Page 1

Triguard SC300E

PDC24 / PAC

Chassis Power Supplies

(PDC24 / PAC)

Issue 3

INTRODUCTION

PURPOSE

Two Power Supply Units (PSUs) provide a dual-redundant source of 5.4Vand 12Vdc onto the

backplane for the modules mounted in a SC300E chassis. The PSUs are mounted one above

the

other in the left hand side of the chassis as shown.

Each PSU has a fault warning system and a power sharing system. The power sharing system

operates

other

when both PSUs are working. Either PSU has the capacity to power the system if the

one fails.

October 2005

Th

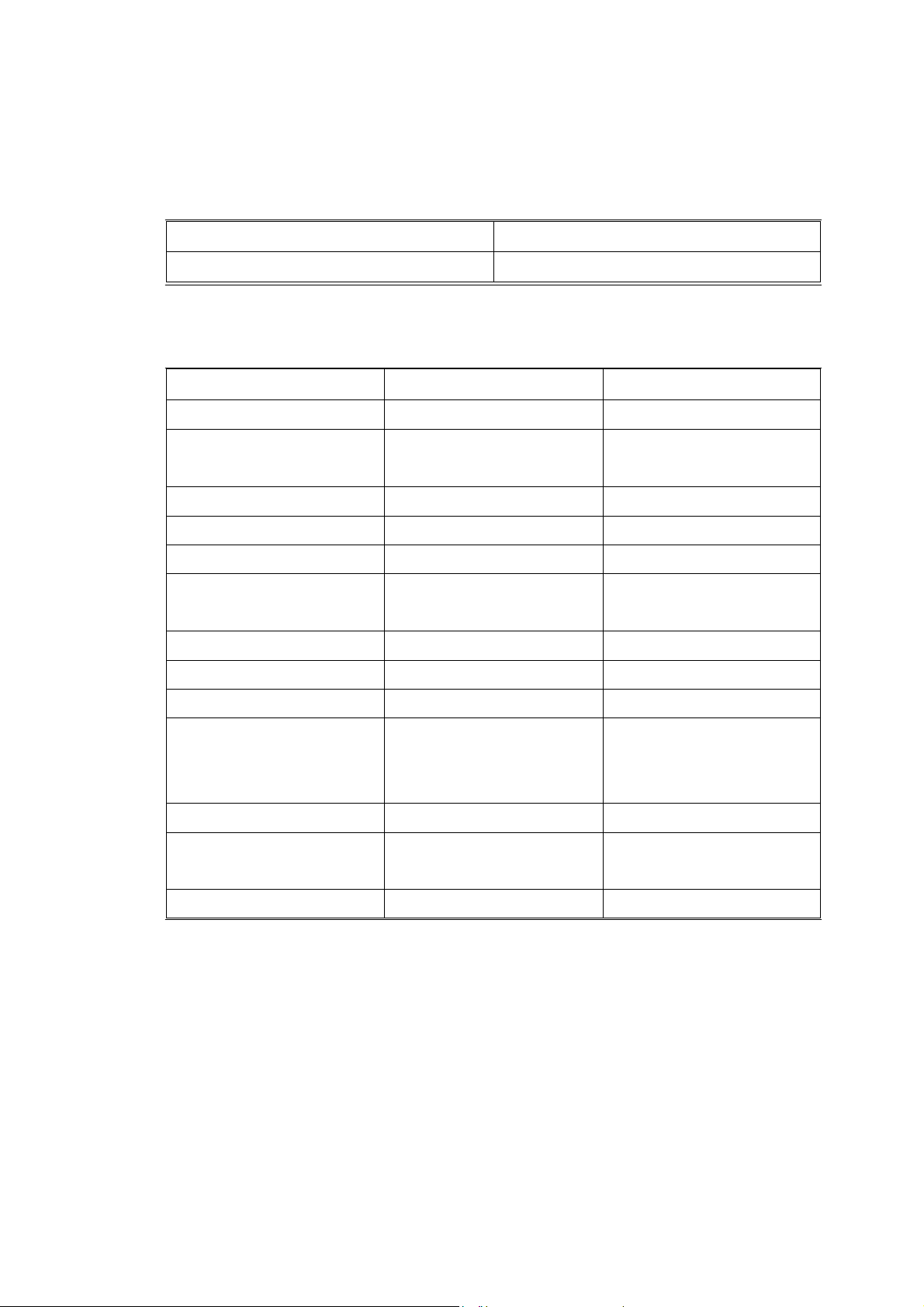

e PSUs operate from the following supplies detailed in Table 1-1:

This document is intended to provide a general understanding of the function of the PAC and

PDC24, sufficient to enable basic maintenance operations to be effected in the field.

Figure 1-1. PDC24 /

008-5098

PAC General view

Page 2

2

PDC24

/

PAC

October

2005–

Iss

ue 3

Triguard

SC300E

ASSOCIATED DOCUMENTATION

Reference

008-5097

Specification

Nominal input voltage

Input voltage range

Inputfrequency range

Input power

Output power

Outputs

Output hold up time

Inrush current

Title

Model

PDC24

Chassis User Manual

24Vdc

20 to 36Vdc

Not applicable

200W

145W

5.4Vdc @ 18A

12Vdc @ 4A

20 mS

170A, 1.5ms time constant

PAC

110/230Vac Auto ranging

92 to 132Vac or

184 to 264Vac

45 to 65Hz

235W

175W

5.4Vdc @ 23A

12Vdc @ 4A

20mS

30A , 4ms time constant

Isolation

Indicators

Alarm contact ratings

Overall size (mm)

Overall size (inches)

Weight

2.5kVdc

Green –

Yellow –

Red –

175V, 0.25A

420H x 200L x 68W

16.5H x 7.87L x 2.67W

2.3kg

Table 1-1. PDC24/PDC data

Normal

Power Share

Fault

3kVac

Green –

Yellow –

Red -

175V, 0.25A

420H x 200L x 68W

16.5H x 7.87L x 2.67W

2.3kg

Normal

Power Share

Fault

Page 3

PDC24

/

PAC

October

2005–

Issue 3

3

Tri

guard

SC300E PDC24 / PAC Chassis Power Supplies

ENVIRONMENTAL SPECIF

The maximum ambient temperature measured at the hottest point within the Triguard system

shall

not be greater than 60 degrees centigrade.

Temp

erature operating:

Temperature

Humidity:

EMC/RFI

Vibration/Shock:

Certification:

General Certification: Ref. SC300E TMR Product Guide (ref 008-5209).

storage:

Immunity:

ICATIONS

+5°C to +60°C

-

25°C to +70°C

5% to 95% non-condensing at ambient < 40°C

Tested and certified to IEC 1131-Part 2 1994

Tested and certified to IEC 1131-Part 2 1994

TRANSPORT AND HANDLING

The PSU must be transported and stored in its original packing material which should be

retained for this purpose.

Page 4

4

PDC24

/

PAC

October

2005–

Iss

ue 3

Triguard

SC300E

TECHNICAL DESCRIPTIO

N

PHYSICAL

The PSU comprises a front plate mounted at right angles to a chassis plate. All the user

controls and indicators are mounted on the front plate as shown in Figure 1-1.

The chassis plate supports three main items:

• Power supply unit: A self-contained switch-mode power supply unit (SMPS).

•

• PSU interface PCB: Contains the power share and fault alarm circuits. Interfaces these

A ribbon cable connects the front panel PCB to the SMPS. A mechanical stop fitted to the AC

system chassis power supply slots (marked AC STUD) prevents the insertion of a PDC24 into

a PAC slot.

Front panel PCB: Contains printed wiring and physical support for the controls and

indicators that are viewed and accessed from the front panel.

circuits

and the SMPS to the SC300E chassis backplane via connector PL3.

Page 5

PDC24

/

PAC

October

2005–

Issue 3

5

Tri

guard

SC300E PDC24 / PAC Chassis Power Supplies

Figure 2-1 PSU Layout and dimensions

Page 6

6

PDC24

/

PAC

October

2005–

Iss

ue 3

Triguard

SC300E

EXTERNAL CONNECTIONS

Chassis backplane connector PL3

The chassis backplane connector details are given in Table 2-1.

DIN41612 type H15 male connector. SK1 acts as a guide to prealign connector PL3 with its

mating socket when the PSU is inserted into its slot.

Pin

4

6

8

10

12

14

Table 2-1. Backplane connector pinouts

5V return

5V return

+5V output

+5V output

5V reutrn sense

5V +ve sense

Signal

16

18

20

22

24

26

28

30

32

12V return

+12V output

Power fail output

Power share

Alarm contact COM

Alarm contacts NO

Ac(N) or dc –ve input

AC(I) or dc +ve input

Earth (mates first)

Page 7

PDC24

/

PAC

October

2005–

Issue 3

7

Test connector

Tri

guard

SC300E PDC24 / PAC Chassis Power Supplies

The 8-way 270º DIN socket located on the front panel. The connector pinout details are given in

Table 2-2.

Table 2-2. Test connector pinouts

PIN

1

2

3

4

5

6

7

8

5V return at SMPS

12V +ve output at SMPS

5V +ve output at SMPS

+5V return at backplane

Power share line

5V supply –

5V supply +ve sense

Power fail interrupt

Signal

ve sense

Figure 2-2 Test connector pin number location

Page 8

8

PDC24

/

PAC

October

2005–

Iss

ue 3

Triguard

SC300E

THEORY OF OPERATION

Main power flow

The 5.4V output allows for a drop of about 0.4V across the auctioneering diodes in each

module supplied.

The output voltage is fed back to the SMPS control circuits via the +ve and -ve

The SMPS then compensates for any voltage drop along the power supply lines by increasing

its output voltage. The rated output voltage is thus present at the load rather than at the PSU

output terminals. The -ve

The 5V supply current sensor is a 0.005-ohm resistance formed by two resistors in parallel.

The voltage developed across the resistors is used as a measure of output current by the

power share and fa

Various system voltages are connected by current limiting resistors to individual pins of the

test

socket on the front panel. The ‘current limiters’ protect the system against accidental

short circuits on any of the test socket pins.

Plant shutdown -

sense input to the SMPS is modified by the power share system.

ult alarm circuits.

Adjusting the power supplies in a running system could result in a

W

ARNING

plant shutdown.

sense lines.

Power share system

The power share control circuit accepts inputs from the 5V supply current sensor, the +ve and

-ve

sense lines, the output adjustment trimmer (O/P ADJ) on the front panel, and the power

share line. It drives the power share line, the power share LED on the front panel, and the

voltage on the -ve

sense line input to the SMPS.

Normally the voltage at the -ve

from the backplane. When the power share control circuit detects that an increase in output

current is required to maintain power balance, the -ve

voltage

output voltage.

between the +ve and -ve sense lines is now greater. The SMPS then increases its

sense input to the SMPS is close to that on the -ve

sense SMPS voltage drops, so that the

sense line

Fault alarm system

The power fail output from the SMPS switches from logic high to low just before the SMPS

output fails (i.e. to give advance warning following a failure of the ac/dc input supply). The fault

alarm circuits de-energise the fault relay in response to:

• The power fail signal

• An input from a 70ºC thermal cut-out on the SMPS

• An undervoltage output condition detected on the +ve and -ve

A set of changeover cont

pair

of

relay contacts is available to operate an external alarm. These contacts open under fault

conditions.

acts controls the Fault and Normal LEDs on the front panel. Another

sense lines

Page 9

PDC24

/

PAC

October

2005–

Issue 3

9

Tri

guard

SWITCHES AND INDICATORS

SC300E PDC24 / PAC Chassis Power Supplies

All user interface is via the front panel (Figure 2-3).

Table 2-3. Front panel facilities

LED Indicator

Normal LED (green)

Power Share LED (yellow) Illuminates to indicate that power sharing is in balance. It can

Fault LED (red)

TEST

ON/OFF

O/P Adi

Indication

Illuminates to indicate normal operation

extinguish

Balance

tests).

NOTE: If one PSU is removed, the Power share LED on the

remaining PSU illuminates.

Illuminates to indicate an over temperature or undervoltage fault

condition

8-way 270º DIN socket. Use as described in XRefColorection

functionality tests, Default ¶ Font. A mating connector is

available

3A (PAC)/10A (PDC24) circuit breaker and ON/OFF push switch

for

supply voltage.

Screwdriver adjustment of current sharing/output voltage.

if

the other PSU supplies about 1.3A more current.

can be adjusted (see Section 3.3 Field functionality

free of charge.

The following facilities are provided:

Page 10

10

PDC24

/

PAC

October

2005–

Iss

ue 3

Triguard

SC300E

Figure 2-3 PDC24/PAC Front panel

Page 11

PDC24

/

PAC

October

2005–

Issue 3

11

Tri

guard

SC300E PDC24 / PAC Chassis Power Supplies

SERVICING

SCOPE

The PSUs have no field replaceable parts. Faulty units should be returned for repair.

CONFIGURATION

No configurable links.

FIELD FUNCTIONALITY TESTS

The 12V supply is not calibrated. Set up the 5V supply as follows. For each test use a digital

voltmeter

Output voltage (5V)

Measure across pins 6 and 7. The voltage should be 5.4V ±0.01V.

Output voltage (12V)

across the relevant pair of pins on the 8-way DIN socket.

Measure across pins 1 and 2. The voltage should be within the range 11.5V to 12.5V.

Output current (5V)

Measure the voltage between pins 1 and 4. This should be proportional to the current supplied

by the PSU at 0.005 Volts per Amp. The current supplied will depend on the configuration of

modules within the system.

SMPS Output voltage (5V)

Measure the voltage between pins 3 and 6. This should not exceed 5.8V. A higher value

(nominally 6.3V) may initiate an overvoltage trip.

Power share line

Measure the voltage between pins 1 and 5. The voltage will depend on the currents being

provided by both power supplies. It should not exceed 4.0V at maximum current.

Power fail interrupt

This can be monitored on pin 8. It is a logic output that is normally pulled up resistively to +5V,

but

is

pulled low if the ac/dc input supply fails.

Page 12

12

PDC24

/

PAC

October

2005–

Iss

ue 3

Triguard

SC300E

Front panel LEDs

Check that the green LED (Normal) is on and the red LED (Fault) is off. A fault condition can

be due to:

• A failure of the ac/dc input supply

• An output below 5.1V

• An SMPS over temperature condition.

Check that the yellow LED (Power Share) is on. It extinguishes when the other PSU is

supplying the greater current.

If the Power Share LED is extinguished and no fault is indicated on either PSU, there could be an

imbalance in output between the two PSUs.

CALIBRATION

Calibration is not required in normal operation.

Calibration of PSUs must not be performed on a running system.

Use the front panel trimmers to adjust the balance until both Power Share LEDs are

illuminated.

PSUs are power sharing to any extent. If this voltage is being measured while adjusting a

trimmer, the other PSU will need to be switched off (or short circuit pins 1 and 5 of one test

socket to disable current sharing) to see any effect on the meter. Adjust both PSUs until the

voltage

The voltage between pins 6 and 7 of both test sockets will be the same if the

is

the same (normally 5.4V ± 0.01V).

Page 13

PDC24

/

PAC

October

2005–

Issue 3

13

Tri

guard

SC300E PDC24 / PAC Chassis Power Supplies

SERVICE SUPPORT

SPARE PARTS

Spare parts and technical advice can be obtained from your local area office.

Loading...

Loading...