Page 1

DeviceNet

Pendant Stations

Bulletin 800E/F

User Manual

Page 2

Important User Information

The illustrations, charts, sample programs, and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

DeviceNet is a trademark of the Open DeviceNet Vendor Association (ODVA).

death, property damage or economic loss.

Page 3

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Preface

This manual gives an overview of the Bulletin 800E/F DeviceNet

Pendant Station and describes how to configure, install, operate and

troubleshoot the device on the DeviceNet Network.. . . . . . . . . . . . . P-1

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Contents of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

EDS Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Chapter 1 Overview of DeviceNet Pendant Station

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Enclosure Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Summary of Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

DeviceNet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

DeviceNet Sealed Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Typical DeviceNet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

DeviceNet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 Quick Start

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Data Rate Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Node Address Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Connection to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Pendant Station Parameter Configuration . . . . . . . . . . . . . . . . . . . . . . 2-2

Scanner Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Page 4

toc–ii Table of Contents

Chapter 3 Installation and Mounting

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DeviceNet Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting the Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting the DeviceNet Node Address . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Hanging the Pendant Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Quick Disconnect Cordsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Recommended Strain-Relief Method . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4 Operations

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Power-up/Reset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Run Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Control/Status Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Resetting the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

DeviceNet Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter 5 Troubleshooting and Maintenance

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Using the LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Replacing a Pilot Light Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Specifications

Mechanical Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Materials of Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Shock and Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Ingress Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Temperature Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Relative Humidity (Non-Condensing) . . . . . . . . . . . . . . . . . . . . . . .A-2

Electrical Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Current Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Publication 800-UM001A-EN-P – June 2004

Page 5

Table of Contents toc–iii

Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

DeviceNet Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Data Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Special Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Publication 800-UM001A-EN-P – June 2004

Page 6

toc–iv Table of Contents

Publication 800-UM001A-EN-P – June 2004

Page 7

Preface

Preface

This manual gives an overview of the Bulletin 800E/F DeviceNet

Pendant Station and describes how to configure, install, operate and

troubleshoot the device on the DeviceNet Network.

Intended Audience

This manual is for the individuals responsible for installing, mounting

and operating the 800E/F DeviceNet Pendant Station in an

industrial environment.

You should understand DeviceNet Network operations, including

how slave devices operate on the network and communicate with a

DeviceNet Master.

Page 8

P–2 Preface

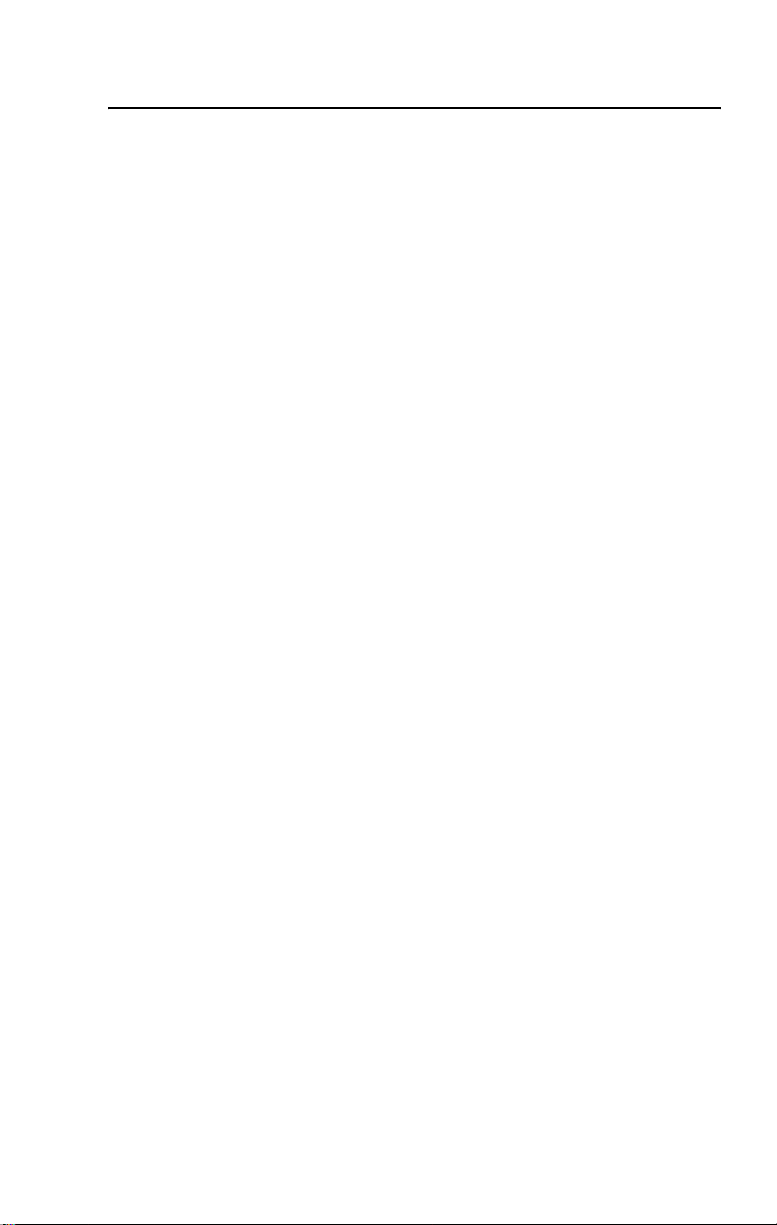

Contents of Manual

This manual is organized as follows:

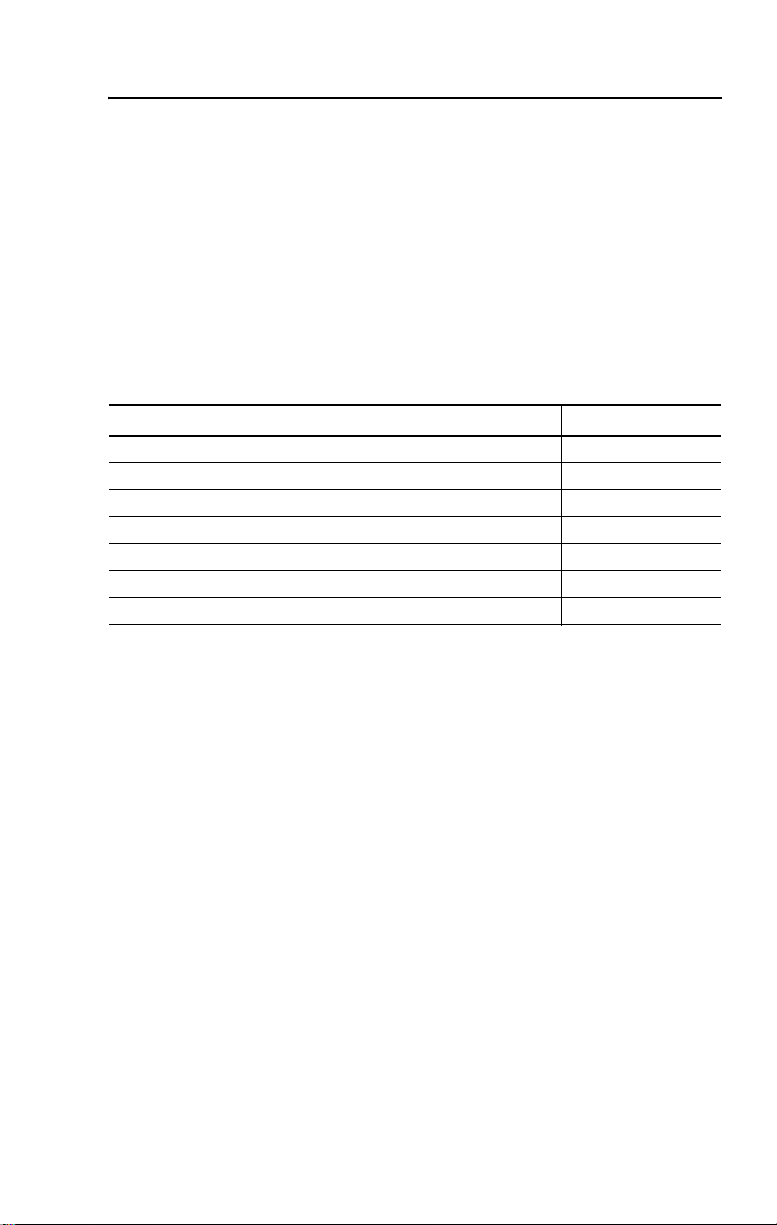

Chapter Title Description

Preface

1 Overview

2 Quick Start

3 Installation and Mounting

4 Operations

5

A Specifications

Troubleshooting and

Maintenance

Describes the purpose and contents of the manual

and the intended audience.

Provides an overview of the 800E/F DeviceNet

Pendant Station and its features.

Describes how to get the 800E/F DeviceNet

Pendant Station operating on the network.

Describes how to configure, mount and install the

800E/F DeviceNet Pendant Station on the

DeviceNet™ Network.

Describes 800E/F DeviceNet Pendant Station

operations and other pertinent information.

Provides information on how to troubleshoot and

maintain this device.

Provides 800E/F DeviceNet Pendant Station

specifications.

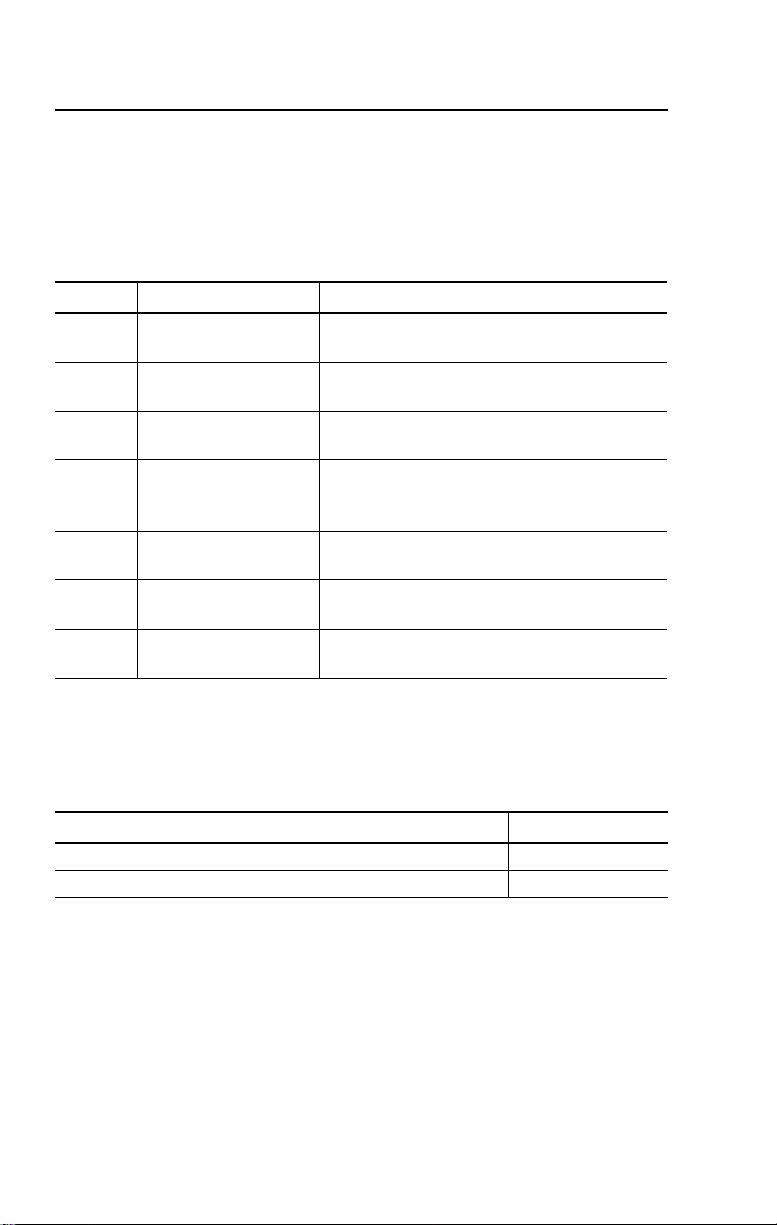

Related Publications

The following table lists DeviceNet Network related publications.

Publication Title Publication No.

DeviceNet Cable System Planning and Installation Manual DN-6.7.2

1756-DNB Scanner Module Configuraiton 1756-6.5.15

EDS Web Site

EDS files are available for downloading at:

www.ab.com/networks/eds/

Publication 800-UM001A-EN-P – June 2004

Page 9

Chapter 1

Overview of

DeviceNet Pendant Station

Chapter Objectives

This chapter provides an overview of the DeviceNet Pendant Station

and its features. It contains the following sections:

Section Page

Description 1-1

Summary of Features 1-2

Enclosure Features 1-2

DeviceNet Connection 1-3

Typical DeviceNet Configuration 1-4

DeviceNet Components 1-5

Replacement Parts 1-5

Description

The 800E/F Pendant Station line offers a DeviceNet connection for

applications where network communication is desired. All of the

functionality for the DeviceNet interface is contained within the

housing. The entire unit is powered from the DeviceNet Network. A

separate power supply is not required.

The 800E/F DeviceNet Pendant Station allows two operators,

1

– input/1 – output.

Page 10

1–2 Overview of DeviceNet Pendant Station

Summary of Features

• Standard configurations

• NEMA Type 4/4X/13

environmental rating

• Easy installation and startup

•DeviceNet connectivity

• Powered by DeviceNet

connection (no power supply

required)

• Available with mini connector

• Integral hanging bracket

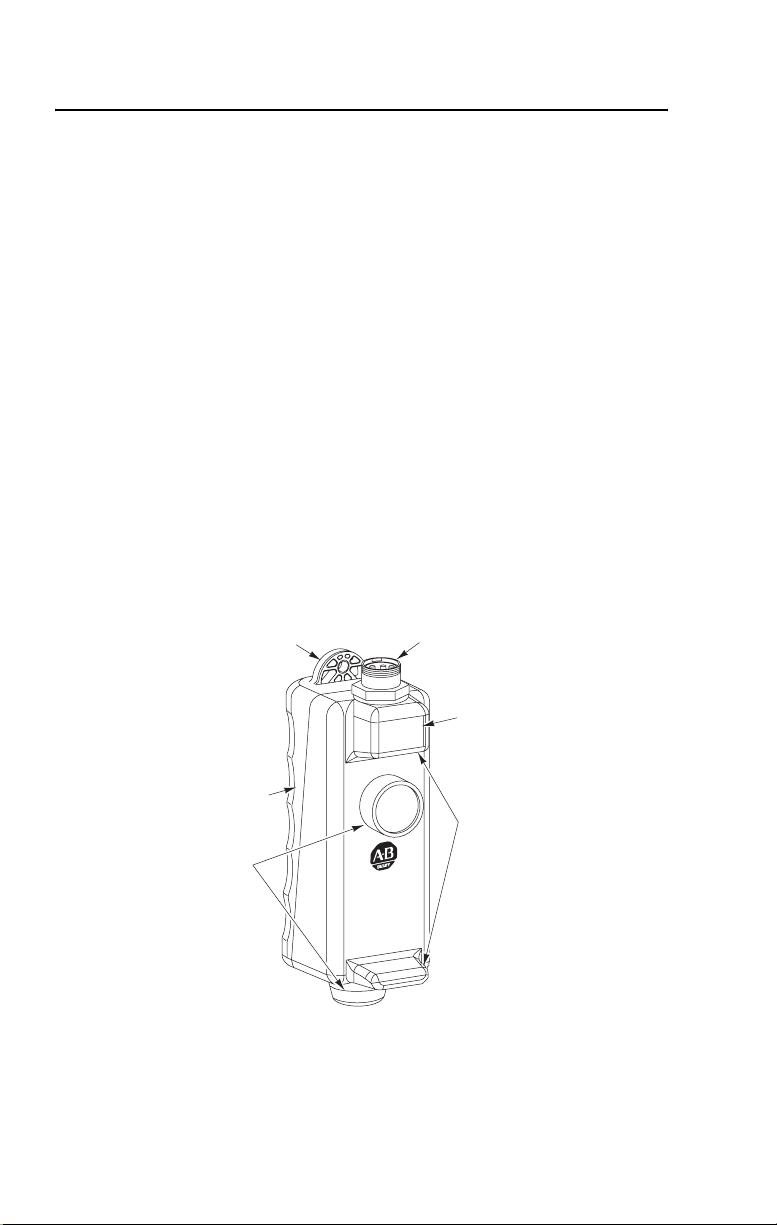

Enclosure Features

Hanging

Bracket

Enclosure

800E/F

Operators

• Standard 800E/F legend

carrier (800E-18xxxxxx or

800F-18xxxxxx)

• Button guards to protect

against inadvertent operation

• Long life LED

• Auto baud

• Auto Device Replace Enabled

• Standard 800E/F operators

Device Net

Connector

800 E/F

Legend

Carrier

Button

Guards

Publication 800-UM001A-EN-P – June 2004

Page 11

Overview of DeviceNet Pendant Station 1–3

DeviceNet Connection

The DeviceNet Pendant receives all power and communications

through the DeviceNet connection. A separate power supply is not

required. This is the only external connection to the DeviceNet

Pendant.

The DeviceNet Pendant connects to the DeviceNet Network using

a mini connector.

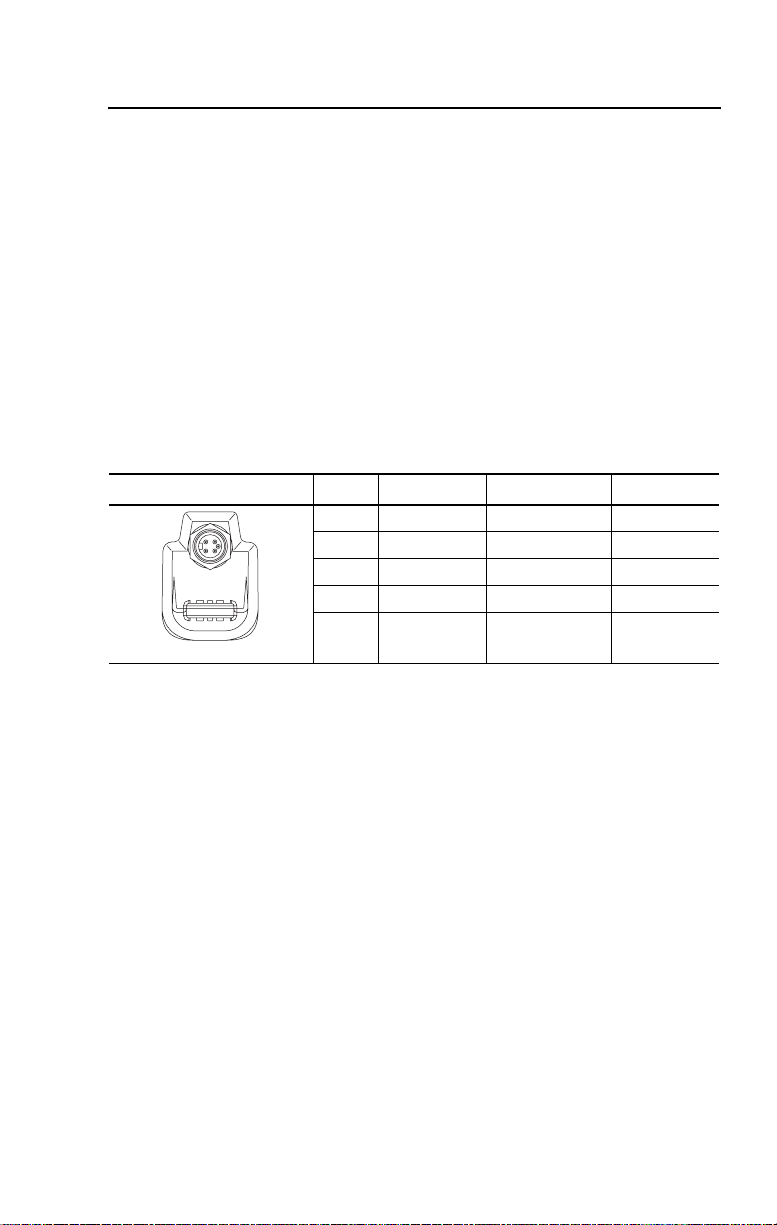

DeviceNet Sealed Connector

Sealed Connector Pin # Signal Function Color

54

3

12

1 SHIELD SHIELD Uninsulated

2 VDC+ Power Supply Red

3 COM Common Black

4 CAN_H Signal High White

5 CAN_L Signal Low Blue

Publication 800-UM001A-EN-P – June 2004

Page 12

1–4 Overview of DeviceNet Pendant Station

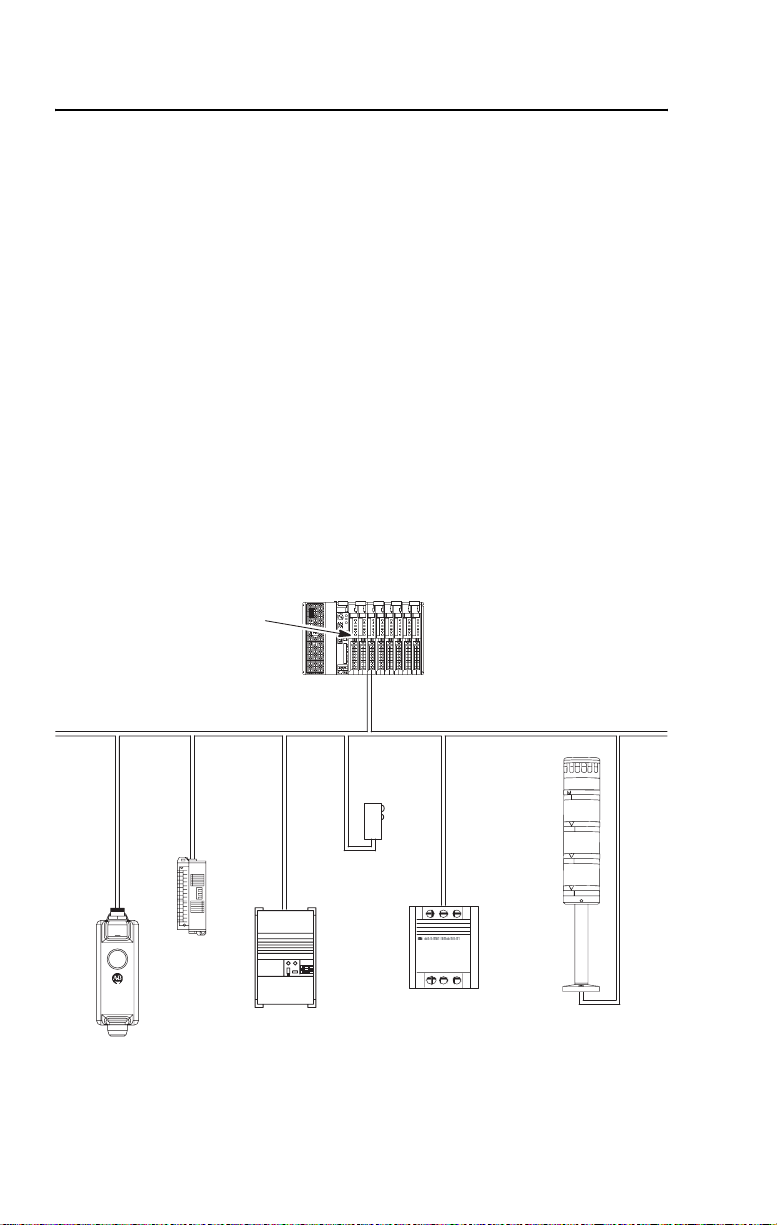

Typical DeviceNet Configuration

A DeviceNet Network supports multiple Pendant devices and

allows them to communicate with other network devices (up to 64).

The DeviceNet Pendant operates on the network as a slave device. It

does not initiate communications except for change-of-state,

duplicate I/O messages and a node address check on power-up. The

master writes data to, and receives data back from, the DeviceNet

Pendant.

The following Device Net configuration shows a variety of products

operating as slaves to a PLC-5 controller with a 1771-SDN

DeviceNet Scanner Module.

PLC-5 Controller

DeviceNet™ Scanner Module

Block I/O

Drive

800E/F Pendant

Publication 800-UM001A-EN-P – June 2004

DeviceNet™ Network

Sensor

SMC

Smart Motor Controller

Stack Light

Page 13

Overview of DeviceNet Pendant Station 1–5

DeviceNet Components

DeviceNet Cables and components are available from

Allen-Bradley as separate catalog numbers.

It is your responsibility to install and implement the DeviceNet

Network and supported devices according to the DeviceNet

guidelines.

Replacement Parts

The DeviceNet Pendant stations come with all the parts required to

install and use the product. The installer needs only to supply the

mounting hardware and cabling.

Replacement parts for 800E/F components (operators and

replacement lamps) are available as separate catalog numbers. Refer

to the Industrial Controls Catalog or 22 mm Push Button Selection

Guide.

Publication 800-UM001A-EN-P – June 2004

Page 14

1–6 Overview of DeviceNet Pendant Station

Publication 800-UM001A-EN-P – June 2004

Page 15

Chapter 2

Quick Start

Chapter Objectives

This chapter provides the necessary steps to get the DeviceNet

Pendant Station operating on the network. It contains the following

sections:

Section Page

Data Rate Configuration 2-1

Node Address Configuration 2-1

Connection to the Network 2-2

Pendant Station Parameter Configuration 2-2

Scanner Configuration 2-4

Data Rate Configuration

This device is Auto Baud enabled. There is no need to configure data

rate.

Node Address Configuration

Node address is set through node commissioning.

For more information on node address configuration, please see

Chapter 3 – Installation and Mounting (Setting the DeviceNet node

address).

Page 16

2–2 Quick Start

Connection to the Network

Wire the DeviceNet Pendant Station to an operating network. It will

be connected with the mini connector. The device is fully powered by

the network.

For more information on system installation, please refer to the

DeviceNet Cable System – Planning and Installation Manual

(Publication DN-6.7.2).

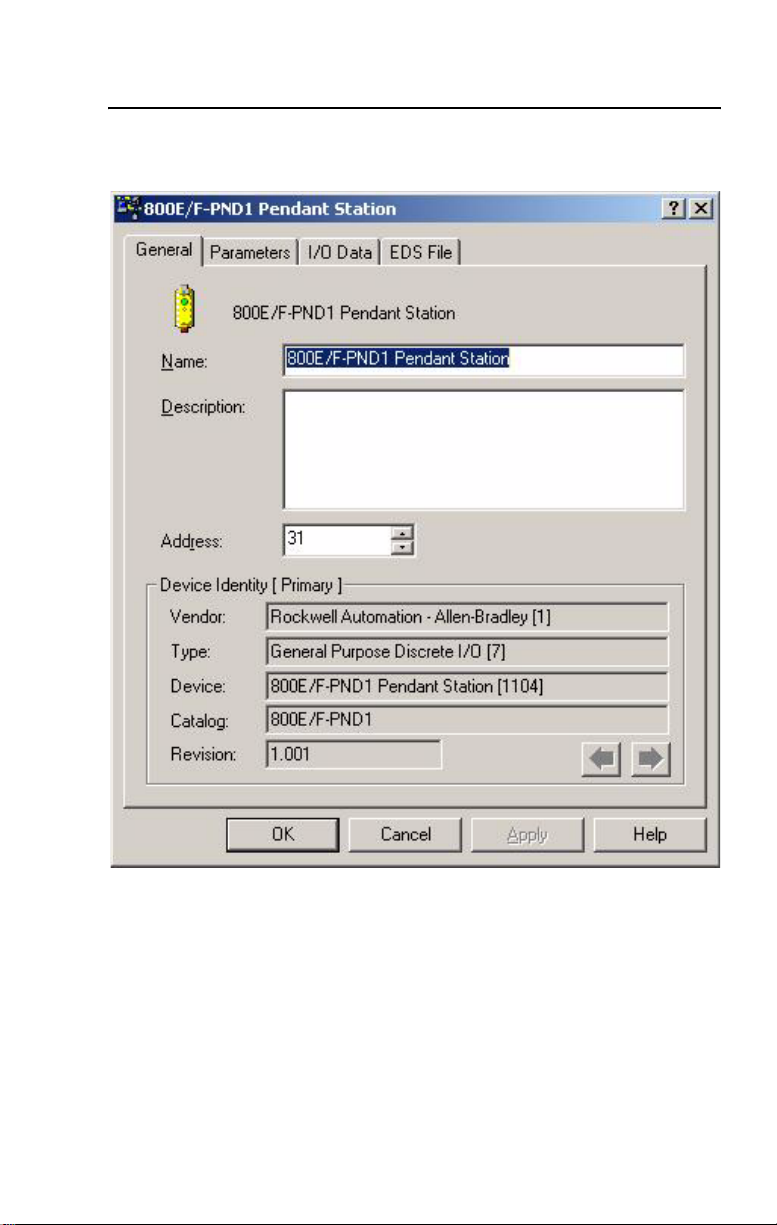

Pendant Station Parameter Configuration

In order for proper operation, the parameters must be configured. The

parameters can be configured using RSNetWorx for DeviceNet.

To access the parameter configuration screen from the Online view,

double click on the 800E/F Pendant Station Icon.

Publication 800-UM001A-EN-P – June 2004

Page 17

Quick Start 2–3

.

Click on the Device Parameters tab.

Publication 800-UM001A-EN-P – June 2004

Page 18

2–4 Quick Start

For more information on device configuration, please see Chapter 4 –

Operations and the RSNetWorx for DeviceNet documentation.

Scanner Configuration

In order for proper operation, the scanner must be configured. The

following graphics show the configuration of a 1756-DNB from the

RSNetWorx for DeviceNet Software.

Publication 800-UM001A-EN-P – June 2004

Page 19

Quick Start 2–5

To access the Scanner Module Configuration screen from an Online

view, double click on the 1756-DNB Scanner Icon.

Publication 800-UM001A-EN-P – June 2004

Page 20

2–6 Quick Start

To access the Scanlist Editor, click on the Scanlist tab.

Publication 800-UM001A-EN-P – June 2004

Page 21

Quick Start 2–7

Add the 800E/F Pendant Station to the Scanlist. Select the Device in

the Available Devices List. To have the software automatically assign

the I/O addresses, select the Automap on Add selection box. Click on

the “>” button.

Publication 800-UM001A-EN-P – June 2004

Page 22

2–8 Quick Start

To view/edit I/O parameters, click on Edit I/O Parameters.

Publication 800-UM001A-EN-P – June 2004

Page 23

Quick Start 2–9

To view/edit the mapping of the Input data, select the Input tab.

Publication 800-UM001A-EN-P – June 2004

Page 24

2–10 Quick Start

To view/edit the mapping of the Output data, select the Output tab.

Publication 800-UM001A-EN-P – June 2004

Page 25

Quick Start 2–11

To view/edit the auto device replacement parameters, click on the

ADR tab. Select the Enable Auto-Address Recovery box. Click on

Load Device Config. Select Configuration Recovery and Auto

Address Recovery.

Publication 800-UM001A-EN-P – June 2004

Page 26

2–12 Quick Start

For more information on scanner configuration, please refer to the

DeviceNet Scanner Configuration Manual (Publication 1756-6.5.15

for the ControlLogix Platform, Publication 1747-6.5.2 for the SLC

500 Platform, or Publication 1711-6.5.118 for the PLC 5 Platform).

Publication 800-UM001A-EN-P – June 2004

Page 27

Chapter 3

Installation and Mounting

Chapter Objectives

This chapter describes how to install and mount a standard or custom

DeviceNet Pendant Station. It contains the following sections:

Section Page

DeviceNet Guidelines 3-1

Equipment Needed 3-1

Setting the DeviceNet Node Address 3-2

DeviceNet Pendant Dimensions 3-3

Hanging the Pendant Station 3-4

Recommended Strain-Relief Method 3-4

DeviceNet Guidelines

It is your responsibility to install and implement the DeviceNet

Network and supported devices according to the DeviceNet

guidelines.

Equipment Needed

There is no need to open the enclosure. The only tools required are for

installing a hanging cable.

Setting the Data Rate

This device contains Autobaud functionality, it will automatically

detect the network data rate and synchronize to it.

The data rate determines the maximum length of the DeviceNet

Cable.

Page 28

3–2 Installation and Mounting

Data Rate Cable Length (Maximum)

125KB 500 m (1600 ft)

250KB 200 m (600 ft)

500KB 100 m (300 ft)

Autobaud See above, based on data rate of connected network

Setting the DeviceNet Node Address

The Node Address for the 800E/F Pendant Stations must be set

through Node Commissioning. The factory default is Node 63.

To set the DeviceNet Node Address:

1. Start RSNetWorx and select TOOLS from the Menu Bar.

2. Select Node Commissioning. The following screen will appear.

3. Select Browse and select the Pendant Station at Node 63.

4. Change the Node Address to the desired address and click on

Apply.

Publication 800-UM001A-EN-P – June 2004

Page 29

Installation and Mounting 3–3

DeviceNet Pendant Dimensions

Figure 3.1 shows the dimensions of the Pendant Stations. Dimensions

in millimeters (inches). Dimensions are not intended to be used for

manufacturing purposes.

Figure 3.1 Pendant Station Dimensions

149

(5.87)

60

(2.36)

81

(3.19)

Publication 800-UM001A-EN-P – June 2004

Page 30

3–4 Installation and Mounting

Hanging the Pendant Station

Dimensions in millimeters (inches). Dimensions are not intended to

be used for manufacturing purposes.

Figure 3.2 Pendant Mounting

∅ 6

(.24)

Quick Disconnect Cordsets

Standard

4-Pin Straight Quick Disconnect

Cable-Mini

Length Cat. No. Length Cat. No.

1.8 m 889N-F4AF-6F 1 m 1485R-P1N5-C

3.7 m 889N-F4AF-12F 2 m 1485R-P2N5-C

6.1 m 889N-F4AF-20F 3 m 1485R-P3N5-C

5-Pin Straight Quick Disconnect

DeviceNet

Cable-Mini

For more information on cabling options, please refer to DeviceNet

Catalog DN-2.15 or Sensor Catalog C113.

Recommended Strain-Relief Method

1/8 in. diameter wire rope/aircraft cable through eyelet of base,

crimped into a loop/eye with aluminum duplex sleeve.

Publication 800-UM001A-EN-P – June 2004

Page 31

Chapter 4

Operations

Chapter Objectives

This chapter contains the following sections:

Section Page

Modes of Operation 4-1

Resetting the Device 4-7

DeviceNet Operations 4-8

Modes of Operation

The 800E/F DeviceNet Pendant Station has 3 operating modes:

• Power-up/Reset Mode

•Run Mode

• Error Mode

Power-up/Reset Mode

During a power-up or reset, the 800E/F DeviceNet Pendant Station:

1. Clears output (turns output off).

2. Performs power-up diagnostic tests.

3. If Autobaud is enabled, device synchronizes to the network.

4. Performs Duplicate MAC ID check.

If a duplicate node occurs, the output remains off and the device

goes to “Bus Off”. You must cycle power to clear the error.

Page 32

4–2 Operations

Run Mode

After a successful power-up or reset, the 800E/F DeviceNet

Pendant Station enters run mode and operates as a slave device to a

master device.

Configuration is done over the network using DeviceNet Manager

or RSNetWorx for DeviceNet software.

ON-DELAY TIMEBASE – Parameter 4

In normal operation, the device shall permit configuration of an on-delay timer for the input. The On-Delay timer is always enabled for debounce on inputs. The device shall permit configuration of the On-Delay Timebase. The default timebase is 1 ms.

Val ue Timebase

0 1 ms

1 10 ms

ON-DELAY PRESET – Parameter 5

In normal operation, the device shall permit configuration of the On-Delay Preset. When this value is reached, the On-Delay timer output is set. It is user-configurable with a maximum value of 65,535. The default for the Preset is 2.

Val ue Preset

User Configurable 2 – 65,535

Publication 800-UM001A-EN-P – June 2004

Page 33

Operations 4–3

OFF-DELAY/ONE-SHOT TYPE – Parameter 6

In normal operation, the device shall permit configuration of an off-delay/one-shot timer for the input. The default value for Off-Delay/One-Shot Type is disabled.

Val ue Function

0 Disabled

1 One-Shot

2 Not Supported

3 Off-Delay

OFF-DELAY/ONE-SHOT TIMEBASE – Parameter 7

In normal operation, the device shall permit configuration of the Off-Delay/One-Shot Timebase. The default timebase is 1 ms.

Val ue Timebase

0 1 ms

1 10 ms

OFF-DELAY/ONE-SHOT PRESET – Parameter 8

In normal operation, the device shall permit configuration of the

Off-Delay/One-Shot Preset. When this value is reached, the

Off-Delay/One-Shot Timer output is set. It is user-configurable with a

maximum value of 65,535. The default for the Preset is 0.

Val ue Preset

User Configurable 0…65,535

Publication 800-UM001A-EN-P – June 2004

Page 34

4–4 Operations

OUTPUT VALUE – Parameter 9

In normal operation, the device shall permit output to be turned on and off. The default for the Output Value is Output Off.

Val ue Output Value

0 Output Off

1 Output On

Important: If the device is connected to a master with I/O

messaging, the I/O messaging will overwrite this

command.

OUTPUT FAULT ACTION – Parameter 11

In normal operation, the device shall permit configuration of the

Output Fault Action. This tells the device what to do with the output

in the case of a fault state. If Fault Value is selected, the device refers

to parameter 12, Output Fault Value, for action on a fault. The default

for Output Fault Value is Fault Value.

Val ue Fault Action

0 Fault Value

1 Hold Last State

OUTPUT FAULT VALUE – Parameter 12

In normal operation, the device shall permit configuration of the

Output Fault Value. If parameter 11, Output Fault Action is set to

Fault Value, this parameter tells the device what to do with the output

in case of a fault state. The default for Output Fault Value is Fault

Output Off.

Val ue Fault Value

0 Fault Output Off

1 Fault Output On

Publication 800-UM001A-EN-P – June 2004

Page 35

Operations 4–5

OUTPUT IDLE ACTION – Parameter 13

In normal operation, the device shall permit configuration of the

Output Idle Action. This tells the device what to do with the output in

the case of an idle state. If Idle Value is selected, the device refers to

parameter 14, Output Idle Value, for action on an idle state. The

default for Output Idle Value is Idle Value.

Val ue Idle Action

0 Idle Value

1 Hold Last State

OUTPUT IDLE VALUE – Parameter 14

In normal operation, the device shall permit configuration of the

Output Idle Value. If parameter 13, Output Idle Action is set to Idle

Value, this parameter tells the device what to do with the output in the

case of an idle state. The default for Output Idle Value is Idle Output

Off.

Val ue Idle Value

0 Idle Output Off

1 Idle Output On

AUTOBAUD – Parameter 15

In normal operation, the device shall permit disabling of the Autobaud feature. The default value for this parameter is Enabled.

Val ue Function

0 Enabled

1 Disabled

Publication 800-UM001A-EN-P – June 2004

Page 36

4–6 Operations

Control/Status Communications

The I/O messaging is set up through client/server connections at

power-up by the master device. Both Change-of-State (COS) and

Strobe messaging connections are supported by this device. COS

communications with the DeviceNet interface will consist of a

single input byte and a single output byte. They are defined as below.

INPUT/STATUS BYTE

Bit Number Function When = 1 Function When = 0

7 N/A N/A

6 N/A N/A

5 N/A N/A

4 N/A N/A

3 Output Status - On Output Status - Off

2 N/A N/A

1 N/A N/A

0 Input 1 On Input 1 Off

Publication 800-UM001A-EN-P – June 2004

Page 37

OUTPUT BYTE

Bit Number Function When = 1 Function When = 0

7 N/A N/A

6 N/A N/A

5 N/A N/A

4 N/A N/A

3 N/A N/A

2 N/A N/A

1 N/A N/A

0 Output 1 Execute Output 1 Idle

Error Mode

Errors are critical and non-critical.

Error Type Description

Critical (non-recoverable)

Non-Critical (recoverable) I/O connection timeout

Failure of diagnostic tests during power-up/reset mode

Duplicate node address detected

Operations 4–7

See the troubleshooting chart in Chapter 5 for details on how to recover from an error.

Resetting the Device

To reset the 800E/F DeviceNet Pendant Station, you must cycle

power to the unit or disconnect and reconnect the DeviceNet

Cabling.

Publication 800-UM001A-EN-P – June 2004

Page 38

4–8 Operations

DeviceNet Operations

The Allen-Bradley 1747-SDN, 1756-DNB, and 1771-SDN

DeviceNet Scanner Modules are master devices on the DeviceNet

Network. The 800E/F Pendant Station supports the Master/Slave

Connection Set for master/slave communications on the DeviceNet

Network.

To communicate with 800E/F Pendant Station, the DeviceNet

Scanner Module must be configured with the Pendant Station:

• Node Address

• Input bytes (1)

• Output bytes (1)

The DeviceNet Scanner Module:

• Connects to the 800E/F Pendant Station slave device

• Performs appropriate connection configuration

• Uses Change-of-State or Strobe Messaging for the 800E/F

Pendant Station I/O

Publication 800-UM001A-EN-P – June 2004

Page 39

Chapter 5

Troubleshooting and Maintenance

Chapter Objectives

This chapter contains the following sections:

Section Page

Preventive Maintenance 5-1

Using the LED Indicator 5-2

Replacing a Pilot Light Lamp 5-3

Preventive Maintenance

• Prevent accumulation of dust and dirt by:

– keeping enclosure clean

– keeping enclosure cover closed

• Periodically check for loose connections.

ATTENTION: To avoid shock hazard, remove

incoming power before checking connections.

!

Page 40

5–2 Troubleshooting and Maintenance

Using the LED Indicator

The LED provides status information on Pendant Station operations.

The LED is visible when the enclosure cover is removed.

The troubleshooting chart shows LED indications. It also shows how

to use the LED to detect and correct common operating problems.

LED

Color State

None

Red Solid

Red Flashing

Green Solid

Green Flashing

What It Means: What To Do:

Check DeviceNet power

Pendant Station is not

receiving input power.

Diagnostics failed on

power-up/reset.

Duplicate DeviceNet node

address. Two nodes cannot

have the same address.

IO connection timeout. Reset device.

Normal operating state and

device is allocated to a

master device.

Device is online and

operating properly, but not

allocated to master.

Device is in idle state.

and cable connections and

the power connection on the

DeviceNet connector.

Internal fault. Reset device. If

fault still exists, return

Pendant Station for repair.

Set Mac ID through Node

Commissioning. (See

“Setting the DeviceNet

Node Address” on page 3-2.)

No action required.

Check DeviceNet master

for correct Pendant Station

configuration information

(node address, input bytes,

output bytes).

Check DeviceNet master

for proper operation.

Publication 800-UM001A-EN-P – June 2004

Page 41

Troubleshooting and Maintenance 5–3

The LED does not indicate the following malfunctions.

Problem What It Means: What To Do:

Check wiring and cable

connections.

Check address setting via

Network Who.

Use an ohmmeter to verify

opening/closing of contacts.

Switch or button operators do

not function.

Loose wiring

Incorrect address

Faulty contacts, switch or

button

Replacing a Pilot Light Lamp

Pilot light lamps can be replaced easily by opening enclosure.

To replace a pilot light lamp:

ATTENTION: To avoid electrical shock or

unintended operation of the equipment, remove power.

!

1. Remove lens cap from the pilot light.

2. Remove lamp from socket. If necessary, use lamp removal tool –

Cat. No. 800F-ALR1.

ATTENTION: Do not use a screwdriver or other metal

object to remove lamp.

!

3. Carefully insert new LED module into latch.

ATTENTION: Use only 24V LED modules.

!

Publication 800-UM001A-EN-P – June 2004

Page 42

5–4 Troubleshooting and Maintenance

ATTENTION: Before replacing the lens cap, be sure

the lamp is seated properly or a short may result.

!

4. Replace the lens cap.

5. Check for proper operation.

Publication 800-UM001A-EN-P – June 2004

Page 43

Specifications

Mechanical Ratings

Materials of Construction

Table A.A Materials of Construction

Appendix A

Relative

Part Description Material

Enclosure PBT/PC Blend Thermo plastic

Enclosure Gasket Nitrile 70 Durometer — —

Shell – Nylon

Insert – PVC

Mini Connector

Screws Stainless Steel AISI 304 — —

800E/F Operators Misc. – See Industrial Control Catalog — —

Contact – Brass w/ Gold Flash Over

Palladium Nickel Plating

Gasket – Neoprene Shore ‘A’

Thermal

Index

248° F

(120° C)

Flammability

Rating

94-5VA

— —

Shock and Vibration

MECHANICAL SHOCK

1. Wave Shape – 1/2 cycle sine wave

2. Duration – 11 ms

3. Frequency – 3 times in each axis

4. Maximum Allowable G Force:

Operational 100 G

Page 44

A–2 Specifications

MECHANICAL VIBRATION

1. Axis Definitions – 3 mutually perpendicular axes

2. Frequency – 10…2000 Hz

3. Duration – 2 hours each axis

4. Maximum Allowable G Force:

Operational 10 G

Environmental Ratings

Ingress Ratings

All Units – Type 4/4X/13, IP66.

Dependent upon rating of installed devices.

Temperature Ratings

Operating Temperature -13° F…+131° F (-25° C…+55° C)

Storage Temperature -40° F…158° F (-40° C…+70° C)

(185° F (85° C) Max. for 24 hours)

Relative Humidity (Non-Condensing)

0…95% Humidity

Electrical Ratings

Supply Voltage

11…25V DC with reverse polarity protection. Class 2 Power Source

required.

Current Consumption

50 mA RMS, 100 mA peak @ 24V DC.

Publication 800-UM001A-EN-P – June 2004

Page 45

Specifications A–3

Input/Output

The voltage on I/O is 24V DC. 1 input and 1 output shall be

supported. Most 800E/F operators will be supported.

DeviceNet Connection

A mini connector will be available. It consists of five 18 AWG wires

for power and communications.

Communications

Data Rates

125 KB, 250 KB, and 500 KB

Distances

500 m (1600 ft) 125 KB

200 m (600 ft) 250 KB

100 m (300 ft) 500 KB

Certifications

UL, CUL, and CE marked for all applicable directives. CE directives

include EN55011, EN50081-2, EN50082-2 and EN60947-5-1. This

product is intended for use in an industrial environment.

Special Notes

Please refer to the Industrial Controls Catalog for 800E/F

operator-specific information.

Publication 800-UM001A-EN-P – June 2004

Page 46

A–4 Specifications

Publication 800-UM001A-EN-P – June 2004

Page 47

Page 48

Publication 800-UM001A-EN-P – June 2004. . . . . . . . . . . . . . . . . . . . . . . . . . . Copyright 2004 Allen-Bradley Company, Inc. Printed in USA

Loading...

Loading...