Page 1

ICS Regent

®

PD-6021

AC Guarded Digital Output Module

110 VAC

(T3464)

Issue 1,

AC Guarded digital output modules provide guarded

switching of user-supplied 110 AC voltages to a maximum of

sixteen field loads. These modules are called Guarded

because no single fault within a module will inadvertently

apply power to an output. Extensive fault detection and

critical redundant circuits ensure that the module operates in

a fail-safe manner.

Features

March, 06

·

Sixteen Guarded output circuits configured as two separately

powered groups of eight circuits each.

·

Fault tolerant operation when connected in parallel with

another module of the same type.

·

Hot-replace

·

100% self-test of all critical circuits.

·

Zero-cross load switching.

·

Individual front panel indicators on each module show

active/fault and output on/off status (field side). A diagnostic

message display provides additional status indicators.

·

Fuses accessible from front panel.

·

2500 volt minimum electrical isolation between field and l

circuits.

·

TÜV certified, Risk Class 5, see Safety Considerations.

Two Guarded output modules can be connected in parallel to

obtain fault tolerant control of power to loads. In this parallel

module configuration, either module can be removed and

able.

ogic

Industrial Control Services

1

Page 2

AC Guarded Digital Output Module

replaced while the other Guarded module continues to control

the loads without interruption.

(T3464)

Module Operation

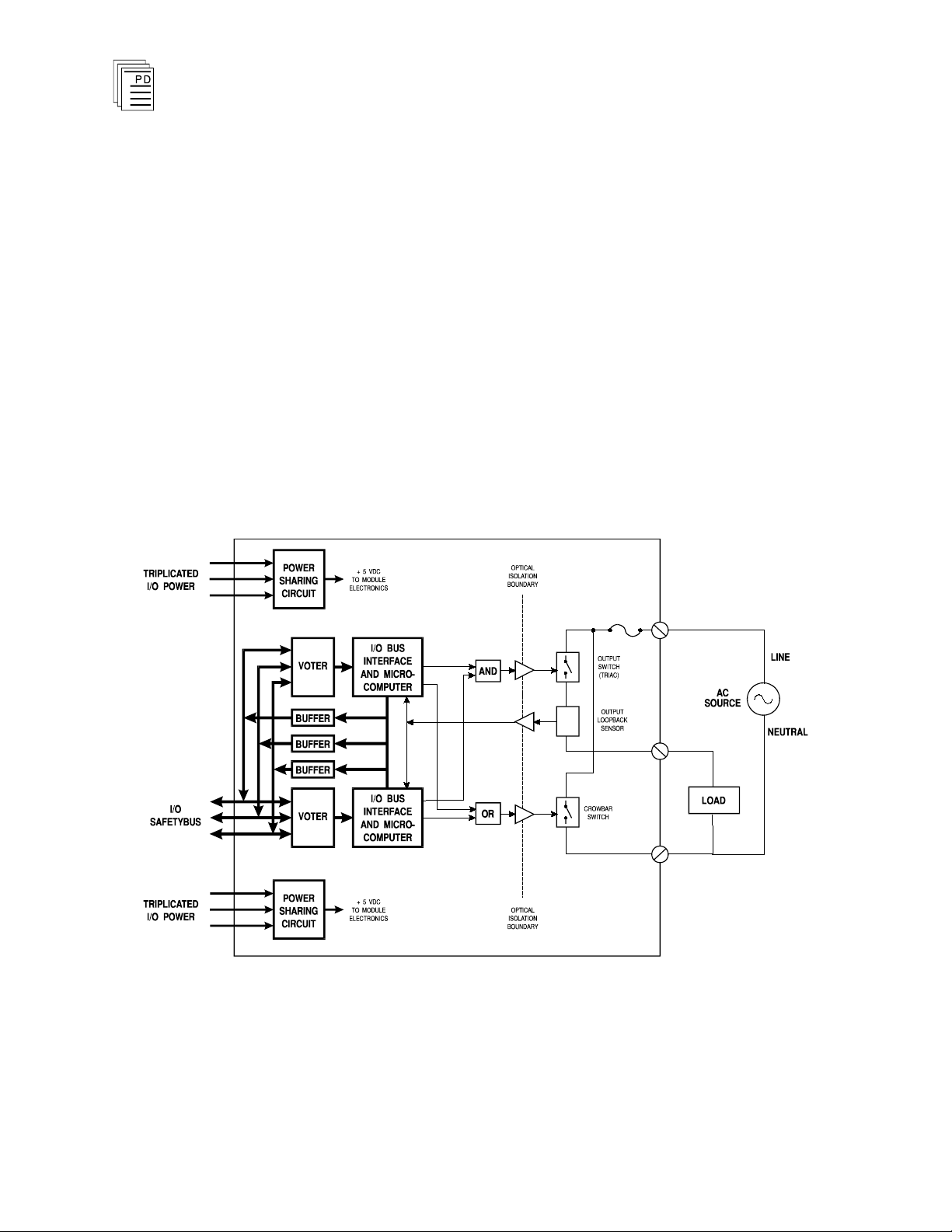

A block diagram of a typical AC Guarded digital output

module is shown in Figure 1.

The processor modules send triplicated write data commands

over the I/O Safetybus to the Guarded output module.

Onboard the Guarded output modules the triplicated data are

routed to two independent voter and microcomputer sections.

Each section independently votes the triplicated data to

generate a logic output drive signal. The two logic drive

signals are ANDed to control the output TRIAC.

2

Figure 1. Block Diagram of the AC Guarded Output Module.

The TRIAC will normally be energized only when both

microcomputer sections command the output to be on. If

either microcomputer section commands the output to be off,

Industrial Control Services

Page 3

(T3464)

AC Guarded Digital Output Module

the TRIAC will be de-energized. If the TRIAC itself fails

shorted when commanded off, either microcomputer section

can trigger an internal crowbar switch that disables the

output by blowing the fuse for that circuit.

The combination of dual independent drive signals, a TRIAC,

and a crowbar circuit provides fail-safe activation of the load

devices. No s

ingle failure can prevent the output from being

turned off when commanded. Single failures result in either

continued correct control or a fail-safe output as shown in

Table 1.

To achieve fault tolerance, two Guarded output modules are

used with their outputs connected in parallel. This

configuration provides for continued correct control even

when an output TRIAC fails open (class 2 and 5 in Table 1).

The module failure is automatically detected and th

e failed

module can be removed and replaced without interrupting

output control.

PD-6021

Mar-06

3

Page 4

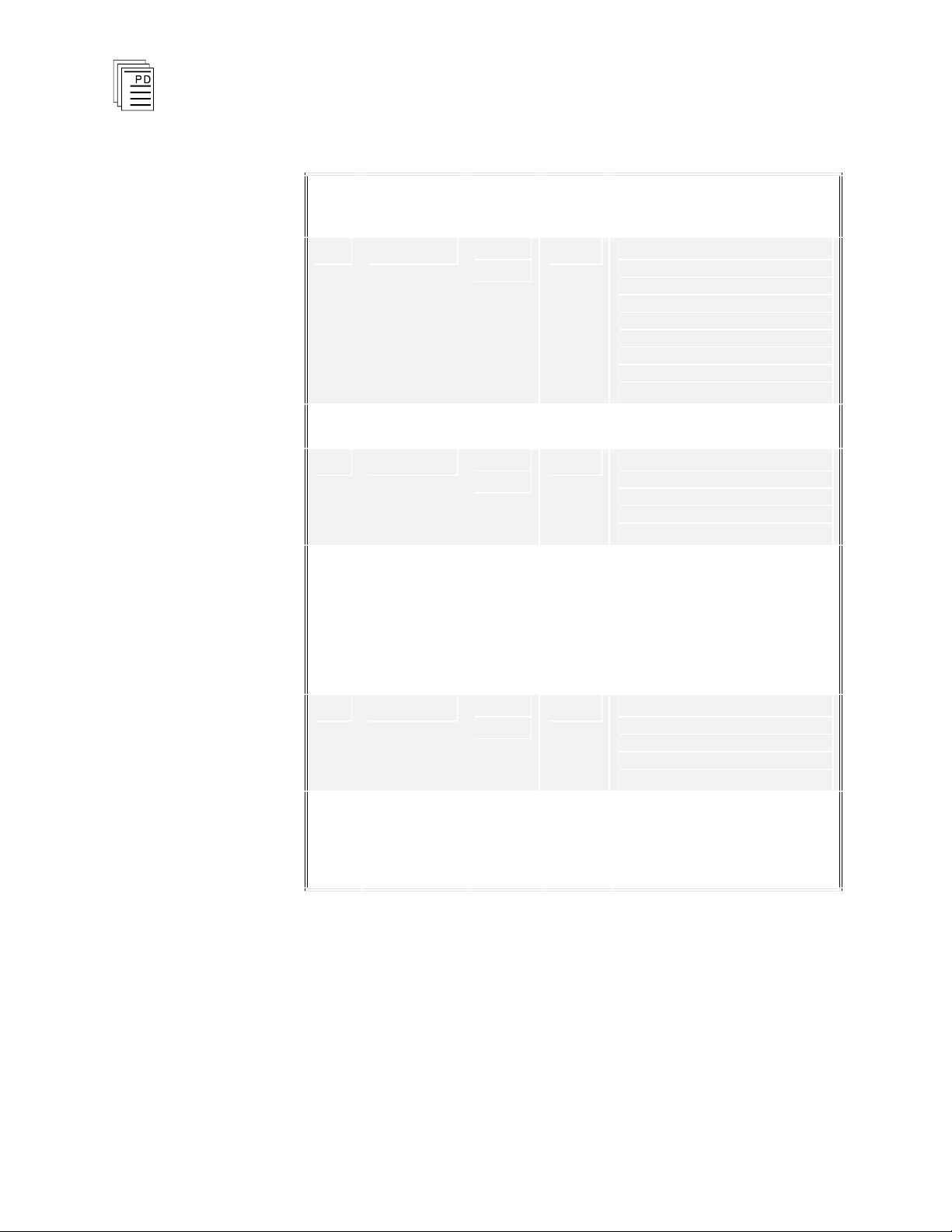

Case

Commanded

Output State

Single

Failure

Actual

Output

to Load

Remarks

1 On

TRIAC

short

On

Continued correct control.

Automatic testing of crowbar

circuit ensures that output will be

able to switch off. If output is

subsequently commanded off,

crowbar switch is energized to

blow fuse and turn off output

(fuse blows 200 msec after

output is commanded off).

2 On

TRIAC

open

Off

Fail-safe output. Automatic

testing detects failed TRIAC.

3 On

Crowbar

fault

On

Continued correct control.

Automatic testing detects failed

crowbar circuit. If output is

subsequently commanded off,

TRIAC will turn off.

4

Off

TRIAC

short

200

msec

bump

A one-time, 200 msec maximum

on-state bump occurs when the

TRIAC shorts. Automatic testing

detects shorted TRIAC and

crowbar switch is activated to

blow fuse. This one-time bump

may not be suitable for certain

energize-to-trip applicatio

ns.

5

Off

TRIAC

open

Off

Fail-safe output. Automatic

testing detects failed TRIAC. If

output is subsequently

commanded on, output will

remain off.

6

Off

Crowbar

fault

Off

Continued correct control.

Automatic testing detects failed

crowbar circuit. If output is

subsequently commanded on,

TRIAC will turn on.

AC Guarded Digital Output Module

(T3464)

Table 1. Output States After Switch Failure.

4

Testing and Diagnostics

The voter and I/O bus interface logic of the Guarded output

modules is automatically tested by the processor modules.

Discrepant data are sent through one of three legs of

the I/O

Safetybus to determine whether the module’s voters are able

to outvote the incorrect data. A failure to return the correct

majority-voted result to the processors produces an I/O

Industrial Control Services

Page 5

(T3464)

AC Guarded Digital Output Module

module error indication at the processor modules and a

module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed in each I/O chassis slot and

how to address that module and its points

specifically. If a

module is removed, or is replaced with a module of a different

type, the processor modules will indicate an I/O module error.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

Fuses are periodically checked for continuity. Blown fuse

detection is independent of load connection or output circuit’s

on/off state.

Incoming AC field power is checked for proper frequency,

stabili

ty, and phase. Tests that depend on AC power timing

information, such as turn-on testing, will not execute if the AC

power is unacceptable. However, crowbar switch activation is

not dependent on these power conditions.

Approximately every 2 seconds, output circuits commanded to

be off are tested for their ability to turn on. Three test pulses

are applied on successive AC voltage phase zero crossings to

verify the output switch's ability to conduct bi-directional

current flow. The pulses are limited to 5

0 volts with a

maximum duration of 1 millisecond. This energy is

insufficient to drive most field loads.

Output TRIACs commanded to be on (output switch closed)

are not tested for their ability to turn off. Instead, the crowbar

circuit is periodically tested for its ability to turn on. If a

TRIAC fails to tuns off when commanded, either

microcomputer can energize the crowbar switch and remove

power from the load by blowing the fuse for that circuit. In

this way, an output’s inability to turn off is not discovered

until the switch is commanded to turn off. The result is a

maximum time to switch off a shorted output (blow the fuse) of

200 milliseconds.

Outputs commanded to be on are occasionally tested for open

load and open circuit (faulty output switch) conditions. If load

current is below the minimum requirements, the module tests

PD-6021

Mar-06

5

Page 6

AC Guarded Digital Output Module

the output switch's ability to conduct current (through an

internal dummy load). If current is conducted, the fault is in

the load. If no current is conducted, the fault is

switch circuit. Healthy outputs commanded to be on but not

wired to an external load will always cause an open load

condition to be displayed.

(T3464)

in the output

Front Panel

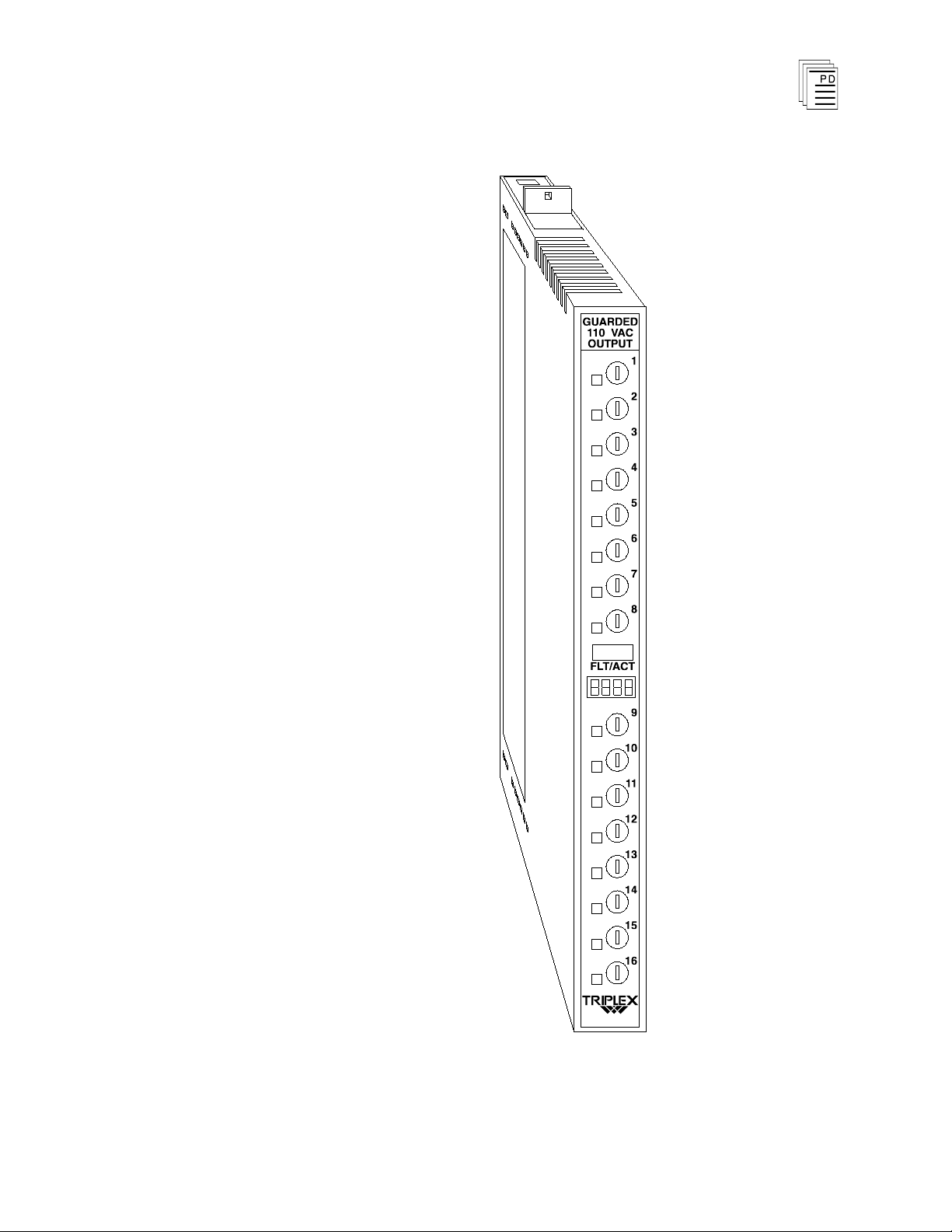

Figure 2 shows the physical features of the AC Guarded

output modules. The front panel contains an active and fault

status indicator, a diagnostic message display, as well as

status indicators and fuses for each output circuit.

Active/Fault Status Indicator

These green and red LEDs indicate the overall health o

f the

module and its field circuits. During normal operation, the

green ACTIVE indicator flashes at the controller’s scan rate.

If a module fault occurs the red FAULT indicator turns on

and the green ACTIVE indicator turns off.

Output Status Indicators

The output status indicators are yellow LEDs, located on the

field side of the output circuit, in parallel with the load. These

indicators are on when the load is energized.

6

Industrial Control Services

Page 7

(T3464)

AC Guarded Digital Output Module

PD-6021

Mar-06

Figure 2. AC Guarded Output Mod

7

ule.

Page 8

Note:

AC Guarded Digital Output Module

(T3464)

Diagnostic Message Display

This four-digit display provides additional fault diagnostics

(such as blown fuse, AC power problems, wiring faults, etc.). If

one or more fault conditions are present, the fault messages

are displayed in rotation for approximately one second each.

These fault messages are self-clearing (which means, for

example, that replacing a blown fuse will clear the blown fuse

message). However, the module’s FAULT indicator can only

be cleared by a voted reset.

Indicator messages are described in the section Maintenance,

beginning on page 18.

Shutdown Indication

Upon loss of communications with the controller, output

modules enter either a shutdown or hold fault mode. If the I/O

unit is set to shutdown, the diagnostic message display will

show Shud when communications with the controller are lost.

If the I/O unit is set to hold, diagnostic message display will

not display this message (see page 14, Fault Mode Jumper).

Application

When the module is installed in the I/O chassis or when logic

power (from the I/O power supply modules) is first applied to

the module, it will be in the shutdown mode until the first

output scan, regardless of the fault mode jumper settings.

Also, removing two I/O transceiver modules, two I/O power

supply modules, or two power legs will cause the module to be

in the shutdown mode.

Each module has separate power terminals for switch groups

1-8 and groups 9-16. The two groups are electrically isolated

from each o

difference between separate power sources cannot be

guaranteed to be less than one degree, both groups should be

wired to the same AC circuit. The microcomputers monitor

this phase difference to validate timing data derived from the

AC power.

When a crowbar circuit blows a fuse, approximately 16

additional amps of current flows through both the line and

neutral circuits until the fuse opens. Normally, only a small

ther by a minimum of 2500 volts. If the phase

8

Industrial Control Services

Page 9

(T3464)

AC Guarded Digital Output Module

current flows through the neutral wire, so it

is important to

size both the line and neutral wiring to enable them to handle

this fault current.

Modules report a open load fault when an output is

commanded on and no user load is connected. All output

circuits in service must have load connections for proper

diagnostic operation. Unused outputs can be left unconnected

so long as they are never commanded to be on. These modules

do not test for load faults when an output circuit is

commanded off.

Blown fuse detection is independent of user load connec

tion or

output circuit on/off state. However; when operating in a fault

tolerant configuration, the module will report an “OC” (open

circuit) fault instead of a “BF” (blown fuse) fault if both

outputs are on and only one of the two outputs has a blown

fuse.

The module should not be used in applications where a one

-

time 200 millisecond load bump (turn-on) cannot be tolerated.

Fail-Safe Configuration

As shown in Figure 3, the fail-safe configuration uses a single

Guarded module.

will cause the output to fail to the off state.

In this configuration, the worst case failure

In a fail-safe configuration, removing the module disables all

outputs.

PD-6021

Mar-06

Figure 3. Fail-Safe Configuration.

9

Page 10

AC Guarded Digital Output Module

(T3464)

Fault Tolerant Configuration

For fault tolerant operation, two Guarded modules are

connected in parallel as shown in Figure 4. In this

configuration, operation continues even if one module fails.

In the fault tolerant configuration, a failed module can be

removed and replaced without interrupting operation of the

loads.

Figure 4. Fault Tolerant Configuration.

Fault Tolerant Configuration with Redundant Actuators

When redundant actuators are installed in the field, the level

of fault protection can be extended to include the field wiring

and actuators. Each actuator should be connected to an

individual guarded output module as shown in Figure 5.

In this configuration continuous operation can be maintained

even if a module, field wiring or load fault occurs.

10

Industrial Control Services

Page 11

(T3464)

AC Guarded Digital Output Module

Figure 5. Fault Tolerant Configuration with Redundant

Field Wiring

Actuators.

Field wiring terminal blocks on the I/O chassis are used to

connect power sources and loads to the module. The terminal

blocks are located directly above and below the slot where the

module is installed. Each terminal block consists of ten #6

wire clamp screw terminals capable of holding two 12-AWG

wires.

Each module has separate power line and neutral terminals

for each output group (group 1: channels 1-8, group 2:

channels 9-16). The two groups are electrically isolated from

each other (2500 volts minimum). Figure 6 shows the proper

field wiring for a single module and Figure 7 shows the field

wiring for fault tolerant modules connected in parallel.

PD-6021

Mar-06

11

Page 12

AC Guarded Digital Output Module

(T3464)

12

Figure 6. Fail-Sa

fe Field Wiring.

Industrial Control Services

Page 13

(T3464)

AC Guarded Digital Output Module

PD-6021

Mar-06

Figure 7. Fault Tolerant Field Wiring.

13

Page 14

Module

Upper

Connector

Lower

Connector

T3464

17

3

AC Guarded Digital Output Module

(T3464)

Fault Mode Jumper

The fault mode jumper is located behind the ID switch cover

in the lower left-hand corner of each I/O chassis. The position

of the fault mode jumper determines the module's response to

system level faults. The fault mode jumper’s position will

cause all output modules in the I/O chassis to either shutdown

(turn off all outputs) or to hold (hold the last state) after a

system level f

failure is the failure of two processor modules.

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

different module type. Figure 8 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the AC Guarded output module are

listed in Table 2.

ailure occurs. An example of a system level

Table 2. Slot Key Positions.

14

Industrial Control Services

Page 15

(T3464)

AC Guarded Digital Output Module

PD-6021

Mar-06

Figure 8. Installing Slot Keys.

Configuration

Each output module is configured using the

W

INTERPRET

Configuration Editor. In the editor you will perform the three

steps described below to configure the output module.

I/O

15

Page 16

AC Guarded Digital Output Module

(T3464)

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

the relay output module from the list.

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open where you can define the output point

definitions.

Figure 9. AC Guarded Output Module Definition.

3) Edit each point:

Choose Edit from the Module Definition dialog box to

define a name and description for each output point. In

the Digital Output Point dialog, enter names and values

for the configuration fields as described below.

Figure 10. Defining a Guarded Digital

Output Point.

16

Industrial Control Services

Page 17

(T3464)

AC Guarded Digital Output Module

Name

Also called the tag name, this is the name used in the

application program to reference the output point. The name

can be up to 12 characters long.

Description

This 40-character field provides a place to describe the output

point definition. The description is used to help document

your system (it does not affect application program operation).

Comm Protect

Marking the Comm Protect check box protects the point from

changes by communications functions such as data write,

forcing, and load initial value when Comm Protect is enabled.

Initial Value

The initial value for the output is loaded to the Regent when

you load the I/O configuration and also when you load the

application program that controls the output.

Final Value

The final value for the output is loaded to the Regent when

the application program that controls the output is deleted.

Unless special circumstances exist, you should always enter

zero, so that the output is turned off when you delete the

application program that control

Output Module Definition

s it.

In addition to configuring output point definitions, you can

configure an output module definition to represent the

combined state of all 16 output points. The module definition

represents the 16 output point definitions as signed, 16-bit

integers. In this format, output 1 is the least significant bit

(LSB) and output point 16 is the most significant bit (MSB).

Programming

Outputs are controlled by writing application programs that

solve for output values. For example, placing an output tag

name on a coil in ladder logic will cause the output to turn on

when there is power flow to the coil in the ladder logic rung.

PD-6021

Mar-06

17

Page 18

AC Guarded Digital Output Module

To program fault tolerant outputs two output coils driven by

the same control logic are used as shown in Figure 11.

(T3464)

Maintenance

Figure 11. Programming Fault Tolerant Outputs.

In this illustration A, B, C, D represent various logic elements

used to drive the outputs; XV103A represents the output on

on

e Guarded output module; and XV103B represents the

output on the other Guarded output module.

No periodic maintenance or calibration is required for this

module.

Fuses can be removed and replaced without removing the

module from the I/O chassis. Turning the fuse holder one

quarter turn from its locked position releases the fuse holder,

extending the fuse and allowing it to be removed.

To prevent damage to the module, replacement fuses must be

of the same rating and type (see Specifications, bel

Diagnostic Messages

-

ow).

18

When the module is first inserted into an I/O chassis or when

system power is applied, the display will go through the

initialization sequence shown in Table 3.

Industrial Control Services

Page 19

(T3464)

Step Display

Description

1

8.8.8.8.

Display test. Displayed for 1 second.

2

AFO

RAM test. Displayed for 1 second. If this test

fails, the testing stops and the AFO message

remains on.

3

PF

PROM test. Displayed briefly. If this test fails

,

the testing stops and the PF message remains

on.

4

. . . . .

Normal display mode. Decimal points blink to

indicate processor activity.

5

- -

.

-

Decimal point number three should be

illuminated constantly after about 15 seconds.

This indicates the AC power source is stable

and output circuits are being tested.

AC Guarded Digital Output Module

The diagnostic messages displayed as the module operates are

used together with the module’s active and fault indicators.

A red FAULT indication on the module together with a

diagnostic message can be caused by either a power, wiring, or

load problem or by a module fault or failure.

Table 3. Initialization Sequence.

A red FAULT indication

without

a diagnostic message display

can indicate either a failed module or a fault that has already

been corrected. If the fault has been corrected, the diagnostic

message display will clear itself; however the module’s FAULT

indicator must be cleared by a voted reset. If the FAULT

indicator does not clear after a voted reset it is because the

module itself has failed and must be replaced.

PD-6021

Mar-06

19

Page 20

Display

Description

AC

AC quality problem (i.e. frequency is out of tolerance, frequency

is unstable, or phase difference between output groups 1-8 and

9-16).

AC.ab

AC power failure at field terminals A/B (output group 1-8).

AC.cd

AC power failure at field terminals C/D (output group 9-16).

Shud

Outputs are shut down (off). Caused by the loss of controller

communications or the module is not configured in the system.

Hold

Outputs are held at last stat

e. Caused by the loss of controller

communications.

BFnn

Blown fuse on output nn.

OLnn

Open load on output nn. Displayed only when output is on.

OCnn

Open circuit on output nn. Switch is not able to close.

SCnn

Short circuit on output nn. Switch is not able to open. The

crowbar switch was activated to blow the fuse. Blown fuse

message is suppressed.

Safetybus Power

1.5 load units

Number of Inputs

16 circuits divided into two

groups of eight

Voltage Range

90 to 130 VAC

Frequency Range

47 to 63 Hz

Phase Difference

1º maximum between group

1-8 and group 9-16

AC Guarded Digital Output Module

Ta

ble 4. Operating Diagnostic Messages.

(T3464)

Safety Considerations

Specifications

Although the AC Guarded output modules provide extensive

diagnostics and testing features, they have only been TÜV

certified to Risk Class 5 as non-interfering. For safety

systems that require TÜV approved equipment, the T3484

Monitored Guarded output module is recommended.

20

Industrial Control Services

Page 21

(T3464)

Load Current (maximum)

1 amp maximum per output

0°

to 40° C, derated linearly

to 0.5 amp at 60° C

16 amps maximum per

module at 0° C, derated

linearly to 8 amps at 60° C

Load Current (minimum)

Guarded mode:

Fault tolerant mode:

50 mA

150 mA

Line Current

Load current plus 16 amps

transient during crowbar

actuation

Neutral Current

16 amps maximum transient

during crowbar actuation

On State Drop

1.6 V, maximum

Surge Current

10 amps for 20 msec

Output Leakage

Guarded mode:

Fault tole

rant mode:

5 mA maximum at 60 Hz

10 mA maximum at 60 Hz

Fusing

One 2 A, 250 V, fast acting

(3AG) per output, front panel

mounted

Turn-On Delay

1 AC cycle maximum

Turn-Off Delay

1.5 AC cycle maximum

Over Voltage Protection

160 VAC, continuous

Load Bump

(Turn-on)

70 V peak for 1.1 msec,

3

pulses, repeating once per

2 seconds.

130 VAC for 200 msec, one

time for shorted output

circuit

Heat Dissipation

33 Watts, 111 BTUs/hour

AC Guarded Digital Output Module

PD-6021

Mar-06

21

Page 22

Isolation

2500 volts minimum (field

wiring to control logic)

2500 volts minimum

(output

group 1-8 to output group

9-16)

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

1 kV damped 1 MHz sine

wave

Safety

Certified to DIN V VDE

0801 for Risk Class 5, non

interfering. Also designed to

meet UL 508 and CSA 22.2,

No. 142-M1981

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

5.0 lbs (2.3 kg)

AC Guarded Digital Output Module

(T3464)

22

Industrial Control Services

Loading...

Loading...