Page 1

PlantPAx Server and Workstation

User Manual

Catalog Numbers 7477-ISVS100,

7477-ISVS250, 7477-IC2VC

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the

Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

office or online at http://literature.rockwellautomation.com

) describes some important differences between solid state equipment and hardwired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all

persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in

this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

available from your local Rockwell Automation sales

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Allen-Bradley, Integrated Architecture, FactoryTalk, FactoryTalk Directory, FactoryTalk Activation, FactoryTalk Administration, FactoryTalk Services, FactoryTalk Batch, FactoryTalk Historian, FactoryTalk View SE, FactoryTalk View

Studio, FactoryTalk Alarms and Events, Logix 5000, Rockwell Automation, Rockwell Software, RSLinx Classic, RSLinx Enterprise, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

PlantPAx Servers and

Workstations

Process Automation Server

(PASS)

Operator Workstation (OWS)

Table of Contents

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Image Backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Process System Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Set Up FactoryTalk Directory Services. . . . . . . . . . . . . . . . . . . . . . . . . 10

Change the Windows Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configure the FactoryTalk Activation Server . . . . . . . . . . . . . . . . . . . . 14

Activate Software on a PASS with Internet Connectivity . . . . . . . 16

Activate Software for a PASS without Internet Connectivity . . . . 19

Start the FactoryTalk Activation Server . . . . . . . . . . . . . . . . . . . . . 21

Start Your Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PASS Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Locate the FactoryTalk Directory Services. . . . . . . . . . . . . . . . . . . . . . 28

Change the Windows Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configure the FactoryTalk Activation Client . . . . . . . . . . . . . . . . . . . . 30

Download the OWS License File to the Activation Server

on the PASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configure an OWS to Use Activations from an Activation

Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Start Your Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

OWS Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Publication 7477-UM001A-EN-E - August 2009 3

Page 4

Table of Contents

Notes:

4 Publication 7477-UM001A-EN-E - August 2009

Page 5

PlantPAx Servers and Workstations

Chapter

1

Introduction

PlantPAx Servers and Workstations

Cat. No. Description

7477-ISVS100 Process automation system server (PASS) with 100 screens

7477-ISVS250 Process automation system server (PASS) with 250 screens

7477-IC2VC Operator workstation (OWS)

Use this manual to configure PlantPAx servers and workstations. The servers

and workstation are prepackaged hardware and software products based on

the PlantPAx characterized system elements. You should have already

completed the procedures in the PlantPAx Process Automation System Quick

Start, publication 7477-QS001.

You can also create image backups of the servers and workstations, as well as

order process-specific support.

Topic Page

Image Backup 5

Process System Support 6

Image Backup

Publication 7477-UM001A-EN-E - August 2009 5

A cloning utility resides on the VersaView Accessories CD which is shipped

with every VersaView Computer.

This cloning utility lets you create a back-up image of your computer’s hard

disk drive. If your system becomes unstable or corrupt, you can restore the

hard disk drive from the back-up image. There is no restriction on the number

of times you create or restore a back-up image.

When using the automated cloning utility, the active system partition of your

computer’s hard disk drive can back up to and restore from the recovery

partition. The active system partition runs the operating system. The recovery

partition stores a back-up image of the system. Each time you create a back-up

image in the recovery partition, the previously archived image is replaced. It is

recommended that the original image stored to the recovery partition remain

intact and all future images be saved to DVD format.

Page 6

Chapter 1 PlantPAx Servers and Workstations

Use the cloning utility to:

• Create, resize, or delete a recovery partition on the hard disk drive.

• Create a back-up of the active system image in the recovery partition of

the hard drive.

• Restore an archived system image from the recovery partition.

• Use the ghost utility to manually perform system operations to create a

bootable CD or DVD with a back-up image.

For information on using the cloning utility, see the Cloning Utility Technical

Data, publication 6000-TD001

. This publication is available on the desktop of

each PlantPAx computer in the folder named PlantPAx Documentation, as

well as via Literature Library.

Process System Support

PriorityConnect Systems Support offers support tailored for process

automation systems available through TechConnect Support. PriorityConnect

contracts offer these features:

• Highly experienced team of engineers with training and systems

experience across the entire Integrated Architecture system for both

process systems

• Process support at a systems level provided by process engineers

• Priority case handling by Senior Systems Support Group with proactive

case resolution follow-up

• Unlimited online support requests

• Access to hundreds of other support engineers as needed

• Use of online remote diagnostic tools

• Access to otherwise restricted TechConnect Knowledgebase content

• Technical Reference Library DVD

• 24x7x365 phone-support coverage upgrade option

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com

.

Additional Resources

Resource Description

PlantPAx Process Automation System Quick

Start, publication 7477-QS001

PlantPAx Process Control System Profile,

publication PROCES-SG001

PlantPAx Process Automation System

Reference Manual, publication

PROCES-RM001

6 Publication 7477-UM001A-EN-E - August 2009

See these documents for more information.

Startup a new PlantPAx server or workstation and configure Windows settings.

Overview of the three typical process architectures: independent, centralized, and

distributed.

Architecture definitions and design recommendations for PlantPAx process automation

systems.

Page 7

PlantPAx Servers and Workstations Chapter 1

You can view or download publications at

http://literature.rockwellautomation.com.

Publication 7477-UM001A-EN-E - August 2009 7

Page 8

Chapter 1 PlantPAx Servers and Workstations

8 Publication 7477-UM001A-EN-E - August 2009

Page 9

Process Automation Server (PASS)

Chapter

2

Introduction

The process automation system server (PASS) is the process system server.

The PASS can also provide HMI, data, and OPC server functions. The

available servers are:

• 7477-ISVS100, PASS with 100 screens.

• 7477-ISVS250, PASS with 250 screens.

To configure a PASS, complete these steps.

1. Set up FactoryTalk Directory services.

2. Change the Windows configuration.

3. Configure the FactoryTalk Activation server.

4. Start your project.

Topic Page

Set Up FactoryTalk Directory Services 10

Change the Windows Configuration 13

Configure the FactoryTalk Activation Server 14

Start Your Project 23

PASS Details 24

Publication 7477-UM001A-EN-E - August 2009 9

Page 10

Chapter 2 Process Automation Server (PASS)

Set Up FactoryTalk Directory Services

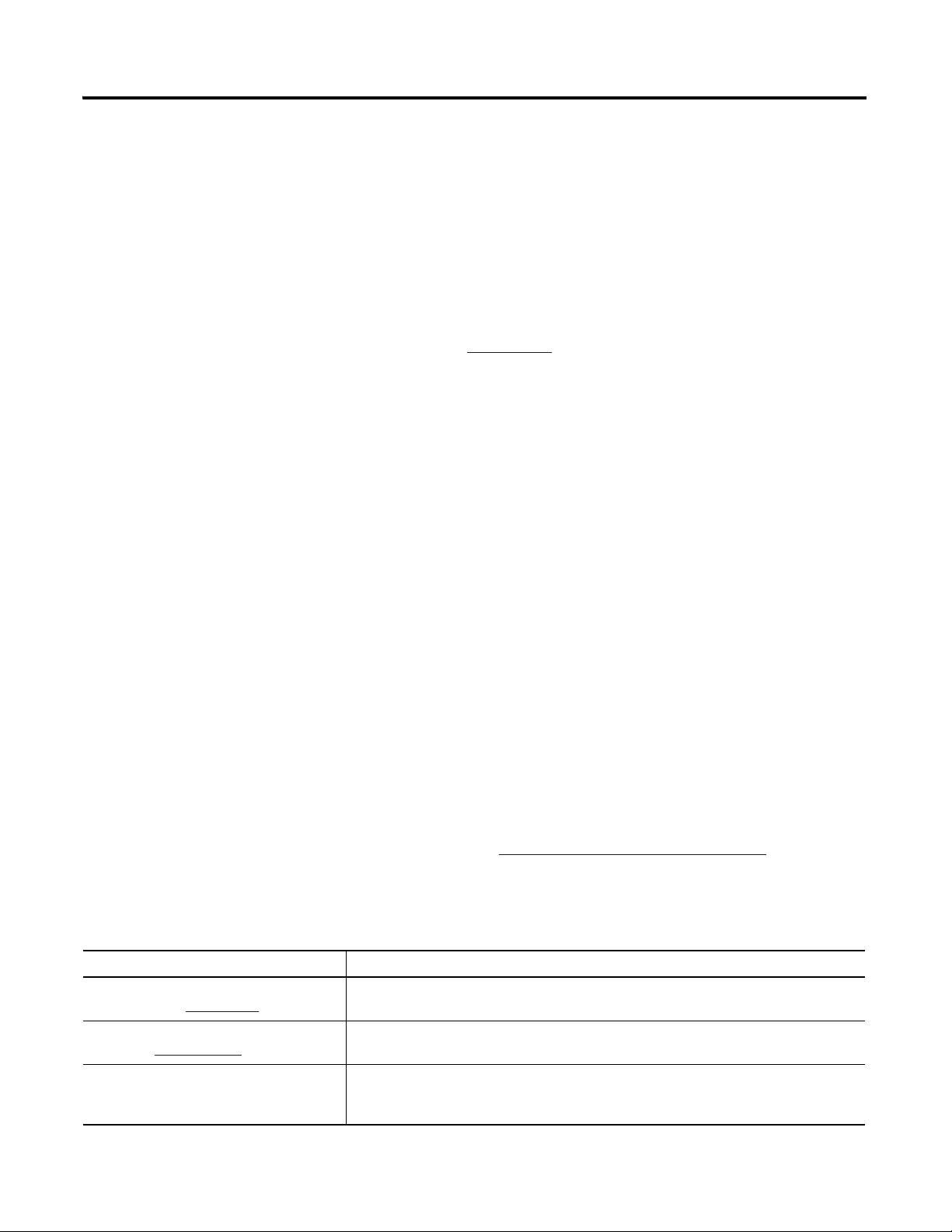

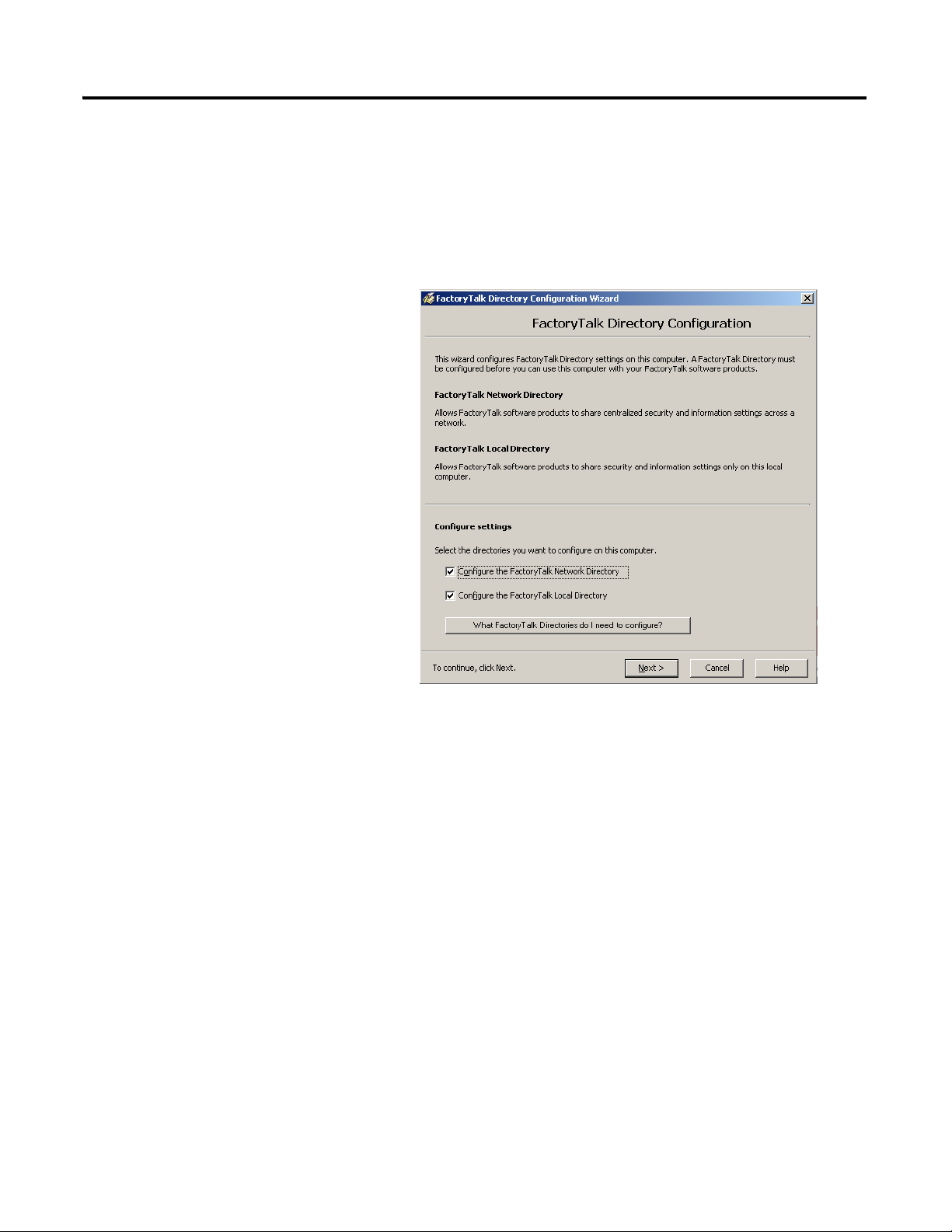

To set up FactoryTalk Directory services, complete these steps.

1. Choose Start>Programs>Rockwell Software>FactoryTalk

Tools>FactoryTalk Directory Configuration Wizard.

The FactoryTalk Directory Configuration Wizard may take a few

minutes to open.

2. Check the boxes to configure both the network directory and the local

directory and click Next.

It may take 30 seconds to process the request.

3. Enter the FactoryTalk Administration Console credentials (see below)

for the network directory configuration and click Next.

Username: administrator

Password: rockwell

It may take 30 seconds to process the request.

4. Enter the credentials for the local directory configuration and click

Next.

If in a Workgroup environment, enter the Windows credentials. These

are the credentials that were created during the Windows mini-setup.

If in a Domain environment, the credentials must include the computer

name in front of the proper Windows user name.

10 Publication 7477-UM001A-EN-E - August 2009

Page 11

Process Automation Server (PASS) Chapter 2

The password remains the same. For example, on a PASS computer with

a computer name of RAPASS, use the credential in the following table.

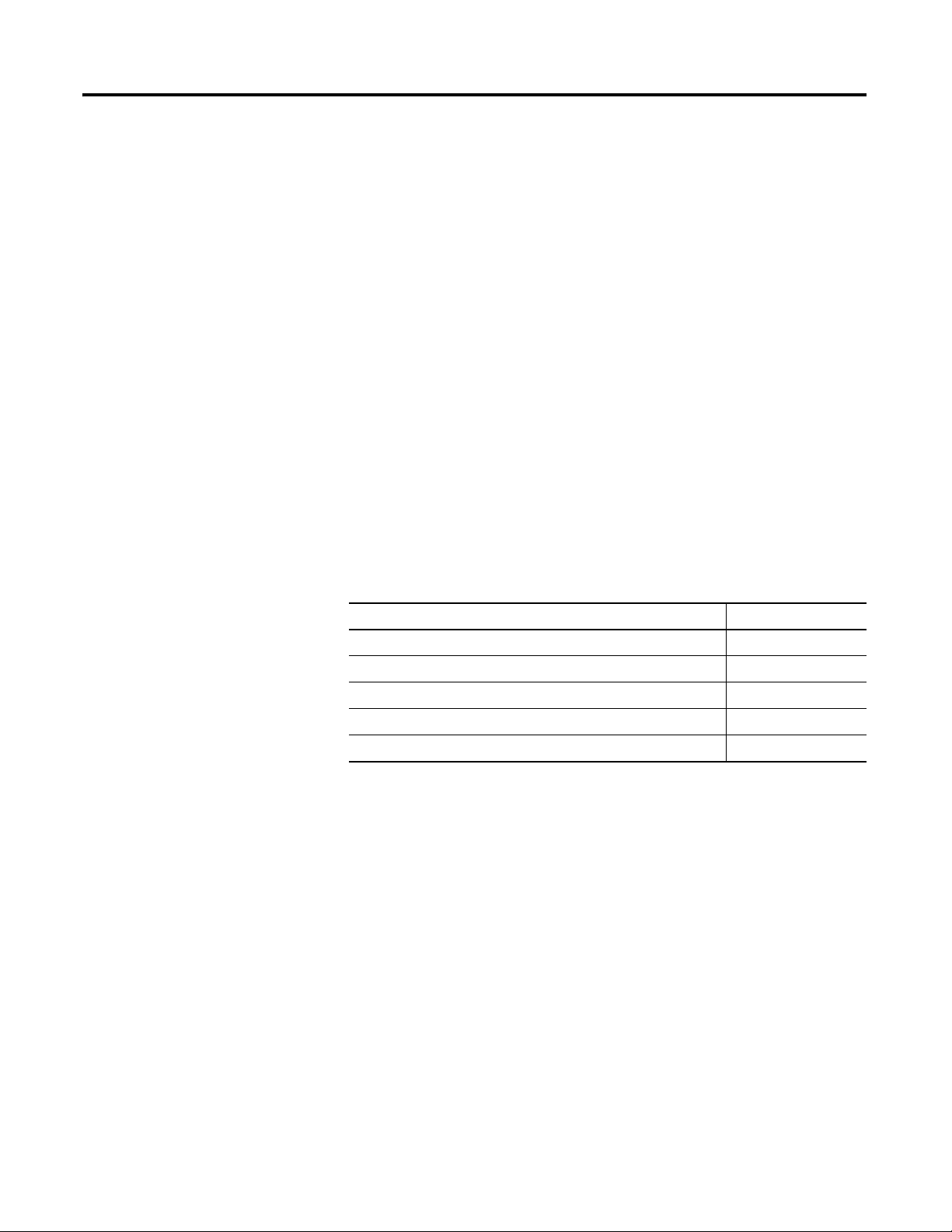

Windows Credentials Workgroup Domain

User Administrator RAPASS/Administrator

Password rockwell rockwell

It may take 30 seconds to process the request.

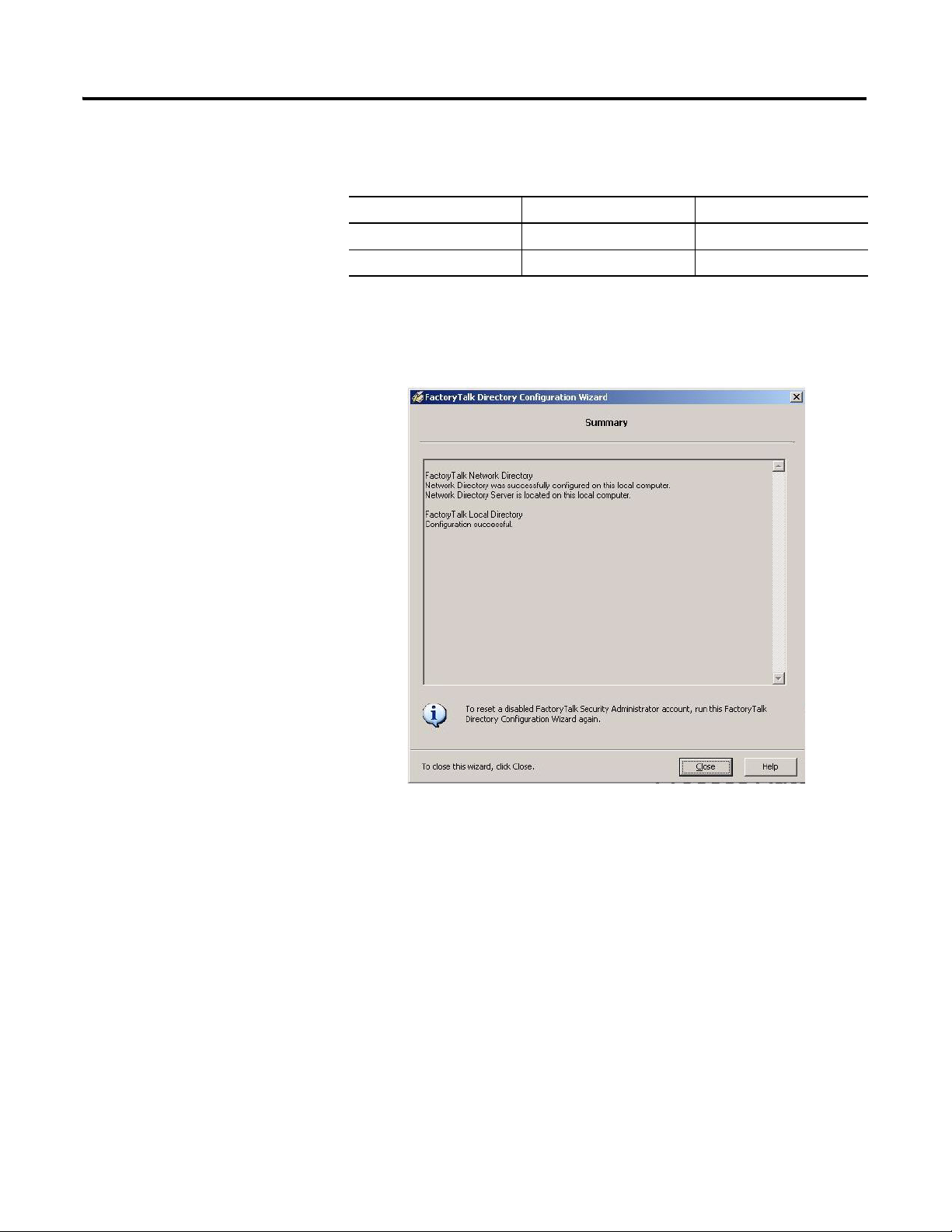

The network and local directory should now be setup and should be shown as

being configured successfully.

Next, delete the old computer name from the FactoryTalk Directory

Administration Console.

1. Choose Start>Programs>Rockwell Software>FactoryTalk

Administration Console.

2. Click Network and click OK.

Publication 7477-UM001A-EN-E - August 2009 11

Page 12

Chapter 2 Process Automation Server (PASS)

3. In the Explorer window, browse to Network (THIS COMPUTER) and

choose System>Computers and Groups>Computers.

4. Right-click RAPASS and choose Delete.

5. Click Yes to continue.

Now you can create a new FactoryTalk Administration Console administrator

account. If you choose not to create a new account, we recommend that you

change the default FactoryTalk Services password.

1. Browse to Network (THIS COMPUTER) and choose System>Users

and Groups>Users.

12 Publication 7477-UM001A-EN-E - August 2009

Page 13

Process Automation Server (PASS) Chapter 2

2. Double-click the administrator account.

3. Click Reset Password and enter a new FactoryTalk Administration

Console password.

Record this password for future reference.

4. Click OK to exit.

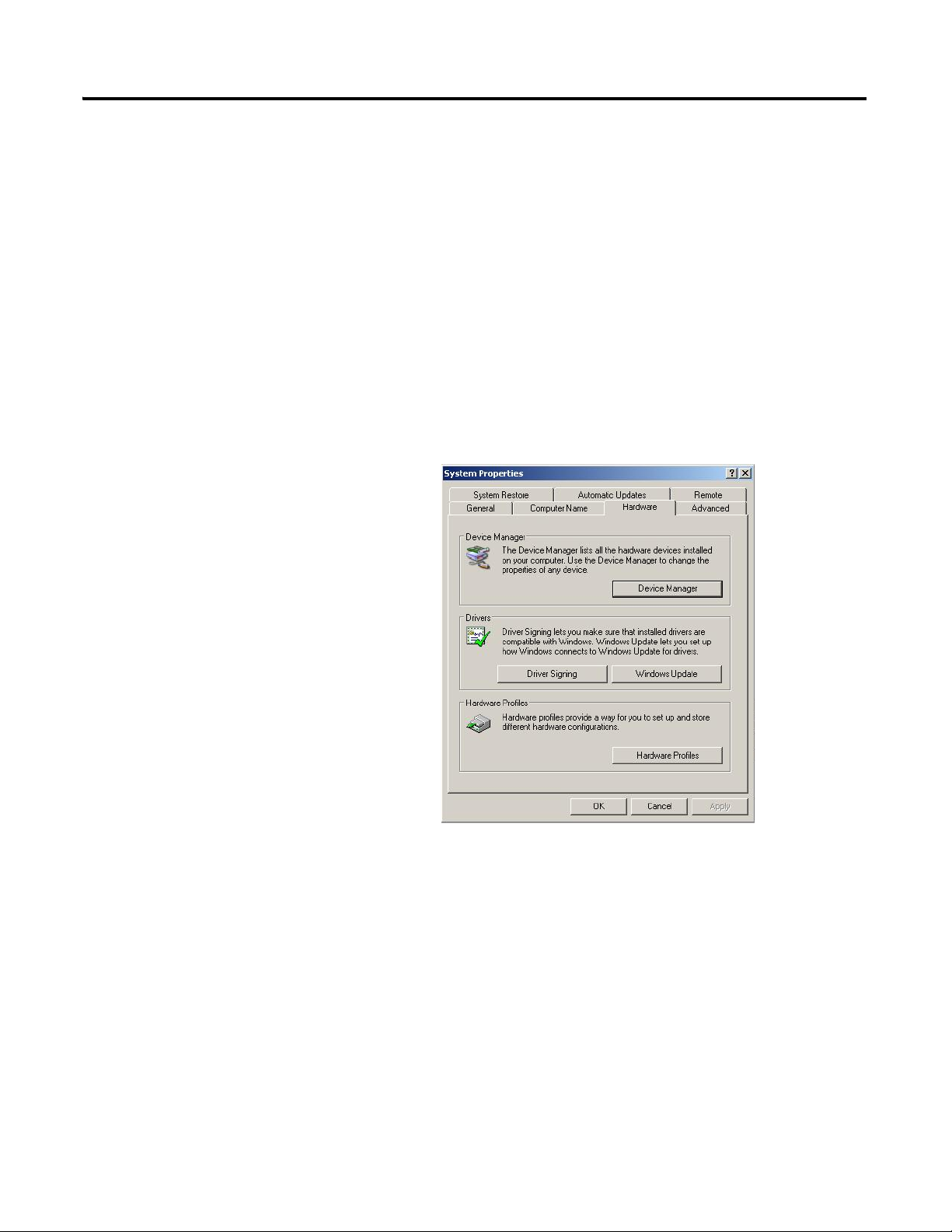

Change the Windows Configuration

Use the Windows desktop to set the speed and duplex settings of the PASS.

1. Choose Start>Settings>Control Panel.

2. Double-click System and click the Hardware tab.

3. Click Device Manager in the Device Manager box.

Publication 7477-UM001A-EN-E - August 2009 13

Page 14

Chapter 2 Process Automation Server (PASS)

4. In the Device Manager window, click the + icon next to Network

adapters.

Configure the FactoryTalk Activation Server

5. Right click the first Network adapter in the list and choose Properties.

6. Click the Advanced tab and select Speed & Duplex in the Property

window.

7. From the Value menu, choose 100 Mbps Full Duplex and click OK.

8. Repeat these steps for the other network adapter.

For continuous use of FactoryTalk products and other Rockwell Software

products, computers running the software must have access to activation files.

FactoryTalk Activation software provides a secure, software-based system for

activating Rockwell Software products and managing software activation files.

With FactoryTalk Activation software, there is no need for a physical master

disk or any physical media. Instead, activation files are generated and

distributed electronically.

Concurrent activations are locked to a central activation-server computer on

the network. The activation server manages a pool of activation keys for

connected clients to share. Floating concurrent activations are assigned

automatically to clients that need them, and returned automatically to the

activation server pool when the software stops running on the client, or when

the client computer shuts down.

14 Publication 7477-UM001A-EN-E - August 2009

Page 15

Process Automation Server (PASS) Chapter 2

Client computers must be set up to obtain floating activations from the

activation server. A continuous network connection is also required for clients

to use floating activations. After a client obtains a floating activation, if the

activation server detects that the client has been disconnected, the activation is

returned to the server pool.

Activation Considerations

Consideration Details

Software that is not activated If the components you have installed cannot be activated, for example, because the

activation server is unavailable, then the software will continue to run for up to seven

days. The seven-day grace period allows time to correct the problem with acquiring

activations, without disrupting critical applications. If activation is restored within seven

days, normal operations will resume. If activation is not restored, the grace period will

expire. After the grace period expires, if you restart the components and activation

remains unavailable, the software will run for two hours in Demo mode.

Location of activation server The PASS is the primary choice for activation management and should be the location of

the activation server. In the instance that the PASS is not an acceptable location, for

example, a customer makes use of a redundant PASS solution, a EWS is the secondary

choice. In this instance, the EWS should be a dedicated station with a permanent Ethernet

connection to the system. The FactoryTalk Activation software can be configured to run as

both a server and client utility.

Options for adding activation files to the

PASS

Protect activation files Activation files are simple text files that must have a .lic extension.

To make concurrent floating activations available to activation clients, first you must

download the activation files to the activation server computer, from the Rockwell

Software Activation website.

If the PASS has Internet access, see Activate Software on a PASS with Internet

Connectivity on page 16.

If the PASS does not have Internet access the activations may have to be downloaded on a

different computer with Internet connectivity and then transferred to the PASS, see

Activate Software for a PASS without Internet Connectivity on page 19

As long as the .lic extension is retained, you can copy or rename an activation file without

harming it. However, tampering with text inside the activation file can disable your

Rockwell Software products.

If an activation file is damaged or deleted, contact Rockwell Automation Technical

Support.

For safekeeping, keep an original set of your activation files on back-up media. Use

descriptive names for the files, so that you can identify them later, and copy them back to

the appropriate computers.

Activation files are locked to the Host IDs of the computers (or dongles) that need them.

Activation will fail for Rockwell Software products on a computer where the specified Host

ID is not recognized by the activation file.

.

Publication 7477-UM001A-EN-E - August 2009 15

Page 16

Chapter 2 Process Automation Server (PASS)

Activate Software on a PASS with Internet Connectivity

To activate software on a PASS with Internet connectivity, complete these

steps.

1. Insert the dongle included with the PASS into any available USB port.

2. Choose Start>Programs>Rockwell Software>FactoryTalk Activation>

FactoryTalk Activation Tool.

3. Click the Get Activations tab.

Do not click 'Use Host ID of a dongle' at this time. You will configure

this later.

4. Click Open Activation Wizard.

16 Publication 7477-UM001A-EN-E - August 2009

Page 17

Process Automation Server (PASS) Chapter 2

The Activation Wizard dialog box appears.

5. Click Next.

If you are activating additional products, check 'Use the Expert Interface

to activate multiple products.' You will need the appropriate serial

numbers and product keys provided with each product.

6. Type the serial number and product key found on the activation

certificate that was included with the PASS computer and click Next.

7. Type the number of PASS computers to be activated, typically 1, in

Activations Requested and click Next.

8. To identify the Host ID the product will be associated to, check 'I need

activation for a hardware dongle…' and click Next.

9. Choose the Host ID of the dongle that was included with the PASS and

click Next.

Publication 7477-UM001A-EN-E - August 2009 17

Page 18

Chapter 2 Process Automation Server (PASS)

10. Confirm your selections and click Next.

11. Print a copy of the LIC file and click Print.

12. Click Finish.

The activations are now downloaded and you can start the Activation

Server (see page 21

18 Publication 7477-UM001A-EN-E - August 2009

).

Page 19

Process Automation Server (PASS) Chapter 2

Activate Software for a PASS without Internet Connectivity

To activate software on a PASS without Internet connectivity, complete these

steps.

1. On a computer with Internet access, go to

http://licensing.software.rockwell.com

2. In the menu tree, choose Get Activations.

.

3. Select the Host ID type as Dongle.

4. Type the Host ID of the dongle that was included with the PASS.

The Host ID can be found on the dongle.

Publication 7477-UM001A-EN-E - August 2009 19

Page 20

Chapter 2 Process Automation Server (PASS)

5. Type the serial number and product key found on the Activation

Certificate that was packaged with the PASS computer.

If you are activating additional products, click 'Use the Expert Interface

to activate multiple products.' You will need the appropriate serial

numbers and product keys provided with each product.

6. Click Next.

7. Type the number of PASS computers to be activated, typically 1, in

Activations Requested and click Next.

8. Validate the data and click Next.

9. Click OK.

10. Click Download Concurrent Activation.

11. Click Save.

12. Save the LIC file to a transportable media (such as a USB thumbdrive).

20 Publication 7477-UM001A-EN-E - August 2009

Page 21

Process Automation Server (PASS) Chapter 2

13. Copy the LIC file to this directory location on the PASS:

C:\Program Files\Common Files\Rockwell\Activations

The activations are now downloaded and you can start the Activation

Server (see page 21

).

Start the FactoryTalk Activation Server

To start the FactoryTalk Activation server, complete these steps.

1. Insert the dongle into an open USB port on the PASS.

2. Open the FactoryTalk Activation Tool and click the Settings tab.

3. Click Start.

Publication 7477-UM001A-EN-E - August 2009 21

Page 22

Chapter 2 Process Automation Server (PASS)

4. Verify that the Activation Server is running.

5. Click the Current Activations tab and click Refresh.

Be sure 'Browse for available activations on start-up' is checked.

22 Publication 7477-UM001A-EN-E - August 2009

Page 23

Process Automation Server (PASS) Chapter 2

6. Verify that the activations appear in the upper window of the

FactoryTalk Activation tool.

Start Your Project

The activation service is now started and the PASS software is ready for

use.

7. Click Exit to close the tool.

Now you are ready to start your project. For example:

• Configure new users and roles.

• Add the PASS to a domain.

• Setup FactoryTalk Directory security.

• Load and develop the application files.

For information on implementing a process system, see the PlantPAx Process

Automation System Reference Manual, publication PROCES-RM001

.

Publication 7477-UM001A-EN-E - August 2009 23

Page 24

Chapter 2 Process Automation Server (PASS)

PASS Details

Characterization of these system elements focuses on a FactoryTalk View SE

application and does not include the use of FactoryTalk Batch or Historian

products.

Computer Configuration - PASS

Attribute PASS

Hardware • Core 2 duo processor

• 1.66 GHz CPU

• 4 GB memory

• Dual, 160 GB hard drives (one for application code; one for logging)

• Dual monitor support

• USB dongle

Configuration • Hardware DEP enabled

• Windows firewall enabled

• No power management

• No screen saver

• No automatic Windows updates

• Remote assistance disabled

• Recovery partition created on C: drive

• Windows classic desktop for Windows XP operating system

• FactoryTalk Directory server specified

• PlantPAx Administrator and default user account for activation server setup

Server Software - PASS

Software Product

Operating system • Windows 2003 R2 server operating system

Visualization software • FactoryTalk View SE server

• FactoryTalk View SE client

• FactoryTalk View Studio software

(1)

• FactoryTalk Alarms and Events software

Infrastructure software • FactoryTalk View Administration Console software

• FactoryTalk Directory server

• RSLinx Enterprise software (includes FactoryTalk Alarms and Events server)

• RSLinx Classic software

(1)

• Logix5000 Clock Tool software

• FactoryTalk Activation server

• Rockwell Automation Support Tool software

Third-party software • Adobe Acrobat Reader software, version 9.0

(1)

This application software is pre-installed but is not activated on the computer. Activations for this software can be purchased separately. Contact your local sales

representative for more information

24 Publication 7477-UM001A-EN-E - August 2009

Page 25

In addition to the application software above, these optional software packages

are supported for use with the PASS.

Optional Software - PASS

Software Product

Optional software • KEPServer Enterprise software

Optional third-party software • Antivirus software

• Microsoft Office products

• MSSQL Server Express software

Process Automation Server (PASS) Chapter 2

Publication 7477-UM001A-EN-E - August 2009 25

Page 26

Chapter 2 Process Automation Server (PASS)

Notes:

26 Publication 7477-UM001A-EN-E - August 2009

Page 27

Operator Workstation (OWS)

IMPORTANT

Chapter

3

Introduction

The operator workstation (OWS) provides the graphical view and interface

into the process. The workstation is a client of either a PASS or application

HMI server. The OWS supports operator interaction and is not meant to

support development or maintenance activities. The available OWS is catalog

number 7477-IC2VC.

To configure an OWS, complete these steps.

Make sure the PASS is already configured. For more

information, see chapter Chapter 2 Process Automation Server

(PASS) on page 9.

1. Locate the FactoryTalk Directory services.

2. Change the Windows configuration.

3. Configure the FactoryTalk Activation client.

4. Start your project.

Topic Page

Locate the FactoryTalk Directory Services 28

Change the Windows Configuration 29

Configure the FactoryTalk Activation Client 30

Start Your Project 32

OWS Details 33

Publication 7477-UM001A-EN-E - August 2009 27

Page 28

Chapter 3 Operator Workstation (OWS)

Locate the FactoryTalk Directory Services

To locate the FactoryTalk Directory services, complete these steps.

1. Choose Start>Rockwell Software>FactoryTalk Tools>Specify

FactoryTalk Directory Location.

2. Click the '…' button next to localhost.

3. Enter your FactoryTalk Directory Administration Console credentials.

By default, the OWS uses the settings below. If a new administrator

account was created, use the new account credentials.

Username: administrator

Password: rockwell

4. Click Remote computer.

Click the '...' button to navigate the network to find the computer name

of the PASS that is hosting the FactoryTalk Directory services.

5. Choose the appropriate PASS computer and click OK.

The Network FactoryTalk Directory location has now been specified.

28 Publication 7477-UM001A-EN-E - August 2009

Page 29

Operator Workstation (OWS) Chapter 3

Change the Windows Configuration

Use the Windows desktop to set the speed and duplex settings of the OWS.

1. Choose Start>Settings>Control Panel.

2. Double-click System and click the Hardware tab.

3. Click Device Manager in the Device Manager box.

4. In the Device Manager window, click the + icon next to Network

adapters.

5. Right click the first Network adapter in the list and choose Properties.

Publication 7477-UM001A-EN-E - August 2009 29

Page 30

Chapter 3 Operator Workstation (OWS)

6. Click the Advanced tab and select Speed & Duplex in the Property

dialog box.

7. From the Value menu, choose 100 Mbps Full Duplex and click OK.

8. Repeat these steps for the other network adapter.

Configure the FactoryTalk Activation Client

After you set up the activation server, specify the server the client computer

connects to in order to retrieve activations. Once a client is connected to a

server, run the application software (such as FactoryTalk View SE client) and

the server automatically issues available activations.

A continuous network connection is required for an activation client to use

floating activations. After a client obtains a floating activation, if the activation

server detects that the client has been disconnected, the activation is returned

to the server pool.

To be sure that critical software components (such as redundant HMI servers)

can always obtain the necessary activations, set up an activation server on the

computer where the software is running.

Download the OWS License File to the Activation Server on the PASS

To download the license file, follow either of these procedures:

• Activate Software on a PASS with Internet Connectivity on page 16

• Activate Software for a PASS without Internet Connectivity on page 19

.

.

Use the serial number and product key provided on the activation certificate

that was packaged with the OWS computer. The Host ID will be the same as

the one for the PASS computer. A license file for each OWS computer is

managed by the activation server on the PASS. The activation client utility on

the OWS only needs to be configured to use the activation server once the

license file is put on the activation server.

30 Publication 7477-UM001A-EN-E - August 2009

Page 31

Operator Workstation (OWS) Chapter 3

Configure an OWS to Use Activations from an Activation Server

To configure the OWS to use activations from an activation server, complete

these steps.

1. Choose Start>Programs>Rockwell Software>FactoryTalk Activation>

FactoryTalk Activation Tool on the OWS.

2. Click the Settings tab.

3. Add the FactoryTalk Activation server computer to the 'Folders and

servers searched by applications' box.

Syntax = PortNumber@ServerName

For example, 27000@servername where 27000 is the default port for

FactoryTalk Activation server.

4. Check 'Browse for Activations on start-up'.

5. Click the Current Activation tab and click Refresh.

Publication 7477-UM001A-EN-E - August 2009 31

Page 32

Chapter 3 Operator Workstation (OWS)

Be sure 'Browse for available activations on start-up' is checked.

Start Your Project

6. Verify that the activation appears in the upper window of the

FactoryTalk Activation tool.

Once the FactoryTalk server has been added to the server list, available

concurrent activations are displayed on Current Activations tab.

Now you are ready to start your project. For example:

• Create and run a FactoryTalk View client

• Create and run a FactoryTalk Batch client

For information on implementing a process system, see the PlantPAx Process

Automation System Reference Manual, publication PROCES-RM001

.

32 Publication 7477-UM001A-EN-E - August 2009

Page 33

Operator Workstation (OWS) Chapter 3

OWS Details

Characterization of these system elements focuses on a FactoryTalk View SE

application, and does not include the use of FactoryTalk Batch or Historian

products.

Computer Configuration - OWS

Attribute OWS

Hardware • Core 2 duo processor

• 1.66 GHz CPU

• 1 GB memory

• One 160 GB hard drive

• Dual monitor support

Configuration • Hardware DEP enabled

• Windows firewall enabled

• No power management

• No screen saver

• No automatic Windows updates

• Remote assistance disabled

• Recovery partition created on C: drive

• Windows classic desktop for Windows XP operating system

• FactoryTalk Directory server specified

• PlantPAx Administrator and default user account for activation server setup

Workstation Software - OWS

Software Product

Operating system • Windows XP SP2 operating system

Visualization software • FactoryTalk View SE client

• FactoryTalk Alarms and Events software

• FactoryTalk Batch client

• FactoryTalk eProcedure software

(1)

(1)

Infrastructure software • FactoryTalk Activation client

• Rockwell Automation Support Tool software

Third-party software • Adobe Acrobat Reader software, version 9.0

(1)

This application software is pre-installed but is not activated on the computer. Activations for this software can be purchased separately. Contact your local sales

representative for more information

In addition to the application software above, these optional software packages

are supported for use with the OWS.

Optional Software - OWS

Software Product

Optional third-party software • Antivirus software

• Microsoft Office products

Publication 7477-UM001A-EN-E - August 2009 33

Page 34

Chapter 3 Operator Workstation (OWS)

Notes:

34 Publication 7477-UM001A-EN-E - August 2009

Page 35

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using

its products. At http://support.rockwellautomation.com

manuals, a knowledge base of FAQs, technical and application notes, sample code and

links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools.

For an additional level of technical phone support for installation, configuration, and

troubleshooting, we offer TechConnect support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

, you can find technical

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the

information that's contained in this manual. You can also contact a special Customer

Support number for initial help in getting your product up and running.

United States 1.440.646.3434

Monday – Friday, 8am – 5pm EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational

when shipped from the manufacturing facility. However, if your product is not

functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case

number (call the phone number above to obtain one) to your distributor

in order to complete the return process.

Outside United

States

Please contact your local Rockwell Automation representative for the

return procedure.

Publication 7477-UM001A-EN-E - August 2009 39

Copyright © 2009 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...