Page 1

Installation and Operating Instructions

Bulletin 802M (2-Circuit Standard) and

802MC (2-Circuit Corrosion Resistant) Limit Switch

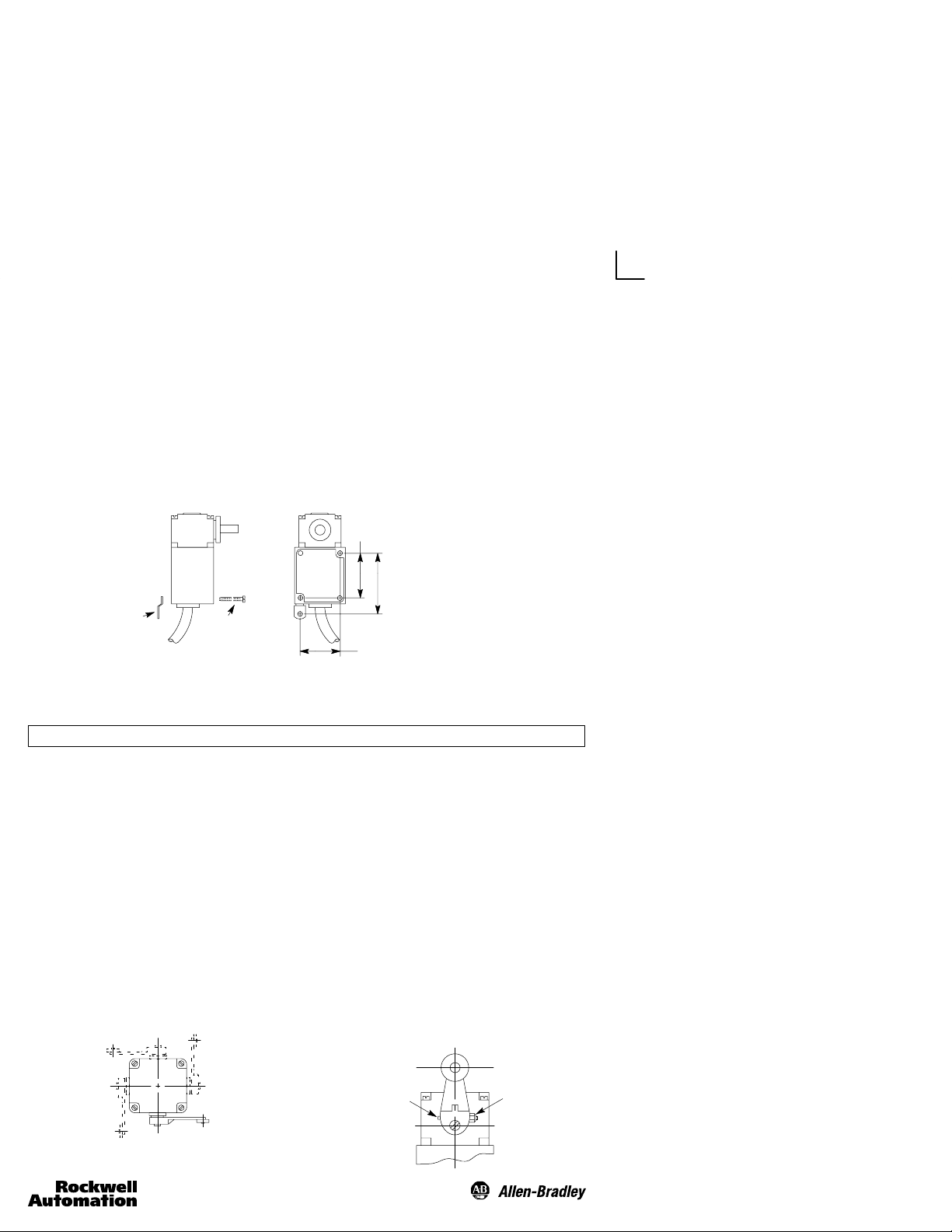

Mounting

Two clearance holes for #10 screws are provided for front mounting. The adapter foot included with

the 2-circuit standard version may be used when it is desired to mount the switch to the dimensions of

a 4-circuit and other larger size limit switches. Place the adapter foot end with the tapped hole into the

rectangular recess at the lower rear corner of the switch and securely tighten (approx. 32 in-lbs.) the

adapter foot with the mounting screw provided. Make sure the exposed end of the adapter foot is flush

with the rear surface of the switch. See Figure 1.

To be compatible with the exposed metal parts of the corrosion resistant version (Bulletin 802MC),

use Type 316 stainless steel mounting hardware.

Figure 1

Bulletin 802M and 802MC 2ĆCircuit

Mounting 46mm (1 13/16in)

Bulletin 802M 4ĆCircuit and

Larger Size Limit Switch

Mounting

Foot

Adapter Foot

Mounting Screw

Mounting 59.5mm (2 11/32in)

29.4mm (1 5/32in)

Wiring

Bulletin 802M and Bulletin 802MC limit switches are pre-wired and factory sealed. Refer to wiring

diagram on nameplate for proper circuit hookup.

CAUTION: The contacts in each switching element must be wired with the same polarity.

The indicating light is prewired and permanently sealed; the LED cannot be replaced.

Optional wiring formats: Some switches may be equipped with a mini-type male connector. If the

mating cord (not supplied by Allen-Bradley) contains a green lead, it should be permanently

reidentified with a color other than green to guard against its use as an equipment grounding

conductor. Refer to wiring diagram on nameplate for proper circuit hook-up.

Some switches may be equipped with 24V DC (Red) LED indicating light. One side of the light will be

wired to either the normally open (LF) or the normally closed (LC) contacts. The other side of the

indicting light will be available through an extra cable lead or mini-type connector pin. This permits

wiring of the inidcating light with the load controlled by the limit switch. Refer to wiring diagram on

nameplate for proper circuit hook-up.

Actuator Head Positioning

All actuator head styles may be placed in any

of four positions on the switch body. Loosen the

four captive head screws, place the head in the

desired position and securely retighten (approx.

11 in-lbs.) the four screws. Figure 2 shows the

rotary operating head with a roller lever.

Figure 2

Lever Positioning

The lever used with rotary actuated devices is

adjustable to any position through 360o around

the shaft. Loosen the lock pin nut, move the

lever to the desired position and securely

retighten the lock pin nut. See Figure 3. Refer

to your Allen-Bradley Sensors catalog for a

complete selection of operating levels.

Figure 3

Lock Pin

Lock Pin

Nut

Page 2

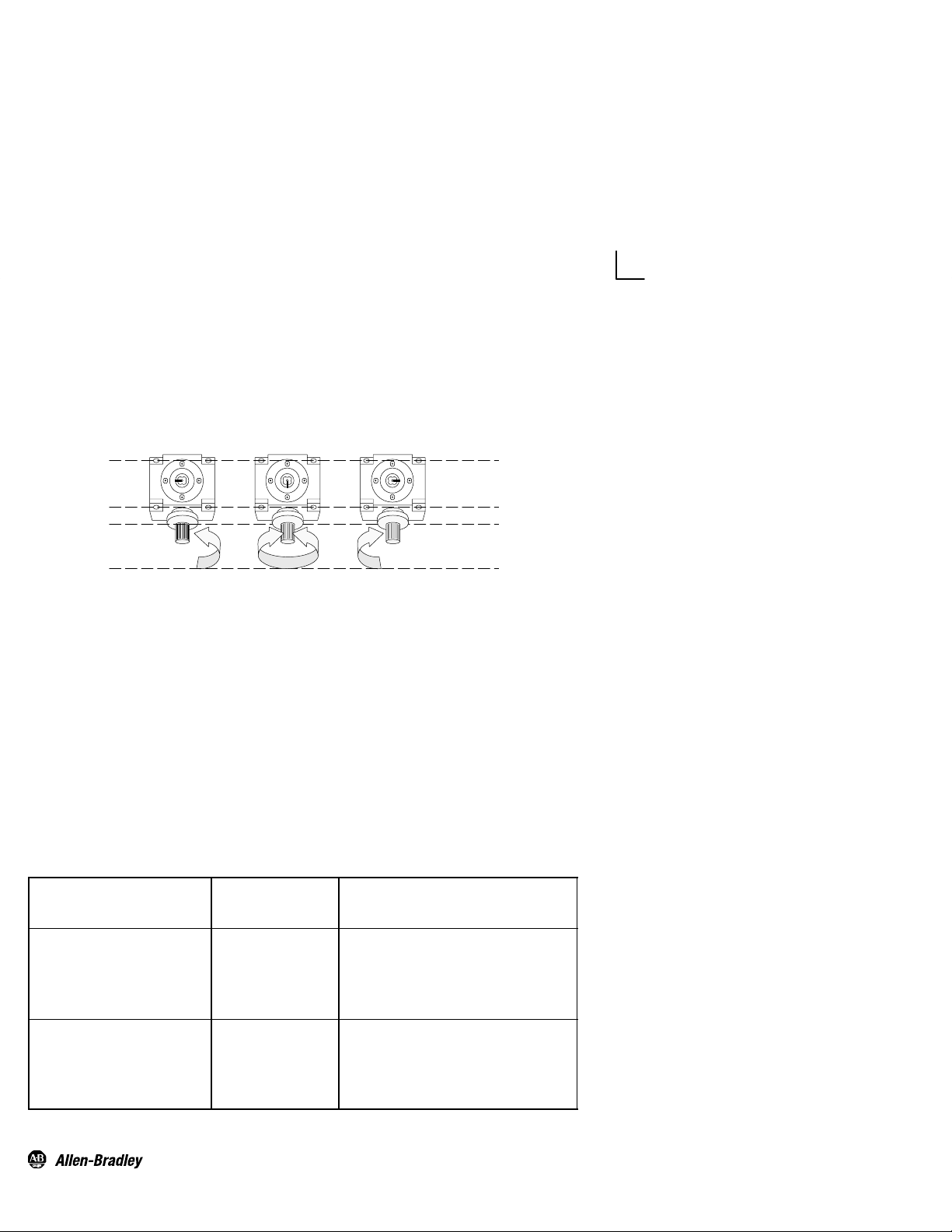

Changing Direction of Actuation

The switch action of spring return, rotary actuated devices can be set to operate with clockwise only,

counterclockwise only or clockwise and counterclockwise shaft movement. To change the direction of

actuation, loosen the four head mounting screws and remove the operating head from the switch

body. Locate the plunger on the underside of the operating head. Pull it outward and rotate it in steps

o

of 90

to provide the operating mode desired. The respective settings are shown in Figure 4. Make

sure the plunger is pushed back inward before the operating head is reattached to the switch body.

Securely retighten (approx. 11 in-lbs.) the operating head mounting screws. Check for desired

actuation mode.

Figure 4

Plunger

Setting

Actuation

Required

CCW Only

CW and CCW CW Only

Renewal Parts

The switch body or operating head may be ordered as a renewal part. Order by catalog number and

series letter as it appears on the nameplate of that part. Make sure rubber sealing ring, provided with

switch body, is properly installed between switch body and operating head.

General Data

Electrical Ratings: NEMA R300 with Cable.

Enclosure Types:

Bulletin 802M (Standard) 1, 4, 6P, 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bulletin 802MC (Corrosion Resistant) 1, 4, 4X, 6P, 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Temperature 32_F to + 180_F (– 0_C to + 82.2_C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage Temperature – 40_F to + 180_F (– 40_C to + 82.2_C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note: Temperature range below + 32_F is based on the absence of freezing moisture or water.

2ĆCircuit

NEMA R150 with MiniĆType Receptacle Option.

24VDC with LF or LC Indicating light option

Interchangeability

May be used in combination with any of the

The following limit switch body only

catalog numbers:

802M-XY5

thru 802M-XY99

802M-XZY5

ąthru 802M-XZY99

802M-XZJ1

ąthru 802M-XZJ9

802MC-XY5

thru 802MC-XY99

802MC-XZ5

ąthru 802MC-XZY99

802MC-XZJ

thru 802MC-XZJ9

With or without any of the

following suffix letters

LF

LC

L1F

L1C

LF

LC

L1F

L1C

following factory or field installed operating head

catalog numbers

802M-AX 802M-CX

802M-A1X 802M-CAX

802M-A2X 802M-DX

802M-AMX 802M-HX

802M-BX 802M-H2X

802M-BAX 802M-KX

802MC-AX

802MC-A1X

802MC-A2X

Visit our web site at:

http://www.ab.com/sensors

40060-358-01 (K)

August 2001

Printed in U.S.A.

Loading...

Loading...