Rockwell Automation PanelView Plus, PanelView Plus 700, PanelView Plus 1250, PanelView Plus 1000, PanelView Plus 1500 User Manual

...Page 1

PanelView Plus Terminals

User Manual

Catalog Number 2711P

400, 600, 700, 1000, 1250, 1500

Term in als

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local

Rockwell Automation sales office or online at http://literature.rockwellautomation.com

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability

for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Allen-Bradley, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

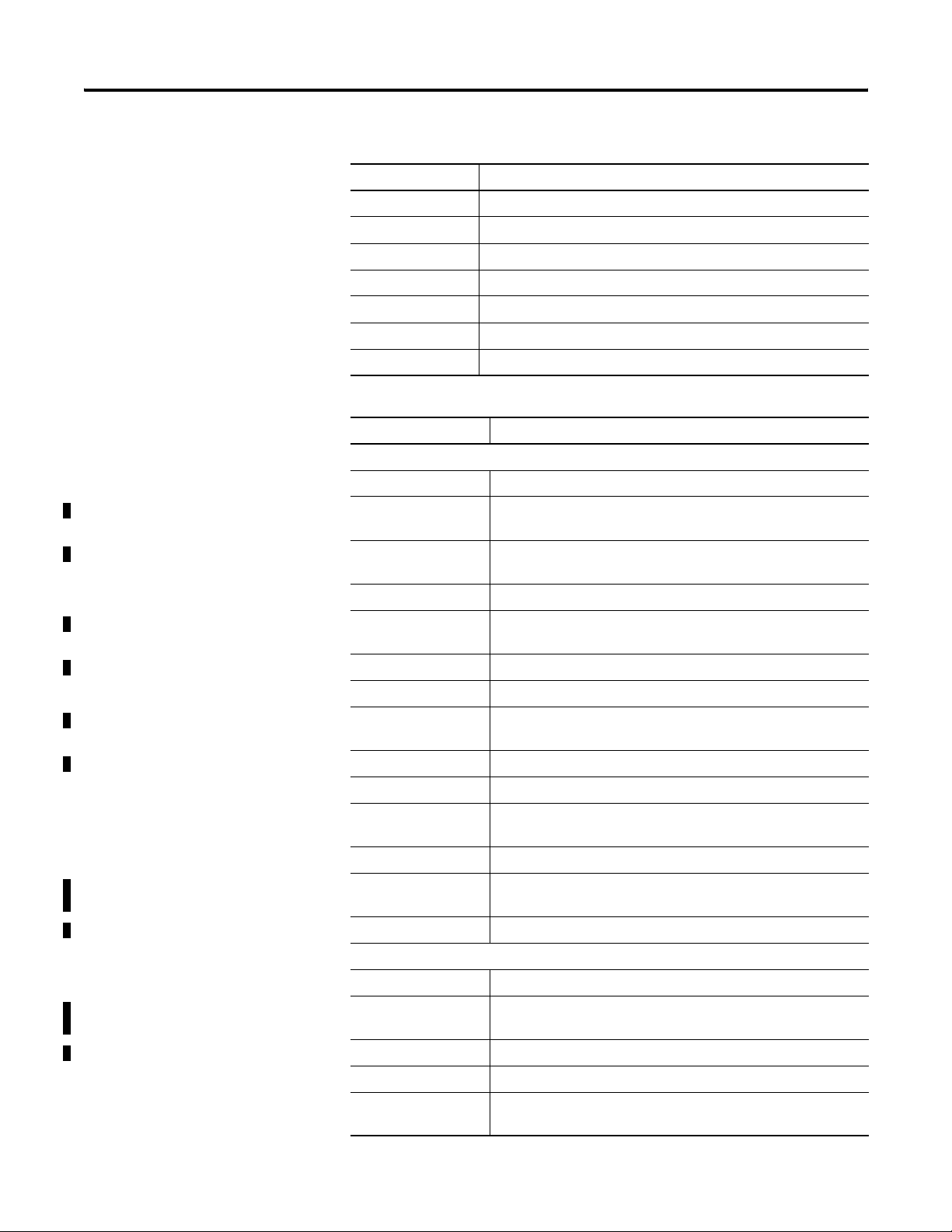

The information below summarizes the changes to this manual since

the last revision.

Revision bars, as shown in the margin, identify updated information.

This document includes the following changes.

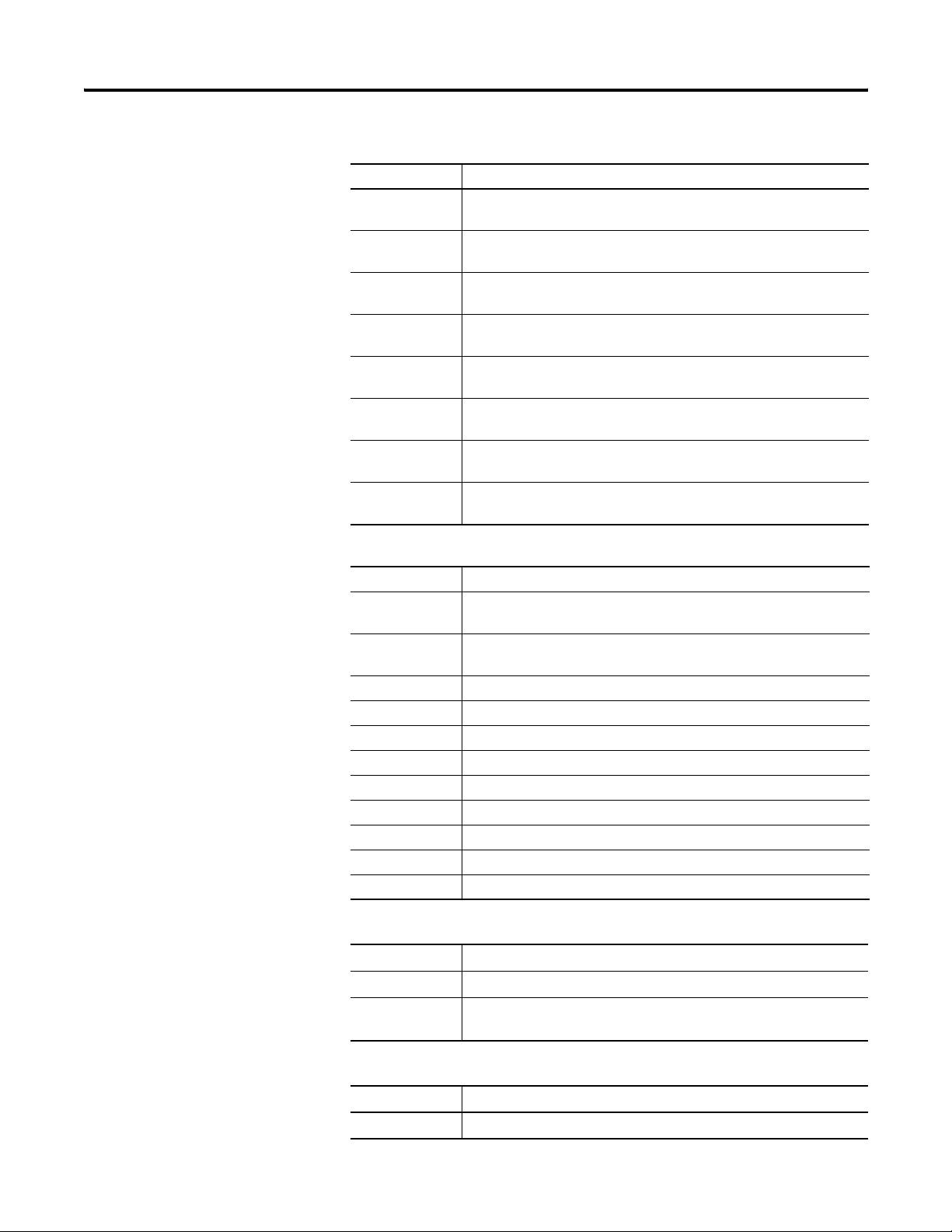

Topic Page

Corrected touchscreen stylus tip radius 15, 16, 21, 22, 88

Added catalog numbers for marine-certified terminals and added

OEM option to catalog number configuration diagram

Updated series information for backlights 26

Added catalog number 2711P-RGB4 for antiglare overlay for

PanelView Plus 400 color keypad/touch terminal

Corrected temperature range around the terminals in Clearances 36

Corrected panel thickness range for lever position 1 38

Added battery type and disposal information 153

23, 25

27

Added footnotes to tables regarding maximum cable length for

DH-485 modules

Modified connector pinout diagram 176

Corrected wiring connections and pinouts in Remote I/O & DH+

depictions

Added message about maximum cable length for DH-485

modules

Added battery disposal information to Maintenance chapter 228

Added environmental information for Airborne Contaminants 230

Updated EMC and LVD Directives 232

168, 169, 170

178, 182, 183

178

3Publication 2711P-UM001I-EN-P - December 2008 3

Page 4

Summary of Changes

4 Publication 2711P-UM001I-EN-P - December 2008

Page 5

Table of Contents

Preface

Overview

Installation

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Software and Firmware Upgrades . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Software Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PanelView Plus 400 and 600 Terminals . . . . . . . . . . . . . . . . 12

PanelView Plus 700 to 1500 Terminals . . . . . . . . . . . . . . . . . 17

Catalog Number Configuration. . . . . . . . . . . . . . . . . . . . . . . 23

PanelView Plus Product Components. . . . . . . . . . . . . . . . . . 23

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Environment and Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . 34

Outdoor Installation for High-bright Displays . . . . . . . . . . . . 34

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Mount the 400 or 600 Terminal in a Panel . . . . . . . . . . . . . . 37

Mount the 700 to 1500 Terminal in a Panel . . . . . . . . . . . . . 39

Product Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Power Connections

Configuration Mode

Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Wiring and Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . 47

Remove and Install the Power Terminal Block . . . . . . . . . . . 48

DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Reset the Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Access Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . 61

Load an Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Run an Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Application Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Terminal Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configure Communications . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configure Network Information . . . . . . . . . . . . . . . . . . . . . . 72

Configure Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Manage Files on the Terminal . . . . . . . . . . . . . . . . . . . . . . . 78

5Publication 2711P-UM001I-EN-P - December 2008 5

Page 6

Table of Contents

Windows CE .NET Operating

System

Modify Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Font Linking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Configure Keypad, Keyboard, or Mouse. . . . . . . . . . . . . . . . 86

Configure the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . 88

Configure Print Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Configure Startup Options . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Configure Startup Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

View and Clear the System Event Log . . . . . . . . . . . . . . . . 101

Display Terminal Information . . . . . . . . . . . . . . . . . . . . . . 102

Display FactoryTalk View ME Station Information. . . . . . . . 104

Modify the Date, Time, or Time Zone . . . . . . . . . . . . . . . . 105

Modify Regional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Windows CE .NET Architecture . . . . . . . . . . . . . . . . . . . . . 113

Windows CE .NET Programs . . . . . . . . . . . . . . . . . . . . . . 114

Windows CE .NET Operating System . . . . . . . . . . . . . . . . . 115

PanelView Plus CE Memory. . . . . . . . . . . . . . . . . . . . . . . . 119

Control Panel Applications . . . . . . . . . . . . . . . . . . . . . . . . 121

Install and Replace Components

Terminal Connections

Chapter 6

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Component Compatibility for PanelView Plus CE Terminals 142

Component Compatibility for PanelView Plus Terminals. . . 142

Install RAM or Internal CompactFlash. . . . . . . . . . . . . . . . . 143

Install or Replace the Logic Module . . . . . . . . . . . . . . . . . . 144

Install or Replace a Communication Module. . . . . . . . . . . . 147

Replace the Display Module . . . . . . . . . . . . . . . . . . . . . . . 151

Replace the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Replace the Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Replace the Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Remove the Product ID Label . . . . . . . . . . . . . . . . . . . . . . 162

Replace the Keypad Legend Inserts . . . . . . . . . . . . . . . . . . 162

Use an External CompactFlash Card. . . . . . . . . . . . . . . . . . 165

Chapter 7

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Wiring and Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . 167

Logic Controller Cable Charts . . . . . . . . . . . . . . . . . . . . . . 168

Communication Port Isolation . . . . . . . . . . . . . . . . . . . . . . 171

USB Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Serial Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

6 Publication 2711P-UM001I-EN-P - December 2008

Page 7

Upgrade Firmware

Troubleshoot the System

Table of Contents

Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

DH-485/DH+/Remote I/O Module . . . . . . . . . . . . . . . . . . . 178

ControlNet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

DeviceNet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Chapter 8

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Transfer Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Create an ActiveSync Connection. . . . . . . . . . . . . . . . . . . . 193

Firmware Upgrade Wizard. . . . . . . . . . . . . . . . . . . . . . . . . 195

Upgrade Firmware with a CompactFlash Card . . . . . . . . . . 196

Upgrade Firmware with a Network (Ethernet) Connection . 200

Upgrade the Operating System (OS) . . . . . . . . . . . . . . . . . 206

Chapter 9

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Isolate the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Startup Information Messages . . . . . . . . . . . . . . . . . . . . . . 213

Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Startup Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Check Terminal Components. . . . . . . . . . . . . . . . . . . . . . . 216

Ethernet Connnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Application Does Not Run. . . . . . . . . . . . . . . . . . . . . . . . . 222

Configuration Mode Access . . . . . . . . . . . . . . . . . . . . . . . . 222

File System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Advanced Diagnostics for CE Terminals . . . . . . . . . . . . . . . 223

System Identification Errors . . . . . . . . . . . . . . . . . . . . . . . . 224

Restart in Safe Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Chapter 10

Maintenance

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Clean the Display Window . . . . . . . . . . . . . . . . . . . . . . . . 227

Disposal Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Appendix A

Specifications

Publication 2711P-UM001I-EN-P - December 2008 7

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Agency Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Page 8

Table of Contents

Compatible USB Devices

Available Fonts for Terminal

Applications

Programmable Key Definitions

Security Considerations

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Appendix C

Download Fonts to Terminal . . . . . . . . . . . . . . . . . . . . . . . 235

PanelView Plus CE Accessories CD . . . . . . . . . . . . . . . . . . 235

RSView Machine Edition Fonts CD. . . . . . . . . . . . . . . . . . . 236

Appendix D

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Appendix E

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

8 Publication 2711P-UM001I-EN-P - December 2008

Page 9

Preface

Objectives

Intended Audience

Parts List

This preface provides information on these topics.

• Intended audience

• Parts list

• Additional resources

• Software and firmware upgrades

Use this manual if you are responsible for installing, operating, or

troubleshooting the PanelView Plus or PanelView Plus CE terminals.

No special knowledge is required to understand this manual or

operate the terminal. However, you must understand the functions

and operations of FactoryTalk View Machine Edition (ME)

applications that will run on the terminal. Consult the application

designer for this information.

Equipment installers must be familiar with standard panel installation

techniques.

The PanelView Plus terminals are shipped with these items.

• Power terminal block

• FactoryTalk View ME runtime software, preloaded

• Mounting levers for 400 and 600 terminals, quantity eight

• Mounting clips for 700 to 1500 terminals, quantity four to eight

• Installation instructions

• Panel cutout template

Additional items are shipped with the PanelView Plus CE terminals.

• Windows CE .NET operating system preloaded with Terminal

Services and Internet Explorer

• PanelView Plus CE Accessory CD with utilities and software

development kit for C++

• Microsoft Windows CE license agreement

9Publication 2711P-UM001I-EN-P - December 2008 9

Page 10

Preface Preface

Additional Resources

For additional information, refer to these publications, that you can

download from http://literature.rockwellautomation.com

Resource Description

DeviceNet Communications for PanelView Plus

Terminals User Manual, publication

2711P-UM004

ControlNet Communications for PanelView Plus

Terminals User Manual, publication

2711P-UM003

Modbus Applications for PanelView Plus

Terminals User Manual, publication

2711P-UM002

Wiring and Grounding Guidelines for PanelView

Plus Devices Technical Data, publication

2711P-TD001

Software Development Kit for PanelView Plus

CE Terminals User Manual, publication

2711P-UM005

Provides procedures for creating a

DeviceNet application to run on a

PanelView Plus terminal.

Provides procedures for creating a

ControlNet application to run on a

PanelView Plus terminal.

Provides procedures for creating a

Modbus application to run on a

PanelView Plus terminal.

Provides grounding and wiring

guidelines for PanelView Plus terminals.

Provides information for programmers to

develop CE applications for PanelView

Plus CE terminals.

.

You may also want to refer to:

• online help for FactoryTalk View Studio or RSLinx software.

• documentation for your controller.

Software and Firmware Upgrades

To receive software updates (software serial number required) and

firmware upgrades for your terminal:

• call your local Rockwell Automation sales office or distributor.

• access http://support.rockwellautomation.com

10 Publication 2711P-UM001I-EN-P - December 2008

Page 11

Overview

Chapter

1

Chapter Objectives

Software Support

This chapter gives an overview of the PanelView Plus terminals.

• Software support

• PanelView Plus 400 and 600 features

• PanelView Plus 700 to 1500 features

• Catalog number configuration

• Product components

FactoryTalk View ME runtime software is included with all PanelView

Plus and PanelView Plus CE terminals. This software provides runtime

and terminal configuration software for the terminals and does not

require activation.

You use FactoryTalk View Studio software on a personal computer to

create applications that run in the terminals. This software is

purchased separately.

The open Windows CE.NET environment of the PanelView Plus CE

terminals provides:

• familiar Windows desktop and user interface.

• terminal server-client support to configured servers

• Internet Explorer web browser.

• software development kit to support custom C++ applications

for Windows CE.NET operating system.

• third-party device support for Windows CE.NET operating

system.

• Windows CE.NET operating system provides the following

programs:

– File viewers for MS Office: Excel, Word, PowerPoint

– PDF file viewer

– WordPad text editor

– WebServer application

– FTP server

– Support for the .NET compact framework

Some of the above software applications are included on the

PanelView Plus CE Accessory CD.

11Publication 2711P-UM001I-EN-P - December 2008 11

Page 12

Chapter 1 Overview

PanelView Plus 400 and 600 Terminals

The PanelView Plus 400 and 600 terminals offer:

• base-configured units.

• communication modules.

• power supply, AC or DC.

• grayscale and color displays.

The PanelView Plus 400 and 600 terminals are HMI devices that

provide these features:

• PanelView Plus 400 terminals

– Color or grayscale graphic displays

– Keypad or keypad and touch screen input support

• PanelView Plus 600 terminals

– Color or grayscale graphic displays

– Keypad, touch screen, or keypad and touch screen input

• Base-configured unit

– RS-232 only

– RS-232, Ethernet, and modular communications interface

• Communication modules provide add-on capability to

base-configured units with a modular communications interface

• Power input, AC (85…264V) or DC (18…30V)

• CompactFlash card slot supports Type 1 CompactFlash cards

• USB port for attaching mouse, keyboard, printer, bar code

scanner, and other devices

• Same panel cutouts as the PanelView Standard 550 terminals

12 Publication 2711P-UM001I-EN-P - December 2008

Page 13

Base-configured Units

The base-configured unit of the 400 and 600 terminals is available in

two versions.

Base Unit with RS-232 Only

Base-configured Unit with RS-232

and USB Port only

Overview Chapter 1

• Base unit with RS-232 port and one USB port

• Base unit with RS-232 port, 10/100BaseT Ethernet port, one USB

port, and a network interface for a communication module

Power Input, AC or DC

CompactFlash Slot

Base Unit with RS-232, Ethernet Port, and Modular Communications Interface

Interface for

Communication Module

Base-configured Unit with

RS-232, USB, Ethernet Port, and Network

Interface for Communication Module.

USB Port

USB Port

RS-232 Port

RS-232 Port

Power Input, AC or DC

CompactFlash Slot

Ethernet Port

Publication 2711P-UM001I-EN-P - December 2008 13

Page 14

Chapter 1 Overview

Communication Modules

You can attach a communication module with a network interface to

the base-configured unit of the PanelView Plus 400 and 600 terminals

to increase your communication capability with these networks:

• DH-485

• DH+

• Remote I/O (single rack)

• Isolated RS-232

• DeviceNet

• ControlNet

The communication module installs easily on the back of the unit.

Communication

Module

Power Options

The base-configured unit of the PanelView Plus 400 and 600 terminals

is available with either AC (85…264V) or DC (18…30V) power input

providing application flexibility.

14 Publication 2711P-UM001I-EN-P - December 2008

Page 15

Overview Chapter 1

Display and Input Options

PanelView Plus 400 and 600 terminals are available with these display

and operator input options:

• 400 terminals: 3.8 in. grayscale (320 x 240) graphics display with

keypad or 3.5 in. (320 x 240) color with keypad or keypad and

touch support

• 600 terminals: 5.5 in. color or grayscale (320 x 240) graphics

display with keypad, touch screen, or keypad and touch support

Touch Screen

The PanelView Plus 600 terminals offer an analog resistive touch

screen for touch input.

600 Touch Grayscale or Color Terminal

IMPORTANT

The touch screen may be operated with a finger, gloved finger,

or plastic stylus device with a minimum tip radius of

1.3 mm (0.051 in.) to prevent damage to the touch screen. Using

any other object or tool may damage the touch screen.

Publication 2711P-UM001I-EN-P - December 2008 15

Page 16

Chapter 1 Overview

Keypad or Keypad and Touch

The keypad versions of the PanelView Plus 400 and 600 terminals are

available with these options:

• 400 terminals: grayscale display with keypad or color display

with keypad or keypad and touch input

• 400 and 600 terminals offer an analog resistive touch screen for

touch input.

• 600 terminals: color or grayscale displays with either keypad, or

keypad and touch input

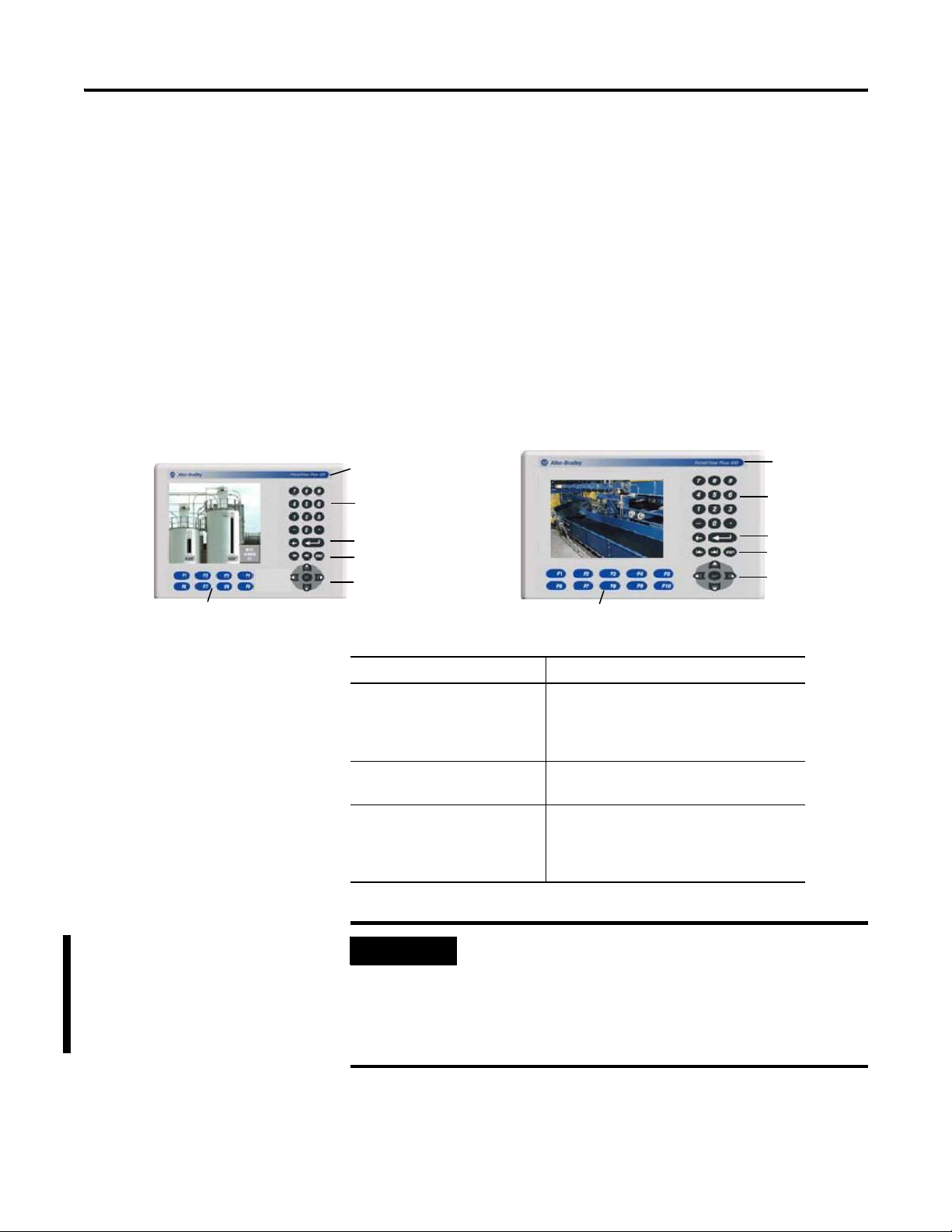

400 Grayscale with Keypad, or 400 Color

with Keypad or Keypad and Touch

8 Programmable Function Keys

600 Grayscale or Color Terminal

with Keypad, or Keypad and Touch Screen

Replaceable ID Label

Numeric Keypad

Backspace and Enter Keys

Tab and Shift Keys

Navigation Keys

10 Relegendable Programmable Function Keys

Replaceable

ID Label

Numeric Keypad

Backspace and

Enter Keys

Tab and Shift Keys

Navigation Keys

Keys Description

400 F1 through F8

600 F1 through F10

Programmable keys that initiate functions

on terminal display. Replaceable legends

are available for the 600 terminals allowing

for custom function key labels.

Numeric Keypad 0…9, ., -, Backspace, Enter, Left and Right

Tab keys, Shift keys

Navigation Keys Use the arrow keys for navigation.

Use the Alt+arrow keys to activate home,

end, page up, and page down functions.

IMPORTANT

The keypad is designed for finger or gloved finger operation.

The touch screen may be operated with a finger, gloved finger,

or plastic touch screen stylus with a minimum tip radius of

1.3 mm (0.051 in.) to prevent damage to the touch screen.

Using any other object or tool may damage the touch screen

or keypad.

16 Publication 2711P-UM001I-EN-P - December 2008

Page 17

Overview Chapter 1

PanelView Plus 700 to 1500 Terminals

This section gives an overview of the PanelView Plus 700, 1000, 1250,

1250H, and 1500 terminals.

• Modular components

• Base-configured unit

• Communication modules

• Logic module, standard or CE

• Power supply, AC or DC

• Display modules

The PanelView Plus 700 to 1500 terminals are HMI devices that offer

these features:

• Graphic color-display modules with keypad, touch screen, or

keypad and touch screen support

• Analog resistive touch screen

• Ethernet and serial communications

• Modular communication interface for easy add-on capability

• Memory expansion modules for field upgrades to 256 MB RAM

and 512 MB CompactFlash

• Power input, AC (85…264V AC) or DC (18…32V DC)

• CompactFlash card slot supports Type 1 CompactFlash cards

• USB ports provide connections for keyboard, mouse, and printer

• Field replaceable bezels

• Same panel cutouts as the PanelView Standard and PanelView

Enhanced terminals

• Standard or CE logic module

Publication 2711P-UM001I-EN-P - December 2008 17

Page 18

Chapter 1 Overview

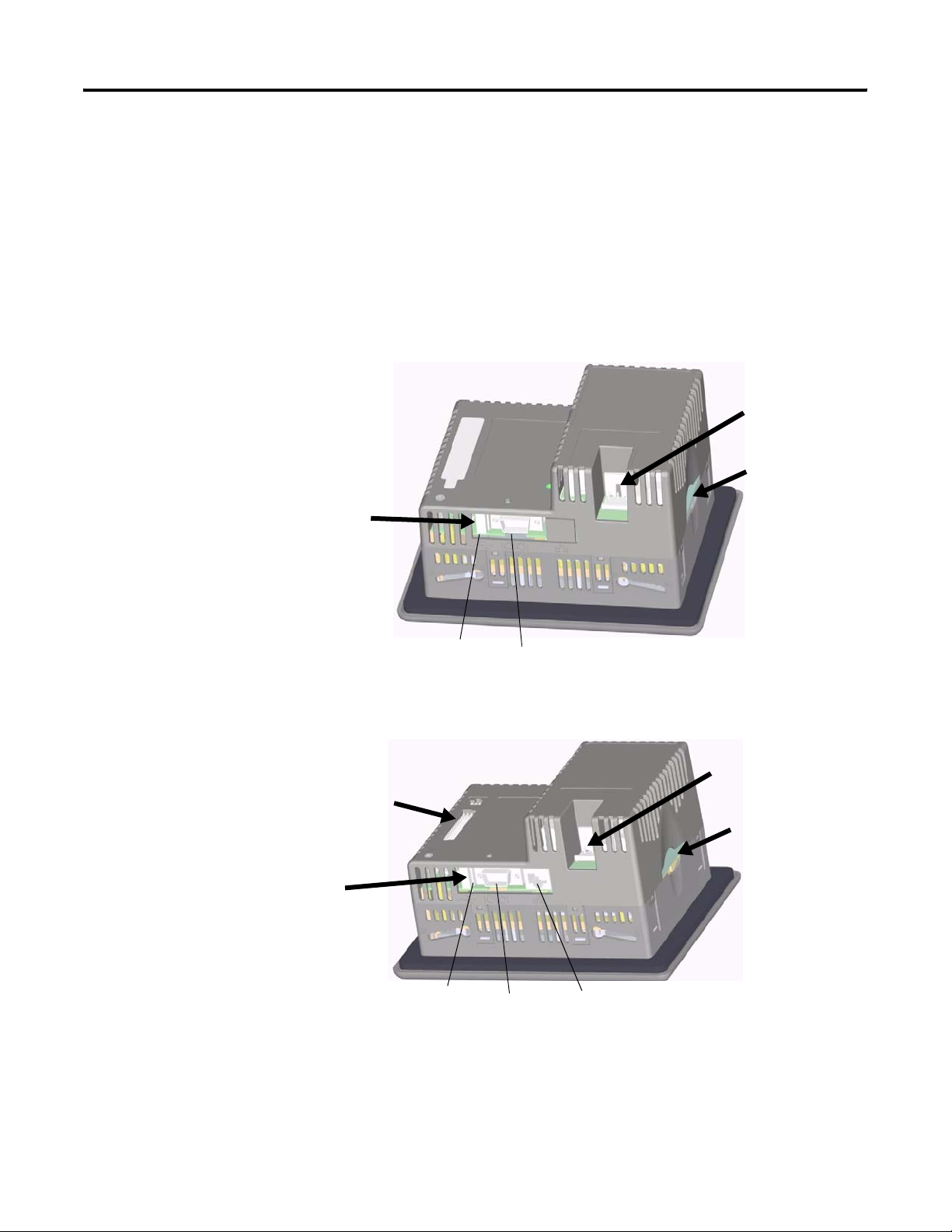

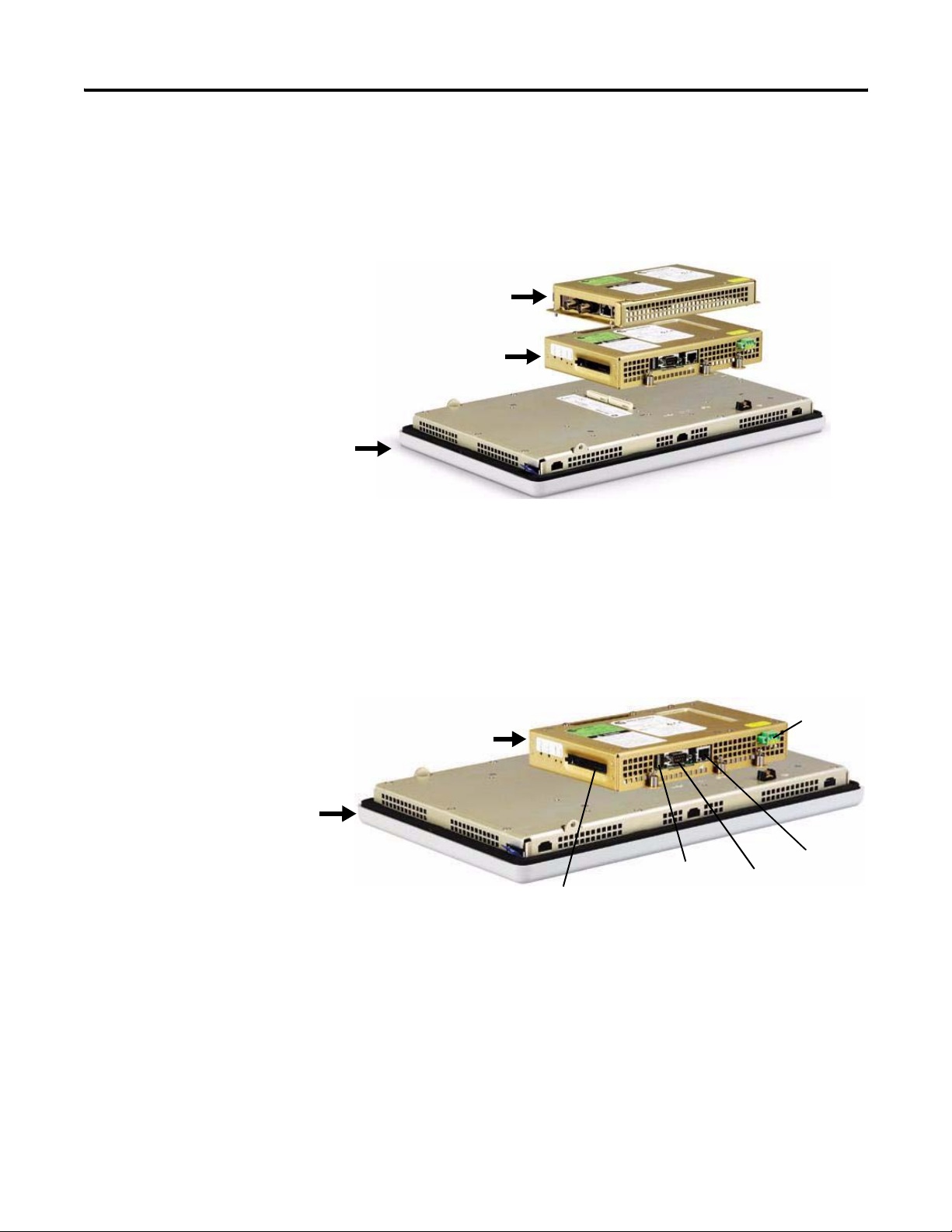

Modular Components

The terminals use modular components allowing for flexible

configuration, installation, and upgrades. You can order items as

separate components or factory assembled per your configuration.

Communication Module

Logic Module

Display Module

Display Module

Base-configured Unit

The base-configured unit of the terminal consists of:

• display module (700, 1000, 1250, 1500) with keypad, touch, or

keypad and touch input.

• logic module.

Logic Module

USB Ports

CompactFlash Card Slot

Serial Port

The logic module contains:

• 24V DC input (18…32V) or AC input (85…264V).

• SDRAM and flash memory, various sizes.

• 10/100 BaseT Ethernet port.

• serial RS-232 port for file transfers, printing, and logic controller

communications.

• two USB ports for attaching mouse, keyboard, or printer.

• card slot for Type I CompactFlash cards.

• battery-backed real-time clock.

Ethernet Port

Power Input,

AC or DC

18 Publication 2711P-UM001I-EN-P - December 2008

Page 19

Overview Chapter 1

Logic Modules and CompactFlash

The logic module is available with or without internal CompactFlash.

The contents of the internal CompactFlash is what differentiates a

PanelView Plus device from a PanelView Plus CE device.

• For the PanelView Plus terminals, the internal CompactFlash

contains FactoryTalk View ME software and flash memory.

• For the PanelView Plus CE terminals, the internal CompactFlash

contains the open Windows CE operating system,

FactoryTalk View ME software, and flash memory.

The internal CompactFlash is available in different sizes and can be

ordered separately or bundled with the logic module.

Communication Modules

You can attach a communication module with a network interface to

the base-configured unit of the terminal to increase your

communication capability with these networks:

• DH+/DH-485/Remote I/O

• DeviceNet

• ControlNet

The communication module installs easily on top of the logic module

on the back of the unit.

Communication Module

Publication 2711P-UM001I-EN-P - December 2008 19

Page 20

Chapter 1 Overview

Power Options

The basic configured units of the 700 to 1500 PanelView Plus

terminals provide application flexibility with three available power

power options:

• AC (85...264V)

• unisolated DC (18...32V)

• isolated DC (18...32V)

For DC applications using AC power, a remote AC-to-DC power

supply, cat. no. 2711P-RSACDIN, is available for DIN-rail mounting.

Display Modules

The terminals offer a range of TFT color graphic displays with either

keypad, touch screen, or keypad and touch screen support.

• 700 (6.5 in.)

• 1000 (10.4 in.)

• 1250 (12.1 in.)

• 1500 (15 in.)

The 700 and 1250 touch displays are available in conformal-coated

options. A 1250 high-bright, touch display module is available for

outdoor installations. Plus the 1250 and 1500 touch displays offer an

integral antiglare overlay.

All displays have common features and firmware providing for easy

migration to a larger display. Field-replaceable bezels are also

available.

20 Publication 2711P-UM001I-EN-P - December 2008

Page 21

Overview Chapter 1

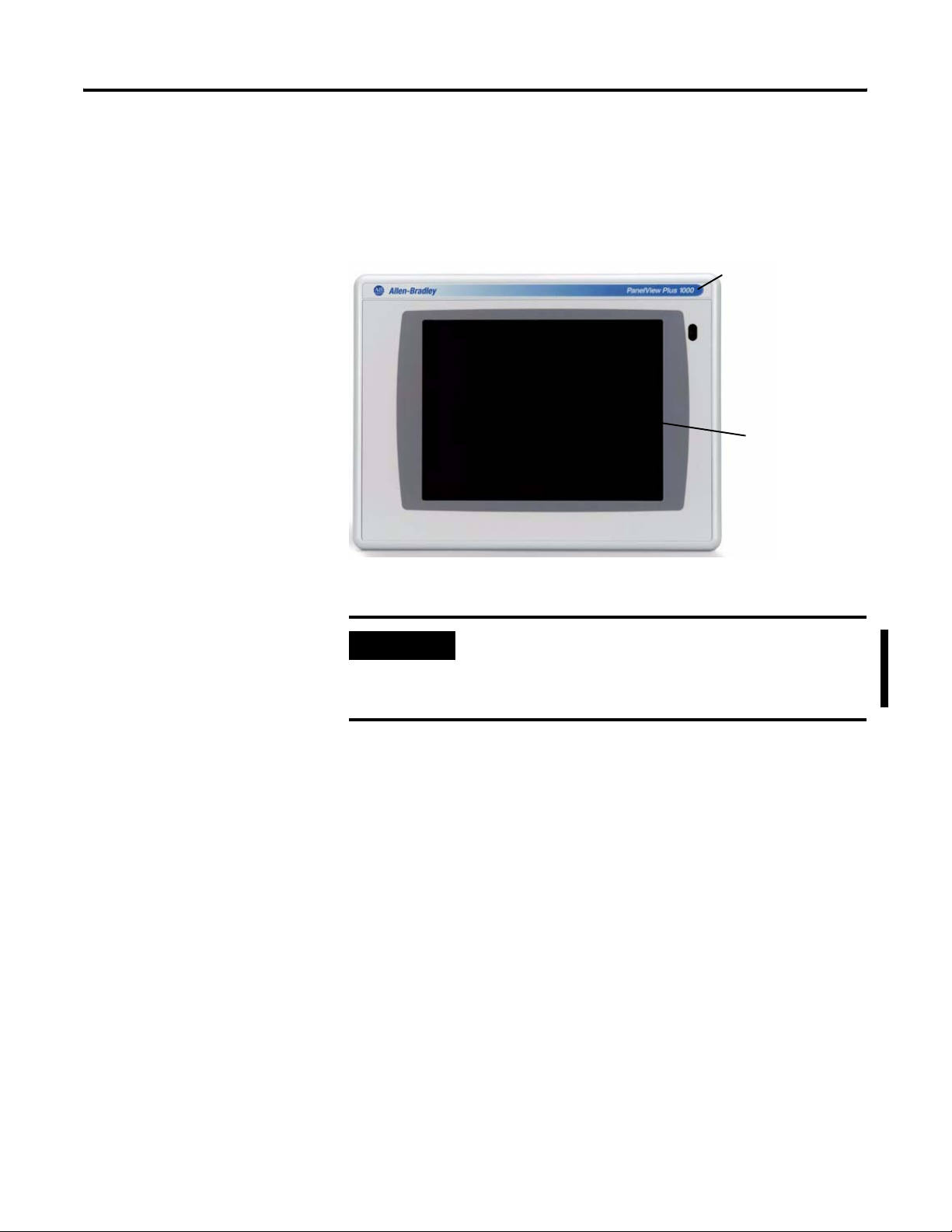

Touch Screen

All touch-screen displays are analog resistive and similar except for

size.

Replaceable ID Label

Touch Screen

IMPORTANT

The touch screen may be operated with a finger, gloved finger,

or plastic stylus device with a minimum tip radius of

1.3 mm (0.051 in.) to prevent damage to the touch screen. Using

any other object or tool may damage the touch screen.

Publication 2711P-UM001I-EN-P - December 2008 21

Page 22

Chapter 1 Overview

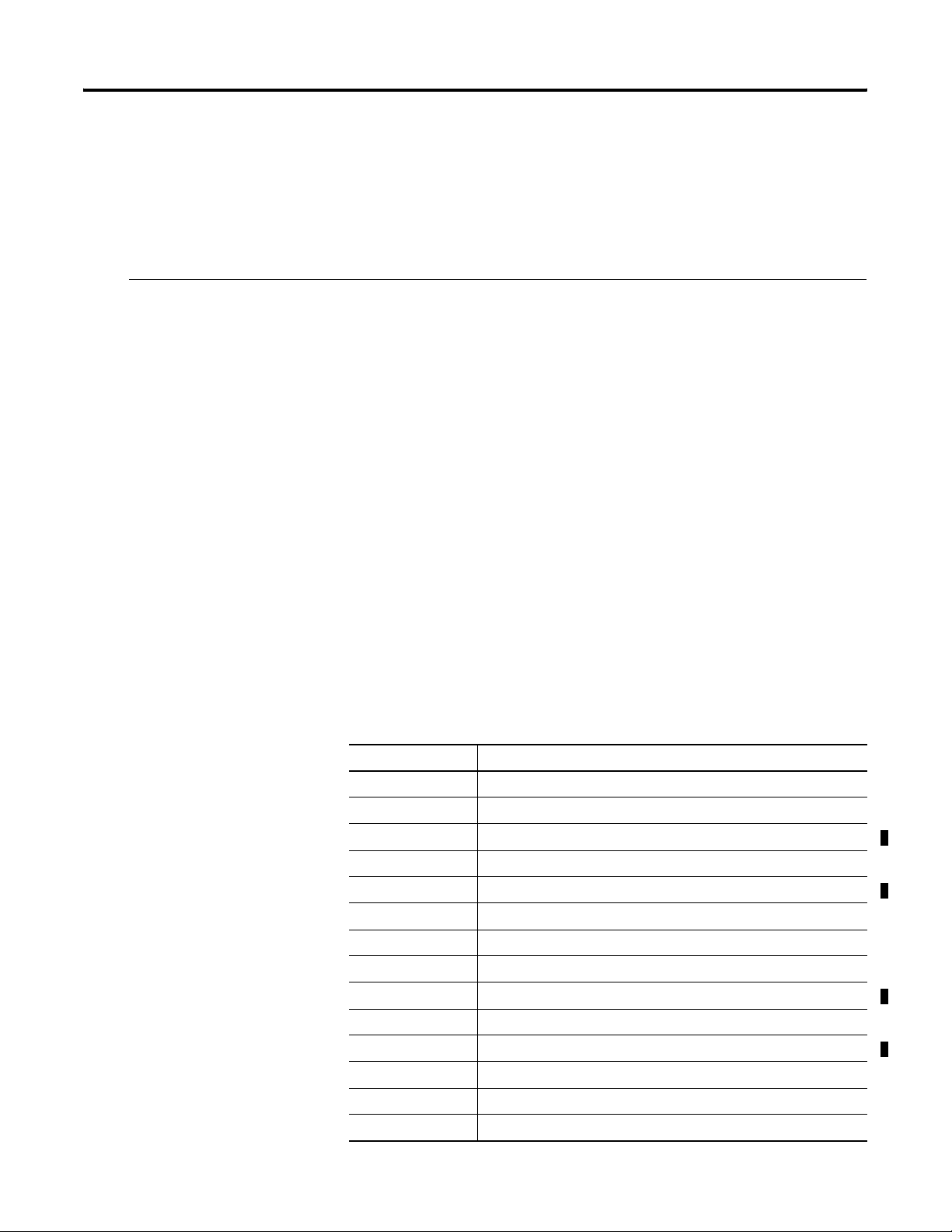

Programmable Function Keys

(optional custom legends)

Keypad or Keypad and Touch

All displays are similar except for size and the number of function

keys available.

Allen-Bradley Label

Numeric Keypad

Backspace

and Enter Keys

Tab and Shift Keys

Esc, CT, Alt Keys

Navigation Keys

Programmable Function Keys

(optional custom legends)

IMPORTANT

The keypad is designed for finger or gloved finger operation.

The touch screen may be operated with a finger, gloved finger,

or plastic stylus device with a minimum tip radius of

1.3 mm (0.051 in.) to prevent damage to the touch screen.

Using any other object or tool may damage the touch screen

or keypad.

The Kxx and Fxx function keys on the keypad terminals are

programmable.

Function Keys Description

Function Keys

700 (F1 through F10, K1 through K12)

1000 (F1 through F16, K1 through K16)

1250 (F1 through F20, K1 through K20)

1500 (F1 through F20, K1 through K20)

Numeric Keypad 0…9, ., -, Backspace, Enter, Left and Right

Programmable keys that initiate functions

on terminal display. Replaceable legends

are available for the terminals allowing for

custom function key labels.

tab, Shift, Esc, Ctrl, Alt keys.

Navigation Keys Use the arrow keys to move cursor in lists

and select objects.

Alt+arrow key activates home, end, page

up, page down functions.

22 Publication 2711P-UM001I-EN-P - December 2008

Page 23

Overview Chapter 1

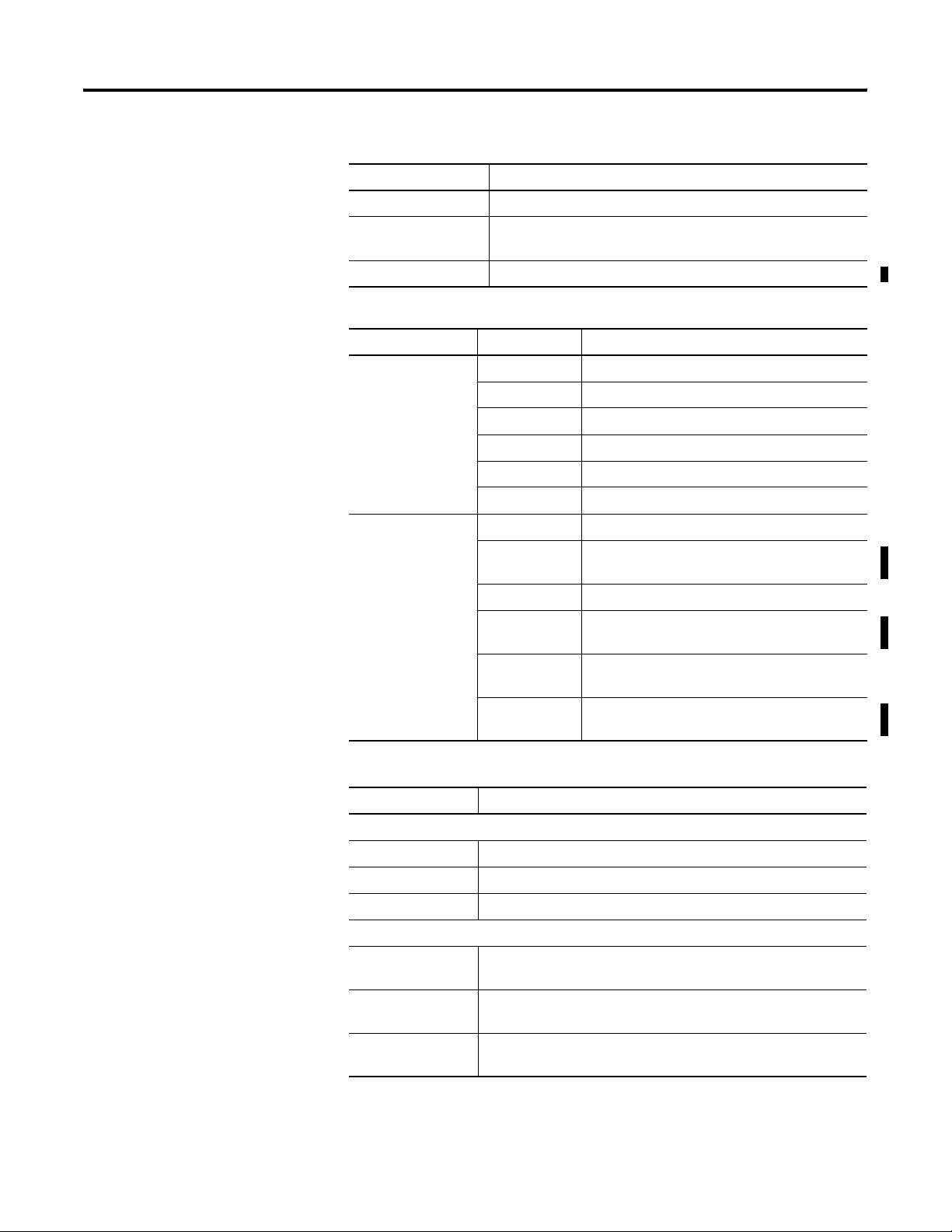

Catalog Number

The table shows the catalog number configuration for configured

versions of the PanelView Plus and PanelView Plus CE terminals. Not

Configuration

Input

Ty pe

||| | | |

2711P- K = Keypad 4 = 3.5 in. C = Color PanelView Plus 400 and 600 Terminals A = AC 1= Logic Module 64 MB K = Conformal-Coated

T = Touch 6 = 5.5 in. M=Grayscale 1 = Remote I/O (single rack), Ethernet,

B = Keypad/Touch 7 = 6.5 in. 3 = DH-485, Ethernet, RS-232 & USB 3 = Logic Module with 256 MB

(1)

Additional communication options are available and can be seen in the following section.

(2)

Applies to PanelView Plus 700 to 1500 terminals only.

Display

Size

10 = 10.4 in. 5 = RS-232 & USB 6 = CE Logic Module with 128 MB

12 = 12.1 in. 8 = DH+, Ethernet, RS-232 & USB 7 = CE Logic Module with 256 MB

15 = 15 in. 20 = Ehernet, RS-232 & USB plus

Display Type

all combinations of options are available for sale.

Communication

RS-232 & USB

Communication Module Interface

PanelView Plus 700 to 1500 Terminals

4 = Ethernet, RS-232 & (2) USB

6 = DH+, DH-485, RIO, Ethernet, RS-232 & (2) USB

15 = ControlNet, Ethernet, RS-232 & (2) USB

(1)

Power Logic Module with

Flash and RAM Memory

D = DC 2 = Logic Module 128 MB

Special Option

(2)

(2)

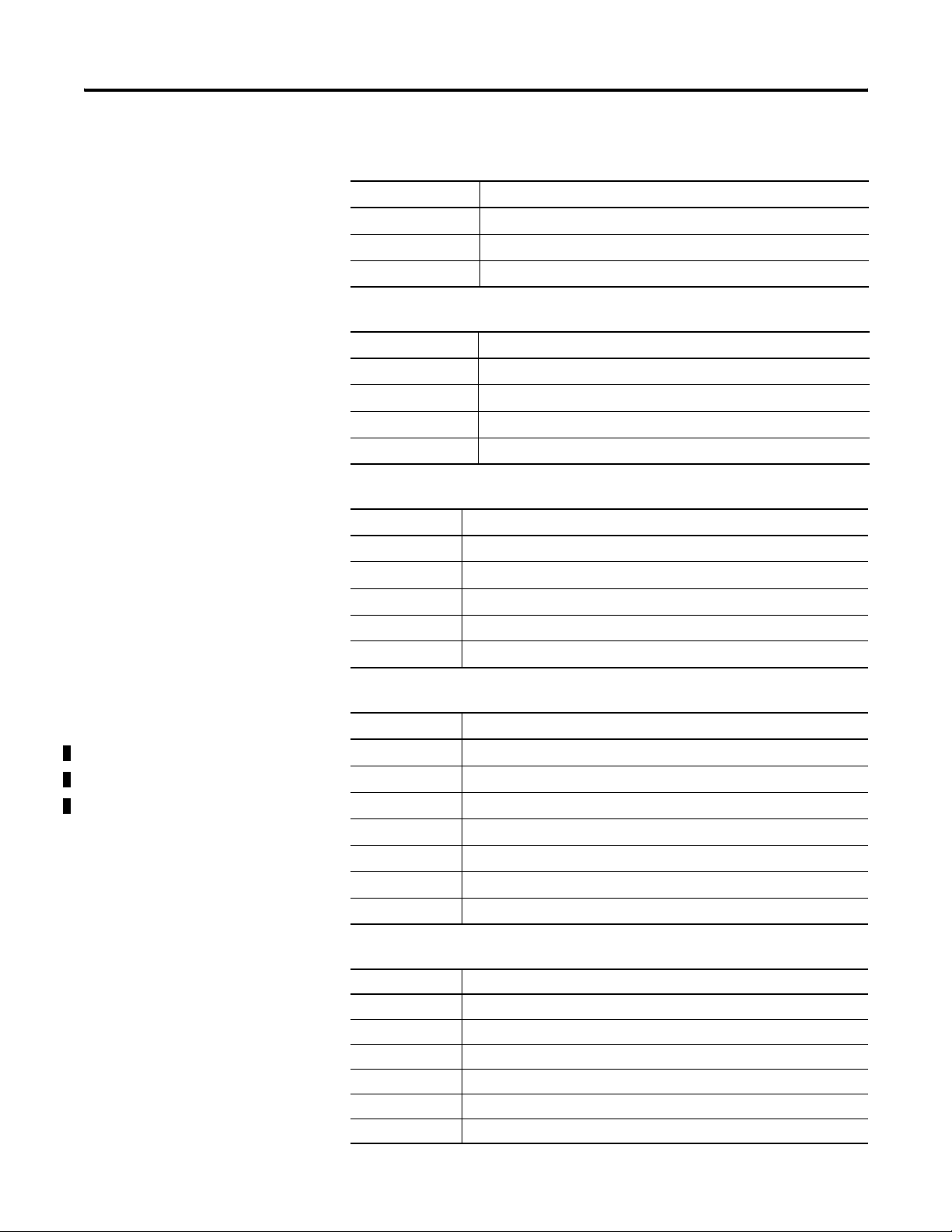

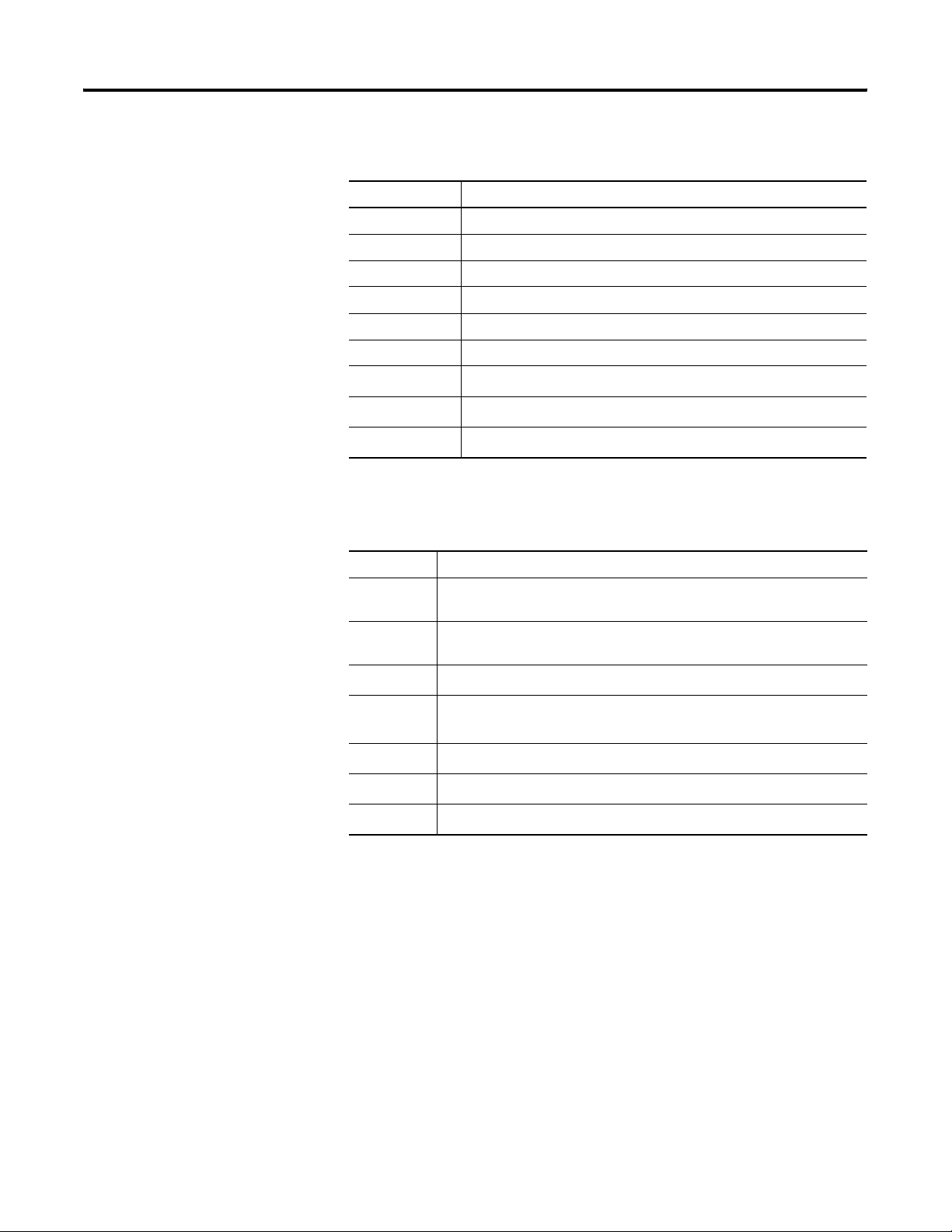

PanelView Plus Product Components

Components are available as separate catalog numbers for field

installation or replacement.

Display Modules (700 to 1500 only)

Cat. No. Description

2711P-RDK7C 700 keypad color display

2711P-RDT7C 700 touch color display

2711P-RDT7CM 700 touch color display, marine certified

2711P-RDB7C 700 keypad and touch color display

2711P-RDB7CM 700 keypad and touch color display, marine certified

2711P-RDT7CK Conformal-coated 700 touch color display

2711P-RDK10C 1000 keypad color display

2711P-RDT10C 1000 touch color display

2711P-RDT10CM 1000 touch display, marine certified

2711P-RDB10C 1000 keypad and touch color display

2711P-RDB10CM 1000 keypad and touch display, marine certified

2711P-RDK12C 1250 keypad color display

2711P-RDT12C 1250 touch color display

2711P-RDT12AG 1250 touch color display with antiglare overlay

Publication 2711P-UM001I-EN-P - December 2008 23

Page 24

Chapter 1 Overview

Display Modules (700 to 1500 only)

Cat. No. Description

2711P-RDT12CK Conformal-coated 1250 touch color display

2711P-RDT12H 1250 high-bright touch color display

2711P-RDB12C 1250 keypad and touch color display

2711P-RDK15C 1500 keypad color display

2711P-RDT15C 1500 touch color display

2711P-RDT15AG 1500 touch color display with antiglare overlay

2711P-RDB15C 1500 keypad and touch color display

Logic Modules (700 to 1500 only)

Cat. No. Description

Standard Logic Modules for PanelView Plus Terminals

2711P-RP Logic module without flash/RAM memory, DC input

2711P-RPD Logic module, without memory, isolated DC input, marine

certified

2711P-RPA Logic module without flash/RAM memory, AC input, marine

certified

2711P-RP1 Logic module with 64 MB flash/64 MB RAM, DC input

2711P-RP1A Logic module with 64 MB flash/64 MB RAM, AC input, marine

certified

2711P-RP1D Logic module with 64MB, isolated DC input, marine certified

2711P-RP2 Logic module with 128 MB flash/128 MB RAM, DC input

2711P-RP2A Logic module with 128 MB flash/128 MB RAM, AC input, marine

certified

2711P-RP2D Logic module with 128MB, isolated DC input, marine certified

2711P-RP2DK Conformal-coated logic module with 128MB, isolated DC input

2711P-RP2K Conformal-coated logic module with 128 MB flash/128 MB RAM,

DC input

2711P-RP3 Logic module with 256 MB flash/256 MB RAM, DC input

2711P-RP3A Logic module with 256 MB flash/256 MB RAM, AC input, marine

certified

2711P-RP3D Logic module with 256MB, isolated DC input, marine certified

CE Logic Modules for PanelView Plus CE Terminals

2711P-RP6 CE logic module with 128 MB flash/128 MB RAM, DC input

2711P-RP6A CE logic module with 128 MB flash/128 MB RAM, AC input,

marine certified

2711P-RP6D CE logic module with 128MB, isolated DC input, marine certified

2711P-RP6DK CE conformal-coated logic module with 128MB, isolated DC input

2711P-RP6K CE conformal-coated logic module with 128 MB flash/128 MB

RAM, DC input

24 Publication 2711P-UM001I-EN-P - December 2008

Page 25

Overview Chapter 1

Logic Modules (700 to 1500 only)

Cat. No. Description

2711P-RP7 CE logic module with 256 MB flash/256 MB RAM, DC input

2711P-RP7A CE logic module with 256 MB flash/256 MB RAM, AC input,

marine certified

2711P-RP7D CE logic module with 256 MB, isolated DC input, marine certified

Communication Modules

Terminal Type Cat. No. Description

2711P-RN1 Single-rack remote I/O communication module

2711P-RN3 DH-485 communication module

2711P-RN8 DH+ communication module

400 and 600

2711P-RN10C DeviceNet communication module

2711P-RN15C ControlNet communication module

2711P-RN22C RS-232 isolated communication module

2711P-RN6 DH+/DH-485/remote I/O communication module

2711P-RN6K Conformal-coated DH+/DH-485/remote I/O

communication module

2711P-RN10H DeviceNet communication module

700 to 1500

2711P-RN10HK Conformal-coated DeviceNet communication

module

2711P-RN15S ControlNet communication module, marine

certified

2711P-RN15SK Conformal-coated ControlNet communication

module

Internal Compact Flash

Cat. No. Description

Internal CompactFlash for Standard Logic Modules

2711P-RW1 64 MB CompactFlash with FactoryTalk View ME software

2711P-RW2 128 MB CompactFlash with FactoryTalk View ME software

2711P-RW3 256 MB CompactFlash with FactoryTalk View ME software

Internal CompactFlash for CE Logic Modules

2711P-RW6 128 MB CompactFlash with FactoryTalk View ME software and the

open Windows CE operating system for the CE logic module

2711P-RW7 256 MB CompactFlash with FactoryTalk View ME software and the

open Windows CE operating system for the CE logic module

2711P-RW8 512 MB CompactFlash with FactoryTalk View ME software and the

open Windows CE operating system for the CE logic module

Publication 2711P-UM001I-EN-P - December 2008 25

Page 26

Chapter 1 Overview

RAM Memory (700 to 1500 only)

Cat. No. Description

2711P-RR64 64 MB SODIMM memory

2711P-RR128 128 MB SODIMM memory

2711P-RR256 256 MB SODIMM memory

Compact Flash Cards (Blank)

Cat. No. Description

2711P-RC2 128 MB blank CompactFlash card

2711P-RC3 256 MB blank CompactFlash card

2711P-RC4 512 MB blank CompactFlash card

2711P-RCH CompactFlash to PCMCIA adapter

Legend Kits

Cat. No. Description

2711P-RFK6 Replacement legends strips for 600 keypad terminal

2711P-RFK7 Replacement legends strips for 700 keypad terminal

2711P-RFK10 Replacement legends strips for 1000 keypad terminal

2711P-RFK12 Replacement legends strips for 1250 keypad terminal

2711P-RFK15 Replacement legends strips for 1500 keypad terminal

Backlights (700 to 1500 only)

Cat. No. Description

2711P-RL7C Replacement color backlight for 700 series A and B display modules

2711P-RL7C2 Replacement color backlight for 700 series C and D display modules

2711P-RL10C Replacement color backlight for 1000 series A display modules

2711P-RL10C2 Replacement color backlight for 1000 series B display modules

2711P-RL12C Replacement color backlight for 1250 series A and B display modules

2711P-RL12C2 Replacement color backlight for 1250 series C display modules

2711P-RL15C Replacement color backlight for 1500 series B display modules

Replacement Bezels

Cat. No. Description

2711P-RBK7 Replacement bezel for 700 keypad terminal

2711P-RBT7 Replacement bezel for 700 touch terminal

2711P-RBB7 Replacement bezel for 700 keypad or keypad/touch terminal

2711P-RBK10 Replacement bezel for 1000 keypad terminal

2711P-RBT10 Replacement bezel for 1000 touch terminal

2711P-RBB10 Replacement bezel for 1000 keypad or keypad/touch terminal

26 Publication 2711P-UM001I-EN-P - December 2008

Page 27

Overview Chapter 1

Replacement Bezels

Cat. No. Description

2711P-RBK12 Replacement bezel for 1250 keypad terminal

2711P-RBT12 Replacement bezel for 1250 touch terminal

2711P-RBT12H Replacement bezel for 1250 high-bright touch terminal

2711P-RBB12 Replacement bezel for 1250 keypad or keypad/touch terminal

2711P-RBK15 Replacement bezel for 1500 keypad terminal

2711P-RBT15 Replacement bezel for 1500 touch terminal

2711P-RBB15 Replacement bezel for 1500 keypad or keypad/touch terminal

Protective Antiglare Overlays

Cat. No.

(1)

Description

2711P-RGK4 Antiglare overlay for PanelView Plus 400 grayscale terminal

2711P-RGB4 Antiglare overlay for PanelView Plus 400 color keypad/touch terminal

2711P-RGK6 Antiglare overlay for PanelView Plus 600 keypad or keypad/touch

terminal

2711P-RGT6 Antiglare overlay for PanelView Plus 600 touch terminal

2711P-RGK7 Antiglare overlay for PanelView Plus 700 keypad or keypad/touch

terminal

2711P-RGT7 Antiglare overlay for PanelView Plus 700 touch terminal

2711P-RGK10 Antiglare overlay for PanelView Plus 1000 keypad or keypad/touch

terminal

2711P-RGT10 Antiglare overlay for PanelView Plus 1000 touch terminal

2711-RGK12 Antiglare overlay for PanelView Plus 1250 keypad or keypad/touch

terminal

2711P-RGT12 Antiglare overlay for PanelView Plus 1250 touch and high-bright touch

terminal

2711P-RGK15 Antiglare overlay for PanelView Plus 1500 keypad or keypad/touch

terminal

2711P-RGT15 Antiglare overlay for PanelView Plus 1500 touch terminal

(1)

All catalog numbers ship with a quantity of three overlays.

Adapter Plates

Cat. No. Description

2711P-RAK4 Adapts a PanelView Plus 400 keypad terminal to a PanelView

Standard 550 keypad cutout

2711P-RAK6 Adapts a PanelView Plus 600 keypad terminal to a PanelView

Standard 600 keypad cutout

2711P-RAK7 Adapts a PanelView Plus 700 keypad terminal to a PanelView

Standard 900 keypad cutout

2711P-RAT7 Adapts a PanelView Plus 700 touch terminal to a PanelView Standard

900 touch cutout

2711P-RAK10 Adapts a PanelView Plus 1000 keypad terminal to a PanelView

1000/1000E keypad cutout

Publication 2711P-UM001I-EN-P - December 2008 27

Page 28

Chapter 1 Overview

Adapter Plates

Cat. No. Description

2711P-RAT10 Adapts a PanelView Plus 1000 touch terminal to a PanelView

1000/1000E touch cutout

2711P-RAK12E Adapts a PanelView Plus 1250 (or PV1000/1000E) keypad terminal to a

PanelView 1200/1400E keypad cutout

2711P-RAT12E2 Adapts a PanelView Plus 1250 (or PV1000/1000E) touch terminal to a

PanelView 1200E touch cutout

2711P-RAT12E Adapts a PanelView Plus 1250 (or PV1000/1000E) touch terminal to a

PanelView 1400E touch cutout

2711P-RAK12S Adapts a PanelView Plus 1250 (or PV1000/1000E) keypad terminal to a

PanelView Standard 1400 keypad cutout

2711P-RAT12S Adapts a PanelView Plus 1250 (or PV1000/1000E) touch terminal to a

PanelView Standard 1400 touch cutout

2711P-RAK15 Adapts a PanelView Plus 1500 keypad or keypad/touch terminal to a

PanelView 1200E/1400E keypad terminal

2711P-RAT15 Adapts a PanelView Plus 1500 touch terminal to a PanelView 1400E

touch cutout

Cables

Cat. No. Description

2711-NC13 RS-232 operating/programming cable (9-pin D-shell to 9-pin D-shell),

5 m (16.4 ft)

2711-NC14 RS-232 operating/programming cable (9-pin D-shell to 9-pin D-shell),

10 m (32.7 ft)

2711-NC17 Remote RS-232 serial cable (9-pin D-shell to 9-pin D-shell)

2711-NC21 RS-232 operating cable (9-pin D-shell to 8-pin mini DIN), 5 m (16.4 ft)

2711-NC22 RS-232 operating cable (9-pin D-shell to 8-pin mini DIN), 10 m (32.7 ft)

1761-CBL-AS03 DH-485 operating cable (6-pin Phoenix to RJ45), 3 m (10 ft)

1761-CBL-AS09 DH-485 operating cable (6-pin Phoenix to RJ45), 9 m (30 ft)

1746-C10 DH-485 network interface cable (SDL AMP to RJ45), 1.83 m (6 ft)

1746-C11 DH-485 network interface cable (SDL AMP to RJ45), .3 m (1 ft.)

1784-CP14 DH-485 network interface cable (5-pin Phoenix to RJ45)

2711P-CBL-EX04 Ethernet CAT5 crossover cable, industrial grade, 4.3 m (14 ft)

Communication Adapters

Cat. No. Description

1761-NET-AIC AIC+ advanced interface converter

1747-AIC DH-485 isolated link coupler for use with DH-485 communication

modules (2711P-RN3, 2711P-RN6)

Remote AC Power Supply (700 to 1500 only)

Cat. No. Description

2711P-RSACDIN DIN-rail power supply, AC-to-DC, 85…265V AC, 47…63 Hz

28 Publication 2711P-UM001I-EN-P - December 2008

Page 29

Overview Chapter 1

Miscellaneous

Cat. No. Description

2711P-RVT12 Solar visor for outdoor high-bright 1250 touch screen display modules

2711P-RY2032 Replacement battery for 700 to 1500 terminals

2711P-RTMC Replacement mounting clips for 700 to 1500 terminals, quantity of 8

2711P-RTFC Replacement mounting levers for 400 and 600 terminals, quantity of 8

2711P-RVAC Replacement AC power terminal block for 400 and 600 terminals

2711-TBDC Replacement DC power terminal block for 400 and 600 terminals

(1)

2711P-RTBDC3

2711P-RTBDC2

2711P-RTBAC3

(1)

Catalog numbers ship with a quantity of ten.

Three-position terminal block for DC logic modules, series A to D

(1)

Two-position terminal block for DC logic modules, series E or later

(1)

Three-position terminal block for all AC logic modules

Firmware Upgrade Kits

Cat. No. Description

2711P-RU310 PanelView Plus media kit includes firmware upgrade wizard, one firmware

license, certificate of authenticity, end user license agreement.

2711P-RUA310PanelView Plus advanced media kit includes the 2711P-RU310 media kit,

PCMCIA to compact flash adapter, and 32 MB CompactFlash card.

2711P-RUL01

Firmware upgrade license kit with one PanelView Plus firmware license.

2711P-RUL05 Firmware upgrade license kit with five PanelView Plus firmware

licenses.

2711P-RUL10

2711P-RUL25

2711P-RUL50

(1)

Also includes certificate of authenticity, end user license agreement, installation instructions.

Firmware upgrade license kit with 10 PanelView Plus firmware licenses.

Firmware upgrade license kit with 25 PanelView Plus firmware licenses.

Firmware upgrade license kit with 50 PanelView Plus firmware licenses.

(1)

(1)

(1)

(1)

(1)

Publication 2711P-UM001I-EN-P - December 2008 29

Page 30

Chapter 1 Overview

30 Publication 2711P-UM001I-EN-P - December 2008

Page 31

Installation

Chapter

2

Chapter Objectives

Hazardous Locations

This chapter provides pre-installation information and procedures on

how to install the terminals.

• Hazardous locations

• Environment and enclosure

• Outdoor installation for 1250 high-bright display module

• Required tools

• Clearances

• Panel cutout dimensions

• Mount the 400 or 600 terminal in a panel

• Mount the 700 to 1500 terminals in a panel

• Product dimensions

This equipment is suitable for these locations:

• Class I, Division 2, Groups A, B, C, D.

• Class I, Zone 2, Group IIC.

• Class II, Division 2, Groups F, G.

• Class III.

• ordinary, nonhazardous locations.

The following statement applies to use in hazardous locations.

WARNING

31Publication 2711P-UM001I-EN-P - December 2008 31

Explosion Hazard

Substitution of components may impair suitability for hazardous

locations.

Do not disconnect equipment unless power has been switched

off and area is known to be nonhazardous.

Do not connect or disconnect components unless power has

been switched off.

All wiring must comply with N.E.C. articles 501, 502, 503,

and/or C.E.C. section 18-1J2 as appropriate.

Peripheral equipment must be suitable for the location in which

it is used.

Page 32

Chapter 2 Installation

The terminals have a temperature code of T4 when operating in a 55

°C (131 °F) maximum ambient temperature. Do not install the

terminals in environments where atmospheric gases have ignition

temperatures less than 135 °C (275 °F).

USB Ports

The terminals contain universal serial bus (USB) ports that comply

with hazardous location environments. This section details the

field-wiring compliance requirements and is provided in accordance

with the National Electrical Code, article 500.

PanelView Plus 400, 600, and 700 to 1500 Terminals Control Drawing

Associated Nonincendive Field Wiring Apparatus

PanelView Plus 400, 600, and 700 to 1500 Host Product

Nonincendive Field

Wiring Apparatus

Nonincendive Field Wiring

USB Port

USB

Peripheral

Device

Table 1 - PanelView Plus 400, 600, and 700 to 1500 USB Port Circuit Parameters

Display Size

400 and 600

C

a

V

oc

I

sc

Groups

A and B

Groups

C and D

Groups

A and B

5.25V DC 1.68 A 10 µF 10 µF 15 µH 15 µH

L

a

Groups

C and D

Series A and B

400 and 600

5.25V DC 1.68 A 10 µF 10 µF 3.5 µH 15 µH

Series C or later

700 to 1500 5.25V DC 1.68 A 10 µF 10 µF 15 µH 15 µH

Selected nonincendive field wiring apparatus must have nonincendive

circuit parameters conforming with Table 2.

Table 2 - Required Circuit Parameters for the USB Peripheral Device

V

max

I

max

Ci + C

+ L

L

i

cable

cable

≥ V

≥ I

£ Ca

£ L

oc

sc

a

32 Publication 2711P-UM001I-EN-P - December 2008

Page 33

Installation Chapter 2

Application Information

Per the National Electrical Code the circuit parameters of

nonincendive field wiring apparatus for use in hazardous locations

shall be coordinated with the associated nonincendive field wiring

apparatus such that their combination remains nonincendive. The

PanelView Plus terminal and the USB peripheral device shall be

treated in this manner.

The circuit parameters of the PanelView Plus terminal USB port are

given in Table 1. The USB peripheral device and its associated cabling

shall have circuit parameters with the limits given in Table 2 for them

to remain nonincendive when used with the PanelView Plus terminal

USB port. If cable capacitance and inductance are not known the

following values from ANSI/ISA-RP 12.06.01-2003 may be used:

C

= 60 pF/ft

cable

L

= 0.20 µH/ft

cable

Nonincendive field wiring must be wired and separated in accordance

with 501.10(B)(3) of the National Electrical Code (NEC) ANSI/NFPA 70

or other local codes as applicable.

This associated nonincendive field wiring apparatus has not been

evaluated for use in combination with another associated

nonincendive field wiring apparatus.

Symbol Definitions

V

I

V

I

C

C

L

L

oc

sc

max

max

i

a

i

a

Open circuit voltge of the host USB port.

Maximum output current of the host USB port.

Maximum applied voltage rating of the USB peripheral device.

shall be greater than or equal to Voc in Table 1. (V

V

max

max

≥ V

oc ).

Maximum current to which the USB peripheral device can be subjected.

I

shall be greater than or equal to Isc in Table 1. (I

max

max

≥ Isc).

Maximum internal capacitance of the USB peripheral device.

Maximum allowed capacitance of the USB peripheral device and its

associated cable. The sum of C

the associated cable shall be less than or equal to C

of the USB peripheral device and C

i

. (Ci + C

a

cable

cable

≤ Ca).

Maximum internal inductance of the USB peripheral device.

Maximum allowed inductance of the USB peripheral device and its

associated cable. The sum of L

the associated cable shall be less than or equal to L

of the USB peripheral device and L

i

. (Li + L

a

cable

cable

≤ La).

of

of

Publication 2711P-UM001I-EN-P - December 2008 33

Page 34

Chapter 2 Installation

Environment and Enclosure

ATTENTION

This equipment is intended for use in a Pollution Degree 2

industrial environment, in overvoltage Category II applications

(as defined in IEC publication 60664-1), at altitudes up to

2000 m (6561 ft) without derating.

The terminals are intended for use with programmable logic

controllers. Terminals that are AC powered must also be

connected to the secondary of an isolating transformer.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11. Without

appropriate precautions, there may be potential difficulties

ensuring electromagnetic compatibility in other environments

due to conducted as well as radiated disturbance.

This equipment is supplied as open-type equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. The terminals meet

specified NEMA Type and IEC ratings only when mounted in a

panel or enclosure with the equivalent rating. Subsequent

sections of this publication may contain additional information

regarding specific enclosure type ratings that are required to

comply with certain product safety certifications.

Outdoor Installation for High-bright Displays

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

• NEMA Standards publication 250 and IEC publication 60529, as

applicable, for explanations of the degrees of protection provided

by different types of enclosure.

For more enclosure and certification information, refer to the

PanelView Plus/PanelView Plus CE Outdoor High-bright Display

Modules Installation Instructions, publication 2711P-IN026.

When using the high-bright display module, cat. no. 2711P-RDT12H,

outdoors, considerations in maximizing the field life of the front bezel

and display are:

• selecting the proper enclosure.

• orientation of the terminal.

, for additional installation requirements.

34 Publication 2711P-UM001I-EN-P - December 2008

Page 35

Installation Chapter 2

Both ultraviolet and infrared radiation can reduce the field life of any

electronic device. While the materials used in the terminal bezels

provide long field life, that life can be extended by proper installation.

Ultraviolet radiation from the sun causes all plastics to fade or yellow

and become brittle over time. Using an antiglare overlay, cat. no.

2711P-RGT12, will protect the front of the terminal from direct

exposure to UV radiation and greatly increase its field life.

When installing the high-bright display module in an environment

where the front of the terminal will be in direct sunlight during the

hottest part of the day and the external ambient temperature can

exceed 40 °C (104 °F), use the visor kit, cat. no. 2711P-RVT12. The

visor reduces the solar load on the front of the display and helps to

maintain internal temperatures within specification.

The high-bright display module has a built-in temperature sensor that

automatically reduces the backlight intensity if the temperature inside

the cabinet exceeds 55 °C (131 °F). This reduces the risk of damage to

the display.

The paint color, size, and power dissipated by the internal

components of an enclosure affect the temperature rise inside the

cabinet. Hoffman, a Rockwell Automation Encompass Partner, has

information to assist you with enclosure selection and heating/cooling

accessories to meet the temperature requirements of the installed

equipment. See website http://www.hoffmanonline.com

.

Stirring fans or active cooling may be required in high altitude and

high ambient temperature locations to keep the internal enclosure

temperature below 55 °C (131 °F). Use a heater in installations where

the ambient temperature is below 0 °C (32 °F).

The backlight of the high-bright display generates a significant amount

of heat when set to full intensity. To minimize the amount of heat

generated and extend the life of the backlight, decrease the display

intensity by using the screen saver with a 5…10 minute delay.

Avoid placing the terminal on the south (north in the southern

hemisphere) or west side of the cabinet, if possible. This will reduce

the heat rise due to solar loading during the hottest part of the day.

Mount the terminal vertically to minimize solar loading on the display.

Do not mount the terminal in a sloped enclosure if it will be exposed

to direct sunlight.

Publication 2711P-UM001I-EN-P - December 2008 35

Page 36

Chapter 2 Installation

Required Tools

Clearances

These tools are required for panel installation:

• Panel cutout tools

• Small, slotted screwdriver

• Torque wrench (lb•in) for tightening the mounting clips on the

PanelView Plus 700 to 1500 and PanelView Plus CE terminals

Allow adequate clearance around the terminal, inside the enclosure,

for adequate ventilation. Consider heat produced by other devices in

the enclosure. The ambient temperature around the terminals must be

between 0…55 °C (32…131 ºF).

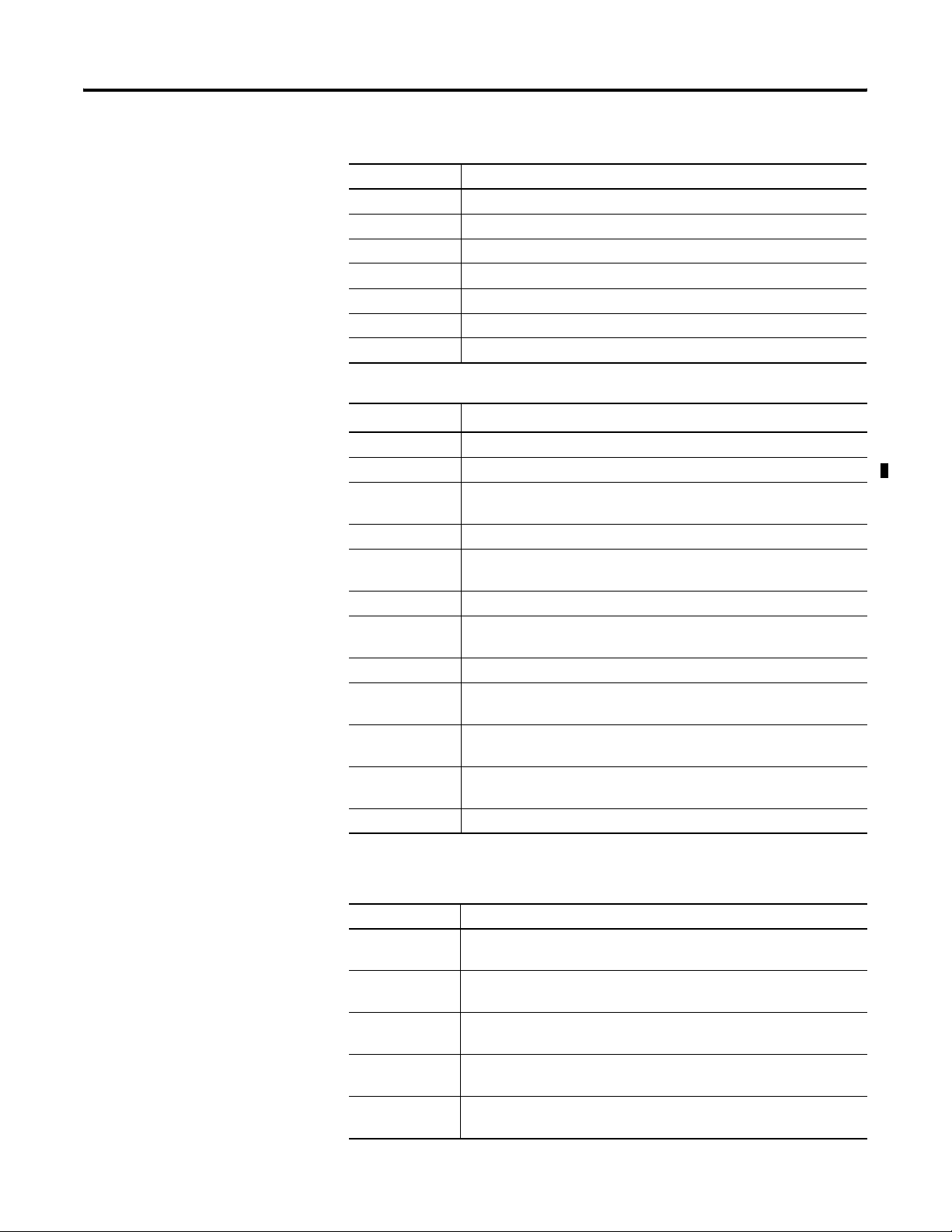

Clearance Area 400 and 600 Terminals 700 to 1500 Terminals

Top 51 mm (2 in.) 51 mm (2 in.)

Bottom 102 mm (4 in.) 51 mm (2 in.)

(1)

Side

Back None 25 mm (1 in.)

(1)

Minimum side clearance for insertion of memory card and cable wiring is 102 mm (4 in.).

25 mm (1 in.) 25 mm (1 in.)

Cutout Dimensions

Use the full size template shipped with your terminal to mark the

cutout dimensions.

Terminal Type Height mm (in.) Width mm (in.)

PanelView Plus 400 and 600 Terminals

400 Keypad or Keypad and Touch 123 (4.86) 156 (6.15)

600 Keypad or Keypad and Touch 142 (5.61) 241 (9.50)

600 Touch 123 (4.86) 156 (6.15)

PanelView Plus and PanelView Plus CE 700 to 1500 Terminals

700 Keypad or Keypad and Touch 167 (6.57) 264 (10.39)

700 Touch 154 (6.08) 220 (8.67)

1000 Keypad or Keypad and Touch 224 (8.8) 375 (14.75)

1000 Touch 224 (8.8) 305 (12.00)

1250 Keypad or Keypad and Touch 257 (10.11) 390 (15.35)

1250 Touch and 1250 High-bright Touch 257 (10.11) 338 (13.29)

1500 Keypad or Keypad and Touch 305 (12.00) 419 (16.50)

1500 Touch 305 (12.00) 391 (15.40)

36 Publication 2711P-UM001I-EN-P - December 2008

Page 37

Installation Chapter 2

Mount the 400 or 600 Terminal in a Panel

Mounting levers secure the terminal to the panel. The number of

levers you use (4 or 6) varies by terminal type.

ATTENTION

Follow these steps to mount the 400 or 600 terminals in a panel.

1. Cut an opening in the panel by using the panel cutout shipped

with the terminal.

2. If a communication module is ordered separately, attach the

module to the base unit before panel installation.

Refer to the instructions shipped with module.

Disconnect all electrical power from the panel before making

the panel cutout.

Make sure the area around the panel cutout is clear.

Take precautions so metal cuttings do not enter any

components already installed in the panel.

Failure to follow these warnings may result in personal injury or

damage to panel components.

3. Make sure the terminal sealing gasket is properly positioned on

the terminal.

This gasket forms a compression-type seal. Do not use sealing

compounds.

Sealing Gasket

4. Install legend strips before installing the terminal if you are

using keypad legend strips on a 600 keypad terminal.

Be careful not to pinch legend strip during installation.

5. Place the terminal in the panel cutout.

If installing the terminal in an existing 550 panel cutout, align

the terminal with the center of the cutout for best gasket sealing.

Publication 2711P-UM001I-EN-P - December 2008 37

Page 38

Chapter 2 Installation

6. Insert all mounting levers into the mounting slots on the

terminal.

Slide each lever until the flat side of the lever touches the

surface of the panel.

Mounting Slots

7. When all levers are in place, slide each lever an additional notch

8. Rotate each lever in the direction indicated until it is in the final

Flat Side of Lever

Mounting Levers

or two until you hear a click.

latch position.

Follow the latching sequence for the optimum terminal fit.

14

4 Levers

Notch

Rotate lever until notch in

lever aligns with proper

alignment mark on terminal.

61

Alignment Marks

3

513

6 Levers

246

2

Use this table as a guide to provide an adequate gasket seal

between the terminal and the panel.

Lever Position Panel Thickness Range Typical Gauge

1 1.5…2.01 mm (0.060…0.079 in.) 16

1

2

3

4

5

6

2 2.03…2.64 mm (0.08…0.104 in.) 14

3 2.67…3.15 mm (0.105…0.124 in.) 12

Terminal

Markings

4 3.17…3.66 mm (0.125…0.144 in.) 10

5 3.68…4.16 mm (0.145…0.164 in.) 8/9

6 4.19…4.75 mm (0.165…0.187 in.) 7

ATTENTION

Follow instructions to provide a proper seal and to

prevent potential damage to the product. Rockwell

Automation assumes no responsibility for water or

chemical damage to the terminal or other equipment

within the enclosure because of improper installation.

38 Publication 2711P-UM001I-EN-P - December 2008

Page 39

Installation Chapter 2

Mount the 700 to 1500 Terminal in a Panel

Mounting clips secure the terminal to the panel. The number of clips

you use (4, 6, or 8) varies by terminal type.

ATTENTION

Follow these steps to mount a 700 to 1500 terminal in a panel.

1. Cut an opening in the panel by using the panel cutout shipped

with the terminal.

2. Make sure the terminal sealing gasket is properly positioned on

the terminal.

This gasket forms a compression-type seal. Do not use sealing

compounds.

Disconnect all electrical power from the panel before making

the panel cutout.

Make sure the area around the panel cutout is clear.

Take precautions so metal cuttings do not enter any

components already installed in the panel.

Failure to follow these warnings may result in personal injury or

damage to panel components.

Sealing Gasket

3. Install the legend strips before installing the terminal if you are

using keypad legend strips on keypad terminals.

Be careful not to pinch the legend strip during installation.

4. Place the terminal in the panel cutout.

Publication 2711P-UM001I-EN-P - December 2008 39

Page 40

Chapter 2 Installation

5. Slide the ends of the mounting clips into the slots on the

terminal.

Mounting Clip

Mounting Clip Slot

6. Tighten the mounting clip screws by hand until the gasket seal

contacts the mounting surface uniformly.

7. Tighten the mounting clips screws to a torque of 0.90…1.1 Nm

(8…10 lb•in) by using the specified sequence, making sure not

to overtighten.

14

Torque Sequence

for 4 Clips

3

ATTENTION

2

Tighten the mounting clips to the specified torque to

513

Torque Sequence

for 6 Clips

246

1

3

Torque Sequence

for 8 Clips

7

5

6

8

4

2

provide a proper seal and to prevent damage to the

product. Allen-Bradley assumes no responsibility for

water or chemical damage to the product or other

equipment within the enclosure because of improper

installation.

40 Publication 2711P-UM001I-EN-P - December 2008

Page 41

Installation Chapter 2

Product Dimensions

Product dimensions for each terminal are in mm (in.).

PanelView Plus 400 Dimensions

400 Keypad or Keypad/Touch Terminal

152

(6.0)

185 (7.28)

90

(3.54)

71 (2.81)

154 (6.08)

60

(2.35)

Publication 2711P-UM001I-EN-P - December 2008 41

Page 42

Chapter 2 Installation

PanelView Plus 600 Dimensions

600 Keypad or Keypad/Touch Terminal

268 (10.47)

185

167

600 Touch Terminal

152

98

71

154 (6.08)

98

71

154 (6.08)

68

68

The depth dimensions are shown for:

• base-configured unit (display module and logic module).

• base-configured unit with communication module.

42 Publication 2711P-UM001I-EN-P - December 2008

Page 43

193

(7.58)

Installation Chapter 2

PanelView Plus and PanelView Plus CE 700 Dimensions

700 Keypad or Keypad/Touch Terminal

a 55 (2.18) Display to Logic Module

a

b

290

(11.40)

700 Touch Screen Terminal

179

(7.04)

246

(9.68)

a 55 (2.18) Display to Logic Module

b 83 (3.27) Display to Communication Module

a

b

The depth dimensions are shown for:

• base-configured unit (display module and logic module).

• base-configured unit with communication module.

Publication 2711P-UM001I-EN-P - December 2008 43

Page 44

Chapter 2 Installation

248

(9.77)

399

(15.72)

PanelView Plus and PanelView Plus CE 1000 Dimensions

1000 Keypad or Keypad/Touch Terminal

a 55 (2.18) Display to Logic Module

b 83 (3.27) Display to Communication Module

a

b

1000 Touch Screen Terminal

248

(9.7)

a 55 (2.18) Display to Logic Module

b 83 (3.27) Display to Communication Module

a

b

329

The depth dimensions are shown for:

• base-configured unit (display module and logic module).

• base-configured unit with communication module.

44 Publication 2711P-UM001I-EN-P - December 2008

Page 45

PanelView Plus and PanelView Plus CE 1250 Dimensions

1250 Keypad or Keypad/Touch Terminal

Installation Chapter 2

282

(11.12)

282

(11.12)

416

(16.36)

a 55 (2.18) Display to Logic Module

b 83 (3.27) Display to Communication Module

a

b

1250 Touch Screen Terminal

a 55 (2.18) Display to Logic Module

b 83 (3.27) Display to Communication Module

a

b

a 74 (2.90) Display to Logic Module

b 101 (3.99) Display to Communication Module

1250

363

(14.30)

a

b

1250 High-bright

The depth dimensions are shown for:

• base-configured unit (display module and logic module).

• base-configured unit with communication module.

Publication 2711P-UM001I-EN-P - December 2008 45

Page 46

Chapter 2 Installation

PanelView Plus and PanelView Plus CE 1500 Dimensions

1500 Keypad or Keypad/Touch Terminal

330

(12.97)

330

(12.97)

469

(18.46)

a 65 (2.55) Display to Logic Module

b 93 (3.65) Display to Communication Module

a

b

1500 Touch Screen Terminal

a 65 (2.55) Display to Logic Module

b 93 (3.65) Display to Communication Module

a

b

416

(16.37)

46 Publication 2711P-UM001I-EN-P - December 2008

Page 47

Power Connections

Chapter

3

Chapter Objectives

Wiring and Safety Guidelines

This chapter covers wiring and safety guidelines, and provides

procedures to:

• remove and install the power terminal block.

• connect DC power.

• connect AC power.

• reset the terminal.

Use publication NFPA 70E Electrical Safety Requirements for

Employee Workplaces, IEC 60364 Electrical Installations in Buildings,

or other applicable wiring safety requirements for the country of

installation when wiring the devices. In addition to the NFPA

guidelines:

• connect the device and other similar electronic equipment to its

own branch circuit.

• protect the input power by a fuse or circuit breaker rated at no

more than 15 A.

• route incoming power to the device by a separate path from the

communication lines.

• cross power and communication lines at right angles if they

must cross.

• Communication lines can be installed in the same conduit as

low-level DC I/O lines (less than 10V).

• shield and ground cables appropriately to avoid electromagnetic

interference (EMI).

• Grounding minimizes noise from EMI and is a safety measure in

electrical installations.

For more information on grounding recommendations, refer to the

National Electrical Code published by the National Fire Protection

Association.

For more information, refer to Wiring and Grounding Guidelines for

PanelView Plus Devices, publication 2711P-TD001. You can locate this

publication in the literature library at this website

http://literature.rockwellautomation.com

47Publication 2711P-UM001I-EN-P - December 2008 47

.

Page 48

Chapter 3 Power Connections

Remove and Install the Power Terminal Block

The terminals are shipped with the power terminal block installed.

You can remove the terminal block for ease of installation, wiring, and

maintenance.

WARNING

ATTENTION

Explosion Hazard

Substitution of components may impair suitability for hazardous

locations.

Do not disconnect equipment unless power has been switched

off and area is known to be nonhazardous.

Do not connect or disconnect components unless power has

been switched off.

All wiring must comply with N.E.C. articles 501, 502, 503,

and/or C.E.C. section 18-1J2 as appropriate.

Peripheral equipment must be suitable for the location in which

it is used.

Disconnect all power before installing or replacing components.

Failure to disconnect power may result in electrical shock or

damage to the terminal.

400 and 600 Terminals

ATTENTION

Follows these steps to remove the terminal block in the PanelView

400 and 600 terminals.

1. Insert the tip of small, flat-blade, screwdriver into the terminal

block access slot.

The AC and DC terminal blocks are keyed and marked

differently so be sure to follow markings. Do not force terminal

blocks into connectors to prevent potential damage to terminal.

48 Publication 2711P-UM001I-EN-P - December 2008

Page 49

Power Connections Chapter 3

2. Gently pry the terminal block away from terminal to release the

locking mechanism.

Follow these steps to replace the terminal block.

1. Press terminal block base in first with block leaning outward.

2. Gently push the top of the terminal block back to the vertical

position to snap in locking tab.

700 to 1500 Terminals

The terminal block used by the 700 to 1500 terminals depends on the

series of the logic module and the power input type.

• Series A to D, DC logic modules use a 3-position terminal block.

• Series E or later, DC logic modules use a 2-position terminal

block.

• All logic modules with an AC power input use a 3-position

terminal block.

Publication 2711P-UM001I-EN-P - December 2008 49

Page 50

Chapter 3 Power Connections

Follow these steps to remove the terminal block.

1. Loosen the two screws that secure the terminal block.

2. Gently pull the terminal block away from the connector.

2-position DC Terminal

Block (Series E or later)

3-position AC or DC

Terminal Block

Follow these steps to install the terminal block.

1. Reattach the terminal block to the connector until seated.

2. Tighten the two screws that secure the terminal block to the

connector.

50 Publication 2711P-UM001I-EN-P - December 2008

Page 51

Power Connections Chapter 3

DC Power Connections

Terminal Wire Type

400 and 600

700 to 1500 logic module

series A to D

700 to 1500 logic module

series E and later

(1)

Two-wire max. per terminal.

Stranded

or solid

PanelView Plus terminals with an integrated, 24V DC power supply

have these power ratings

Power Type Terminal Input Range

400 and 600 24V DC nom (18…30 V DC)

DC

700 to 1500 24V DC nom (18…32 V DC)

25 W max (1.0 A at 24V DC)

70 W max (2.9 A at 24V DC)

The power supply is internally protected against reverse polarity of

the DC+ and DC- connections. Connecting DC+ or DC- to the earth

terminal may damage the device.

The input power terminal block is removeable and supports these

wire sizes.

Wire Specifications for DC Power Terminal Block

Dual-wire

(1)

Gauge

Cu 90 °C (194 °F) 22…16 AWG 22…14 AWG

Single-wire

Gauge

Terminal Screw

To rq ue

0.45…0.56 Nm

(4…5 lb•in)

0.23…0.34 Nm

(2…3 lb•in)

0.56 Nm (5 lb•in)

Publication 2711P-UM001I-EN-P - December 2008 51

Page 52

Chapter 3 Power Connections

External Power Supply For Non-insolated DC Terminals

TIP

TIP

To identify non-isolated DC logic modules refer to the Logic

Modules (700 to 1500 only) table on page 24.

All 400 and 600 DC terminals contain non-isolated DC power

supplies.

Use a single, 24V DC power supply to power each PanelView Plus

device, such as cat. no. 2711P-RSACDIN. Using a separate, isolated

and ungrounded source to power each terminal prevents ground loop

currents from damaging the terminals.

The output on the power supply must be isolated from the input and

not connected to earth/ground.

The non-isolated power supply does not provide galvanic isolation. A

Class 2 or Safety Extra-Low Voltage (SELV) isolated power supply with

a 24V DC nominal output voltage is required to power the terminal.

ATTENTION

Use a Class 2 or SELV supply as required by local wiring

codes for your installation. The Class 2 and SELV power

sources provide protection so that under normal and

single-fault conditions, the voltage between the conductors,

and between the conductors and functional earth or

protective earth does not exceed a safe value.

Multiple AC Power Supplies to Power Multiple DC Terminals

L1L2

AC/DC Power Supply

(2711P-RSACDIN)

dc+

PanelView Plus

dc- dc+ dc-

Circuitry Circuitry

PanelView Plus

AC/DC Power Supply

(2711P-RSACDIN)

L1L2

52 Publication 2711P-UM001I-EN-P - December 2008

Page 53

Power Connections Chapter 3

External Power for 700 to 1500 Isolated DC Terminals (2711P-RxxDx Logic Modules)

Use an SELV or PELV 24V DC power supply, such as cat. no.

2711P-RSACDIN, to power the isolated DC PanelView Plus terminal.

The isolated DC terminals may be powered by the same power source

as other equipment, by a DC power bus.

ATTENTION