Page 1

Reference Manual

Rockwell Automation Library of Process Objects:

Operator Prompt (P_Prompt)

Version 3.5

IMPORTANT

This manual applies to the Rockwell Automation Library of Process Objects version 3.5 or earlier.

For Rockwell Automation Library of Process Objects version 5.0, see

• PROCES-RM200

For Rockwell Automation Library of Process Objects version 4.0 or later, use the following manuals:

• PROCES-RM013 contains logic instructions

• PROCES-RM014 contains display elements

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, RSLogix, Log ix5000, FactoryTalk, PlantPAx, and ControlLogix are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Operator Prompt (P_Prompt)

Software Compatibility and Content Revision. . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Prompt Demonstrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configure a Standalone Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configure the Prompt with the Sequencer Object. . . . . . . . . . . . . . . 23

Display Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Input Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Selection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Response Prompts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Sequencer Branching Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Required Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Controller File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Visualization Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Controller Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Prompt InOut Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Prompt Input Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Prompt Output Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Display Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Status/Quality/Threshold Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using Display Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Faceplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

P_Prompt Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

P_Prompt Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

P_Prompt Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 3

Page 4

Table of Contents

Notes:

4 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 5

Preface

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

Software Compatibility and Content Revision

Table 1 - Summary of Changes

Top ic Pag e

Updated version in rung import file from 3_1 to 3_5 33

Split visualization files table by type and reordered to align with installation requirements 33

For the latest compatible software information and to download the Rockwell

Automation® Library of Process Objects, see the Product Compatibility and

Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/pcdc.page

For general library considerations, see Rockwell Automation Library of Process

Objects, publication PROCES-RM002

.

.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 5

Page 6

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PlantPAx® Distributed Control System Selection Guide,

publication PROCES-SG001

PlantPAx Distributed Control System Reference Manual,

publication PROCES-RM001

FactoryTalk® View Machine Edition User Manual,

publication VIEWME-UM004

FactoryTalk View Site Edition User Manual,

publication VIEWSE-UM006

Logix5000™ Controllers Add-On Instructions

Programming Manual, publication 1756-PM010

For general library considerations, see Rockwell

Automation Librar y of Process Objects,

publication PROCES-RM002

Rockwell Automation Sequencer Object Reference

Manual, publication PROCES-RM006

Provides information to assist with equipment

procurement for your PlantPAx system.

Provides characterized recommendations for

implementing your PlantPAx system.

Provides details on how to use this software package for

creating an automation application.

Provides details on how to use this software package for

developing and running human-machine interface (HMI)

applications.

Provides information for designing, configuring, and

programming Add-On Instructions.

Details how to monitor an input condition to raise an

alarm. Information includes acknowledging, resetting,

inhibiting, and disabling an alarm. Generally the P_Alarm

faceplate is accessible from the Alarms tab.

Provides details on how to configure a sequence by using

the Sequencer Object.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

6 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 7

Operator Prompt (P_Prompt)

Add-On Instruction

Face pla te

Global Object

Operator Prompt (P_Prompt)

The P_Prompt (Operator Prompt) Add-On Instruction is a universal

mechanism for operator interaction that can be used within a control scheme.

The instruction presents an operator with configurable message or data fields and

accepts operator response data and confirmation.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 7

Page 8

Operator Prompt (P_Prompt)

Guidelines

The configuration data for a set of prompts are stored in an array of user-defined

types (UDTs). Each configured prompt instance is a member of the Prompts

array. By referencing different members of the prompt configuration array, the

same P_Prompt instruction can be used to access multiple user-prompt

combinations, one at a time.

A single prompt can include the following:

• An 82-character message

• Up to four numeric value displays

• Up to four numeric value entries

• Choose one choice among 2…4 options

• Up to four text responses

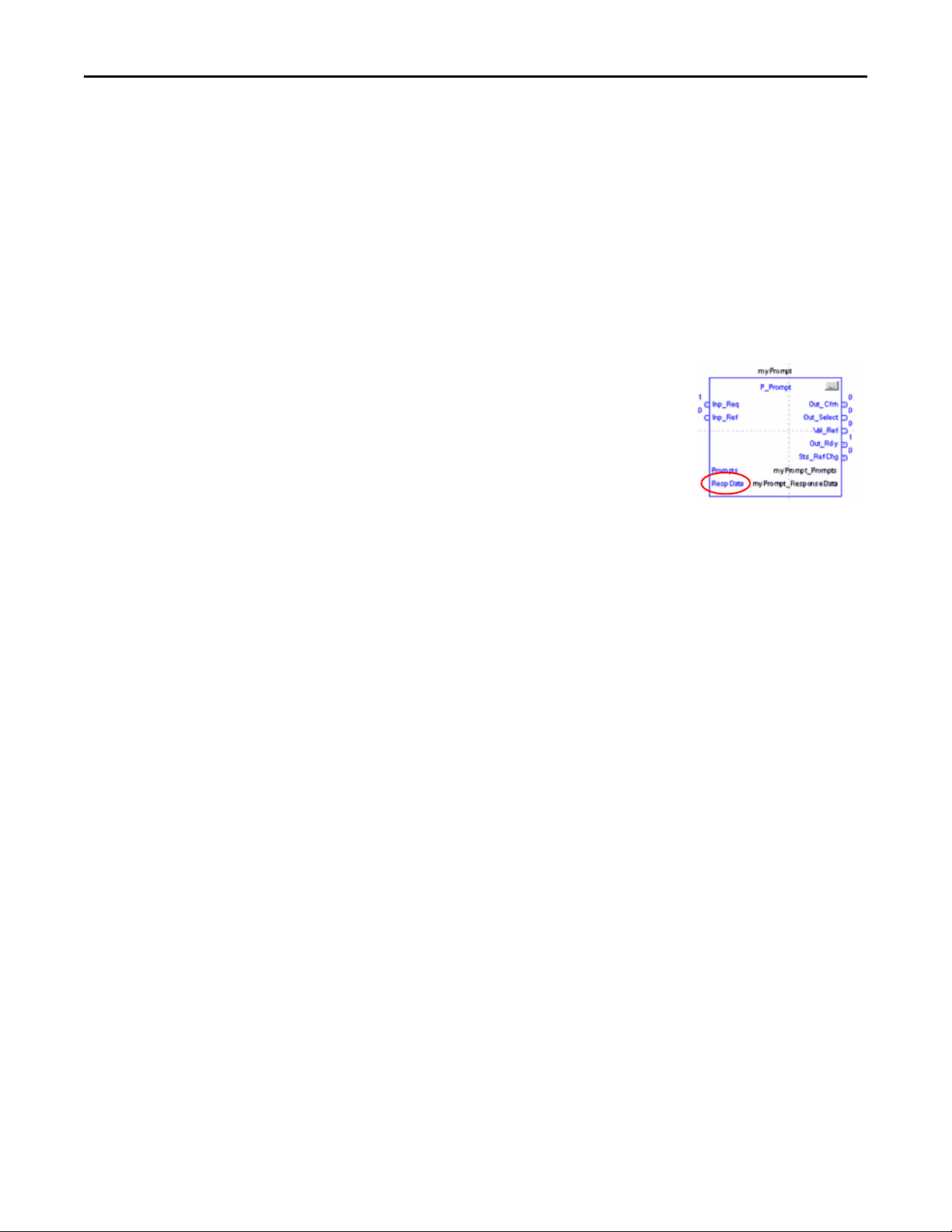

The RespData tag at the bottom of the P_Prompt

function block lets you define where to store

operator responses. This tag stores any operator

response as a string in the application.

8 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 9

Operator Prompt (P_Prompt)

Functional Description

Use a prompt to request input from an operator. The input can be any of

the following:

• Acknowledging the prompt

• Viewing and confirming data

• Making a selection

• Entering numeric data

• Entering text data

Do not use a prompt in place of an alarm or an alert:

• An alarm, per ANSI/ISA-18.2-2009, is used to notify an operator of an

abnormal situation that requires a response

• An alert is used to notify an operator of an abnormal situation that does

not require a response

• A prompt requires a response, but does not advise of an abnormal situation

Normal Operat ion Abnormal Situation

Operator Response Not Required Normal values and status Alert

Operator Response Required Prompt (P_Prompt) Alarm (P_Alarm)

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 9

Page 10

Operator Prompt (P_Prompt)

Prompt Demonstrations

There are two separate demonstrations that show how you can use the prompt

functionality:

• Standalone prompt

• Sequencer prompt faceplates (see page 13

Standalone Prompt

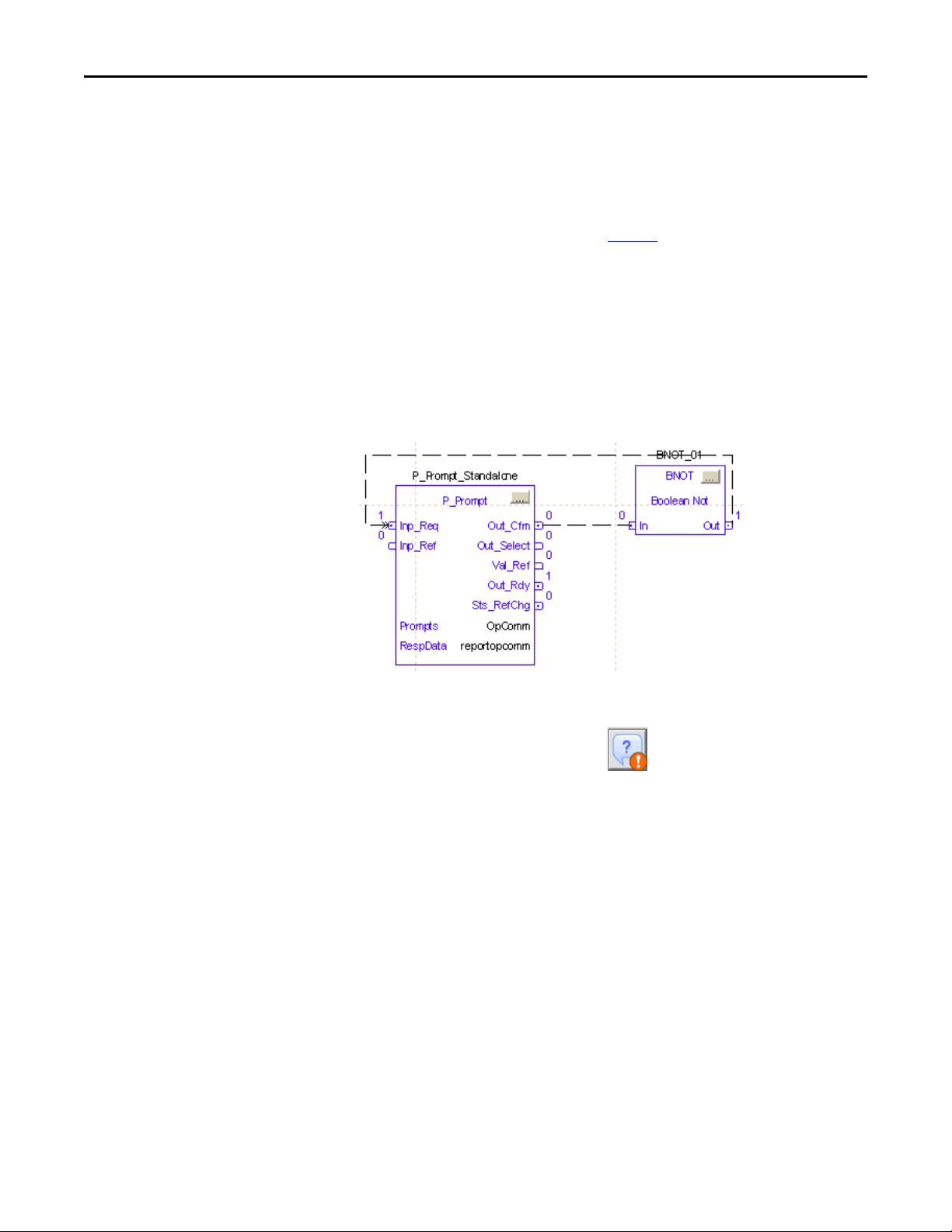

In its simplest form, the P_Prompt instruction provides operator interaction and

can be invoked from a number of users. This example shows how to program and

configure the P_Prompt instruction to solicit an operator comment.

The example below shows the logic for the Prompt instruction to continually

reset to provide for more operator entries.

)

The Inp_Req is set to '1' to buffer the prompt configuration and trigger the

prompt. This causes the prompt button on the FactoryTalk View display

to be active.

10 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 11

Operator Prompt (P_Prompt)

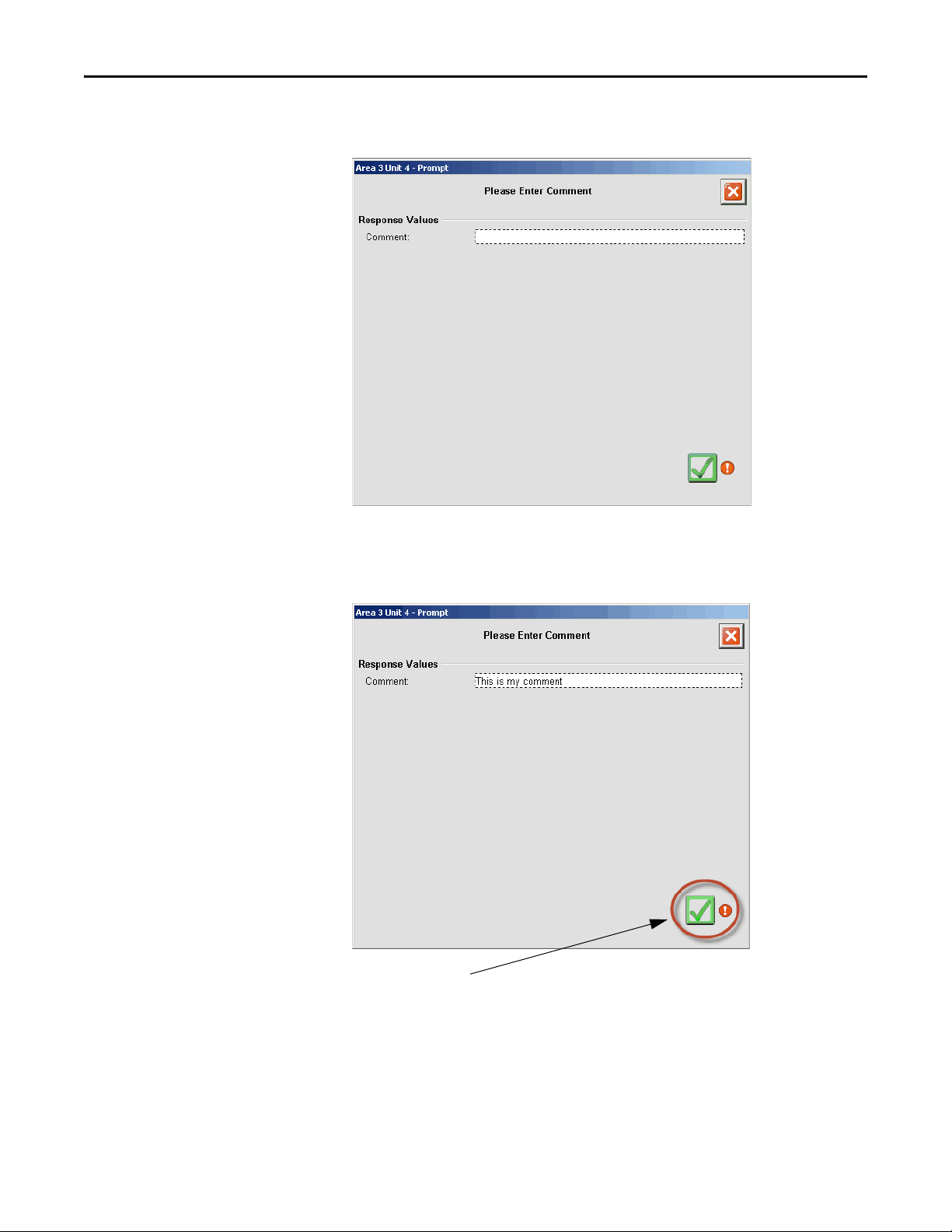

Click the prompt button to access the prompt faceplate shown below to let the

operator enter a comment in the text box.

The Boolean output (Out_Cfm) remains low (0) until the operator clicks the

Acknowledge button (green check mark circled below) on the prompt faceplate

in the FactoryTalk View client.

Clicking this button on the faceplate causes the boolean output (Out_Cfm) to

transition to a one (1).

The function block logic then inverts the Boolean value and feeds it back

to the Inp_Req input. When this input goes to zero (0), it causes the output

(Out_Cfm) to be reset to zero (0), which reasserts the input again and retriggers

the instruction.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 11

Page 12

Operator Prompt (P_Prompt)

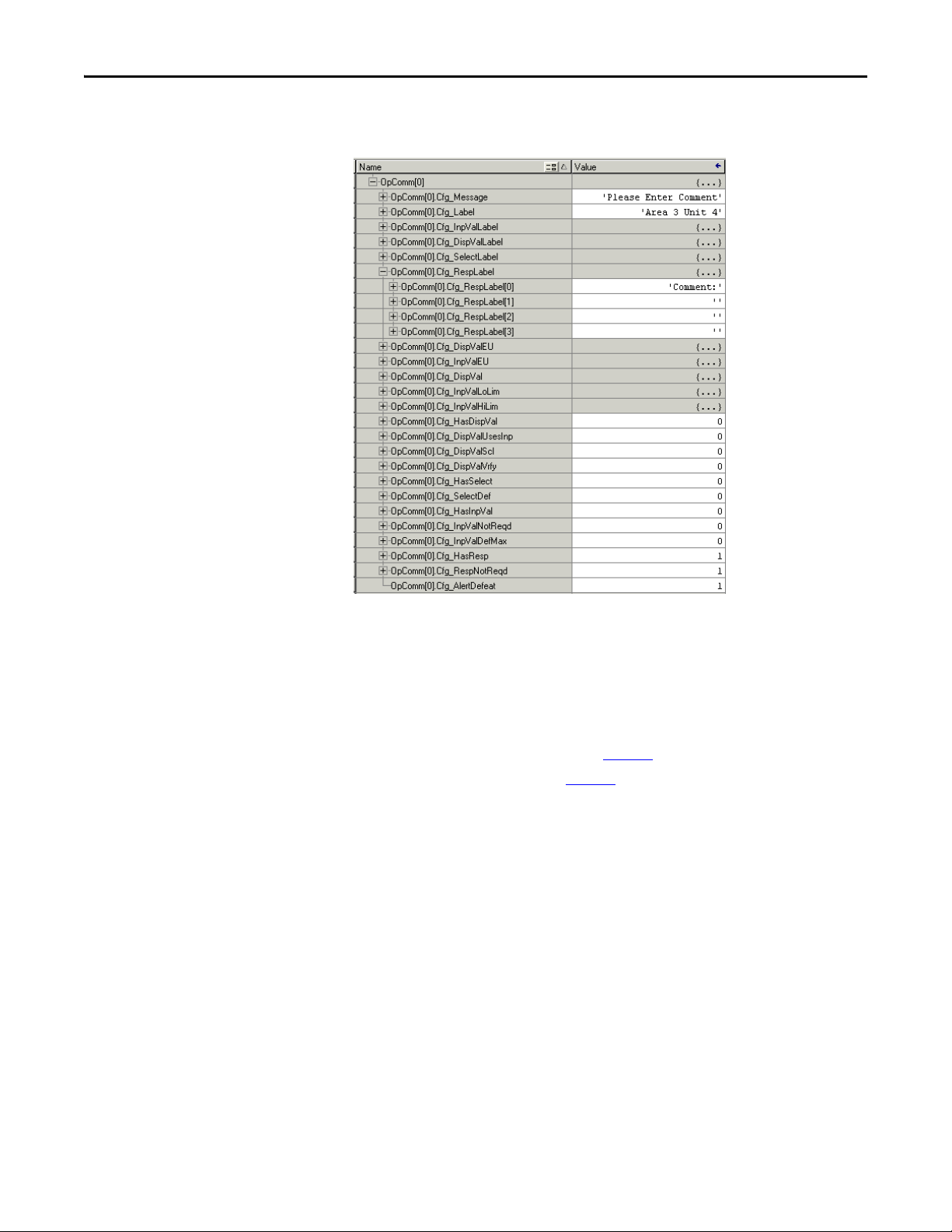

The standalone prompt example is achieved by setting the following values in the

configuration array element zero [0].

The desired configuration can be moved into the configuration array from other

Logix entities or populated from a P_Prompt configuration display. The

P_Prompt configuration display can be called from the global object file

(RA-UI) Prompt Objects.ggfx.

For additional information, see the following:

• Standalone programming basics, page 20

• Tag configuration options, page 27

12 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 13

Operator Prompt (P_Prompt)

IMPORTANT

Operator Attention Required Breadcrumb

Access to Detail Faceplate

Prompt

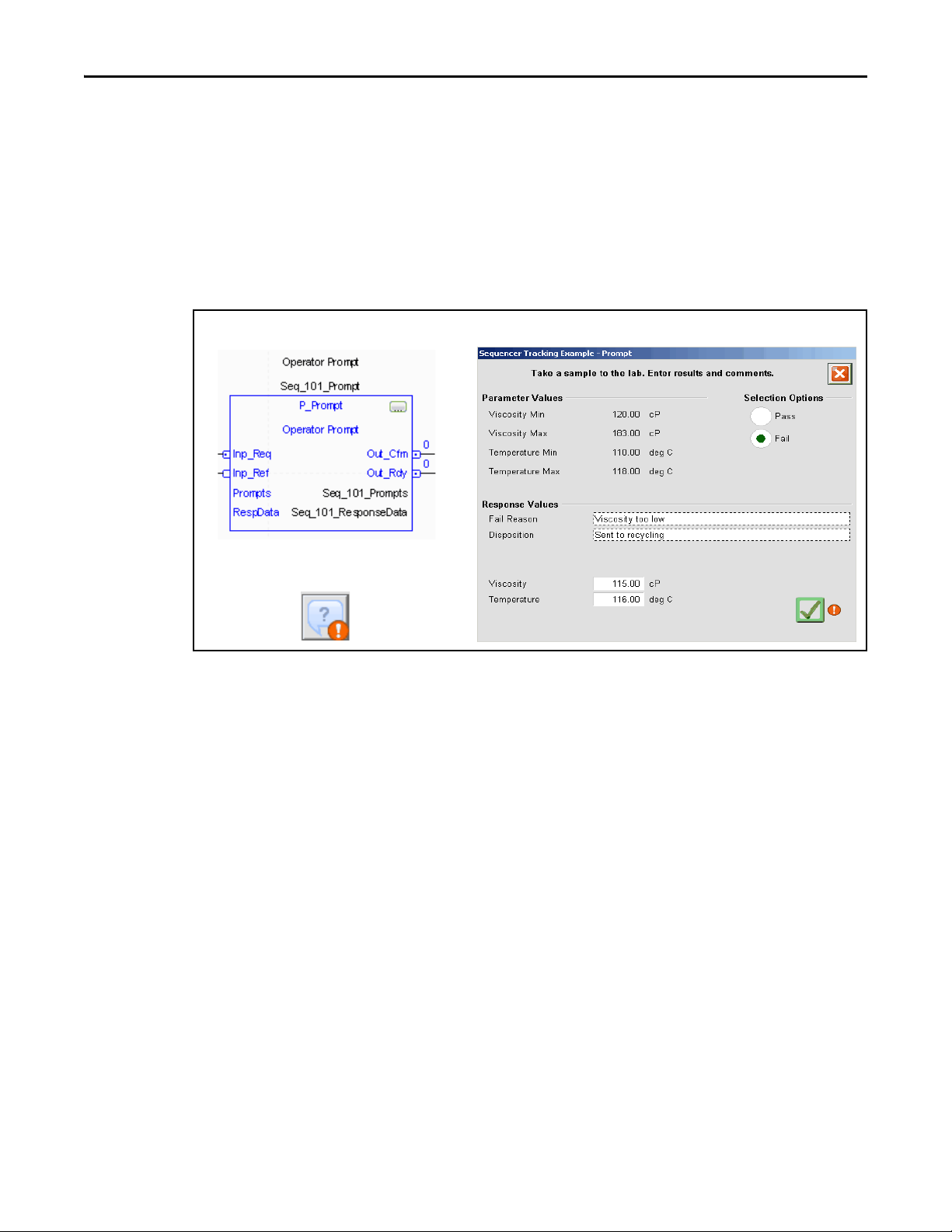

Sequencer Prompt Faceplates

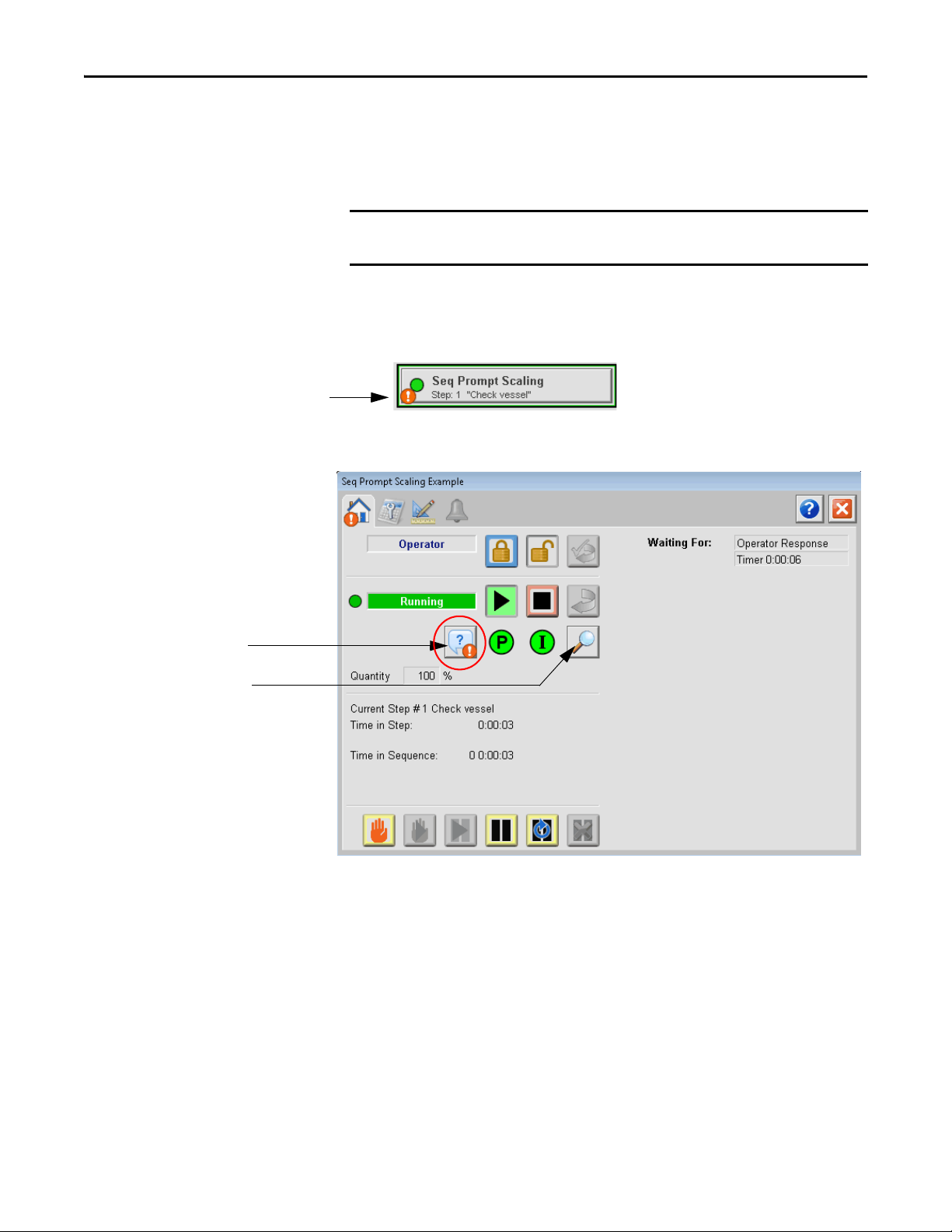

This section illustrates basic prompt functionality by using the Sequencer Object

(P_Seq) instruction and faceplates.

This demonstration uses the Sequencer’s Run Time Detail faceplate as an

example only. You can use the prompt with other tasks and processing tools.

1. After placing the Sequencer’s display element into your project, click the

object.

Our example is Seq Prompt Scaling.

The Operator tab for the P_Seq instruction appears with buttons,

including the Prompt (circled below).

These same buttons also are available on the Run Time Detail faceplate

that visually arranges the progress of the steps and prompts.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 13

Page 14

Operator Prompt (P_Prompt)

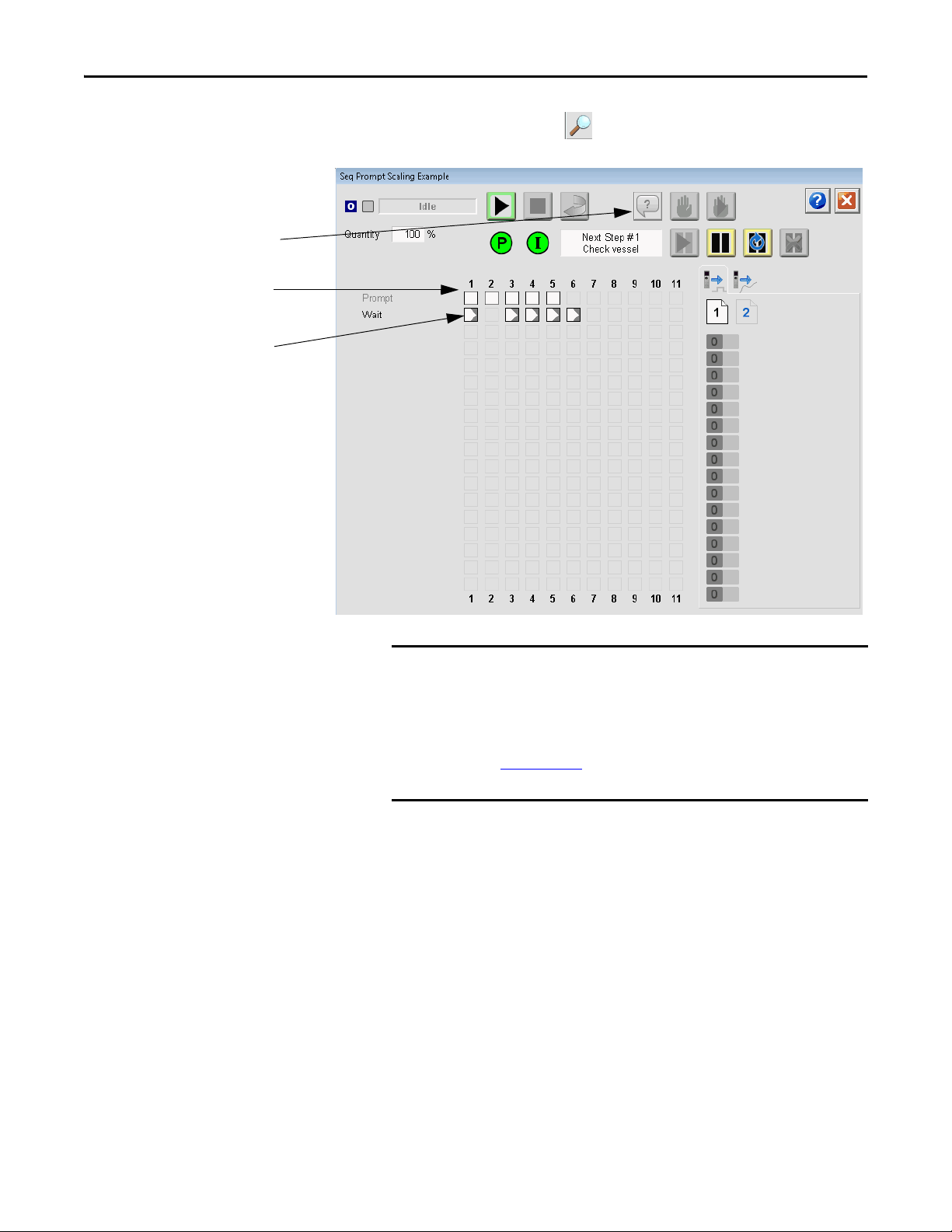

Prompts

Sequence Steps

Prompt Button

IMPORTANT

2. Click the magnifying glass button to access the Run Time Detail

faceplate.

The following faceplates show different types of prompts that can be

configured for a sequence. Our example shows the prompts in close

succession merely as a teaching tool and likely is not the case for

your sequence.

See the Sequencer Object Reference Manual, publication

PROCES-RM006

, for how to configure a sequence by using

the Sequencer Object.

14 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 15

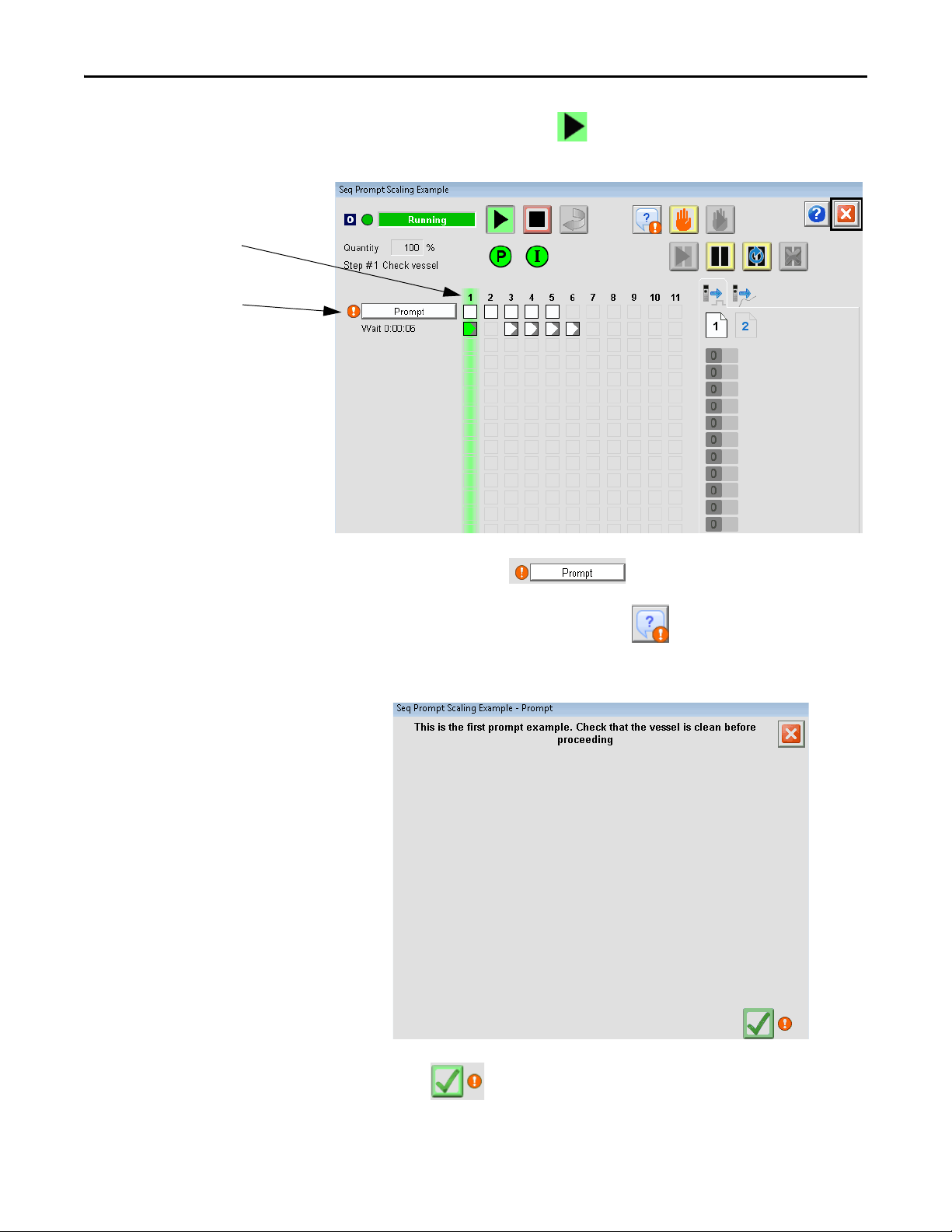

3. Click the Start command button.

Column turns green to show

the current step in progress.

Prompt icon appears to notify

the operator that some type of

interaction is necessary.

Prompt Example 1

Operator Prompt (P_Prompt)

4. Click the Prompt button when it appears during a step.

You also can click the Prompt button when it is active on the

Sequencer’s Run Time Detail faceplate or the Operator tab.

A Prompt window appears to tell the operator what action is necessary.

5. Click to acknowledge the prompt.

The sequence continues until the next configured prompt occurs.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 15

Page 16

Operator Prompt (P_Prompt)

The prompt in Example 2 provides some data in addition to the string

used in Example 1.

Prompt Example 2

6. Click to acknowledge the prompt after the ingredients are added.

16 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 17

Operator Prompt (P_Prompt)

Minimum entry box turns yellow if the

value is below the pre-set minimum.

The prompt in Example 3 lets the operator enter data used by the

application.

Prompt Example 3

7. Click the text box to enter a value.

A keypad appears to let you enter a value.

8. Type a value and click OK.

The value carries over to the prompt display.

9. Click to acknowledge the prompt.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 17

Page 18

Operator Prompt (P_Prompt)

The prompt in Example 4 shows how you can use different strings for

operator interaction.

Prompt Example 4

10. Click to acknowledge you are confirming the prompt.

18 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 19

Operator Prompt (P_Prompt)

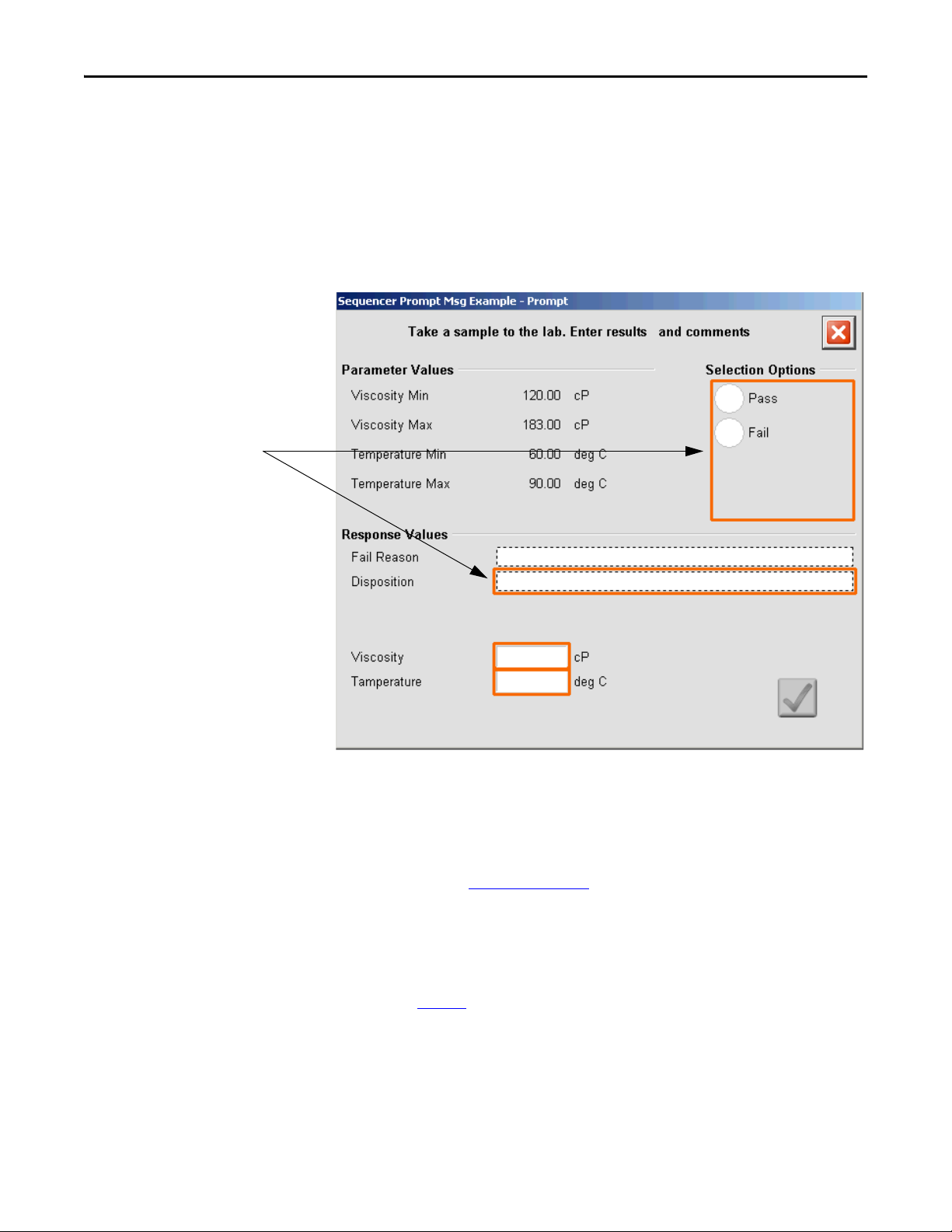

Orange box indicates

required entry fields.

The prompt in Example 5 provides the operator with several options:

• Basic text display

• Display of application data (with labels and units of measure)

• Set of options, from which they must choose one

• Text boxes for data (with labels)

• Entry boxes for numeric data (with labels and units of measure)

Prompt Example 5

The Selection Options (in the upper right corner) in this example

are configured to work with the branching capability of the

P_Seq instruction.

For more information on the P_Seq instruction and branching capability,

see the Rockwell Automation Sequencer Object Reference Manual,

publication PROCES-RM006

.

11. Choose one of the following Selection Options:

• Pass: In this example, clicking Pass ends the sequence.

• Fail: Sequence branches to the third step after clicking Fail.

See page 32

for how to use the prompt with branching in the

Sequencer Object.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 19

Page 20

Operator Prompt (P_Prompt)

Prompt Tag Name

Same Prompt Tag Name Plus ‘s’

IMPORTANT

Define Array Size

Programming Example

This section includes two basic examples for configuring the P_Prompt

instruction: standalone or with the Sequencer Object faceplates.

Configure a Standalone Prompt

The P_Prompt instruction provides the flexibility for configuring a prompt via

faceplates or by moving data from some other Logix activity, such as a program

or phase. This section describes standalone procedures.

1. Create and name the P_Prompt instruction; our example is ‘MyPrompt’.

The tag name can be any name you want. However, the Prompts tag must

be the prompt name plus an ‘s’.

It’s good practice to also name the RespData tag and the

P_PromptTitle tag the same as the prompt name, but it’s not a

requirement. The P_PromptTitle tag in the Global Objects Parameters

Values table (see page page 38

) tells the operator what type of

interaction is necessary.

2. Right-click MyPrompts and choose Edit Properties to define the prompt

array size.

3. On the Tag Properties dialog box, type a number into the bracket of the

array tag (P_PromptCfg) to specify a number of prompt instances

supported by the instruction.

20 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 21

Operator Prompt (P_Prompt)

Create

Display

Respond

Choices for

Configuring an

Operator Prompt

Button for

Operator

Response

The three rungs of the Ladder Diagram show the minimal amount of

effort to set up tags to create, display, and respond to a standalone prompt.

The program logic is shown in standard Ladder Diagram, but you can use

Function Block Diagram or Structured Text to program the P_Prompt

instruction.

You also have the ability to display many prompt configurations, stored in

the Prompts array. These configurations can be built as templates or you

can populate data ad hoc from any location.

You develop the prompt configuration by using FactoryTalk View Studio

software and the global objects file (RA-UI) Prompt Objects.ggfx.

On the bottom, left side of the Prompt Objects folder, there are four

choices to configure a prompt text box.

4. Drag and drop the prompt text box into a new workspace and give it

a name.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 21

Page 22

Operator Prompt (P_Prompt)

5. Drag and drop the standalone prompt button into the workspace.

The illustration shows a series of graphics for how the operator uses each

configuration to set up a prompt.

6. Click the Prompt text box to access the Prompt Selection window.

7. Click Browse (button with ellipsis circled above) to access the Prompt

Configuration dialog box to define the type of prompt.

See page 27

for details of the Prompt Configuration dialog box.

22 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 23

Operator Prompt (P_Prompt)

Prompt Tag Name Plus ‘s’

Define Array Size

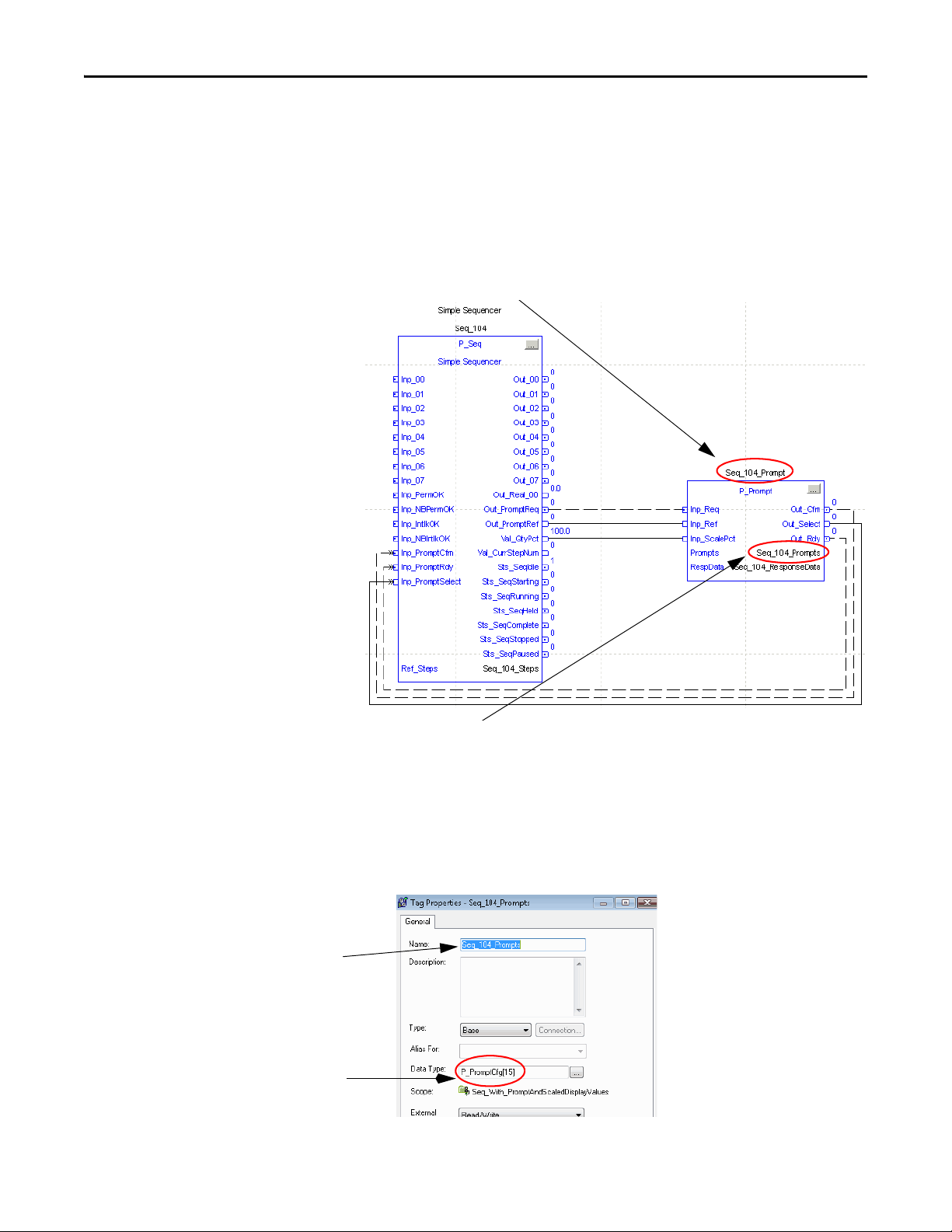

Configure the Prompt with the Sequencer Object

This section describes how to configure prompts to use faceplates with the

P_Seq instruction.

1. Create and name the P_Seq instruction.

2. Create the P_Prompt instruction and name it the

Sequencer tag name plus ‘_Prompt’, for example Seq_104_Prompt.

3. Type a name for the Prompts array tag that is the same as the Prompt tag

name, plus the letter ‘s’. This applies for both a standalone prompt or if

you are using the P_Seq instruction.

In general, with or without the P_Seq instruction, the Prompt faceplates

look for configuration data in the Prompts array.

4. Right-click your new Prompts name (example, Seq_104_Prompts) to

access the Tag Properties dialog box.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 23

Page 24

Operator Prompt (P_Prompt)

Step-By-Step Sequence Configuration

Enable Prompt Check Box

The data type is P_PromptCfg[1].

5. Type a number into the square bracket to create the number of prompt

configuration instances you need for your sequence, and click OK.

6. Attach the pins from the P_Prompt instruction to the P_Seq instruction

as shown on page 23

.

7. Save and download the file.

8. If you make modifications from the HMI, save the .acd file again.

Prompt Configuration Faceplates

Configure the prompts through a set of FactoryTalk View dialog boxes that let

you select individual prompts in the prompt array. The Engineering tab of the

P_Seq instruction contains checkboxes and buttons to configure a prompt with a

step in a sequence.

For details on configuring steps in a sequence, see the Rockwell Automation

Sequencer Object Reference Manual, publication PROCES-RM006

.

You have the ability to display many prompt configurations, stored in the

Prompts array, depending on what type of action is required from the operator in

a given step of a sequence. But, in general, the procedures are similar for

configuring the prompts.

1. On the Engineering tab, check The sequencer has an Operator Prompt

24 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Queue.

Page 25

Operator Prompt (P_Prompt)

IMPORTANT

Click to access the

Prompt Selection

Accesses the Prompt

Selection Window

Leave this checkbox blank if the sequence does not use prompts. Note, at

this point we are still on the sequence config, not the step config.

For a complete description of the Engineering tab, see the Rockwell

Automation Sequencer Object Reference Manual,

publication PROCES-RM006

.

2. At the bottom of the Engineering tab, type the number of the step that is

being configured for the prompt.

3. Click the Display Step Config Window button.

The Home Step Configuration dialog box appears for the selected step.

4. Check Enable an operator prompt.

A blank prompt text box appears.

5. Click the prompt text box.

The Prompt Selection window appears.

6. Click Browse (button with ellipsis circled above) next to a blank row to

credate a new prompot configuration. (Click the browse button next to a

fill-in row to edit that prompt configuration.)

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 25

Page 26

Operator Prompt (P_Prompt)

IMPORTANT

TIP

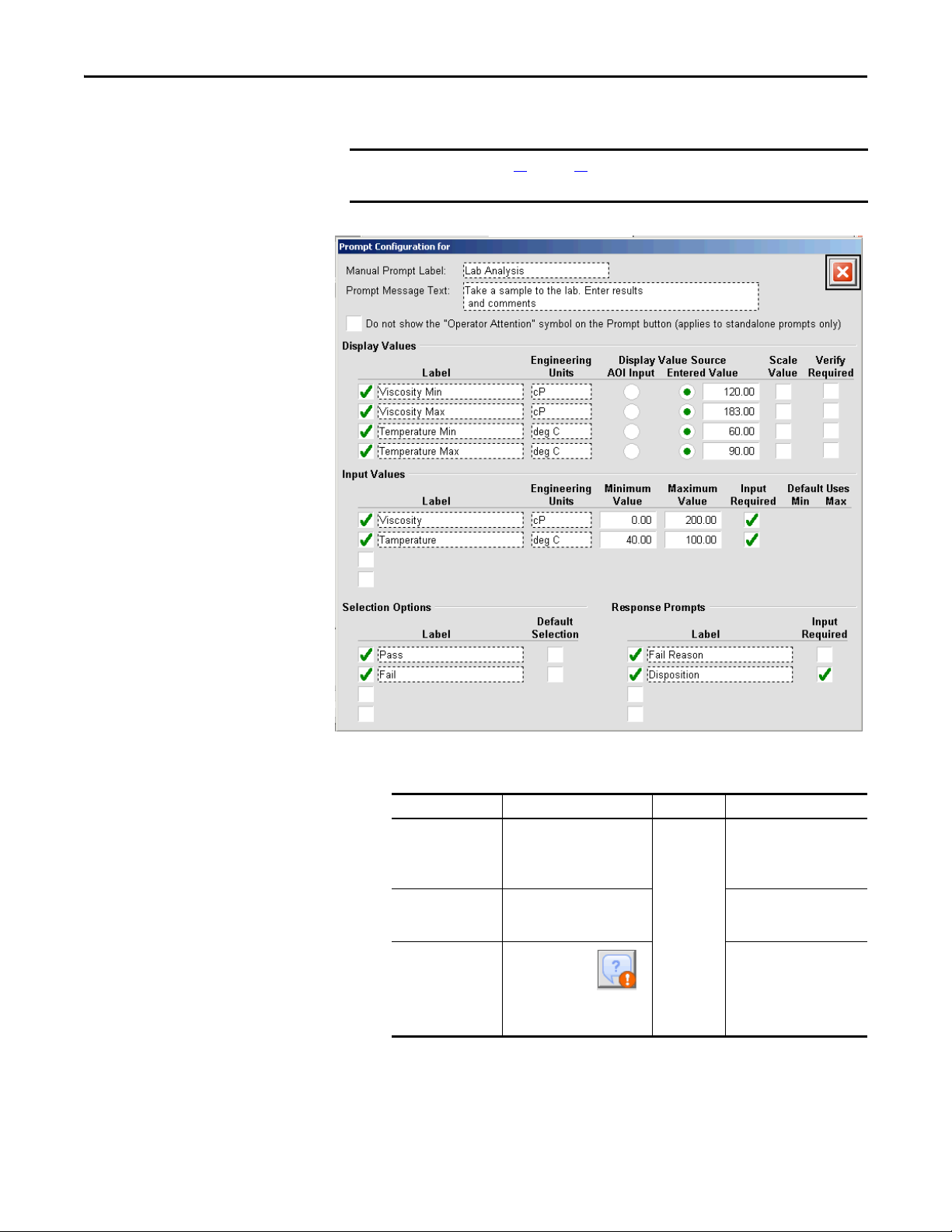

The Prompt Configuration dialog box appears.

See pages 40 through 42 for examples of the Display Values, Input Values, and

Selection Options on the Prompt Configuration faceplate.

7. Complete the Prompt Configuration dialog box.

Function Action Security Configuration Parameters

Manual Prompt Label Type a label for the prompt.

IMPORTANT: Be sure to press

Enter or Page Down a fter typing

in a text box to save your work.

Prompt Message Text Type a text message that

Do not show the

“Operator Attention”

symbol on the Prompt

button (applies to

standalone prompts

only)

explains to the operator the

purpose of this prompt.

Check the

checkbox to not

show the

operator

attention symbol (exclamation

point) on the prompt button.

For instructional purposes, the dialog box is divided into separate

sections to explain Display Values, Input Values, Selection Options, and

Response Prompts in the text that follows.

26 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Engineering

Configuration

(Code E)

Cfg_Label

Cfg_Message

Cfg_AlertDefeat

Page 27

Operator Prompt (P_Prompt)

Display Values

Display values create a prompt that shows the operator floating point

values in run time. This informs the operator of specific quantities

or operating conditions. An Entered Value can be scaled by a programmatic

percentage.

Function Action Security Configuration Parameters

Display Value Enable Check to enable a Label

Label Type a label. Cfg_DispValLabel

Engineering Units Type an engineering unit. Cfg_DispValEU

Display Value Source

• 'AO I I nput '

• Entered Value

Scale Value Check to scale the value by the

Verify Required Check to require the operator to

text field.

Check to either display a value from

the prompt 'AOI Input' or the value

that you enter in the box that

appears.

entered value and the Inp_ScalePct.

See Scale Value

verify the displayed value.

on page 28.

Engineering

Confi guration

(Code E)

Cfg_HasDispVal

Cfg_DispValUsesInp

Cfg_DispValScl

Cfg_DispValVrfy

Programmatic Display Value Configuration

The following P_Prompt configuration tags provide a programmatic interface to

values and functions of the Display Values.

Parameter Data Type Description

Cfg_HasDispVal.x

Cfg_DispValLabel[x] STRING_20 Text field for entry label.

Cfg_DispValEU[x] STRING_8 Engineering units text for entry.

Cfg_DispValUsesInp.x BOOL 1 = Use 'AOI Input'.

Cfg_DispValScl.x BOOL 1 = Apply scaling to value.

Cfg_DispValVrfy.x BOOL 1 = User must confirm reading the value.

(1) x = 0…3 for each of the entries.

(1)

BOOL Bits enable numeric display entries.

0 = Use entered value.

0 = Use value as is.

Programmatic Display Value Parameters

The following P_Prompt parameters are in the Add-On Instruction associated

with the Display Values.

Parameter Description

Input Values are buffered when Inp_Req makes a low to high (0…1) transition:

Output None used.

RespData (InOut) None used.

• Inp_Real_x -- Input sources used when the ‘AOI Input’ configuration is chosen.

• Inp_ScalePct --Input percent scale used when a field is configured for

‘Scale Value’.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 27

Page 28

Operator Prompt (P_Prompt)

Scale Value

A scaled input value is calculated by the Inp_ScalePct and the Entered Value in

the Display Values section. See the illustrations below.

Entered Value = 100 pints x 0.75 = 75 pints

Unscaled AOI Input = 53 soda buckets (Inp_Real_2)

28 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 29

Operator Prompt (P_Prompt)

Input Values

Input values let the operator enter floating point values via the prompt that are

used programmatically. Minimum and maximum values are entered for a range.

Value entry can be optionally required (default).

Function Action Security Configuration Parameters

Input Value Enable Check to enable a Label

Label Type a label for the input value. Cfg_InpValLabel

Engineering Units Type an engineering unit. Cfg_InpValEU

Minimum Value Type a minimum value for the

Maximum Value Type a maximum value for the

Input Required Check to require an operator to

Default Uses

• Min

• Max

text box.

entry.

entry.

enter a value.

If an input is not required, click

Minimum or Maximum to be used

for the entry.

Engineering

Confi guration

(Code E)

Cfg_HasInpVal

Cfg_InpValLoLim

Cfg_InpValHiLim

Cfg_InpValNotReqd

Cfg_InpValDefMax

Programmatic Input Value Configuration

The following P_Prompt configuration tags provide a programmatic interface to

values and functions of the Input Values.

Parameter Data Type Description

Cfg_HasInpVal.x

Cfg_InpValLabel[x] STRING_20 Text field for entry label.

Cfg_InpValEU[x] STRING_8 Engineering units text for entry.

Cfg_InpValLoLim[x] REAL[4] Input entry low limit.

Cfg_InpValHiLim[x] REAL[4] Input entry high limit.

Cfg_InpValNotReqd.x BOOL 0 = User input is required.

Cfg_InpValDefMax.x BOOL 0 = Input entry minimum limit.

(1) x = 0…3 for each of the entries.

(1)

BOOL Bits enable numeric input entries.

1 = User input is not required.

1 = Input entry maximum limit.

Programmatic Input Value Parameters

The following P_Prompt parameters are in the Add-On Instruction associated

with the Input Values.

Parameter Description

Input None used.

Output Parameter values change when you click the green checkbox to confirm.

Out_Real_x -- Outputs used for the user entered values.

RespData (InOut) Field changes when you click the green checkbox to confirm.

ResponseData.NumericInput[0-…3] -- Contains the string representation of the

entered values.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 29

Page 30

Operator Prompt (P_Prompt)

Selection Options

Selection options let the operator choose one choice from two to four offerings.

One of the selections can be designated a default, but none need to be designated

as such.

Function Action Security Configuration Parameters

Selection Enable Check to enable a Label

Label Check and type a label for the

Default Selections Click to designate a selection as

text box.

selection option.

the default.

Programmatic Selection Option Configuration

The following P_Prompt configuration tags provide a programmatic interface to

values and functions of the Selection Options.

Parameter Data Type Description

Cfg_HasSelect.x

Cfg_SelectLabel[x] STRING_20 Text field for selection label.

Cfg_SelectDef.x BOOL 0 = Entry is not default.

(1)

BOOL Bits enable numeric selection entries.

1 = Entry is default.

Engineering

Confi guration

(Code E)

Cfg_HasSelect

Cfg_SelectLabel

Cfg_SelectDef

(1) x = 0…3 for each of the entries.

Programmatic Selection Option Parameters

The following P_Prompt parameters are in the Add-On Instruction associated

with the Selection Options.

Parameter Description

Input None used.

Output Parameter value tracks your changes until you click the green checkbox to confirm.

Out_Select -- The number of the selection chosen by the user (0…4).

RespData (InOut) Field changes when you click the green checkbox to confirm.

ResponseData.Selection -- Contains the label string of the chosen selection.

30 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 31

Operator Prompt (P_Prompt)

Response Prompts

Response prompts let the operator enter string-based information (comments, lot

numbers, and so forth). Response entry is required by default, but can be

configured as optional.

Function Action Security Configuration Parameters

Response Enable Check to enable a Label

Label Check and type a label for the

Input Required Check to require an input. Cfg_RespNotReqd

text box.

response prompt.

Programmatic Response Prompt Configuration

The following P_Prompt configuration tags provide a programmatic interface to

values and functions of the Response Prompts.

Parameter Data Type Description

Cfg_HasResp.x

Cfg_RespLabel[x] STRING_20 Text field for response label.

Cfg_RespNotReqd.x BOOL 0 = User response is required.

(1)

BOOL Bits enable numeric response entries.

1 = User response is not required.

Normal

Production

(Batches &

Lots)

(Code J)

Cfg_HasResp

Cfg_RespLabel

(1) x = 0…3 for each of the entries.

Programmatic Response Prompt Parameters

The following P_Prompt parameters are in the Add-On Instruction associated

with the Response Prompts.

Parameter Description

Input None used.

Output None used.

RespData (InOut) Field changes when the user clicks the green checkbox to confirm.

ResponseData.CharInput[0…3] -- Contains the string responses.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 31

Page 32

Operator Prompt (P_Prompt)

First selection option (no branch).

Second, third, fourth selection options (branch).

IMPORTANT

Sequencer Branching Configuration

The P_Prompt instruction uses the Selection Options section of the Prompt

Configuration dialog box to implement branching in the Sequencer Object

instruction. When used this way, the first selection option continues to the next

sequential step in the Sequencer; any other selection option causes the Sequencer

to take the branch.

For branch procedures and guidelines, see the Rockwell Automation Sequencer

Object Reference Manual, publication PROCES-RM006.

The Out_Select parameter tracks the number of the selection chosen by the user.

This output parameter is used by the Sequencer instruction to know whether to

take a branch. Any number greater than 1 instructs the Sequencer to branch.

32 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 33

Operator Prompt (P_Prompt)

IMPORTANT

Required Files

The remainder of this document explains the parameters and display elements

that comprise the P_Prompt instruction.

Controller File

The P_Prompt_3_5-00_AOI.L5X Add-On Instruction must be imported into

the controller project to be able to be used in the controller configuration. The

service release number (boldfaced) can change as service revisions are created.

Visualization Files

This Add-On Instruction has associated visualization files that provide a

common user interface. These files can be downloaded from the Product

Compatibility and Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/pcdc.page

The visualization file dependencies require Process Library content imports to

occur in a specific order as reflected in the following tables:

• Images

• Global Objects

• Standard Displays

• HMI Tags

• Macros

.

Images are external graphic files that can be used in displays. They must be

imported for FactoryTalk View to make use of them.

When PNG files are imported, they are renamed by FactoryTalk View with

a .bmp file extension, but retain a .png format.

Table 2 - Visualization Files: Images (.png)

FactoryTalk View SE Software FactoryTalk View ME Software Description

All .png files in the images folder All .png files in the images folder These are the common icons used in the global objects and

standard displays for all Process Objects.

The Global Object files (.ggfx file type) in the following table are Process Library

display elements that are created once and referenced multiple times on multiple

displays in an application. When changes are made to a Global Object, all

instances in the application are automatically updated.

Table 3 - Visualization Files: Global Objects (.ggfx)

FactoryTalk View SE Software FactoryTalk View ME Software Description

(RA-BAS) Common Faceplate Objects (RA-BAS-ME) Common Faceplate Objects Global objects used on process object faceplates.

(RA-UI) Prompt Objects (RA-UI-ME) Prompt Objects Prompt global objects used on process object faceplates.

The Standard Display files (.gfx file type) in the following table are the Process

Library displays that you see at runtime.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 33

Page 34

Operator Prompt (P_Prompt)

Table 4 - Visualization Files: Standard Displays (.gfx)

FactoryTalk View SE Software FactoryTalk View ME Software Description

(RA-BAS) Common-AnalogEdit N/A Faceplate used for analog input data entry. The FactoryTalk

(RA-UI) P_Prompt-Config (RA-UI-ME) P_Prompt-Config Display used to configure the prompt.

(RA-UI) P_Prompt-Response (RA-UI-ME) P_Prompt-Response The Display to enter the prompt response.

(RA-UI) P_Prompt-Config (RA-UI-ME) P_Prompt-Config Optional

(RA-UI) P_Prompt-Response (RA-UI-ME) P_Prompt-Response Optional

(RA-UI) P_Prompt-Select (RA-UI-ME) P_Prompt-Select Optional

View ME faceplates use the native analog input data entry

so no file is required.

Display used to configure the prompt.

The Display to enter the prompt response.

The display to select a prompt for the sequence step.

HMI Tags are created in a FactoryTalk View ME application to support tab

switching on Process Library faceplates. The HMI tags may be imported via the

comma-separated values file (.csv file type) in the following table.

Table 5 - Visualization Files: HMI Tags (.csv)

FactoryTalk View SE Software FactoryTalk View ME Software Description

N/A FTVME_PlantPAxLib_Tags_3_5_xx.csv

where xx = the service release number.

These tags must be imported into the

FactoryTalk View ME project to support switching tabs on

any Process Object faceplate.

34 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 35

Operator Prompt (P_Prompt)

Controller Code

This section describes the parameter references for this Add-On Instruction.

Prompt InOut Structure

In/Out Parameters Data Type Alias For Description

Prompts P_PromptCfg[x] None Prompt instance configuration data (Array must have one or more members).

RespData P_PromptResp Structure to hold most recent res ponse data in string format.

Prompt Input Structure

Input parameters include the following:

• Input data elements (Inp_) are typically used to connect field inputs from

I/O modules or signals from other objects.

• Commands (PCmd_, OCmd_, MCmd_) are used by program logic,

operators, and maintenance personnel to request instruction actions.

Input Parameter Data

Type

EnableIn BOOL 1 Ladder Diagram:

Inp_Req 0 1 = Enable button to access operator prompt.

Inp_Ref DINT 0 Pointer into the prompt configuration array indicating which element to use for

Inp_ScalePct REAL 100.0 Percent by which to scale configured numeric display values.

Inp_Real_0 Inp_Real[0] 0.0 Input real value to display (0).

Inp_Real_1 Inp_Real[1] 0.0 Input real value to display (1).

Inp_Real_2 Inp_Real[2] 0.0 Input real value to display (2).

Inp_Real_3 Inp_Real[3] 0.0 Input real value to display (3).

OCmd_Cfm BOOL 0 Operator command to confirm and close prompt.

Alias For Default Description

If the rung-in condition is true, the instruction’s Logic routine executes. If the

rung-in condition is false, the instruction’s EnableInFalse routine executes.

Function Block Diagram:

If true, or not connected, the instruction’s Logic routine executes. If the parameter

is exposed as a pin and wired, and the pin is false, the instruction’s EnableInFalse

routine executes.

Structured Text:

No effect. The instruction’s Logic routine executes.

the prompt.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 35

Page 36

Operator Prompt (P_Prompt)

Prompt Output Structure

Output parameters include the following:

• Output data elements (Out_) are the primary outputs of the instruction,

typically used by hardware output modules; however, they can be used by

other application logic.

• Value data elements (Val_) are numeric outputs of the instruction for use

by the HMI. Values also can be used by other application logic or

software packages.

• Status data elements (Sts_) are bit outputs of the instruction for use by the

HMI. Status bits also can be used by other application logic.

• Error data elements (Err_) are outputs of the instruction that indicate a

particular configuration error. If any Err_ bit is set, then the Sts_Err

configuration error summary status is set and the Invalid Configuration

indicator is displayed on the HMI.

• Ready data elements (Rdy_) are bit outputs of the instruction used by the

HMI to enable or disable Command buttons and Setting entry fields.

Output Parameter Data Type Alias For Description

EnableOut BOOL Enable Output: The EnableOut signal is not manipulated by this instruction. Its output state

Out_Cfm Operator confirmation output. 1 = Operator has entered required data confirmed prompt.

Out_Rdy 1 = Prompt is ready to be displayed.

Out_Select SINT OSet_Select Value of operator response to selector.

Out_Real_0 REAL Out_Real[0] Value (REAL) of operator numeric entry (0).

Out_Real_1 Out_Real[1] Value (REAL) of operator numeric entry (1).

Out_Real_2 Out_Real[2] Value (REAL) of operator numeric entry (2).

Out_Real_3 Out_Real[3] Value (REAL) of operator numeric entry (3).

Val_Ref DINT Number of the prompt configuration in the array that was used.

Sts_Alert BOOL Status for alert breadcrumb.

Sts_RefChg 1 = The Inp_Ref has changed (single scan).

Sts_Err 1 = Error in configuration; see detail bits for reason.

Err_PromptCfgSize 1 = Error in size of an array in the P_PromptCfg UDT definition.

Err_RespDataSize 1 = Error in size of an array in the P_PromptResp UDT definition.

Err_MsgRef 1 = Error in value of Inp_Ref (past end of prompt array).

Rdy_Cfm 1 = Prompt ready for operator confirmation.

always reflects EnableIn Input state.

36 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 37

Operator Prompt (P_Prompt)

TIP

Operations

Display Elements

The P_Prompt Add-On Instruction does not use modes, alarms, or simulation.

A display element (global object) is created once and can be referenced multiple

times on multiple displays in an application. When changes are made to the

original (base) object, the instantiated copies (reference objects) are

automatically updated. Use of global objects, in conjunction with tag structures

in the ControlLogix® system, aid consistency and save engineering time.

Table 7 - P_Prompt Display Elements Description

Display Element Name Display Element Description

GO_PromptButtonSP Standalone prompt button that assumes the P_Prompt

GO_Promp tButtonWithText Prompt di splay indicator for use on faceplates and displays

instruction is present and the button is always visible. The

Prompt instruction controls the button’s enabled state and

alert indicator visibility.

for objects that possibly do not have a prompt instruction.

Status/Quality/Threshold Indicators

One of these symbols appears to the left of the graphic symbol when the

described condition is true.

Graphic Symbol Description

Invalid configuration if an input is set to an array index that is beyond the end of the array.

When the Invalid Configuration indicator appears, you can find what

configuration setting is invalid by following the indicators. Click the graphic

symbol to open the faceplate. The Invalid Configuration indicator appears next

to the appropriate tab at the top of the faceplate to guide you in finding the

configuration error. Once you navigate to the tab, the misconfigured item is

flagged with this indicator or appears in a magenta box.

For the P_Prompt object, the Invalid Configuration indicator appears for the

following:

• An array in the Prompt Configuration is the wrong size

(UDT: P_PromptCfg)

• An array in the Response Data is the wrong size

(UDT: P_PromptResp)

• Inp_Ref value points to a Prompt Configuration that is outside of the

P_PromptCfg entries

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 37

Page 38

Operator Prompt (P_Prompt)

Using Display Elements

The global objects for P_Prompt can be found in the global object file

(RA-UI) Prompt Objects.ggfx. Follow these steps to use a global object.

1. Copy the global object from the global object file and paste it in the

display file.

2. In the display, right-click the global object and choose Global Object

Parameter Values.

The Global Object Parameter Values dialog box appears.

38 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 39

Operator Prompt (P_Prompt)

Name Value Current Tag Value

#101 {::[Area1]Program:MaterialAddtion.PromptTitle} Add Mat Y to T100

#102 {::[Area1]Program:MaterialAddtion.Prompt}

#104 {::[Area1]Program:MaterialAddtion.PromptArrayInstance} 1

The global object parameters are as follows.

Name Description Purpose Syntax Tag

#101 Title for Prompt Selection window

(string tag)

#102 Prompt tag (P_Prompt or sim ilar) Reference to t he P_Prompt controller tag {::[shor tcut]Progra m:ProgramName. TagName} Progra m scope

#104 Prompt array instance tag This tag’s value highlights the

This tag’s value appears at the top of the

Prompt Configuration dialog box

prompt selection

{::[shortcut]Program:ProgramName.TagName} Program scope

{::[shortcut]TagName} Controller scope

{::[shortcut]TagName} Controller scope

{::[shortcut]Program:ProgramName.TagName} Program scope

{::[shortcut]TagName} Controller scope

3. In the Value column, type the tag or value as specified in the Description

column. See the examples.

4. On the Global Object Parameter Values dialog box, click OK.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 39

Page 40

Operator Prompt (P_Prompt)

A

B

C

D

Faceplates

The P_Prompt instruction has three faceplates: Configuration, Response,

and Selection.

P_Prompt Configuration

The Prompt Configuration dialog box has four sections to configure a prompt.

A - Display Values

The source of each value can be a fixed configuration value (default) or

programmatic values received on the corresponding instruction input.

Figure 1 - Example Display Value Configuration and Prompt Display

40 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Fixed configuration values can

optionally be scaled. See page 27

page 28

for details.

and

Page 41

Operator Prompt (P_Prompt)

B - Input Values

Value entry can be optionally required (default). If the input is not required, a

default of either the minimum or maximum value must be selected.

For entry field details, see page 29

Figure 2 - Example Input Value Configuration and Prompt Display

.

The Acknowledge button (green checkmark) activates when the operator

enters a value.

This is an example of Response Data values.

This is an example of the Outputs.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 41

Page 42

Operator Prompt (P_Prompt)

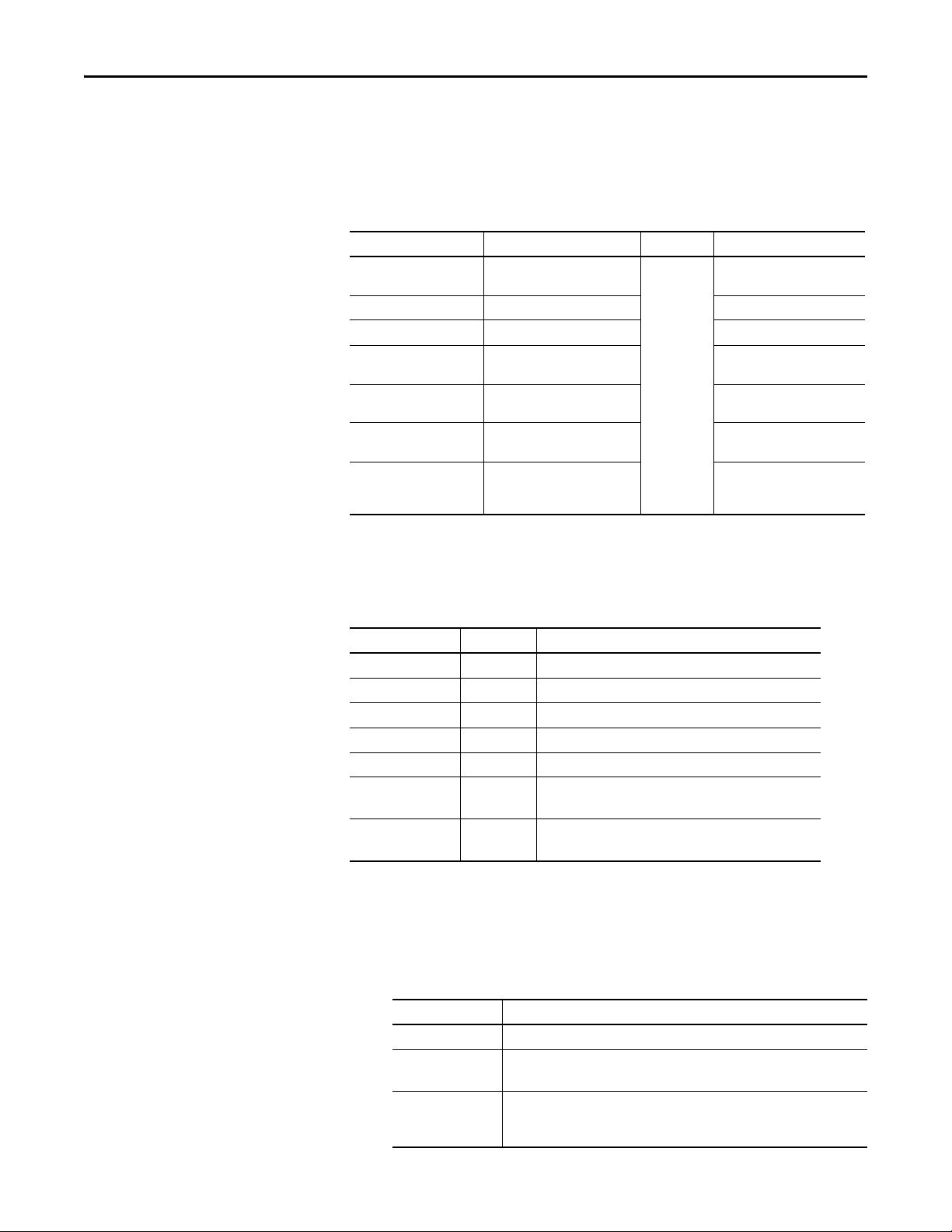

C- Selection Options

Any one or none of the enabled selections can be designated as the default. If you

leave all selections unchecked, the operator is required to make a selection before

acknowledging the prompt.

For entry field details, see page 30

Figure 3 - Example Selection Options Configuration and Prompt Display

.

The Acknowledge button (green checkmark) activates when the operator

makes a selection.

This is an example of the Response Data value.

This is an example of the Outputs.

42 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

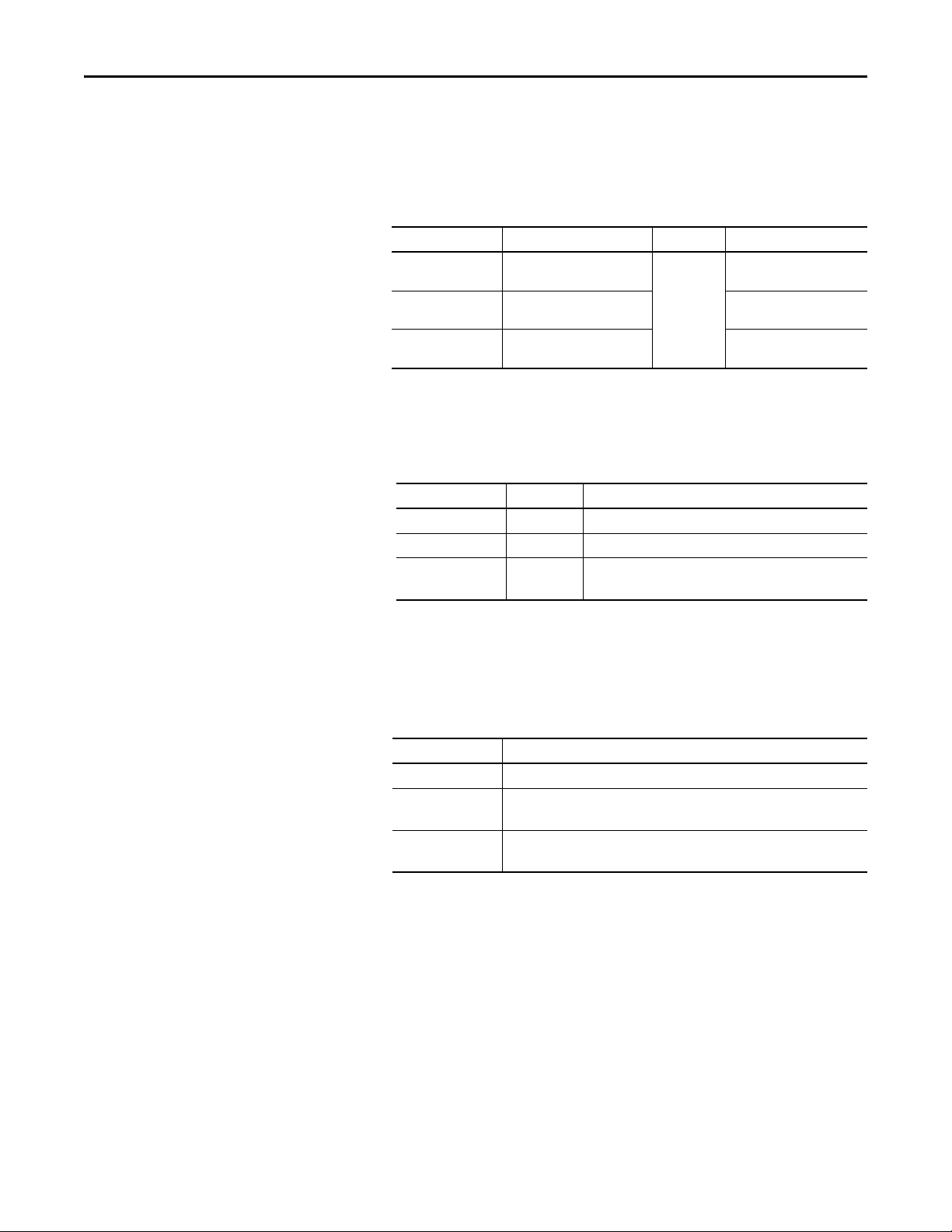

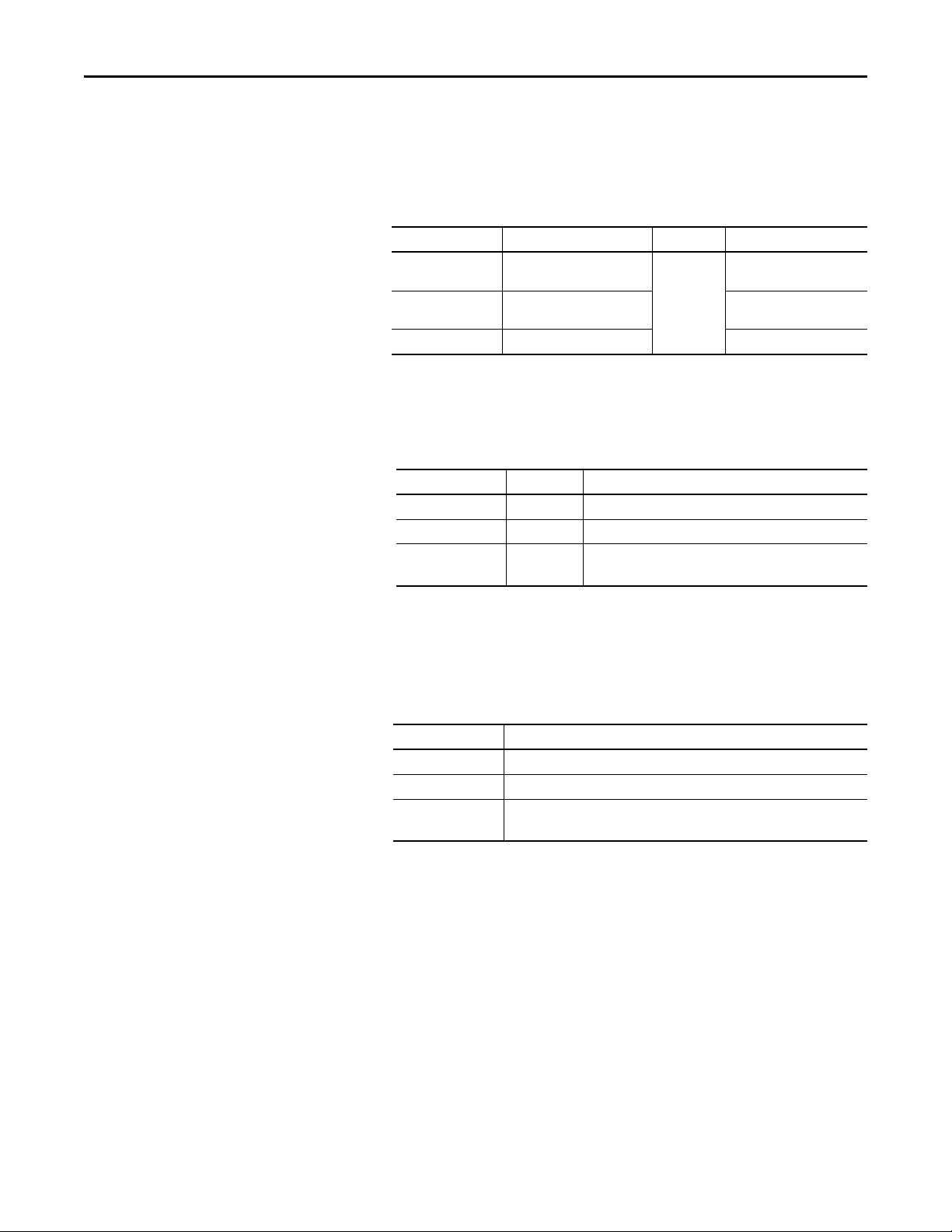

Page 43

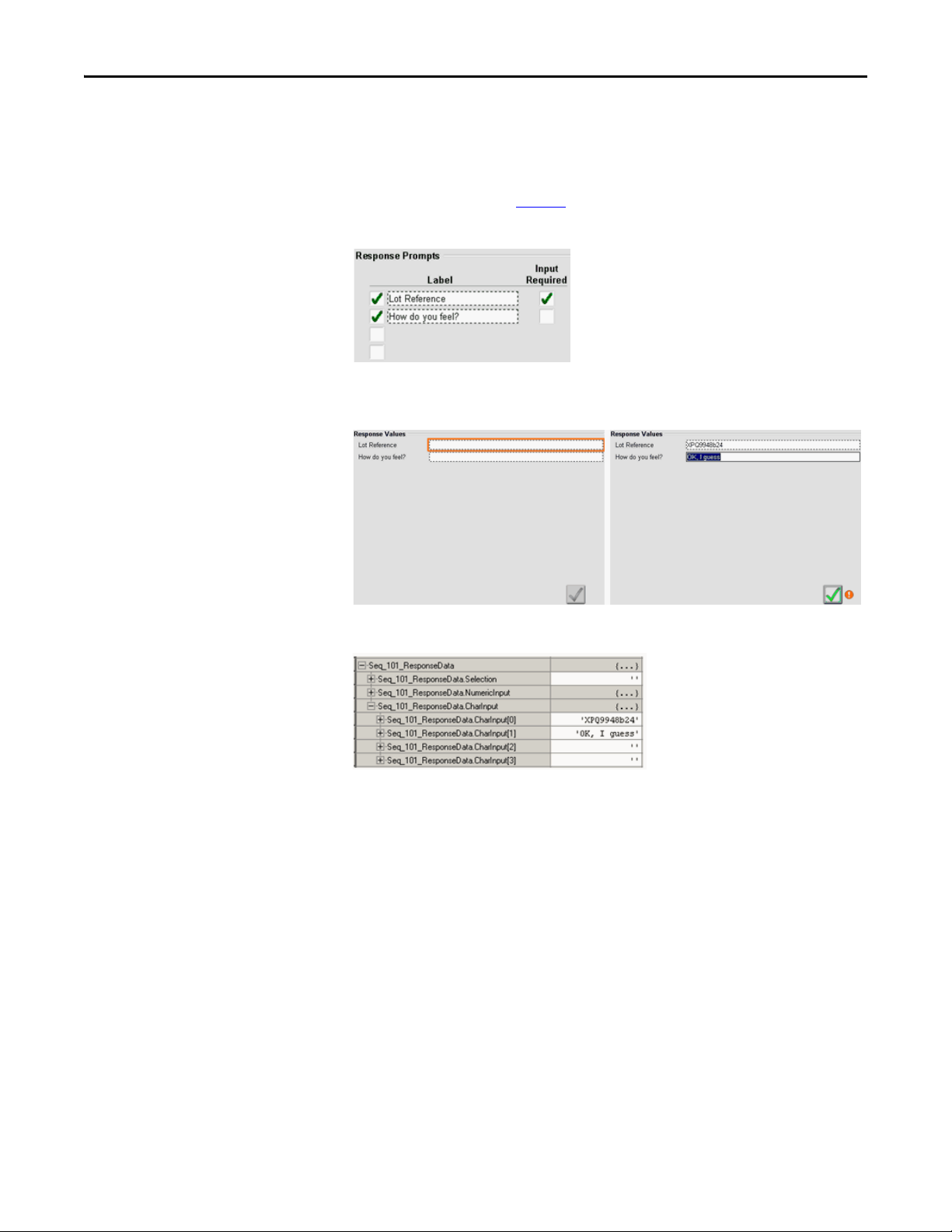

D- Response Prompts

Any of the responses can be designated as Input Required.

Operator Prompt (P_Prompt)

For entry field details, see page 31

Figure 4 - Example Response Prompts Configuration and Prompt Display

.

The Acknowledge button (green checkmark) activates when the operator has

entered text in all responses designated as Input Required.

This is an example of the Response Data values.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 43

Page 44

Operator Prompt (P_Prompt)

Security code ‘J’ is required to

enter data. Click the green

checkmark to confirm.

P_Prompt Response

This dialog box lets the operator review and record data based on the prompt.

The Parameter Values, Selection Options, and Response Values are configured on

the Prompt Configuration dialog box.

See page 26

for descriptions of the entry boxes on the Prompt Configuration

dialog box.

44 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

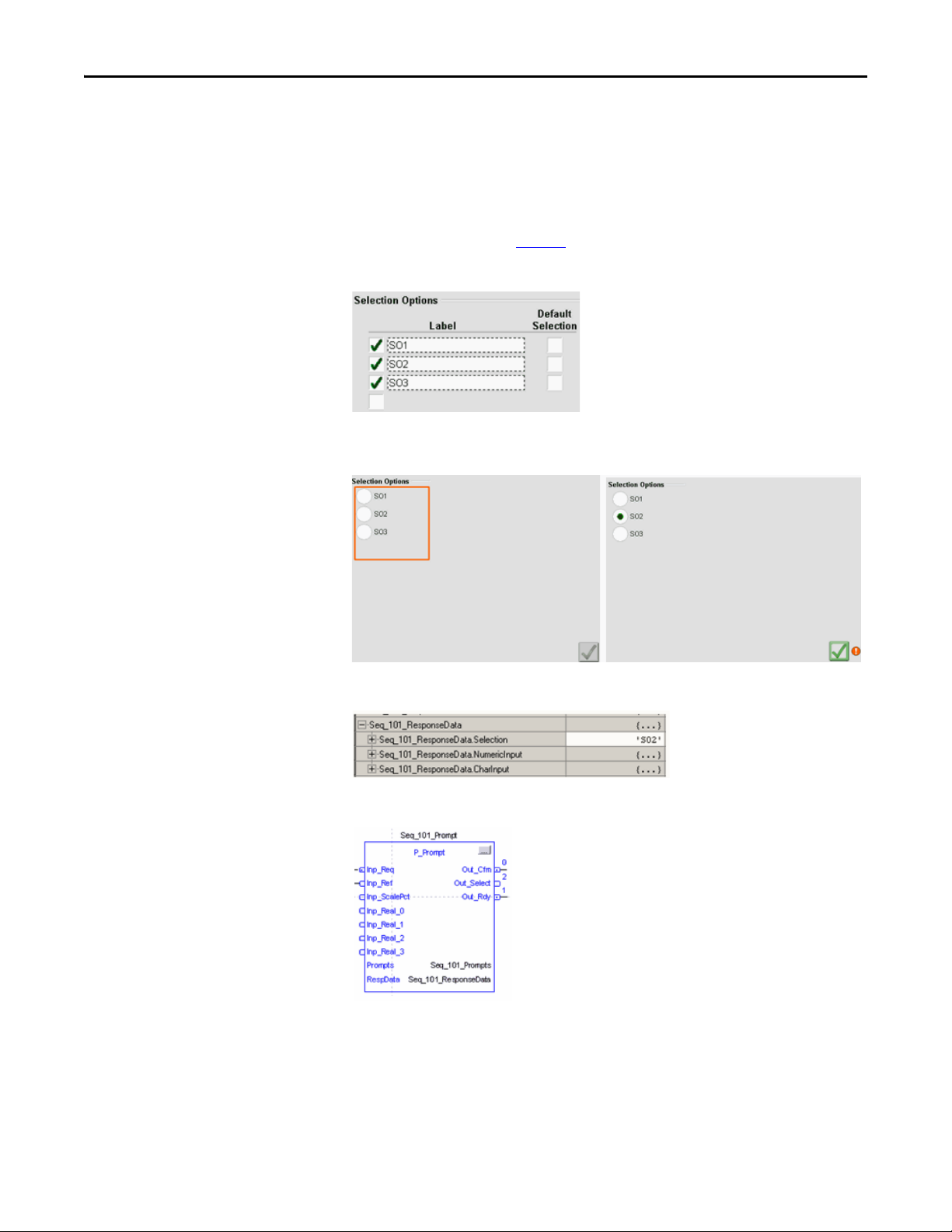

Page 45

Operator Prompt (P_Prompt)

Browse Button

P_Prompt Selection

The Prompt Selection display provides access to the configuration dialog box for

a given prompt configuration in the Prompts array by clicking the corresponding

Browse button.

The highlighted box (green dot) is determined by the values entered in the

#104 tag of the Global Object Parameter Values dialog box.

See page 38

for more information on the Global Objects Parameter Values

dialog box.

Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016 45

Page 46

Operator Prompt (P_Prompt)

Notes:

46 Rockwell Automation Publication SYSLIB-RM046C-EN-P - January 2016

Page 47

Page 48

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwi de Lo cato r

Rockwell Automation representative.

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

, available at http://www.rockwellautomation.com/literature/.

.

Publication SYSLIB-RM046C-EN-P - January 2016

Supersedes Publication SYSLIB-RM046B-EN-P - August 2014 Copyright © 2016 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...