Page 1

Reference Manual

Rockwell Automation Library of Process Objects:

PowerFlex 6000 Drive (P_PF6000)

IMPORTANT

This manual applies to the Rockwell Automation Library of Process Objects version 3.5 or earlier.

For Rockwell Automation Library of Process Objects version 5.0, see

• PROCES-RM200

For Rockwell Automation Library of Process Objects version 4.0 or later, use the following manuals:

• PROCES-RM013 contains logic instructions

• PROCES-RM014 contains display elements

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, ControlLogix, FactoryTalk, Logix5000, PlantPAx, PowerFlex, Rockwell Automation, Rockwell Software, RSL ogix, and Studio 5000 Log ix Designer are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PowerFlex 6000 Drive (P_PF6000) Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Required Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controller File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Visualization Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controller Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PowerFlex Drive InOut Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PowerFlex 6000 Drive Input Structure . . . . . . . . . . . . . . . . . . . . . . 14

PowerFlex 6000 Drive Output Structure . . . . . . . . . . . . . . . . . . . . 19

PowerFlex 6000 Drive Local Configuration Tags. . . . . . . . . . . . . 23

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Display Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

State Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Status/Quality Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mode Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Alarm Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Maintenance Bypass Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Quick Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Operator Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maintenance Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Engineering Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Diagnostics Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Trends Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Alarms Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

PowerFlex Drive Faceplate Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 3

Page 4

Table of Contents

Notes:

4 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 5

Preface

This manual describes the Add-On Instruction that controls and monitors a

PowerFlex® 6000 Medium Voltage Variable Frequency Drive.

Software Compatibility

Additional Resources

For the latest compatible software information and to download the Rockwell

Automation® Library of Process Objects, see the Product Compatibility and

Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/pcdc.page

For general library considerations, see Rockwell Automation Library of Process

Objects, publication PROCES-RM002

.

These documents contain additional information concerning related products

from Rockwell Automation.

Table 1 - Additional Resources

Resource Description

PlantPAx® Distributed Control System Selection Guide,

publication PROCES-SG001

PlantPAx Distributed Control System Reference Manual,

publication PROCES-RM001

Rockwell Automation Library of Process Objects,

publication PROCES-RM002

FactoryTalk® View Machine Edition User Manual,

publication VIEWME-UM004

FactoryTalk View Site Edition User Manual,

publication VIEWSE-UM006

PowerFlex 6000 Medium Voltage Variable Frequency Drive

Parameter Manual, publication 6000-TD004

Rockwell Automation Library of Process Objects: Common

Alarm Block (P_Alarm) Reference Manual, publication

SYSLIB-RM002

Rockwell Automation Library of Process Objects: Interlocks

with First Out and Bypass (P_Intlk) Reference Manual,

publication SYSLIB-RM004

Rockwell Automation Library of Process Objects: Common

Mode Block (P_Mode) Reference Manual, publication

SYSLIB-RM005

Rockwell Automation Library of Process Objects: Permissives

with Bypass (P_Perm) Reference Manual, publication

SYSLIB-RM007

Provides information to assist with equipment

procurement for your PlantPAx system.

Provides characterized recommendations for

implementing your PlantPAx system.

Provides general considerations for the PlantPAx system

library of process objects.

Provides details on how to use this software package for

creating an automation application.

Provides details on how to use this software package for

developing and running human-machine interface

(HMI) applications that can involve multiple users and

servers, distributed over a network.

Provides details regarding functions, parameters, and

troubleshooting information for medium voltage

PowerFlex 6000 drives.

Details how to monitor an input condition to raise an

alarm. Information includes acknowledging, resetting,

inhibiting, and disabling an alarm. Generally the

P_Alarm faceplate is accessible from the Alarms tab.

Explains how to collect (sum up) the interlock

conditions that stop or de-energize a running or

energized piece of equipment or prevent it from

starting or being energized.

Explains how to choose the Mode (owner) of an

instruction or control strategy. The Mode instruction is

usually embedded within other instructions to extend

their functionality.

Details how to collect permissive conditions to start a

piece of equipment.

.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 5

Page 6

Preface

Table 1 - Additional Resources

Resource Description

Rockwell Automation Library of Process Objects: Restart

Inhibit for Large Motor (P_ResInh) Reference Manual,

publication SYSLIB-RM009

Rockwell Automation Library of Process Objects: Run Time

and Starts (P_RunTime) Reference Manual, publication

SYSLIB-RM010

Explains how to protect a large motor from damage

caused by repeated starts.

Explains how to accumulate the total run time and

count of starts for a motor or other equipment.

6 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 7

PowerFlex 6000 Drive (P_PF6000)

Add-On Instruction FaceplateGlobal Objects

IMPORTANT

The P_PF6000 (PowerFlex 6000 drive) object is used to operate one

variable-speed motor by using a PowerFlex 6000 medium voltage variable

frequency AC drive. The drive operates via an add-on EtherNet/IP interface.

The Add-On Instruction controls the drive in various modes and monitors fault

conditions. The global objects and faceplate that is shown are examples of the

graphical interface tools for this instruction.

Guidelines

This instruction operates a motor connected to a PowerFlex 6000 variable

frequency AC drive, which is communicating with the controller over an

EtherNet/IP network.

The PowerFlex 6000 drive has specific parameter read/write functionality. For

details, see Knowledgebase Answer ID 1008677 at

https://www.rockwellautomation.custhelp.com

Do not use this instruction in these situations:

• You need to operate a single-speed motor (running and stopped only). Use

• You need to operate a two-speed motor (fast, slow, and stopped only). Use

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 7

The drive interface is designed to work with the Studio 5000 Logix Designer®

application, Version 20 and later.

.

the P_Motor instruction instead.

the P_Motor2Spd instruction instead.

Page 8

PowerFlex 6000 Drive (P_PF6000)

• You need to operate a simple reversing motor (forward, reverse, and

stopped only). Use the P_MotorRev instruction instead.

• You need to operate a motor with multiple discrete speeds. You need

specific logic for this motor. The P_PF6000 instruction is designed for

motors with continuously variable (analog) speed, not multiple discrete

speed selections. You can use the P_D4SD or P_nPos instruction for

motors with multiple discrete speeds.

• You are using a drive other than the PowerFlex 6000 drive. Instead, use

these Add-On Instructions:

– P_PF52x for the PowerFlex 523 or PowerFlex 525 drive on an

EtherNet/IP network

– P_PF753 for the PowerFlex drive with 20-COMM-E EtherNet/IP

Interface

– P_PF755 for the PowerFlex AC variable frequency drive

– P_PF7000 for the PowerFlex 7000 medium voltage AC variable

frequency drive with 20-COMM-E EtherNet/IP interface.

– P_VSD for third-party drives, drives on other networks, or via

hardwired I/O

Functional Description

The P_PF6000 instruction provides the following capabilities:

• Ownership of the drive through the standard P_Mode Add-On

Instruction and modes.

• Ability to start and stop the drive and motor, control the drive speed (via

speed reference), and monitor the drive run status and speed feedback to

verify whether the drive is running or stopped. Provides alarms and drive

shutdown for Fail to Start and Fail to Stop if the feedback does not follow

the commanded state within a configured amount of time.

• Reading from the drive, the instruction displays drive faults, general drive

status data, and a number of operating parameters.

• Ability to read fault data from the drive and provide descriptive text with

fault codes.

• Indication of Warning or Alarm status as received from the drive.

• Input and alarm for a drive fault condition and an output to send a drive

fault reset to the drive. Provide a configurable time to pulse the drive fault

reset output when a reset command is received.

• Permissives (bypassable and non-bypassable) that are conditions that

enable a drive start and Interlocks (bypassable and non-bypassable) that are

conditions that stop the drive and help prevent starting. Provide an alarm

when an Interlock stops the drive. Provide maintenance the capability to

bypass the bypassable Permissives and Interlocks.

8 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 9

PowerFlex 6000 Drive (P_PF6000)

IMPORTANT

• Maintenance personnel can disable (soft lock out) the drive. This

capability is not a substitute for hard lockout/tagout (LOTO) procedures.

• Monitor an I/O fault input and a communication watchdog timer, and

alarm on an I/O or communication failure. The failure condition can

optionally de-energize the outputs to the drive, requiring a reset.

• In Override mode, provide an override state input that determines if the

override is to run or stop the drive (default = stop), and, if the drive is to

run, an override speed reference and direction.

• The instruction provides simulation capability. Outputs to the drive are

kept de-energized, but the object can be manipulated as if a working drive

were present, including a basic ramp-up of speed feedback value on

starting and ramp-down on stopping. The simulated ramp-up-to-speed

time is configurable. This capability is often used for activities such as

system testing and operator training.

Required Files

Add-On Instructions are reusable code objects that contain encapsulated logic

that can streamline implementing your system. This functionality lets you create

your own instruction set for programming logic as a supplement to the

instruction set provided natively in the ControlLogix® firmware. An Add-On

Instruction is defined once in each controller project, and can be instantiated

multiple times in your application code as needed.

Controller File

The P_PF6000_3_5-00_RUNG.L5X rung import must be imported into the

controller project to be used in the controller configuration. The service release

number (boldfaced) can change as service revisions are created.

Visualization Files

This Add-On Instruction has associated visualization files that provide a

common user interface. These files can be downloaded from the Product

Compatibility and Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/pcdc.page

The visualization file dependencies require Process Library content imports to

occur in a specific order as reflected in the following tables:

• Images

• Global Objects

• Standard Displays

• HMI Tags

• Macros

.

Images are external graphic files that can be used in displays. They must be

imported for FactoryTalk View software to make use of them.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 9

Page 10

PowerFlex 6000 Drive (P_PF6000)

When PNG files are imported, they are renamed by FactoryTalk View software

with a .bmp file extension, but retain a .png format.

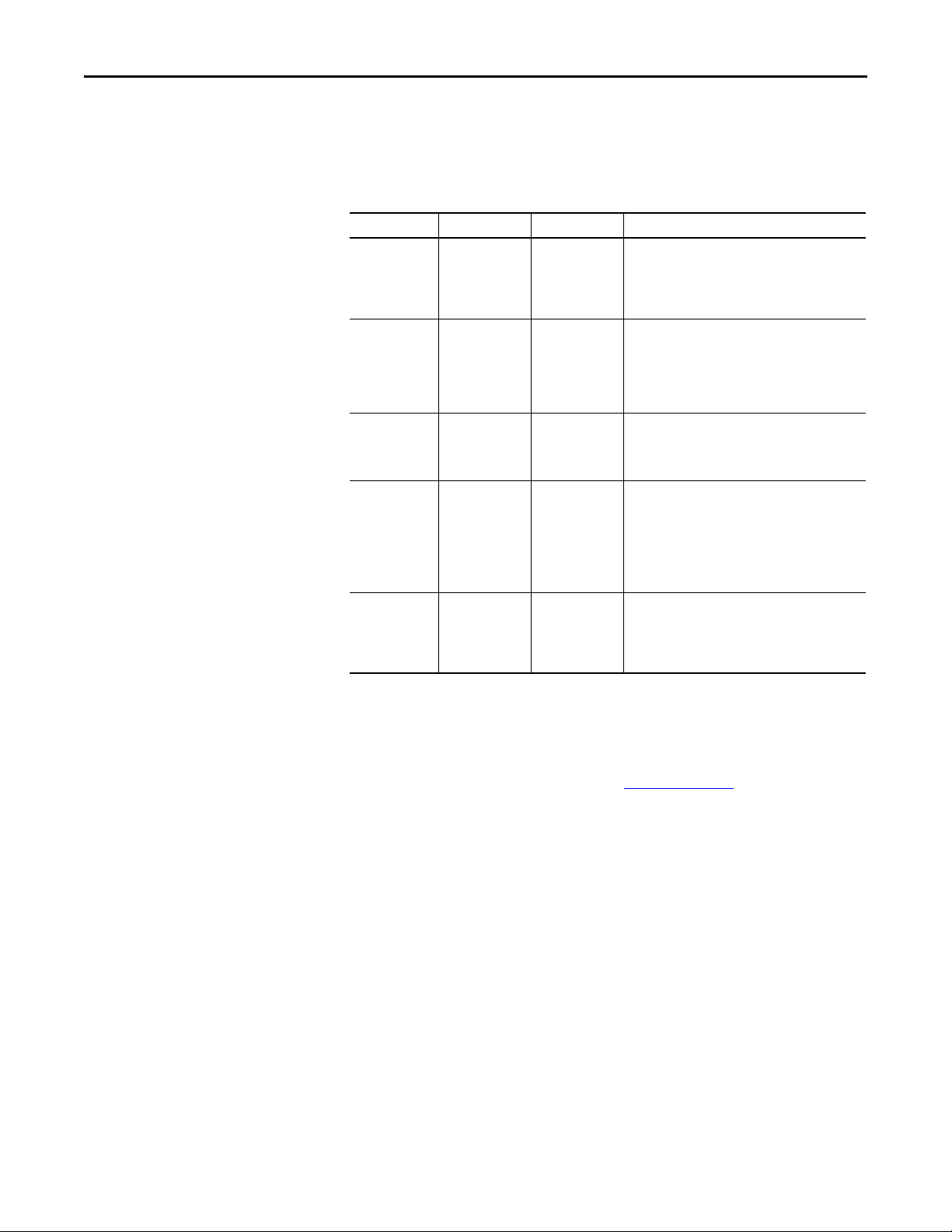

Table 2 - Visualization Files: Images (.png)

FactoryTalk View SE Software FactoryTalk View ME Software Description

All .png files in the images folder All .png files in the images folder These are the common icons that are used in the global

objects and standard displays for all Process Objects.

The Global Object files (.ggfx file type) in the following table are Process Library

display elements that are created once and referenced multiple times on multiple

displays in an application. When changes are made to a Global Object, all

instances in the application are automatically updated.

Table 3 - Visualization Files: Global Objects (.ggfx)

FactoryTalk View SE Software FactoryTalk View ME Software Description

(RA-BAS) Common Faceplate Objects (RA-BAS-ME) Common Faceplate Objects Global objects used on process object faceplates.

(RA-BAS) P_VSD Graphics Library (RA-BAS-ME) P_VSD Graphics Library Drive global object device symbols used to build

(RA-BAS) Process Alarm Objects (RA-BAS-ME) Process Alarm Objects Global objects used for managing alarms on process

(RA-BAS) Process Diagnostic Objects (RA-BAS-ME) Process Diagnostic Objects Diagnostic global objects used on process

(RA-BAS) Process Faceplate Motor Objects (RA-BAS-ME) Process Faceplate Motor Objects Motor global objects used on process object faceplates.

(RA-BAS) Process Help Objects (RA-BAS-ME) Process Help Objects Global objects used for all process objects help displays.

(RA-BAS) Process Interlock Objects (RA-BAS-ME) Process Interlock Objects Global objects used for managing interlocks and

(RA-BAS) Process Mode Objects (RA-BAS-ME) Process Mode Objects Global objects used for managing modes on process

process graphics.

object faceplates.

object faceplates.

permissives on process object faceplates.

object faceplates.

The Standard Display files (.gfx file type) in the following table are the Process

Library displays that you see at runtime.

Table 4 - Visualization Files: Standard Displays (.gfx)

FactoryTalk View SE Software FactoryTalk View ME Software Description

(RA-BAS) Common-AnalogEdit N/A Faceplate used for analog input data entry. The FactoryTalk

(RA-BAS) P_Alarm-Faceplate (RA-BAS-ME) P_Alarm-Faceplate The faceplate that is used for the object

(RA-BAS) P_Alarm-Help (RA-BAS-ME) P_Alarm-Help Alarm Help information that is accessed from the

(RA-BAS) P_Mode-Config (RA-BAS-ME) P_Mode-Config The Configuration Display used to configure the

(RA-BAS) P_Mode-Help (RA-BAS-ME) P_Mode-Help Mode Help information that is accessed from the

(RA-BAS) P_PF6000-Faceplate (RA-BAS-ME) P_PF6000-Faceplate The faceplate display that is used for the object

(RA-BAS) P_PF6000-Quick (RA-BAS-ME) P_PF6000-Quick The Quick display that is used for the object

(RA-BAS) Process Motor Family-Help (RA-BAS-ME) Process Motor Family-Help The Help display for Motor objects

View ME faceplates use the native analog input data entry

so no file is required.

P_AIarm faceplate.

P_Mode object.

Help faceplate.

10 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 11

Table 4 - Visualization Files: Standard Displays (.gfx)

FactoryTalk View SE Software FactoryTalk View ME Software Description

(RA-BAS) P_Intlk-Faceplate (RA-BAS-ME) P_Intlk-Faceplate Optional

The interlock faceplate used for the object.

Use this file if your Discrete Output has an associated

P_Intlk object and you enable navigation to its faceplate

from the Discrete Output faceplate.

(RA-BAS) P_Perm-Faceplate (RA-BAS-ME) P_Perm-Faceplate Optional

Permissive faceplate that is used for the object

Use this file if your object has an associated P_Perm object

and you enable navigation to the P_Perm faceplate from

the object faceplate.

(RA-BAS) P_ResInh-Faceplate (RA-BAS-ME) P_ResInh-Faceplate Optional

Restart/inhibit faceplate display that is used for the object

Use this file if your object has an associated P_ResInh

object and you enable navigation to the P_ResInh

faceplate from the object faceplate.

(RA-BAS) P_RunTime-Faceplate (RA-BAS-ME) P_RunTime-Faceplate Optional

RunTime faceplate display that is used for the object

Use this file if your object has an associated P_RunTime

object and you enable navigation to the P_RunTime

faceplate from the object faceplate.

(RA-BAS) Process Interlock Family-Help (RA-BAS-ME) Process Interlock Family-Help Optional

Interlock/permissives help display that is used for

the object

Use this file if you use the P_Intlk or P_Perm faceplate.

PowerFlex 6000 Drive (P_PF6000)

HMI Tags are created in a FactoryTalk View ME application to support tab

switching on Process Library faceplates. The HMI tags can be imported via the

comma-separated values file (.csv file type) in the following table.

Table 5 - Visualization Files: HMI Tags (.csv)

FactoryTalk View SE Software FactoryTalk View ME Software Description

N/A FTVME_PlantPAxLib_Tags_3_5_xx.csv

where xx = the service release number.

These tags must be imported into the

FactoryTalk View ME project to support switching tabs on

any Process Object faceplate.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 11

Page 12

PowerFlex 6000 Drive (P_PF6000)

TIP

Controller Code

This section describes the parameter references for this Add-On Instruction.

PowerFlex Drive InOut Structure

InOut parameters are used to link the Add-On Instruction to external tags that

contain necessary data for the instruction to operate. These external tags must be

of the data type shown.

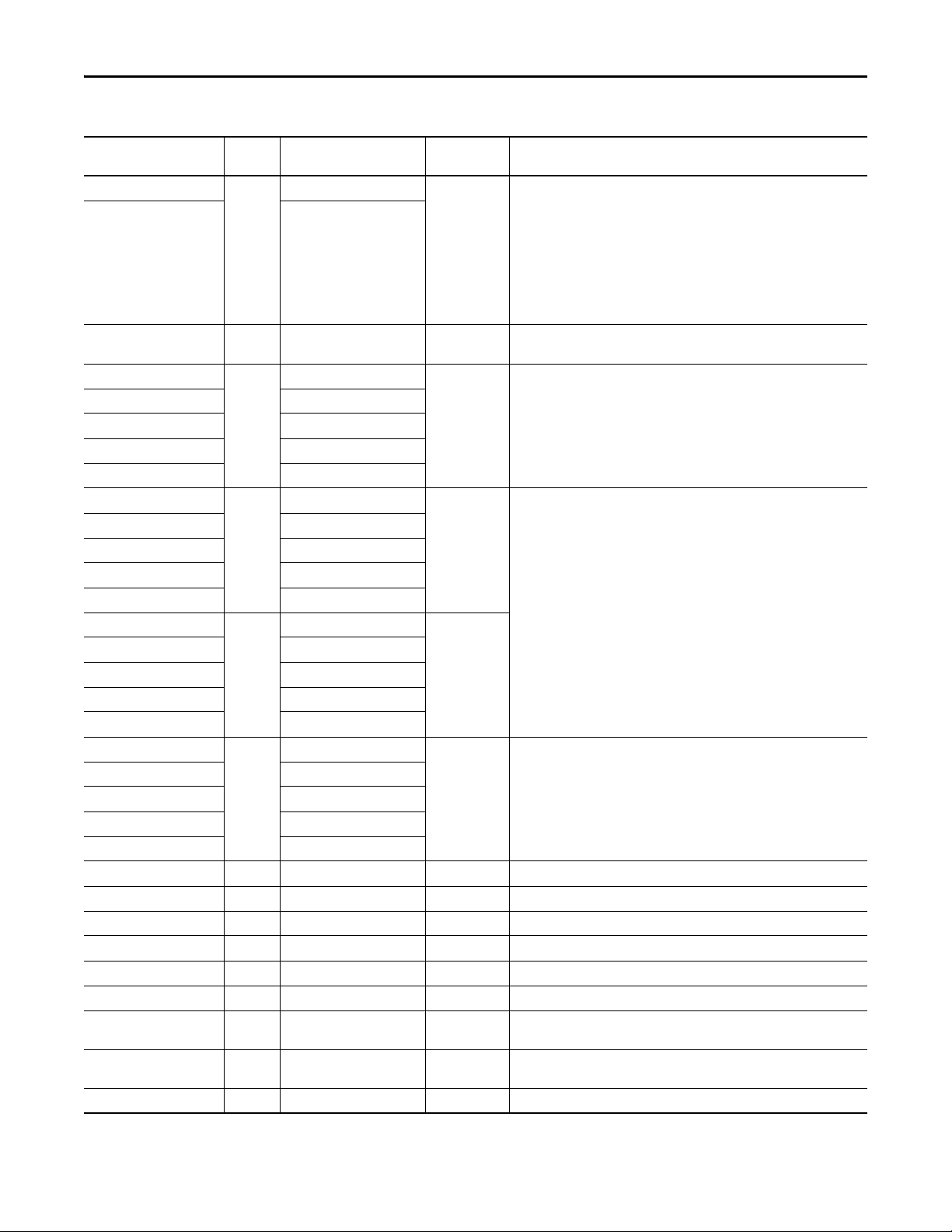

Table 6 - P_PF6000 Drive InOut Parameters

Tag Name Data Type Description

Inp P_PF6000_Inp PowerFlex 6000 input assembly.

Out P_PF6000_Out PowerFlex 6000 output assembly.

Ref_FaultCodeList P_DescList Tag containing list of fault codes (DINT) and descriptions (STRING_40).

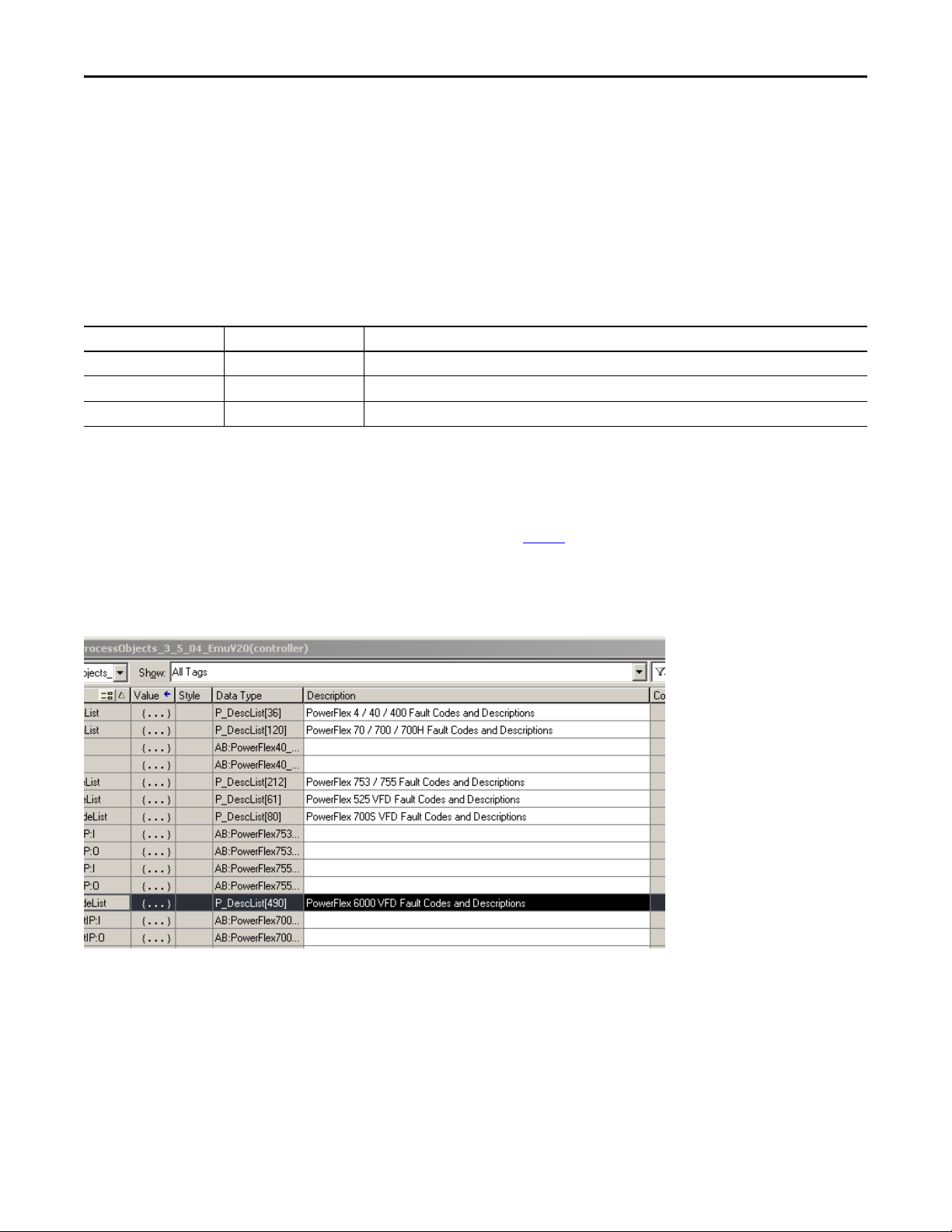

The user-defined data types (UDTs) and the Array tag containing the list of

PowerFlex 6000 fault codes and descriptions are included in the RUNG import

that brings in the P_PF6000 Add-On Instruction. See the programming

example on page 28

for details.

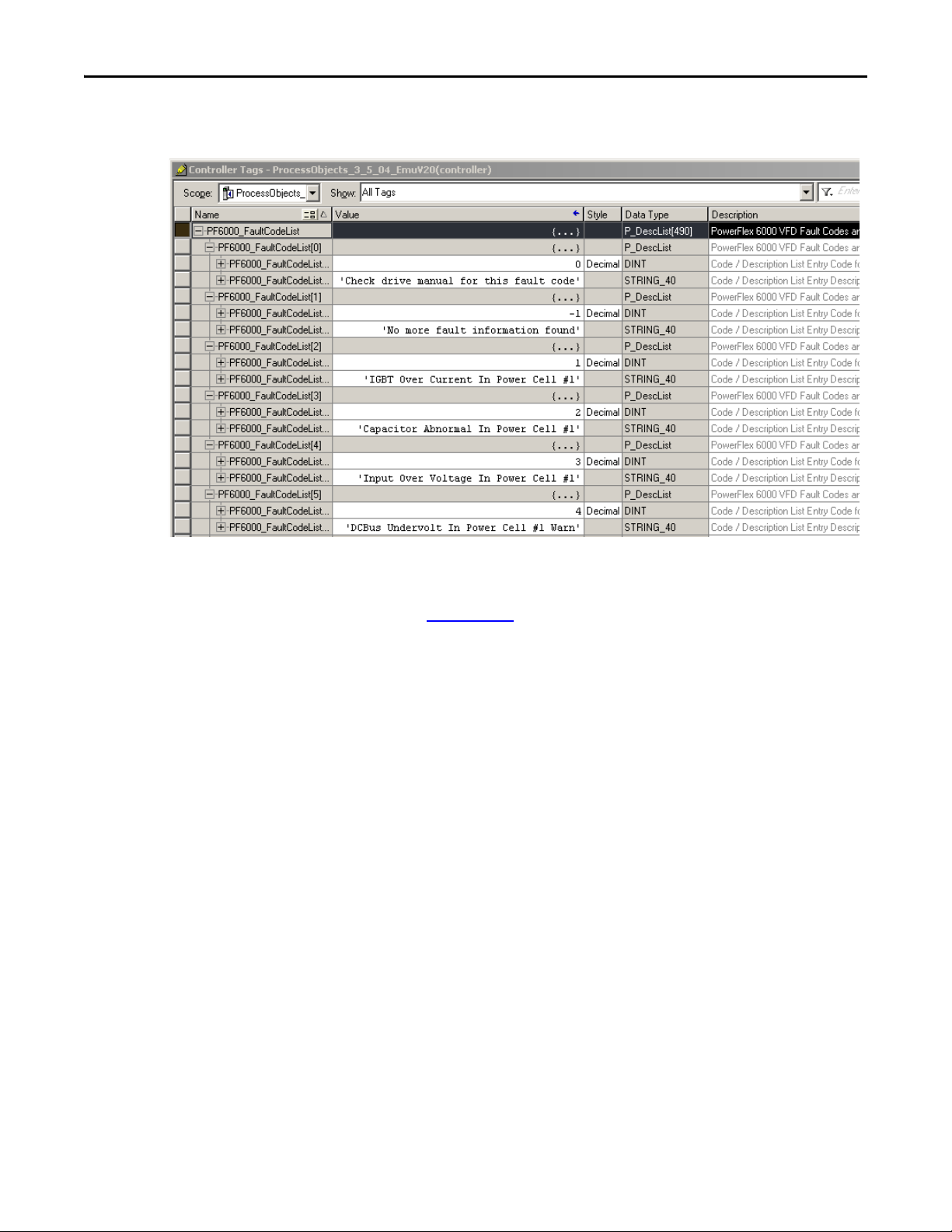

The figure shows the drive fault table tags that are in each template.

Make sure the tag 'PF6000_FaultCodeList' is entered in the P_PF6000

Ref_FaultCodeList parameter.

12 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 13

PowerFlex 6000 Drive (P_PF6000)

Each fault code list provides pre-configured fault codes and descriptions for a

given drive family.

For a complete list of fault codes, refer to the PowerFlex 6000 Medium Voltage

Variable Frequency Drive Firmware, Parameters, and Troubleshooting Manual,

publication 6000-TD004

.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 13

Page 14

PowerFlex 6000 Drive (P_PF6000)

Table 7 - P_PF6000 Drive Input Parameters

PowerFlex 6000 Drive Input Structure

Input parameters include the following:

• Input data elements (Inp_) are typically used to connect field inputs from

I/O modules or signals from other objects.

• Configuration data elements (Cfg_) are used to set configurable

capabilities and features of the instruction.

• Command data elements (PCmd_, OCmd_, MCmd_) are used by

program logic, operators, and maintenance personnel to request

instruction actions.

• Setting data elements (PSet_, OSet_, MSet_) are used by program logic,

operators, and maintenance personnel to establish runtime setpoints,

thresholds, and so forth. Set_ data elements (without a leading P, O, or M)

establish runtime settings regardless of role or mode.

Input Parameter Data

Type

EnableIn BOOL 1 Ladder Diagram:

Inp_PermOK BOOL 1 1 = Permissives OK, drive can start.

Inp_NBPermOK BOOL 1 1 = Non-bypassable permissives OK, drive can start.

Inp_IntlkOK BOOL 1 1 = Interlocks OK, drive can start/run.

Inp_NBIntlkOK BOOL 1 1 = Non-bypassable interlocks OK, drive can start/run.

Inp_Sim BOOL 0 Simulation input. When set to 1, the instruction keeps outputs de-energized

Inp_Hand BOOL 0 1 = Request to acquire Hand mode.

Inp_Ovrd BOOL Mode.Inp_Ovrd 0 1 =Request to acquire Override mode.

Inp_OvrdCmd SINT 0 Override mode command:

Inp_OvrdSpeed REAL 0.0 Value to set speed reference in Override mode (SpeedRef engineering units).

Inp_Reset BOOL 0 1 = Reset drive fault conditions and latched alarms.

Cfg_AllowLocal BOOL 0 1 =Allow Local Star t/Stop without alarm.

Cfg_HasPermObj BOOL 0 1 = Tells HMI a P_Perm is connected to Inp_Perm.

Cfg_HasIntlkObj BOOL 0 1 =T ells HMI a P_Intlk is connected to Inp_Intlk.

Cfg_HasResInhObj BOOL 0 1 = Tells HMI a P_ResInh Restart Inhibit is connected.

Cfg_HasRunTimeObj BOOL 0 1 =T ells HMI a P_RunTime is connected.

Alias For Default Description

If the rung-in condition is true, the instruction’s Logic routine executes. If the

rung-in condition is false, the instruction’s EnableInFalse routine executes.

Function Block Diagram:

If true, or not connected, the instruction’s Logic routine executes. If the parameter

is exposed as a pin and wired, and the pin is false, the instruction’s EnableInFalse

routine executes.

Structured Text:

No effect. The instruction’s Logic routine executes.

(zero) and simulates a working drive. When set to 0, the instruction operates the

drive normally.

0 = Release Hand mode.

0 = Release Override mode.

0 = None

1 = Stop

2 = Start

0= Start/Stop from HMI/Program only.

14 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 15

Table 7 - P_PF6000 Drive Input Parameters

PowerFlex 6000 Drive (P_PF6000)

Input Parameter Data

Type

Cfg_SetTrack BOOL 1 1 = PSets track OSets in Operator, OSets track PSets in Program.

Cfg_SetTrackOvrdHand BOOL 0 1 = Program/Operator settings track Override/Hand speed reference.

Cfg_PCmdClear BOOL Mode.Cfg_PCmdClear 1 When this parameter is 1, program commands are cleared once they are acted

Cfg_ProgDefault BOOL Mode.Cfg_ProgDefault 0 This parameter defines the default mode. When this parameter is 1, the mode

Cfg_OperStopPrio BOOL 0 1 = OCmd_Stop available in any mode.

Cfg_OCmdResets BOOL 0 1 = New Operator drive command resets fault.

Cfg_OvrdPermIntlk BOOL 0 1 = Override ignores bypassable permissives/interlocks.

Cfg_ShedOnFailToStart BOOL 1 1 = Stop motor and alarm on Fail to Start.

Cfg_ShedOnIOFault BOOL 1 1 = Stop motor and alarm on I/O Fault.

Cfg_SimScaleEU BOOL 0 1 = In simulation, scale Speed Ref EU to Speed Fdbk EU.

Cfg_SimScaleRaw BOOL 0 1 = In simulation, scale Speed Ref EU to raw, then raw to Speed Fdbk EU.

Cfg_HasFailToStartAlm BOOL FailToStart.Cfg_Exists 0 These parameters determine whether the corresponding alarm exists and is

Cfg_HasFailToStopAlm FailToStop.Cfg_Exists

Cfg_HasIntlkTripAlm IntlkTrip.Cfg_Exists

Cfg_HasDriveFaultAlm DriveFault.Cfg_Exists

Cfg_HasIOFaultAlm IOFault.Cfg_Exists

Cfg_FailToStar tResetReqd BOOL FailToStart.Cfg_ResetReqd 0 These parameters determine whether a reset is required to clear the alarm status.

Cfg_FailToStopResetReqd FailToStop.Cfg_ResetReqd

Cfg_IntlkTripResetReqd IntlkTrip.Cfg_ResetReqd

Cfg_DriveFaultResetReqd DriveFault.Cfg_ResetReqd

Cfg_IOFaultResetReqd IOFault.Cfg_ResetReqd

Cfg_FailToStartAckReqd BOOL FailToStart.Cfg_AckReqd 1 These parameters determine whether an acknowledgement is required for an

Cfg_FailToStopAckReqd FailToStop.Cfg_AckReqd

Cfg_IntlkTripAckReqd IntlkTrip.Cfg_AckReqd

Cfg_DriveFaultAckReqd DriveFault.Cfg_AckReqd

Cfg_IOFaultAckReqd IOFault.Cfg_AckReqd

Alias For Default Description

0 = No tracking.

upon. When set to 0, program commands remain set until cleared by the

application program logic.

IMPORTANT: Clearing this parameter online can cause unintended program

command execution.

defaults to Program if no mode is being requested. When this parameter is 0, the

mode defaults to Operator if no mode is being requested.

IMPORTANT: Changing this parameter online can cause unintended mode

changes.

0 = OCmd_Stop only in Operator and Maintenance modes.

0 = Reset required to clear fault.

0 = Always use permissives/interlocks.

0 = Alarm only on Fail to Start.

IMPORTANT: If a condition is configured to shed the device to the Off state on a

fault, a reset is required to clear the shed fault to command the drive to a state

other than Off.

0 = Alarm only on I/O Fault.

IMPORTANT: If a condition is configured to shed the device to the Off state on a

fault, a reset is required to clear the shed fault to command the drive to a state

other than Off.

checked or if the alarm does not exist and is not used. When these parameter are

1, the corresponding alarm exists.

When these parameters are 1, the alarm is latched ON when the alarm occurs.

After the alarm condition returns to normal, a reset is required to clear the alarm

status (for example, PCmd_Reset, OCmd_Reset, or Inp_Reset are required to

clear Alm_FailtoStart after the alarm is set and the value returns to normal).

When these parameter are 0, no reset is required and the alarm status is cleared

when the alarm condition returns to normal.

IMPORTANT: If the reset clears the alarm, it also acknowledges the alarm.

alarm. When these parameters are 1, the acknowledge (ack) bit is cleared when

the alarm occurs. An acknowledge command (for example,

PCmd_FailtoStartAck) are required to acknowledge the alarm. When set to 0, the

Acknowledge bit is set when an alarm occurs indicating an acknowledged alarm

and no acknowledge command is required.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 15

Page 16

PowerFlex 6000 Drive (P_PF6000)

Table 7 - P_PF6000 Drive Input Parameters

Input Parameter Data

Cfg_FailToStar tSeverity INT FailToStart.Cfg_Severity 1000 These parameters determine the severity of each alarm that gauges the color and

Cfg_FailToStopSeverity FailToStop.Cfg_Severity 1000

Cfg_IntlkTripSeverity IntlkTrip.Cfg_Severity 500

Cfg_DriveFaultSeverity DriveFault.Cfg_Severity 1000

Cfg_IOFaultSeverity IOFault.Cfg_Severity 1000

Cfg_MinSpdRef REAL 0.0 Minimum speed reference in engineering units (for limiting).

Cfg_MaxSpdRef REAL 60.0 Maximum speed reference in engineering units (for limiting).

Cfg_SpeedRefEUMin REAL 0.0 Speed reference minimum in Engineering units (for scaling).

Cfg_SpeedRefEUMax REAL 60.0 Speed reference maximum in engineering units (for scaling).

Cfg_SpeedFdbkEUMin REAL 0.0 Speed feedback minimum in engineering units (for scaling).

Cfg_SpeedFdbkEUMax REAL 60.0 Speed feedback maximum in engineering units (for scaling).

Cfg_SimRampT DINT 10 Time to ramp speed feedback when in simulation (seconds).

Cfg_FailToStar tT DINT 15 Time after start to get run feedback before fault (seconds).

Cfg_FailToStopT DINT 15 Time after stop to drop run feedback before fault (seconds).

Cfg_ResetPulseT DINT 2 Time to pulse Out_Reset to clear drive fault.

Cfg_WatchdogT DINT 5 Communication Watchdog Timeout time (sec).

Cfg_OperKeep SINT 2#0000_0000 Operator keeps control in Program mode:

Cfg_ProgKeep SINT 2#0000_0000 Program keeps control in Operator mode:

PSet_SpeedRef REAL 0.0 Program setting of speed reference (engineering units).

PSet_Owner DINT 0 Program Owner Request ID (nonzero) or Release (zero).

OSet_SpeedRef REAL 0.0 Operator setting of speed reference (engineering units).

PCmd_Start

PCmd_Stop

PCmd_Fwd

PCmd_Acq BOOL Mode.PCmd_Acq 0 When Cfg_PCmdClear is 1:

PCmd_Rel Mode.PCmd_Rel

Type

BOOL 0 When Cfg_PCmdClear is 1:

Alias For Default Description

symbol that are used to indicate alarm status on the faceplate and global object.

The following are valid values:

1…250 = Low

251…500 = Medium

501…750 = High

751…1000 = Urgent

IMPORTANT: These severity priorities drive only the indication on the global

object and faceplate. The Alarm and Events definition severity drives the color

and symbol that is used on the alarm banner. The definition severity also provides

an alarm summary and the value returned by the FactoryTalk Alarm and Events

software display commands.

Bit .0 = Reference

Bit .1 = Start/stop

Bit .0 = Reference

Bit .1 = Start/stop

• Set PCmd_Start to 1 to start the Drive

• Set PCmd_Stop to 1 to stop the motor

• These parameters are reset automatically

When Cfg_PCmdClear is 0:

• Set PCmd_Start to 1 to start the drive

• Set PCmd_Start to 0 to stop the driver

• PCmd_Stop is not used

• These parameters do not reset automatically

• Set PCmd_Acq to 1 to Acquire

• Set PCmd_Rel to 1 to Re lease

• These parameters reset automatically

When Cfg_PCmdClear is 0:

• Set PCmd_Acq to 1 to Acquire

• Set PCmd_Acq to 0 to Release

• PCmd_Rel is not used

• These parameters do not reset automatically

16 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 17

Table 7 - P_PF6000 Drive Input Parameters

PowerFlex 6000 Drive (P_PF6000)

Input Parameter Data

Type

PCmd_Lock BOOL Mode.PCmd_Lock 0 When Cfg_PCmdClear is 1:

PCmd_Unlock Mode.PCmd_Unlock

PCmd_Reset BOOL 0 • Set PCmd_Reset to 1 to reset all alarms requiring reset

PCmd_FailToStar tAck BOOL FailToStart.PCmd_Ack 0 • Set PCmd_<Alarm>Ack to 1 to Acknowledge alarm

PCmd_FailToStopAck FailToStop.PCmd_Ack

PCmd_IntlkTripAck IntlkTrip.PCmd_Ack

PCmd_DriveFaultAck DriveFault.PCmd_Ack

PCmd_IOFaultAck IOFault.PCmd_Ack

PCmd_FailToStar tSuppress BOOL FailToStart.PCmd_Suppress 0 When Cfg_PCmdClear is 1:

PCmd_FailToStopSuppress FailToStop.PCmd_Suppress

PCmd_IntlkTripSuppress IntlkTrip.PCmd_Suppress

PCmd_DriveFaultSuppress DriveFault.PCmd_Suppress

PCmd_IOFaultSuppress IOFault.PCmd_Suppress

PCmd_FailToStar tUnsuppress BOOL FailToStart.PCmd_Unsuppress 0

PCmd_FailToStopUnsuppress FailToStop.PCmd_Unsuppress

PCmd_IntlkTripUnsuppress IntlkTrip.PCmd_Unsuppress

PCmd_DriveFaultUnsuppress DriveFault.PCmd_Unsuppress

PCmd_IOFaultUnsuppress IOFault.PCmd_Unsuppress

PCmd_FailToStartUnshelve BOOL FailToStart.PCmd_Unshelve 0 • Set PCmd_<Alarm>Unshelve to 1 to Unshelve alarm

PCmd_FailToStopUnshelve FailToStop.PCmd_Unshelve

PCmd_IntlkTripUnshelve IntlkTrip.PCmd_Unshelve

PCmd_DriveFaultUnshelve DriveFault.PCmd_Unshelve

PCmd_IOFaultUnshelve IOFault.PCmd_Unshelve

OCmd_Start BOOL 0 Operator command to start drive.

OCmd_Stop BOOL 0 Operator command to stop drive.

OCmd_Bypass BOOL 0 Operator command to bypass all bypassable interlocks and permissives.

OCmd_Check BOOL 0 Operator command to check (not bypass) all interlocks and permissives.

MCmd_Disable BOOL 0 Maintenance command to disable drive.

MCmd_Enable BOOL 0 Maintenance command to enable (permit to run) drive.

MCmd_Acq BOOL Mode.MCmd_Acq 0 Ma intenance Command to Acquire Ownership (Op erator/Program/Overload to

MCmd_Rel BOOL Mode.MCmd_Rel 0 Maintenance Command to Release Ownership (Maintenance to Operator/

OCmd_AcqLock BOOL Mode.OCmd_AcqLock 0 Operator Command to Acquire (Program to Operator)/Lock Ownership.

Alias For Default Description

• Set PCmd_Lock to 1 to Lock

• Set PCmd_Unlock to 1 to Unlock

• These parameters are reset automatically

• When Cfg_PCmdClear is 0:

• Set PCmd_Lock to 1 to Lock

• Set PCmd_Lock to 0 to Unlock

• PCmd_Unlock is not used

• These parameters do not reset automatically

• This parameter is always reset automatically

• These parameters are reset automatically

• Set PCmd_<Alarm>Suppress to 1 to sup press alarm

• Set PCmd_<Alarm>Unsuppress to 1 to unsuppress alarm

• These parameters reset automatically

When Cfg_PCmdClear is 0:

• Set PCmd_<Alarm>Suppress to 1 to sup press alarm

• Set PCmd_<Alarm>Suppress to 0 to unsuppress alarm

• PCmd_<Alarm>Unsuppress is not used

• These Parameters do not reset automatically

• These parameters are reset automatically

Maintenance).

Program/Overload).

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 17

Page 18

PowerFlex 6000 Drive (P_PF6000)

Table 7 - P_PF6000 Drive Input Parameters

Input Parameter Data

Type

OCmd_Unlock BOOL Mode.OCmd_UnlockRel 0 Operator Command to Unlock/Release (Operator to Program) Ownership

OCmd_Reset BOOL 0 Operator command to reset all alarms requiring reset.

OCmd_ResetAckAll BOOL 0 Operator command to acknowledge and reset all alarms and latched shed

Alias For Default Description

conditions.

18 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

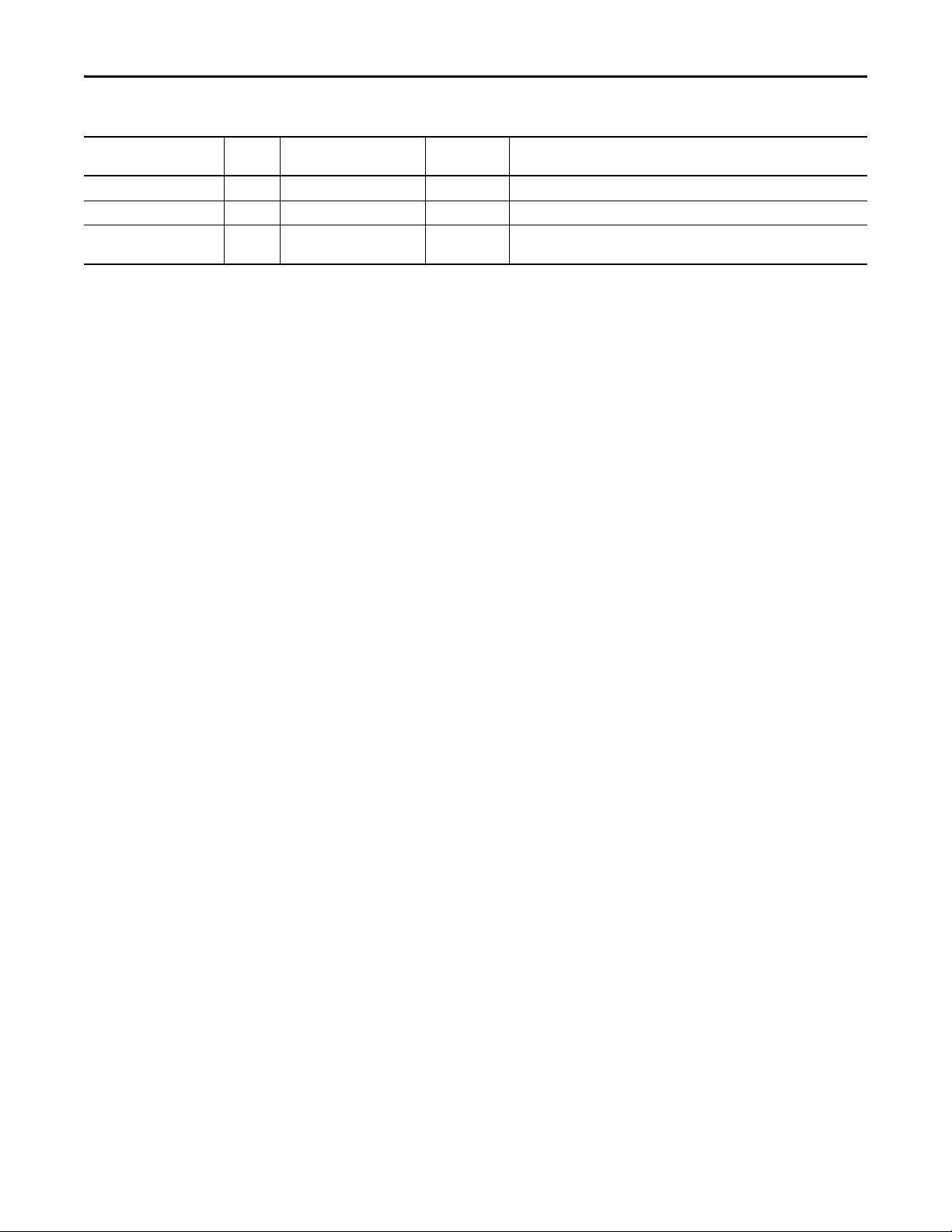

Page 19

Table 8 - P_PF6000 Drive Output Parameters

PowerFlex 6000 Drive (P_PF6000)

PowerFlex 6000 Drive Output Structure

Output parameters include the following:

• Value data elements (Val_) are numeric outputs of the instruction for

use by the HMI. Values can also be used by other application logic or

software packages.

• Source and Quality data elements (SrcQ_) are outputs of the instruction

used by the HMI to indicate PV source and quality.

• Status data elements (Sts_) are bit outputs of the instruction for use by the

HMI. Status bits can also be used by other application logic.

• Error data elements (Err_) are outputs of the instruction that indicate a

particular configuration error. If any Err_ bit is set then the Sts_Err

configuration error summary status is set and the Invalid Configuration

indicator is displayed on the HMI.

• Not Ready data elements (Nrdy_) are bit outputs of the instruction for use

by the HMI for displaying the Device Not Ready indicator. Status bits can

also be used by other application logic.

• Alarm data elements (Alm_) are outputs of the instruction that indicate a

particular alarm has occurred.

• Acknowledge data elements (Ack_) are outputs of the instruction that

indicate the corresponding alarm has been acknowledged.

• Ready data elements (Rdy_) are bit outputs of the instruction used

by the HMI to enable or disable Command buttons and Setting

entry fields.

Output Parameter Data Type Alias For Description

EnableOut BOOL Enable output: The EnableOut signal is not manipulated by this instruction. Its output state

Val_SpeedRef REAL Speed reference (target, in engineering units) to drive.

Val_SpeedFdbk REAL Speed feedback (actual, in engineering units) from drive.

Val_SpeedRefRaw REAL Copy of speed reference output (in raw units) for faceplate.

Val_SpeedFdbkRaw REAL Copy of speed feedback input (in raw units) for faceplate.

Val_SpeedRefEUMin REAL Minimum of speed reference = MIN (Cfg_SpeedFdbkEUMin, Cfg_SpeedFdbkEUMax).

Val_SpeedRefEUMax REAL Maximum of speed re ference = MAX (C fg_SpeedFdbkEUMin, Cfg_SpeedFdbkEUMax).

Val_SpeedFdbkEUMin REAL Minimum of speed feedback = MIN (Cfg_SpeedFdbkEUMin, Cfg_SpeedFdbkEUMax).

Val_SpeedFdbkEUMax REAL Maximum of speed feedback = MAX (Cfg_SpeedFdbkEUMin, Cfg_SpeedFdbkEUMax).

Val_MotorCurrent REAL Drive output current (amps).

Val_MotorCurrentPct REAL Motor current (% full load amps).

Val_MotorVoltage REAL Motor voltage (volts).

Val_Outpu tPower REAL Drive output power (k W).

Val_MotorPowerPct REAL Motor power (% rated power).

always reflects EnableIn input state.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 19

Page 20

PowerFlex 6000 Drive (P_PF6000)

Table 8 - P_PF6000 Drive Output Parameters

Output Parameter Data Type Alias For Description

SrcQ_IO SINT I/O signal source and quality.

SrcQ Final drive source and quality.

GOOD 0 = I/O live and confirmed good quality

1 = I/O live and assumed good quality

2 = No feedback configured, assumed good quality

TEST 8 = Device simulated

9 = Device loopback simulation

10 = Manually entered value

UNCERTAIN 16 = Live input, off-specification

17 = Value substituted at device/bus

18 = Value substituted by maintenance (Has and not Use)

19 = Shed, using last good value

20 = Shed, using replacement value

BAD 32 = Signal failure (out-of-range, NaN, invalid combination)

33 = I/O channel fault

34 = I/O module fault

35 = Bad I/O configuration (for example, scaling parameters)

Val_Cmd SINT Device command:

Val_Fdbk SINT Device feedback:

Val_Sts SINT Device confirmed status:

Val_Fault SINT Device fault status:

Val_Mode SINT Mode.Val The current mode is shown with status bits and also as an enumeration ‘Val_Mode’ as follows:

Val_Owner DINT Current object owner ID (0 = not owned).

0 = None

1 = Stop

2 = Start

0 = Stopped

1 = Running

0 = None

1 = Stopped

2 = Running

6 = Stopping

7 = Starting

33 = Disabled

0 = None

16 = Fail to Start

17 = Fail to Stop

18 = Drive Fault

32 = I/O Fault

34 = Configuration error

0 = No mode

1 = Hand

2 = Maintenance

3 = Override

4 = Program (locked)

5 = Operator (locked)

6 = Program (unlocked, Operator is default)

7 = Operator (unlocked, Program is default)

8 = Program (unlocked, Program is default)

9 = Operator (unlocked, Operator is default)

20 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 21

PowerFlex 6000 Drive (P_PF6000)

Table 8 - P_PF6000 Drive Output Parameters

Output Parameter Data Type Alias For Description

Val_Notify SINT Current alarm level and acknowledgement (enumeration):

0 = No alarm

1 = Alarm cleared: a reset or acknowledge is required

2 = Low (acknowledged)

3 = Low (unacknowledged)

4 = Medium (acknowledged)

5 = Medium (unacknowledged)

6 = High (acknowledged)

7 = High (unacknowledged)

8 = Urgent (acknowledged)

9 = Urgent (unacknowledged)

Sts_Stopped BOOL 1 = Drive requested to stop and is confirmed stopped.

Sts_Starting BOOL 1 = Drive requested to run and awaiting run feedback.

Sts_Running BOOL 1 = Drive requested to run and is confirmed running.

Sts_Stopping BOOL 1 = Drive requested to stop and awaiting stopped feedback.

Sts_NotReady BOOL 1 = Drive is not ready to run.

Sts_WatchdogTO BOOL 1 = Drive communication watchdog timed out (communication fail).

Sts_SpeedLimited BOOL 1 = Speed reference setting exceeds configured maximum/minimum limit.

Sts_LogicSts INT Logic status word from drive input assembly (see drive manual for bit assignments).

Sts_Available BOOL 1 = Drive available for control by automation (program).

Sts_Bypass BOOL 1 = Bypassable interlocks and permissives are bypassed.

Sts_BypActive BOOL 1 = Bypassing active (bypassed or maintenance).

Sts_Disabled BOOL 1 = Drive is disabled.

Sts_NotRdy BOOL 1 = Motor is not ready to run (independent of mode). - Check interlocks and permissives.

Nrdy_Disabled BOOL 1 = Device not ready due to the following:

Nrdy_CfgErr

Nrdy_Intlk

Nrdy_Perm

Nrdy_OperPrio

Nrdy_Fail

Nrdy_IOFault

Nrdy_Trip

Nrdy_DriveNR

Nrdy_NoMode

Sts_MaintByp BOOL 1 = Maintenance bypass is active, display icon.

Sts_AlmInh BOOL 1 = Alarm is shelved, disabled, or suppressed, display icon.

Sts_Err BOOL 1 = Error in configuration: See detail bits for reason.

Err_Timer BOOL 1 = Error in configuration: Invalid check or reset pulse time (use 0…2,147,483).

Err_Sim BOOL 1 = Error in configuration: Simulation timer preset (use 0…2,147,483).

Err_Alarm BOOL 1 = Error in configuration: Alarm minimum On time or severity.

Err_FdbkEU BOOL 1 = Error in configuration: Speed Fdbk EU Min = Max.

Err_RefLim BOOL 1 = Error in configuration: Speed Ref Limit Min > Max.

• Device disabled by Maintenance

• Configuration error

• Interlock not OK

• Permissive not OK

• Operator state 0 priority command requires reset

• Device failure (shed requires reset),

• I/O Fault (shed requires reset)

• Device tripped (Drive fault)

• Drive not ready

• Device logic disabled/no mode.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 21

Page 22

PowerFlex 6000 Drive (P_PF6000)

Table 8 - P_PF6000 Drive Output Parameters

Output Parameter Data Type Alias For Description

Err_RefEU BOOL 1 = Error in configuration: Speed Ref EU Min = Max.

Sts_Hand BOOL Mode.Sts_Hand 1 = Mode is Hand (supersedes Maintenance, Override, Program, Operator).

Sts_Maint BOOL Mode.Sts_Maint 1 = Mode is Maintenance (supersedes Override, Program, Operator).

Sts_Ovrd BOOL Mode.Sts_Ovrd 1 = Mode is Override (supersedes Program, Operator).

Sts_Prog BOOL Mode.Sts_Prog 1 = Mode is Program (auto).

Sts_Oper BOOL Mode.Sts_Oper 1 = Mode is Operator (manual).

Sts_ProgOperLock BOOL Mode.Sts_ProgOperLock 1 = Program or Operator has requested mode lock.

Sts_NoMode BOOL Mode.Sts_NoMode 1 = No mode (disabled because EnableIn is false).

Sts_MAcqRcvd BOOL Mode.Sts_MAcqRcvd 1=Maintenance Acquire command received this scan

Sts_FailToStar t BOOL FailToStart.Inp 1 = Drive failed to start.

Sts_FailToStop FailToStop.Inp 1 = Drive failed to stop.

Sts_IntlkTrip IntlkTrip.Inp 1 = Drive was stopped by an interlock not OK (one-shot).

Sts_DriveFault DriveFault.Inp 1 = Drive Fault (see drive display or manual).

Sts_IOFault IOFault.Inp I/O Communication fault status:

0 = OK

1 = Bad

Ack_FailToStart BOOL FailToStart.Ack 1 = Fail to Start, Fail to Stop, Interlock Trip, Drive Fault, or I/O Fault alarm has been

Ack_FailToStop FailToStop.Ack

Ack_IntlkTrip IntlkTrip.Ack

Ack_DriveFault DriveFault.Ack

Ack_IOFault IOFault.Ack

Alm_FailToStart BOOL FailToStart.Alm 1 = Drive failed to start alarm.

Alm_FailToStop FailToStop.Alm 1 = Drive failed to stop alarm.

Alm_IntlkTrip IntlkTrip.Alm 1 = Alarm: Drive stopped by an interlock not OK.

Alm_Drive Fault Dr iveFa ult.A lm 1 = Al arm: Driv e Faul t (se e dri ve di spla y or m anual) .

Alm_IOFault IOFault.Alm 1 = I/O Fault alarm.

Sts_FailToStartDisabled BOOL FailToStart.Disabled 1 = Fail to Start, Fail to Stop, Interlock Trip, Drive Fault, or I/O Fault alarm has been disabled (by

Sts_FailToStopDisabled FailToStop.Disabled

Sts_IntlkTripDisabled IntlkTrip.Disabled

Sts_DriveFaultDisabled DriveFault.Disabled

Sts_IOFaultDisabled IOFault.Disabled

Sts_FailToStartSuppressed BOOL FailToStart.Suppressed 1 = Fail to Start, Fail to Stop, Interlock Trip, Drive Fault, or I/O Fault alarm has been suppressed

Sts_FailToStopSuppressed FailToStop.Suppressed

Sts_IntlkTripSuppressed IntlkTrip.Suppressed

Sts_DriveFaultSuppressed DriveFault.Suppressed

Sts_IOFaultSuppressed IOFault.Suppressed

acknowledged.

Maintenance).

by Program.

22 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 23

PowerFlex 6000 Drive (P_PF6000)

Table 8 - P_PF6000 Drive Output Parameters

Output Parameter Data Type Alias For Description

Sts_FailToStartShelved BOOL FailToStart.Shelved 1 = Fail to Start, Fail to Stop, Interlock Trip, Drive Fault, or I/O Fault alarm has been shelved (by

Sts_FailToStopShelved FailToStop.Shelved

Sts_IntlkTripShelved IntlkTrip.Shelved

Sts_Dr iveFaultShelved DriveFaul t.Shelved

Sts _IO Faul tSh elv ed IO Faul t.S hel ved

Rdy_Start BOOL 1 = Ready to receive OCmd for Start, Stop, Bypass, or Check (enables HMI button).

Rdy_Stop

Rdy_Bypass

Rdy_Check

Rdy_Disable BOOL 1 = Ready to receive MCmd Disable or Enable (enables HMI button).

Rdy_Enable

Rdy_Reset BOOL 1 = Ready to receive OCmd_Reset (enables HMI button).

Rdy_ResetAckAll BOOL 1 = At least one alarm or latched shed condition requires reset or acknowledgement.

Rdy_SpeedRef BOOL 1 = Ready to receive OSet_SpeedRef (enables data entry field).

P_PF6000 BOOL Unique parameter name for auto-discovery.

Operator).

PowerFlex 6000 Drive Local Configuration Tags

Configuration parameters that are arrayed, string, or structure data types cannot

be configured as parameters for Add-On Instructions. Configuration parameters

of these types appear as local tags to the Add-On Instruction. Local tags can be

configured through the HMI faceplates or in Studio 5000 Logix Designer

application by opening the Instruction Logic of the Add-On Instruction instance

and then opening the Data Monitor on a local tag. These parameters cannot be

modified by using controller logic or Logix Designer application export/import

functionality.

Table 9 - Local Configuration Tags

Tag Name Data Type Default Description

Cfg_Desc STRING_40 'PowerFlex 6000

Varia ble Fr eque ncy

Drive'

Cfg_Label STRING_20 'Motor Speed Control' Label for graphic symbol displayed on HMI. This string appears on the graphic symbol.

Cfg_SpeedFdbkEU STRING_8 'Hz' Speed feedback engineering units for display on HMI.

Cfg_SpeedRefEU STRING_8 Speed reference engineering units for display on HMI.

Cfg_Tag STRING_20 'P_PF6000' Tagname for display on HMI. This string is shown in the title bar of the faceplate.

Val_ Fault Code D INT[10] {…} Fa ult co de nu mbers fo r active faults in drive (-1 = no fault).

Val_FaultCode[0] DINT 0

Val_ Faul tCod e[1 ]

Val_ Faul tCod e[2 ]

Val_ Faul tCod e[3 ]

Description for display on HMI. This string is shown in the title bar of the faceplate.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 23

Page 24

PowerFlex 6000 Drive (P_PF6000)

Table 9 - Local Configuration Tags

Val_FaultCode[4] DINT 0 Fault code numbers for active faults in the drive (-1 = no fault).

Val_ Faul tCod e[5 ]

Val_ Faul tCod e[6 ]

Val_ Faul tCod e[7 ]

Val_ Faul tCod e[8 ]

Val_ Faul tCod e[9 ]

Val_FaultDesc STRING_40[10] {…} Description of the drive fault (given Fault Code).

Val_FaultDesc[0] STRING_40

Val_ Faul tDe sc[1 ]

Val_ Faul tDe sc[2 ]

Val_ Faul tDe sc[3 ]

Val_ Faul tDe sc[4 ]

Val_ Faul tDe sc[5 ]

Val_ Faul tDe sc[6 ]

Val_ Faul tDe sc[7 ]

Val_ Faul tDe sc[8 ]

Val_ Faul tDe sc[9 ]

24 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

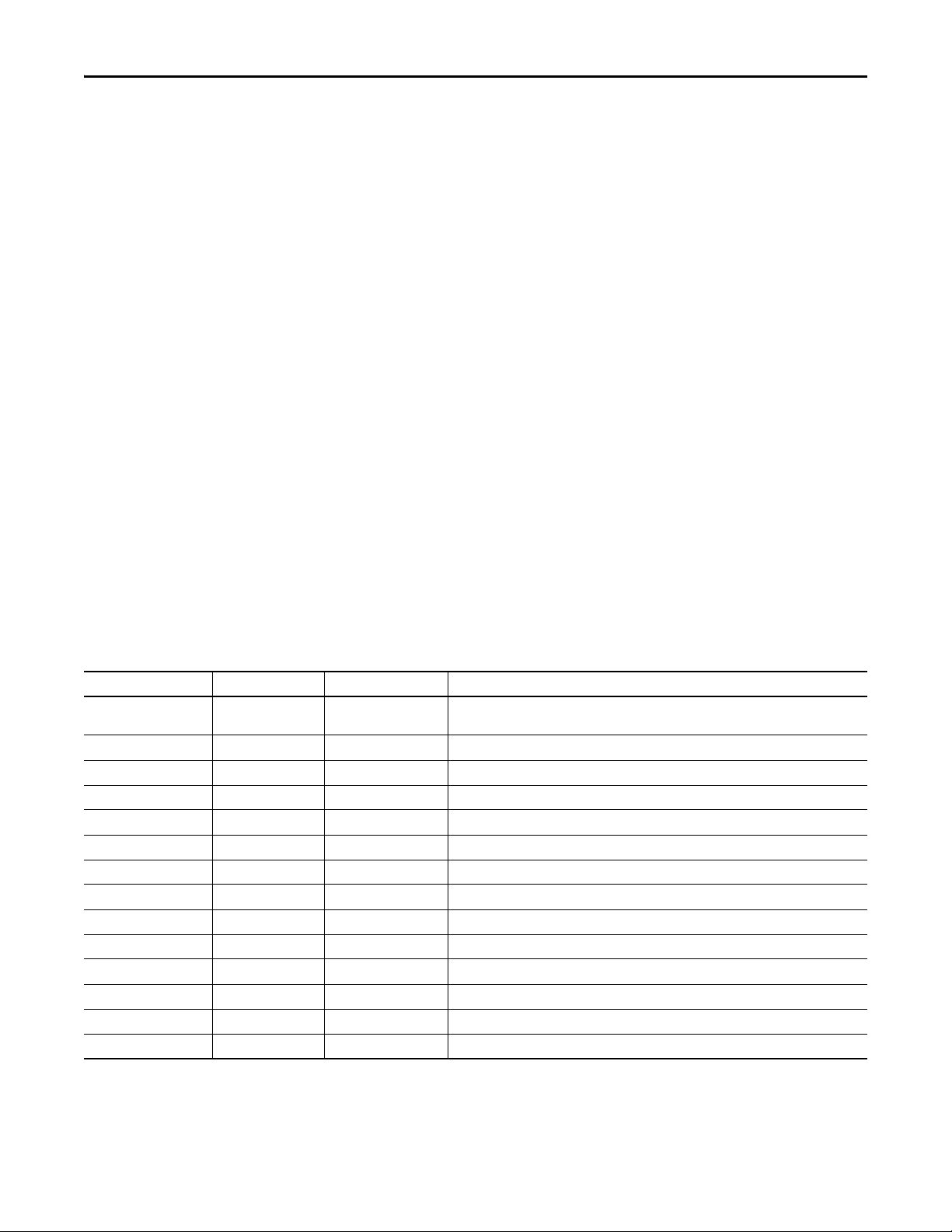

Page 25

PowerFlex 6000 Drive (P_PF6000)

IMPORTANT

Operations

This section describes the primary operations for Add-On Instructions.

Modes

This instruction uses the following standard modes, which are implemented by

using an embedded P_Mode Add-On Instruction.

Mode Description

Operator The Operator owns control of the device. Operator commands (OCmd_) and Operator settings

(OSet_) from the HMI are accepted.

Program Program logic owns control of the device. Program commands (PCmd_) and Program settings

(PSet_) are accepted.

Override Priority logic owns control of the device and supersedes Operator and Program control. Override

Inputs (Inp_OvrdCmd and other Inp_OvrdXxxx values) are accepted. If so configured,

bypassable interlocks and permissives are bypassed.

Maintenance Maintenance owns control of the device and supersedes Operator, Program, and Override

control. Operator commands and settings from the HMI are accepted. Bypassable interlocks and

permissives are bypassed, and device timeout checks are not processed.

Hand Hardwired logic or other logic outside the instruction owns control of the device. The instruction

tracks the state of the device for bumpless transfer back to one of the other modes.

No Mode The device is disabled and has no owner because the EnableIn input is false. The main

instruction Logic routine is not being scanned. See Execution sec tion for more information on

EnableInFalse processing.

Instructions with Cfg_OperKeep and Cfg_ProgKeep keep some aspects of the

device operation with the operator or program regardless of whether the main

mode is Program or Operator mode.

See Rockwell Automation Library of Process Objects: Common Mode Block

(P_Mode) Reference Manual, publication SYSLIB-RM005

, for more

information.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 25

Page 26

PowerFlex 6000 Drive (P_PF6000)

Alarms

This instruction uses the following alarms, which are implemented by using

embedded P_Alarm and P_Gate Add-On Instructions.

Alarm Name P_Alarm Name P_Gate Name Description

Drive Fault DriveFault None Raised when the drive detects a fault and sets its

Faulted status bit. Check the Fault Code and

description to determine the cause. Issuing a Reset of

this object causes a Clear Fault command to be sent to

the drive in an attempt to clear the fault.

Fail to Start FailToStart None Raised when the drive has and is using run feedback,

an attempt is made to start the drive, and the run

feedback does not indicate that the drive is running

within the configured time. If Fail to Start is

configured as a shed fault, the drive is stopped and a

reset is required to start the drive.

Fail to Stop FailToStop None Raised when the drive has and is using run feedback,

an attempt is made to stop the drive, and the run

feedback does not indicate that the drive stopped

within the configured time.

Interlock Trip IntlkTrip None Raised when the drive is running and an interlock ’not

OK’ condition causes the drive to stop.

If interlocks are not bypassed, a bypassable inter lock

or a non-bypassable interlock 'not OK' condition

initiates an interlock trip. If interlocks are bypassed,

only a non-bypassable interlock 'not OK' condition

initiates an interlock trip.

I/O Fault IOFault None Raised when the Inp_IOFault input is true. This input

is used to indicate to the instruc tion that a

communication failure has occurred for its I/O. If the

I/O Fault is configured as a shed fault, the drive is

stopped and not per mitted to start until reset.

Parameters of the P_Alarm object can be accessed by using the following

convention: [P_Alarm Name].[P_Alarm Parameter].

See Rockwell Automation Library of Process Objects: Common Alarm Block

(P_Alarm) Reference Manual, publication SYSLIB-RM002

, for more

information.

26 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 27

PowerFlex 6000 Drive (P_PF6000)

Simulation

Simulation in P_PF6000 de-energizes the outputs, ignores inputs, and provides

the feedback of a working drive. It lets you operate the Add-On Instruction as if a

working drive, even if no drive is physically present.

You must set the Inp_Sim parameter in the controller to ‘1’ to enable simulation.

The Simulation icon is displayed at the bottom left of the Operator

faceplate indicating the device is in simulation.

You can also use Cfg_SimRampT to set the time (in seconds) to ramp the speed

feedback.

When you have finished in simulation, set the Inp_Sim parameter in the

controller to ‘0’ to return to normal operation.

Execution

The following table explains the handling of instruction execution conditions.

Condition Description

EnableIn False (false rung) Processing for EnableIn False (false rung) is handled the

Powerup (prescan, first scan) Processing of modes and alarms on Prescan and Powerup

Postscan (SFC Transition) No SFC Postscan logic is provided.

same a s if the dri ve were Disa bled by Comm and. The drive

outputs are de-energized and the drive is shown as

disabled on the HMI.

is handled by the embedded P_Mode and P_Alarm

Add-On Instructions. See their specifications for details.

On Powerup, the drive is treated as if it had been

Commanded to Stop.

See the Logix5000™ Controllers Add-On Instructions Programming Manual,

publication 1756-PM010

, for more information.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 27

Page 28

PowerFlex 6000 Drive (P_PF6000)

Bits used by Add-On Instruction.

Bits not used by

Add-On Instruction and

available for use.

Programming Example

This example uses the P_PF6000 instruction to control the motor of a planetary

mixer in a concrete batch plant.

In the drive command word, the Add-On Instruction uses bits .0...3. The

instruction does not use the rest of the bits in the 'Out' reference parameter in the

InOut structure. These unused bit are available for your application to use.

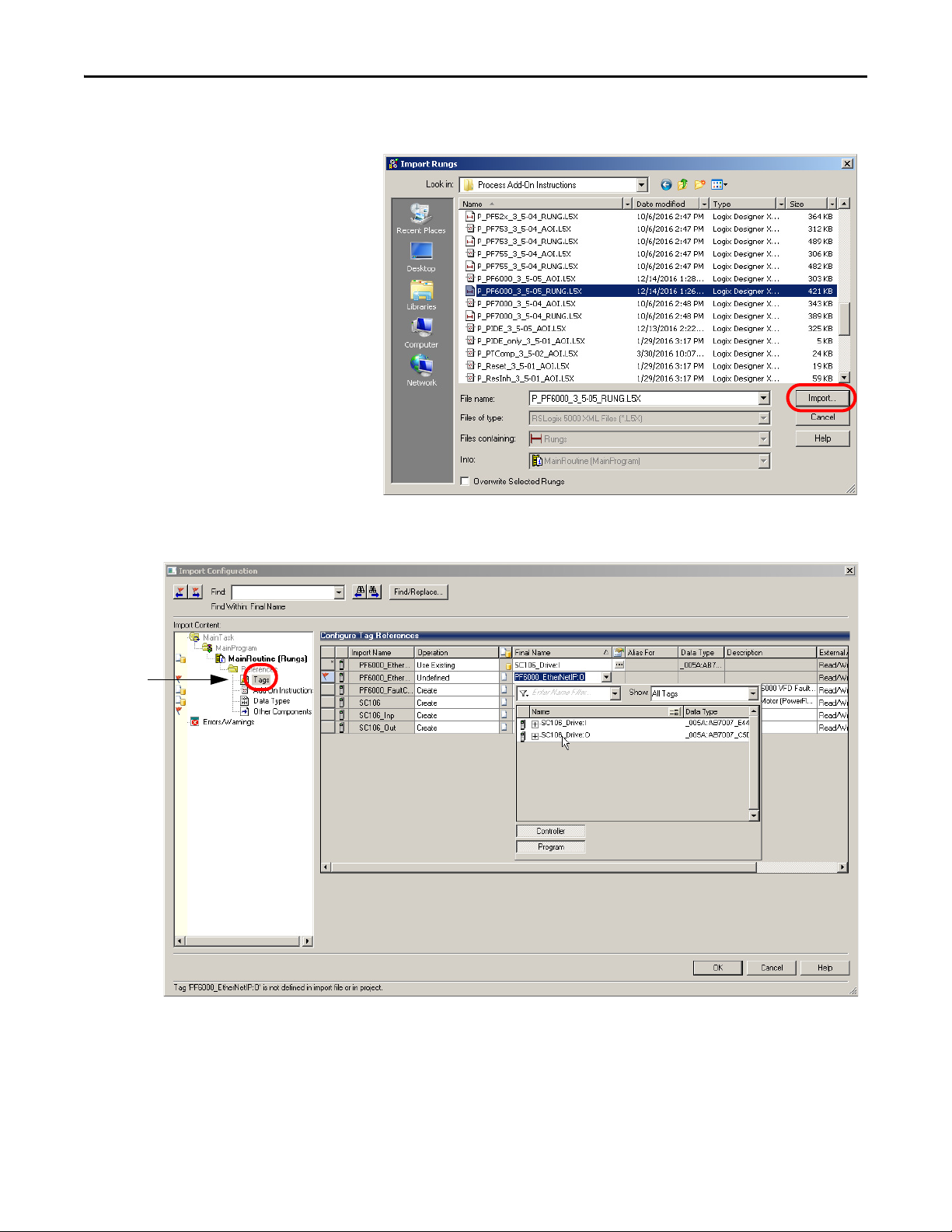

Follow these steps to import the P_PF6000 rung into your project.

1. On the Controller Organizer, add your PowerFlex drive to the I/O

Configuration and name the drive.

2. Under Tasks, click in front of Main Task.

3. Double-click Main_Routine to open this ladder logic routine.

4. Right-click one of the rungs and choose Import rungs.

28 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 29

PowerFlex 6000 Drive (P_PF6000)

5. On the Import rungs dialog box, select the P_PF6000 instruction and

click Import.

During the import process, you can name the tags for the routine in the

Import Configuration dialog box.

6. Click Tags in the Import Content tree and type the names of the variables

that match your process and the drive name in the Final Name column.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 29

Page 30

PowerFlex 6000 Drive (P_PF6000)

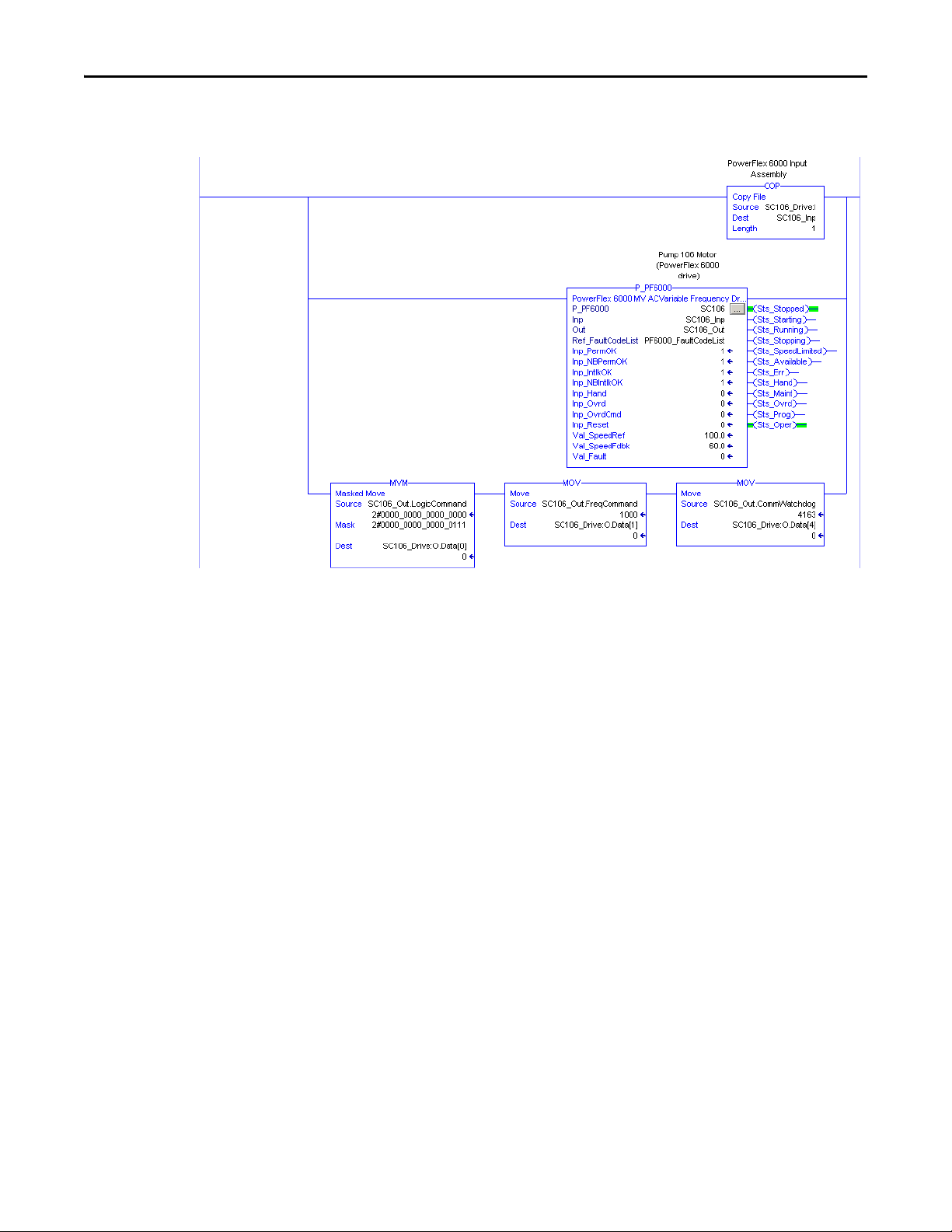

Your ladder logic routine now looks like the example. Observe that the tag

names and your drive's name are automatically placed in the instruction.

30 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

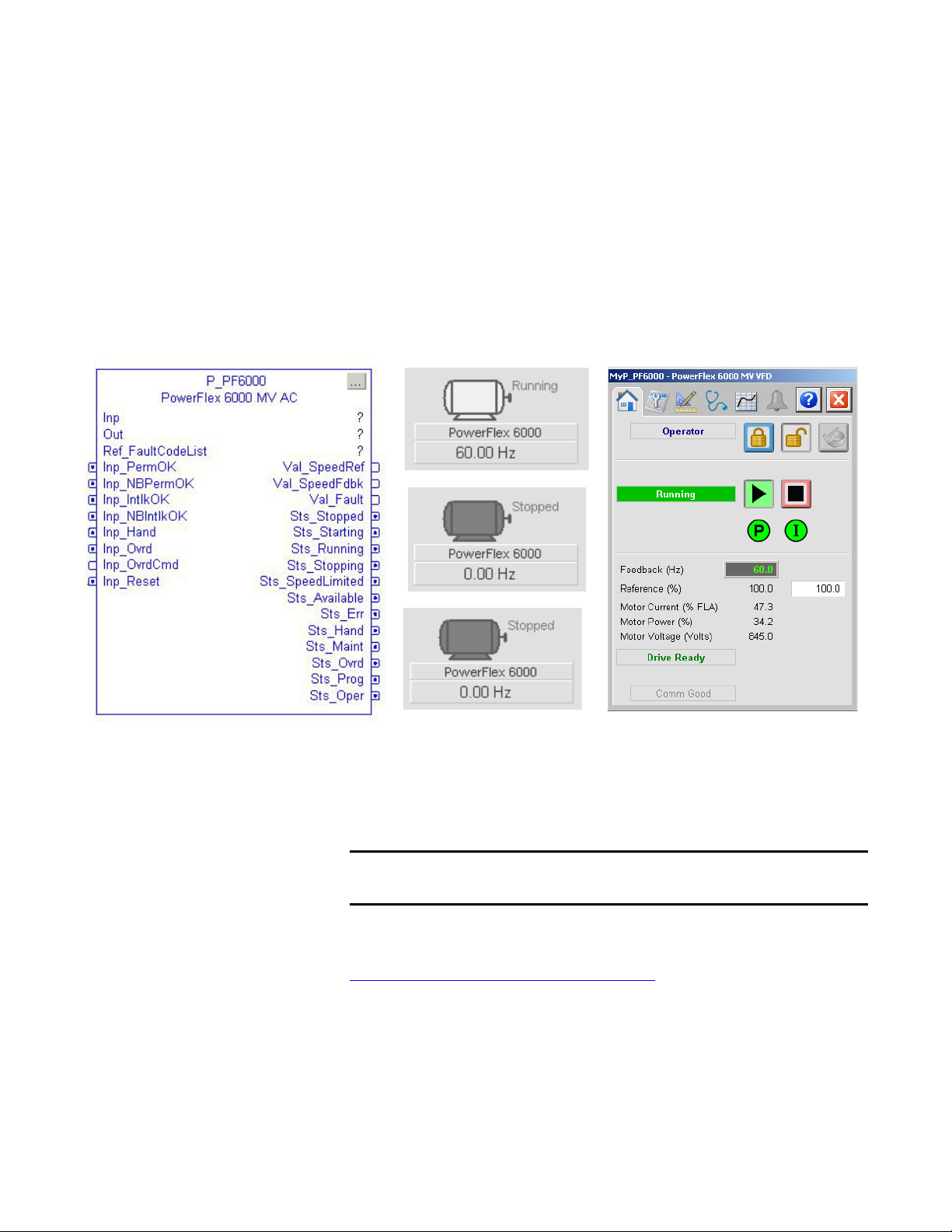

Page 31

PowerFlex 6000 Drive (P_PF6000)

Display Elements

The P_PF6000 instruction uses the same HMI display elements that are used for

the Variable Speed Drive (P_VSD) instruction.

A display element (global object) is created once and can be referenced multiple

times on multiple displays in an application. When changes are made to the

original (base) object, the instantiated copies (reference objects) are

automatically updated. Use of global objects, with tag structures in the

ControlLogix system, aid consistency and save engineering time.

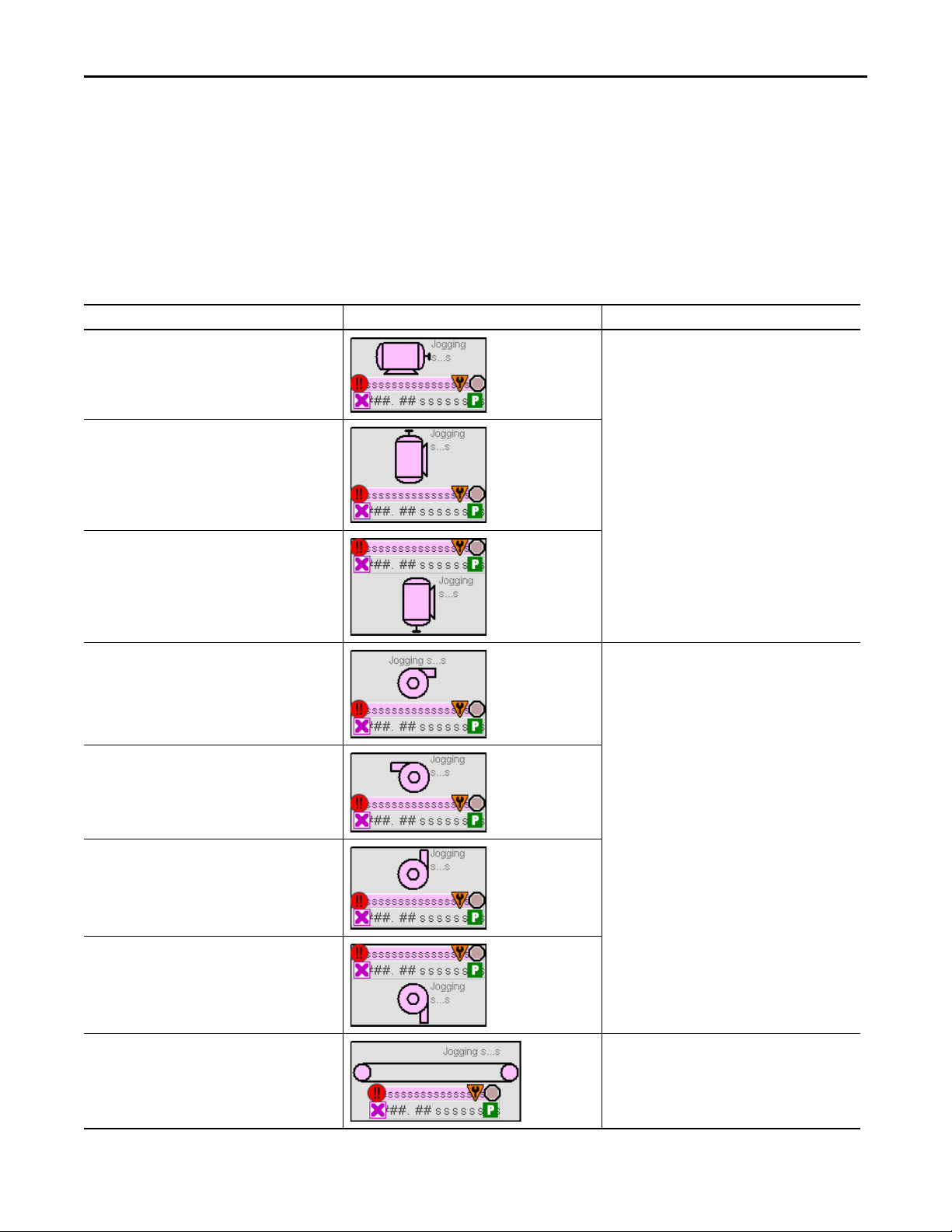

Table 10 - P_PF6000 Drive Display Elements Description

Display Element Name Display Element Description

GO_P_VSD_R These display elements show the different

GO_P_VSD_U

GO_P_VSD_D

motor positions.

GO_P_VSD_Blower_R These display elements show the different

GO_P_VSD_Blower_L

GO_P_VSD_Blower_U

GO_P_VSD_Blower_D

GO_P_VSD_Conveyer_R This display element illustrates a conveyer.

blower positions.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 31

Page 32

PowerFlex 6000 Drive (P_PF6000)

Table 10 - P_PF6000 Drive Display Elements Description

Display Element Name Display Element Description

GO_P_VSD_Inline_U These display elements show the different

GO_P_VSD_Inline_R

GO_P_VSD_Inline_L

GO_P_VSD_Inline_D

inline motor positions.

GO_P_VSD_Pump_R These display elements show the different

GO_P_VSD_Pump_L

GO_P_VSD_Pump_U

GO_P_VSD_Agitator_D This display element illustrates an agitator.

GO_P_VSD_Mixer_U This display elements shows a mixer.

pump positions.

32 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 33

PowerFlex 6000 Drive (P_PF6000)

Alarm Border

Status/Quality Indicator

Label

State Text

Mode Indicator

Engineering Units TextSpeed Feedback Display

Alarm Indicator

Status/Quality Indicator

Maintenance Bypass Indicator

Table 10 - P_PF6000 Drive Display Elements Description

Display Element Name Display Element Description

GO_P_VSD_RPump_U This display element shows a rotary gear pump.

GO_P_VSD_Fan_D This display element shows a fan.

Common attributes of the P_PF6000 global objects include the following:

• Graphical representation of the driven equipment

• Speed feedback display with engineering units

• Status/quality indicators

• Mode indicator

• Maintenance Bypass indicator

• State

• Label

• Color changing alarm border that blinks on unacknowledged alarm

• Alarm indicator that changes color with the severity of an alarm

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 33

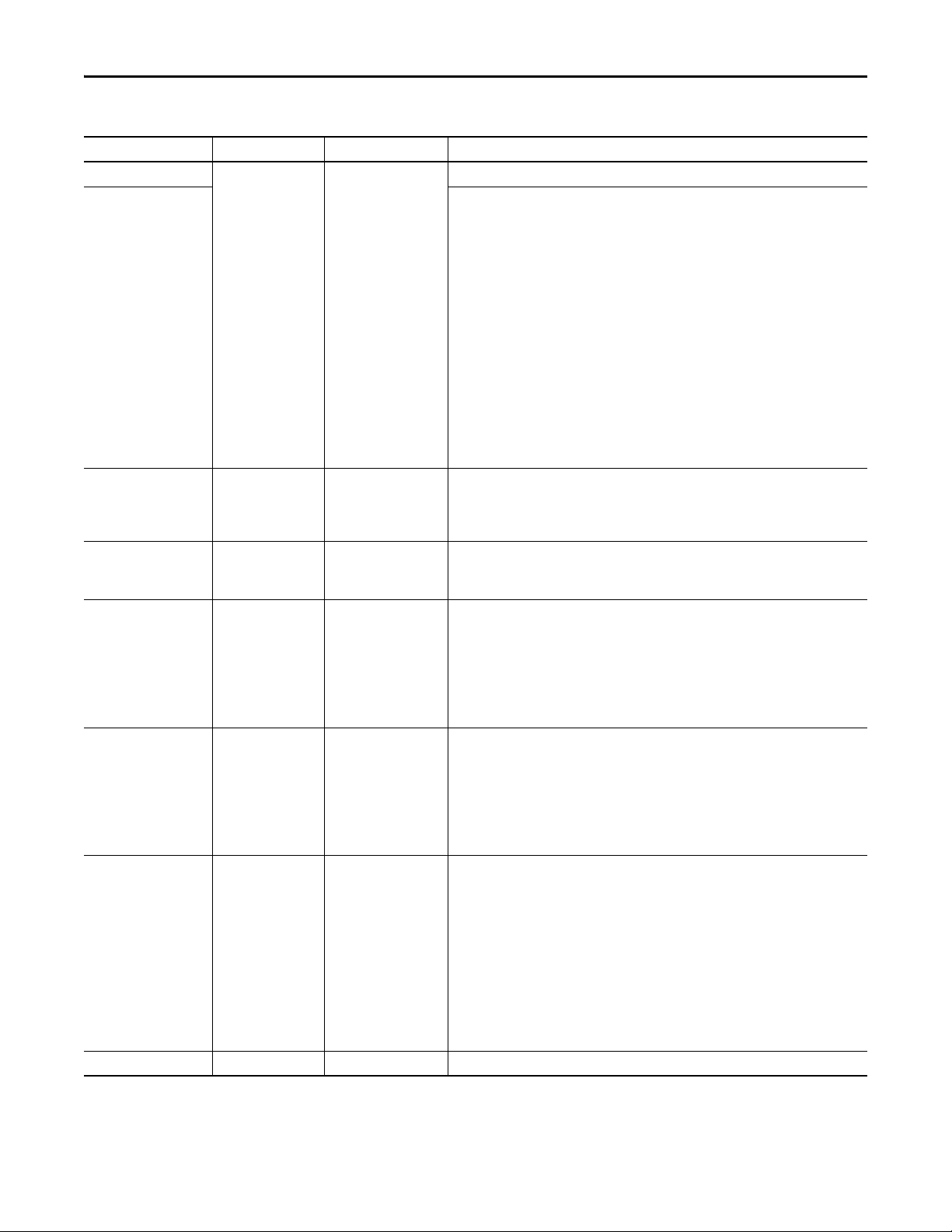

Page 34

PowerFlex 6000 Drive (P_PF6000)

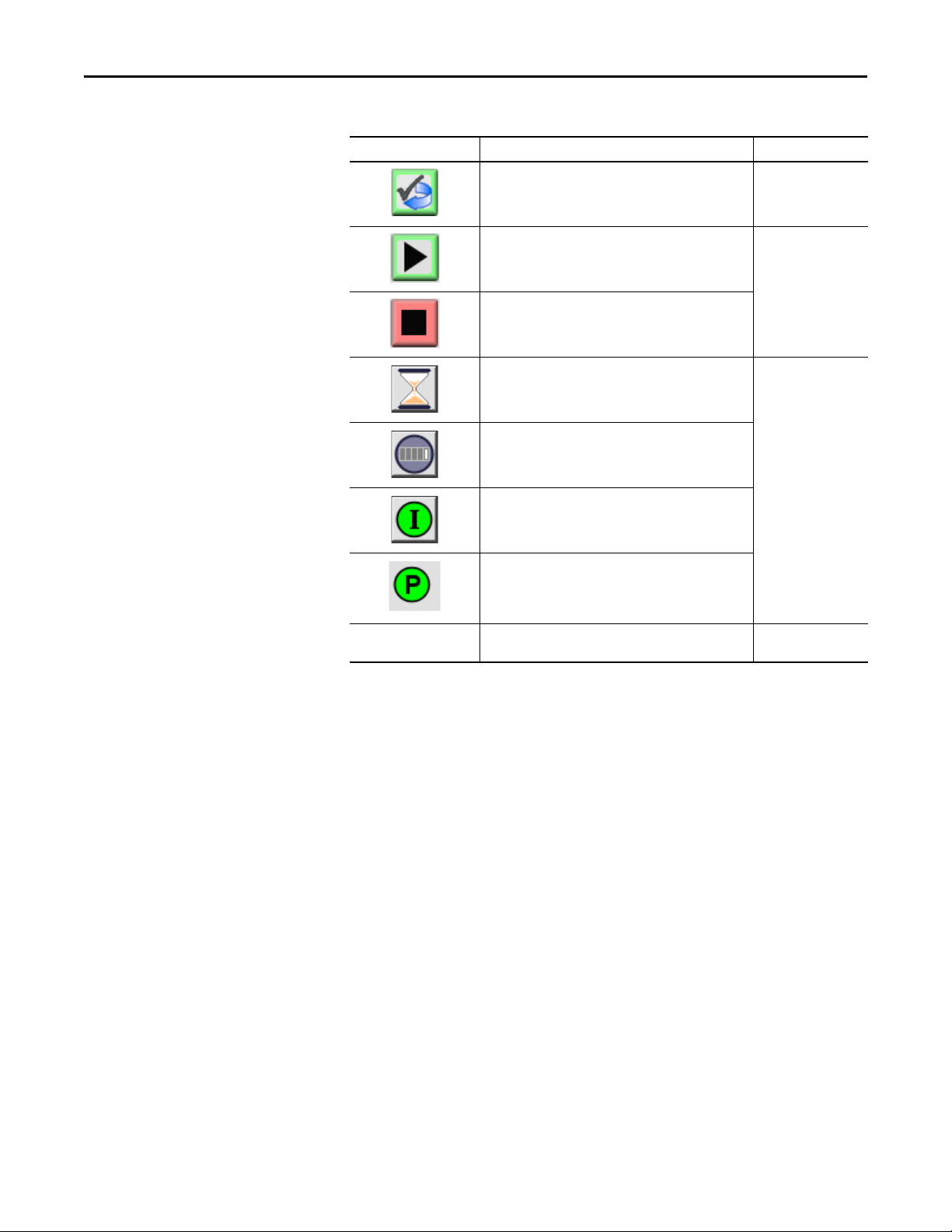

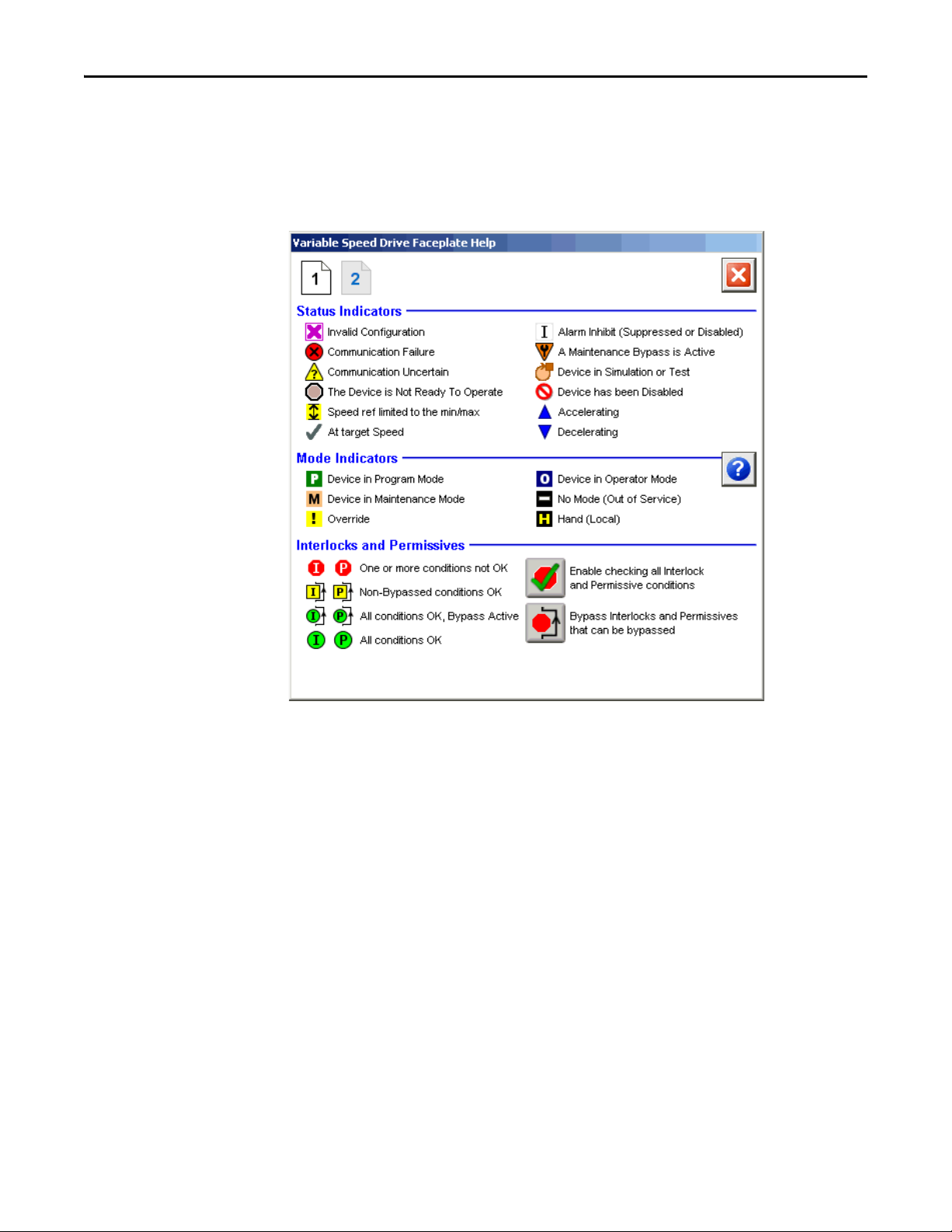

State Indicators

The State Indicator text changes and the display element color changes

depending on the state of the drive.

Color State

Blue Stopping

Dark gray Stopped

Light blue Jogging

Blue Starting

White Runn ing

Status/Quality Indicators

One of these symbols appears on the graphic symbol when the described

condition is true.

Graphic Symbol Description

Invalid configuration.

Data quality bad/failure.

Data Quality degraded: uncertain, test, simulation, substitution, or out of specification.

The input or device has been disabled.

Device not ready to operate.

Speed reference limited to minimum/maximum.

Motor is at target speed.

Drive is accelerating.

Drive is decelerating.

34 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 35

PowerFlex 6000 Drive (P_PF6000)

TIP

TIP

When the Invalid Configuration indicator appears, you can find what

configuration setting is invalid by following the indicators. Click the graphic

symbol to open the faceplate. The Invalid Configuration indicator appears next

to the appropriate tab at the top of the faceplate to guide you in finding the

configuration error. Once you navigate to the tab, the misconfigured item is

flagged with this indicator or appears in a magenta box.

For the PowerFlex 6000 Drive Instruction, the Invalid Configuration Indicator

appears under the following conditions:

• The Fail to Start check time, Fail to Stop check time, Reset Pulse time,

or Maximum Jog time is set to a value less than zero or greater than

2,147,483 seconds.

• The Speed Scaled EU Minimum and EU Maximum scaling parameters are

set to the same value.

• The Maximum Speed Reference clamp value is less than the Minimum

Speed Reference clamp value, or either clamp value is less than zero.

• The Simulated Speed Ramp Time is set to a value less than zero or greater

than 2,147,483 seconds.

• An Alarm Minimum On Time is set to a value less than zero or greater

than 2,147,483 seconds.

• Alarm Severity is set to a value less than 1 or greater than 1000.

When the Not Ready indicator appears, you can find what condition is

preventing operation by following the indicators. Click the graphic symbol to

open the faceplate. The Not Ready indicator appears next to the appropriate

tab at the top of the faceplate to guide you in finding the condition. When you

navigate to the tab, the condition preventing operation is flagged.

For the PowerFlex 6000 Drive Instruction, the Device Not Ready indicator

appears under the following conditions:

• Device has been disabled by Maintenance.

• There is a configuration error.

• An Interlock or Permissive is not OK.

• Operator state 0 priority command requires reset.

• There has been a device failure or I/O Fault and Shed requires reset.

• Device has tripped and generated a Drive Fault.

• Drive is not ready.

• Device logic is disabled or there is no mode.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 35

Page 36

PowerFlex 6000 Drive (P_PF6000)

TIP

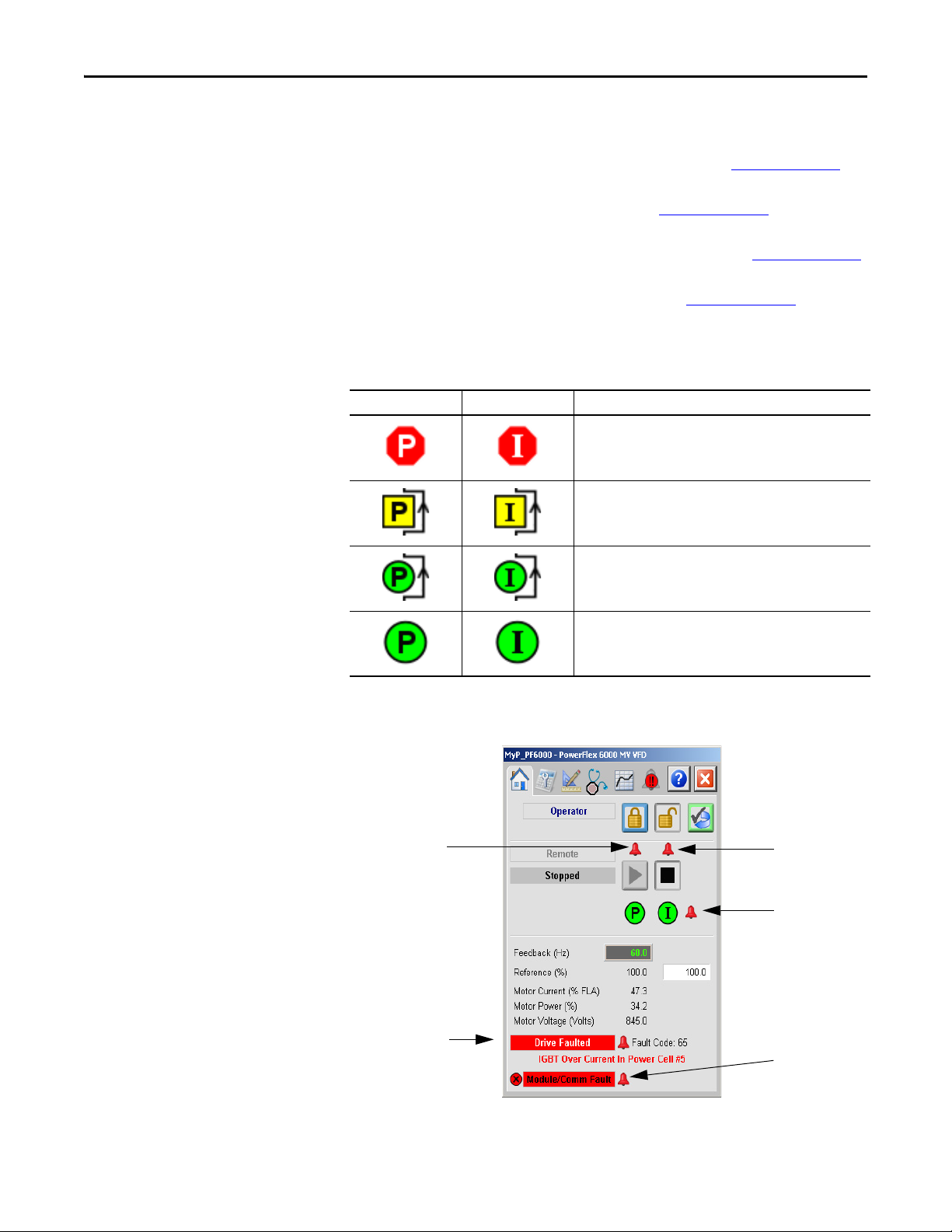

Mode Indicators

One of these symbols appears on the right side of the graphic symbol to indicate

the mode of the object instruction.

Graphic Symbol Description

Transparent Operator mode (if the default mode is Operator and the current mode is Operator, the mode

indicator is transparent).

Operator mode (if the default mode is Program).

Operator mode locked.

Transparent Program mode (if the default mode is Program and the current mode is Program, the mode

indicator is transparent).

Program mode (if the default mode is Operator).

Program mode locked.

Override mode

Maintenance mode.

Hand mode

No mode.

The images provided for the Operator and Program default modes are

transparent; therefore, no mode indicators are visible if the device is in its

default mode. This behavior can be changed by replacing the image files for

these mode indicators with images that are not transparent.

See Rockwell Automation Library of Process Objects: Common Mode Block

(P_Mode) Reference Manual, publication SYSLIB-RM005

information.

36 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

, for more

Page 37

PowerFlex 6000 Drive (P_PF6000)

TIP

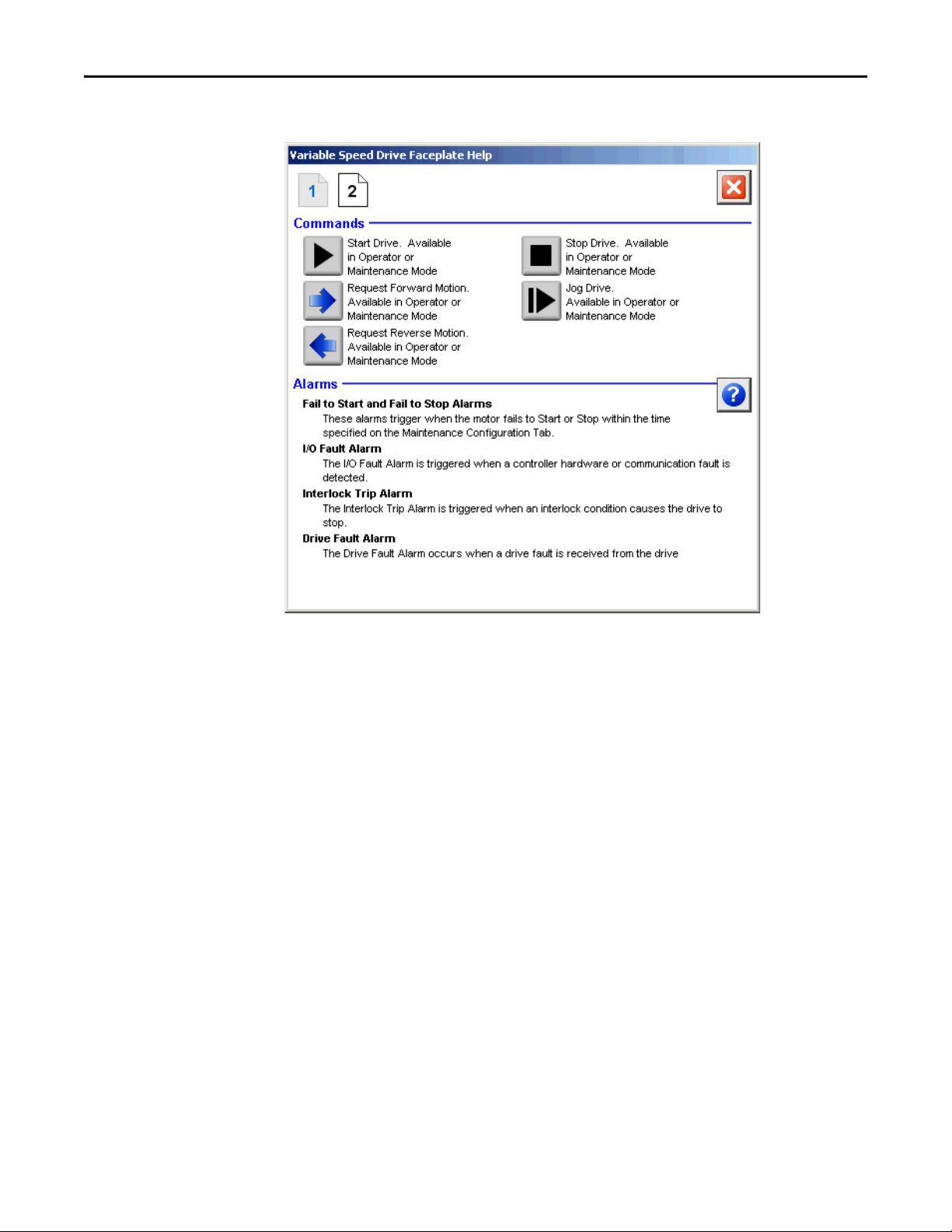

Alarm Indicators

One of these symbols appears on the left side of the label to indicate the described

alarm condition. The alarm border and label background blink if

acknowledgement of an alarm condition is required. Once the alarm is

acknowledged, the alarm border and label background remain the color that

corresponds to the severity of the alarm.

Symbol Border and Label Background Description

No change in color Alarm Inhibit: an alarm is suppressed by the Program,

disabled by Maintenance, or shelved by the Operator.

White Return to normal (no alarm condition), but a previous

Blue Low severity alarm.

Yel low Me diu m se ver ity ala rm.

Red High severity alarm.

Magenta Urgent severity alarm.

No symbol No change in color No alarm or alarm inhibit condition, and all alarms

alarm has not been acknowledged.

are acknowledged.

See Rockwell Automation Library of Process Objects: Common Alarm Block

(P_Alarm) Reference Manual, publication SYSLIB-RM002

, for more

information.

Maintenance Bypass Indicator

This symbol appears to the right of the label to indicate that a maintenance

bypass has been activated.

Graphic Symbol Description

A maintenance bypass is active.

No symbol displayed No maintenance bypass is active.

When the Maintenance Bypass Indicator appears, you can find what condition

was bypassed by following the indicators. Click the graphic symbol to open the

faceplate. The Maintenance Bypass Indicator appears next to the appropriate

tab at the top of the faceplate to guide you in finding the bypass. Once you

navigate to the tab, the bypassed item is flagged with this indicator.

For the PowerFlex 6000 Drive Instruction, the Maintenance Bypass Indicator

appears when the bypassable interlocks and permissives have been bypassed.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 37

Page 38

PowerFlex 6000 Drive (P_PF6000)

TIP

Using Display Elements

The global objects for P_PF6000 can be found in the global object file

(RA-BAS) P_VSD Graphics Library.ggfx. Follow these steps to use a

global object.

1. Copy the global object from the global object file and paste it in the

display file.

2. In the display, right-click the global object and choose Global Object

Parameter Values.

The Global Object Parameter Values dialog box appears.

3. Type the tag or value in the Value column as specified in the Description

column.

You can click the ellipsis (. . .) to browse and select a tag.

Values for items marked ‘(optional)’ can be left blank.

38 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 39

PowerFlex 6000 Drive (P_PF6000)

Click to navigate to full faceplate.

4. Click OK.

The global object parameters are as follows.

Parameter Required Description

#102 Y Object tag to point to the name of the associated object Add-On Instruction

#103 Y Path used for display navigation features to other objects. Include program

#120 N Additional parameter to pass to the display command to open the faceplate.

#121 N Additional parameter to pass to the display command to open the faceplate.

#122 Y These are the options for the global objec t display:

in the controller.

scope if tag is a program scope tag.

Typ ica lly us ed t o de fin e position for the faceplate.

if defining X and Y coordinate, separate parameters so that X is defined by

#120 and Y is defined by #121. This lets the same parameters be used in

subsequent display commands originating from the faceplate.

0 = Always show faceplate

1 = Show Quick Display for users without Maintenance access (Code C)

2 = Always show Quick Display

Quick Display

The Quick Display screen provides a means for operators to perform simple

interactions with the P_PF6000 instruction instance. From the Quick Display,

you can navigate to the faceplate for full access for operation, maintenance, and

configuration.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 39

Page 40

PowerFlex 6000 Drive (P_PF6000)

Operator

Maintenance

Engineering

Diagnostics

Tre nd s

Alarms

Help

Exit

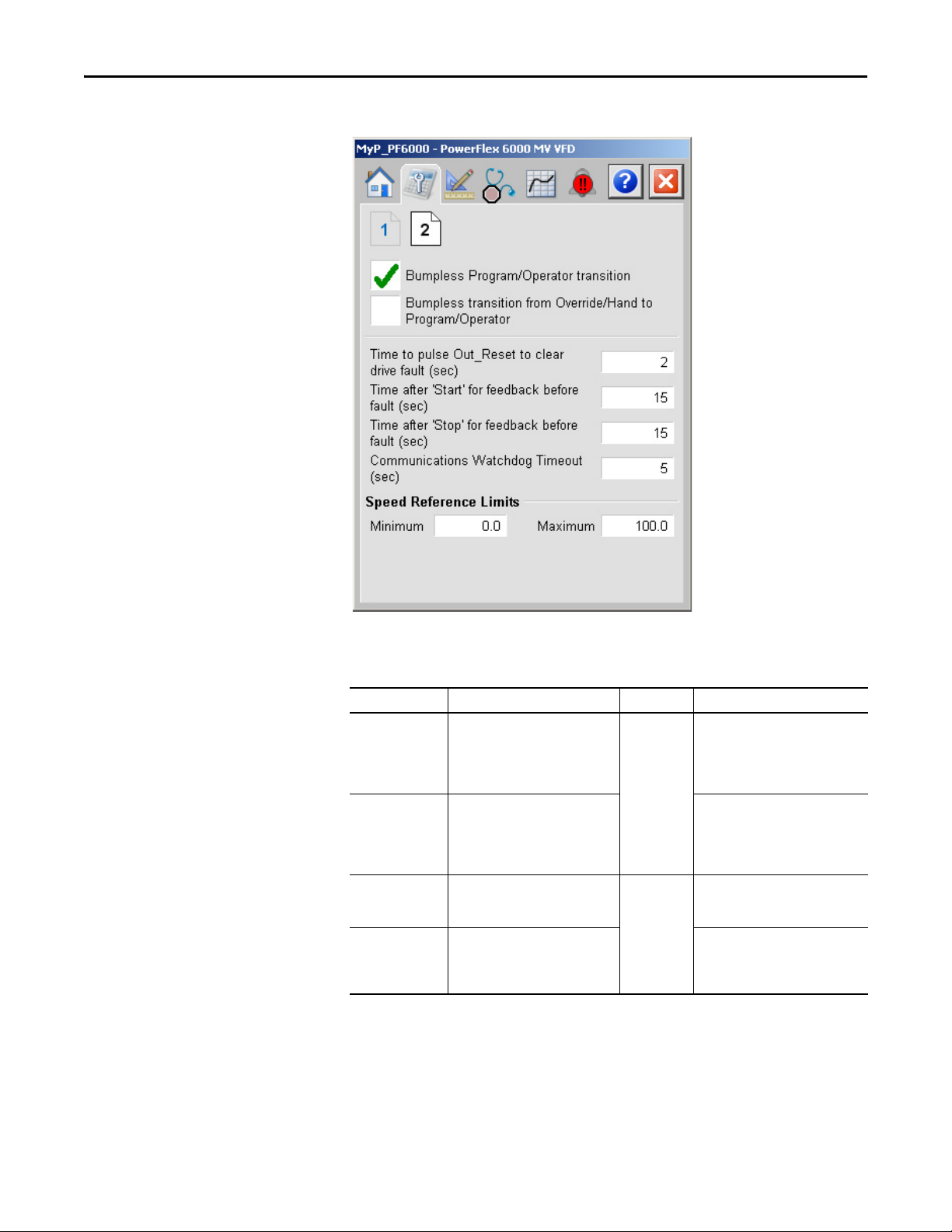

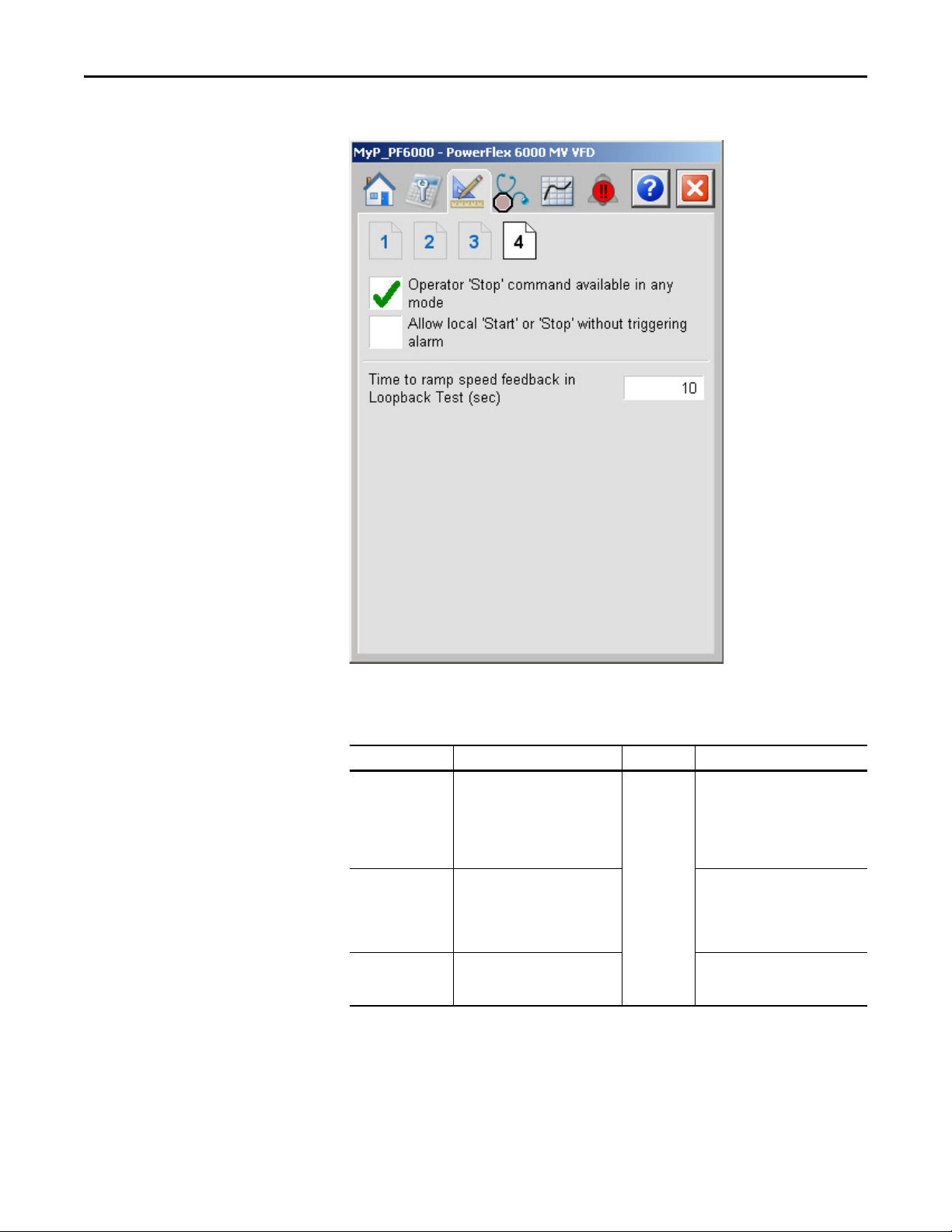

Faceplate

The P_PF6000 faceplate consists of six tabs and each tab consists of one or more

pages.

The title bar of each faceplate contains the value of local configuration tags

Cfg_Tag and Cfg_Desc.

The Operator tab is displayed when the faceplate is initially opened. Click the

appropriate icon at the top of the faceplate to access a specific tab.

The faceplate provides the means for operators, maintenance personnel,

engineers, and others to interact with the P_PF6000 instruction instance,

including viewing its status and values and manipulating it through its commands

and settings. When a given input is restricted via FactoryTalk View security, the

required user security code letter is shown in the tables that follow.

Operator Tab

The Faceplate initially opens to the Operator (‘Home’) tab. From here, an

operator can monitor the device status and manually operate the device when it is

in Operator mode.

The Operator tab shows the following information:

• Current mode (Operator, Program, Override, Maintenance, or Hand)

• Requested mode indicator (appears only if the Operator or Program mode

has been superseded by another mode.)

• Input Source and Quality indicator (See 'SrcQ' in the Output parameters

for details).

table on page 20

• Drive Motion State (Accelerating, Decelerating, or At Speed)

• Drive Ready indicator (Drive Ready, Drive Not Ready, or Drive Faulted)

• Actual Speed and requested speed

• Output current and output power

• Torque current

40 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 41

PowerFlex 6000 Drive (P_PF6000)

Reset and Acknowledge

All Alarms Button

Mode Indicator

Drive State

Interlock Navigation

Button

Permi ssive N avigati on

Button

Drive Start Command Button

Drive Stop Command Button

Operator Mode Request/Lock

and Release/Unlock Buttons

Reference

Drive Ready Indicator

Input Source and Quality Icon

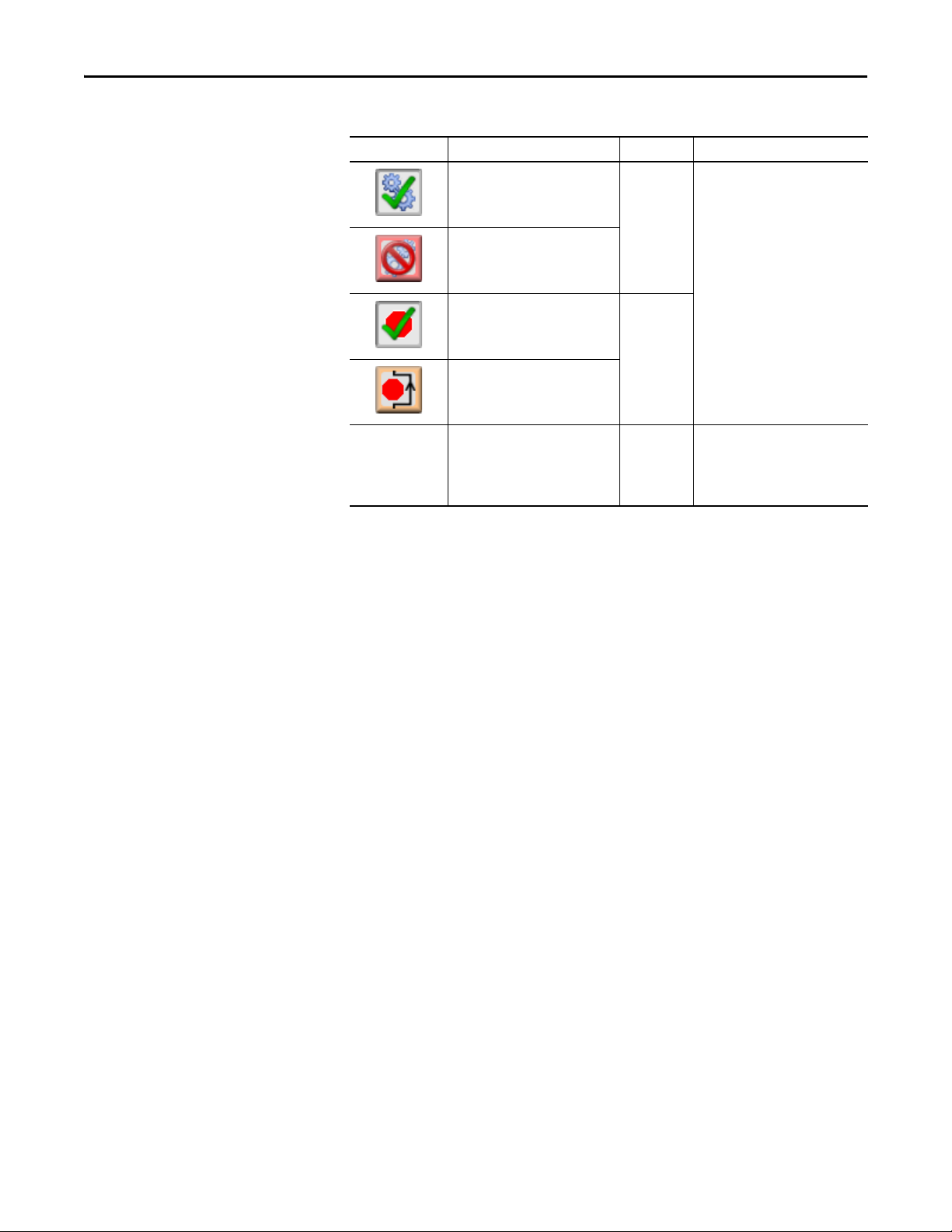

The following table shows the functions that are included on the Operator tab.

Table 11 - Operator Tab Description

Function Action Security

Click to release Operator mode lock. Manual Device

Click to lock in Operator mode.

Click to request Program mode.

Operation

(Code B)

Click to request Operator mode.

Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017 41

Page 42

PowerFlex 6000 Drive (P_PF6000)

Table 11 - Operator Tab Description

Function Action Security

Click to reset and acknowledge all alarms. Acknowledge Alarms

(Code F)

Click to start the drive. Normal Operation of

Click to stop the drive.

Click to open the Restart Inhibit faceplate. None

Click to open the Run Time faceplate.

Click to open the Interlocks faceplate.

Click to open the Permissive faceplate.

Reference (Hz) Type the desired speed in engineering units. Normal Operation of

Devi ces (Code A)

Devi ces (Code A)

If the object is configured to have permissive and interlock objects (for example,

Cfg_HasIntlkObj is true), the permissive and interlock indicators become

buttons. These buttons open the faceplates of the source objects used as a

permissive or interlock (often this is a P_Intlk interlock or P_Perm permissive

object). If the object is not configured in this way, the permissive/interlock icons

are indicators only.

The Operator tab also has a button to open the Restart Inhibit faceplate if the

drive is configured to use the P_ResInh object (Cfg_HasResInh = 1). When the

object is not configured to have an P_ResInh instruction, the Restart Inhibit

button is not displayed.

The Operator tab also has a button to open the Run Time faceplate if the drive is

configured to use the P_RunTime object (Cfg_HasRunTime = 1). When the

object is not configured to have an P_RunTime instruction, the Run Time

button is not displayed.

42 Rockwell Automation Publication SYSLIB-RM057A-EN-P - January 2017

Page 43

PowerFlex 6000 Drive (P_PF6000)

Fail to Stop

Alarm

Fail to Star t

Alarm

I/O Fault Alarm

Drive Fault

Alarm

Interlock Trip

Alarm

See these publication for more information: