Page 1

Installation Instructions

OneGear™ MV SMC Flex Solid-State Motor Controller

Publication Number 7760-IN001B-EN-P

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the Additional Resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Equipment Overview

Transportation and Handling

Equipment Installation

Table of Contents

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2

Unpacking and Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cabinet Handling Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overhead Lifting Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rod or Pipe Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fork Lift Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shipping Skid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 3

Removal of Overhead Lifting Brackets and Channels . . . . . . . . . . . . . . . . . 9

Opening the Front Medium Voltage Doors of the Converter Cabinet . . 9

Remove Medium Voltage Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . 10

Disconnect Fiber Optic Cables to Converter Roll-out Modules . . . . . . 10

Disconnect Flexible Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Disconnect Current Loop Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Disconnect Mechanical Fastening of Converter Modules . . . . . . . . 13

Install Converter Roll-out Module Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install Converter Roll-out Module Pull Handle. . . . . . . . . . . . . . . . . . . . . 15

Removal of Lifting Provisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install the Converter Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

With Back Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Without Back Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inter-Cabinet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Floor Anchoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation of Power Bus Bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Install Power Bus Bushing Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connect Power Bus to Switchgear Risers . . . . . . . . . . . . . . . . . . . . . . . 23

Install Lower Bus Links in the Converter Cabinet. . . . . . . . . . . . . . . 24

Installation of Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ground Bus Linking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Electromechanical Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

OneGear Standard Plenum

General Reference

Chapter 4

Assemble Standard Plenum to Cabinetry. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix A

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 1

Page 4

Table of Contents

Notes:

2 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 5

Equipment Overview

Incoming Line Unit

Main Unit

Converter Cabinet

Bypass Unit

650 mm

650 mm

1500 mm

650 mm

Chapter 1

Overview

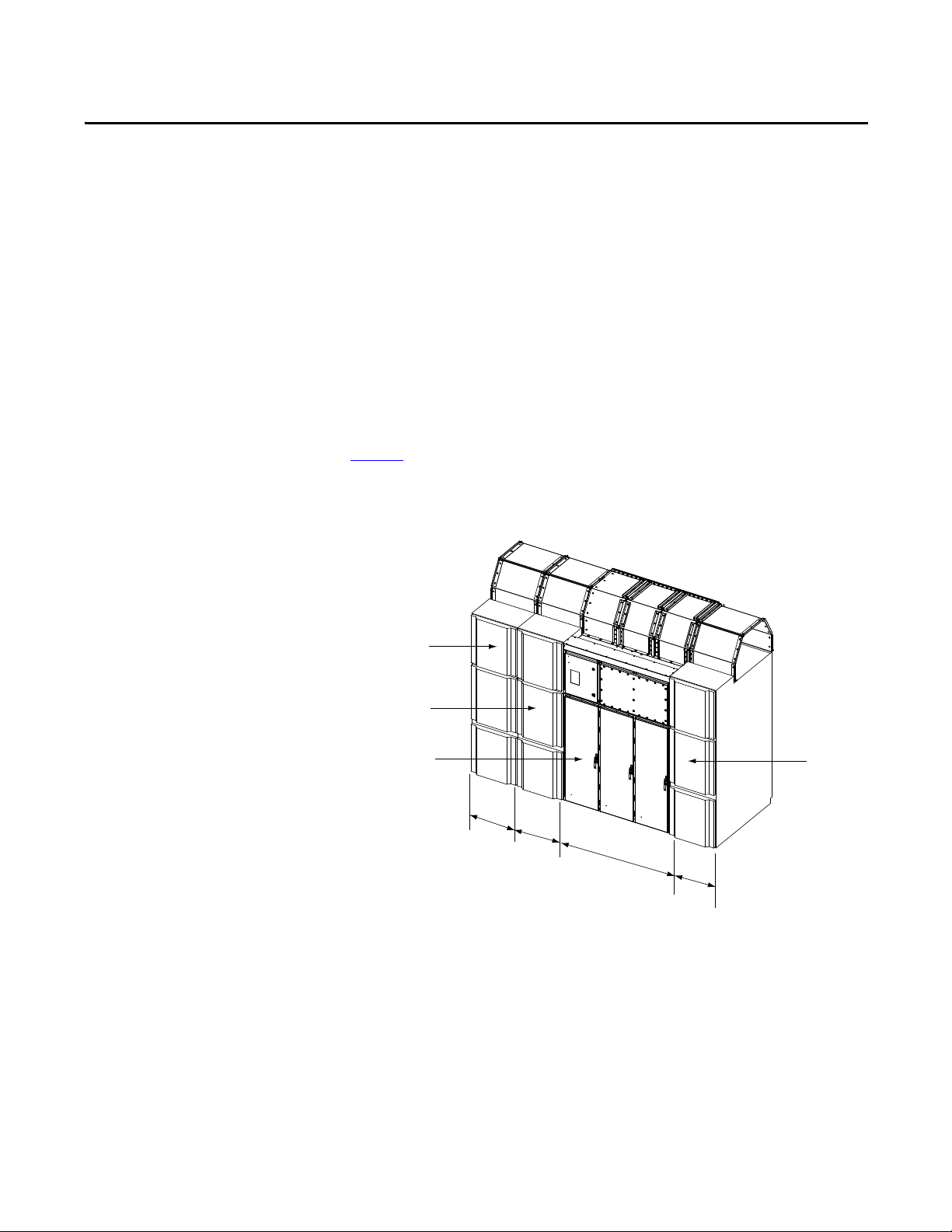

The OneGear™ MV SMC controller family consists of the following

configurations:

• Bul. 7760 – Retrofit Controller

• Bul. 7761 – OEM Controller (converter cabinet)

• Bul. 7762 – Complete Controller utilizing vacuum contactors

• Bul. 7763 – Complete Controller utilizing vacuum breakers.

Figure 1

shows an overview of a typical Bulletin 7762/7763 controller complete

with incoming line unit. Refer to project documentation for specific

configuration details and dimensions.

Figure 1 - Typical Bulletin 7762/7763 OneGear MC SMC Controller

The Incoming Line Cabinet, Main Cabinet, and Bypass Cabinet are switch-gear

cabinets and are referred to as such throughout the remainder of this document.

All cabinets are shipped individually. This document describes the handling and

installation of the converter cabinet and the interconnections with the adjacent

switchgear cabinets.

Installation and connection instructions for switchgear cabinets, that are adjacent

to each other is covered by the respective manufacturer’s documentation and is

not included in this document.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 3

Page 6

Chapter 1 Equipment Overview

Notes:

4 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 7

Transportation and Handling

IMPORTANT

IMPORTANT

Chapter 2

Unpacking and Inspecting

Before leaving the factory, the controller has been tested mechanically and

electrically. Immediately upon receiving the controller, remove the packing and

check for possible shipping damage. Report any damage immediately to the

claims office of the carrier.

After unpacking, check the items received against the Bill of Lading to ensure

that the nameplate description of each item agrees with the material ordered.

Inspect the controller for physical damage as stated in the Rockwell Automation

Conditions of Sale.

All claims for breakage and damage, whether concealed or obvious, must be

made to the carrier by the customer as soon as possible after receipt of the

shipment. Rockwell Automation will render reasonable assistance in the

securing of adjustment for such damage claims.

Remove all packing material, wedges or braces from within the controller. If any

part of the equipment will not be installed when it is unpacked, it should be

stored in a clean dry place. The storage temperature must be between

-20...75 °C(-4...167° F) with a maximum humidity of 95% non-condensing.

The controller sections are shipped on wooden skids bolted to the cabinetry.

Lifting brackets are installed at the top corners of the cabinetry. The controller

sections must be maintained in the upright position during any handling.

ATT EN TI ON : Ensure that the load rating of all lifting equipment is sufficient to

safely raise the controller sections. Refer to the packing slip for shipping

weights.

Round rollers can be used to assist in moving the equipment to the installation

site. Once at the final site, rollers can be used to place the sections in their desired

position.

ATT EN TI ON : Use either a forklift or the pipe rolling technique for positioning

purposes to ensure that the equipment is not scratched, dented or damaged.

Stabilize the controller during handling to guard against tipping and injury to

personnel.

Customer installation duties must be performed correctly. Errors can cause

delays in commissioning or damage to the equipment.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 5

Page 8

Chapter 2 Transportation and Handling

Cabinet Handling Instructions

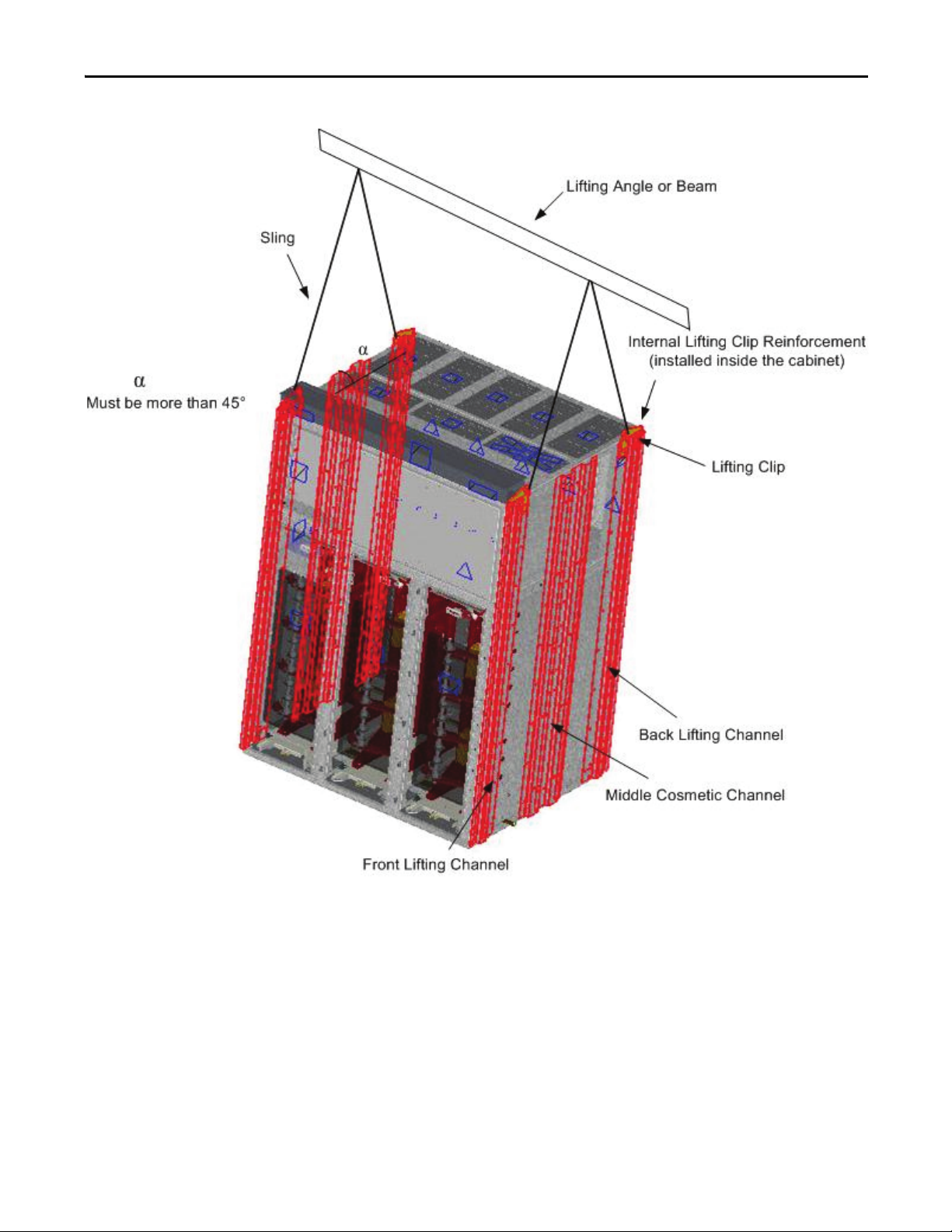

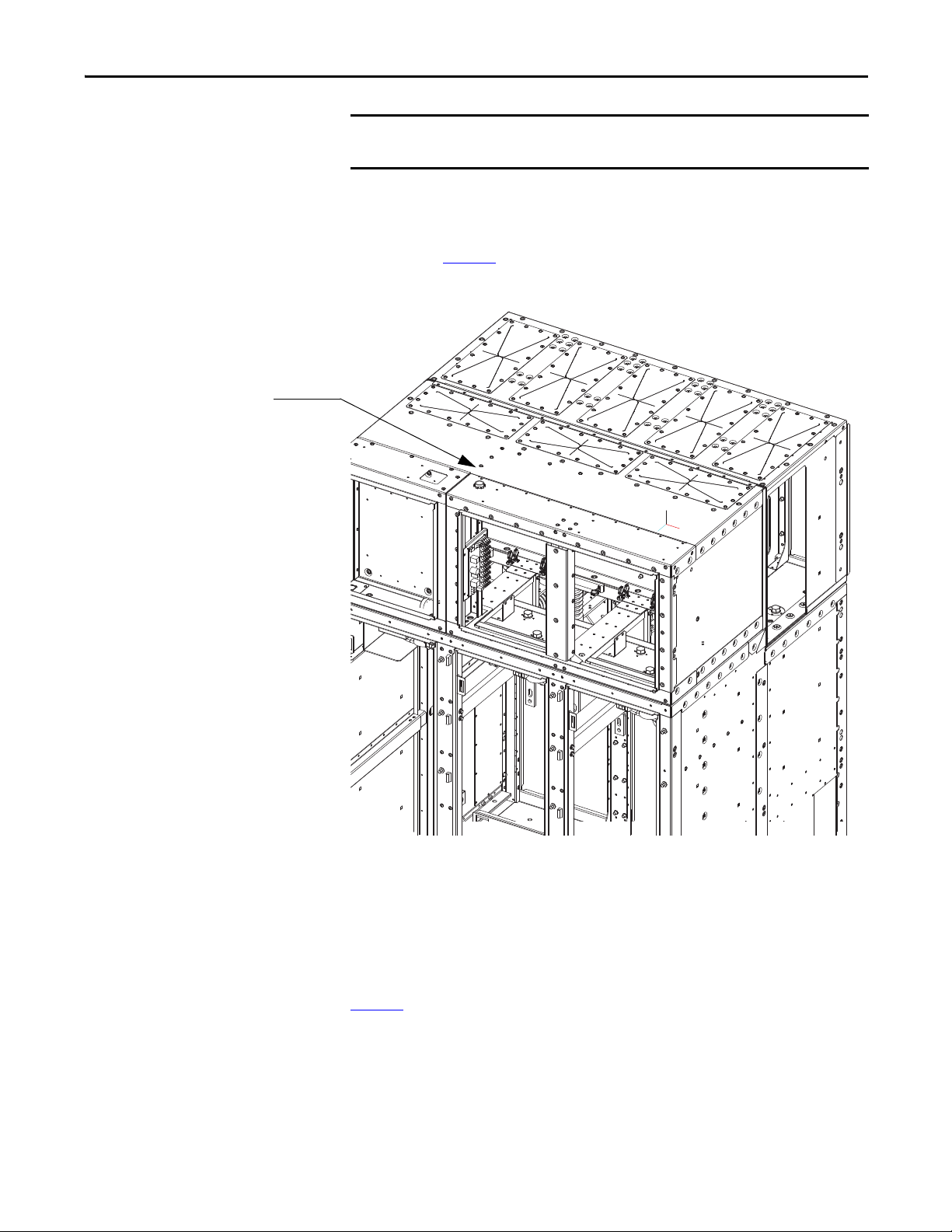

When lifting the 1500 mm wide converter cabinet, the lifting instructions

specified below must be followed.

WARNING: Do not pass cables or ropes through support holes. Always use

load-rated shackles or safety hooks in support holes. The legs of swing must not

exceed 45° from vertical.

Overhead Lifting Method

1. Verify that the front/back lifting channels and the middle cosmetic

channels are all installed and that the connecting hardware is tightened to

the cabinet.

2. Verify that the four lifting clips have corresponding internal lifting clips

installed and connected. Lifting clip holes are 30 mm.

3. Figure 2

different depending on customers’ decision and availability of the lifting

hardware. Verify shipping weight and capacity of lifting equipment.

4. The angle between the slings (Figure 2

more (70° is ideal).

is only for lifting demonstration purpose. The lifting parts may be

) and horizontal must be 45° or

5. The centre to centre distance of the two lifting points of the lifting angle or

beam is to be 1500 mm +/- 150 mm (60” +/- 6.0”).

6 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 9

Figure 2 - Overhead Lifting of Converter Cabinet

Transportation and Handling Chapter 2

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 7

Page 10

Chapter 2 Transportation and Handling

2 x 6 in. minimum (50.8 x 152.4 mm)

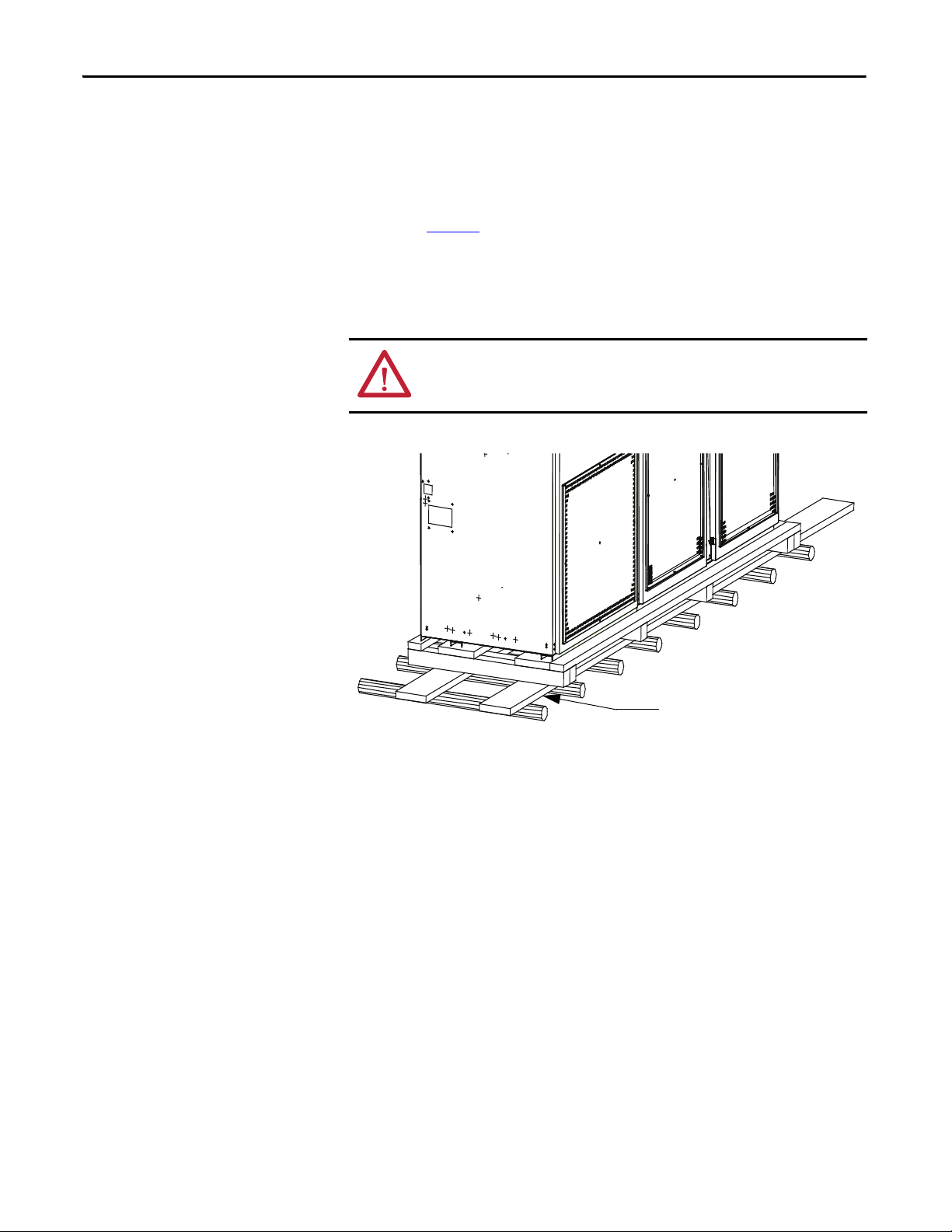

Rod or Pipe Rollers

This method is only suitable when there are no inclines and the controller is

being moved on level floor. Boards 50 x 152 mm (2 x 6”) or equivalent and at

least 300 mm longer than the controller must be placed under the shipping skid,

as shown in Figure 3

Carefully ease the shipping skid over the rollers until the equipment weight is

borne on the rollers. The controller can be rolled to its desired location. Steady

the load to prevent tipping.

Figure 3 - Rod or Pipe Rollers

.

ATT EN TI ON : Ensure that the load rating of all lifting equipment is sufficient to

safely raise the controller sections. Refer to the packing slip for shipping

weights.

Fork Lift Truck

A single fork lift truck may be used, extreme caution must be exercised.

1. Insert the forks into openings of the shipping skid from the rear of the

controller.

2. Carefully balance the controller on the forks and apply safety straps.

Shipping Skid Removal

Internal access is not required to remove the wooden shipping skid from the

converter cabinet. External angle brackets attached to the enclosure are used to

attach the enclosure to the wooden skid.

Remove the angle brackets and the associated hardware. When the enclosure is

lifted by overhead means, the wooden skid can be removed.

8 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 11

Equipment Installation

Chapter 3

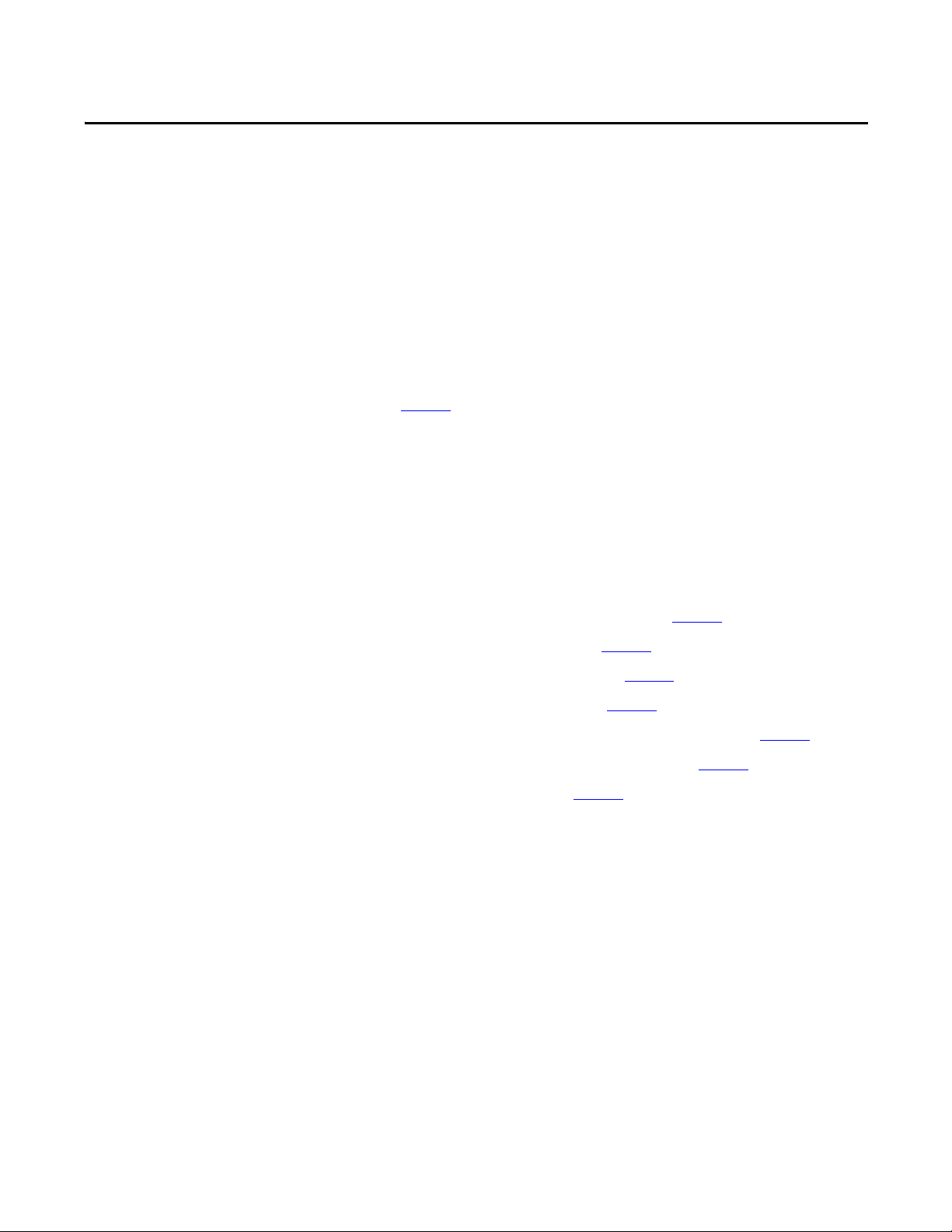

Removal of Overhead Lifting Brackets and Channels

Before joining to adjacent equipment, the lifting brackets and exterior vertical

lifting channels from the converter cabinet must be removed.

Removing of the lifting brackets requires access to the interior of the enclosure

where corresponding internal brackets are located and require removal. Please

refer to page 16

It will be necessary to remove the converter roll-out modules from the enclosure

to install power connections to the adjacent equipment and to install hardware to

secure the enclosure to its floor.

To remove converter modules from the cabinet, the following operations are

necessary:

1. Open the Medium Voltage Doors (see below)

2. Remove the Medium Voltage Front Cover (page 10

3. Disconnect Fiber Optic Cables (page 10

4. Disconnect Flexible Braided Links (page 12

5. Disconnect Current Loop Wire (page 12

6. Disconnect Mechanical Fastening of Converter Module (page 13

for hardware removal details.

)

)

)

)

)

Opening the Front Medium Voltage Doors of the Converter Cabinet

7. Installation of converter roll-out module ramp (page 14

8. Installation of Pull Handle (page 15

Access to the medium voltage converter section is attained by opening the three

lower doors. The left door is generally equipped with interlocking with upstream

equipment. The specifics of this interlocking depends on customer requirements

and is provided in the customer drawings.

Rotating the door handle unlatches the door allowing it to be opened. DO NOT

force open the doors.

The middle and right medium voltage doors are mechanically interlocked with

the left medium voltage door such that the left door must be opened before the

middle and right doors can be opened. Similarly, the left door cannot be closed

until both the middle and right doors are closed and latched.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 9

)

)

Page 12

Chapter 3 Equipment Installation

Medium Voltage

Front Cover

Remove Medium Voltage Front Cover

Access to the medium voltage area above the middle and right doors is attained

by removing the bolts that hold the cover in place (Figure 4

ATT EN TI ON : Ensure that power to the unit has been shut down and locked out

before accessing medium voltage areas. Failure to do so may result in severe

injury or death.

Figure 4 - Medium Voltage Front Cover Identification

).

Disconnect Fiber Optic Cables to Converter Roll-out Modules

ATT EN TI ON : Fiber optic cables can be damaged by bending the cables with a

radius of less than 50 mm (2 in.).

To disconnect the fiber optic cables on each of the converter modules, it is

necessary to remove the Front Medium Voltage front cover located over the

middle and right medium voltage doors. Removal of this panel provides access to

the multi-channel fiber optic circuit board.

10 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 13

IMPORTANT

Multi-channel Fiber

Optic Board location

Equipment Installation Chapter 3

Note the locations of the fiber optics from the fiber optic circuit board before

disconnecting them.

The fiber optic cables are individually identified. Fiber optic cables are

disconnected from the circuit by squeezing the latch lever of each fiber optic

terminal and pulling the fiber optic line out of the multi-channel fiber optic

circuit board (Figure 5

Figure 5 - Multi-channel Fiber Optic Circuit Board Location

)

The cables should be carefully coiled on top of the PowerBricks, so they will not

be damaged when the cart is removed

Reconnection of fiber optic cables requires that the fiber optic cables, for each

phase of converter module, must be connected to the transmitter terminals of the

appropriate phase location on the fiber optic multiplexer circuit board. Within

each phase of fiber optic connectors the order of connection is not critical.

Figure 6

shows a close-up view of the fiber optic multiplexer board and the

grouping of fiber optic connections per phase.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 11

Page 14

Chapter 3 Equipment Installation

IMPORTANT

Figure 6 - Fiber Optic Multiplexer Board

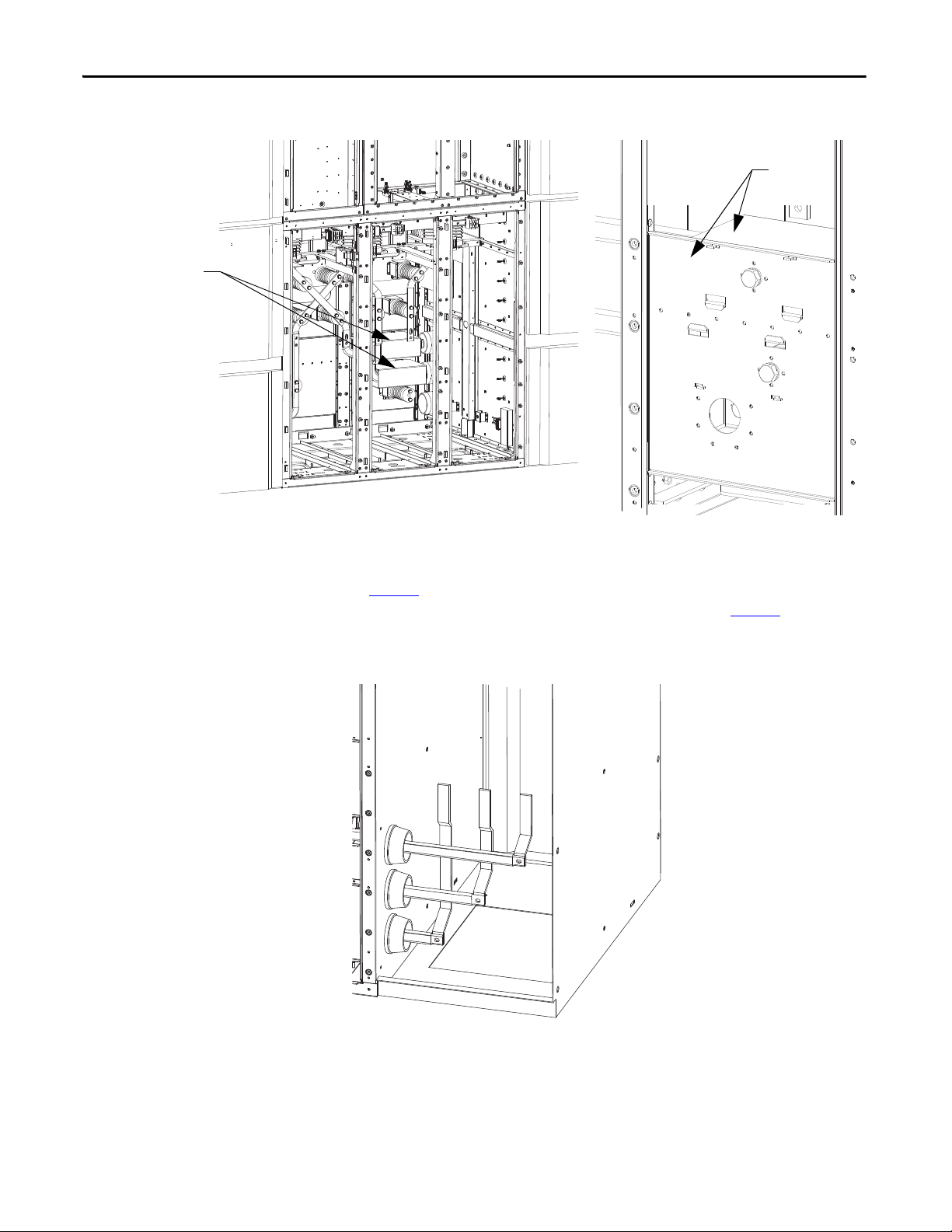

Disconnect Flexible Links

At the top of each roll-out converter module, two flexible links are provided to

connect power to the converter module. A 13 mm hex tool is needed to remove

the hardware at the upper end of the flexible link. The location of the top flexible

link connections to the converter bus are shown in Figure 7

The cable from the rear of the cart must be freed from the clamps that secure it to

the structure.

The cable must be re-attached to these clamps when the cart is re-installed.

.

Disconnect Current Loop Wires

Power for the gate driver circuit boards is provided by current transformers that

derive power from a low voltage loop of wire that is visible at the front of the rollout converter modules. The current loop wire terminations are accessible at the

front and can be disconnected at terminal blocks located above each of the

converter modules, as shown in Figure 7

.

12 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 15

Equipment Installation Chapter 3

Terminal Block for Current Loop

Top Bo lt

Location for

Mechanical

Attachment of

Roll-out

Conver ter

Modules

Fastener

Location for

Flexible

Power

Connections

Fastener location for

anchoring roll-out Converter

Module Base to enclosure

Disconnect Mechanical Fastening of Converter Modules

The three roll-out converter modules are mechanically attached within the

cabinet by hardware at the top and bottom. A 13 mm hex tool is needed to

remove the two sets of hardware (Figure 7

At the front bottom of each module, on its sheet metal base, two bolts are used to

secure the module to the cabinet. Removal of the bolts (using 17 mm hex tool) is

required to extract the module from the cabinet, as shown in Figure 7

Figure 8

Figure 7 - Removal of Fasteners at Top of Converter Module

.

) at the top of the module.

and

Figure 8 - Removal of Fasteners at Bottom of Converter Module

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 13

Page 16

Chapter 3 Equipment Installation

IMPORTANT

IMPORTANT

Install Converter Roll-out Module Ramp

A metal ramp assembly is provided that is required for the safe removal and

installation of the converter roll-out modules. The ramp has tabs that locate into

slots of the cabinetry (Figure 9

Figure 9 - Insertion of Ramp for Roll-out Converter Module

).

A clear space of 1500 mm is required in front of the equipment to facilitate

removal of the converter modules is required.

This method of removing the roll-out converter modules is only valid if the

equipment is installed on a level floor. If the equipment is installed on an

elevated platform, alternate means are required. Consult factory for details.

14 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 17

Equipment Installation Chapter 3

IMPORTANT

IMPORTANT

Pull Handle

Ramp

Install Converter Roll-out Module Pull Handle

Do not push or pull on the clear barrier to remove the converter module.

At the base of the converter roll-out module, an attachment point for the pull

handle is provided.

The pull handle connects to the module base with a pin (Figure 10

Each converter roll-out module should be extracted by pulling outwards. The

converter roll-out module should be maintained level and not be tilted at least

until the middle wheels reach the ramp attachment points to the cabinet, as

shown in (Figure 11

Figure 10 - Insertion of Pull Handle for Roll-out Converter Module

).

).

Check the fiber optic and current loop cables are not being snagged or pinched

when removing or installing the converter module.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 15

Page 18

Chapter 3 Equipment Installation

IMPORTANT

External Lifting Lugs

Vertical Lifting Channels

Figure 11 - Converter Module being Extracted from Enclosure

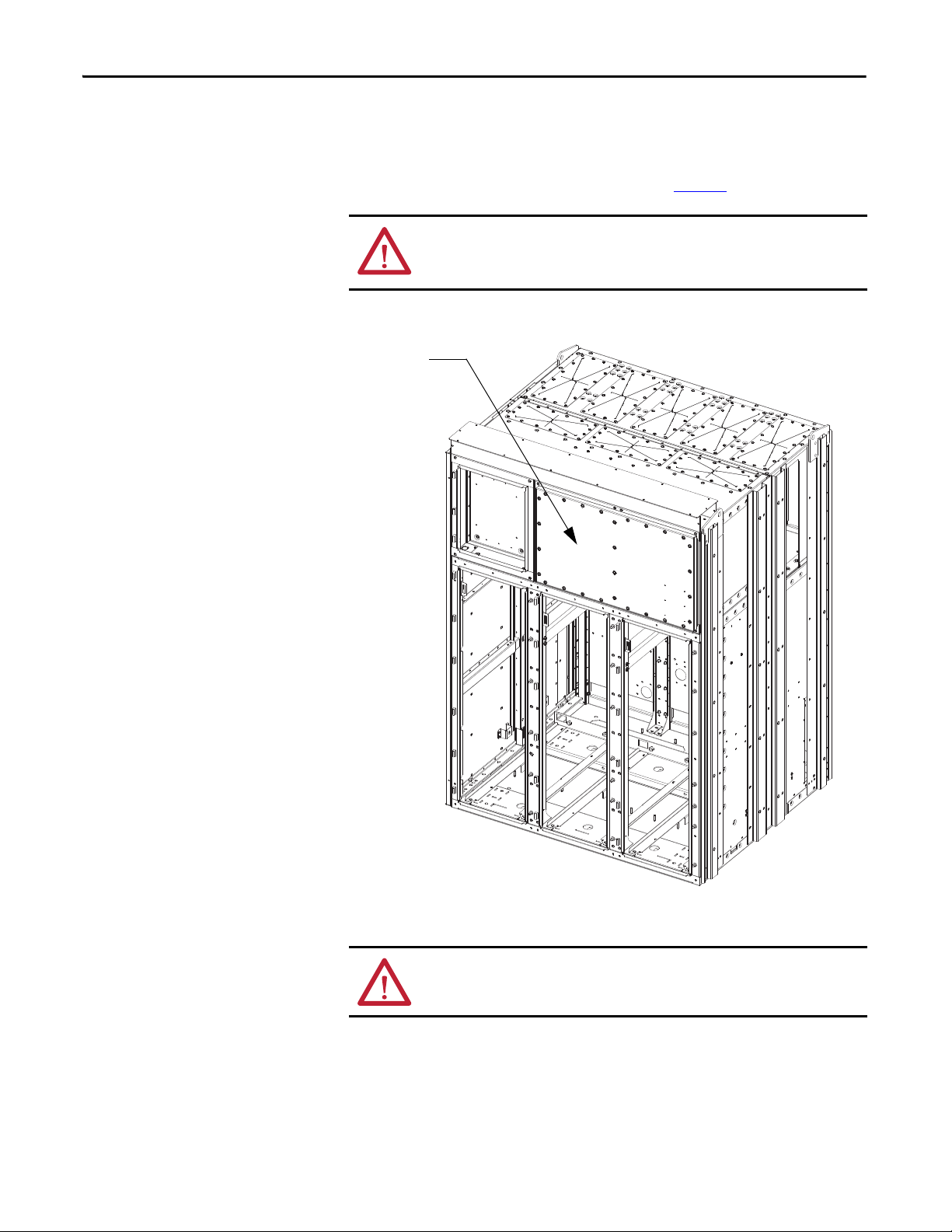

Removal of Lifting Provisions

Once it has been determined that overhead lifting of the controller is no longer

needed, the lifting components may be removed. There are 6 (six) vertical

channels, 4 (four) external lifting lugs (Figure 12

mounting brackets (Figure 13

). Rear access is required to remove the two internal

) and 4 (four) internal lug

lug mounting brackets at the rear of the structure. Care must be taken not to drop

the internal brackets into the cabinet while removing them.

The channels and external lifting lugs must be removed prior to mating to any

adjacent switchgear components.

Figure 12 - External Lifting Components

16 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 19

Figure 13 - Internal Lifting Components

Internal Lifting Lug

Mounting Brackets

located in top four

corners

Equipment Installation Chapter 3

Install the Converter Cabinet

With Back Access

The installation method described below is valid for (the preferred) situations

when back access to the equipment is available.

Prior to moving one cabinet next to the other, the Horizontal Power Bus and

Bushings need to be inserted into the converter cabinet. Bushings will be fastened

to the adjacent switchgear cabinets at a later step.

At each end of the Bus Module, place a Bushing inside the enclosure with the fl at

surfaces facing out. Slide the bus through the bushing’s openings and the slots in

the supporting brackets until it is through the opposite side. For 1250 A rating

(single bus per phase) bus placement is in the lower of the two slots for each

phase, as shown in Figure 14

. Both slots will be used for 2000 A rating.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 17

Page 20

Chapter 3 Equipment Installation

Lower slots for

1250A bus rating

Power Bus Bushing

Flat side facing o ut

Power Bus Bushing

Flat Side facing out

Adjacent switchgear cabinet

Power bus flush

with sidesheet

Figure 14 - Horizontal Power Bus and Bushing Placement

Depending on which side the converter cabinet will fit up to, the bus should be

flush with the side plate facing the mating side of the adjacent switchgear cabinet.

Figure 15 - Horizontal Power Bus Placement

18 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 21

Equipment Installation Chapter 3

Rear Junction

Point

Front Flange Faces

Front Junction Points

(inside cabinet)

Without Back Access

If no back access to the equipment is available, the Horizontal Power Bus

Bushings must be installed and fastened on the respective switchgear cabinets

prior to connecting with the converter cabinet. The switchgear cabinets must be

first installed with the front, flush with the converter cabinet, then transversally

slid into place such that the bushings clear the associated openings in the

Converter Cabinet Main Bus Module.

Inter-Cabinet Connections

This section describes the electrical and mechanical connections between the

converter and the adjacent switchgear cabinets. For details regarding interconnections between two switchgear cabinets (e.g. Incoming Line Unit and

Bypass Unit), refer to the respective manufacturer’s instruction manuals.

Once the converter and adjacent switchgear cabinets are positioned next to each

other, ensure that both front flanges are flush (Figure 16

Figure 16 - SMC and Switchgear Cabinet Alignment

).

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 19

Page 22

Rear Junction

Point s (x5)

Front Junction

Point s inside

LV Panel (x2)

Front

Junction

Points inside

MV section

(x4)

Chapter 3 Equipment Installation

Locate the cabinetry junction points in the converter cabinet which connect the

converter cabinet with the adjoining switchgear equipment (M10 nuts). Fasten

with M10 hardware at these locations (6 along front, 5 along rear), as shown in

Figure 17

. Repeat operation for joining both switchgear cabinets to the converter

cabinet.

Figure 17 - Junction Point Locations

20 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 23

Equipment Installation Chapter 3

SMC Floor

Anchoring

Adjacent Switchgear Cabinets

IMPORTANT

Floor Anchoring

The general location of the converter cabinet floor anchoring points is shown in

Figure 18

Refer to project specific dimension drawing for exact dimensions and anchoring

bolt mounting locations for all cabinets. Anchor holes accommodate 12 mm

(0.50”) hardware.

Figure 18 - Floor Anchoring

.

Installation of Power Bus Bushings

This step is only necessary if the installation procedure outlined in With Back

Access on page 17, (i.e. if the horizontal power bus bushings have been

inserted onto the horizontal power bus and currently reside loose on the bus

inside the converter cabinet’s main bus box.)

Move bushing against the side sheet of the adjacent switchgear cabinet, as

illustrated in Figure 19

and fasten using the supplied M8 hardware. This is typical for both sides.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 21

. Align holes in bushing with holes in switchgear cabinet

Page 24

Chapter 3 Equipment Installation

Power Bus Bushing

Figure 19 - Installation of Power Bus Bushing

Install Power Bus Bushing Inserts

Partially slide bus through bushing and into the switchgear cabinet. Slide the

supplied bus bushing inserts onto bus as shown in Figure 20

supplied for the connections between the horizontal bus and the switchgear

risers, slide the bus boots caps next to the bushing inserts (refer to manufacturer

documentation for details).

Slide horizontal bus into the switchgear cabinet past the switchgear risers and

close to the side wall opposite the converter section.

Following the steps outlined above, insert the Power Bus bushing inserts and bus

boot caps (if applicable) onto the horizontal bus inside the switch-gear cabinet on

the opposite side of the converter cabinet.

. If bus boots were

22 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 25

Equipment Installation Chapter 3

Switchgear Risers

Power Bus Bushing

Inserts

Once these operations are complete for both switchgear cabinets adjacent to the

converter cabinet, the equipment is ready for connecting the Power Bus to the

switchgear vertical risers.

Figure 20 - Installation of Power Bus Bushing Inserts (cutaway view)

Connect Power Bus to Switchgear Risers

Refer to the switchgear equipment documentation for detailed procedures on

connecting the Power Bus to the vertical risers and on installing the Insulating

Boots. Use the supplied M12 hardware and torque the connections (Figure 21

to the values indicated in the switchgear manufacturer’s documentation. This

needs to be completed for both switchgear cabinets adjacent to the converter

cabinet (e.g. Bypass unit, Main unit), as well as for switchgear units adjacent to

each other (e.g. Incoming Line Unit, Bypass Unit).

Once each phase of the Power Bus is bolted and torqued, slide bus inserts towards

the bushings from the switchgear cabinets until they are seated inside the bushing

tabs.

)

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 23

Page 26

Chapter 3 Equipment Installation

Bolted Connections

between Power Bus

and vertical bus risers

Bus links

Bus bushings

Figure 21 - Installation of Power Bus (cutaway view)

Install Lower Bus Links in the Converter Cabinet

The Converter Bus Bushings are to be installed in the lower rear section of the

Power Converter section.

Figure 22 - Installation of Lower Bus Links, Line Side

24 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 27

Equipment Installation Chapter 3

IMPORTANT

On the left side (line side) of the converter cabinet, install (3) bus links as

indicated in Figure 22

.

Fasten the bus links to the Converter Bus using the supplied M12 hardware.

Fasten the bus links to the back insulators using the supplied M10 hardware.

Torque all connections to the values indicated on page 37

. DO NOT OVER

TIGHTEN.

On the right side (load side) of the converter cabinet (Figure 23

and middle bus links first. DO NOT install lower link yet.

Figure 23 - Installation of Lower Bus Link, Load Side

), install the top

Fasten the bus links to the Converter Bus using the supplied M12 hardware.

Fasten the bus links to the back insulators using the supplied M10 hardware.

Torque all connections to the values indicated on page 37

.

Two clear barriers are supplied to cover the top two bus links. Install the clear

barrier over each bus link (Figure). The longer barrier is mounted over the

upper bus link. Once installed, the bottom bus link may be installed.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 25

Page 28

Chapter 3 Equipment Installation

Rear view of

barrier tabs

Barriers

Figure 24 - Installation of Lower Bus Link Barriers

Within the switchgear cabinet, the lower bus links are to be fastened to the bus

stabs using the hardware supplied on these connections, using the torque values

on page 37

the cap screws to fasten barriers in this area, as described on page 27

. These special cap screws have an internal thread within the head of

. Install the

supplied white barriers using the nylon screws provided.

Figure 25 - Installation of Lower Bus Links within Switchgear Cabinet (rear view)

26 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 29

Equipment Installation Chapter 3

Nylon Screw

mounting location

Barrier 1

Barrier 2

Installation of Barriers

One (1) clear barrier is provided for installation over the top of the bus

connections, as shown in Figure 26

. Install the barrier onto the rear side of the

bus links within the switchgear cabinet, using the metric nylon screws supplied.

Note the orientation of the barriers as shown below. Installation is typical for

both sides depending on controller configuration.

Figure 26 - Installation of switchgear barrier (rear view)

Two clear barriers (Figure 27) are provided for installation inside the converter

cabinet.

Figure 27 - Clear barriers for installation inside SMC cabinet

Install barriers in the lower rear section of converter cabinet, noting the

orientation shown in Figure 28

. Use the existing hardware from bottom cover

plates.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 27

Page 30

Chapter 3 Equipment Installation

Mounting Provision

Barrier 2

Barrier 1

Ground Bus Link

Ground Bus Link

Figure 28 - Installation of SMC Barriers (cutaway view)

Ground Bus Linking

Connect the supplied links from the converter cabinet ground bus to the

switchgear cabinet ground bus, as shown in Figure 29

hardware using values on page 37

Figure 29 - Installation of Ground Bus Link (cutaway view)

.

(typical both sides). Fasten

28 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 31

Equipment Installation Chapter 3

IMPORTANT

TIP

TIP

Electromechanical Interlock

The Bulletin 776X interlocking system is comprised of both an electrical and a

mechanical system. The unit has been shipped with the interlocking system

disabled for ease of transportation, inspection and installation.

The medium voltage access doors, on the front of the converter cabinet are

equipped with a Guardmaster electromechanical interlock. Once door latch is

installed, control power and inter-cabinet control wire must be completed.

These doors will not open once the door latch is installed unless control power

is applied and wiring is complete.

WARNING: Failure to install the interlock latch and completion of the

electromechanical interlocking system, may lead to personal injury or death,

property damage, or economic loss.

The door latch of the Guardmaster electromechanical lock is not installed on the

door flange when the unit is shipped from the factory. The door latch is shipped

loose, inside a bag attached to the inside of the leftmost MV door (Figure 30

Ensure the following steps have been completed before installing the door latch

on the door flange.

1. Complete the mechanical installation of the equipment into final position.

).

2. Complete low voltage wiring between functional units and ensure control

circuit is functioning properly.

3. Ensure control power is connected to the controller.

The electromechanical interlock is a fail safe device. Once the door latch is

installed and the door is closed, it will remain locked in the closed position

until all control wiring is complete and to permit energization of the low

voltage controls within the converter cabinet.

Once steps 1 through 3 noted above are completed, the door latch may be

installed and interlock integrity tested.

To install the Guardmaster door latch, attach it to the bracket already attached to

the rear of the leftmost medium voltage door, using only the supplied hardware

(Figure 31

interlock is operating properly before putting controller into service. Refer to

project specific electrical diagrams for control power connections and

operational details.

). Interlock is setup and adjusted at factory before shipment. Ensure

The mechanical interlocking system prevents the mechanical latching of the

left most medium voltage door unless the middle and right medium voltage

doors are closed and latched.

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 29

Page 32

Chapter 3 Equipment Installation

Figure 30 - Location of Guardmaster Door Latch shipped loose

Figure 31 - Guardmaster door latch, screws and tool bit

Figure 32 - Guardmaster door latch installed

30 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 33

OneGear Standard Plenum

Chapter 4

Assemble Standard Plenum to Cabinetry

1. Use drawing 81020-780 as a general guideline for fixing the panels. This

assembly drawing should be supplied with the order.

2. Identify the right materials necessary for this operation (see following

figures).

• Inner connecting brackets to switchgear, qty.3 (81020-999-54/56,

81023-001-54).

• Outer connecting brackets to switchgear, qty.5 (81023-07501/02/03).

• Plenum front and back assembly, qty.3 (81020-990-52).

• One Gear inner connecting brackets, qty.6 (81023-001-53,

81020999-53/55).

• One Gear outer connecting brackets, qty.10 (81020-991-04/05/06).

• If a 7760 or 7761 is ordered there will be an extension and end

components included (81021-282-52, 81021-637-02, and 81020-998).

• Hardware (M8 HHCS - 29107-304-04, Flat washer 19 mm (0.75”)

OD, Flat washer 28 mm (1.125”) OD, Lock washer, M6 self-tapping

screws 29171-640-01 for extension).

• 25 mm (1”) Gasket and silicone tube

Figure 33 - Components for Plenum Assembly

3. Install the switchgear gas duct per manufacturer’s instructions (e.g. ABB

UniGear type ZS1 – Standard Gas Duct Assembling Procedure).

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 31

Page 34

Chapter 4 OneGear Standard Plenum

4. Locate the rear inner connecting bracket for connecting to the switch-gear

(81020-999-56) and temporarily fasten in place using M8 hardware

(Figure 34

Figure 34 - Attaching from and rear, inner bracket

).

5. Fasten the front inner connecting bracket for connection to the switchgear

(81020-999-54) temporarily using M8 hardware.

6. Apply gasket to the bottom flange of all front and rear assemblies

(Figure 35

Figure 35 - Gasket location

).

7. Locate the mounting holes on top of the OneGear unit to mount the front

and rear assembly (Figure 36

32 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

).

Page 35

Figure 36 - Mounting location for front and rear assembly

OneGear Standard Plenum Chapter 4

8. Take the front and rear assembly, position it as shown in Figure 37 and use

the M8 hardware (M8 HHCS, 28 mm (1.125”) OD flat washers and lock

washers) to fasten it.

Figure 37 - Front and rear assembly mounted on top of cabinet

9. Attach the outer side bracket (81023-075-02) at the rear and front using

the M8 hardware (M8 HHCS, 19 mm (0.75”) OD flat washers and lock

washers). Refer to Figure 38

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 33

.

Page 36

Chapter 4 OneGear Standard Plenum

Figure 38 - Front and rear outer side bracket attached

10. Remove the temporarily fastened hardware from Step 4 and 5; the inner

side bracket should stay in place as a result of Step 9.

11. Attach the outer side bracket that is on an angle (81023-075-01) at the

front and rear of the plenum using M8 hardware (M8 HHCS, 19 mm

(0.75”) OD flat washers and lock washers). Refer to Figure 39

.

Figure 39 - Attach outer side bracket at front and rear

12. Install the inner top bracket (81023-001-54) and outer top bracket

(81023-075-03) using M8 hardware (M8 HHCS, 19 mm (0.75”) OD flat

washers and lock washers), refer to Figure 40

.

34 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 37

OneGear Standard Plenum Chapter 4

Figure 40 - Attaching outer and inner top brackets

At this point, the OneGear SMC plenum should be completely attached to the

switchgear equipment. Apply silicone to gaps or holes located at bends and

corners. Continue with installation of the OneGear plenum components.

13. Temporarily attach the inner rear and front bracket (81020-999-56/53)

similar to step 4.

14. Take the front and rear assembly, position it as shown in figure 6 and use

the M8 hardware (M8 HHCS, 28 mm (1.125”) OD fl at washers and lock

washers) to fasten it.

15. Attach the outer side bracket (81020-991-05) similar to Step 9.

16. Remove the temporarily fastened hardware in Step 13 and attach the outer

side bracket at the front and rear that is on an angle (81020-991-04) as in

Step 11.

17. Install the inner top bracket (81023-001-53) and outer top bracket

(81020-991-06) using M8 Hardware (M8 HHCS, 19 mm (0.75” OD) flat

washers and lock washers), as in Step 12.

Two sections of the OneGear plenum should now be fully installed (Figure 41

Apply silicone to gaps or holes located at bends and corners. Repeat steps 13-17

to complete the assembly of the OneGear plenum. Review the assembly and

silicone any remaining gaps or holes in the connection.

).

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 35

Page 38

Chapter 4 OneGear Standard Plenum

IMPORTANT

Figure 41 - Two sections of the OneGear Plenum installed

18. If a Bulletin 7761 product is ordered, an end plate (81020-998) and

extension with screen will be required (81021-282-52, 81021-637-02).

Install the end plate with M8 hardware.

If an end plate is ordered with no exit hole, it must be installed first or it will be

very difficult to attach to the top plate, see Figure 42

Figure 42 - OneGear Unit on the end (7761)

.

19. Attached the extension to the end plate using M6 self-tapping screws.

Subsequent extensions are attached using M8 hardware.

For Bulletin 7760, 7762 and 7763 equipment, switchgear is provided on both

sides of the SMC. Therefore, steps 4-12 will need to be repeated using the

switchgear front and rear assembly.

36 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 39

General Reference

Appendix A

Torque Requirements

The following table contains the recommended torquing values for hardware

required to fasten electrical connections (bus-bus or bus-flexible bus links).

Hardware Recommended Torque

N•m ft•lb

M6 6.0 4.4

M8 14.0 11.0

M10 29.0 21.0

M12 50.0 37.0

M16 124.0 91.0

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 37

Page 40

Appendix A General Reference

Notes:

38 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 41

Notes:

General Reference Appendix A

Rockwell Automation Publication 7760-IN001B-EN-P - June 2013 39

Page 42

Appendix A General Reference

Notes:

40 Rockwell Automation Publication 7760-IN001B-EN-P - June 2013

Page 43

Page 44

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

code and links to software service packs, and a MySupport feature that you can customize to make the best use of these

tools. You can also visit our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

information, support chat and forums, software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application notes, sample

for FAQs, technical

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

SM

Te c h C o n n e c t

representative, or visit http://www.rockwellautomation.com/support/

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwi de Lo cato r at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Medium Voltage Products, 135 Dundas Street, Cambridge, ON, N1R 5X1 Canada, Tel: (1) 519.740.4100, Fax: (1) 519.623.8930

Online: www.ab.com/mvb

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Publication 7760-IN001B-EN-P - June 2013

Supercedes Publication 7760-IN001A-EN-P - January 2013 Copyright © 2013 Rockwell Automation, Inc . All rights reserved. Printed in Canada.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...