Page 1

Installation and Operating Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

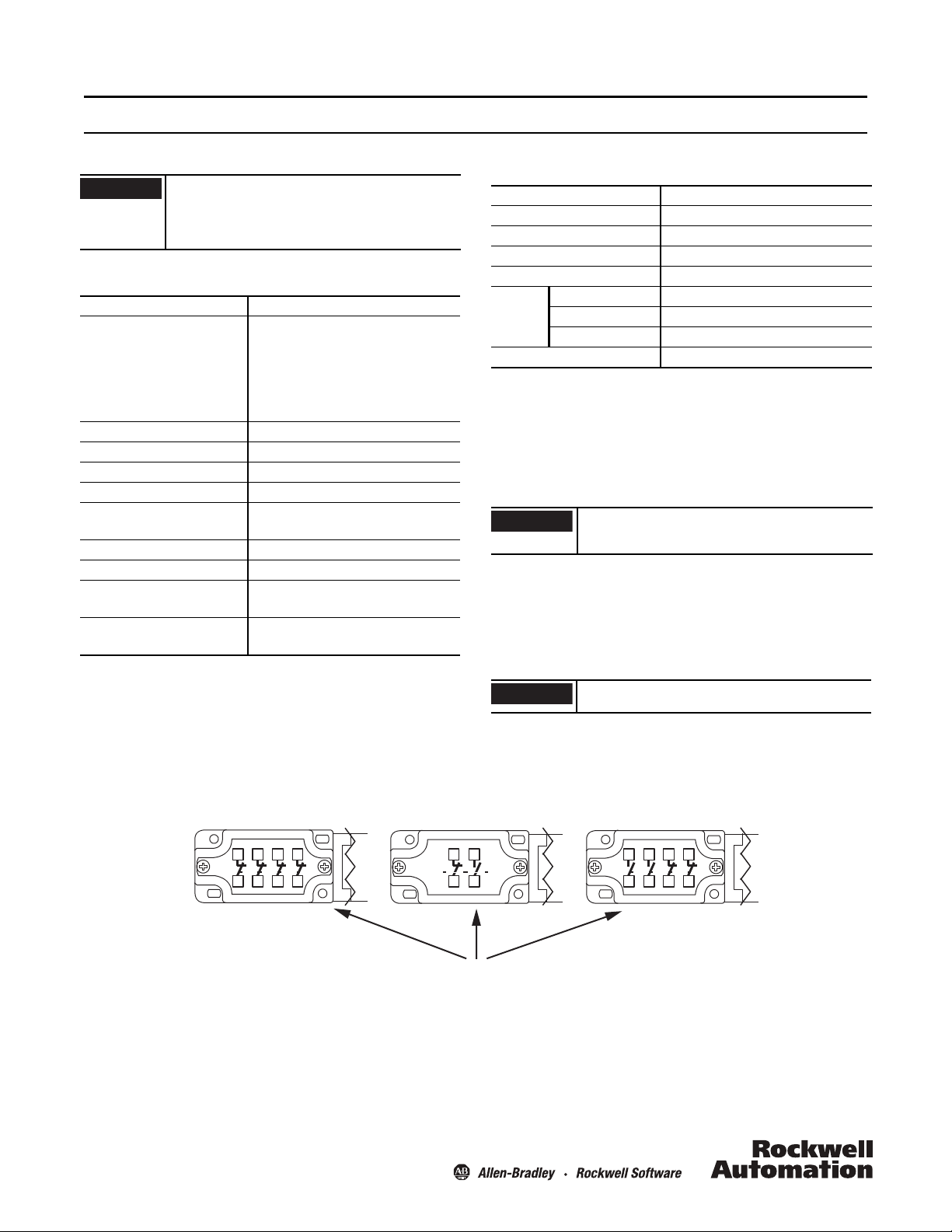

Typical Wiring Diagrams

4 N.C.

41 31 21

11

423222

12

2 N.O. 2 N.C.

43 33 21

11

44 34 22 12

Same polarity this side of block

1 N.O. 1 N.C.

11 23

12 24

IMPORTANT

IMPORTANT

Bulletin 802K DIN 50041 IEC/Large Metal Body Standard Limit Switch

IMPORTANT

Installation of Allen-Bradley products should be in

accordance with local and/or national codes.

Servicing energized industrial control equipment can be

hazardous if not in accordance to recommended safety

procedures.

Specifications

AC/DC Designation A600; Q600

AC/DC Utilization Category Alternating current: AC15 (50/60 Hz)

Ue (V): 120 240 500 600

le (A): 6 3 1.4 1.2

Direct current: DC13

Ue (V): 125 250 500 600

le (A): 0.55 0.27 0.13 0.1

Max. Fusing Rate 10 A fast acting

Impulse Voltage (Uimp) 2500V

Enclosure Protection IP66

Pollution Degree 3

Storage/Operating

Temperature

Direct Opening Action Normally closed only

Conductor Sizes Use copper conductors only

Stranded 0.75…2.5 mm2 (0.02…0.09 in.2)

Solid 0.75…2.5 mm2 (0.02…0.09in.2)

-25…+65 °C (-13…+149 °F)

(18…14 AWG)

(18…16 AWG)

Torque/Mounting

Location Torque

Heads 1.2 N•m (0.86 lb•ft)

Covers 1.6 N•m (1.18 lb•ft)

M5 Mounting 2.5…3.0 N•m (1.84…3.21 lb•ft)

Wire Clamp 0.9…1.0 N•m (0.66…0.74 lb•ft)

Lever

Clamp

M5 Hex Screw 1.8 N•m (1.33 lb•ft)

M3/M4 Hex Screw 1.5 N•m (1.11 lb•ft)

Adj. Lever Screw 1.0 N•m (0.74 lb•ft)

Conduit 1.0 N•m (0.74 lb•ft)

Rotating Operator Heads

When rotating operator heads, follow these steps:

1. Loosen the head mounting screws and remove the operating

head from the switch enclosure.

Internal operator head components can become dislodged when removing operator heads. Use caution

during removal and assembly.

2. Orient the operator head in one of the four positions offered.

Make sure the loose parts are positioned correctly before

affixing the operator head to the switch enclosure.

3. Tighten the four screws per the recommended torque

specifications above.

Check for switch operation with a continuity indicator

before placing product in service.

Page 2

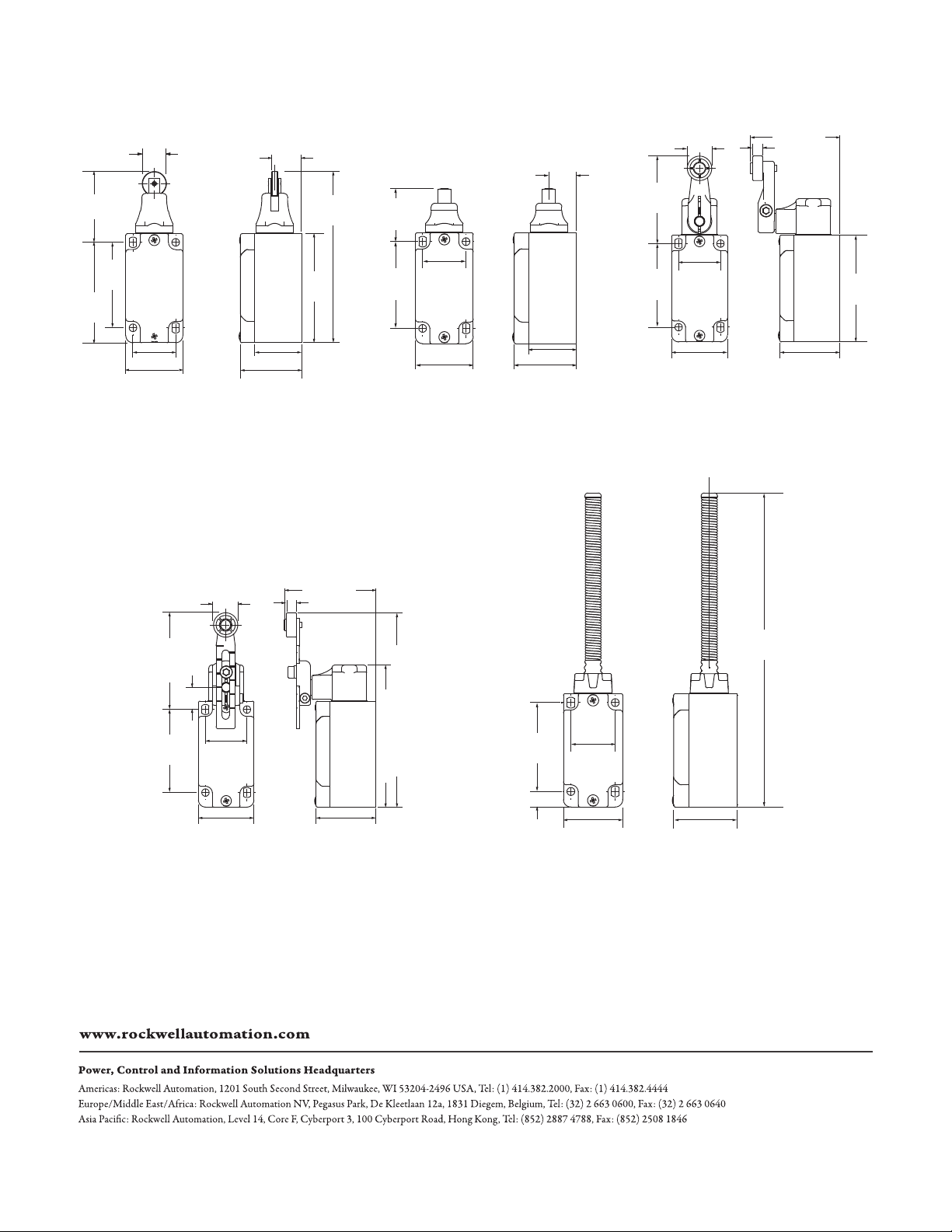

Open Conduit Dimensions [mm (in.)]

33 (1.29)

60

(2.36)

30 (1.18)

40 (1.57)

36.6

(1.44)

19

(0.74)

43 (1.69)

Roller Plunger Dome Plunger Short Lever

Adjustable Lever Spring Rod

48

(1.88)

70.5

(2.76)

60

(2.36)

17 (0.66)

Dia.

30 (1.18)

40 (1.57)

21

(0.82)

33 (1.29)

43 (1.69)

76.5

(3.01)

118

(4.64)

63

(2.48)

60

(2.36)

18 (0.7)

Dia.

30 (1.18)

40 (1.57)

64 (2.51)

7 (0.27)

43 (1.69)

133

(5.23)

85

(3.34)

Max.

(0.62)

60

(2.36)

16

17 (0.66)

Dia.

30 (1.18)

40 (1.57)

64 (2.51)

7 (0.27)

43 (1.69)

103 (4.05)

211

(8.3)

30 (1.18)

60

(2.36)

172 (6.77) Max. Extension

11 (0.43)

40 (1.57)

43 (1.69)

10000237915 Ver 01

June 2012

Copyright © 2012 Rockwell Automation, Inc. All Rights Reserved.

Loading...

Loading...