Rockwell Automation Allen-Bradley Guardmaster TLSZ Series, Allen-Bradley Guardmaster TLSZR-GD2 User Manual

Page 1

User Manual

Original Instructions

TLSZ Guardmaster Guard Locking Switch

Catalog Numbers 440G-TZS21UPRH, 440G-TZS21UPLH, 440G-TZS21UTRH, 440G-TZS21UTLH

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Preface

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General Description Guardmaster TLSZ Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Catalog Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Packaging Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installation General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Actuator/Target Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Allowable Approach Directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Minimum Operating Radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Manual Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Manual Override Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pair Proximity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Guide Repositioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Steel Locking Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Actuator Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

OSSD Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

OSSD Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Auxiliary Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Lock Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Commissioning Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

First Time Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Learning First Target . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Learning Additional Targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Commissioning Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Power-up Self Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Functional Testing Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Rockwell Automation Publication 440G-UM001C-EN-P - January 2018 3

Page 4

Table of Contents

Application and Wiring Examples Wiring to GLP Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Wiring to GLT Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wiring to DI and EMD Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wiring to DG Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring to CR30 Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wiring to 1734 Guard Point I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wiring to 1732 ArmorBlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Diagnostics and Troubleshooting Tools Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Optional Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Step 1 — Status Indicator OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Step 2 — Status Indicator Flashing Red at 4 Hz . . . . . . . . . . . . . . . . . 45

Wrong Target . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Missing Target . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Target Not Mounted Correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Pair Proximity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Mechanical Pressure on Safety Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Long Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Voltage Supply Dips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Rapid Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Step 3 - Status Indicator Flashes Red at 1 Hz . . . . . . . . . . . . . . . . . . . . 49

Capacitive Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Step 4 — Status Indicator Flashes Green at 1 Hz . . . . . . . . . . . . . . . . 50

Step 5 — Flashing Red and Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Step 6 — Indicator Solid Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Step 7 — Other Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Distribution Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

GSR Relays on Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Specifications and Safety Ratings Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Safety Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4 Rockwell Automation Publication 440G-UM001C-EN-P - January 2018

Page 5

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• Who would use this manual

• The purpose of this manual

• Related documentation

• Conventions used in this manual

Who Should Use This Manual

Purpose of This Manual

Conventions Used in This Manual

Use this manual to design, install, program, or troubleshoot systems that use

the TLSZ Guardmaster® guard locking safety switches.

You are required to have a basic understanding of electrical circuitry and

familiarity with safety-related control systems. If you do not, obtain the proper

training before using this product.

This manual is a reference guide for the Guardmaster TLSZ guard locking

switch. It describes the procedures you use to install, wire, and troubleshoot

your switch. This manual:

• Explains how to install and wire your TLSZ switch,

• Provides an overview of the Guardmaster TLSZ guard locking switch.

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

Additional Resources

The following documents offers additional information about related

Rockwell Automation products.

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication

Product Certifications website,

Rockwell Automation

Guardmaster 440C-CR30 Configurable Safety Relay

Wiring Diagrams

Allen-Bradley

1770-4.1

rok.auto/certifications Provides declarations of conformity, certificates for the

Functional Safety Data Sheet Provides functional safety data and details for

Industrial Automation Glossary Glossary of industrial automation terms and

You can view and download publications at

Provides general guidelines for installation of a

RockwellAutomation® industrial system.

TLSZ guard locking switch.

RockwellAutomation products.

Provides example wiring diagrams for the CR30 software

configuration safety relay.

abbreviations

http://

www.rockwellautomation.com/literature/ . To order paper copies of technical

documents, contact your local Rockwell Automation distributor or sales

representative.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 5

Page 6

Preface

Terminology

The Industrial Automation Glossary contains terms and abbreviations used by

Rockwell Automation to describe industrial automation systems. Below is a list

of specific terms and abbreviations used in this manual.

NC No connection

N.C. (Normally

Closed)

N.O. (Normally

Open)

PLC A programmable logic controller or a programmable

PTL (Power to

Lock)

PTL (Power to

Release)

Reaction Time Describes the time between the true state of the input to

An electrical contact whose normal state (for example,

no pressure or electrical potential applied) is in the

closed position.

An electrical contact whose normal state (i.e., no

pressure or electrical potential applied) is in the open

position.

automation controller.

Apply 24V to the lock command to lock the switch. This

command applies to the TLSZL switch.

Apply 24V to the lock command to unlock the switch.

This command applies to the TLSZR switch.

the ON state of the output.

Response Time Describes the time between the trigger of the input to

the OFF state of the output. Throughout this manual,

the safety outputs may be described as turning off

immediately. This means that the safety outputs will

turn off within the response time.

RFID Radio frequency identification.

OSSD (Output

Signal

Switching

Device)

Standard

coding

TLSZL TLSZ power-to-lock guard locking switch

TLSZR TLSZ power-to-release guard locking switch

Unique coding Same as High coding as defined in ENISO14119:2013

Typically a pair of solid-state signals pulled up to the DC

source supply. The signals are usually tested for short

circuits to the DC power supply, short circuits to the

DC common, and short circuits between the two

signals.

Same as Low coding as defined in ENISO14119:2013

6 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 7

General Description

Chapter 1

Guardmaster TLSZ Overview

This Guardmaster® TLSZ guard locking switch functions by locking it

actuator, which prohibits the opening of a guard.

TLSZ uses radio frequency identification, RFID, coding to detect the

The

appropriate target.

This version of the Guardmaster TLSZ guard locking switch features OSSD

outputs. These outputs are enabled only when the actuator is locked and the RF

target is sensed.

This device is intended to be part of the safety-related control system of a

machine. Perform a risk assessment before installation to determine whether

the specifications of this device are suitable for all operational and

environmental characteristics of the machine. See

certification information and ratings.

Use nonremovable screws, bolts, or nuts to mount the switch and actuators. Do

not over torque the mounting hardware.

TLSZ guard locking switches are classified according to ISO 14119 as Type 4

switching devices. The RFID targets are classified as having a high level of

coding.

Specifications on page 55 for

Measures are to be taken to minimize the need to defeat and to manage the use

and availability of spare RFID targets.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 7

Page 8

Chapter 1 General Description

Catalog Numbers

The schema for the TLSZ catalog number is shown in Table 1. The parts of the

schema are shown in Table 2.

Table 1 - TLSZ Catalog Number Setup

440 G T Z S21 U P R H

1 234 5 6789

Table 2 - TLSZ Catalog Number Detail

Parameter Value Description

1 440 Safeguards the Product

2 G Guard locking switch

3 T Titan Locking Switch

4 Z PLe rated, cascadable safety signals

5 S21 Solid-state outputs, 2 safety (OSSD), 1 aux

6 U Unique coded RFID target

7PTAux signal shows lock status

Aux signal shows door status

8RLPower to Release

Power to Lock

9 H 8-pin M12 QD connector

ATTENTION: Guard lock switches that use the Power to Lock principle can

only be used after a risk assessment has shown that the Power to Release

principle is inappropriate for the application. If a power supply loss occurs

with Power to Lock switches, the switches immediately become unlocked

and the user may have access to the hazards.

8 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 9

General Description Chapter 1

Packaging Contents

Figure 1 shows the contents in the shipping package. The contents include:

•Switch

• Actuator

• RFID target

• T20 security Torx bit

• Two steel bolts and nuts

•Plug

• Installation instructions (not shown)

Figure 1 - Package Contents

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 9

Page 10

Chapter 1 General Description

Notes:

10 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 11

Installation

Chapter 2

General Considerations

Actuator/Target Mounting

The TLSZ guard locking switch is designed for use on guards that are engineered to

be rigid and without sag. The TLSZ uses radio frequency identification, RFID,

coding to detect the appropriate target.

Figure 2 shows the correct and incorrect ways to mount the target with the

actuator.

The TLSZ must only be used with the fully flexible actuator. The replacement

part number for the actuator is catalog number 440G-A27143.

Figure 2 - Target/Actuator Mounting

Tar ge t

Actuator

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 11

Page 12

Chapter 2 Installation

Allowable Approach Directions

The actuator and target must be always mounted as “close coupled” and can

approach the switch in any of the three entry slot positions that are shown in

Figure 3. Approach from the underside is not allowed, as the distance from the

target to the internal RF sensor is too far for reliable operation.

Figure 3 - Allowable Approach Direction

This approach requires

guide repositioning, see

page 14.

Minimum Operating Radius

When applied to hinged doors, the minimum operating distances along the

length and perpendicular is shown in

Figure 4 - Minimum Operating Distance [mm (in.)]

80 (3.19)

Figure 4.

80 (3.19)

80 (3.19)80 (3.19)

Figure 5 shows the location of the two 1.5 mm (0.06 in.) set screws that can be

adjusted to preset the actuator to an optimal angle, if needed.

Figure 5 - Actuator Set Screw

1.5 mm (0.06 in.)

12 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 13

Installation Chapter 2

Manual Release

The manual release feature only applies to TLSZR (Power to Release) switch.

In some cases, you must manually release the locked actuator.

Figure 6 shows the two locations from which the actuator can be manually

released.

Remove the T20 Torx screw.

1.

2. To release the actuator, insert a small screwdriver or rod in the hole.

If power is applied to the switch when the actuator is released, the OSSD safety

outputs turn OFF and the switch goes to a faulted state with the status

indicator flashing red at 4 Hz. Power then has to be cycled to the switch to

return it to an operational state.

Figure 6 - Manual Release

3

1

2

T20

Manual Override Cover

2

≤ 2.5 (0.10) Ø

Figure 7 on page 14 shows an optional cover that is available only for the

TLSZR (Power to Release) switch. This cover has a lever that allows you to

manually unlock the actuator at any time. Rotate the lever 90° to unlock the

actuator.

If power is applied to the switch when the actuator is released, the OSSD safety

outputs turn OFF, and the switch goes to a faulted state with the status

indicator flashing red at 4 Hz. Power is then cycled to the switch to return it to

an operational state.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 13

Page 14

Chapter 2 Installation

Figure 7 - Manual Override Cover

Pair Proximity

1

1.2 N•m (10.62 lb•in)

90°

2

90°

If a pair of TLSZ switches are mounted too close to each other, the two RF

fields could interact causing crosstalk. Cross talk results in nuisance faults.

An absolute minimum of 200 mm (8 in.) must be used to help achieve correct

operation.

The restriction also applies if a TLSZ switch is mounted close to the 440G-LZ

guard locking and the 440N-Z SensaGuard™ switches.

Guide Repositioning

The actuator guide can be repositioned to facilitate alignment of the actuator.

In steps 8…11, rotate the metal guide to allow the switch body to be fastened

flush to the mounting surface.

Figure 8 - Guide Repositioning

2

3

1

8

5

4

180°

10

9

6

11

7

14 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 15

Installation Chapter 2

Steel Locking Bolts

The TLSZ is assembled in the factory with plastic pins that secure the actuator

guide. The plastic pins are rated for a holding force of 1500 N (337 lb). The

plastic pins must be replaced with the steel bolts to achieve a holding force of

2000 N (585 lb).

Figure 9 shows how to remove the cover to replace the blue

plastic pins with steel bolts.

Figure 9 - Steel Bolt Installation

1.2 N•m (10.62 lb•in.)

5 (0.20)

dia.

Steel bolts

2 x M5

1.4 N•m

(12.39 lb•in.)

1.2 N•m (10.62 lb•in.)

2 x M5

1.4 N•m (12.39 lb•in.)

Plastic pins

15 (0.59)

Actuator Clearance

Fzh = 1500 N (337 lb)

Fzh = 2000 N (450 lb)

Figure 10 shows the clearance requirements for the TLSZ. The switch must

not be used as a guard stop. You must provide a mechanical stop at least 1mm

(0.04 in.) away from the actuator guide. The actuator must be inserted within

4mm (0.16 in.) or less from the actuator guide to be sure it locks.

Figure 10 - Clearance and Insertion Distance

1…4 (0.04…0.16)

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 15

Page 16

Chapter 2 Installation

As shown in Figure 11, the TLSZ has two slotted holes to facilitate

installation. The slots allow up to 8 mm (0.31 in.) of movement of the switch

body to achieve the proper clearance with the actuator.

1. Use the slotted holes for initial installation.

2. After alignment with the actuator, secure the switch body in place by

adding mounting hardware in the circular holes.

3. To attain the maximum holding force, replace the plastic pins with steel

screws inside the cover.

Figure 11 - Mounting Slots for Alignment [mm (in.)]

M5

12

3

Status/

Diagnostic

8 (0.31)

16 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 17

Installation Chapter 2

Dimensions

Figure 12 shows the dimensions for the switch, target, and actuator.

Figure 12 - Dimensions [mm (in.)]

14

(0.55)

33 (1.3)

3 (0.12)

86 (3.39)

3 (0.12)

M12

14 (0.55)

57 (2.24)

6.5 (0.26)

Status/

Diagnostic

LED

73 (2.87)

126 (4.96)

9 (0.35)

105 (4.13)

5 (0.2)

M5 x 4

31.5 (1.24)

52.5 (2.07)

6.5 (0.26)

Do not use cable gland knockouts, two places

60.5 (2.38)

67.5 (2.66)

21

(0.83)

17 (0.67)

43 (1.69)

Target Alignment Mark

23.2 (0.91)

11.9

(0.47)

440G-ATZAE-xxxx

Tar ge t

18

(0.71)

29.3 (1.15)

M5

7

(0.28)

5.5

(0.22)

5 (0.2)

5.5 (0.22)

6 (0.24)

19

(0.75)

20

(0.79)

5 (0.2)

25.5 (1)

20.5 (0.81)

14 (0.55)

22 (0.87)

6.5 (0.26)

21 (0.83)

14.5

(0.57)

4 (0.16)

27 (1.06)

17

(0.67)

39 (1.54)

19

31 (4.22)

40 (1.57)

52 (2.05)

Actuator

13

(0.51)

(0.75)

8

(0.31)

51

(2.0)

20

(0.79)

24

(0.94)

2.2 (0.09)

4.2 (0.17)

19.2 (0.76)

Connector location and

dimensions

2 x M3

4 x 5.5 (0.22)

6.8

(0.27)

Use with exible actuator only:

Figure 13 on page 18 shows the dimensions for mounting the target that is next

to the actuator.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 17

Page 18

Chapter 2 Installation

Figure 13 - Actuator/Target Mounting Dimensions [mm (in.)]

7 (0.28)

5.5 (0.22)

6 (0.24)

6 (0.24)

20

(0.79)

Tar ge t

Actuator

35

(1.38)

40

(1.57)

13 (0.51)

19

(0.75)

3 x M5

86.5

(3.4)

18 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 19

Wiring

Chapter 3

Connections

The TLSZ is only available with an 8-pin DC Micro M12 quick-disconnect

connector. Figure 14 and Table 3 show the pin assignments and their functions

and typical mating cordsets. Other cordsets are available at

DC Micro Cordsets

and Patchcords.

Figure 14 - 8-pin Micro Quick Disconnect Cables

3 Lock Command

2 24V DC+

8 Safety A+ Input

4 Safety B+ Input

1 Aux

7 0V

5 Safety A Output

6 Safety B Output

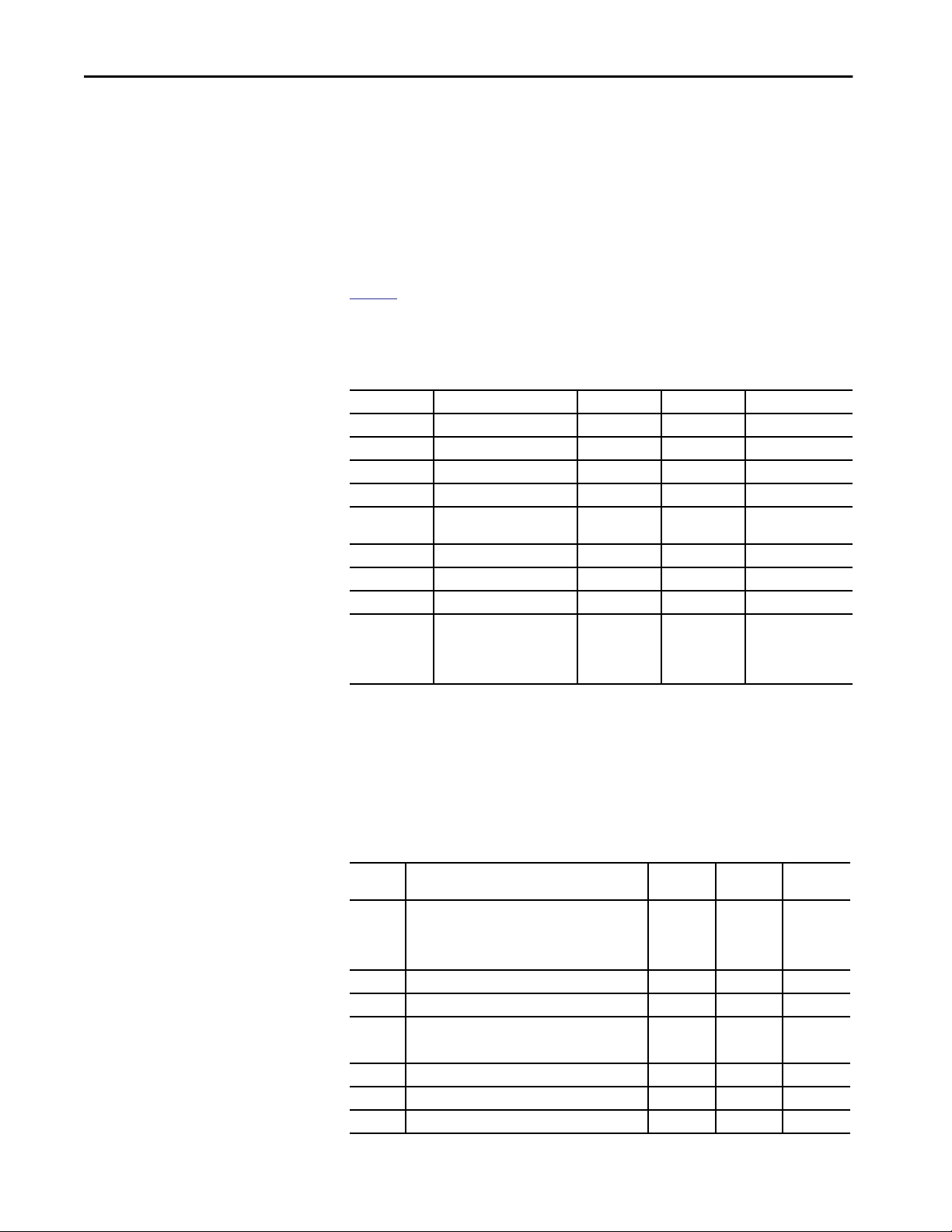

Table 3 - TLSZ Quick Disconnect Pin Assignments

Typical Mating Cordsets Color Function Pin

889D-F8NB-x

(Red, PVC)

889D-F8AB-x

(Black, PVC)

1

1

White Aux 1

Brown 24V DC Supply 2

Green Lock Command 3

Yellow Safety B+ Input 4

Grey Safety A Output (OSSD A) 5

Pink Safety B Output (OSSD B) 6

Blue Ground (0V) 7

Red Safety A+ Input 8

OSSD Inputs

OSSD Outputs

1

Replace symbol with 2 [2 m (6.56 ft)], 5 [5 m (16.4 ft)], 10 [10 m (32.8 ft)], 15 [15 m (49.2 ft)] 20 [20 m [65.62 ft)] or 30 [30 m

(98.4ft)] for standard cable lengths. The TLSZ has been tested to operate with up to 120 m (393.7 ft) of the mating cables.

The OSSD inputs are Safety A+ and Safety B+. These inputs can be pure

24VDC, or they can contain test pulses. The OSSD inputs allow the TLSZ

switches to be connected in-series while maintaining a high level of safety

performance.

The OSSD outputs are Safety A and Safety B. These outputs are 24V signals

that contain test pulses. The test pulses are used to detect short circuits to 24V,

to 0V and cross faults (from Safety A to Safety B). This description of the test

pulses is provided for informational purposes; you cannot modify them.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 19

Page 20

Chapter 3 Wiring

Figure 15 shows the safety output test pulses when connected to a 1K resistive

load for hardware (HW) revisions A and B, and for firmware (FW) revisions A

through C. The pulses are 25 μs wide and repeat every 20 ms. The exact shape

of the pulses depends on the nature of the load. The capacitive and resistive

effects of the load are determined with the combination of cabling, cable

routing, and connected devices.

Figure 15 - Output Test Pulses

Safety B (Pink)

Safety A (Grey)

5V/Div

Auxiliary Output

Lock Command

25μs/Div

Table 4 shows the auxiliary output functions. The auxiliary output is a 24V

DC logic signal, whose function is dependent on the catalog number selected.

The auxiliary signal responds independently of the OSSD safety outputs. The

auxiliary output is not a safety-rated signal and must only be used to indicate

the status of the switch.

Table 4 - Auxiliary Output Function

Catalog Number Function Value

440G-TZS21UPRH

440G-TZS21UPLH

440G-TZS21UTRH

440G-TZS21UTLH

Lock Status 24V when actuator is unlocked

0V when actuator is unlocked

Actuator Status 24V when actuator inserted (gate closed)

0V when actuator removed (gate open)

Table 5 shows the lock command function. The lock command is a 24V logic

signal, with a current of less than 5 mA. The function of the logic signal is

dependent on the catalog number. The 24V power supply connection provides

the power to operate the locking solenoid.

Table 5 - Lock Command Function

Catalog Number Switch Type Function

440G-TZS21UPRH

440G-TZS21UTRH

440G-TZS21UPLH

440G-TZS21UTLH

20 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Power to Release 24V unlocks the actuator

0V locks the actuator

Power to Lock 24V locks the actuator

0V unlocks the actuator

Page 21

Chapter 4

Commissioning

Before use, the switch must first “learn” a new RFID target. This step is not

done at the factory.

The switch can learn up to eight targets consecutively. Use this process if there

is a potential for the target to become damaged, inoperable, or lost. When a

new target is learned, the switch no longer recognizes the older target.

Preparation

Wire up the switch with at least the functionality shown in Figure 16.

• Power — connect brown wire to +24V.

• Gnd — connect blue wire to 0V.

• Lock — Leave the green wire ‘open’ when learning the first target.

Connect the green wire to 24V to teach a TLSZR switch subsequent

targets. The TLSZL switch ignores the Lock command during learning.

• Safety A+ and Safety B+ — connect red and yellow wires to 24V during

commissioning. If 24V is not applied to the A+ and B+ inputs, then the

indicator flashes green after commissioning if the switch is locked.

• Safety A and Safety B — optional, no connection required for

commissioning.

• Aux — optional, no connection required for commissioning.

Figure 16 - Commissioning Wiring

+24V DC

TLSZ-GD2

Status Diag

889D-F8NB-x

or

889D-F8AB-x

Brown (+24)

Red (Safety A+)

Yellow (Safety B+)

Green (Lock)

Gray (Safety A)

Pink (Safety B)

White (Aux)

Blue (Gnd)

24V DC Com

Lock

NC

NC

NC

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 21

Page 22

Chapter 4 Commissioning

First Time Power-up

Learn First Target

Turn on the 24V DC power without the actuator and target.

The Status/Diagnostic indicator blinks green 3 times, pauses 2 seconds, and

then blinks green 8 times. Eight is the number of times a new target can be

learned. The switch continuously repeats the two-second pause followed by the

eight blink sequence.

Table 6 shows the events that take place when the first target is learned. The

lock command is ignored until after the switch learns its first target, therefore,

the lock command can be 24V or 0V during the first-time learning sequence.

Table 6 - First Target Learning Events

Step Event Indicator Color Blink Rate D uration

1 Apply power to switch Red Solid —

2 Present actuator/target Red Solid —

3 Detect target Red Solid 2…25 s

4 Verifying target Green/Red 1 Hz 15 s

5 Report commissioning error

(see Table 8) or continue

6 Programming switch Green/Red 4 Hz 15 s

7 Finalizing Red Solid 2 s

8 Number of learns remaining Green # of learns 15 s

9 Learn completed

PTR Green Solid Continuous

PTL Red

———

Learning Additional Targets

Table 7 shows the steps that take place when teaching the switch to recognize

an additional target. For PTR switches, the lock command must connect to

+24V to learn additional targets. The PTL switch ignores the lock command

during learning.

Table 7 - Additional Target Learning Steps

Step Event Indicator

1 Apply power to switch Red Solid —

PTR: Apply 24V to lock command

PTL: Ignores lock command

2 Present new actuator/target Red Sold —

4 Detect target Red Solid 3…25 s

5 PTR: Solenoid automatically locks Red Solid 05.s

PTL: No action

6 Verifying target Green/Red 1 Hz 15 s

7 Report commissioning error (see Table 8) or continue — — —

8 Programming switch Green/Red 4 Hz 15 s

22 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Color

Blink Rate Duration

Page 23

Commissioning Chapter 4

Commissioning Errors

Step Event Indicator

Color

9 Finalizing Red Solid 2 s

10 Number of learns remaining Green # of learns 15 s

11 PTR: Solenoid unlocks then locks — — 0.5 s

PTL: no action

12 Learn completed

PTR Red 4 Hz Continuous

PTL Red Solid

13 PTR: Cycle power — — —

PTL: Ready for use

Blink Rate Duration

During commissioning, the switch performs certain checks. If an error is

detected, the Status/Diagnostic indicator reports the error.

Table 8 lists the

commissioning error codes. The error code is generated after the switch verifies

the target. If an error code is generated, the switch must be power cycled before

further learning is started.

Table 8 - Commissioning Error Codes

Indicator Flashes (4 Hz) Code

Red-Red-Red-Green-Green Target already learned

Red-Red-Red-Green-Green-Green Bad RFID

Target that is removed while programming PTL

Red-Red-Red-Green-Green-Green-Green Exceeded learning eight targets

Power-up Self-check

Upon power-up, the TLSZ performs an internal self-check, which takes

approximately three seconds. Whether the actuator/target is inserted and the

lock command is present; the indicator remains red or turns green after the

self-check.

Table 9 shows the indicator sequence during self-check with the

actuator/target inserted. The self-check sequence occurs only once.

Table 9 - Self-check Indicator Sequence

Model Lock Signal Indicator Sequence OSSD Outputs

TLSZR OFF Green-Green-Green-Red-Green ON

ON Green-Green-Green-Red OFF

TLSZL OFF Green-Green-Green-Red OFF

ON Green-Green-Green-Red-Green ON

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 23

Page 24

Chapter 4 Commissioning

Notes:

24 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 25

Functional Testing

A manual functional electric test must be made:

• After installation

• After any maintenance or change of component

• If the guard is used infrequently

– Less than once per month for SIL 3/PLe

– Less than once per year for SIL 2/PLd

Chapter 5

Testing Procedure

ATTENTION: During the functional test, confirm that there are no persons in

the danger area and that the machine startup causes no hazard.

1. Confirm that the guard door is open.

2. Connect the 24V DC power to pin 2 and ground (0V) to pin 7. The

switch conducts a self-testing routine at the end of which the diagnostic

indicator shows solid red.

3. Test to confirm that the machine cannot start.

4. Confirm the lock command at pin 3 is set to 0V for PTR and 24V for

PTL types.

5. Test again to confirm that the machine cannot start.

6. Close the guard door and then confirm that the guard is mechanically

locked and the diagnostic indicator shows solid green.

7. Test to confirm that the machine can now start.

8. Change the lock command at pin 3. Set it to 24V for PTR and 0V for

PTL types.

9. Confirm the machine stops, the guard door is mechanically unlocked,

and the machine cannot restart.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 25

Page 26

Chapter 5 Functional Testing

Notes:

26 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 27

Chapter 6

Application and Wiring Examples

The following application and wiring examples are intended to show how the

TLSZ products can be applied. If you are the user or the designer, you may

require variations to these examples in order to meet their specific

requirements.

Wiring to GLP Relay

+24V DC

TLSZR-GD2

Status Diag

889D-F8NB-2

Brown (+24)

Red (OSSD A+)

Yellow (OSSD B+)

Green (Lock)

Grey (OSSD A)

Pink (OSSD B)

White (Aux)

Blue (Gnd)

Safety

Gate

The GLP safety relay is designed to operate with PTR switches. To use a PTL

switch, you must use an interposing relay on the lock command at GLP

terminal 51. In the example shown in

Figure 17, the GLP allows the gate to be

unlocked when the motor is running at a Safely-limited Speed.

Figure 17 - GLP and TLSZR Schematic

L1 L2 L3

Gate

Unlock

Request

LOGIC

9

8

7

GLP

440R-GL2S2P

51

0

1

4

56

L61

A1X14 X24 S44S54

SLS1

2

9

3

8

7

56

A2S12 S22 L11

AP

0

1

4

SLS2/TIME

2

3

P12 P22

Reset &

Gate Lock

Request

Y32

9

8

7

L12

0

1

2

3

4

56

Proximity Sensors

871TM-DH10NP30-D4

889D-F4AC-2

PowerFlex

11 +24V DC

1 Stop

2 Start

5 Preset Freq 1

4 Gnd

Gate control

power supply

Gate control

circuit

S1

S2

RTS

525

UWV

M

24V DC Com

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 27

Page 28

Chapter 6 Application and Wiring Examples

Circuit Status as Shown

The gate is open and unlocked. The motor is off. The GLP is ready for reset.

The GLP has a Logic setting of 3: (Safely-limited Speed with Logic IN OFF), a

Safely-limited Speed (SLS1) setting of 5 (5 Hz) and a maximum (SLS2) speed

setting of 8 (2000 Hz). The safety outputs (X14 & X24), the single wire safety

output (L11), and the auxiliary output (Y32) are OFF.

IMPORTANT Start the GLP logic configuration from “0” to configure X14 and X24 for use

as safety outputs.

Starting

Close the gate and press Reset to lock the gate and turn on the GLP safety

outputs. Press Start to turn the motor ON.

Safely-limited Speed

Wiring to GLT Relay

A normal production stop is performed by pressing Stop. Access through the

safety gate is initiated by pressing Gate Unlock Request. The Y32 output of the

GLP turns ON and commands the PowerFlex® drive to bring the motor to a

safe slow speed (Preset Freq 1). When the proximity sensors detect the speed

has dropped below the Safely-limited Speed (5 Hz), the gate becomes

unlocked. The operator can enter the machine cell, as the motor continues to

run at the safe slow speed. After you leave the cell and close the gate, press Reset

to lock the gate and return the machine to production speeds.

The circuit meets the safety requirements up to Category 3, Performance

Leveld in accordance with ISO 13849-1 and SIL CL 2 in accordance with

IEC 62061.

The GLT safety relay is designed to operate with PTR switches. To use a PTL

switch, you must use an interposing relay on the lock command at terminal 51

of the GLP.

In this example shown in

command to the drive to turn OFF. After eight seconds, the GLT turns off its

safety outputs and unlocks the gate. The risk assessment must determine

adequate time delay for the machine to achieve a safe state before unlocking the

gate.

Figure 18 on page 29, the GLT sends an immediate

28 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 29

+24V DC

Application and Wiring Examples Chapter 6

Figure 18 - GLT and TLSZR Schematic

Safety

Gate

TLSZR-GD2 440G-TZS21xxRH

Status Diag

889D-F8NB-2

Brown (+24)

Red (OSSD A+)

Yellow (OSSD B+)

Green (Lock)

Gray (OSSD A)

Pink (OSSD B)

White (Aux)

Blue (Gnd)

Gate

Unlock

Request

LOGIC

9

8

7

GLT

440R-GL2S2T

51

0

RANGE

1

2

9

3

8

4

56

7

A2S12 S22 24

L61

A1S11 S12 S44S54

L11

0

56

1

2

3

4

L12 14

Reset &

Gate Lock

Request

Y32

TIME

9

8

7

L1 L2 L3

PowerFlex

525

11 +24V DC

1 Stop

2 Start

B2

0

1

2

3

4

56

4 Gnd

Gate control

power supply

RTS

Gate control

circuit

S1

S2

UWV

M

24V DC Com

Circuit status as shown: The gate is open and unlocked. The motor is off. The

GLT is ready for reset. The GLT has a Logic setting of 3: (Category 1 Stop), a

Range setting of 4 (10 seconds) and a Time setting of 8 (80%). The Y32 output

turns OFF immediately; 8 seconds later, the safety outputs turn OFF.

The safety outputs (14 and 24) and the single wire safety output (L11) are

OFF and the auxiliary output (Y32) is ON.

IMPORTANT Start the GLT logic configuration from “0” to configure 14 and 24 for use with

pulse testing; the PF525 can operate with pulse tested inputs to S1 and S2.

Starting

Close the gate. Press Reset and Gate Lock Request to lock the gate and turn on

the GLT safety outputs. Press Start to turn the motor ON.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 29

Page 30

Chapter 6 Application and Wiring Examples

Stopping

Normal production stops are performed by pressing Stop. Access through the

safety gate is initiated by pressing the Gate Unlock Request. The Y32 output of

the GLP turns OFF, which commands the PowerFlex drive to bring the motor

to a stop. After the configured time delay (eight seconds) expires, the GLT

safety outputs turn off, and the gate becomes unlocked. After you leave the cell

and close the gate, press Reset to lock the gate and return the machine to a

production state.

The circuit meets the safety requirements up to Category 3, Performance

Leveld in accordance with ISO 13849-1 and SIL CL 2 in accordance with

IEC 62061.

Wiring to DI and EMD Relay

The TLZ can be connected to the DI and EMD safety relays. The DI monitors

the safety outputs of the TLZR and the EMD enables the gate to be unlocked

after a configured delay time expires.

B1 is connected to B2 to allow for retriggering. If you open and close the

E-stop and press Reset before the delay expires, the EMD timer resets.

Upon initial power-up, the TLSZ must be cycled for the DI to recognize the

TLSZ OSSD signals.

In the example shown in

shutdown. After an eight-second delay, the TLZR is allowed to be unlocked

and the hazards that remain are turned OFF. A selector switch is required to

maintain the gate in an unlock state. The risk assessment must determine

adequate time delay for the machine to achieve a safe state before unlocking the

gate.

Figure 19 on page 31, an E-stop initiates the machine

30 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 31

+24V DC

TLSZR-GD2 440G-TZS21xxRH

Application and Wiring Examples Chapter 6

Figure 19 - DI with EMD and TLSZR Schematic

Safety

Gate

Reset

24V DC Com

Status Diag

889D-F8NB-2

Brown (+24)

Red (OSSD A+)

Yellow (OSSD B+)

Green (Lock)

Grey (OSSD A)

Pink (OSSD B)

White (Aux)

Blue (Gnd)

S11 S21 S12S22

LOGIC

8

7

5

DI

440R-D22R2

S32 L11 Y32L12

6

A1

13 23

0

1

2

3

4

14S42 24

A2

S34

X32

A1

0

RANGE

9

8

4

7

56

EMD

440R-EM4R2D

L12

B1 B2

TIME

1

2

10

3

9

8

L11 38

Unlock

17 27 37 47

1

2

3

4

5

67

X32

4818 28A2

K3 K4K1 K2

Circuit Status as Shown

The E-stop is released. The gate is open and unlocked. K1, K2, K3, and K4 are

OFF. The DI is configured for two inputs with monitored manual reset. The

EMD is configured for 8-second off-delay; Range setting of 2 is 10 s, Time

setting of 8 is 80% of the range. The X32 terminal is ON because the EMD

safety outputs are OFF.

Starting

With the Unlock switch open, close the gate. Press Reset to lock the gate and

turn on the K1…K4 safety contactors.

Stopping

Stopping is initiated by pressing the E-stop. K1 and K2 contactors turn off

immediately. The single wire safety signal from the DI (L11) to the EMD

(L12) also turns off immediately, and the EMD starts the off-delay timer. After

8 seconds, contactors K3 and K4 turn OFF and X32 goes to 24V. The unlock

switch is enabled, and the gate can be unlocked. While the gate is unlocked, the

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 31

Page 32

Chapter 6 Application and Wiring Examples

DI cannot turn the safety outputs back ON. After you leave the cell and close

the gate, open the unlock switch to lock the gate, and release the E-stop.

The circuit can meet the safety requirements up to Category 4, Performance

Level e in accordance with ISO 13849-1 and SIL CL 3 in accordance with

IEC62061.

Wiring to DG Relay

TLSZR

+24V DC

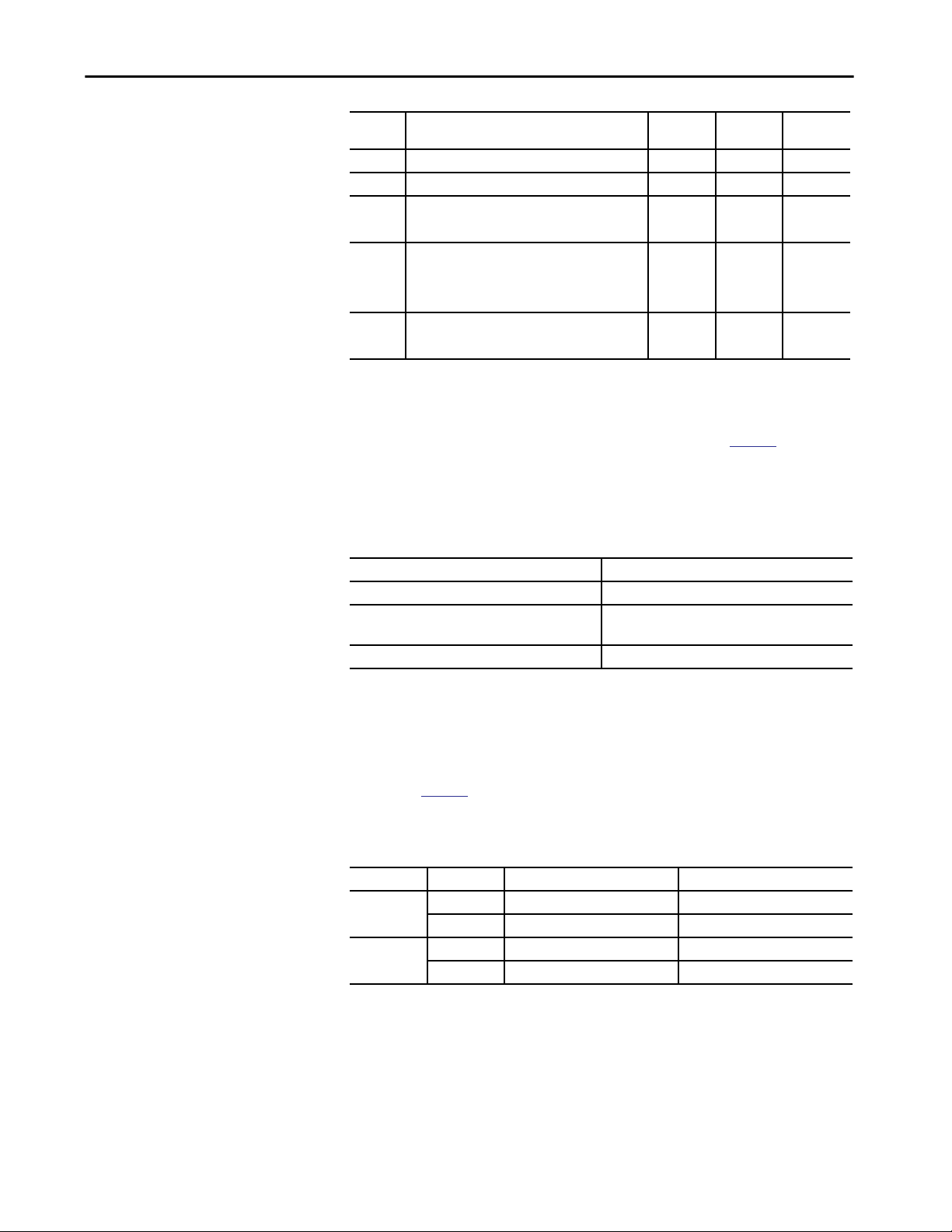

The TLSZR can be used in GuardLink® applications; the TLSZL cannot be

used in GuardLink applications. The GuardLink system uses taps to connect a

series of devices to one relay. The GuardLink system provides control and

status information between the machine control system and the safety system.

Figure 20 shows four TLSZR switches that are connected on two GuardLink

circuits from one DG relay. The DG relay can accommodate up to 32 devices

on each input. The devices can be a mix of many different safety devices. When

guard locking devices are included in the GuardLink system, the lock/unlock

command must come from the machine control system through the

440R-ENETR module.

See publication

Figure 20 - DG with TLSZR Schematic

TLSZR

440R-UM015 for further details.

INPUTINPUT

Control

Status

TLSZR

INPUTINPUT

+24V Com

TLSZR

Machine

Control

System

+

A

B

C

440R-ENETR

S12 S21S22

DG

440R-DG2R2T

S32 X3

S11

Control

Status

X2

32 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

TIME

0

.

4

1

.

2

1

.

0

X1

L1

L2 L3

A1

13 23

.

2

.

4

.

6

.

8

.

1

14S42

A2

X4

K1

K2

24

M

K2

K1

Page 33

Application and Wiring Examples Chapter 6

Wiring to CR30 Relay

+24V DC

TLSZR-GD2

440G-TZS21UTRH

Status Diag

889D-F8NB-2

Brown (+24)

Red (OSSD A+)

Yellow (OSSD B+)

White (Aux)

Gray (OSSD A)

Pink (OSSD B)

Green (Lock)

Blue (Gnd)

Safety

Gate

The CR30 is a software configurable relay that can easily interface with the

TLSZ guard locking switch. Version 10 and later of Connected Components

Workbench™ has a locking function that is useful for guard locking

applications.

Figure 21 shows an example schematic. The CR30 monitors the motor

running signal from the PowerFlex® 525. When the motor is not running, the

safety gate can be unlocked, and the PowerFlex 525 goes to a Safe Torque Off

state.

Figure 21 - CR30 Schematic

L1 L2 L3

Lock

Unlock

Reset

020100 03 04

CR30

A1 15 20 2116

440C-CR30-22BBB

12 13 14

05

06

071908 10 11

18A2

17

Motor Not Running

09

PowerFlex

525

11 +24V DC

1 Stop

2 Start

R5

R6

4 Gnd

Gate control

power supply

RTS

t081=2

Gate control

circuit

S1

S2

NC

UWV

M

24V DC Com

Figure 22 on page 34 shows an example CR30 configuration that works with

the schematic in Figure 21.

The TLSZR OSSD outputs drive the Safe Torque Off (STO) signals of the

PF525. The STO is enabled after the gate is locked and the Reset is pressed.

The PF525 STO inputs can tolerate the pulse test that is generated by the

CR30 outputs.

The Lock_Ctrl_1 block controls the unlock command to the TLSZR. The

unlock Stop Time delay is set to five seconds, and the ULR Latch (Unlock

Request) is set to ON. When an unlock request is made, the command is issued

five seconds after the motor stops running, and the unlock request is latched

ON.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 33

Page 34

Chapter 6 Application and Wiring Examples

Figure 22 - CR30 Configuration in CCW

Wiring to 1734 Guard Point I/O

The TLSZ can be connected to a 1734 Guard POINT I/O™. The catalog

number 889D-F8NB cordset has 24-AWG wires; which allows three wires that

are connected to one terminal. This wiring example shows a Power to Lock

switch with a Door Status auxiliary signal. The PLC logic checks to see if the

door is closed before issuing a lock command. The schematic for this example is

shown in

Figure 23 on page 35.

34 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 35

Safety

Gate

Application and Wiring Examples Chapter 6

Figure 23 - 1734 and TLSZL Schematic

TLSZL-GD2

Status Diag

440G-TZS21STLH

Aux = Gate Status

889D-F8NB-10

White (Aux)

Gray (OSSD A)

Pink (OSSD B)

Blue (0V)

Green (Lock)

Red (OSSD A+)

Yellow (OSSD B+)

Brown (+24V)

Power to Lock

1734-IB8S1734-AENT 1734-OB8S

Ethernet I/P

to GuardLogix

PLC and HMI

24V DC Com

+24V DC

0

1

2

3

45

6

7

I0

I2

COM COM

T0

K1

I1

I3

T1M

K2

I4

I5

I6

I7

COM COM

T2

T3M

O1

O0

O2 O3

COM COM

COM COM COM COM

K1

O4

O6 O7

COM COM

K2

Figure 24 shows the General Tab of the 1734-IB8S Module Properties. The

Input Status must be set to “Combined Status – Muting” as this setting is used

by the Dual Channel Input Stop logic block to verify that 1734-IB8S is

operational. The Output Data must be set to “Test,” as the test outputs are used

to generate test pulses for the output contactors.

O5

Figure 24 - 1734-IB8S Module Properties – General

Figure 25 on page 36 shows the Input Configuration tab of the 1734-IB8S

Module Properties. In this example, Points 0 and 1 monitor the OSSD outputs

of the TLSZL. The Type is set to Single (to allow the Logix program to detect

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 35

Page 36

Chapter 6 Application and Wiring Examples

potential faults) and Mode must be set to Safety. Points 2 and 3 monitor the

status of the output contactors K1 and K2. Set the Type to Single (to allow the

program to detect potential faults). Safety pulse testing detects potential faults

in the monitoring circuit. The TLSZ can operate with the Input Delay Time

set to zero.

Figure 25 - 1734-IB8S Module Properties – Input Configuration

Figure 26 shows the Test Output tab of the 1734-IB8S Module Properties. In

this example, Points 0 and 1 are set to pulse test as these points help check the

integrity of contactors K1 and K2. Points 2 and 3 are set to “Standard.” Point 2

is the lock command, and Point 3 applies power to the TLSZL and supplies

power to the OSSD inputs. By setting it to standard, you can programmatically

turn Points 2 and 3 off and on.

Figure 26 - 1734-IB8S Module Properties –Test Output

36 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 37

Application and Wiring Examples Chapter 6

Figure 27 shows the General Tab of the 1734-OB8S Module Properties. The

Output Data must be set to “Safety,” as it is controlling the output safety

contactors.

Figure 27 - 1734-OB8S Module Properties – General

Figure 28 shows the Output Configuration tab of the 1734-OB8S Module

Properties. Points 0 and 1 drive the output contactors K1 and K2. The point

Types are set to Dual, and the Modes are set to Safety.

Figure 28 - 1734-OB8S Module Properties – Output Configuration

Figure 29 on page 38 shows an example logic program. A Dual Channel Input

Stop function block monitors the TLSZL and a Configurable Redundant

Output function block controls two contactors. This example can be used as a

starting point for implementation; you must incorporate additional logic that

is based on the risk assessment for the machine.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 37

Page 38

Chapter 6 Application and Wiring Examples

Figure 29 - Studio 5000® Example Logic Program

38 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 39

Application and Wiring Examples Chapter 6

Wiring to 1732 ArmorBlock

Brown (+24)

Red (OSSD A+)

Yellow (OSSD B+)

Gray (OSSD A)

Blue (Gnd)

Pink (OSSD B)

Green (Lock)

White (Aux)

889D-F8NB-5

The TLSZ can be connected to a 1732ES or 1732DS ArmorBlock® by using an

871A-TS5-DM1 field attachable connector. The cordset 889D-F8NB has 24AWG wires that connect to one pin. An example schematic is shown in

Figure 30.

As an alternative, you can use an 871A-TS8-D1 field attachable connector at

the TLSZ and a 5-wire cordset (889D-M5NC-x).

Figure 30 - ArmorBlock Schematic

1732ES-IB12XOB4

871A-TS5-DM1 5 pin

Field Attachable Connector

N/C

EtherNet

21

354

X100 X1X10

1 T1

2 I1

3 C

AE

4 I0

5 T0

1 T1

2 I1

3 C

BF

4 I0

5 T0

21

354

1 T1

2 I1

3 C

4 I0

5 T0

1 T1

2 I1

3 C

4 I0

5 T0

Status Diag

TLSZR-GD2

Safety

Gate

Power

1+24

2 O1

3 C

4 O0

5 C

1+24

2 O1

3 C

4 O0

5 C

4

1

3

2

889D-E5NC-10

100S or 700S or 700-HPS

Contactors and Relays

White (2) A1 A2 Blue (3)

Black (4) A1 A2 Gray (5)

K1

K2

Brown (1) White (2)

K1

K2

Black (4)

Gray (5)

24V Com

+24V DC

889D-E5NC-10

1 T1

2 I1

3 C

4 I0

5 T0

1 T1

2 I1

3 C

4 I0

5 T0

4

1

2

3

CG

DH

Figure 31 on page 40 shows the General Tab of the ArmorBlock Module

Properties. The Input Status must be set to “Combined Status — Muting” and

the Output Data must be set to “Combined.”

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 39

Page 40

Chapter 6 Application and Wiring Examples

Figure 31 - Module Properties - General

Figure 32 shows the Input Configuration tab of the ArmorBlock Module

Properties. In this example, Points 0 and 1 monitor the OSSD outputs of the

TLSZR. The Type is set to Single (to allow the Logix program to detect

potential faults), and Mode must be set to Safety. Points 4 and 5 monitor the

status of the output contactors K1 and K2. Set the Type to Single to allow the

Logix program to detect potential faults. The safety pulse test is used to detect

potential faults in the monitoring circuit.

Figure 32 - Module Properties – Input Configuration

Figure 33 on page 41 shows the Test Output tab of the ArmorBlock Module

Properties. In this example, Points 0 and 1 are set to Standard. The Standard

setting allows these two points to be controlled by the program. Point 0 applies

power to the TLSZR. By setting it to Standard, you can programmatically turn

40 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 41

Application and Wiring Examples Chapter 6

this point off and on if the TLSZ switch has a fault condition. Point 1 is the

lock/unlock command. In this example, the TLSZ is a PTR type, so 24V

unlocks the switch. Use Points 4 and 5 to monitor the contactor outputs and

are set to pulse test.

Figure 33 - Module Properties – Test Output

Figure 34 shows the Output Configuration tab of the ArmorBlock Module

Properties. Points 0 and 1 drive the output contactors K1 and K2. The point

Types are set to Dual, and the Modes are set to Safety.

Figure 34 - Module Properties – Output Configuration

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 41

Page 42

Chapter 6 Application and Wiring Examples

Figure 35 shows an example program. A Dual Channel Input Stop function

block monitors the TLSZR and a Configurable Redundant Output function

block controls two contactors. This example can be used as a starting point for

implementation; based on the risk assessment for the machine, you can

incorporate additional logic.

Figure 35 - Example Studio 5000 Program

42 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 43

Chapter 7

Diagnostics and Troubleshooting

Most importantly, persons who are trained in the safety of machine systems

must conduct troubleshooting procedures. This training includes knowledge

of all sources of energy (for example electrical, pneumatic, safety, thermal,

others).

The best approach to troubleshooting the TLSZ guard locking switches is to

observe the status indicator on the switch and follow the flow diagram that is

shown in

Figure 36 on page 44.

Tools Needed

Required Tools

1. T20 security-Torx screwdriver bit. Notice that the security Torx has a

hollowed center. You need this bit to remove the cover of the TLSZ.

2. You need a medium-sized flat screwdriver for terminal screws, to

remove terminal blocks, and to configure the switches on the front face

of the relays.

3. Digital Multi-meter (DMM) — to measure signal levels and resistance.

Optional Tools

1. Oscilloscope — dual or four channel storage scope to view input and

output signals and to capture signals and noise transients.

2. Metal paper clips — to insert into the terminals and allow connection of

scope probes to terminals.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 43

Page 44

Chapter 7 Diagnostics and Troubleshooting

Flowchart

Figure 36 shows a flow diagram to help diagnose the condition of the TLSZ

switch.

Figure 36 - Troubleshooting Flow Diagram

Look at the Status Indicator

Yes

Is it OFF?

No

Is it Flashing Red

at 4Hz?

No

Is it Flashing Red

at 1Hz?

No

Is it Flashing Green

at 1Hz?

No

Is it Flashing

Red and Green?

No

Go to Step 1

Yes

Go to Step 2

Yes

Go to Step 3

Yes

Go to Step 4

Yes

Go to Step 5

Step 1 — Status Indicator OFF

Yes

Is it Solid Red?

No

Is it Solid Green?

No

Contact Product Support

Go to Step 6

Yes

Go to Step 7

When the status indicator is OFF, the TLSZ is not connected properly to

either the 24V power supply or ground.

1. Use the Torx screwdriver to remove the TLSZ cover.

2. Use a digital multi-meter (DMM) to measure the voltage at the power

supply terminals (blue wire is 0V and brown wire is plus), as shown in

Figure 37 on page 45.

The voltage must measure between 20.4V and 26.4V DC.

44 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 45

Diagnostics and Troubleshooting Chapter 7

Figure 37 - Measure the Voltage at the Power Supply Terminals

Step 2 — Status Indicator Flashing Red at 4 Hz

Acceptable Range

20.4V DC to 26.4V DC

DMM

24

Volts

Terminal Color: QD pin - Function

Green: 3 - Lock/Unlock

White: 1 - Aux

Red/Yellow: 4 - Safety B+

Red/White: 6 - Safety B

Red: 8 - Safety A+

Red/Black: 5 - Safety A

No Connection

Brown: 2 - +24V DC

Blue: 7 - 0V

If 24V is present at the wiring terminals, then check that the wires are stripped

and the terminal screws are tight. If the wires are okay, then replace the switch.

If 24V is not present at the terminals, then check the power supply and the

wiring up to the TLSZ switch.

The status indicator flashes red at a 4-Hz rate when an inconsistency is

detected with the RFID sensor. A number of scenarios can cause this fault

indication.

Wrong Target

The TLSZ is configured to detect a specific target. If a non-configured target is

presented to the TLSZ, the TLSZ goes into fault mode and its status indicator

flashes red at 4 Hz.

To correct this condition:

1. Replace the incorrect target with a correct target.

2. Cycle the power to clear the fault.

When received from the factory, the TLSZ is not configured to detect any

target. You must configure the TLSZ to detect a target. The configuration can

be a one-time event, or the TLSZ can be configured to be able to learn up to

eight different targets. The TLSZ can only recognize one target. If the target

gets damaged, the TLSZ can be configured to learn another target, if initial

configuration is set to multi-time learning, see

page 23.

Commissioning Errors on

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 45

Page 46

Chapter 7 Diagnostics and Troubleshooting

Missing Target

If the actuator is inserted into the TLSZR without the target present, the status

indicator flashes red at 4 Hz.

To correct this condition:

1. Remove the actuator from the switch.

2. Cycle power to the TLSZR

3. Mount the target next to the actuator as shown in

Figure 38.

Insert the actuator/target into the switch.

Target Not Mounted Correctly

If the actuator is mounted incorrectly, the TLSZ can operate correctly, but

with reduced tolerance to misalignment of the target. The status indicator

intermittently goes to a fault state with the status indicator flashing red at 4 Hz.

To correct this condition:

1. Remove the actuator/target from the switch.

2. Cycle power to the TLSZ to clear the fault.

3. Mount the target next to the actuator as shown in

4. Insert the actuator/target into the switch.

Figure 38 - Mounting of Target and Actuator

Tar ge t

Figure 38.

Actuator

46 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 47

Diagnostics and Troubleshooting Chapter 7

Pair Proximity

The RF field from a neighboring switch can cause intermittent faults. Switches

with similar RF technology include the TLSZ, the SensaGuard™ switches, and

the 440G-LZ guard locking switches.

To correct this condition:

1. Make sure that the neighboring switches are mounted at least 200 mm

(8 in.) from any edge of the TLSZ.

2. Cycle power to the TLSZ switch to clear the fault.

Mechanical Pressure on Safety Gate

If a mechanical load (pressure) is applied to the gate during unlocking, the

TLSZR goes to a fault mode. The status indicator flashes green three times and

then red once. It repeats this process for 10 seconds, and then the status

indicator flashes red at 4 Hz. Firmware 1.003 and earlier have a 10-second

limit. Firmware 1.004 attempts to lock for 10 minutes.

1. Check the allowable spacing between the TLS and mechanical gate stop.

2. Adjust the spacing to be between 1 mm (0.04 in.) and 4 mm (0.16 in.)

between the actuator and the metal guide as shown in

Figure 39.

3. Cycle power to the TLSZ switch to clear the fault.

The safety gate needs a little freedom to move when locked.

Figure 39 - Clearance in Closed Position [mm (in.)]

1…4 (0.04…0.16)

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 47

Page 48

Chapter 7 Diagnostics and Troubleshooting

Long Wiring

Long input wiring adds resistance and decreases the supply voltage to the

switch and reduces the safety OSSD outputs. The size of the wire also makes a

difference; smaller wires have higher resistance.

Figure 40 shows the typical TLSZ test pulses when connected to a resistive

load with short [2 m (6.56 ft) wiring. The test pulses are about 25 ms wide.

IMPORTANT The OSSD outputs are about 23V and the test pulses go to zero volts.

Figure 40 - TLSZ Test Pulses Into a 1K Resistive Load

In Figure 41 on page 49, a TLSZR and GSR-SI operate successfully with long

wiring. The OSSD outputs drop to approximately 21V and the test pulses only

drop to approximately 8V (not 0V).

48 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 49

Diagnostics and Troubleshooting Chapter 7

Figure 41 - Effect of 300 ohms of Wire Resistance Going Into a GSR-SI Safety Relay

Voltage Supply Dips

When you energize the TLSZ solenoid, it causes a 350 mA in-rush current on

the power supply wire. If multiple TLSZ switches are energized

simultaneously, the voltage supply can dip below the 20.4V voltage

specification and cause the switch to go to fault mode.

Voltage drop is by:

1. The number of switches being energized simultaneously,

2. The power supply wire size, and

3. The wire length.

IMPORTANT The lock/unlock command on the TLSZ is not like the older TLS1, TLS2, and

on the TLSZ (both Power to Lock and Power to Release) is a logic level signal;

about 3…5 mA. The power to energize the solenoid is provided by the

‘brown’ power supply wire.

To avoid the power supply dip, it is recommended that you stagger the lock/

unlock command to successive switches by at least 170 ms.

Rapid Locking

The TLSZL Power to Lock switches cannot withstand rapid locking and

unlocking. This action results in the indicator flashing red at 4 Hz. Although

the TLSZR Power to Release switches are more tolerant to rapid unlocking/

locking, they can also go to a fault state with the indicator flashing red at 4 Hz.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 49

Page 50

Chapter 7 Diagnostics and Troubleshooting

It is recommended you check that the locking operation frequency is no faster

than 1 Hz with 50% duty cycle (500 ms lock, 500 ms unlock).

Step 3 - Status Indicator Flashes Red at 1 Hz

This status indicates that an undetermined fault has occurred.

Cycle the power. If the switch does not recover, cycle it again. If the switch does

not recover, then run a separate cable directly from the power supply to the

switch. This cable can run on the floor away from any extraneous signals. You

can also provide a temporary selector switch to execute the lock/unlock

command.

Case 1. Switch Operates OK. Check the routing of the cable from the power

supply to the switch. Be sure of adequate separation of switch cabling to sources

of electromagnetic noise, such as drives and motion systems.

Case 2: Switch Faults. If the switch fails with the cabling on the floor (clear of

all electromechanical noise), then replace the switch.

Capacitive Loading

The OSSD outputs of the TLSZ uses pulse testing to detect faults. The pulse

testing is subjected to the capacitive loading of the cabling (longer cabling

creates additional capacitance) and capacitance from the device to which it is

connected.

Cable capacitive loading is not an intermittent issue. Once resolved, the

capacitance can remain unchanged until conditions, such as cabling changes,

occur.

Use an oscilloscope to measure the pulse tests.

typical effect; curved leading edge indicates capacitive loading.

The TLSZR can withstand a capacitive load up to 375 nF. Higher capacitance

causes the OSSD outputs to turn OFF and the indicator flashes red at 1 Hz.

Higher levels of capacitance can be tolerated by adding a 10K resistor from the

OSSD signal to ground.

Figure 42 on page 51 shows the

50 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 51

Figure 42 - Typical Capacitive Effect on Pulse Tests

Diagnostics and Troubleshooting Chapter 7

Step 4 — Status Indicator Flashes Green at 1 Hz

Step 5 — Flashing Red and Green

When the status indicator is flashing green at 1 Hz, the switch is indicating that

it is waiting for 24V to be applied to the OSSD A+ and OSSD B+ input

signals.

Upon power-up, the TLSZ performs internal checks. During this time, the

status indicator flashes green three times, shows solid red for about two

seconds. If the OSSD A+ and OSSD B+ inputs are not connected to 24V, the

status indicator then flashes green at 1 Hz.

Corrective Action:

1. If you have multiple switches that are connected in series, check the

OSSD outputs of the prior switch.

a. If the prior switch is flashing green, go to then next prior switch to

determine why its OSSD outputs are OFF.

b. If the TLS is the only switch or the first switch in a series connection

of switches, check the power supply connections of OSSD A+ (red

wire) and OSSD B+ (yellow wire).

The TLSZ switch was initially configured for multi-time use. The flashing red

and green indicator indicates the number of configurations that can be

completed, see

Commissioning on page 21.

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 51

Page 52

Chapter 7 Diagnostics and Troubleshooting

Step 6 — Indicator Solid Red

Step 7 — Other Considerations

The solid red indicator occurs when specific faults have not been detected.

1. Try to cycle power.

2. Remove the cable and reconnect the switch to a separate cable and use

the existing power supply.

a. If the switch recovers, check the existing cable routing to be sure that

the switch cable is not along motor or other high–noise wiring. Also

check the grounding scheme, the 0V of the switch must be very close

to the safety logic device to which it interfaces.

a. If the switch does not recover, proceed to Step 3.

3. Remove the switch from the installation and apply a bench test circuit.

a. If the switch still exhibits solid red indicator, replace the switch.

b. If the switch recovers, then re-examine the cable routing and the

grounding scheme.

Distribution Block

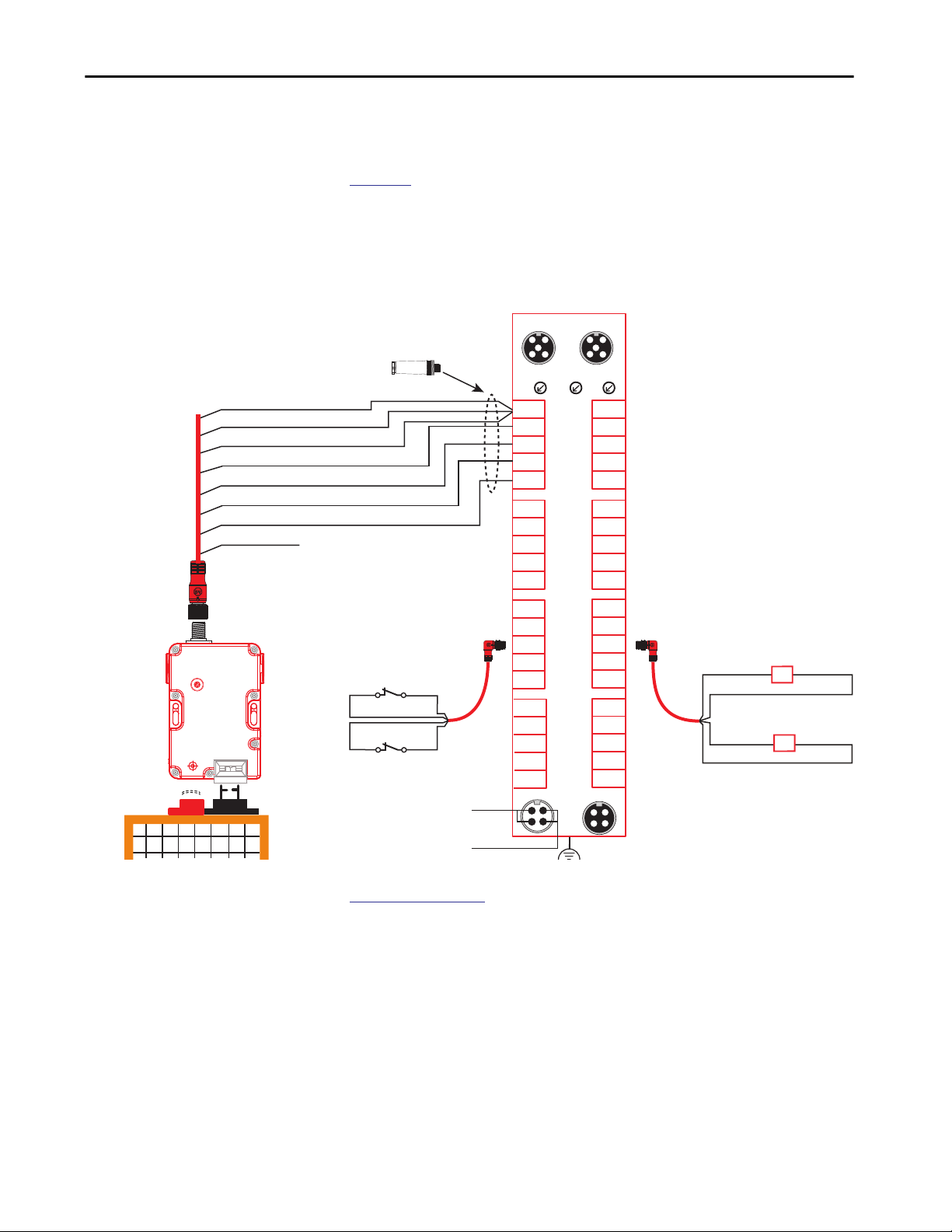

The TLZ can be connected the 898D distribution block. The block is available

with either four or eight ports. An example with eight ports is shown in

Figure 43 on page 53. This application requires a couple of special

considerations:

1. The cable length in this example, are all 30 m (98.4 ft) long. The cable

length causes a 1.5V drop in power at the switch.

2. If the power supply is set to 24V, the voltage at the terminals inside each

switch is 22.5V.

Common Lock Signal

The lock/unlock command is simultaneously applied to all eight switches.

Each switch has a 300 mA nominal (350 mA max) inrush current that lasts

about 110 ms (see

at the same, the inrush current is 2.4 A. The power supply must be able to

accommodate this inrush.

Figure 44 on page 53). With all 8 switches locked/unlocked

52 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 53

Figure 43 - TLSZ with 898D Distribution Block

Diagnostics and Troubleshooting Chapter 7

Figure 44 - In-rush Current on the Power Supply at the Switch

GSR Relays on Power-up

Upon power-up, the Guardmaster safety relays (GSR) input does not recognize

the status of the TLSZ outputs; the IN1 indicator remains OFF. The TLSZR

must be unlocked and then locked. Then the GSR relay recognizes the OSSD

outputs of the TLS. This sequence only occurs on power-up and is a function

of the GSR (not the TLSZ).

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 53

Page 54

Chapter 7 Diagnostics and Troubleshooting

Notes:

54 Rockwell Automation Publication 440G-UM002A-EN-P - March 2019

Page 55

Specifications and Safety Ratings

Appendix A

Specifications

Attribute 440G-TZS21UPRH, 440G-TZS21UPLH,

440G-TZS21UTRH, 440G-TZS21UTLH Cat. Nos.

Operating Characteristics

TLSZR-GD2 Power to Release

TLSZL-GD2 Power to Lock

Assured Locking Distance 13 mm (0.51 in.) Maximum target distance

Torque for M5 Mounting 1.4 N•m (12.39 lb•in)

Torque for Cover Mounting 1.2 N•m (10.62 lb•in)

Locking Force Fmax Plastic pins: 1950 N (488 lb)

Locking Force Fzh per EN/ISO 14119 Plastic pins: 1500 N (337 lb)

Maximum Output Current (all outputs) 200 mA

Current Consumption

solenoid not energized, no output load

solenoid energized, no output load

Inrush Current

Solenoid Duty Cycle 100%

Off-State Current < 0.5 mA DC

Maximum number of switches connected in series Unlimited. See Unit Response Time on page 8

Operating Voltage Ue 24V DC +10% / -15%, Class 2 Source Required

Frequency of Solenoid Operating Cycle 1 Hz, max

Actuation Speed 160 mm/s (6.29 in/s), max

Response Time (turn Off) 75 ms first switch, 25 ms additional for each switch

Utilization Category per IEC 60947-5-2 DC-13, 24V 200 mA

Impulse Withstand Voltage Uimp 250V

Protection Class 2

Mechanical Life 1,000,000 c ycles

Environmental

Operating Temperature [C (F)] -10…+60 °C (+14…140 °F)

Operating Humidity [% relative] 5…95

Risk Time, Max [ms]

If the RFID door target moves outside of the operating distance,

the safety outputs are deactivated

Rated Insulation Voltage Ui [V] 500

Enclosure Ingress Rating NEMA 3, 4X, 12, 13, IP66, IP67, IP69K

Shock per IEC 68-2-27 [g, ms] 30, 11

4 mm (0.16 in.) Maximum clearance between actuator base

and switch in the door closed position

Steel bolts: 2600 N (585 lb)

Steel bolts: 2000 N (450 lb)

75 mA

120 mA

350 mA

100 mm/min (3.94 in/min), min

60

Rockwell Automation Publication 440G-UM002A-EN-P - March 2019 55

Page 56

Appendix A Specifications and Safety Ratings

Safety Ratings

Attribute 440G-TZS21UPRH, 440G-TZS21UPLH,

440G-TZS21UTRH, 440G-TZS21UTLH Cat. Nos.

Vibration IEC 68-2-6 [Hz, mm] 10…55, 0.35

Radio frequency IEC 61000-4-3

IEC 61000-4-6

Pollution Degree 3

Altitude, Max [m(ft)] 2000 (6562)