Page 1

Bulletin 700-P (10A), 700DC-P (10A), 700-PL (10A), 700-PT (10A), 700-PK (20A), 700DC-PK (20A),

700-PH (35A), 700DC-PH (35A), 700-CP1, 700-CPM, 700-CPR, 700-CPH

Industrial Control Relay and Accessory Installation Instructions

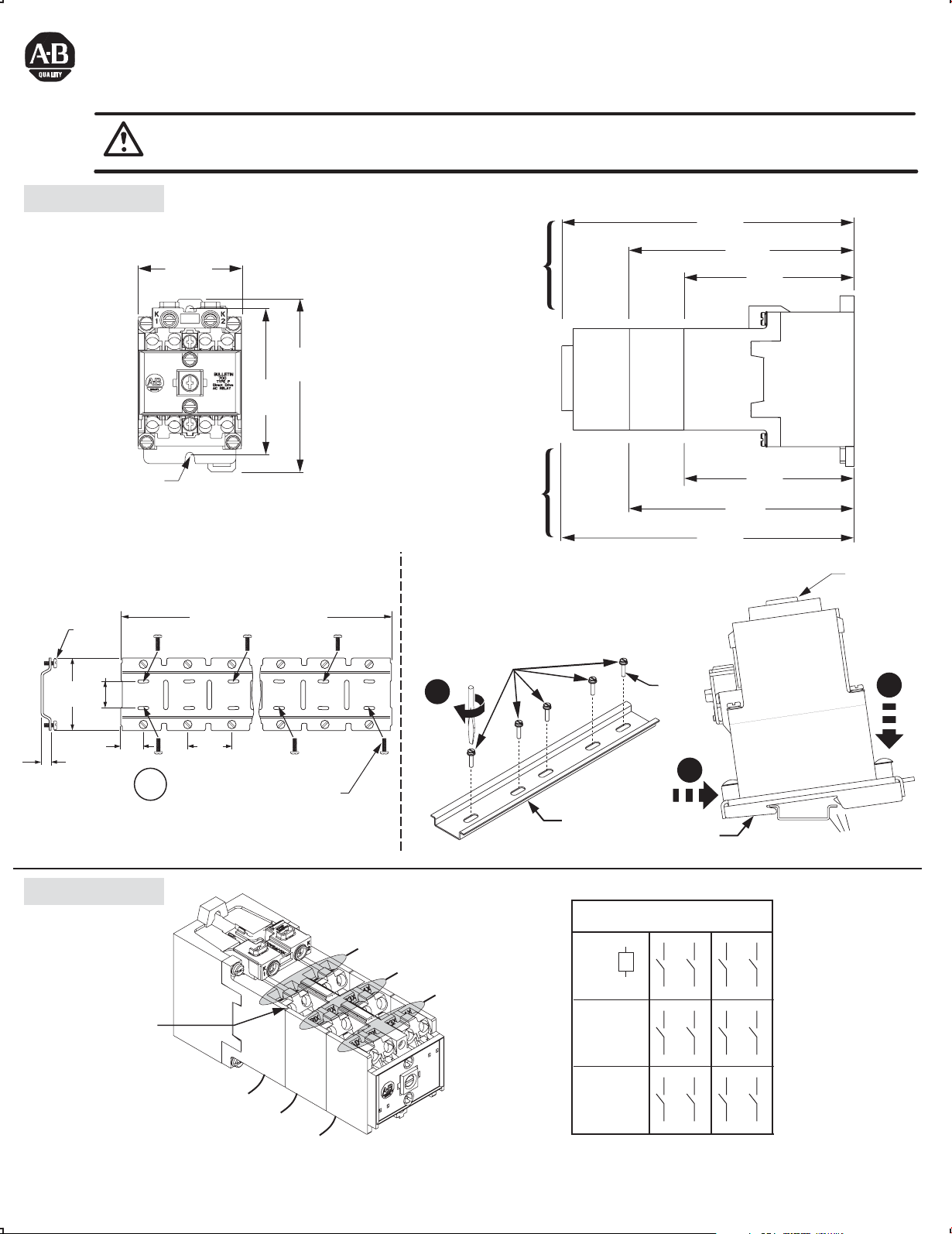

Relay Installation

Panel Mounting

ATTENTION: To prevent electrical shock, disconnect from power source before installing or servicing. Install in suitable enclosure.

Keep free from contaminants.

It is necessary to adhere to the torque values listed for proper operation.

6 - 45/64

(170.10)

5 - 25/64

2-1/4

(57.2)

3 - 1/8

(79.4)

AC

3 - 17/32

(89.7)

(136.75)

4 - 5/64

(103.43)

Provision for 2 - #8 (M4)

Mtg. Screws

Relay Rail Mounting

14-20 lb-in

(1.6-2.3 N-m)

1-3/8

(34.9)

3 - 5/8

(92)

1/2

(12.7)

in

(mm)

Wire Installation

Cat. 700-MP4 - 9" (228.6)

Cat. 700-MP8 - 18" (457.2)

Cat. 700-MP12 - 27" (685.8)

Cat. 700-MP16 - 36" (914.4)

2-1/4

(57.1)

14-20 lb-in

(1.6-2.3 N-m)

#8 (M4)

DC

DIN Rail Mounting

14 - 20 lb-in

(1.6 - 2.3 N-m)

1

199-DR1

Contact Arrangement and Markings

#10 (M5)

Max

2

700-DRA

7-3/8

(187.17)

(120.49)

6-1/16

(153.83)

4-3/4

DC Relay Only

3

CLICK

1 x #18 AWG (.75 mm2)

2 x #12 AWG (4.0 mm2)

8 - 12 lb-in

A1Y A2Y A3Y A4Y

B1Y B2Y B3Y B4Y

C1Y C2Y C3Y C4Y

A1X A2X A3X A4X

B1X B2X B3X B4X

C1X C2X C3X C4X

4 - Pole

Relay

8 - Pole

Relay

12 - Pole

Relay

A2X

A3X

A3Y

B3X

B3Y

C3X

C3Y

A4X

A4Y

B4X

B4Y

C4X

C4Y

A1X

K1

K2

A1Y

B1X

B1Y

C1X

C1Y

A2Y

B2X

B2Y

C2X

C2Y

Page 2

Contact Cartridges

5/16"

(7.9 mm)

8 -12 lb-in

(.9 - 1.4 N-m)

Cat. No. Contact Ratings

Standard

Overlap

Master

Safety (Standard) 700-CPS 10 A

700-CP1

700-CP11Z

700-CPM

Lt. Grey

Black

Lt. Grey

Red

Continuous

600V AC

10 A

10 A

20 A

35 ALt. GreyTandem (2 Masters) 700-CPH

600V DC

5 A

5 A

10 A

20 A

5 A

Contact Ratings

Make / Break

600V AC

NEMA

A600

NEMA

A600

(2) X NEMA

A600

(2) X NEMA

A600

NEMA

A600

600V DC

NEMA

P600

NEMA

P600

(2) X NEMA

P600

(2) X NEMA

P600

NEMA

P600

Use Copper Wire Only

min - 1 x #18 AWG (.75 mm2)

max - 2 x #12 AWG (4.0 mm2)

Any combination of N.O. & N.C.

red cartridges must be used.

Do not use in Timers or Latches.

Contact Cartridges Reconfiguration (N.O. N.C.)

Remove front cover.

1

Remove drive bar.

2

Safety (Master) 700-CMS 20 A

Logic Reed 700-CPR 500ma

Red

White

@ 150 VDC

25 W (Max)

10 A

200ma

@ 30 VDC

6 W (Max)

(2) X NEMA

A600

500ma

@ 150 VDC

25 W (Max)

(2) X NEMA

P600

200ma

@ 30 VDC

6 W (Max)

ATTENTION: Do not install the logic reed cartridge in a relay, timer or latch unit that is located next to a

Bulletin 700 Type R, RM, RTC sealed contact relay or other device with a strong magnrtic leakage field.

As erratic contact action could result. Because the logic reeds require very little force to operate. At least

2 standard cartridges are required in the relay to provide maximum mechanical life.

Remove contact

3

cartridge.

Convert contacts

5

N.O. N.C.

Loosen screw(s).

4

35A Jumper Kit Installation

ATTENTION: Both cartridges must be of the same configuration (N.O. or N.C.) (4 N.C. or 6 N.O.

Jumper Kits Maximum per AC or DC Relay) . If a kit is added to the third deck of an AC Relay, be

sure the enclosure is a 700-N31 Series B which has an electrical tape added inside the cover.

Because of a high inner barrier, Jumper Kits should be used on Series B 700-PT pneumatic timers.

7

7 - 14 lb-in

(.8 - 1.6 N-m)

Tighten terminal

screw(s).

Install contact

6

cartridge.

(2)

Install front cover

9

8 -12 lb-in

(.9 -1.4 N-m)

#10 AWG

8

18 - 25 lb-in

(2.0 - 2.82 N-m)

14 - 18 lb-in

(1.6 - 2.0 N-m)

Install drive

bar

7 - 14 lb-in

(.8 - 1.6 N-m)

2

#10 AWG

Page 3

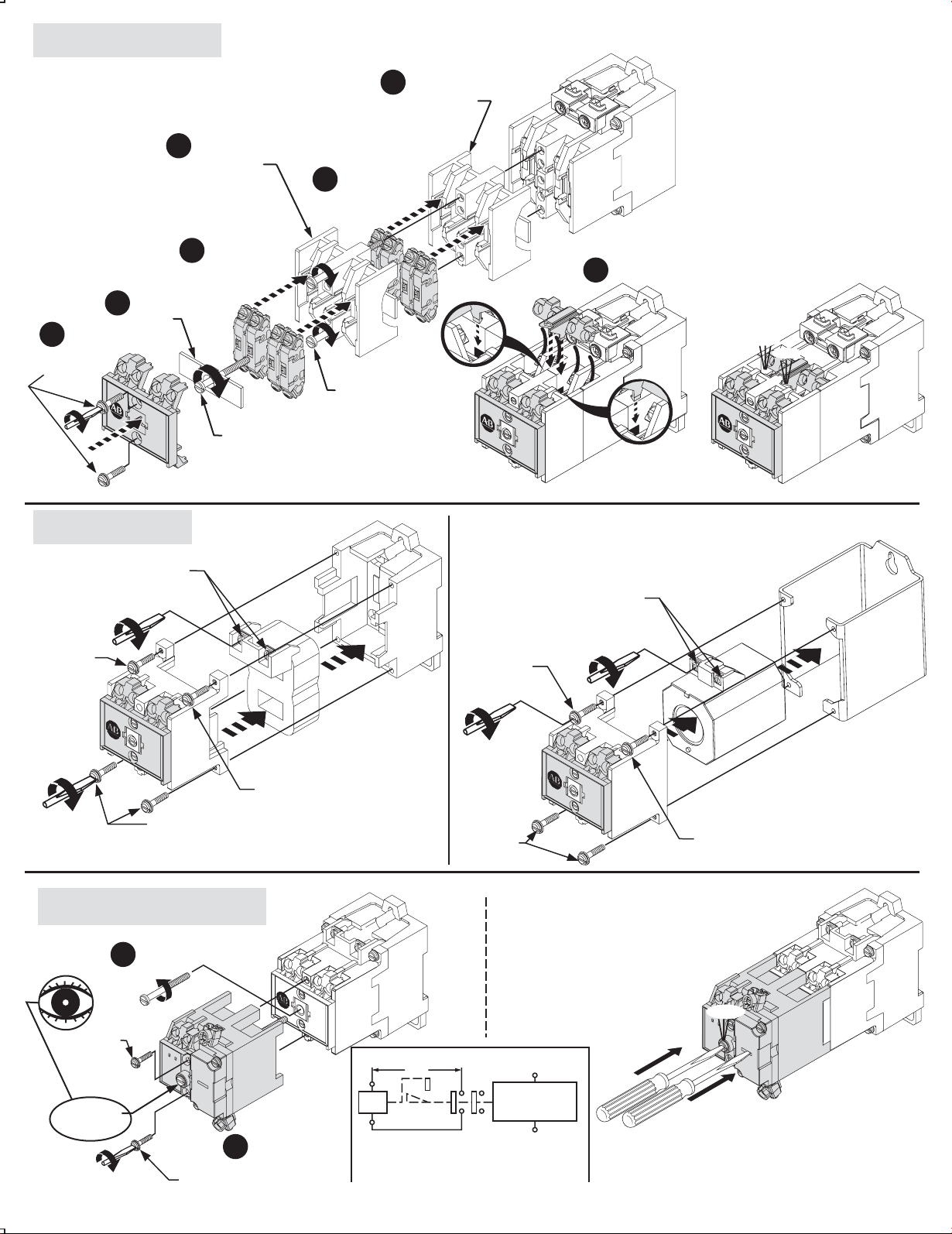

Adder Deck Installation

Install third deck

3

as required.

700-PC_ _

or

700-PKC_ _

4

Install cross bar

with longer drive

5

screw.

Install top

6

cover.

8 -12 lb-in

(.9 -1.4 N-m)

Install contact

cartridges

as required.

14 - 18 lb-in

(1.6 - 2.0 N-m)

Install contact

2

cartridges

as required.

8 - 12 lb-in

(.9 - 1.4 N-m)

Install second deck

1

as required.

700-PB_ _

or

700-PKB_ _

Install terminal shield.

7

CLICK

CLICK

Coil Replacement

AC Coil DC Coil

18 - 22 lb-in

(2.0 - 2.5 N-m)

8 - 12 lb-in

(.9 - 1.4 N-m)

18 - 22 lb-in

(2.0 - 2.5 N-m)

18 - 22 lb-in

(2.0 - 2.5 N-m)

Latch Attachment Installation

(Single Deck Relays Only)

Remove crossbar

1

screw.

18 - 22 lb-in

(2.0 - 2.5 N-m)

18 - 22 lb-in

(2.0 - 2.5 N-m)

8 - 12 lb-in

(.9 - 1.4 N-m)

18 - 22 lb-in

(2.0 - 2.5 N-m)

NOTE: For test putposes only. Do not engage

the latch and unlatch at the same time.

8 - 12 lb-in

(.9 - 1.4 N-m)

14 - 20 lb-in

(1.6 - 2.3 Nm)

8 - 12 lb-in

(.9 - 1.4 N-m)

Install Latch

2

Attachment.

FOR DC LATCH UNITS

D.C.

K3

D.C.

K4

To operate unlatch coil, apply DC to K3-D2X

Arc suppressors (diodes or RC) are the only circuits that can

be connected directly across the unlatch coil, K3-K4

A D.C. latch unit can be added to anyType P or PK single deck

AC or DC relay.

D2X D1X

D2Y D1Y

K1

Mechanical tie to

Single-Deck Relay

thru Central Drive

Screw K

K2

(3)

CLICK

Push to latch

Push to unlatch

Page 4

Latch Attachment Contact

Cartridges Reconfiguration

Rotate arm 90˚

2

clockwise.

Remove cover.

1

Unlatch Coil Replacement

Remove terminal

1

covers.

Remove old coil.

2

Remove contact

3

cartridge

and reconfigure

per page 2.

5

Install contact

4

cartridge.

Rotate arm 90˚

counter clockwise.

Install new coil.

3

8 - 12 lb-in

(.9 - 1.4 N-m)

Install cover.

6

8 - 12 lb-in

(.9 - 1.4 N-m)

Install terminal covers.

4

Timer Attachment Installation

(Single Deck Only)

Remove crossbar

1

screw.

8 - 12 lb-in

(.9 - 1.4 N-m)

14 - 20 lb-in

(1.6 - 2.3 Nm)

8 - 12 lb-in

(.9 - 1.4 N-m)

Timer Attachment Contact

Cartridges Reconfiguration

Rotate arm 90˚

2

clockwise.

Install timer attachment

2

("ON-Delay" mode is

factory installed).

Remove contact

3

cartridge

and reconfigure

per page 2.

Convert to "OFF-Delay"

4

by removing timing unit

and rotating 180˚.

8 - 12 lb-in

(.9 - 1.4 N-m)

Rotate arm 90˚

5

counter clockwise.

ON Delay

Install cover.

6

OFF Delay

1

PN-15096

Printed in U.S.A.

Remove cover.

Install contact

4

cartridge.

8 - 12 lb-in

(.9 - 1.4 N-m)

Loading...

Loading...