Page 1

Installation Instructions

IMPORTANT

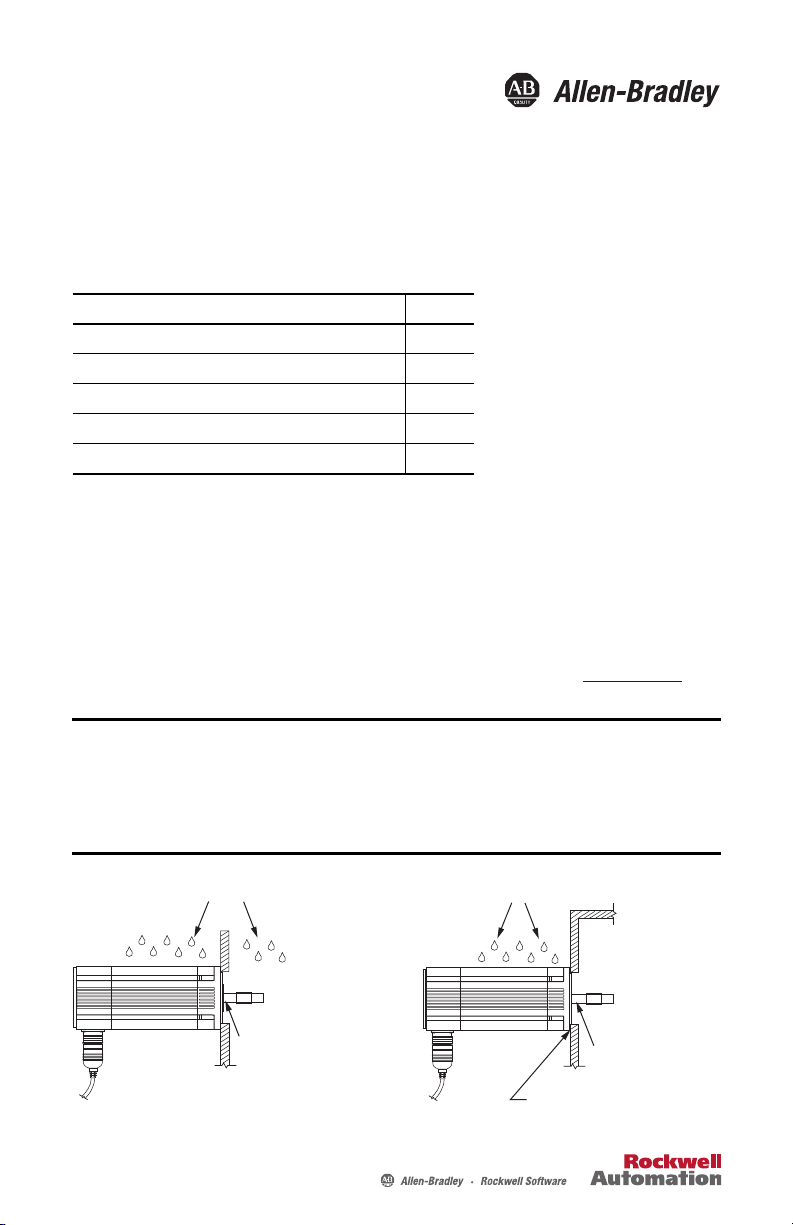

Oil, Fluids, and Fine Dust

Oil, Fluids, and Fine Dust

Shaft Seal Installation

is Recommended

Shaft Seal Installation

is Not Recommended

Sealant between Motor

and Machine (optional)

Motor Shaft and

End Bell are Exposed

to Containments

Motor Shaft and

End Bell are Protected

From Containments

Shaft Seal Kits

Catalog Numbers VPL-SSN, VPF-SSN, MPL-SSN, MPF-SST, MPS-SST, TL-SSN

Topi c Pag e

About Shaft Seals 1

Required Tools 2

Install a Shaft Seal 2

Shaft Seal Kit Catalog Numbers 4

Additional Resources 6

About Shaft Seals

A shaft seal is recommended if the motor shaft and end bell are exposed to significant amounts of

containments, such as oil, fluids, or fine dust. Use a shaft seal in these environments to prolong

the life of the motor. A shaft seal and Bulletin 2090 cables with environmentally sealed

connectors are required for an IP66 rating or greater.

See Kinetix® Motion Accessories Specifications Technical Data, publication GMC-TD004

find Bulletin 2090 cables with environmentally sealed connectors for your motor.

, to

The shaft seal is not recommended in applications where the motor shaft and end bell are free of oil, fluids, or

fine dust, and a lower IP rating is sufficient.

Shaft seals are subject to wear and require periodic inspection and replacement. Replacement is recommended

every 3 months, not to exceed 12 months, depending on use.

If you paint the motor, do not get paint on the shaft seal area or the shaft. This can decrease the life of the shaft

seal.

Page 2

2 Shaft Seal Kits

IMPORTANT

IMPORTANT

Required Tools

Use these tools to install a shaft seal:

• Rubber/wooden mallet, or a metal hammer and wooden work piece

• Socket, pipe, or tubing (various sizes)

• Abrasive cloth (to remove any nicks or burrs from the motor shaft)

Install a Shaft Seal

ATT EN TI ON : To avoid injury or damage to the equipment, remove power from the motor before installing the

shaft seal.

Follow these steps to install the shaft seal.

1. Verify that power is removed from the motor.

2. Remove the shaft key (if installed).

3. Remove the old shaft seal (if installed).

4. Remove any dirt or grease from the motor shaft and the area around the front end bell of

the motor near the bearing.

5. Use an abrasive cloth to remove any nicks or burrs from the motor shaft.

6. Cover the sharp edges of the keyway with tape to protect the seal lip from damage.

7. Lubricate the inner and outer lip of the shaft seal with the lubricant in the kit.

Shaft seals must be lubricated. Lubricant is supplied with the shaft seal kits.

8. Position the shaft seal so that the sealing lip faces outward on the shaft.

9. Slide the shaft seal onto the motor shaft.

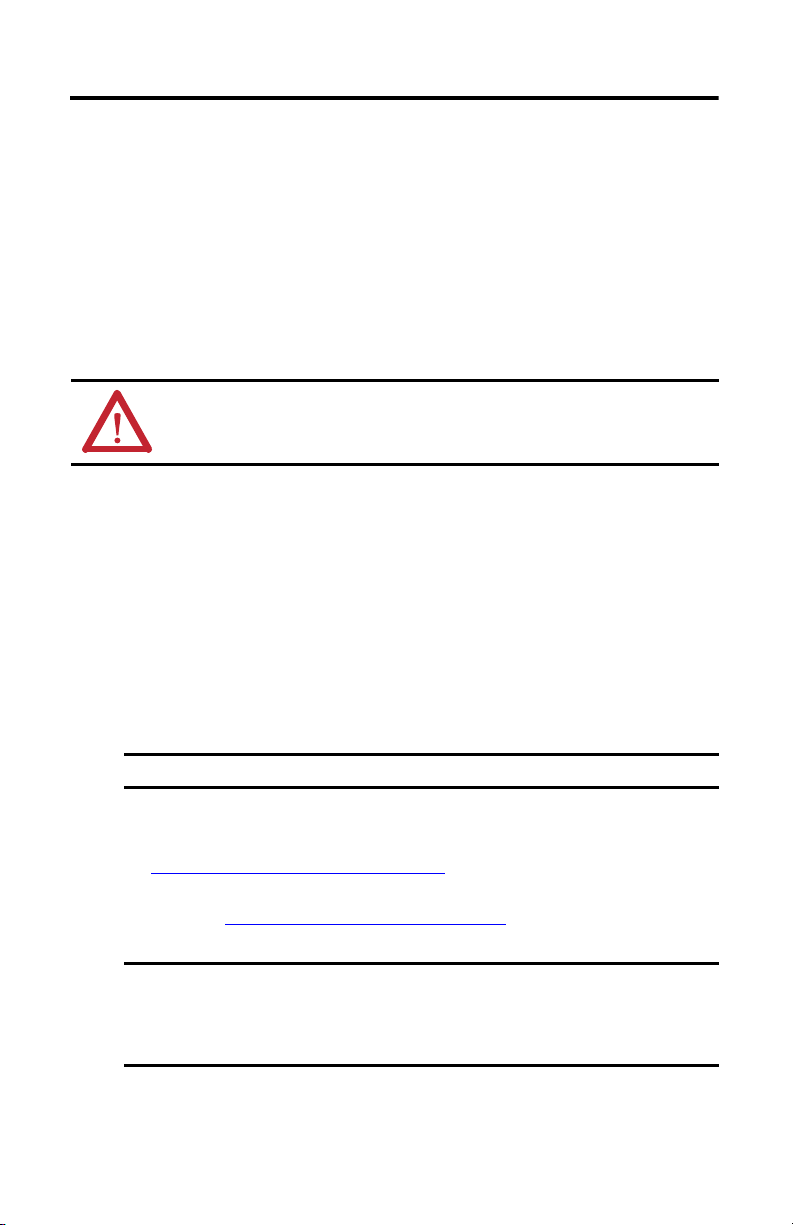

10. See Shaft Seal Installation Clearances

the shaft seal.

11. Use one of the Shaft Seal Installation Methods

diameter of the shaft seal into the motor.

Verify that the shaft seal is installed to the correct installation clearance.

If the shaft seal is installed too deep, it can be subject to excessive wear and require frequent

replacement.

If the shaft seal is installed too shallow, it can reduce the effectiveness of the protective seal.

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

on page 3 for the correct installation clearance of

on page 4 to gently press the outer

Page 3

Shaft Seal Kits 3

Front Surface

of Motor

Shaft Seal Pressed

Flush with Front

Surface of Motor

Shaft Seal Pressed

Below Front

Surface of Motor

Front Surface

of Motor

Nom

Nom

Min

Max

Shaft Seal Installation Clearances

Motor Cat. No. Shaft Seal Installation Clearance

Min, mm (in.) Nom, mm (in.) Max, mm (in.)

VPL-A/Bxxx Press the shaft seal so that the seal is flush or below the front surface of the motor.

VPF-A/Bxxx

VPS-Bxxx

MPL-A/B15xx

MPL-A/B2xx

All other MPL-A/Bxxx Press the shaft seal so that the seal is flush or below the front surface of the motor.

MPF-A/Bxxx

MPS-A/Bxxx

MPM-xxxx Press the shaft seal so that the seal is flush or below the front surface of the motor.

MDF-SBxxx 1.40 (0.055) 1.50 (0.060) 1.65 (0.065)

TL-Series Press the shaft seal so that the seal is flush or below the front surface of the motor.

1.40 (0.055) 1.50 (0.060) 1.65 (0.065)

1.50 (0.060) 2.00 (0.080) 3.00 (0.120)

1.40 (0.055) 1.50 (0.060) 1.65 (0.065)

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Page 4

4 Shaft Seal Kits

IMPORTANT

IMPORTANT

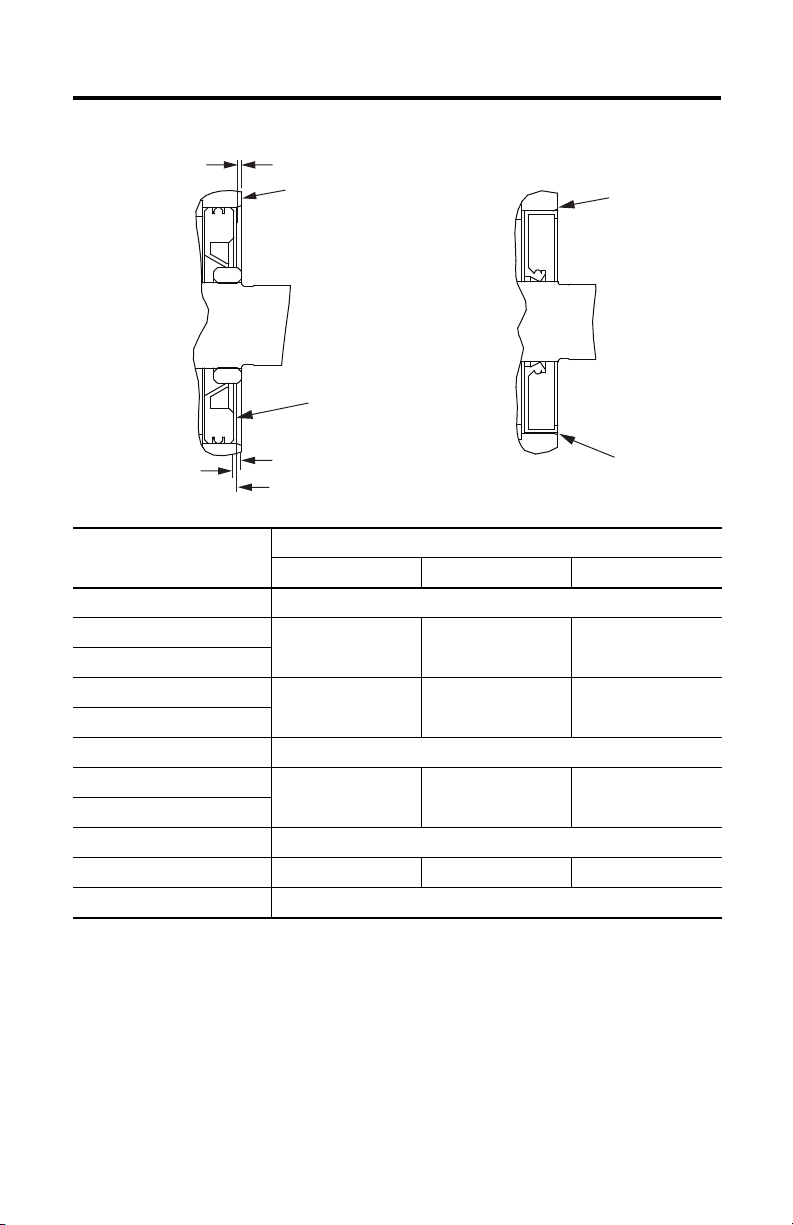

Socket, Pipe, or Tubing

(supplied by the customer)

Motor

Metal

Hammer

Shaft Seal

Wood en

Work

Piece

Rubber or

Wooden Mallet

Motor

Shaft Seal

Socket, Pipe, or Tubing

(supplied by the customer)

Or

Shaft Seal Installation Methods

This section shows the recommended installation methods for the shaft seals.

Do not hammer directly on the shaft seal. Gently tap the socket, pipe, or tubing evenly around the outer

edge of the shaft seal until the shaft seal is pressed into place.

Shaft Seal Kit Catalog Numbers

Third-party shaft seals are not approved for use with these motors. The use of third-party shaft seals voids any

implied or expressed warranties.

Kinetix VP Low Inertia Motors

Motor Cat. No. Shaft Se al Kit Cat. No.

VPL-A063xx and VPL-B063xx

VPL-A075xx and VPL-B075xx

VPL-A100xx and VPL-B100xx MPL-SSN-A3B3

VPL-A115xx and VPL-B115xx MPL-SSN-A4B4

VPL-A130xx and VPL-B130xx MPL-SSN-A5B5

VPL-B165xx MPL-SSN-F165

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

VPL-SSN-F063075

Kinetix VP Food Grade Motors

Motor Cat. No. Shaf t Seal Kit Cat. No.

VPF-A063xx and VPF-B063xx

VPF-A075xx and VPF-B075xx

VPF-A100xx and VPF-B100xx MPF-SST-A3B3

VPF-A115xx and VPF-B115xx MPF-SST-A4B4

VPF-A130xx and VPF-B130xx MPF-SST-A45B45

VPF-B165xx MPF-SST-F165

Kinetix VP Stainless Steel Motors

Motor Cat. No. Shaf t Seal Kit Cat. No.

VPS-B1304D MPS-SST-A45B45

VPS-B1653D MPS-SST-F165

VPF-SSN-F063075

Page 5

Shaft Seal Kits 5

MP-Series Low Inertia Motors

Motor Cat. No. Shaft Seal Kit Cat. No.

MPL-A15xx and MPL-B15xx

MPL-A2xx and MPL-B2xx

MPL-A3xx and MPL-B3xx MPL-SSN-A3B3

MPL-A4xx and MPL-B4xx MPL-SSN-A4B4

MPL-A45xx and MPL-B45xx MPL-SSN-A5B5

MP L-A52 0 and MPL- B520

MP L-A54 0 and MPL- B540

MP L-A56 0 and MPL- B560

MPL-B580 MPL-SSN-F165-32MM

MPL-B6xx MPL-SSN-A6B6

MPL-B8xx MPL-SSN-A8B8

MPL-B9xx MPL-SSN-A9B9

MPL-SSN-F63F75

MPL-SSN-F165

MP-Series Food Grade Motors

Motor Cat. No. Shaft Seal Kit Cat. No.

MPF-A3xx and MPF-B3xx MPF-SST-A3B3

MPF-A4xx and MPF-B4xx MPF-SST-A4B4

MPF-A45xx and MPF-B45xx MPF-SST-A45B45

MPF-A5xx and MPF-B5xx MPF-SST-F165

MP-Series Medium Inertia Motors

Motor Cat. No. Shaft S eal Kit Cat. No.

MPM-A115xx and MPM-B115xx MPL-SSN-A4B4

MPM-A130xx and MPM-B130xx MPL-SSN-A5B5

MPM-A165xx and MPM-B165xx MPL-SSN-F165

MPM-A215xx and MPM-A215xx MPL-SSN-A6B6

Kinetix 6000M Integrated Drive-Motor

Motor Cat. No. Shaft Seal Kit Cat. No.

MDF-SB1003 MPF-SST-A3B3

MDF-SB1153 MPF-SST-A4B4

MDF-SB1304 MPF-SST-A45B45

TL-Series Motors

Motor Cat. No. Shaft Seal Kit Cat. No.

TLY-A1xx and TL-A1xx TL-SSN-1

TLY-A2xx and TL-A2xx TL-SSN-2

TLY-A25xx and TL-A25xx

TLY-A3xx

TL-A4xx TL-SSN-4

TL-SSN-3

MP-Series Stainless Steel Motors

Motor Cat. No. Shaft Seal Kit Cat. No.

MPS-A3xx and MPS-B3xx MPS-SST-A3B3

MPS-A45xx and MPS-B45xx MPS-SST-A45B45

MPS-B5xx MPS -SST-F165

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Page 6

6 Shaft Seal Kits

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

Resource Description

Kinetix Motion Control Selection Guide,

publication GMC-SG001

Kinetix Rotary Motion Specifications,

publication GMC-TD001

Kinetix Motion Accessories Specifications,

publication GMC-TD004

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, http://www.ab.com

Overview of Kinetix servo drives, motors, actuators, and motion

accessories designed to help make initial decisions for the motion control

products best suited for your system requirements.

Product specifications for Kinetix VP (Bulletin VPL, VPF, VPS), MP-Series™

(Bulletin MPL, MPM, M PF, MPS), Kine tix 6000M (Bulletin MDF),

TL-Series™, RDD-Series™, and HPK-Series™ rotary motors.

Product specifications for Bulletin 2090 motor and interface cables,

low-profile connector kits, drive power components, and other servo drive

accessory items.

Provides general guidelines for installing a Rockwell Automation industrial

system.

Provides declarati ons of conformity, cer tificates, and other ce rtification

details.

You can view or download publications at http://www.rockwellautomation.com/literature/

. To

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Page 7

Notes:

Shaft Seal Kits 7

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Page 8

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact

your local distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/rockwellautomation/support/overview.page

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

you can find technical and application notes, sample code, and links to software

for software updates, support chats

at

, or contact your

.

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Allen-Bradley, Rockwe ll Software, Rockwell Automation, Kinetix, MP-Series , RDD-Series, HPK-S eries, and TL-Series are trademarks of

Rockwell Automation, Inc.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 2090-IN012C-EN-P - February 2014 PN-237636

Supersedes Publication 2090-IN012B-EN-P - January 2007 Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...