Page 1

8000 SERIES TMR SYSTEM

OPERATOR AND

MAINTENANCE MANUAL

DOCUMENT NUMBER 552864

ISSUE 02 JUNE 2004

Page 2

Page 3

OPERATOR AND MAINTENANCE MANUAL

Copyright © ICS Triplex Technology 1998-2004

Printed in England

Doc No 552864

Issue 02 June 2004 Page i

Page 4

OPERATOR AND MAINTENANCE MANUAL

This page intentionally blank

Doc No 552864 Page ii

Issue 02 June 2004

Page 5

OPERATOR AND MAINTENANCE MANUAL

Issue Record

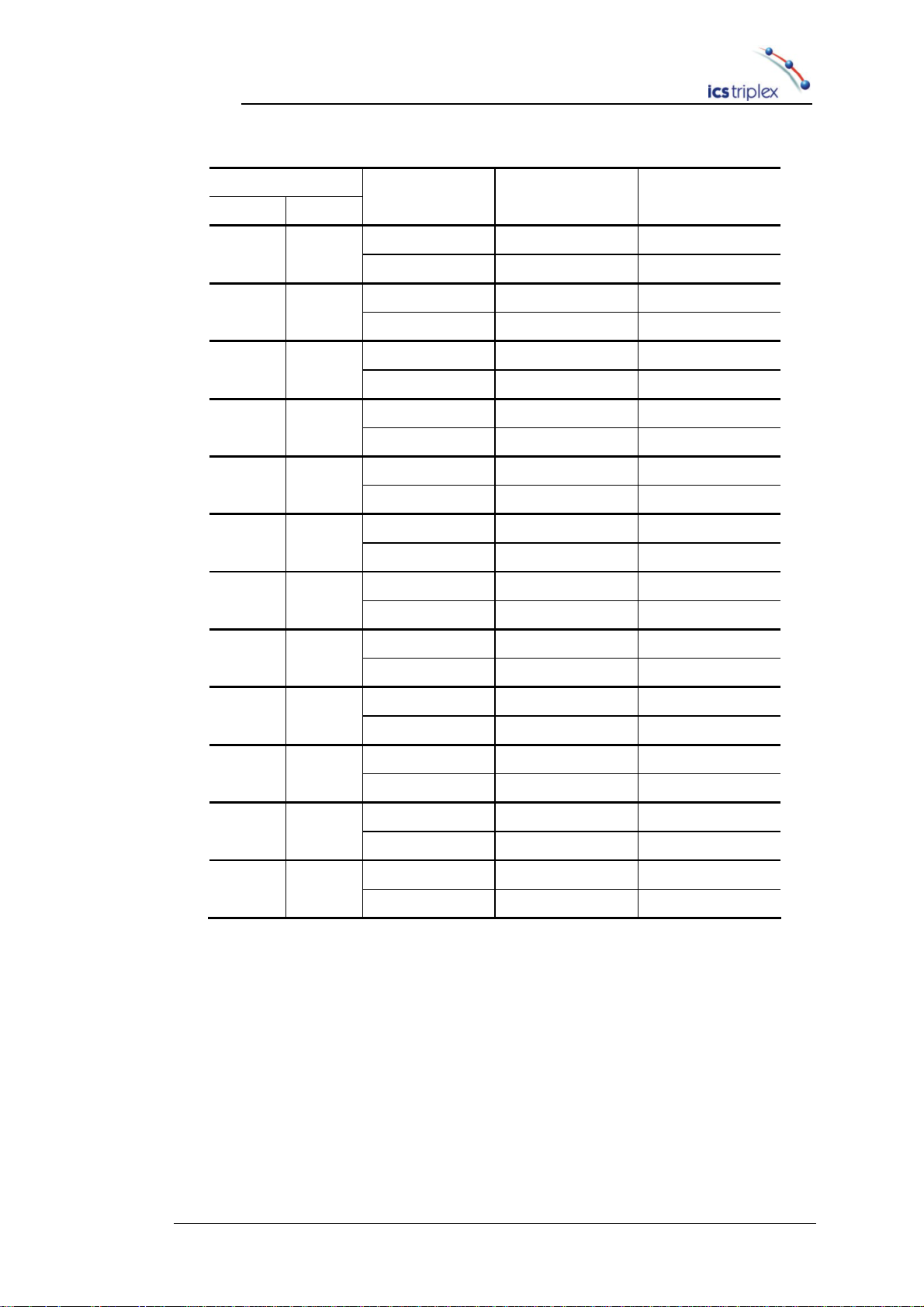

Issue Revised by Checked by Authorised by

Number Date

Issue 1 May J Bourn

Issue 2 June N Owens

Doc No 552864

Issue 02 June 2004 Page iii

Page 6

OPERATOR AND MAINTENANCE MANUAL

NOTICE

The content of this document is confidential to ICS Triplex Technology Ltd.

companies and their partners . It may not be given away, lent, resold, hired out or

made available to a third party for any purpose without the written consent of ICS

Triplex Technology Ltd.

This docum ent contains proprietary information that is protected by copyright. All

rights are reserved.

Microsoft, W indows, W indows 95, W indows NT, W indows 2000, and W indows XP

are registered trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice.

The reader should, in all cases, consult ICS Triplex Technology Ltd. to determine

whether any such changes have been made. From time to time, amendm ents to

this document will be made as necessary and will be distributed by ICS Triplex

Technology Ltd.

Information in this docum entation set may be subject to change without notice and

does not represent a commitment on the part of ICS Triplex Technology Ltd.

The contents of this doc ument, which may also include the loan of software tools,

are subject to the confidentiality and other clause(s) within the Integrator

Agreement and Software License Agreement.

No part of this documentation m ay be reproduced or transmitted in any form or by

any means, electronic or mechanic al, including photoc opying and recording, for any

purpose, without the express written permission of ICS Triplex Technology Ltd.

DISCLAIMER

The illustrations, figures, char ts, and layout examples in this manual are intended

solely to illustrate the text of this manual.

The user of, and those responsible for applying this equipment, must satisfy

themselves as to the acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication.

While efforts have been made to be accurate, the information contained herein

does not purport to cover all details or variations in hardware or software, nor to

provide for every possible contingency concerning installation, operation, or

maintenance. Features may be described herein which are not present in all

hardware or software systems. ICS Tr iplex T echnology Ltd. assumes no obligation

of notice to holders of this document with respect to changes subsequently made.

ICS Triplex Technology Ltd. makes no representation or warranty, expressed,

implied, or statutory with respect to, and assumes no responsibility for the

accuracy, completeness, sufficiency, or usefulness of the information contained

herein. No warranties of merchantability or fitness for purpose shall apply.

Doc No 552864 Page iv

Issue 02 June 2004

Page 7

OPERATOR AND MAINTENANCE MANUAL

REVISION AND UPDATING POLICY

All new and revised information pertinent to this docum ent shall be issued by ICS

Triplex Technology Ltd. and shall be incorporated into this docum ent in accordance

ith the enclosed instructions. The change is to be recorded on the Amendment

w

Record of this document.

PRECAUTIONARY INFORMATION

WARNING

Warning notices call attention to the use of materials, processes, methods,

procedures or lim its which must be followed precisely to avoid personal injury or

death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to

avoid damage to the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the

understanding of the information contained in this document

Doc No 552864

Issue 02 June 2004 Page v

Page 8

OPERATOR AND MAINTENANCE MANUAL

MAINTENANCE MUST BE PERFORMED ONLY BY Q UALIFIED PERSONNEL.

WARNING

RADIO FREQUENCY INTERFERENCE

MOST ELECTRONIC EQUIPMENT IS INFLUENCED BY RADIO FREQUENCY

INTERFERENCE (RFI). CAUTION SHOULD BE EXERCISED WITH REGARD

TO THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT AROUND

SUCH EQUIPMENT. SIGNS SHOULD BE POSTED NEAR THE EQUIPMENT

CAUTIONING AGAINST THE USE OF PORTABLE COMMUNICATIONS

EQUIPMENT.

MAINTENANCE

OTHERWISE PERSONAL INJURY OR DEATH, OR DAMAGE TO THE

SYSTEM, MAY BE CAUSED.

CAUTION

STATIC SENSITIVE DEVICES

MODULES IN THE TMR SYSTEM MAY CONTAIN STATIC SENSITIVE

DEVICES WHICH CAN BE DAMAGED BY INCORRECT HANDLING OF THE

MODULE. THE PROCEDURE FOR MODULE REMOVAL IS DETAILED IN

RELEVANT PRODUCT DESCRIPTIONS AND MUST BE FOLLOWED. ALL

TMR SYSTEMS MUST HAVE LABELS FITTED TO THE EXTERIOR SURFACE

OF ALL CABINET DOORS CAUTIONING PERSONNEL TO OBSERVE ANTISTATIC PRECAUTIONS WHEN TOUCHING MODULES.

Doc No 552864 Page vi

Issue 02 June 2004

Page 9

OPERATOR AND MAINTENANCE MANUAL

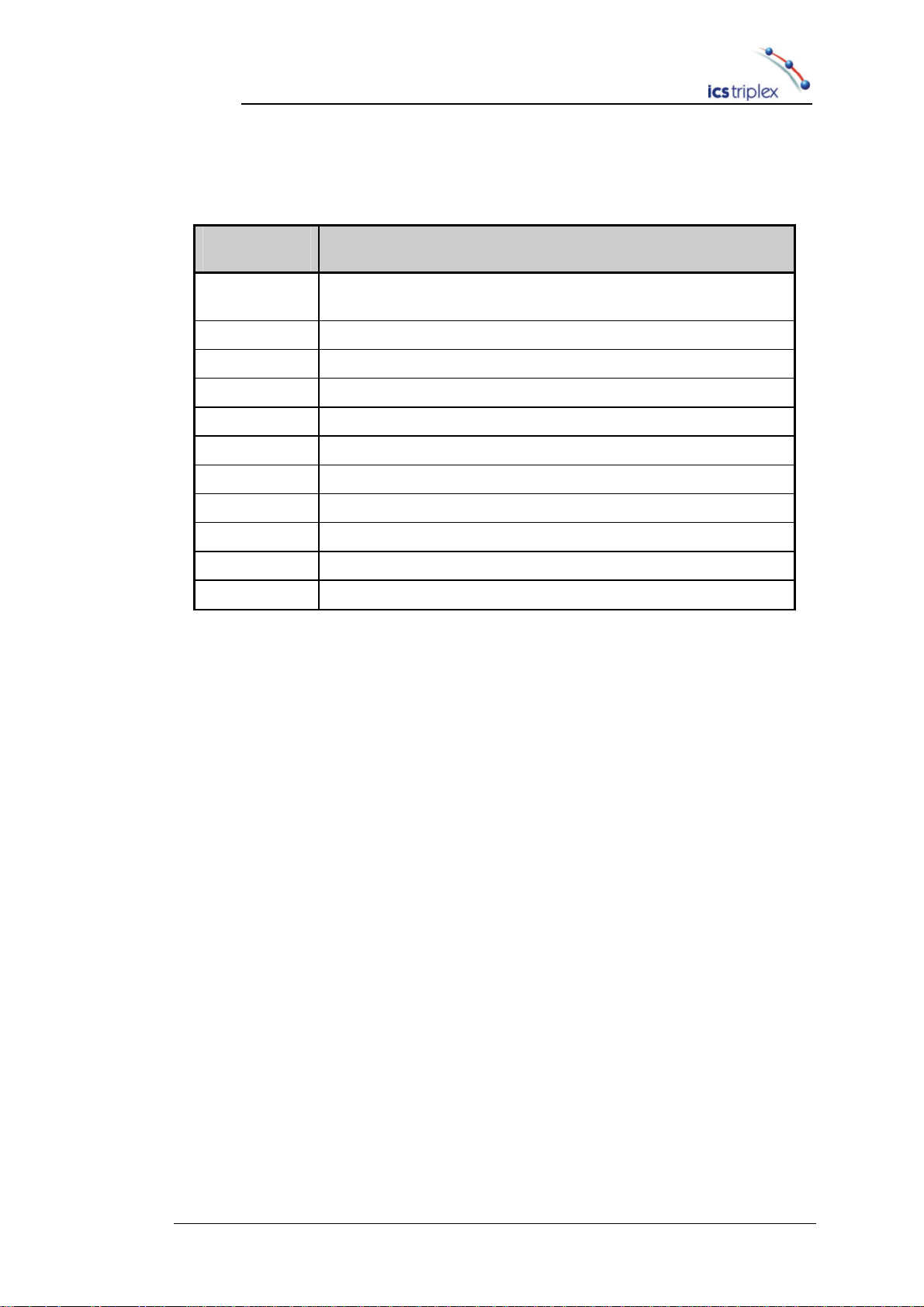

RECORD OF AMENDMENTS

Issue

Number

Issue

1

Changes

Initial Issue

Doc No 552864

Issue 02 June 2004 Page vii

Page 10

OPERATOR AND MAINTENANCE MANUAL

TABLE OF CONTENTS

1. INTRODUCTION ............................................................................................1

1.1 MAINTAINING SAFETY ............................................................................1

1.2 OPERATION AND MAINTENANCE PLAN................................................1

1.3 PLANNED MAINTENANCE.......................................................................1

.4 FIELD DEVICE MAINTENANCE...............................................................2

1

1.5 MODULE FAULT HANDLING....................................................................2

1.6 MONITORING............................................................................................3

1.7 DIAGNOSTIC ACCESS.............................................................................3

1.8 MODULE REPLACEMENT CONFIGURATION ........................................4

1.9 INPUT AND OUTPUT FORCING..............................................................5

1.10 MAINTENANCE OVERRIDES...................................................................6

2. OPERATION...................................................................................................7

3. MAINTENANCE..............................................................................................8

3.1 MODULE MAINTENANCE REQUIREMENTS ..........................................9

4. MODULE STATUS INDICATORS ................................................................10

4.1 8000 SERIES TMR PROCESSOR..........................................................10

4.2 8000 SERIES TMR INTERFACE.............................................................11

4.3 8000 SERIES TMR COMMUNICATIONS INTERFACE..........................11

4.4 8000 SERIES I/O MODULES ..................................................................12

5. FAULT FINDING...........................................................................................13

5.1 FAULT DETECTION....................................................................................14

5.2 FAULT ANNUNCIATION.........................................................................15

5.3 FAULT FINDING TECHNIQUES .............................................................15

5.4 CLEARING FAULTS................................................................................16

6. SYSTEM DIAGNOSTICS..............................................................................17

6.1 TEMPERATURE ALARMS......................................................................17

6.2 POWER SUPPLY UNIT...........................................................................17

6.3 FEED FAILURE.......................................................................................17

7. MODULE REPLACEMENT...........................................................................18

7.1 MODULE EJECTOR LEVERS AND KEY................................................18

7.2 MODULE RETURNS POLICY.................................................................18

7.3 TMR INTERFACE MODULE REPLACEMENT .......................................19

7.4 ACTIVE/STANDBY CHANGEOVER .......................................................19

7.5 COMPANION SLOT MODULE REPLACEMENT....................................20

7.6 SMARTSLOT (VERSION 2) REPLACEMENT ........................................21

8. RESTART PROCEDURE .............................................................................22

8.1 INTRODUCTION .....................................................................................22

8.2 POWER UP PROCEDURE .....................................................................22

8.3 8000 SERIES CABINET ..........................................................................22

8.4 FINAL.......................................................................................................23

Doc No 552864 Page viii

Issue 02 June 2004

Page 11

OPERATOR AND MAINTENANCE MANUAL

OPERATOR AND MAINTENANCE MANUAL

1. INTRODUCTION

1.1 MAINTAINING SAFETY

This manual should be read in conj unction with the safety manual (pr oduct number

8094)

1.2 OPERATION AND MAINTENANCE P LAN

This Operation and Maintenance requirement ensures that functional safety

continues beyond the design, production, installation and commissioning of the

system. The in-service operation and m aintenance is norm ally beyond the system

integrator responsibility. However, guidance and procedur es shall be provided to

ensure that the persons or organisations responsible for Operation and

Maintenance maintain the intended safety levels.

The Operating and Maintenance Plan shall include the following:

• Although the TMR

requirements, it is possible that the project specific implementation will

dictate specific action sequences. These sequences shall be clearly

defined, ensuring that the sequences cannot result in periods of the

system’s inability to respond safely whilst a hazard may be present.

• The Maintenance Plan shall detail the procedures to be adopted when

re-calibrating sensors, actuators and I/O modules. The recommended

calibration periods shall also be included.

• The Maintenance Plan shall include the procedure to be adopted for

testing the system, and the maximum intervals between manual testing.

• Sensor and actuator maintenance will require the application of overrides

in certain circumstances. Where these are required, they shall be

implemented in accordance with the guidance provided within this

document.

product requires no specif ic power-up and power- down

1.3 PLANNED MAINTENANCE

In most system configurations there will be some elements that are not test ed by

the system’s internal test facilities. These may be the final passive elements in

some I/O modules types, the sensors and actuators themselves and the field

wiring. A regime of Planned Maintenance testing shall be adopted to ensure that

faults do not accumulate within those elements that could ultimately lead to the

system’s inability to perform its required safety functions. The maxim um interval

between these tests shall be defined during the system design, i.e. before

installation. It is highly recommended that the test interval be less than 12 months.

Doc No 552864

Issue 02 June 2004 Page1 of 22

Page 12

OPERATOR AND MAINTENANCE MANUAL

1.4 FIELD DEVICE M AINTENANCE

During the lifetime of t he system , it will be necessar y to undertake a number of field

maintenance activities that will include re-calibration, testing and replacement of

devices. Facilities should be included within the system design to allow these

maintenance activities to be undertak en. Similarly, the operating and maintenance

plan needs to include thes e maintenance activities, and their effec t on the system

operation and design. In general, adequate provision for these measures will be

defined by the client. Provided the facilities, i.e. maintenance overrides, are

implemented within the requirements specified within this document, no further

safety requirements are necessary.

It is highly recommended that the I/O forcing capability should NOT be used to

support field device maintenance. This facility is provided to support application

testing only. Should this facility be used, the requirements defined in para. 1.9 shall

be applied.

1.5 MODULE FAULT HANDLING

When properly configured and installed, the TMR system is designed to operate

continuously and correctly even if one of its modules has a f ault. When a m odule

does have a fault it should be replaced promptly to ensure that faults do not

accumulate, thereby causing multiple failure conditions that could cause a plant

shutdown. All modules permit live rem oval and replacem ent, and modules within a

fault-tolerant configuration can be removed with no further action. Modules in a

non-redundant or fail-safe configuration will require the application of override or

bypass signals for the period of the module removal to ensure that unwanted safety

responses are not generated inadvertently.

On-site repair of modules is not supported; all failed modules should be returned for

repair and/or fault diagnosis. The return procedure for modules should include

procedures to identify the natur e and circumstances of the f ailure and the system

response. Records of module failures and repair actions shall be maintained.

Doc No 552864 Page 2 of 22

Issue 02 June 2004

Page 13

OPERATOR AND MAINTENANCE MANUAL

1.6 MONITORING

In order to establish that the safety objectives have been m et thr ough the lif etime of

the system it is important to maintain r ecords of the faults , failures and anomalies.

This requires the maintenance of records by both the end-user and the system

integrator. The rec ords maintained by the end-user are outside the scope of this

document; however, it is highly recommended that the following information be

included:

• Description of the fault, failure or anomaly

• Details of the equipment involved, including module types and serial

numbers where appropriate

• When the fault was experienced and any circumstances leading to its

occurrence

• Any temporary measures implemented to correct or work around the

problem

• Description of the resolution of the problem and reference to remedial

action plans and impact analysis

Each system integrator should define the f ield returns, repair and defect handling

procedure. The inform ation requirements placed on the end user because of this

procedure should be clearly documented and provided to the end user. The defect

handling procedure shall include:

• Method of detecting produc t related defects and the reporting of these to

the original designers.

• Methods for detecting systematic f ailure that m ay affect other elem ents of

the system or other systems, and link s to the satisfac tory resolution of the

issues.

• Procedures for track ing all reported anomalies, their work around and/or

resultant corrective action where applicable.

1.7 DIAGNOSTIC ACCESS

The TMR Pr ocessor supports c omprehensive diagnostic fac ilities. Some of these

facilities have the capability of modifying the system’s operation and are therefore

password protected, to provide access protection in addition to that afforded by

physical access to the system.

The password is defined in the secur ity section of the s ystem.ini file. The password

is encoded and is not readily decodable from the system.ini text file.

A default password is implemented automatically, however it is

recommended that a specific p assword be defined wit hin the system.ini file.

It is important that this password be made available only to personnel

requiring access to the additional diagnost ic capabilities (typ ically only ICS

Triplex Technology Ltd. personn el). If this password is lost, there is no capability

of accessing these functions without reconfiguring the system.

Doc Number 552864

Issue 02 June 2004 Page 3 of 23

Page 14

OPERATOR AND MAINTENANCE MANUAL

1.8 MODULE REPLACEMENT CONFIGURATION

The system supports 3 forms of High Density I/O module replacement:

a. Companion slot (Hot-swap pair)

b. SmartSlot pair

c. Live insertion and removal

In the companion slot conf iguration, two adjacent module positions are coupled to

provide and active and standby module pair. If it intended that the system be able

to start-up (including application stop and re-star t), on the primar y module position,

there is no requirement to define the secondary module position.

If it is intended to allow the system to start with only the secondary module

position occupied, it is important that the module positions be included

within the system.ini file. Identical con figuration settings shall be entered for

both primary and secondary module positions.

For SmartSlot pair oper ation, it is not possible to start-up using the “ spare” mod ule

position. The spare module position need not be in the same chassis as the

primary module position.

If it is intended to perform live inser tion and removal without transfer to a standby

module no specif ic configuration is required. If it is intended to start-up a system

without the primary module installed in either a SmartSlot or single module live

insertion and removal configuration, the “simulate” configuration option should be

set. The simulate option will allow the system to start with these modules om itted,

the corresponding states and values being set to their fail-safe conditions.

1. A consistent module replacement philosophy should be used within any

single system. Where mixed philoso phies are used, there shall be clear

indication of the repair approach applicable to each module or group of

modules.

2. In hot-swap and SmartSlot configurations, the accuracy with both

modules installed shall be within the plant required safety accuracy

specification. If tighter tolerance is required, ensure that each sensor

within a redundant configuration is allocated to independent modules and

procedural measures are implemented to ensure that only a single module

within this set of modules is paired at any instant.

3. If the SmartSlot module replacement is used, the system shall include

provision for testing the SmartSlot linking cable. This cable shall be

tested before use; the testing of this cable shall be included in the

Operating and Maintenance Manual.

4. In hot-swap configurations, a secondary module that does not pair with

the primary module in a reasonable amount of time (less than the second

fault occurrence time) must be removed.

5. In SmartSlot configurations, a secondary module that does not pair with

the primary module in a reasonable amount of time (less than the second

fault occurrence time) when th e SmartSlot linking cable is inst alled must

be removed.

Doc No 552864 Page 4 of 22

Issue 02 June 2004

Page 15

OPERATOR AND MAINTENANCE MANUAL

1.9 INPUT AND OUTPUT FORCING

Locking and forcing of individual inputs and outputs from the IEC1131 W orkbenc h

are supported for engineering, installation and commissioning purposes. Inservice, maintenance overrides for safety-related inputs and outputs should be

implemented using the application program. The IEC1131 Workbench initiated

locking and forcing requires:

• The TMR Processor keyswitch to be in the “Maintain“ position to make

changes to the lock or force status of any point

• Access to the workbench lock & write com mands, which are multi-level

password protected.

A list of the currently locked points are read back from the T MR

available within the IEC1131 Workbench.

The TMR Processor inhibit LED will indicate when one or more I/O points are

locked. The application program can determine how many points are currently

locked by using the information available from the TMR Processor complex

equipment; it is highly recommended that this be used to control additional status

display and/or for logging purposes.

All input and output locks (and forces) can be removed using either a single

function from the IEC1131 Workbench or from an edge triggered signal to the

TMR Processor b oard within the application program. If locking is used, a

safety-related input connected to an operator accessible switch shall be

implemented to initiate the removal of the lock and force conditions.

It is important that t he effec ts of f orcing input and output points on the proc ess and

their safety impact are understood by any person using these facilities.

The system will allow the forced conditions to be maintained during normal

operation. When returning to normal operation it is recommended that all

locked and forced points be returned to normal operation. It is the plant

operators’ responsibility to ensure that if forc ed conditions are present that they do

not jeopardise the functional safety.

system and made

Doc Number 552864

Issue 02 June 2004 Page 5 of 23

Page 16

OPERATOR AND MAINTENANCE MANUAL

1.10 MAINTENANCE OVERRIDES

aintenance Overrides set inputs or outputs to a defined state that can be

M

different from the real state during safety operation. They are used during

maintenance, usually to override input or output conditions in order to perform a

periodic test, calibration, or repair of a module, sensor or actuator.

To correctly implement a m aintenance override scheme within the TMR

Controller

the override, or ‘bypass’ logic shall be programm ed within the Application Program,

with a separate set of safety-related input points or variables enabling the bypass

logic.

In order to accommodate maintenance overrides safely, TÜV has

documented a set of prin ciples that shall be followed. These principles are

published in the document "Maintenance Override" by TÜV Süddeutschland /

TÜV Product Service GmbH and TÜV Rheinland.

http://www.tuvasi.com/modr_3_d.htm

There are two basic methods now used to check safety-related peripherals

connected to the TMR system

:

1. Special switches connec ted to conventional system inputs. T hese inputs are

used to deactivate sensors and actuators during maintenance. The

maintenance condition is handled as part of the system’s application

program.

2. Sensor s and actuators are electrically switched off during maintenance and

are checked manually.

In some installations, the m aintenance console m ay be integrated with the operator

display, or maintenance may be covered by other strategies.

Doc No 552864 Page 6 of 22

Issue 02 June 2004

Page 17

OPERATOR AND MAINTENANCE MANUAL

2. OPERATION

A safety Instrumented system ( SIS) is dorm ant by nature, therefore in nor mal plant

perating situations the SIS is not required and is o nly called upon to operate in an

o

emergency situation.

A SIS should be designed to operate automatically and so requires no operator

interaction. It is essential however that the SIS and associated field devices are

maintained, to ensure they operate when required.

Before accepting ownership of a system an operator should be satisfied that the

SIS has been installed and comm is s ioned to the latest appr oved des ign documents

and signed off by certifying authorities (where applicable). It is essential that

document masters are maintained and fully traceable.

Modifications should not be carried out without a saf ety ass essment and relevant

approval. Modifications to a SIS, including the application, field devices and

hardware, may impact the reliability and availability of the system.

Operators should know which SIS diagnostic and operational alarms are

annunciated, and where they appear. For example, a system m ay be configured to

annunciate a common status diagnostic alarm to an operator interface

(SCADA/DCS etc) that requires further investigation at the panel, while all

operational alarms may be individually reported on a first up basis.

Operators should be familiar with the location of the SIS documentation, spares

and contact details for technical support.

Doc Number 552864

Issue 02 June 2004 Page 7 of 23

Page 18

OPERATOR AND MAINTENANCE MANUAL

3. MAINTENANCE

The operator maintenance schedule for testing the SIS, sensors and actuators

should reflect the test interval used in the reliability/availability calculations.

The system should be conf igured to allow testing from the I/O module to the field

device.

Inputs

The purpose of the override is to allow testing of the sensor without executing a trip.

Inputs may be configured to have an override in the application logic which should

prevent the executive action but annunciate the alarm to the operator interface.

Analogue inputs should be tested over their full range.

Outputs

Output modules perform diagnostic tests as detailed in the Product descriptions.

Final element testing is usually performed by operators during scheduled plant

shutdowns.

Some systems use the 8000 Series Valve monitor module to perform frequent

partial valve tests while the plant is live. The cumulative data is analysed and

provides details of covert failures and wear, allowing planned maintenanc e bef or e a

failure occurs.

Plant Maintenance

Maintenance to SIS sensors and final elements, e.g. calibration or

repair/replacement while the plant is live, will require a maintenance override

facility. Refer to paragraph 1.10.

SIS Housekeeping

The system should be kept clean at all times. Recommended 3 monthly

maintenance should include

(1) Visually inspect the following:

1) All fuses to ensure that they are intact.

2) All 8000 Series Cabinets rack and roof fan units are working satisfactorily.

3) All terminals for tightness.

4) All modules, relays and other equipment for corr ect and secure location in their

sockets.

5) For signs of contamination and corrosion, paying particular attention to cable

joints, cable terminations, MCBs, trunking etc.

(2) Lubricate all hinges and locks.

(3) Check that the 8000 Series Cabinets are correctly ventilated and grilles are free

from dust. In dusty environments, this check may be necessary more

frequently.

Doc No 552864 Page 8 of 22

Issue 02 June 2004

Page 19

OPERATOR AND MAINTENANCE MANUAL

3.1 MODULE MAINTENANCE REQUIREMENTS

There are no user-maintainable parts in any of the 8000 Series System modules.

Doc Number 552864

Issue 02 June 2004 Page 9 of 23

Page 20

OPERATOR AND MAINTENANCE MANUAL

test

4. MODULE STATUS INDICATORS

The following sub-paragraphs detail the front panel LEDs of the 8000 Series

System range of modules together with their function and status.

4.1 8000 SERIES TMR PROCESSOR

LED INDICATION

Healthy

Active Steady green when module is in Active mode.

Standby Steady green when module is in Standby mode.

Educated Steady green when module is educated.

Run Flashing green when module is in normal operation with full

Inhibit Flashing green when any input or output is locked.

System Healthy

User 1 and User 2 General purpose red LEDs for use under software control.

Overall health of each processor slice:

Steady = healthy

Red flashing = slice failed.

Flashing green when module has changed from Active to

Standby mode.

Flashing green when being educated.

Off when module is not educated, or application is stopped.

integrity.

Steady green in standby.

Off when the application in the Active Processor is stopped.

This LED also flashes green if a changeover from Active to

Standby is attempted when the current Standby Processor has

incompatible system configuration.

System health:

Steady green = healthy

Flashing red = system boot-up, system fault, or selffail, IMB error, or 8000 Series I/O module error.

Active/standby module failing to respond,

has a slice error, channel fault, or a module

is being simulated. Regent I/O module error. A module is

failing to respond.

Off = illegal state

Note: If the Healthy LED is green flashing and power is switched off, then on again, the

faulty slice may fail to operate again. When the Healthy LED is flashing red,

processing is automatically switched to the standby Processor.

Doc No 552864 Page 10 of 22

Issue 02 June 2004

Page 21

OPERATOR AND MAINTENANCE MANUAL

4.2 8000 SERIES TMR INTERFACE

LED INDICATION

Healthy Overall health of each processor slice:

Steady green = healthy.

Flashing green = fault.

Active Steady green when module is in Active mode.

Standby Steady green when module is in Standby mode.

Educated Steady green when module is educated.

Flashing green during module education.

Off when module is not educated.

I/O Healthy I/O sub-system health:

Steady green = healthy

Flashing Green = fault.

4.3 8000 SERIES TMR COMMUNICATIONS INTERFACE

LED INDICATION

Healthy Module health.

Steady green = healthy.

Flashing red = fault.

Active Steady green when module is in Active mode.

Standby Not used.

Educated Not used. Set to steady green at power up.

Communications

Six tri-coloured LEDs indicate data transfer activity on all

serial communication ports and both Ethernet ports.

The LEDs flash red when responding and green when

receiving.

The Ethernet LEDs indicate steady green in the absence of a

network connection.

Doc Number 552864

Issue 02 June 2004 Page 11 of 23

Page 22

OPERATOR AND MAINTENANCE MANUAL

4.4 8000 SERIES I/O MODULES

LED INDICATION

Healthy Module health.

Off = No power applied to the module.

Amber = Slice is in the start-up state (momentary after

Green = healthy.

Flashing red = fault present on the associated slice but the

slice is still operational.

Red (momentary) = On installation – power applied to the

associated slice.

Red = The associated slice is in the fatal state. A

critical fault has been detected and the slice

Active Off = module is not in the Active state.

Green = module is in the Active state.

Flashing red = Module is in the shutdown state if the

Standby LED is off.

Flashing red = Module is in the fatal state if the Standby

LED is also flashing red.

Standby Off = module is not in the Standby state.

Green = module is in the Standby state.

Flashing red = module is in fatal state. The Active LED will

also be flashing red..

Educated Off = module is not educated.

Green = module is educated.

Flashing green = module is recognised by the processor but

education is not complete.

Channel LED

(40-off)

Off = open field switch (contact).

Green = closed field switch (contact).

Flashing red = associated channel faulty.

Flashing green = associated channel input voltage out of

range, i.e. either below the lowest trip

threshold or above the highest.

installation or power-up).

has been disabled.

Note: The LEDs indicating channel status may be configured to suit user

requirements by implementing the procedure for configuring a System.INI file

detailed in PD-8010.

Doc No 552864 Page 12 of 22

Issue 02 June 2004

Page 23

OPERATOR AND MAINTENANCE MANUAL

5. FAULT FINDING

The 8000 Series System is capable of detecting and isolating faults to module

level, while its two-out-of-three voting architecture pr events faults fr om propagating

to the system outputs. Various means are provided for directing maintenance

personnel to the faulty module. Most system modules are hot-replaceable,

providing continuous system operation.

The following paragraphs describe how faults are detected, annunciated, and

cleared in the 8000 Series

procedures that the user should follow when diagnosing faults and repairing the

8000 Series

System.

Note: System repair must be done prom ptly to ensure continued fault-tolerant operation

of the 8000 Series

System. TUV certification does not specify a minimum

replacement tim e for faulty modules, becaus e safety is not compromised and the

faulty channel will fail-safe if further faults develop. However, it is recommended

that modules that have been diagnosed as having f ailed should always be replaced

within eight hours to maintain production (availability). Systems with a safety

integrity level (SIL) rating will have a time to repair as part of the c alculation, which

must be followed to maintain the SIL. Modules must be replaced before the

Second Fault Occurrence T ime (the average probable time bef ore a second fault)

to avoid shutdown.

System. They also describe some of the basic

Doc Number 552864

Issue 02 June 2004 Page 13 of 23

Page 24

OPERATOR AND MAINTENANCE MANUAL

5.1 FAULT DETECTION

There are three levels of fault detection used in the 8000 Series System:

1. Discrepancy logic in each I/O module compares the 8000 Series TMR

Processor output data on eac h bus cycle. A fault is recorded whenever the

data in one processor disagrees with the other two processors of the 8000

Series TMR Processor.

2. Loopback logic on Interfaces and I/O modules is exercised by the 8000

Series TMR Processors on a background basis to detect output data faults.

3. Self-test circuitry in the 8000 Series TMR Processor and 8000 Series TMR

Interface. In addition, power supplies contain circuits for checking their

output voltages.

The 8000 Series TMR Processor is responsible for sorting the fault information

received from the various levels and alerting the operator when system repair is

required. Faults are c ategorised as transient or permanent based on the rate at

which they occur. A separate filtering algorithm is applied to each fault type,

preventing nuisance alarms fr om occu rring on a transient fault. Figur e 1 illustrates

this filtering algorithm.

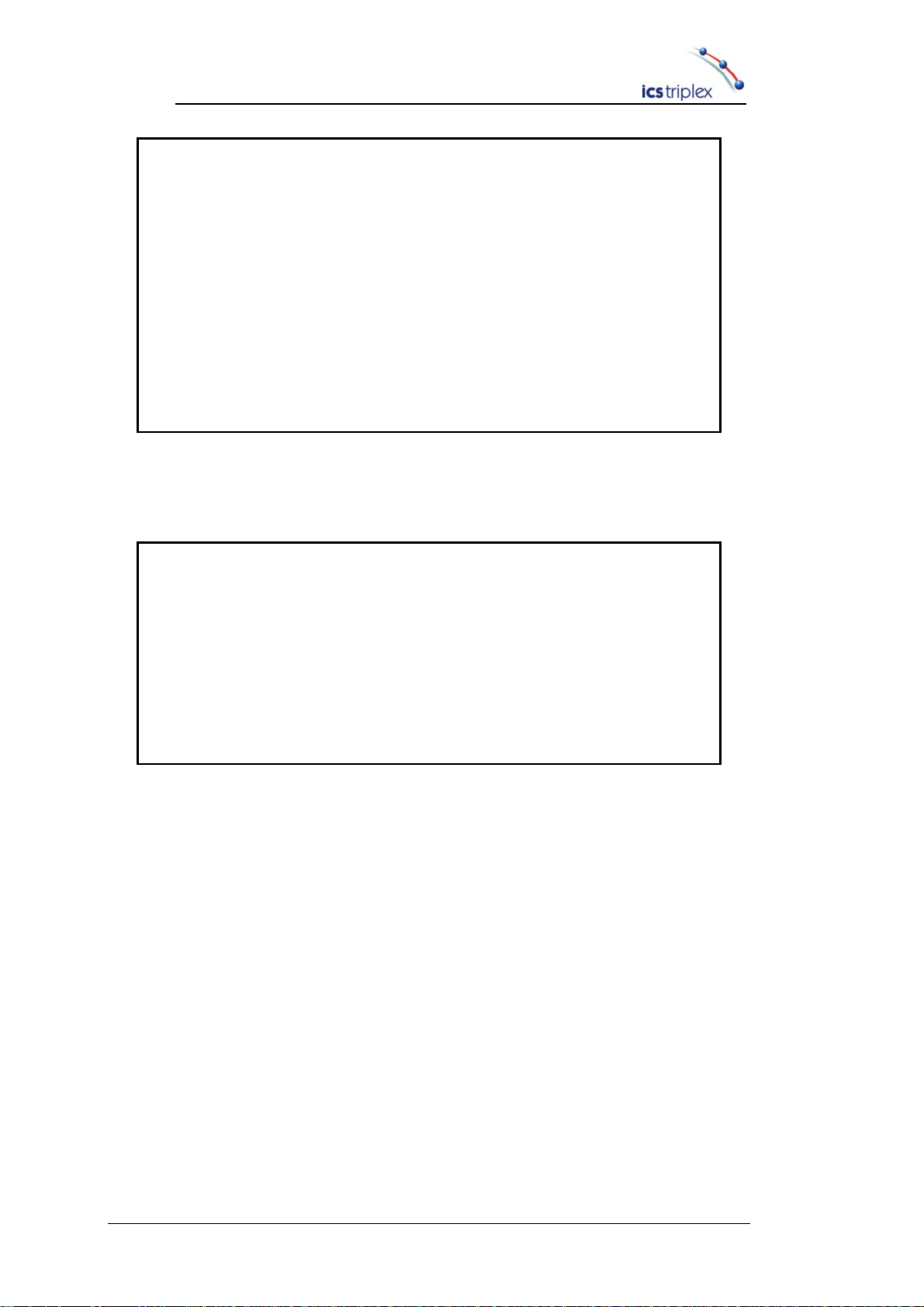

Latche d Until Reset

Permanent Error Threshold

Transient

Transient Reset

Test Cycle

Transient

Transient

Transient

Permanent

Figure 1 Fault Filtering

The system check s its fault s tatus on a cyclic basis and if a f ault is detected during

that cycle, it increments a fault counter and r ecor ds a tr ansient f ault. If a fault is not

detected, the counter is dec remented. If the c ounter value exceeds a threshold, a

permanent fault is recorded and the counter state is held until the operator

executes a reset. Whilst in the permanent state, the operator is alerted to the

failure by various system annunciators. The 8000 Series

System allows

approximately four faults in succession bef ore a permanent fault is recorded. If a

fault is detected on a 8000 Series TMR Processor, a recovery process is

automatically initiated to re-synchronise the module and update its mem ory. If the

recovery process fails af ter the fourth attempt, no further attempts are made and

the fault is annunciated.

Doc No 552864 Page 14 of 22

Issue 02 June 2004

Page 25

OPERATOR AND MAINTENANCE MANUAL

5.2 FAULT ANNUNCIATION

The 8000 Series System annunciates faults via the status LEDs f itted to the front

panels of the modules.

ote: A fault indication does not necessarily mean that a module is not operational.

N

Some faults within a module have no im mediate consequenc e. The failure c an be

masked or it can be located in the test circ uitry. Nevertheless, the module should

be replaced and returned for repair.

8000 Series module status LEDs and their f unct ion in fault indication are detailed in

paragraph 2.

5.3 FAULT FINDING TECHNIQUES

CAUTION

ALWAYS INIT IATE A RESET AFTER REPLACING A MODULE. W AIT FOR THE

RESET TASK TO COMPLETE (LED INDIC ATORS ARE RE-ENABLED) BEF ORE

PROCEEDING WITH FAULT FINDING.

Fault finding should always start at the 8000 Series TMR Processor since it

contains the first level of inform ation regarding the operational status of the 8000

Series

System.

After scanning the fault indicators of the system modules to locate the affected

module(s), it is good practice to examine modules and connectors for proper

seating, then initiate a reset to determine if the fault is permanent.

If the fault persists, then module replacement is usually the next action to take.

Transient faults should be exa mined using the diagnostics fac ility to determine the

frequency of occurrence and whether any corrective action is warranted.

When removing a module f r om an I/O sub-system, always be careful to ensur e that

neighbouring modules are not disturbed accidentally.

Doc Number 552864

Issue 02 June 2004 Page 15 of 23

Page 26

OPERATOR AND MAINTENANCE MANUAL

5.4 CLEARING FAULTS

Faults occurring in the 8000 Series TMR Processor, 8000 Series T MR Interface

and 8000 Series Comm unications I nterface m odules are non- latching, allowing the

system to recover automatically once the fault condition has been rectified.

Faults occurring in the I/O sub-system are latched and are cleared only by first

rectifying the fault, then pressing the Reset button on the 8000 Series TMR

Processor. Indication of the pres ence of a fault in the I/O sub-sys tem is provided

by the System Healthy indicator being off.

The following events take place once a reset of the system has been initiated:

1. Fault status information, indicators and fault contacts are cleared to a ‘no

fault’ state. If the fault cause is transient fault rate, a single re-test (as a

minimum) must be passed before returning the system to a ‘no fault’ state.

2. The System Healthy indicator on the 8000 Series TMR Processor is lit to

indicate that the reset operation is complete.

During the reset oper ation, all programs continue to run at their nor mal scan rate.

There is no noticeable change in system performance and no additional

vulnerability to faults. The time required to com plete the reset is related directly to

the processor scan time.

Doc No 552864 Page 16 of 22

Issue 02 June 2004

Page 27

OPERATOR AND MAINTENANCE MANUAL

6. SYSTEM DIAGNOSTICS

The 8000 Series System diagnostic requirements will depend upon client

requirements. The recommended minimum diagnostics are included in the

Software manual. Whilst some alarm s indicate a f ault on the module (which require

replacement), others ar e used for analysis of the 8000 Series

a fault in a secondary component.

6.1 TEMPERATURE ALARMS

Each module has dedicated m onitoring points for temperature. A high temper ature

may indicate a faulty fan unit.

6.2 POWER SUPPLY UNIT

System and indicate

Redundant or N+1 configuration tolerates the loss of a power supply unit. A Power

supply fault is annunciated via status contacts f rom the power supply to inform the

operator that a power supply needs replacing.

6.3 FEED FAILURE

Should a system feed fail, and the two power feeds are isolated up to the 8000

Series

System, all three slice LED’s flash red on all modules.

Doc Number 552864

Issue 02 June 2004 Page 17 of 23

Page 28

OPERATOR AND MAINTENANCE MANUAL

7. MODULE REPLACEMENT

7.1 MODULE EJECTOR LEVE RS AND KEY

When inser ting a module, the ejector levers s hould be open and the module should

be pushed into the slot using the fascia. When the module connectors have located

on the backplane and field cable connectors , the module should be pushed firmly

into place before closing the ejector levers.

Module ejector levers should only be opened using a 8000 Series ejector key

(supplied with the 8000 Series TMR Processor). This prevents damage to the

ejector levers and module. T he module should be handled only by the plastic case

and not the connectors or pins, becaus e the internal components are sensitive to

static.

7.2 MODULE RETURNS POLICY

To enable efficient and comprehensive analysis of a module, a report detailing

information that includes the conditions under which it failed should accompany the

returned module. If the operator has the ‘Dumptrux’ macro, a ‘single module’

diagnostic report should be included with the returned module. The use of

‘Dumptrux’ is outside the scope of this document.

RMA: RETURNED MATERIAL FOR INVESTIGATION REPORTING FORM

Customer: …………………………….. Contact:……...………………………………..

Unit Serial No : ……………………… Module Type: : …………………………………..

Operating condition at the time of the reported failure. Tick the relevant

condition/supply information

Normal Running/Commissioning/Shutdown/System Testing/Other:

………………………………………………………………………………………………...

Description of the fault:

………………………………………………………………………………………………...

………………………………………………………………………………………………...

Doc No 552864 Page 18 of 22

Issue 02 June 2004

Page 29

OPERATOR AND MAINTENANCE MANUAL

7.3 TMR INTERFACE MODULE REPLACEMENT

This procedure is only applicable when the TMR Interface m odule has f ailed (faulty

lice) and no standby module is configured in the 8000 Series Controller.

s

1. Insert the replacement module in the adjacent slot.

2. After the replacement module has been educated, remove the faulty module.

3. Restart the system using the ‘START APPLICATION’ procedure from the

Workbench.

Note: If a catastrophic failure of the TMR Interface module has occurred, the replacem ent

module may be fitted in the same slot as the failed module and the system restarted as described above.

7.4 ACTIVE/STANDBY CHANGEOVER

8000 Series Expander Interfaces, 8000 Series Expander Processors and 8000

Series TMR Interfac e operate in the active/standby mode when a spare m odule is

fitted in the adjacent slot. Fitted spare modules are not required to achieve fault

tolerant operation of the system.

Failures occurring in any of these m odules automatically initiate an active/standby

changeover, if a spare m odule is fitted. If no spare is f itted, insert a module of the

same type, with compatible firmware and har dware, into the adj ac ent slot. Onc e the

previously standby module has been educated, indicated by the Educated LED

adopting the steady green state, the faulty module may be removed for repair.

Please refer to ICS Triplex Technology for advice on compatibility.

8000 Series TMR Processor: If the system.ini file in the replacement module is

identical to the installed module then a changeover occurs as above. If the

replacement TMR Processor has a different system.ini file then the replacement

module is educated with the system.ini file and application. At this stage, the

replacement module has not yet initialised and to indicate this, the faulty module

stage indicates Inhibit. The replacem ent module must be removed from the chassis

power and then plugged back in to initialise the ‘boot’ file. When this has been

done, the changeover occurs and the faulty module can be removed from the

system.

Doc Number 552864

Issue 02 June 2004 Page 19 of 23

Page 30

OPERATOR AND MAINTENANCE MANUAL

7.5 COMPANION SLOT MODULE REP LACEMENT

Each I/O module in a 8000 Series System m ay have a Companion Slot configured

via a double-width I/O connector, but not necessarily occupied. This enables a

faulty module to be replaced without disrupting the System.

Replacement is effected by simply inserting a working module of the same type,

with compatible firmware and hardware, in the adjacent slot. The 8000 Series

TMR Processor automatically initiates the education of the replacement module

with the appropriate data. This is indicated by the Educated LED flashing. When

education is complete, the Educated LED becomes steady green, the previously

active faulty module indicates ‘standby’ and the replacement module indicates

‘active’. Check that the remaining LEDs on the front panel of the replacement

module are healthy (refer to section 4, Module Status Indicators). The faulty module

should be removed from the System and repaired.

The 8000 Series System should have a m odule back in the left hand (primary) slot

as soon as a working module is available. Inser t the new module in the left hand

(primary) slot and initiate a changeover by opening the ejector levers on the right

hand (companion slot) m odule. DO NOT REMOVE THE RIGHT HAND MOD ULE

until the changeover has com pleted, the left hand module indicates ‘ac tive’ and the

right hand module indicates ‘standby’. The right hand module can now be removed.

Doc No 552864 Page 20 of 22

Issue 02 June 2004

Page 31

OPERATOR AND MAINTENANCE MANUAL

7.6 SMARTSLOT (VERSION 2) REPLACEMENT

I/O modules in a 8000 Series system may be configured as SmartSlot, allowing

modules to be replaced with another in an allocated Smar tSlot. T his r educes the

number of slots required in a system, bec ause a group of modules can now have

ne SmartSlot instead of a com panion slot f or every module. The cable required t o

o

connect the existing and replacement module is different for input and output

modules, and so a system using Sm artSlot needs at leas t one input SmartSlot and

one output SmartSlot. A Zone Interf ace Module (which can be configured as both

inputs and outputs) uses an output type SmartSlot cable. The Sm artSlot cable is

fitted to the chassis at the allocated slot and has a connector to link to the slot

containing the faulty module.

SmartSlot Version 2 replacement (changeover) is effected by following the

procedure detailed below.

Bridge the faulty module and SmartSlot positions by connecting the

SmartSlot jum per connec tor to the ex posed ‘C’ type connector on the rear of

the faulty module I/O connector.

Insert a working module of the correct type, with compatible firmware and

hardware, in the SmartSlot position. The 8000 Series TMR Processor

automatically initiates the education of the replacement module with the

appropriate data. This is indicated by the Educated LED flashing. W hen

education is complete, the Educated LED becomes steady green, the

previously active faulty module indicates ‘standby’ and the replacement

module indicates ‘active’. Check that the rem aining LEDs on the fr ont panel

of the replacement module are healthy (refer to section 4, Module Status

Indicators).

The faulty module should be removed from the System and repaired.

The 8000 Series System should have a module back in the normal

(primary) slot as soon as a working module is available. Insert the new

module in the primary slot and initiate a changeover by opening the ejector

levers on the SmartSlot module. DO NOT REMOVE THE SMARTSLOT

MODULE until the changeover has completed, the prim ary module indicates

‘active’ and the SmartSlot module indicates ‘standby’. The Smar tSlot m odule

can now be removed.

Disconnect the SmartSlot connector.

Doc Number 552864

Issue 02 June 2004 Page 21 of 23

Page 32

OPERATOR AND MAINTENANCE MANUAL

8. RESTART PROCEDURE

8.1 INTRODUCTION

The procedure desc ribed below is necess ary to restore the 8000 Series System to

full operation after a total loss of power including the loss of the incoming power

supplies. The sequence is based on the assumption that the incoming power

supplies have been restor ed af ter all the MCBs, c ontac tors and is olators have been

opened. It is assumed that all the application software and system INI configuration

have been installed.

Note

(1) Before powerin g the system, ascertain the st atus of the p lant and ensure

that no danger to personnel or damage to the plant will occur.

(2) It is recommended that the 8000 Series System should always be

powered up in this sequence from cold.

(3) The last item to be powered–up will be the two Controller chassis.

8.2 POWER UP PROCEDURE

(1) Ensure that any system or devices attached to the system are ready for the

powering sequence.

(2) Open the 8000 Series System Cabinet doors to gain access to the incoming

240VAC system isolators. Ensure that the supply voltage is a nominal

240VAC. Close the 240VAC isolators.

(3) Close all the 240VAC MCBs. Check that both the 8000 Series System Power

Supply chassis are powered.

(4) Power the fan trays and roof fan assemblies, by closing the pairs of 24VDC

MCBs located on the MCB Panel.

(5) Power the main 8000 Series System I/O Chassis by closing the associated

pairs of 24VDC MCBs located on the MCB Panel.

(6) Finally, power the 8000 Series System Controller Chassis by closing the

associated pairs of 24VDC MCBs located on the MCB Panel.

(7) Close the 240VAC Utilities Assembly MCBs mounted in the 8000 Series

System Cabinets.

(8) Ensure that the 8000 Series System Engineering Workstation has power (if

applicable).

8.3 8000 SERIES CABINET

(1) Press the reset pushbutton on the 8000 Series System Processor Modules.

(2) Ensure that all 8000 Series System Modules are healthy, and that the 8000

Series System PLC is communicating.

(3) Close and lock all doors.

Doc No 552864 Page 22 of 22

Issue 02 June 2004

Page 33

OPERATOR AND MAINTENANCE MANUAL

8.4 FINAL

(1) Ensure that all external interfac es to other systems and devices are connected

and functioning correctly.

(2) Ensure that all modules are in the healthy condition relative to the state of the

plant.

The 8000 Series System is now ready to control and monitor trips and alarms.

Doc Number 552864

Issue 02 June 2004 Page 23 of 23

Loading...

Loading...