Page 1

Installation and Operating Instructions

Bulletin 802T 4ĆCircuit Direct Opening Action Limit Switch

ATTENTION: To avoid electrical shock

and unintended operation of equipment,

disconnect all power to the limit switch and

the controlled equipment before

proceeding with any repair or adjustment of

the limit switch.

Overview

Bulletin 802T Direct Opening Action limit switches have been

designed for use in applications requiring control reliability

performance per ANSI B11.19 and in safety applications

when applied as shown in ISO 14119.

Limit switches are used in electrical control systems to sense

position. They are actuated by the predetermined motion of a

cam, machine component or piece part. These limit switches

are suitable for use in control systems requiring control

reliability performance or safety related performance per ISO

13849–1.

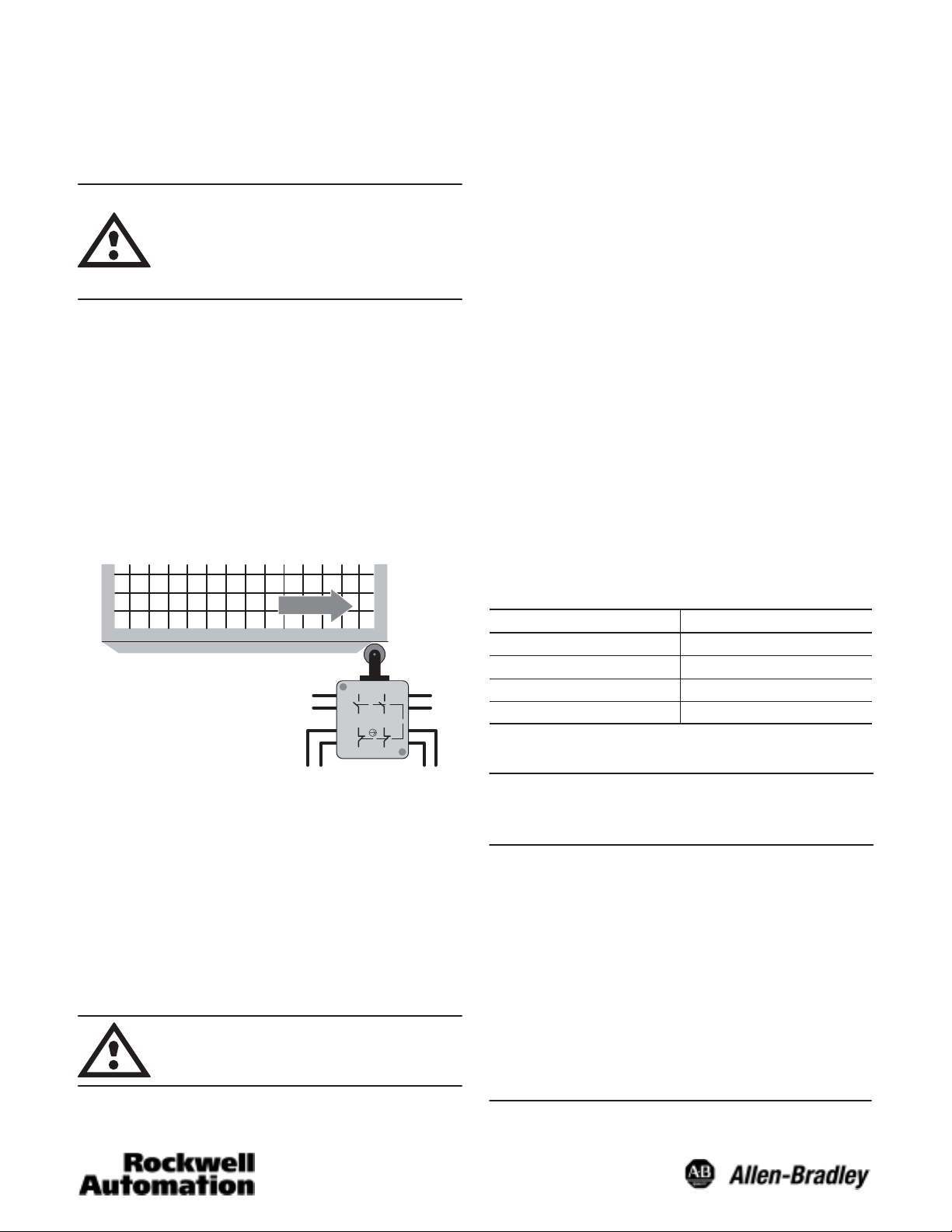

Typical Example of a Dual Channel Safety Application

Guard Closed

1

5

Aux 1

Channel 1

Before installation in a safety application, a risk assessment

should be performed to determine whether the specifications

of this device are suitable for foreseeable operational and

environmental characteristics of the machine which is to be

controlled. Only the normally closed set of contacts are

considered safety contacts. When applying these limit

switches in a safety system application, all applicable

standards for application should be followed. Operating

specifications must be followed and actuator must be

displaced beyond the point where Direct Opening Action

occurs. These devices are not to be used to directly control a

motor.

2

3

4

Safety

6

7

8

Aux 2

Safety

Channel 2

ATTENTION: Adjustable length lever

actuators should not be used in a safety

systems application.

General Data

S Safety Contacts: 2 Normally Closed

S Auxiliary Contacts: 2 Normally Open

S Enclosure Rating:

S NEMA 4, 6P, 12 and 13

S IP67

S Operating rate and speed Ê

S Lever Type: 150/minute @ 9m (30ft)/min Ë

S Top Push Roller: 150/minute @ 9m (30ft)/min Ì

S Side Push Roller: 150/minute @ 9m (30ft)/min Ì

S Operating Temperature (standard models) 18_C to 110_C

(0_F to 230_F)

S Short Circuit Protection: 10 amp slow or 15 amp fast

acting. Overload protection should be sized to load

requirements.

Mounting

Limit switches should be securely mounted using the

mounting holes provided. During installation, ensure that the

actuator will be displaced beyond the point where Direct

Opening Action takes place. Adjustable levers or rod

actuators should not be used in safety systems applications.

Description Tightening Torque

Terminal Screws 18inĆlb

Front to Rear Base 16 to 20inĆlb

Head Screws 12 to 18inĆlb

Lever Arm 25 to 36inĆlb

Wiring

Important: The contacts in each switching element

must have the same polarity. The circuit

diagram is shown on the nameplate.

The pressure type connector terminals in the base will accept

No. 12 AWG and smaller solid or stranded wire. For proper

tightening, it is suggested that nothing smaller than No. 18

AWG be used. Before inserting wire under the pressure

plates, strip the insulation approximately 3/8 inch. Tighten all

pressure plate terminals whether used or not, to avoid

interference with the switch cover.

After wiring has been completed, check that all wires are in

the wiring cavity of the terminal block so they will not interfere

with the switch when it is plugged into the terminal block.

Recheck all wiring terminal screws for tightness.

Note: For switches that have been factory wired, check wire

color and their position in the terminal block for proper

circuit hookup.

Ê Based on operation temperature of 68_F to 86_F.

Ë Using 802T-W1A operating lever.

Ì Using 30_ nonĆovertravel dog.

Page 2

S Grounding of switch should be achieved per National

Electric Code (NFPA 70) requirements. Grounding terminal

is located in the terminal block housing.

S Arrange control wiring according to terminal markings.

S Tighten terminal screws according to specifications.

S Only use insulated connectors.

Important: Pay close attention to the terminal

numbering on the terminal block when

wiring this switch. Terminals 1 and 2 or 5

and 6 are normally open contacts.

Terminals 3 and 4 or 7 and 8 are normally

closed contacts.

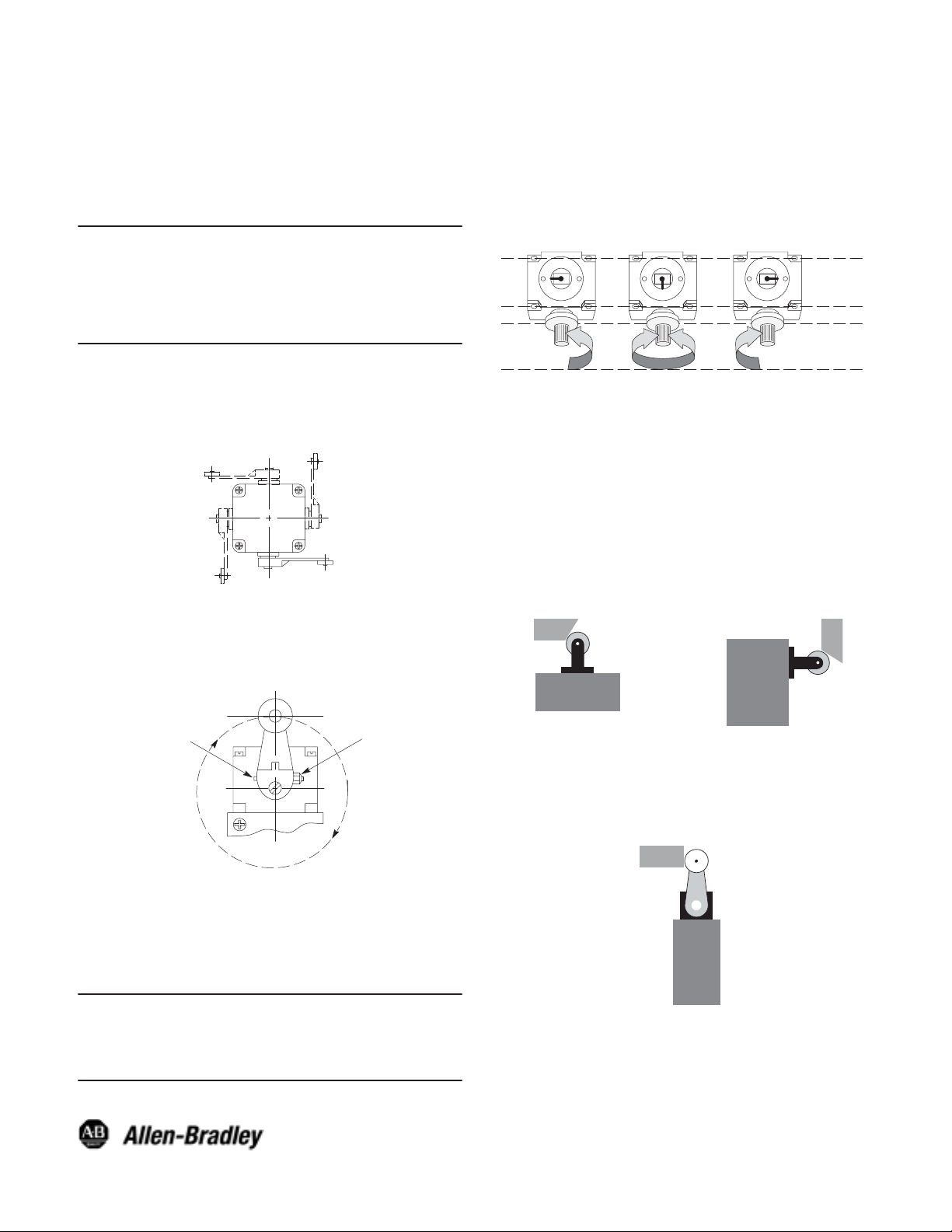

Actuator Head Positioning

The actuator head may be placed in any of four positions on

the switch body. Loosen the four captive screws. Place the

head in the desired position and securely retighten the four

screws (see figure below).

Step 1: Loosen the four head mounting screws and remove

the operating head from the switch body.

Step 2: Locate the plunger on the underside of the operating

head.

Step 3: Pull the plunger outward and rotate it in steps of 90_

to provide the operating mode desired. The

respective settings are shown in the figure below.

Plunger

Setting

Actuation

Required

CCW Only CW OnlyCW & CCW

Step 4: Make sure the plunger is pushed back inward and

the “O” ring is properly seated before the operating

head is reattached to the switch body.

Step 5: Securely retighten the operating head mounting

screws.

Step 6: Check for the desired actuation mode.

Methods of Actuation Examples

Lever Positioning

The lever on rotary actuated devices is adjustable to any

position through 360_ around the shaft. Loosen the nut, move

the lever to the desired position and securely retighten the nut

(see figure below).

Lock Pin

Nut

Changing Direction of Actuation

The switch action of lever operated limit switches may be

adjusted to operate with either a clockwise, a

counterclockwise or both directions movement of the shaft.

To change the actuation direction, follow the steps below:

Important: This procedure must be performed in a

clean environment to avoid the

introduction of foreign material into the

operating mechanism.

802T–DPD

Top Push Roller

30_ Non-Overtravel Dog

Vmax = 30ft/min @ actuator

F max = 150 cycles/min

802T–W1A 1.5I Long

90_ Non-Overtravel Dog

Vmax = 30ft/min @ actuator

F max = 150 cycles/min

802T–KPD

Side Push Roller

30_ Non-Overtravel Dog

802T–APD

Publication 75023–092–01(A)

September 2002

Printed in USA

Loading...

Loading...