliability device as well as defined in ANSI

B11.19-1990, 5.5 and OSHA 29 CFR 1910.212.

2.1. System design

GuardShield Safe 4 light curtains consist of a

transmitter and a receiver (Figure 1).

The transmitter as well as the receiver of GuardShield

Safe 4 have a standard built-in intelligent laser

alignment system ILAS.

This allows a much easier adjustment during installation

and system testing compared to conventional safety

light curtains. The ILAS may also be used as a

vibration indicator at the installation.

Finger (14 mm) and hand protection (30 mm)

Large range with a compact profile type:

14 mm resolution: 0 m to 6 m

30 mm resolution: 0 m to 6 m

Tolerant to dust, soiling, pollution

Short cir

cuit protected semiconductor

outputs

Built-in d

iagnostic LEDs

Very compact design: 30 x 40 mm (1.2” x 1.6”)

Optical syn

chronisation, no electrical

cable needed between transmitter and

receiver

Ma

intenance-free and cost effective

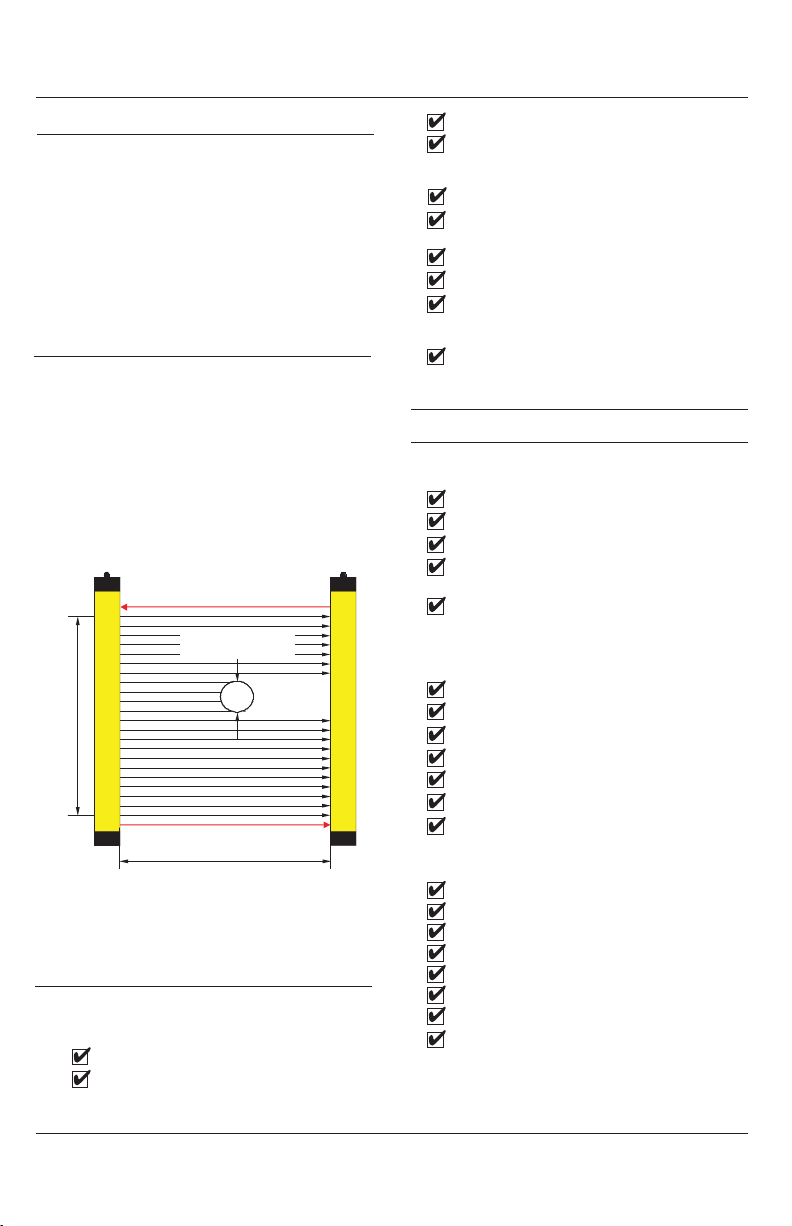

3. Applications

3.1. Typical applications

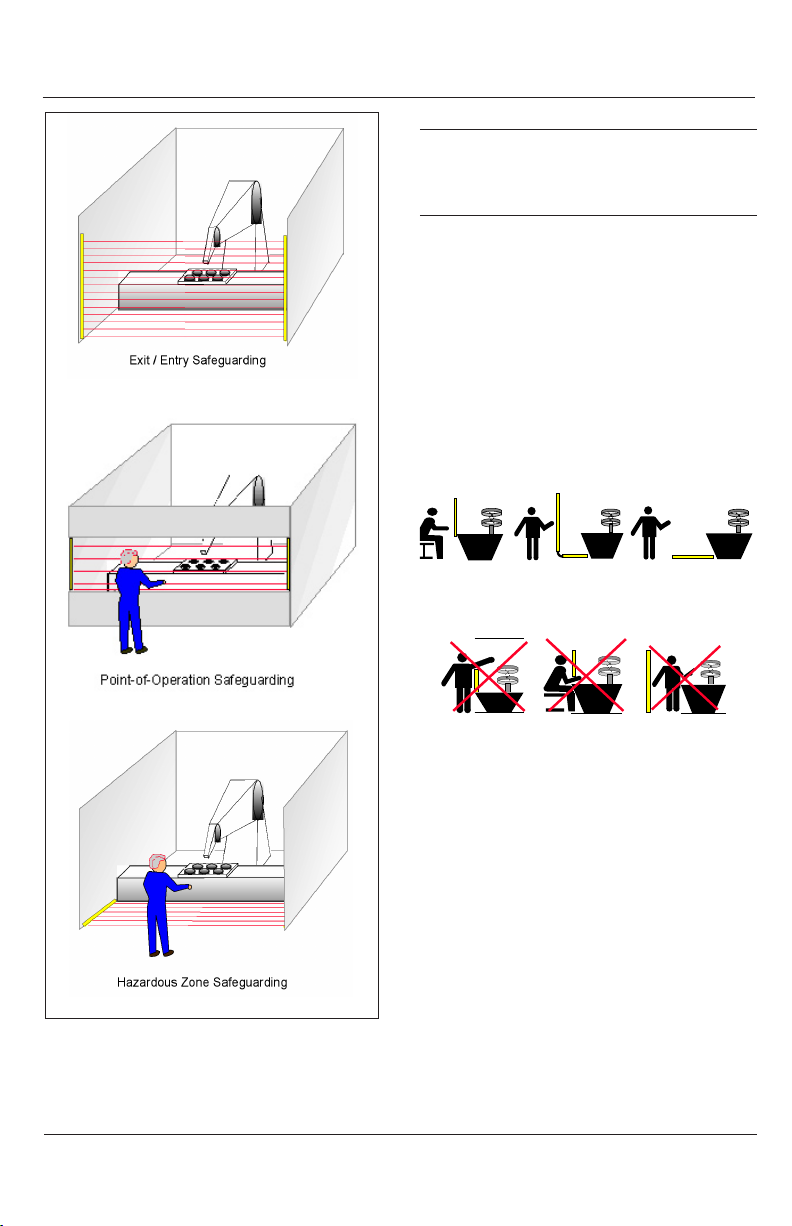

GuardShield Safe 4 systems are used for (Figure 2):

Entry / exit safeguarding

Poin

Hazards area safeguarding

Combination of entry and area

safeguading

Combination of entry, area and point-of-

operation safeguarding

Typical areas of applications are:

Robotic assembly line

Weldi

Processing machinery

Rotation machines

Conveyor machines

Automated paint shops

Entry / exit of au

t-of-operation safeguarding

ng robots

tomatic storage facilities

Figure 1: Main system parameters

The products are a modular construction housed in a

very compact and sturdy extruded aluminium profile.

2.2. Special features

The outstanding features of the safety light curtain

systems of the GuardShield Safe 4 are:

Integrated laser alignment (ILAS)

M

ax. 256 beams per system

Typical markets are:

Automotive

Appara

tus

Semi conductor industry

Metal processing

Paper processing

Wood processing

Glass manufacturing

Textile industry.

5

Page 6

GuardShield Safe 4 Operation Manual

3.2. Applications restrictions

GuardShield Safe 4 is not designed and approved for

any application in explosive EX or radioactive areas.

3.3. Application conditions

The safe application of the light curtain system

GuardShield Safe 4 needs certain precautions:

1. The control unit of the machine or system must

be able to be electrically stopped and the stop

time must be known.

2. The hazardous moving parts of the machine

must always be stoppable and must achieve a

safe position or complete standstill within the

specified stop time of the machine.

3. When installing GuardShield Safe 4, the only

way to access the hazard must be through the

sensing field of the GuardShield Safe 4.

Figure 3: Correct installation

Figure 4: Incorrect installation

For the professional installation and connection,

please consult the relevant laws and regulations.

The safety officer of the manufacturing facilities,

the local authorities (OSHA in USA, HSE in GB)

or the respective industry associations as well as

the intensively trained employees of ROCKWELL

AUTOMATION are available for any safety related

queries.

3.3.1. Corner mirrors

The protective field between transmitter and receiver

can be guided around a corner using a mirror to allow

safeguarding of two or three hazardous areas. Note

that using one mirror will help reduce max. operating

Figure 2: Typical Applications

6

range by approx. 15 %.

It is not recommended to use more than two mirrors

due to alignment difficulties that may occur.

Page 7

Operation Manual GuardShield Safe 4

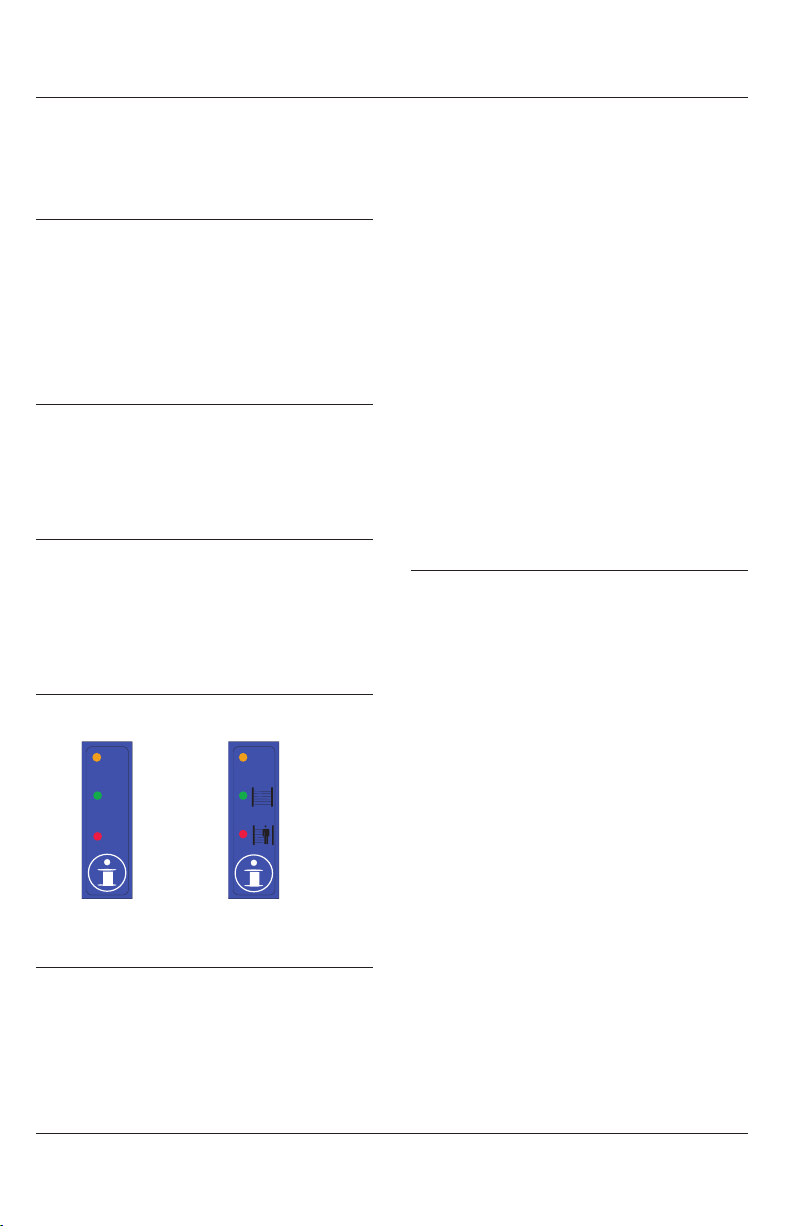

POWER

Transmitter

Power on

(orange)

POWER

Receiver

Power on

(orange)

Output active

(green)

Output inactive

(red)

OK

Normal operation

(green)

TEST

Test input

(red)

Optical

(IR light)

Optical

(IR light)

As accessories two types of mirrors are available,

with different mounting plates and sizes. Detailed

information is available from ROCKWELL

AUTOMATION.

4. Principles of operation

The transmitter sends coded infrared light pulses to

the receiver, which evaluates them. If an object e.g.

a finger (14 mm) or a hand (30 mm) penetrates the

protective field, the fully redundant solid state Output

Signal Switching Devices OSSD of the receiver switch

off to stop the machine. As soon as the protective field

is cleared, both outputs switch on again (automatic

restart).

4.1. Mode of operation

GuardShield Safe 4 operates in the guard only mode

with automatic restart. Other modes of operation e.g.

PSDI mode (break mode), muting, external relay

monitoring can be realized using external safety

devices.

4.2. Intelligent Laser Alignment System ILAS

The ILAS is a most convenient feature to make

alignment a pleasure. The ILAS can be activated at

any time during installation or operation. It provides

the possibility to check if the sensor is still perfectly

aligned. In addition it indicates any vibrations at the

mounting base.

4.3. LED indicators

The GuardShield Safe 4 PAC is a multiple beam

safety light curtain designed for perimeter or access

detection around hazardous machinery or equipment.

The Safe 4 PAC is offered in 2 or 3 beam configurations

with 360mm spacing between segments for a 2 beam

pair and 360mm spacing for 3 beam pairs. Both the 2

and 3 beam Safe 4 PACs have a 30 meter operating

range.

The clear front window of the Safe 4 PAC allows for

easy identification of the active sensing modules and

the Integrated Laser alignment system simplifies

the alignment of the Safe 4 PAC in long range and

complex applications.

The GuardShield Safe 4 PAC multi beam safety light

curtain may be used as an optical electronic fence;

detecting the presence of personnel as they pass

through the sensing field or for safe guarding access

to a hazardous area or machine process.

The protective field and the active elements

respectively, are clearly recognized as black surfaces

with the integrated optical lenses. The not monitored

areas (passive elements) are also clearly indicated as

yellow surfaces.

4.5. Muting

Muting of the GuardShield Safe 4 PAC is best

accomplished by connecting the Safe 4 PAC to an MSR

42 multi function safety module. The MSR 42 allows

two muting sensors to be connected for uni directional

muting. The muting sensors can be positioned on the

same side of the Safe 4 PAC in parallel for entry or

exit end muting of a machine process. The two muting

sensors may also be positioned in a crossed or X

configuration for bi directional muting.

Rockwell Automation offers a number of muting

solutions. Check with your local Rockwell Automation

office or Rockwell Automation authorized distributor for

muting application possibilities and muting application

notes.

Figure 5: LED Indicators

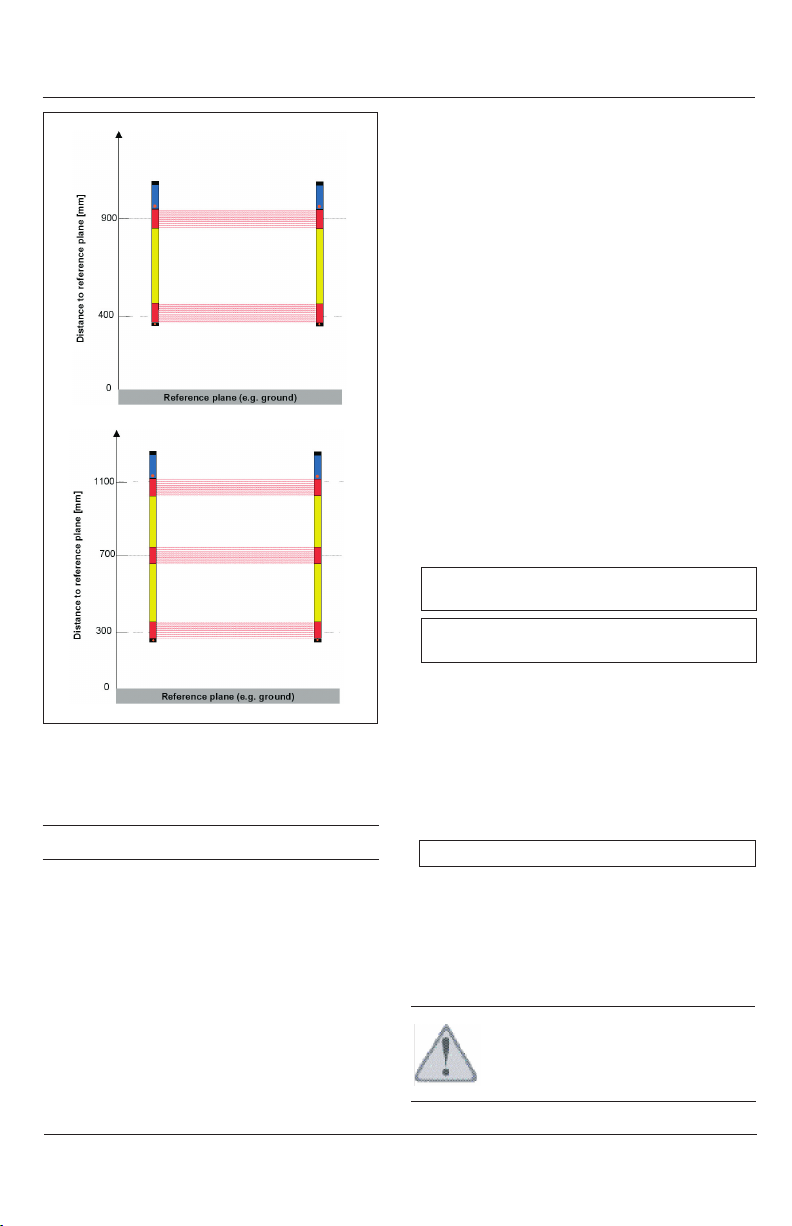

4.4. Perimeter systems

Perimeter systems are usually produced by means of

several single beam light barriers. But the flexibility

of the GuardShield Safe 4 system allows also the

production of vertical entry safeguarding according to

the standard EN 999. Such systems are composed of

active and passive elements in one compact profile.

The active length of each is 120 mm.

7

Page 8

GuardShield Safe 4 Operation Manual

AT T EN T IO N : T he G uardShield safety light

cur tains m ust b e m ount ed at a sufficien t

distance from th e pinch point or po int o f

op erat ion hazar d to help ensure that th e mac hine

stops be fore a pe rson’s finger, hand, ar m(s),

or bo dy r eaches the hazar d.

5.1.1. IEC Safety distance to danger point

According to the standards, the GuardShield Safe 4

light curtain and the point of danger must be separated

by a defined safety distance. This minimum distance

safeguards that the danger point may only be reached

after the hazardous motion has stopped. The safety

distance (see also standards EN 294, EN 775, EN

811, EN 999) depends on

• Machine stop time

• Response time of the protective device (light

curtain + safety relays)

• Resolution of the protective device

• Approaching speed to the danger point

• Position of the AOPD

The approaching speed is dependent on safety

distance S as follows

S ≤ 500 mm, speed = 2 mm / ms

S > 500 mm, speed = 1.6 mm / ms

In cases of ‘vertical’ installation of the light curtains

within an industrial environment and a resolution of

Figure 6: Perimeter Systems

(2 and 3 beams), accord. to EN999 (1998)

5. Installation

5.1. Regulations and standards

The compliance with the fundamental health & safety

requirements as detailed in the EU Machinery Directive

EC/98/37 and control reliability according to OSHA 29

CFR 1910.212, ANSI B11.19 and ANSI B11.20 has to

be achieved with the correct implementation of safety

components. With the help of a hazard analysis as

laid out in EN 292 and EN 1050, a comprehensive

safety evaluation has to be made when designing and

planning machinery and machinery control equipment.

If Active Optoelectronic Protective Devices (AOPD)

are used, the required safety distances, sufficient

protective height and all application conditions must

be considered during the planning phase.

the light curtain system

mm), the safety distance

calculated according to the formula:

For 100 mm ≤ S ≤ 500 mm:

S = 2 mm / ms x T + 8 x (d - 14)

For S > 500 mm

S = 1.6 mm / ms x T + 8 x (d - 14)

S = Safety distance in mm

T = Total response time in ms

(machine stop time + Safe2+ / Safe4

response time + safety relay response time)

d = Resolution of GuardShield Safe 4 in mm

In the case of perimeter systems (chapter 4.5) or light

curtains with a resolution

is calculated for vertical mounted light curtains and

horizontal approach, according to the formula:

S = 1.6 mm / ms x T + 850 [mm]

More detailed information regarding safety distance

and safety height can be found in EN 999 or EN 294,

depending on mounting type of application.

5.1.2 North American Safety Distance Formulas

US Safety Distance Formula

d, (where 14 mm ≤ d ≤ 40

S to the point of danger is

d > 40 mm the safety distance

8

Page 9

Operation Manual GuardShield Safe 4

This distance, referred to as the safety distance, must

be properly calculated prior to determining the safety

light curtain protective height and mounting the light

curtains on the machine. Failure to properly calculate

this safety distance may result in operator injury.

In the United States there are two formulas that are

used to properly calculate the safety distance. The

first, the OSHA formula, is the minimum requirement

for the calculation of the safety distance. The

second formula, the one recommended by Rockwell

Automation, is the ANSI formula, which incorporates

additional factors to be considered when calculating

the safety distance.

OSHA Safety Distance Calculation Formula

The OSHA safety distance formula as specified in

CFR Subpart O 1910.217 is as follows:

Ds = 63 X T

Ds Safety Distance

63 Is the OSHA recommended hand speed

S

constant in inches per second

TS Is the total stop time of all devices in

the safety circuit, measured in seconds.

This value must include all components

involved in stopping the hazardous motion

of the machinery. For a mechanical power

press it is the stopping time measured

at approximately the 90o position of the

crankshaft rotation.

Note: The T

number must include the response

S

times of all devices, including the response

time of the safety light curtain, the safety light

curtain controller (if used), the machine’s

control circuit and any other devices that react

to stop the hazardous motion of the machinery.

Not including the response time of a device or

devices in the stop time calculation will result in

insufficient safety distance for the application.

This may result in operator injury.

The ANSI Safety Distance Formula

The ANSI safety distance formula, which is the

Rockwell Automation recommended formula, is as

follows:

DS = K x (TS + TC + Tr + Tbm) + D

Ds Minimum safety distance between the safe

guarding device and the nearest point of

pf

operation hazard, in inches.

K Hand speed constant in inches per second.

The ANSI standard value is 63 inches per

second when the operator begins reaching

toward the point of operation hazard from rest.

NOTE: ANSI B11.19 1990 E4.2.3.3.5 states

“The value of the hand speed constant, K,

has been determined by various studies and

although these studies indicate speeds of 63

inches/second to over 100 inches/second,

they are not conclusive determinations. The

employer should consider all factors, including

the physical ability of the operator, when

determining the value of K to be used.”

Ts Stop time of the machine tool measured at the

final control element.

Tc Response time of the control system.

Note: TS and TC are usually measured by a stop time

measuring device.

Tr Response time of the presence sensing device

(safety light curtain) and its interface, if any.

This value is generally stated by the device

manufacturer or it can be measured by the

user.

Tbm Additional time allowed for the brake monitor to

compensate for variations in normal stopping

time.

Dpf Depth penetration factor. It is an added

distance to allow for how far into the protective

field an object, such as a finger or hand, can

travel before being detected. D

to the safety light curtain’s object sensitivity.

is related

pf

Object sensitivity is the smallest diameter

object which will always be detected anywhere

in the sensing field.

5.1.3. Height of protective field

The protective field is clearly visible as the black

area with the optical lenses on the transmitter and

receiver.

In addition the height of the protective field A is found

on the label of each system and in the selection tables,

described in chapter 8.2 (resolution 14 and 30 mm).

ATTENTION

The laser beams of the ILAS are not

part of the protective field.

Use only the protective field as

mentioned on the product label.

Otherwise serious injury or death may

occur.

5.1.4. Response time – light curtain

The response time t

from the selection tables 8.2.

is found on the product label, or

R

9

Page 10

GuardShield Safe 4 Operation Manual

Receiver

Transmitter

Transmitter

Receiver

Transmitter

Receiver

TransmitterReceiver

dangerous point

reflective surface

E

R

optical axis

S

2

R

5.1.5. Distance to reflective surfaces

Reflective surfaces may cause reflections within

the transmitter and receiver aperture angle, i.e.

an interruption of the protective field would not be

recognized (Figure 7).

Figure 7: Distance to reflective surfaces

Should reflective surfaces arise, i.e. aluminium

container passing near the light curtain or if the

danger point itself is reflective, i.e. a steel blade, the

safety distance S

reflective surface lies within the distance S

The increase of the safety distance is dependant of

must be increased, such that no

2

.

2

the actual operation range R according to IEC 61496

and may be calculated as follows:

Safe4

S2 = 72 mm for R < 3 m

S2 = R x 0.0219 for R ≥ 3 m

5.1.6. Multiple light curtain arrangement

When using several optoelectronic safety devices

in the same application, the systems should be

installed in such a way that they cannot interfere

with each other. Care must be taken that each

receiver only receives light from its own transmitter

(Figure 8).

The safety light curtain has been thoroughly

tested against light interferences according to the

stringent requirements of IEC 61496. Nevertheless

any direct interference into the receiver with other

infrared sources like through beam photoelectric

sensors, laser scanner, transmitters etc. should be

avoided.

5.2. Mechanical installation

Be aware that a rigid, flat base, isolated against

shock and vibration should be selected to mount

the GuardShield Safe 4. This in combination with

the standard mounting brackets set will keep the

initial alignment during operation even in harsh

industrial environments.

5.2.1. Mounting brackets

The backside of the light curtain profile has

continuous grooves to attach the mounting

brackets at any position along the light curtain

housing (Figure 18).

Each system is delivered with four mounting

brackets.

Optional available mounting brackets (Figure 9):

• Vertical mounting brackets for mounting the

light curtain in the vertical axis of the light

curtain. (± 4o adjustable)

• POC and SICK FGS mounting profiles (not

adjustable

The mounting brackets contain all necessary

mounting parts and a separate instruction sheet

to help ensure that the parts are assembled

properly.

Figure 8: Multiple light curtain arrangement

10

5.2.2. Intelligent Laser Alignment System ILAS

WARNING: Class 2 Laser

Do not expose your eyes to the

laser beam to prevent exposure to

dangerous radiation!

ILAS off if not used!

Turn

To switch on ILAS:

• Touch the hand symbol

Operation: Laser beam is blinking

To switch off ILAS

:

• Touch the hand symbol again

• Automatically after 5 minutes

Page 11

Operation Manual GuardShield Safe 4

11

M6 x 40

M4 x 16

29

M4 x 12

M6 x 40

77

3.031

37

1.457

36.4

1.433

37

1.457

43.6

1.717

M4

40

1.575

70

2.756

36.4

1.433

25

0.984

8

0.315

R2.8

0.108

5.5

0.217

M4x30

445L-AF6140

Standard mounting brackets

• For side mounting

• Adjustable by ± 4°

445L-AF6144

Vertical mounting brackets (optional)

• For mounting in the vertical

axis of the light curtain

• Adjustable by ± 4°

445L-AF6141

180° Mounting, rotation ±

90°, for applications where

the mounting angle is not

set using the mounting

frame.

(2 brackets per kit)

Figure 9: Different mounting brackets for a GuardShield Safe 4

11

Page 12

GuardShield Safe 4 Operation Manual

Incorrect

Correct

Transmitter

Receiver

Transmitter

Receiver

5.2.3. Adjustment Procedure without ILAS

1. Mount the transmitter and the receiver with

the adjustable mounting brackets. Make

sure that the longitudinal axis of both are

oriented parallel. A spirit level might help to

find the correct position.

2. Take care that the receiver and transmitter

are oriented in the same direction. This

means, the controllers of the transmitter

and receiver have to be at the same end of

the protective field.

It is not allowed to mount GuardShield Safe

4 systems turned by 180° (Figure 10)

Figure 10: Layout of the transmitter / receiver

3. After aligning the longitudinal axis of transmitter

and receiver, rotate the receiver around the

longitudinal axis to find the receiving angle.

During rotation, the receiving angle is shown

when the green LED of the receiver controller is

on.

4. Adjust the receiver to the centre point of the

operating angle, and tighten.

5. After aligning the receiver rotate the transmitter

to find the emitting angle. During rotation, the

emitting angle is shown when the green LED of

the transmitter controller is on.

6. Adjust the transmitter to the centre point of the

operating angle, and tighten.

7. Control the operation of the GuardShield Safe

4 light curtain by using the test rod (

Figure

12). Introducing the test rod into the protective

field at any position must lead to a protective

field interruption (shining of the red LED on the

receiver).

5.2.4. Adjustment Procedure with ILAS

1. Mount the transmitter and the receiver with the

adjustable mounting brackets. Look for that the

longitudinal axis of both are oriented parallel.

Take care that receiver and transmitter are

oriented in the same direction. This means, the

controllers of transmitter and receiver have to be

at the same end of the protective field. It is not

allowed to mount GuardShield Safe 4 systems

turned by 180° (Figure 10).

2. The ILAS is activated by touching the hand

symbol at the transmitter and at the

receiver.

3. Adjust the transmitter and receiver in a way

that both laser points hit the laser target on the

opposite unit. Small deviations are harmless as

long as they are within the aperture angle.

4. Tighten all screws firmly.

5. Switch the ILAS off when aligned.

6. Control the operation of the light curtain by using

the test rod (Figure 12). Introducing the test rod

into the protective field at any position must lead

to a protective field interruption (shining of the

red LED on the receiver).

5.2.5. Remarks to ILAS

Due to dimensional tolerances the red ILAS light spot

deflects from the target center when the light curtain

is aligned optimally in the center of the operating

range. The optimal operating point can be found after

alignment with ILAS (chapter 5.2.4) when moving the

axis in X- (left, right) and Z- (up, down) direction. The

optimal operating point is in the middle of the two end

points, where the receiver output switches from active

to inactive condition.

When mounting Perimeter Systems adjust the heights

according to the recommendations in the relevant

standard, i.e, EN 999, ANSI/RIA 15.06 etc.

12

Page 13

Operation Manual GuardShield Safe 4

R

D

On optimal alignment of the light

curtain the ILAS light point can deflec t

from the ILAS target point. The

maximum deflection adds up to the

following value due the operating

distance:

2 m R = 7 mm D = 7 mm

6 m R = 20 mm D = 21 mm

9 m R = 30 mm D = 32 mm

18 m R = 60 mm D = 63 mm

30 m R = 99 mm D = 105 mm

Transmitter

Receiver

1) Operation with internal test

2) Test using a relay contact

3) Test using a PNP output

+24 VDC

0 V

1

2

3

4

Not connected

5

6

7

1)

3)

2)

Not connected

+24 VDC

0 V

1

2

3

5

4

6

7

R

L

R

L

OSSD 1

OSSD 2

Not connected

Not connected

Transmitter

Receiver

3

= 0 V

4

= Test 1

1

= + 24 VDC

2

= Test 2

Pin 5

= PE

Transmitter:

3

= 0 V

4

= OSSD 1

1

= + 24 VDC

2

= OSSD 2

5

= PE

Receiver:

Pin

Pin

Pin

Pin

Pin

Pin

Pin

Pin

Pin

Figure 11: Adjustment with ILAS

5.2.6. Testing the protection field

After Installation and Alignment of the GuardShield

Safe 4 safety light curtain, the protection field has

to be tested with the test rod for the corresponding

resolution (14 or 30 mm) according Figure 12.

Figure 12: Correct testing of the protective field

using a test rod

5.3. Electrical Installation

5.3.1. Connection diagram

The transmitter and receiver are connected to the

machine control using a 5-wire cable.

For the transmitter and the receiver two M12 (for

cable - Ø 3 ... 6.5 mm) are supplied.

Figure 13: Terminal block connection (see also

Figure 18)

Figure 14: M12/5 Pin connector

13

Page 14

GuardShield Safe 4 Operation Manual

+24 VDC

0 V

OSSD 1

OSSD 2

+24 VDC

0 V

1) Operation with internal test

2) Test using a relay contact

3) Test using PNP output

Transmitter

3)

3)

2)

2)

PE

Pin 1 (brown)

Pin 3 (blue)

Pin 4 (black)

Pin 2 (white)

Pin 5 (grey)

Receiver

PE

Pin 1 (brown)

Pin 3 (blue)

Pin 4 (black)

Pin 2 (white)

Pin 5 (grey)

1)

1)

Test 1

Test 2

Test input

OSSD 1 / OSSD 2

t

2

t

3

t

1

open

short circuit ed

Figure 16: Test timing diagram

tR means the response time of the respective

GuardShield Safe 4 type (see product label).

Internal test Description Value

Continuous test current I 10 mA

Figure 15: Wiring of the connecting cables of the

M12/5 Pin connector

Transmitter and receiver are supplied with M12/5 pin

connectors. The wiring of such connecting plugs is

given in Figure 14 and Figure 15.

5.3.2. Test input to transmitter

Normally the test input at the transmitter is installed

with a short circuit jumper to activate the transmitter. If

an external test is desired, a contact can be connected

to the test input (Figure 13).

The following points have to be considered:

• In case of operation in the modus “self

monitoring” both OSSD outputs have to be

connected separately to the safety switching

of the machine.

The timing of test input is as follows (Figure 16):

Time Value in ms

Response time on test signal t

Time to test t

Restart time after test t3 ≤ 800

≤ tR + 15

1

> t

2

1

Peak test current I

Time of peak test current t

Internal test Transmitter Test LED

Transmitter

Short circuited (closed) Active Green

Open Inactive Red

5.3.3. Power supply

GuardShield Safe 4 are devices of electrical safety

level III (extra low voltage). 24 VDC ± 20 % has to be

supplied by a power supply that complies with IEC /

EN 60204 and IEC / EN 60742. Such a power supply

meets the electrical safety requirements and maintains

the minimum power of 18 VDC during 20 ms even in

the event of voltage dips

5.3.4. Bringing into operation

After the power has been applied to the GuardShield

Safe 4 and the automatic power-up test is successfully

completed (power up test time < 3 s) the green LED on

the receiver and transmitter will light on. The system is

now ready to operate.

The automatic power-up test will only be successful,

if the transmitter and receiver are properly aligned,

correctly connected and the protective field is not

interrupted.

Any intrusion of an object into the protective field will

switch the OSSD off within the specified response

time and the LED at the receiver toggles from green

to red.

100 mA

P

20 µs

P

14

5.3.5. Outputs

The two redundant Output Signal Switching Devices

(OSSD) are fully monitored. Any short circuits are

detected. The maximum load is 0.4 A, higher currents

are limited through short circuit protection. Increased

output loads may be realized using external safety

interfaces.

Page 15

Operation Manual GuardShield Safe 4

Important information:

Safety devices for connection of GuardShield Safe 4 must

be built with PNP logic. The outputs will be periodically

controlled for short-circuit and cross-fault detection.

The output voltage at the solid-state outputs is

dependant on the power supply and the output load

(see chapter 11 Technical Data).

5.3.6. Trouble shooting

Possible errors and operation status are indicated with

the LED indicators on the transmitter and receiver.

Following combinations are relevant:

Table 1: Transmitter

Status LED

Orange

Green Red

(Power) (ok) (Test)

No power supply off off on

(external)

Test input closed on on off

(external)

Test input open on off on

(external)

Controller error flashing off on

(internal)

Protective field error flashing off flashing

(internal)

Table 2: Receiver

Status LED

Orange

field not field

No power supply off off off

(external)

No sufficient power on off off

(external)

OSSD on (on-load operation, on on off

protective field not interrupted,

normal)

OSSD off (off-load operation,

protective field interrupted or

insufficient alignment of the

system)

OSSD error (external, short all 3s

circuit between OSSD 1 and short time off flashing

OSSD 2, towards 0 V and off

24 VDC)

Controller error (internal) irregular off on

flashing

Protective field error (internal) flashing off flashing

flashing off on

Green Red

(Power) (Protective (Protective

interrupted) interrupted)

External error: An external interface error can be

resolved by correcting the installation, due to

1. Receiver: short circuit of both OSSDs, of OSSD

to Usp, of OSSD to GND

2. Transmitter: Test input open

3. None or too low power supply

4. Inadequate adjustment of transmitter and

receiver

Internal error (orange LED is irregularly flashing):

Please contact the nearest ROCKWELL

AUTOMATION representative.

Normal operation

Transmitter Receiver Operation status

Test input closed OSSD on Protective field free

Test input closed OSSD off Protective field interrupted

Test input open OSSD off Test active

6. Interfacing to safety devices

The interfacing of the light curtain with the machine

control has to be control reliability, i.e. a correct

interface with a safety PLC or safety relays with

positive guided relay contacts.

Figure 17 - Diagram for automatic reset mode shows a diagram of a typical emergency stop relay

component.

Other applications are mentioned in the application

note “Safety Interfaces with GuardShield Safe 4”, on

the ROCKWELL AUTOMATION homepage.

ATTENTION

The safety devices and the interconnection to

the machinery have to comply with the basic

safety requirements as mentioned in the current

regulations and standards.

Direct interfacing of a safety light curtain to

machine control that does not meet the necessary

safety integrity level, i.e. use of general purpose

PLCs or general purpose relays can cause serious

injury or death of persons.

If necessary, c

onsult a professional safety

engineer!

15

Page 16

GuardShield Safe 4 Operation Manual

Figure 17: Safe 4 or Safe 4 PAC for Automatic Reset mode using MSR 126T safety relay module

Figure 18: Safe 4 or Safe 4 PAC for Monitored Manual Reset mode using MSR 126R safety relay module

16

Page 17

Operation Manual GuardShield Safe 4

Figure 19: Safe 4 or Safe 4 PAC for Automatic Reset mode using MSR 127TP safety relay module

Figure 20: Safe 4 or Safe 4 PAC for Monitored Manual Reset mode using MSR 127RP safety relay module

17

Page 18

GuardShield Safe 4 Operation Manual

120

4.724

240

9.449

120

4.724

240

9.449

120

4.724

360

14.173

120

4.724

120

4.724

passive

activeactive

active

passive

1.177

29.9

4

0.157

1051

41.378

40

1.575

40

1.575

active active

passive

1.177

29.9

4

0.157

810.5

31.909

All dimensions:

mm [inch]

Blatt1

Part Name

Part No.

1/2

Change No.

Standard Tolerance

1

Scale

Page

Material Surface Treatment

Material Specification

Surface Treatment

1:5

CWI

RIC/SEG

Approved

Designed

25.02.09

25.02.09

Standard Tolerances

Release No.

Change Date

Changed by

2 3 4 5 6 7 8 9 10 11

06.04.09

RIC

Figure 21: Safe 4 or Safe 4 PAC for Two Sensor Muting using MSR 42 multi-function safety module

and MSR 45 E safety relay expansion module

Figure 22: Safe 4 PAC - 2 and 3 passive elements

18

Page 19

Operation Manual GuardShield Safe 4

57

35

M16

M12

145

ILAS Emitter

ILAS target

25

A

ILAS target

ILAS Emitter

3

B

Start of protective field

30

40

Pin 1

Pin 7

4

3

2

Cross section with

connector pinning

Transmitter Receiver

Detail

mounting groove

7. Dimensional drawings

7.1. System with integrated controller component

Figure 23: Dimensional drawing, cross Section with Pin-out of connector

19

Page 20

GuardShield Safe 4 Operation Manual

8. Selection of a safety light curtain

8.1. Check list

In consideration of following points the selection of a

proper GuardShield Safe 4 safety light curtain will be

simplified:

1. Regulations

Look up carefully the actual regulations and

codes applicable to the particular application in

your country. Local authorities and professional

organisations as well as ROCKWELL

AUTOMATION representatives will provide

necessary assistance.

USA: Occupation Safety and Health

Administration OSHA, others like ANSI, RIA and

further professional organisations

GB: Health and Safety Executive HSE, safety

con-sultants and professional organisations.

8.2. Selection table

Table 3: 14 mm resolution with ILAS

Catalog No. Protective Total length B Response time tR Max. range Resolution Weight per pair

height A

(mm)

445L-P4L0120YD 120 290 10.5 6 14 1.0

445L-P4L0240YD 240 410 15.8 6 14 1.4

445L-P4L0360YD 360 530 21.1 6 14 1.8

445L-P4L0480YD 480 650 26.3 6 14 2.2

445L-P4L0600YD 600 771 31.6 6 14 2.6

445L-P4L0720YD 720 891 36.9 6 14 3.0

445L-P4L0840YD 840 1’011 42.2 6 14 3.5

445L-P4L0960YD 960 1’131 47.5 6 14 4.0

445L-P4L1080YD 1’080 1’252 52.8 6 14 4.0

445L-P4L1200YD 1’200 1’372 58.1 6 14 4.5

445L-P4L1320YD 1320 1492 63.4 6 14 5.0

445L-P4L1440YD 1440 1612 68.7 6 14 5.5

445L-P4L1560YD 1560 1733 74.0 6 14 6.0

445L-P4L1680YD 1680 1853 79.3 6 14 6.5

445L-P4L1800YD 1800 1973 84.6 6 14 7.0

445L-P4L1920YD 1920 2145 89.9 6 14 7.5

(mm) (ms) (m) (mm) (kg)

2. Protective field

Determination of

• required operating range,

• protective height (available in increments

of 120 mm),

• resolution (object detection capability: 14

mm or 30 mm)

Operating range and protective height must

be chosen so that the danger points are only

accessible through the protective field.

3. Response time

The response time t

4 can be found on the product label and in the

selection table (next section).

4. Corner mirrors

Using corner mirrors allows safeguarding of two

or three protective fields with one light curtain.

Each corner mirror helps reduce the operating

range by approximately 15 % per mirror.

of a GuardShield Safe

R-BWS

20

Page 21

Operation Manual GuardShield Safe 4

Table 4: 30 mm resolution with ILAS

Catalog No. Protective Total length B Response time tR Max. range Resolution Weight per pair

height A

(mm)

445L-P4S0120YD 120 290 7.8 6 30 1.0

445L-P4S0240YD 240 410 10.5 6 30 1.4

445L-P4S0360YD 360 530 13.1 6 30 1.8

445L-P4S0480YD 480 650 15.8 6 30 2.2

445L-P4S0600YD 600 771 18.4 6 30 2.6

445L-P4S0720YD 720 891 21.1 6 30 3.0

445L-P4S0840YD 840 1’011 23.7 6 30 3.5

445L-P4S0960YD 960 1’131 26.3 6 30 4.0

445L-P4S1080YD 1’080 1’252 29.9 6 30 4.0

445L-P4S1200YD 1’200 1’372 31.6 6 30 4.5

445L-P4S1320YD 1’320 1’492 34.3 6 30 5.0

445L-P4S1440YD 1’440 1’612 36.9 6 30 5.5

445L-P4S1560YD 1’560 1’733 39.6 6 30 6.0

445L-P4S1680YD 1’680 1’853 42.2 6 30 6.5

445L-P4S1800YD 1’800 1’973 44.9 6 30 7.0

445L-P4S1920YD 1920 2’093 47.6 6 30 7.5

Table 5: Safe 4 PAC with ILAS

Safe 4 PAC Part Numbers

Catalog No. Protective Total length Response Max. range Beam Spacing Number Weight per

height mm (in)

445L-P4S2500YD 600 (23.6 ) 811(31.9) <_ 10.5 30 500 (19.7) 2 4

445L-P4S3400YD 840 (33.0) 1051 (41.4) <_ 13.1 30 400 (15.7) 3 4.5

For further information, dimensional drawings in different file formats are available on our ROCKWELL AUTOMATION

homepage.

8.3. Accessories / Components

(mm) (ms) (m) (mm) (kg)

mm (in) time tR (ms) (m) mm (in) of Beams pair (kg)

Table

6 - Corner Mirror

GuardShield Safe 2 / Safe 4 Narrow Corner Mirror, Catalog Number Wide Corner Mirror, Catalog Number

Protective Height (mm) short range 0...4M Long range 4...15M

120 / 240 440L-AM0750300 440L-AM1250300

360 440L-AM0750450 440L-AM1250450

480 440L-AM0750600 440L-AM1250600

600 440L-AM0750750 440L-AM1250750

720 / 840 440L-AM0750900 440L-AM1250900

960 440L-AM0751050 440L-AM1251050

1080 440L-AM0751200 440L-AM1251200

1200 440L-AM0751350 440L-AM1251350

1320 / 1440 440L-AM0751500 440L-AM1251500

1560 440L-AM0751650 440L-AM1251650

1680 440L-AM0751800 440L-AM1251800

1800 / 1920 None Available None Available

21

Page 22

GuardShield Safe 4 Operation Manual

Table 7

ROCKWELL AUTOMATION Description

Part No

445L-AF6140 Standard mounting kit (4 pieces)

445L-AF6141 Adjustable mounting kit

445L-AF6142 Shock mount kit

445L-AF6144 Mounting kit for POC AND Sick FGS adapter (4 pieces)

445L-AF6150 Optical Interface (incl. software)

9. Inspection and service

All light curtains contain only electronics and therefore

need limited preventive maintenance.

9.1. Cleaning

The optical windows are to be cleaned with nonaggressive materials only. The interval between

cleaning is dependant on the operating environment

at the installation.

9.2. Inspections

The light curtain must, depending on the valid

regulations, be periodically tested by qualified and

trained persons.

The function of the light curtain can be tested with the

supplied test rod, which has a diameter corresponding

to the resolution of the light curtain. The status is

indicated through the LED display in the ROCKWELL

AUTOMATION GuardShield Safe 4 light curtain.

.

ATTENTION

Do not use aggressive solvents or abrasive

substances. Otherwise range reduction

and false switching could arise.

9.3. Decommissioning

The safety light curtain may only be removed, if the

machinery or assembly line will be closed definitively.

This has to be done by removing the main supply

from the machinery. It must be impossible to bring the

machinery into operation without using tools.

The light curtain can be reused provided the current

regulations are taken into consideration.

If the light curtain has to be disposed, it can easily

be disassembled and recycled using state of the art

recycling technology and following current disposal

regulation. It does not contain harmful materials

except small quantities of materials used in electronic

PCBs.

10. Product labels

All relevant ratings are given on the 2 product labels.

The labels are attached to the receiver as well as the

transmitter light curtain.

Functional Test

The function of the light curtain can be tested using

the test rod, (Figure 12), which has a diameter

corresponding to the resolution of the light curtain.

The status is displayed at the 3 LEDs at the transmitter

and receiver. The status can be easily read from

the trouble shooting labels “Transmitter Status” and

“Receiver Status” (table 1 and 2, page 15).

22

Page 23

Operation Manual GuardShield Safe 4

11. Technical Data

Table 8

Description Value Remarks

Protective heights 120 mm to 1920mm 120mm increments

Operating range 0 ... 9 m Resolution 14 mm

0 ...6m Resolution 30 mm

Object detection capability 14 mm

(Resolution) 30 mm

Power supply Usp 24 VDC ± 20 % PELV, IEC 60 204-1

Power supply ripple < 10 % of U

Equipment Class III VDE 0106 part 100

Time for self check when switching on U

< 3 s

sp

Current consumption < 500 mA No-load operation

Outputs, short circuit proof 2 x PNP, 0.3 A Max. capacitive load 0.5 µF

Output voltage > U

Response time t

Selection table Page 18

R-BWS

sp

Connector M12 qd

Connection cable Max length 5 m

Cross section max. 1.5 mm

Outside diameter of cable 3 ... 6.5 mm for M12

Mode of operation Guard only with automatic restart

Safety category Type 4 Self testing

Standards IEC 61496 part1+2

Electromagnetic compatibility (EMC) IEC 61 496 part 1

Enclosure rating IP65

Temperature range 0 ... +55°C

-20 ... +60°C Storage / transport

Relative air humidity 15 ... 95 % Non condensing

Enclosure Aluminum profile 30 x 40 mm

Optical window Polycarbonate, bonded

Enclosure treatment Polyester powder coated Silicon free manufactured

ILAS Laser class 2 EN 60 825

Dimensions Dimensions and selection tables Page 17 + 18

Weight Selection tables Page 18

PAC operating range 0 - 30m 2 and 3

sp

– 1 Load 0.1 A

2

Operation with ILAS

segments

23

Page 24

Please contact us for T echnical Assistance:

In

the U.S.: 1-440-646-5800

Outside U.S.: 001-440-646-5800

On

line: http://www.ab.com/safety

P N -

29484

10000026005 Ver 01

April 2009

Loading...

Loading...