Page 1

ICS Regent

®

PD-6024

Thermocouple Input Assembly

Input Module, Mux, Termination Panel and Cable

(T3431-IM, T3431-Mux, T3431-TP and T3431-CA)

Is

sue 1,

March, 06

The thermocouple input assembly consists of a thermocouple

input module (T3431-IM), a thermocouple input multiplexer

(T3431-MUX), a thermocouple termination panel (T3431-TP),

and a thermocouple termination cable (T3431-CA). This

equipment provides terminations and temperature conversion

for as many as 24 thermocouple inputs, arranged in 3 groups

of eight inputs.

Features

·

Twenty-four thermocouple inputs.

·

Configuration options:

Thermocouple type:

Units:

Resolution:

Filter response:

·

Complete linearization, cold junction compensation and

automatic calibration.

·

Remote terminations up to 50 cable feet from I/O chas

·

2500 volt isolation between Input Module and Mux.

·

High speed acquisition.

·

Hot-replaceable input module and Mux.

·

Extensive fault diagnostics.

·

Thermocouple burnout detection (downscale).

·

TÜV certified, Risk Class 5, non-interfering.

The input module plugs into an I/O chassis slot and receives

data from the thermocouple input multiplexer (or Mux). The

thermocouple input multiplexer plugs into the termination

panel and provides low level signal conditioning,

J, K, S, T (in groups of eight)

Degrees F or degrees C

Units or tenths

50 Hz, 60Hz rejection

sis.

Industrial Control Services

1

Page 2

Thermocouple Input Assembly

multiplexing, and analog-to-digital conversion. The

termination panel can be located as far as 50 cable feet from

the I/O chassis.

Each module’s triplicated I/O Safetybus interface ensures that

no failure in the module can affect the operation of the Regent

system or other I/O modules in the system. Extensive fault

detection and annunciation of critical redundant circuits help

prevent the controllers from receiving erroneous data from a

faulty input module. The fault tolerant boundary may be

extended by using three input modules and three termination

panels. A single thermocouple is wired to three different

termination panels for fault tolerance. The fault tolerant

boundary may be further extended into the process by wiring

three separate thermocouples, all measuring the same process

parameter, to three separate termination panels. In either

triplicated configuration, a failed module or multiplexer can

be removed and replaced without interrupting the inpu

signals.

(T3431)

t

Module Operation

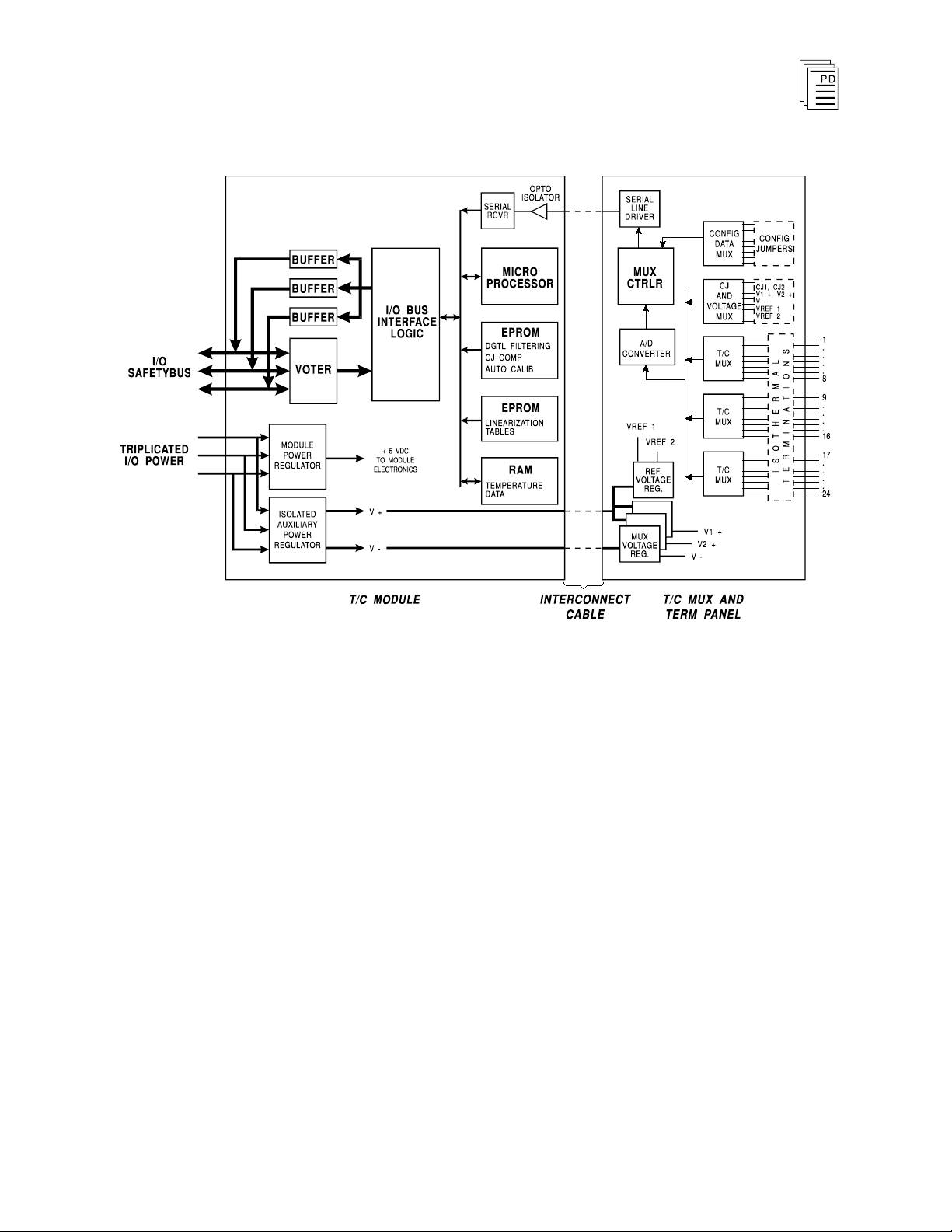

A simplified block diagram of the thermocouple input

assembly is shown in Figure 1.

Thermocouples are terminated at the termination panel. The

termination panel routes the thermocouple signals to the Mux

for multiplexing, signal conditioning, and A to D conversion.

The Mux also senses the cold junction sensor voltages. Cold

junction sensors are mounted on the termination panel near

the screw terminations.

The termination cable connects the termination panel to the

input module. A DC-to-DC converter on the input module

shares three power legs from the I/O backplane power and

provides isolated power to the Mux over the termination cable.

The Mux transmits digitized serial thermocouple data back to

the input module. The maximum allowable cable length is 50

feet.

2

Industrial Control Services

Page 3

Thermocouple Input Assembly

(T3431)

Figure 1. Block Diagram of the Thermocouple Input Assembly.

The Serial data received from the Mux is optically coupled at

the input m

odule to provide electrical isolation. The input

module's 68000-based microcomputer processes the

thermocouple data. This microcomputer’s functions include:

·

Digital filtering

·

Automatic calibration

·

Cold junction compensation

·

Temperature conversion and linearization

·

Diagnostics

The processor modules send triplicated read data req

the thermocouple input module over the I/O Safetybus. The

processors’ addressing data and data read requests are voted

by the module (preventing I/O Safetybus failures upstream

from the module from affecting module operations). The voted

result is then passed to the I/O bus interface logic.

uests to

PD-6024

Mar-06

3

Page 4

Thermocouple Input Assembly

After receiving the voted data read request, the

microcomputer transmits the conditioned temperature data to

the Safetybus interface. This interface places the voted

temperature data onto the triplicated Saf

Each of the three bus drivers is independently powered and

controlled (by the I/O transceiver modules) — preventing

failures in a single driver from propagating to the other two

I/O busses. The bus drivers then transmit the data via the

backplane I/O Safetybus to the I/O transceiver modules which,

in turn, transmit the data to the processors.

The thermocouple input data is packaged as a 16-bit word for

each input. The format of each word is shown in Figure 2.

The most significant bit in the word is used as an alarm bit to

indicate an out-of-range thermocouple input signal. The

remaining 15 bits contain signed 15-bit integer data

representing the temperature in degrees C or F and in units

or tenths of degrees, as configured by jumper settings on the

Mux.

(T3431)

etybus bus drivers.

Figure 2. Thermocouple Input Data Format.

Testing and Diagnostics

Input Module Testing

Each module’s voter circuits are periodically tested by the

p

rocessor modules. Discrepant data are sent through one of

three legs of the I/O Safetybus to determine whether the

module’s voter is able to outvote the incorrect data. A failure

to return the correct majority-voted result to the processors

produces an I/O module error indication at the processor

modules and a module fault indication at the I/O module.

4

Industrial Control Services

Page 5

Thermocouple Input Assembly

(T3431)

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed

in each I/O chassis slot and

how to address that module and its points specifically. If a

module is removed, or is replaced with a module of a different

type, the processor modules will indicate an I/O module error.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

Multiplexer Testing

The serial communications link to the thermocouple Mux is

continuously monitored. Additionally the data r

eceived from

the Mux is checked for proper data format, parity and numeric

range reasonableness. The cold junction sensor values are

monitored and compared to detect a failed cold junction

sensor. The precision voltage references on the multiplexer

are also checked to verify that the power to the Mux is present

and that the voltage references are within tolerance.

Input Module Front Panel Indicators

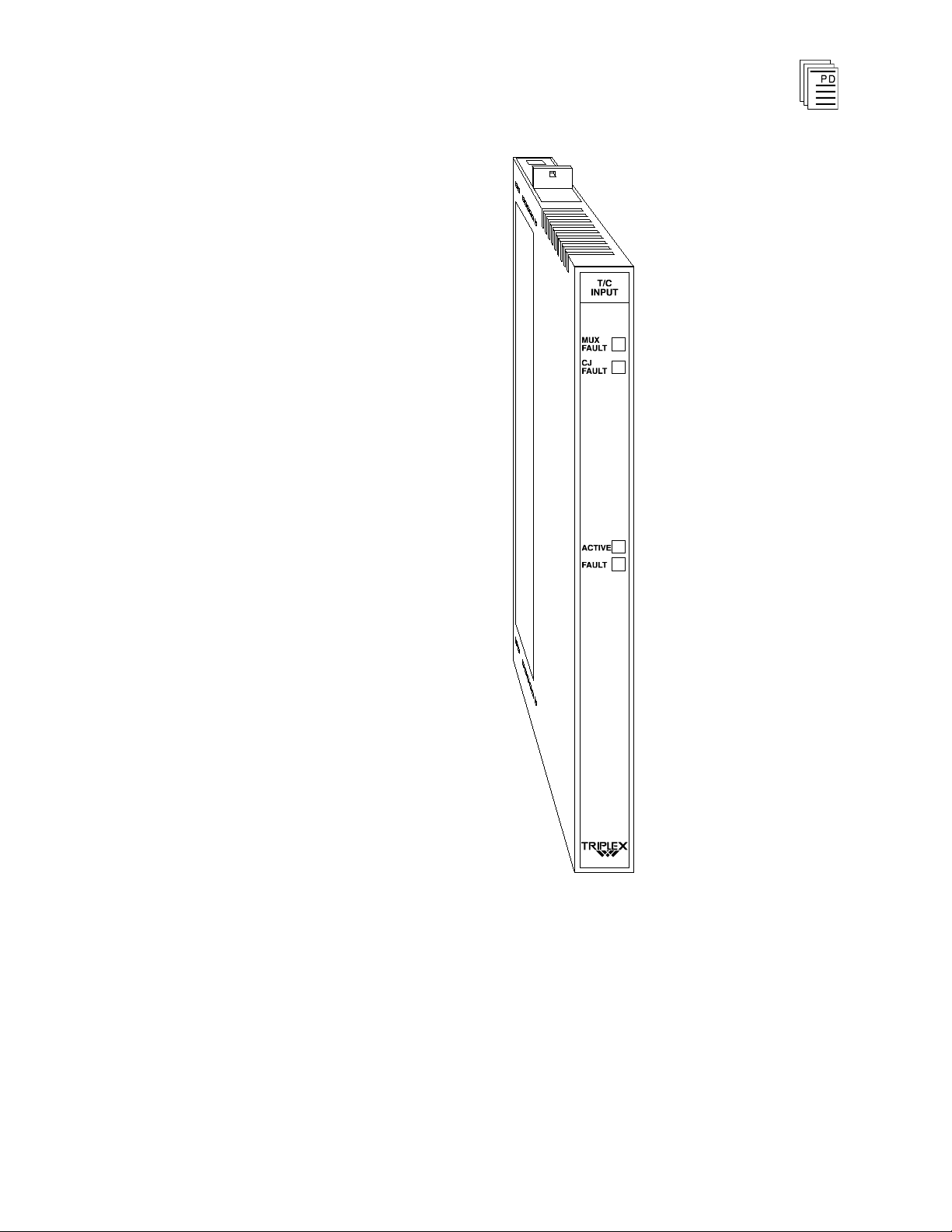

Figure 3 shows the physical features of the thermocouple

input module. The front panel of each module contains status

indicators to display the operational status of the input

module, multiplexer and cold junction sensors.

Active and Fault Status Indicators

These green and red LEDs indicate the overall health of the

module. During normal operation the green ACTIVE

indicator flashes at the controller's scan rate. If a module

fault occurs the red FAULT indicator turns on and the green

ACTIVE indicator turns off.

PD-6024

Mar-06

MUX Fault Indicator

The red MUX FAULT indicator turns on when any

following fault conditions are detected:

·

No data received from the Mux.

·

Corrupted data from the Mux.

·

Unreasonable data values from the Mux.

5

of the

Page 6

Thermocouple Input Assembly

Failure of the DC-to-DC converter supplying power to the

termination panel or the receiver circuitry can also result in a

MUX fault. Both of these faults are input module faults.

(T3431)

CJ Fault Indicator

There are two cold junction sensors located on the termination

panel. The red CJ FAULT indicator turns on when any of the

following fault conditions are detected:

·

Either CJ sensor temperature is < -5°

·

Either CJ sensor temperature is > 65° C (149° F)

·

The CJ sensors differ by more than 2.8° C (5° F)

C (23° F)

6

Industrial Control Services

Page 7

Thermocouple Input Assembly

(T3431)

PD-6024

Mar-06

Figure 3. Thermocouple Input Module.

Termination Panel and Multiplexer

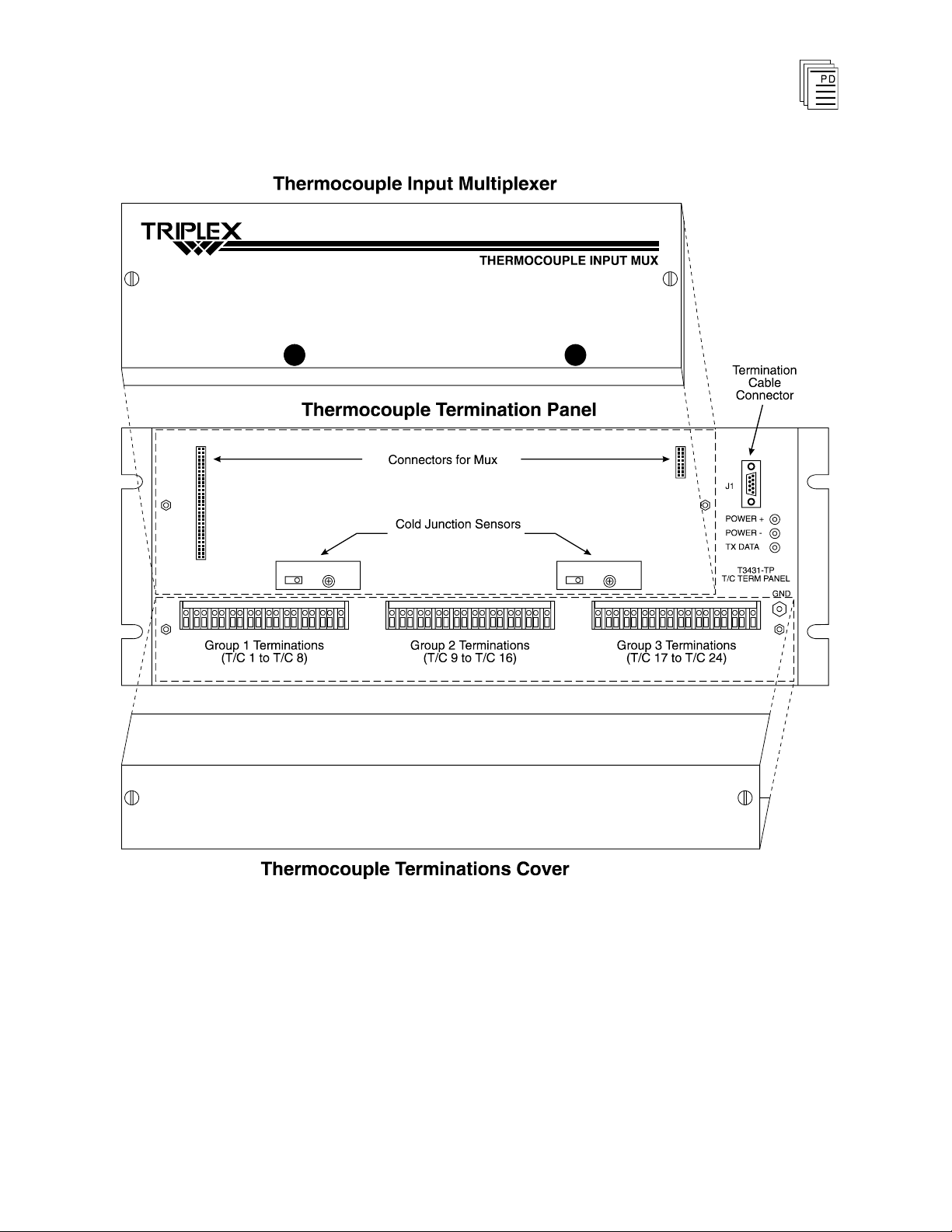

Figure 4 shows the physical features of the Termination Panel

and Multiplexer. The multiplexer plugs into the termination

panel and is secured in place with two thumb screws located at

each end of the multiplexer.

7

Page 8

Thermocouple Input Assembly

The termination cable plugs into the DB-9 connector located

at the upper right corner of the termination panel.

Thermocouple inputs are ter

located along the bottom of the termination panel. These

terminals are arranged in three groups of eight inputs. Two

screw terminals are provided for each thermocouple input.

Two additional ground terminals within each group are

provided to connect thermocouple cable shield wires if desired.

(T3431)

minated at the screw terminals

Termination Panel Indicators

The termination panel has status indicators for power supply

voltages, and transmit data. When positive and negative

supply voltages are present at the termination panel, the

POWER + and POWER -

indicators are on. The TX DATA

indicator is on when the Mux is transmitting data to the input

module. Normally, all these green indicators should be on.

8

Industrial Control Services

Page 9

Thermocouple Input Assembly

(T3431)

PD-6024

Figure 4. Thermocouple Termination Panel and Multiplexer.

Mar-06

9

Page 10

Thermocouple Input Assembly

(T3431)

Application

Simplex Configuration

Thermocouple input modules provide a suitable interface to

non-critical input signals. Although many of the circuits in

the thermocouple input module and multiplexe

automatically tested and annunciated, some logic circuits and

most of the field-side sensing circuits are simplex and non

tested. This simplex input configuration is illustrated in

Figure 5.

r are

-

Figure 5. Simplex Thermocouple Input Configuration.

Fault Tolerant Configurations

For critical inputs, redundant input modules, multiplexers

and termination panels are used in a 2oo3 or 1oo2 fault

tolerant configuration. In these configurations the redundant

thermocouple input equipment is connected to single or

multiple thermocouples. If redundant thermocouples are

installed in the field, each thermocouple connects to one

termination panel, multiplexer and input module. These

configurations are illustrated in Figure 6, showing triple

redundant input modules. Each thermocouple input module,

cable, term panel and multiplexer is hot replaceable. In

redundant input configurations, if a fault occurs in one

equipment, the failed equipment can be removed and replaced

set of

1 0

Industrial Control Services

Page 11

Thermocouple Input Assembly

(T3431)

while the system continues to sense the inputs from the

remaining two sets of equipment.

PD-6024

Figure 6. Fault Tolerant Thermocouple Input Configurations.

Mar-06

11

Page 12

Thermocouple Type

Bit 4

Bit 2

Bit 1

J

Low Low Low

K

Low Low High

S

High Low Low

T

High Low High

Thermocouple Input Assembly

(T3431)

Thermocouple Multiplexer Configuration

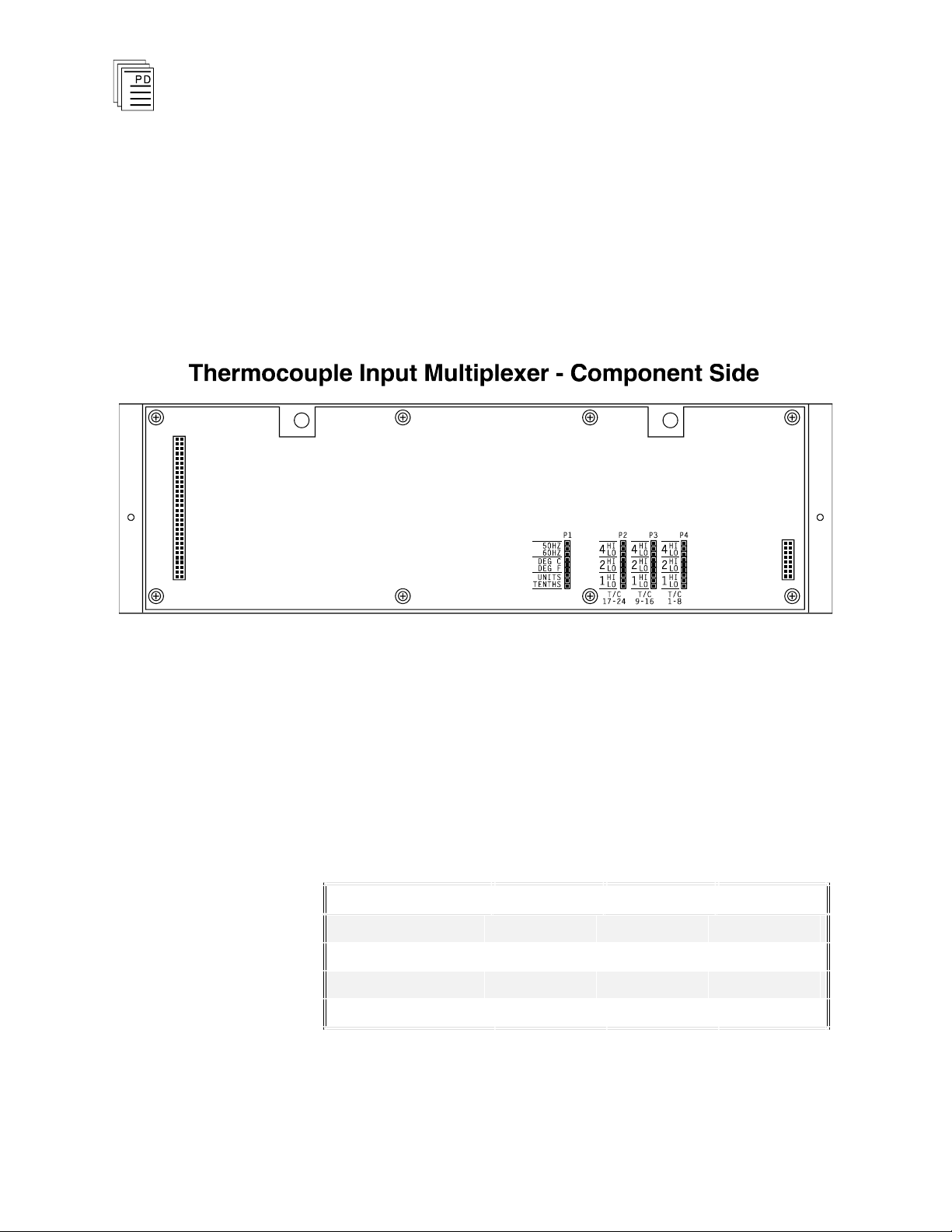

The thermocouple input multiplexer provides jumpers to

configure the thermocouple types, noise filtering, temperature

units, and temperature resolution. All thermocouple

configuration jumpers are located on the component side of

the Mux as shown in Figure 7. To access these jumpers the

Mux must be removed from the termination panel.

Figure 7. Location of Configuration Jumpers on Mux.

Thermocouple Type Configuration

Each group of eight inputs, 1-8, 9-16, and 17-24, is

individually configured for thermocouple type J, K, S, or T

using three jumpers for each group of inputs. The

three

jumpers are labeled Bit 4, Bit 2 and Bit 1. The jumper

settings for each thermocouple type are shown in Table 1.

Table 1. Thermocouple Type Jumper Settings.

To assign the thermocouple type, find the associated jumper

block for the group T/C 1-8, T/C 9-16, or T/C 17-24 and place

each jumper next to the appropriate high or low designation.

12

Industrial Control Services

Page 13

Thermocouple Input Assembly

Maximum

Range Limits

Resolution: 1º

Resolution: 0.1º

(T3431)

Note: There are four unused codes. Using any of these codes

will cause a Mux fault indication.

Thermocouple Noise Filtering

Thermocouples and their associated wiring may be installed

in electrically noisy environments. Noise filtering is required

to ensure that this noise does not affect the reading of the low

level thermocouple signals. Three jumper posts are located on

the Mux to select between 50 Hz or 60 Hz digital filtering.

Choose the frequency which represents the predominant

source of electri

cal noise in the thermocouple environment

(e.g. electrical motors). This configuration selection applies to

all 24 thermocouple inputs. Position the jumper on the upper

two posts to select 50 Hz filtering. Position the jumper on the

lower two posts to select 60 Hz filtering.

Thermocouple Data Format

The thermocouple input module provides linearized

temperature data to the processors in degrees Fahrenheit or

Celsius. Three jumper posts are located on the Mux to select

between degrees C or F. Position

the jumper on the upper two

posts to select degrees C. Position the jumper on the two lower

posts to select degrees F.

PD-6024

Mar-06

The temperature data resolution must also be configured for

units (data increments of 1 degree), or tenths (data increments

of 0.1 degree). Position the jumper on the upper two posts to

select units. Position the jumper on the two lower posts to

select tenths.

Note: the thermocouple data is always presented as integer

data to the processor modules. When you select tenths

resolution, t

here is an implied fixed place decimal before the

least significant digit in the temperature data. For example

the temperature data value 1527 would represent 152.7º.

The ranges of temperature data for each type of thermocouple

are shown in Table 2. The thermocouple data format

selections apply to all 24 thermocouple inputs.

Table 2. Temperature Data Ranges

13

Page 14

T/C

Type

Scale

Lower

Limit

Upper

L

imit

Lower

Limit

Upper

Limit

Lower

Limit

Upper

Limit

J ºC 0 750 0 750 0.0 750.0

ºF 32

1382 32 1382 32.0

1382.0

K ºC -200

1250 -

200 1250

-

200.0

1250.0

ºF -328

2282 -

328 2282

-

328.0

1638.3

S ºC 0

1450 0 1450 0.0

1450.0

ºF 32

2642 32 2642 32.0

1638.3

T ºC -

200 350 -

200 350

-

200.0 350.0

ºF -328 662 -

328 662

-

328.0 662.0

Thermocouple Input Assembly

(T3431)

Note for thermocouple types K and S: If a 0.1° F resolution is

selected, the

maximum usable temperature is 1638.3° F.

Even though the range limit has not been reached, the value

will be clamped at 1638.3 because of word length limitations.

Changing the resolution jumper to units will allow the entire

data range to be passed without clamping.

Thermocouple Burnout Detection

Open thermocouple channels are automatically driven

downscale (downscale burnout). The temperature value will

be equal to the lower limit value for the particular

thermocouple type. An open circuit on either terminal will

cause a downscale reading. This is not affected by a ground

connection at the thermocouple.

In application programming, the NOSIG contact in ladder

logic can be used to sense the thermocouple burnout

condition. For more information, see Programming, starting

on page 21.

Installation Planning

Accuracy Considerations

Use the following guidelines to maximize overall system

accuracy:

1. Temperature gradients should be minimized at the

term

ination panel. Avoid forced air cooling or placing heat

dissipating components directly underneath the terminal

14

Industrial Control Services

Page 15

Thermocouple Input Assembly

(T3431)

block areas. Install the thermocouple terminations cover

provided with the termination panel. Allow at least four

hours for temperature stabilization after any significant

temperature change.

2. If possible, terminate unused input channels with the

same thermocouple signal as the next channel, or short the

terminals of the unused input. This will minimize the

pulling affect of a preceding inp

ut.

3. Minimize the resistance of the thermocouple extension

wire by using heavier wire gauges.

Radiated Field Susceptibility

Transmitting equipment should not be operated within the

vicinity of the termination panel. Power levels greater than

one watt at a distance of one foot may degrade thermocouple

measurements and eventually cause a permanent fault to be

logged, resulting in a shutdown (clear to 0) of all inputs on the

affected panel.

Grounding

The termination panel should be connected to the sys

tem’s

safety or system ground. Use a minimum of #18 stranded

wire. A chassis ground terminal is provided for this purpose.

It is located underneath the wire cover near thermocouple

input 24.

Additional ground terminals are provided at either end of

each terminal block group. These terminals are electrically

connected to the chassis and can be used for thermocouple

shield terminations.

Installing the Termination Panel

PD-6024

Mar-06

The thermocouple termination panel can be mounted in a 19

inch rack or flush mounted to a panel. Refer to Figure 8 for

overall mounting dimensions for the termination panel and

Mux.

-

15

Page 16

Thermocouple Input Assembly

(T3431)

Figure 8. Mounting Dimensions for the Termination Panel.

Termination Panel Cable

The termination panel cable connects the input module to the

termination panel. It carries power to the panel and routes

serial data to the input module. One end of the cable has a

male DB-9 nine-pin connector that plugs into the terminatio

panel. The opposite end should be cut to the desired length

and wired to the I/O chassis terminal block immediately above

the input module. Do not connect the shield wire at this end.

The six wires in the cable are connected to the I/O slot

terminals as shown in Figure 9.

n

16

Industrial Control Services

Page 17

Thermocouple Input Assembly

(T3431)

PD-6024

Mar-06

Figure 9. Termination Cable Connections.

17

Page 18

Thermocouple Input Assembly

(T3431)

Thermocouple Terminations

Thermocouple wires are connected to the screw terminals

located at the bottom of the t

ermination panel as shown in

Figure 10. When terminating thermocouple wiring, follow the

recommendations listed below.

1. Greater accuracy is maintained with a heavier gauge

thermocouple extension wire.

2. All thermocouples within a group of eight must be the

same thermocouple type.

3. Terminate unused thermocouple inputs with the same

signal as preceding inputs, or short the two input

terminals together.

4. Install the termination cover after completing the wiring

connections.

18

Figure 10. Wiring Thermocouples to Term Panel.

Industrial Control Services

Page 19

Thermocouple Input Assembly

(T3431)

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

different module type. Figure 11 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the thermocouple input module is

listed in Table 3.

PD-6024

Mar-06

Figure 11. Installing Slot Keys.

19

Page 20

Module

Upper

Connector

Lower

Connector

T3431

15 15

Thermocouple Input Assembly

(T3431)

Table 3. Slot Key Positions.

Configuration

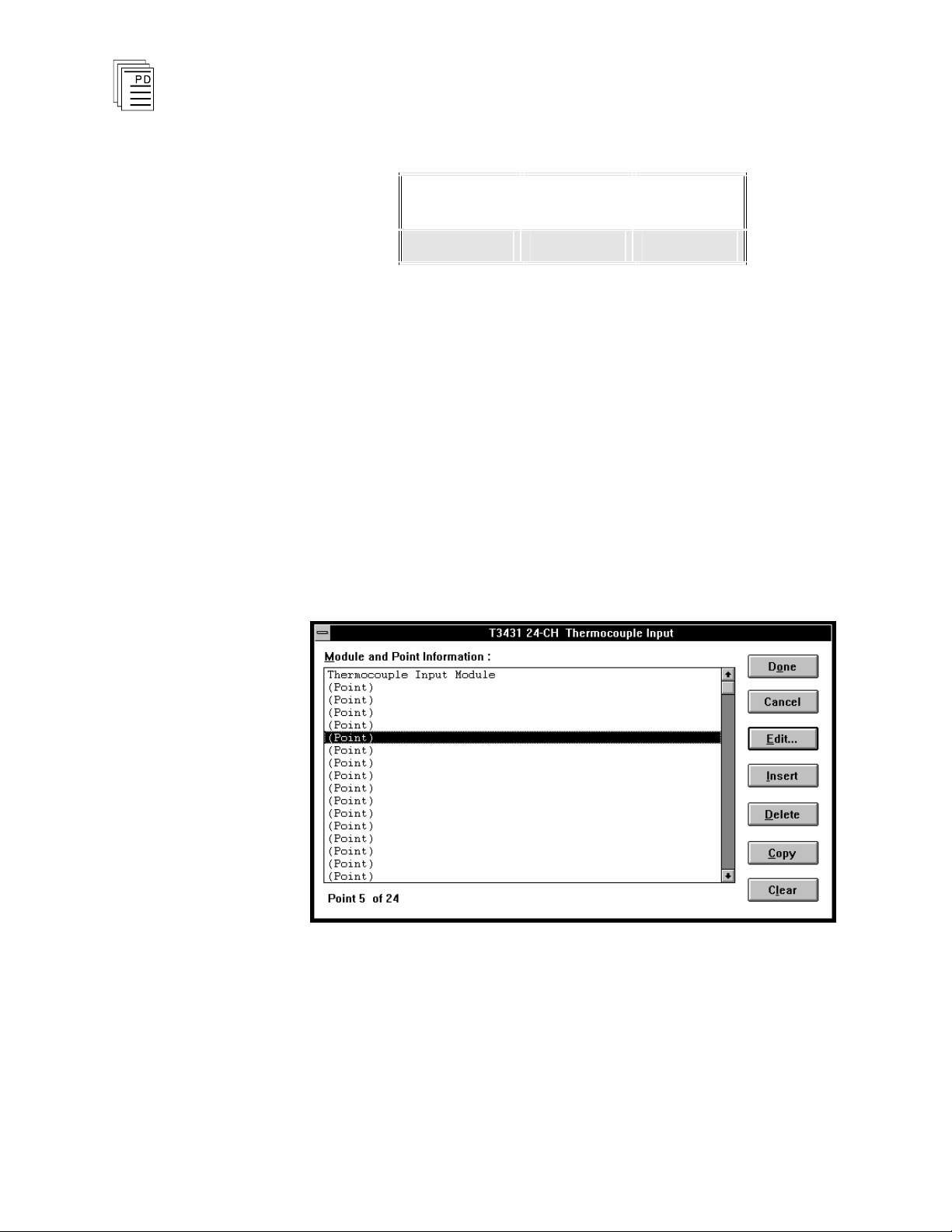

Each input module is configured using the

W

INTERPRET

I/O

Configuration Editor. In the editor, you will perform the

three steps described below to configure the input module.

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

the thermocouple input module from the list.

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open where you can define the input point

definitions.

20

Figure 12. Thermocouple Input Module Definition.

3) Edit each point:

Position the cursor on a Point definition and choose Edit

from the Module Definition dialog box to define a name

and description for each input point. In the Thermocouple

Input Point dialog, enter a tag name (up to 12 characters

)

and a description (up to 40 characters). The tag names are

Industrial Control Services

Page 21

Thermocouple Input Assembly

(T3431)

used in the application program to represent the value of

the thermocouple input in your control algorithms and

interlocks. The input data is in the units and format as

configured on the thermocouple Mux. For more

information, see Thermocouple Multiplexer Configuration,

starting on page 12.

Figure 13. Defining a Thermocouple Input Point.

Programming

Inputs are referenced in the application program through the

tag names defined in the I/O Configuration Editor. The

thermocouple inputs variables will be in the engineering units

(degrees F or C) and resolution (1 or 0.1 degree) as configured

on the thermocouple multiplexer. Because the input data is

already represented in engineering units, there is no need to

scale the thermocouple input variables in the application

program.

Note: The MSB of each thermocouple input represents out-of

range (or NOSIG) status. This bit is normally equal to one.

When

thermocouple inputs are used in application program

instructions, this MSB is masked and the sign bit is shifted to

the MSB. This allows the application program instructions to

evaluate only the data portion of the temperature value. This

is true for all application program instructions except Block

Move (in ladder logic). The Block Move instruction moves the

entire word of data without masking off the NOSIG bit.

PD-6024

Mar-06

21

Page 22

Thermocouple Input Assembly

(T3431)

Programming Fault Tolerant Thermocouple Inputs

To program fault tolerant configurations u

sing triplicated

thermocouple input modules, a midvalue element can be used

as shown in Figure 14.

Figure 14. Programming Fault Tolerant Thermocouple

Inputs.

In this illustration, VALUE_A_NAME, VALUE_B_NAME,

and VALUE_C_NAME represent the three thermocouple

inputs to be mid-value selected. ERROR_A_NAME,

ERROR_B_NAME and ERROR_C_NAME are the error bits

for the T/C inputs. RESULT_NAME is the result of the mid

value instruction. The field Limit is the integer value, in

similar units to the Value A, B and C variables, that a

thermocouple input can deviate from the mid-value result

before signaling an error (via the Error A, B or C bits). Once

an error bit is set, it is latched. RESET_NAME is the reset bit

used to reset the latched error bits.

22

Thermocouple Burnout and Out of Range Conditions

The NOSIG contact in ladder logic function blocks can be used

to detect an out of range thermocouple input signal. The

NOSIG contact will

be true if the thermocouple input reaches

the limits of its usable range (see Table 2, Temperature Data

Ranges). The temperature value will be equal to the lower or

upper limit value listed in the table for maximum data range

while the temperature remains out of range.

Note: For Type K and S thermocouples, the maximum

input value is clamped at 16383 due to data format

limitations. The NOSIG contact will not be true until the

thermocouple signal reaches the maximum upper limit

value defined in Table 2.

Industrial Control Services

Page 23

Thermocouple Input Assembly

(T3431)

Maintenance

Calibration

The Mux contains an ultra-stable voltage reference circuit for

auto-calibration of all thermocouple channels. This circuit

does not require re-adjustment.

Cold junction sensors do not require re-adjustment.

Troubleshooting

The following procedure is used for troubleshooting the

thermocouple input. The only assumption made is that the

input module fault indicator is on.

1. If both the Mux and CJ indicators are off, repla

module.

2. If only the Mux indicator is on, check the termination

panel’s status indicators.

If either POWER indicator is off, verify that the

termination panel cable is connected and that the cable

connections at the I/O chassis are correct (refer to Figure

9

). Replace the input module.

ce the input

PD-6024

Mar-06

If the POWER indicators remain off, replace the Mux.

If both POWER indicators are on but the TX DATA

indicator is off, replace the Mux.

If both the POWER and TX DATA indicators are

replace the Mux. If the Mux indicator is still on, replace

the input module.

3. If only the CJ indicator is on, check that the temperature

at the termination panel is between 0° and 60° C and that

there are no significant thermal gradients present.

Remove the Mux and check for damaged cold junction

sensors. The sensors are mounted to the termination

panel directly above the terminal block area.

If the sensors are not damaged, replace the Mux. If th

indicator is still on, consult ICS for CJ sensor replacement

procedures and parts.

lit,

e CJ

23

Page 24

Safetybus Power

1.8 load units (input module)

Number of Inputs

24 differential

Thermocouple Input Types

Type J:

Type K:

Type S:

Type T:

Iron/constantan

Chromel/alumel

Pt/Pt-10% Rh

Copper/constantan

Thermocouple Units

Degrees Centigrade or

degrees Fahrenheit

Thermocouple Resolution

Tenths or units

Thermocouple Ranges

Type J:

Type K:

Type S:

Type T:

0°

to +750° C

(+32° to +1382° F)

-

200° to +1250° C

(-

328° to +2282° F)*

0°

to +1450° C

(+32° to +2642° F)*

-

200° to +350° C

(-

328° to +662° F)

*

If 0.1° F resolution is selected,

the maximum usable temperature

is +1638.3° F

Thermocouple Burnout

Downscale driven

Differential Input Resistance

2M ohms (typical)

Thermocouple Input Assembly

(T3431)

Safety Considerations

Specifications

The thermocouple input modules are TÜV certified as non

interfering and can be used for non-safety critical inputs in

Risk Class 5 safety applications.

For additional safety considerations, please refer to the Safety

Considerations section of the Regent User’s Guide.

-

24

Industrial Control Services

Page 25

Thermocouple Input Assembly

Input to Chassis Resistance

1.1M ohm (typical)

Bias Current

100 nA (typical)

Common Mode Operating

Range

7 volts, maximum w/r chassis

ground

Input Over voltage

Protection

120 volts RMS between any

two terminals

Response Time (Total)

Step Input:

Ramp Input:

50 msec maximum (0 to 99%)

25 msec maximum tracking

delay for input rates less

than 8° C/ms (15° F)

Noise Rejection (Conducted)

Normal Mode:

Common Mode:

70 dB minimum at 60/120

Hz or 50 Hz (jumper

selectable)

100 dB minimum at 50/60

Hz, 60 dB minimum

elsewhere

Noise Rejection (Radiated)

Walkie-talkie:

0.1% (range) maximum error

for 1 watt at 1 foot from Mux

(any polarization)

(T3431)

PD-6024

Mar-06

25

Page 26

Thermocouple Accuracy

Maximum error (0° to 60° C).

Add ±0.5 LSB resolution error to

the following:

Type J, Full range:

Type K

< -100° C:

> -100° C:

Type S

< 540° C:

> 540° C:

Type T

< 0° C:

> 0° C:

±1.6° C (3.0° F)

±4.2° C (7.6° F)

±2.4° C (4.3° F)

±13° C (24° F)

±7° C (12.5° F)

±4.8° C (8.7° F)

±2.1° C (3.8° F)

Wire Resistance Effects

Type J, Full range:

Type K

< -100° C:

> -100° C:

Type S

< 540° C:

> 540° C:

Type T

< 0° C:

> 0° C:

-

0.0020° C/ohm (.0036° F)

-

0.0066° C/ohm (0.0120° F)

-

0.0033° C/ohm (0.0060° F)

-

0.0200° C/ohm (0.0360° F)

-

0.0100° C/ohm (0.0180° F)

-

0.0066° C/ohm (0.0120° F)

-

0.0025° C/ohm (0.0045° F)

Adjacent Channel Effects

Chann

el n =

top

of range

channel; n-1 = bottom of range

Type J:

Type K:

Type S:

Type T:

-

1.0° C (1.7° F)

-

1.5° C (2.7° F)

-

4.0° C (7.2° F)

-

0.8° C (1.5° F)

Channel n = bottom

of range; n-1

= open circuit

Type J:

Type K:

Type S:

Type T:

-

3.0° C (5.4° F)

-

4.0° C (7.2° F)

-30°

C (54° F)

-

4.5° C (8.1° F)

Thermocouple Input Assembly

(T3431)

26

Industrial Control Services

Page 27

Termination Panel Cable Length

Maximum 50 cable feet

(15 m)

Isolation

2500 volts minimum (field

wiring to control logic)

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Safety

Certified to DIN V VDE

0801 (non-interfering) and

designed to meet UL 508 and

CSA 22.2, No. 142-M1981

Heat Dissipation

Input module:

Termination panel/Mux:

4.5 Watts, 15 BTUs/hour

2.5 Watts, 9 BTUs/hour

Dimensions

Input Module

Height:

Width:

Depth:

Termination Panel

He

ight:

Width:

Depth:

Mux

Height:

Width:

Depth:

12.6” (320 mm)

1.27” (32 mm)

10.125” (257 mm)

6.94” (176 mm)

19.0” (483 mm)

2.25” (57.2 mm)

4.5” (114 mm)

15.0” (381 mm)

1.25” (31.8 mm)

Weight

Input module:

Mux:

Termination panel:

3.5 lbs (1.6 kg)

2 lbs (0.9 kg)

5.6 lbs (2.5 kg)

Thermocouple Input Assembly

(T3431)

PD-6024

Mar-06

27

Loading...

Loading...