Page 1

Triguard SC300E

MSR04XI

Serial Communications Module

RS232

(MSR04XI

Issue 8

INTRODUCTION AND TEC

HNICAL DATA

PURPOSE

The Serial Communications Module provides a serial interface between the SC300E

environment

one Serial Communications Module must be used in the system and fitted in Slot 10 of the

main

workstations.

ladder

be fitted to any other I/O slot, ‘wrong slotting’ is prevented by mechanical coding blocks (Figure

2-1 ). The system software identifies the module via a built-in hardware identifier.

and a variety of remote devices complying with the standardRS232-C. At least

chassis to enable communications between the system processors and the

The workstation link is used for loading the application software and monitoring

and diagnostic functions. The link utilises Port 0 of the module. Additional modules can

October 2005

)

Circuit triplication and voting procedures make the module single fault tolerant and front panel

indicators show Tx/Rx activity, the circuit on-line status and the health of the module.

Communications

these

connections are duplicated on the field connector (J2) at the rear. A fifth port is for

diagnostic purposes only. The module is compatible with ‘single slot hot repair’ and the front

panel has a switch to enable a request that the module be taken off line.

This document is intended to provide a general understanding of the function of Serial

Communications Module, sufficient to enable basic maintenance operations to be effected in

the

field.

conne

ctions are via four identical ports on the front panel (Ports 0 to 3) and

008-5099

Page 2

2

MSR04X

I

October

2005–

Issue 8

Triguard

SC300E

Ejector lever

User COMMports

Diagnosticport

(Voltage Mon)

Link LK2

echanical

M

(Upper)

Connector J1

(Module ID)

Link LK2

oding

c

lock

b

Link LK4

Tx / Rx LEDs

Health LED

ON/OFF LEDs

ON/OFF Line

Request switch

Ejector lever

Connector J2

RS232 Daughterboard

Mechanical coding block

(Lower)

Page 3

MSR04X

I

October

2005–

Issue 8

3

Triguard

SC300E MSR04XI Serial Communications Module RS232

ASSOCIATED DOCUMENTATION

Reference No

008-5097

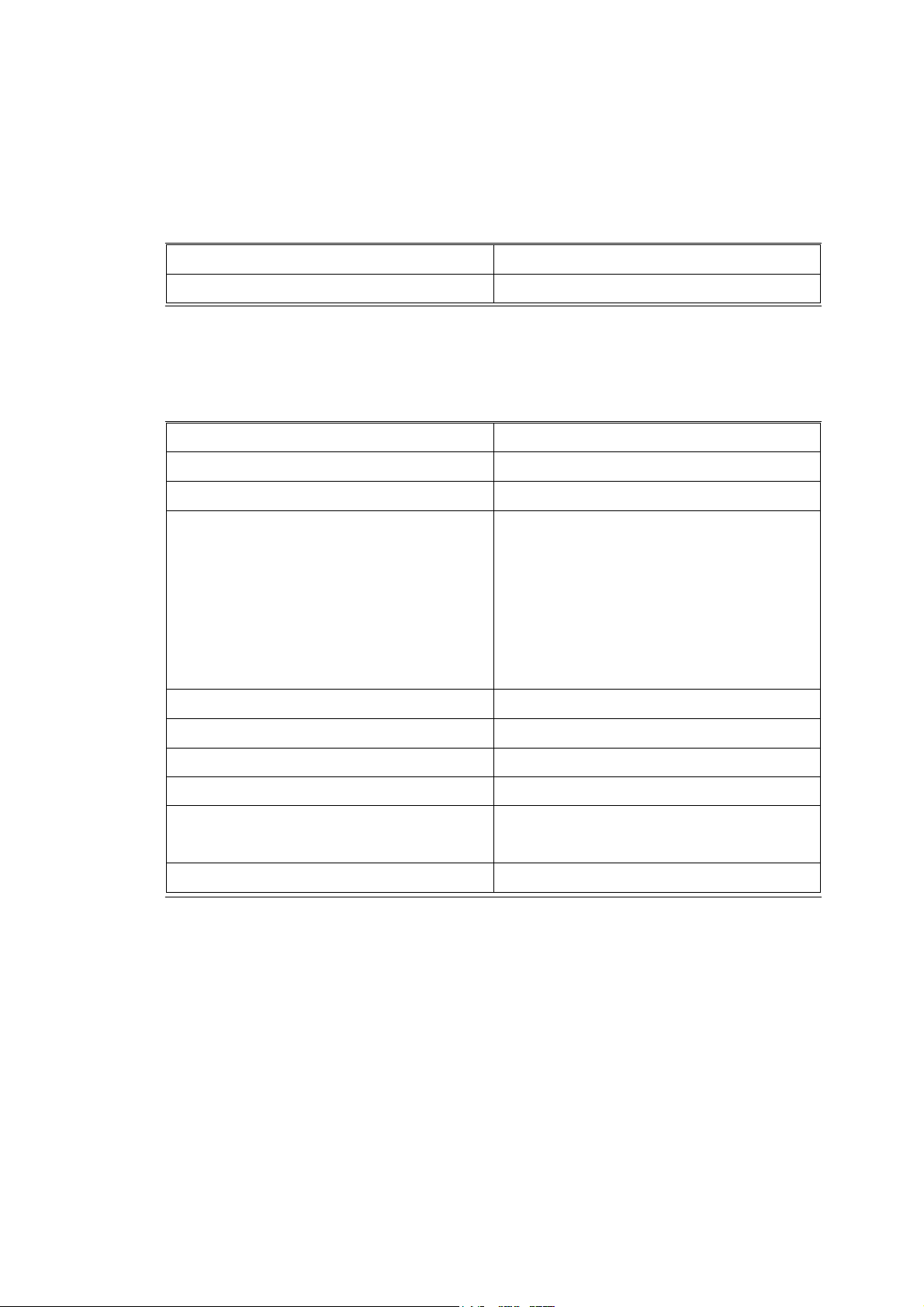

SPECIFICATION

Model

Communications

Mictrocontroller

Communication ports:

rate. Isolation

Chassis User Manual

MSR04XI

Serial RS232

Intel family

Port 0: RS232 9600 or 19200 Baud

Port 1:

Port 2: RS232 9600 or 19200 Baud (see Note)

Port 3: RS232 9600 or 19200 Baud (see Note)

Diagnostic:

Ports

rate.

Ports 0 to 3, 1kV

RS232

for diagnostics purposes only

2 & 3 must be set to the same Baud

Title

9600 or 19200 Baud

Note

:

Indicators

Hot repair procedure

Module power consumption

Overall size (mm)

Overall size (inches)

Weight

Tx, Rx, Health, 3 x On Line

Single slot

3.5W

400(9U)H x 397L x 28W

15.75H x 15.63L x 1.1W

1.3kg

Page 4

4

MSR04X

I

October

2005–

Issue 8

Triguard

SC300E

ENVIRONMENTAL SPECIF

The maximum ambient temperature measured at the hottest point within the Triguard system

shall not be greater than 60 degrees centigrade.

Temperature operating:

Temperature storage:

Humidity

EMC/RFI

Vibration/Shock

Certification:

General Certification: Ref. SC300E Product Guide (ref 008-5209)

Immunity

ICATIONS

+5°C to +60°C

-

25°C to +70°C

5% to 95% non-condensing at ambient <40°C

Tested and certified to IEC 1131-Part 2 1994

Tested and certified to IEC 1131-Part 2 1994

TRANSPORT AND HANDLING

The MSR04XI module must be transported and stored in its original packing material which

should be retained for this purpose.

Page 5

MSR04X

I

October

2005–

Issue 8

5

Triguard

SC300E MSR04XI Serial Communications Module RS232

TECHNICAL DESCRIPTIO

N

PHYSICAL

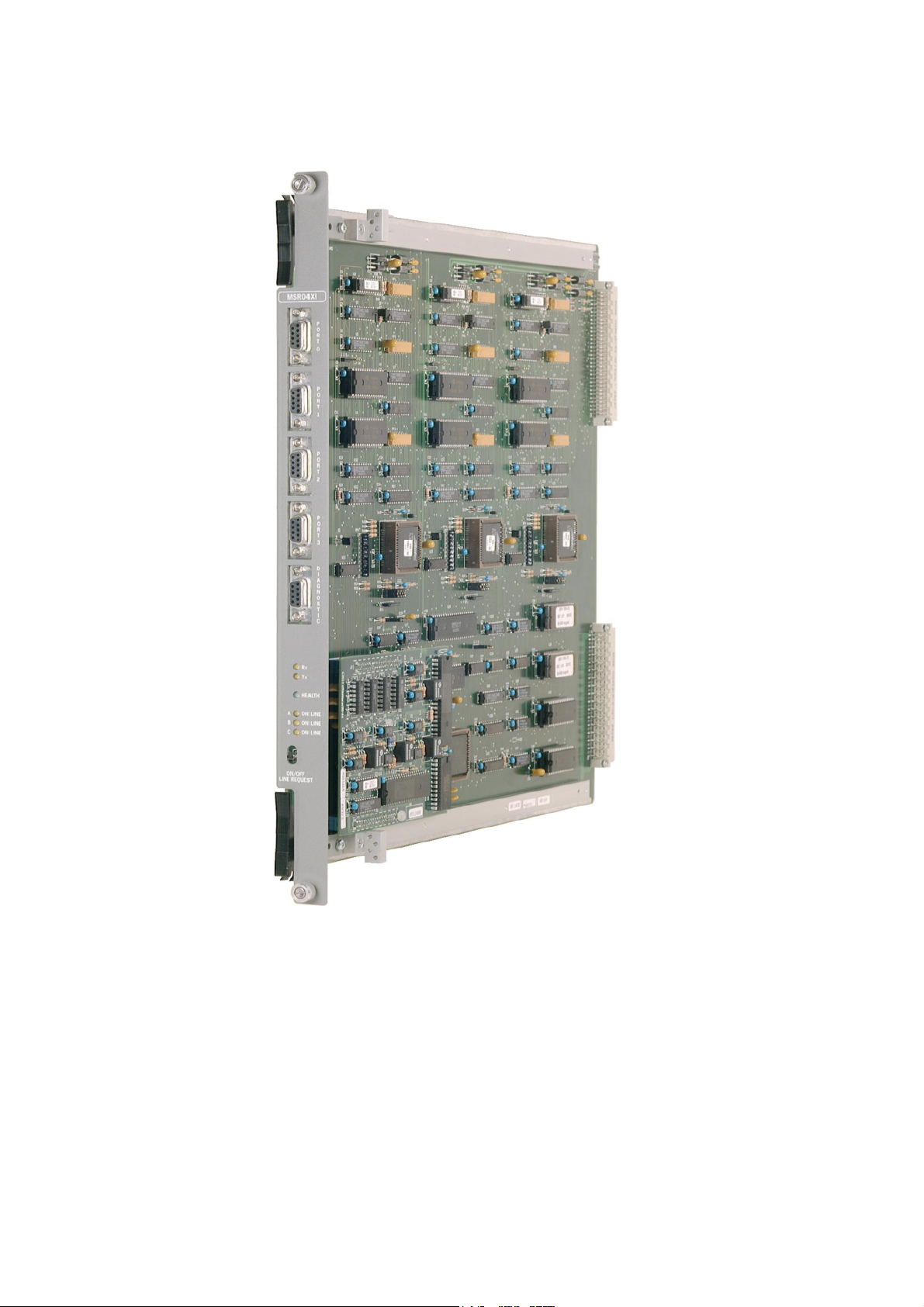

The Serial Communications Module is a 9U high PCB with integral front panel and front and

rear

connectors; a plug-in daughter board carries the RS232 interface circuits. Figure 1-1

shows the general layout, location of the connectors and front panel components.

Mechanical coding blocks

All Input/Output modules carry two mechanical coding blocks equipped with pins which mate

with

holes in corresponding blocks in the chassis and prevent the module being inserted into

the wrong slot. The pins in the module blocks are factory installed in a

the module and corresponding set screws are removed from the chassis coding blocks to

enable

block configuration for this module is shown in Figure 2-1

fitting. Unused holes are plugged with set screws. The chassis mechanical coding

.

pattern determined by

Figure 2-1 Chassis mechanical coding block configurations

Links

The PCB has a total of nine links. For the top section of the PCB the links are located and

configured as follows:

Three LK1 links (3-pin) located approximately 80mm down from the top ofthe module, not user

configurable,

Three LK2 links (8-pin) located approximately 210mm down from the top of the module Module ID links which should always be fitted (refer to Figure 1-1).

link not fitted.

Page 6

6

MSR04X

I

October

2005–

Issue 8

Triguard

SC300E

On the lower section of the PCB are three further links, LK2, LK3 and LK4, located and

configured as follows:

LK2 (2-pin) located approximately 220mm down from the top of the module and 110mm in from

the

front face, used in the voltage monitoring circuit, always fitted.

LK3 (3 factory fitted hard wired, all pins linked for 3-2-1 mode.

LK4 (3-pin) located approximately 250mm down from the top of the module and 220mm from

the

pin) located beneath the plug in daughterboard. Used for 3-2-1-or 3-2-0 operation,

front face, used for the daughterboard clock speed setting, pins 1 and 2 linked.

LK1 (3 off x 3 pin)

LK2 (3 off x 8 pin)

LK2 (2 pin)

LK3 (3 pin)

LK4 (3 pin)

Table 2-1. Default link settings

Link

Default setting

Links not fitted

Hard wired (all pins linked)

Fitted (pins 1 & 2 link

Fitted

Fitted

ed)

Page 7

MSR04X

I

October

2005–

Issue 8

7

Triguard

SC300E MSR04XI Serial Communications Module RS232

EXTERNAL CONNECTIONS

Pinouts and signals for front panel connectors J4 to J6 through to J2 backplane are given in

Table 2-2.

Is your interface DTE (data terminal equipment) or DCE (data communications equipment)?:

The

Transmit and receive leads (2 or 3) can be reversed depending on the use of the equipment,

either

Port 0

(9-way)

point of reference for all signals is the terminal (or PC).

DTE or DCE.

1

2

3 Tx

4

5 Ground

Table 2-2. Front panel & backplane connector pinouts with signals

(backplane

Rx

J2

n/c

A4

C2

n/c

A6

Port 1

(9-way)

1

2

3 Tx

4

5 Ground

Rx

J2

(backplane)

n/c

A12

C10

n/c

A14

6

7 RTS

8 CTS

9

Port 2

(9-way)

1

2

3 Tx

4

5 Ground

6

7 RTS

8 CTS

9

n/c

n/c

Rx

n/c

n/c

n/c

A2

C4

n/c

J2

(backplane)

n/c

A20

C18

n/c

A22

n/c

A18

C20

n/c

6

7 RTS

8 CTS

9

Port 3

(9-way)

1

2

3 Tx

4

5 Ground

6

7 RTS

8 CTS

9

n/c

n/c

Rx

n/c

n/c

n/c

A10

C12

n/c

J2

(backpl

n/c

A28

C26

n/c

A30

n/c

A26

C28

n/c

ane)

n/c =No connection

Wiring schematic for serial communication cables are shown in Figure 2-2

.

Page 8

8

MSR04X

I

October

2005–

Issue 8

Triguard

SC300E

Page 9

MSR04X

I

October

2005–

Issue 8

9

Triguard

SC300E MSR04XI Serial Communications Module RS232

Figure 2-2 Serial communications cable wiring

THEORY OF OPERATION

Triplicated data enters and leaves the module (Figure 2-3 ) via the chassis backplane

connector

loaded into dual port RAM in each of the three circuit branches and is voted 2-oo-3 before being

passed

communications port.

Data received at th

RAM

the

set

of

The four communications ports are configured to run in full duplex mode using an RS232

interface and having a maximum rate of 19200 Baud. The communications ports are isolated

from

module.

distances.

J1

and is isolated from the MPP by bus transceivers. Dat a for transmission is

to

the USARTs on the daughter board where it is serialised and sent to the appropriate

e ports is converted to parallel form by the USART and written to dual port

in

each branch, the data is accompanied by information about the status of the ports and

embedded microprocessor. The dual port memory is then read by the MPP via a second

transceivers.

the module circuits by opto-isolators and connected t

The ports are capable of powering modems or line drivers for transmission over long

o field connector J2 at the rear of the

Power for the module circuits is derived from the dual redundant SC300E power supply units,

individual auctioneering and regulating circuits supplying various logic areas. The

communications port opto-isolators and interfaces also have separate supplies.

Page 10

10

MSR04X

I

October

2005–

Issue 8

Triguard

SC300E

Figure 2-3

Serial communications module –

Block diagram

Page 11

MSR04X

I

October

2005–

Issue 8

11

Triguard

SC300E MSR04XI Serial Communications Module RS232

SERVICING

SCOPE

CAUTION: 1

The module contains components that may be electrostatically sensitive, it should be

transported and stored in its original packaging material.

System repair is by module replacement. Faulty modules are not repairable in the field; they

should

be

returned for repair.

DIA

GNOSIS

The TriBuild workstation is used for fault diagnosis. In the case of an Input/Output fault the

Health LED on the faulty module will be extinguished.

REMOVAL AND REPLACEMENT

CAUTION 2

Failure to take the faulty module off-line before removing it from the chassis could trigger a fault

alarm

or

cause plant shutdown.

CAUTION 3

When inserting a module ensure that it is aligned with the markings on the chassis rails and

that

it

engages with the upper and lower guides. Improper insertion may cause damage tothe

module and/or chassis connectors.

Operate the On/off Line Request switch on the faulty module, the three On Line LEDs should

all extinguish to indicate that the MPPs have recognised the request and taken the module off

line.

Slacken the two module securing screws and use the black ejection levers (top and bottom) to

draw

the module from its slot.

Insert the new module ensuring that it engages properly in the upper and lower guides in the

chassis, the top and bottom chassis rails carry alignment marks to assist. Pull out the

ejection levers and as the module is pushed back engage the levers on the chassis rails. The

levers

should then be used to draw the module into position, some resistance will be felt as the

rear

connector pins engage. The module should be fixed in position with the securing screws.

-

Page 12

12

MSR04X

I

October

2005–

Issue 8

Triguard

SC300E

Operate the On/off Line Request switch and check that the three On Line LEDs illuminate for

one second, extinguish for one second and then illuminate permanently to indicate that the

module has been put on-line. If the LEDs do not illuminate either the first or second time or fail

to remain illuminated, then the module must be considered faulty.

PREVENTIVE MAINTENAN

No preventive maintenance is necessary.

CE

Page 13

MSR04X

I

October

2005–

Issue 8

13

Triguard

SC300E MSR04XI Serial Communications Module RS232

SERVICE SUPPORT

SPARE PARTS

Spare parts and technical advice can be obtained from your local area office

.

Loading...

Loading...