Page 1

Bulletin 802PR — Type LA and Type XA — Series C

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Prewired cable Threaded conduit

opening

Prewired

receptacle

Conduit coupler

(Millimeters)

(Inches)

(Millimeters)

Sensing Distance (inches)

Targ et

Release

Operate

Targ et

Square Target Size (x in Inches)

(Millimeters)

Half Hard Cold

Aluminum (Alloy #1100-H14)

Cold Rolled Low Carbon

Cold Rolled

(Millimeters)

Head On Sensing Distance (inches)

Stainless Steel (AISI 304)

Half Hard

Brass (Alloy 260 ASTM

Rolled Copper (ASTM-

Sensing Head Facing

Sensing Faces in Same Plane

3 in. minimum

2 in. minimum

Sensing

Face

Metal

Sensing

Face

Targ et

Targ et

Targ et

Metal

Metal

Sensing

Face

D

D

D

1/4 in. Clearance

Figure 4a: Metal adjacent to one

side of head. Sensing distance D

increases approximately 2%.

Figure 4b: Metal su rrounds head.

Sensing distance D increases

approximately 10%.

Figure 4c: Metal surrounds switch. Sensing

distance D increases approximately 8%.

WARNING

If a hazardous condition can result from

unintended energization of this device, access to

the sensing area should be guarded.

Proximity

Switch

LOAD

Fuse

(if used)

(110/120V AC

L

1

L

2

LOAD

(110/120V AC

L

1

L

2

HAZARDOUS LOCATION SWITCHES — Switches for hazardous

locations meet Division 2; Class I Groups A, B, C, & D; Class II,

Groups F & G; and, Class III requirements. For additional

information refer to Publication GI-2.8 — A Summary of

National Electrical Code Requirements for Hazardous Locations.

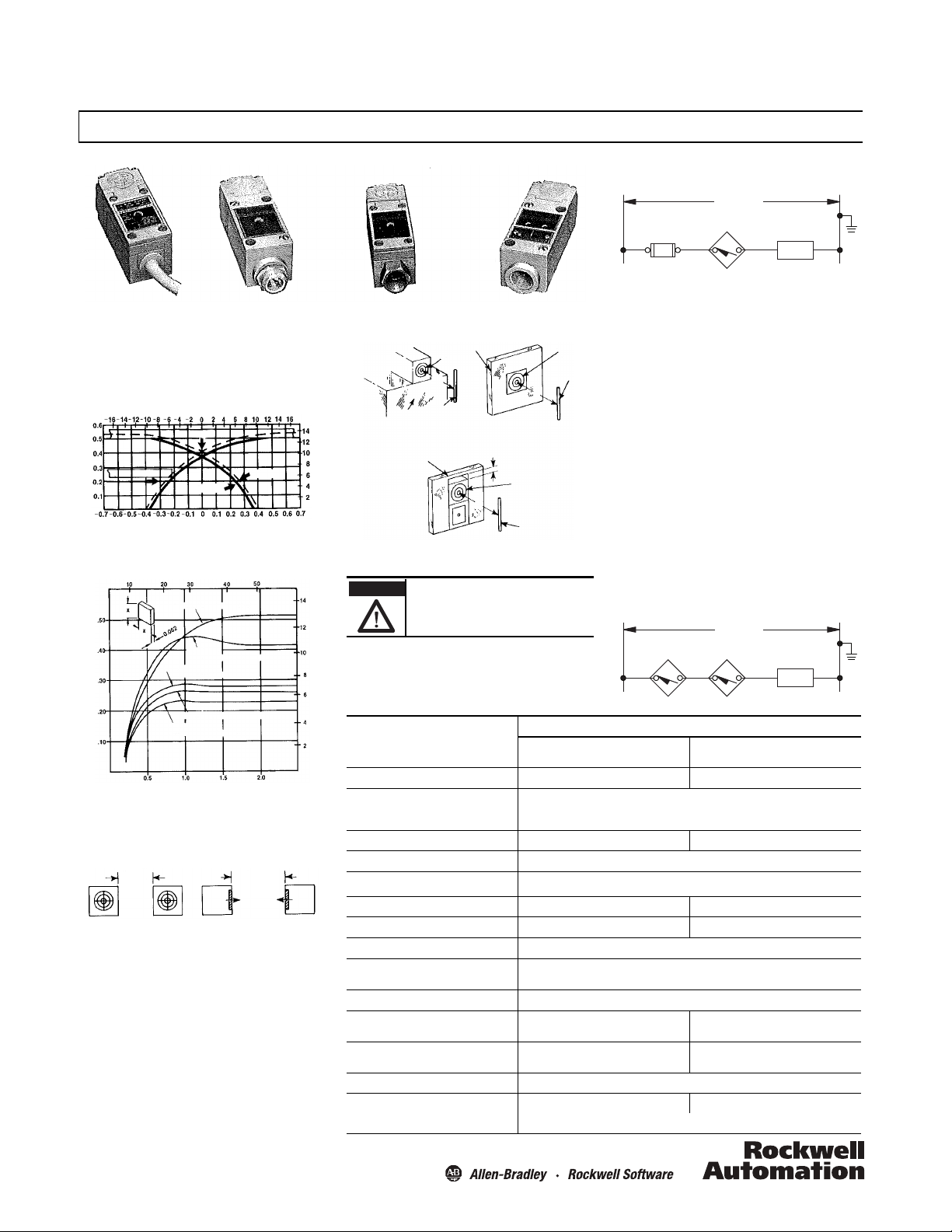

Figure 1: Typical sensing characteristics

Effects of Target Size and Materials on Sensing Distance

Installation Instructions

Figure 4: Effects on nearby meta l surfaces on sensing distances.

CONNEC TION DIAGRAM

Figure 5: Typical wiring diagram

NOTE: To guard against the load remaining energized when the

switch is in an open condition, the minimum load release current

must be greater than the maximum leakage current of the

proximity switch.

GROUNDING — The Bulletin 802PR does not require a ground

connection. The load side of the110/120V AC source can be

grounded as indicated in the connection diagram.

SHORT CIRCUIT PROTECTION — A fuse is recommended in the

circuit to provide short circuit protection for the switch. Use a fast

acting Type KAW10 or KAX10 fuse.

SERIES CONNECTED SWITCHES —

Normally Open Fixed Output — Do not connect two or more

of the switches in series. Erratic operation may result.

Programmable Normally Open/Normally Closed Output

— Two switches can be connected in series with a load. For

proper operation, the operating load voltage must be less than or

equal to the minimum supply voltage less the sum of the onstate voltage drops across the series connected proximity

switches. The load will be energized when the OUTPUT LEDs of

both proximity switches are ON.

CONNEC TION DIAGRAM

WIRING — Connect the proximity switch and load as shown in

Figure 5 using AWG #18 through #14 wire (1.0/1.5mm

of the switch will be ON when the load is energized.

SPECIFICATIONS

Description

Operating voltage range 102…132V, 50/60 Hz 60…132V, 50/60 Hz

Figure 2: Typical sensing distance vs. target size for various metals

SPACING BETWEEN SWITCHES — When installing switches

side-by-side or face-to -face, the minimum spacings in Figure 3

should be maintained.

EFFECTS OF NEARBY METAL SURFACES ON SENSING

DISTANCES — The sensing distance will increase if the

proximity switch is installed so that metal is adjacent to the

Load current Max. continuous: 1 A to +40°C linearly derated to 0.5 A at +75°C

Max. leakage current (load off) 0.0065 A 0.0035 A

Max. voltage drop (load on) 7.5V

Operating temperature range -25…+75°C (-13…+167°F)

Max. operate time 25 ms 25 ms

Max. release time 35 ms 25 ms

Delay on power-up target present 20 ms, typical (no output occurs with target absent)

Sensing distance Steel: 0.525 in. +10% -5%. Refer to Figure 1

sensing head surfaces as illustrated in Figure 4.

Hysteresis (operate — release differential) 0.075 in. max.

Sensing distance drift with temperature ±5% 0…+75°C (32…167°F)

Max. sensing distance drift with voltage ±0.5% 102…132V ±1% 90…132V

Repeat accuracy (10 successive operation s) 0.001 in. max. deviation at constant temperature and supply voltage

Operating speed

(operations per minute)

2

). The LED

Output Mode

Fixed

Normally Ope n

Max. inrush: 10 A, 1 second max.

Min.: 0.025 A

Nonferrous metals: 0.25 in. typical

±10% -25…+75°C (-13…167°F)

1000 1200

Based on max. operate and release time

±5% +15…+50°C (59…122°F)

±10% -25…+75°C (-13…167°F)

±3% 60…132V

Programmable

Normally Open/Normally Closed

Page 2

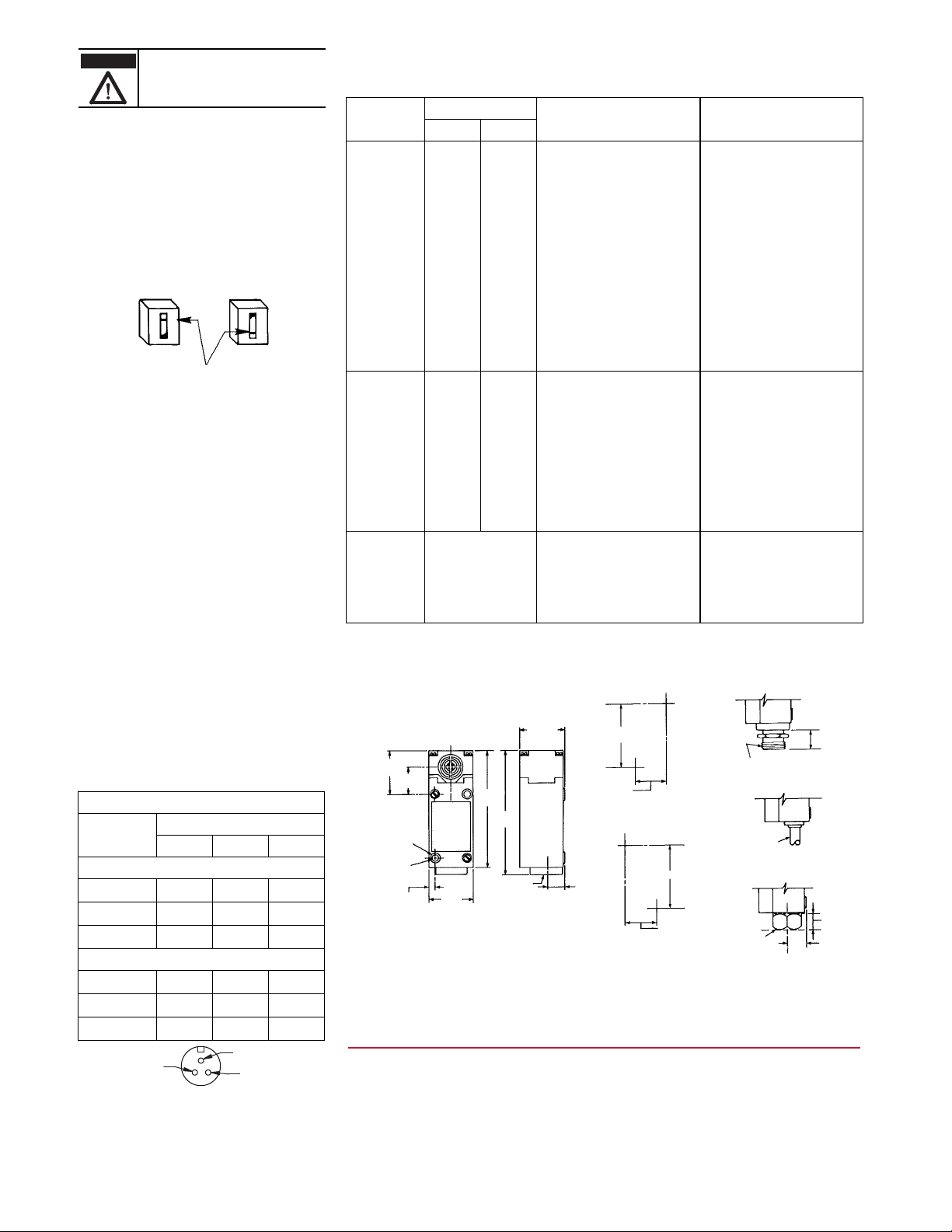

PROGRAMMABLE OUTPUT SELECTION — The programmable

ATTENTION

Do NOT connect two or more Bulletin 802PR

switches in parallel. Erratic operation may

result.

Normally

closed

mode

Depress recessed rocker near

indicating line to change output mode

Normally

open

mode

Short Pin —

Connects to Terminal 1

Short Pin —

Connects to Terminal 2

Long Pin — Not used

41

(1-5/8)

26

(1-1/84)

109

(4-11/32)

117

(4-5/8)

42

(1-21/32)

6 (15/84)

dia. holes

Front mounting

US (1-5/32 x 2-11/32)

DIN (30 x 60)

6 (15/84)

41

(1-5/8)

1/2 in.-14 NPT

Inside threads

Threaded Con duit Openin g

15

(19/32)

(1-5/32)

(2-11/32)

Rear mounting hole pattern

front view

2 #10-32 tapped holes

9.5 (3/8) deep

30

(1-5/32)

60

(2-11/32)

Front mounting hole pattern

front view

2 holes for #10 or M5 screws

22

(13/16)

7/8 in.-16N

outside threads

Prewired cable

1 in. hub

1/2 in.-14 NPT

inside threads

15

(19/32)

Conduit Coupler

10 (13/32) dia.

16 AWG

2 conductor

STO cable

Prewired receptacle

16

(5/8)

Typ e LA onl y.

Also available with ISO 20- 1.5 threads.

N.O./N.C. proximity switch is factory preset in either the normally

open or normally closed output mode.

To change the switch output mode use the following instructions.

1. Remove the lower legend plate on the front of the switch.

2. A line on the recessed rocker indicates the output mode of

the switch.

3. To change the output, depress the recessed rocker of the

switch with a pointed tool.

Note: Do not use a tool whose point could break and jam the

switch.

4. Replace the lower legend plate.

To return the output mode to its original setting, simply reverse

the above procedure. The OUTPUT LED will be ON when the

switch output is conducting.

HARD WIRED CONTACTS — When hard wired contacts are

connected in parallel with the Bulletin 802PR, a surge suppressor

MUST BE connected in parallel with the load. Surge suppression is

not required when hard wired contacts are connected in series

with the load. For recommended surge suppressors for various

devices, refer to publication 802PR-2.1 product data.

NOTE: Hard wired contacts that are operating in series or parallel

with the Bulletin 802PR Type LA or Type XA will cause a delay of

approximately 200 ms. This power-up delay will reduce the

maximum number of operations per minute and may result in a

momentary de-energization of the load.

CONDUIT CO UPLED SWITCHES — Threaded conduit opening

bases are suitable for use with flexible conduit. Conduit coupler

bases are suitable for use with both flexible conduit and rigid

conduit. Both bases connect to 1/2 in.-14 NPT threaded conduit.

Switches with a “S6” suffix in their catalog number are suitable

for connection to ISO 20-1.5 threaded conduit.

PREWIRED CABLE SWITCHES — These switches include a

prewired cable for connection directly into a junction box. The

cable is a two conductor, oil resistant thermoplastic (STO).

PREWIRED RECEPTACLE SWITCHES — These switches include

a prewired receptacle suitable for use with the connector-cable

assemblies listed in the table below. Figure 6 indicates which two

pins of the receptacle are wired internally to terminals 1 and 2.

The third pin is not used.

Manufacturer

Standard Color Code (green, black, white)

Brad Harrison 40901 40902 40903

Joy X8984-3 8984-4 8984-5

CAM-LOK E2057-624 E2057-625 E2057-626

Automotive Color Code (green, red, red)

Brad Harrison 40958 40959 40960

Joy X8984-13 X8984-14 X8984-15

CAM-LOK E2057-824 E2057-825 E2057-826

Figure 6: End view of prewired receptacle

Connector Cable (supplied by user)

Connector Cable Part Numbers

3-ft cable 6-ft cable 12-ft cable

TROUBLESHOOTING GUIDE — The following guide provides basic troubleshooting information for installation and use of the proximity

switch. If a problem occurs, attem pt to determine the POSSIBLE CAUSE as listed. Apply the suggested SOLUTION.

NOTE: The switch may continue to operate even if the LED (will not light) is damaged.

Output LED

Symptom

Load wil l not

energize

OFF OFF A. Power supply off. A. Apply power.

OFF ON B. Incorre ct voltage applied B. Apply correct voltage.

Possible Cause SolutionN.O. N.C.

OFF OFF C. Broken wires or loose connections. C. Repair wiring or tighten loose connections.

OFF ON D. Improper wiring. D. Recheck con nection diagrams. Rewire

OFF N/A E. Target too small or o ut of sensing range. E. Increase ta rget size of move target or switch

N/A OFF F. Target or metal object within sensing range. F. Remove target or metal object. Refer to

OFF OFF G. Two or more proximity switches placed too

close together.

accordingly.

within sensing range.

EFFECTS OF NEARBY METAL SURFACES.

G. Move sensing faces of switches apart. Refer

to SPACING BETWEEN SWITCHES.

ON ON H. Load device faulty or incorrect. H. Replace load or size load correctly.

Load wil l not

de-energize

ON N/A A. Target or metal object within sensing range. A. Remove target or metal object. Refer to

N/A ON B. Target too small or o ut of sensing range. B. Increase target size of move target or switch

ON ON C. Two or more proximity switches placed too

close together.

ON OFF D. Improper wiring. D. Recheck connection diagrams. Rewire

EFFECTS OF NEARBY METAL SURFACES.

within sensing range.

C. Move sensing faces of switches apart. Refer

to SPACING BETWEEN SWITCHES.

accordingly.

OFF OFF E. Load device faulty or incorrect. E. R eplace load or size load correctly.

Load energizes and

de-engerizes

intermittently

Programmable N.O./N.C. switches have two LEDs. The POWER LED will be ON when power is applied.

N/A — Not Applicable.

ON & OFF intermittently A. Broken wires or loose connections. A. Repair wiring or tighten loose connections.

B. Target fluctuates in and out of sensing

range and hysteresis zone.

C. Two or more proximity switches placed too

close together.

B. Stabilize target within the sensing range.

Refer to SPECIFICATIONS — Hysteresis.

C. Move sensing faces of switches apart. Refer

to SPACING BETWEEN SWITCHES.

MOUNTING DIMENSIONS — Dimensions shown in mm (inches).

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fas: (852) 2508 1846

802PR-IN002A-EN-P 77050-001-01

July 2013 Printed in Dominican Republic

Loading...

Loading...