Page 1

User Manual

PowerFlex 7000 Medium Voltage AC Drive Liquid-Cooled ("C" Frame) - ForGe Control

Publication 7000L-UM301D-EN-P

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

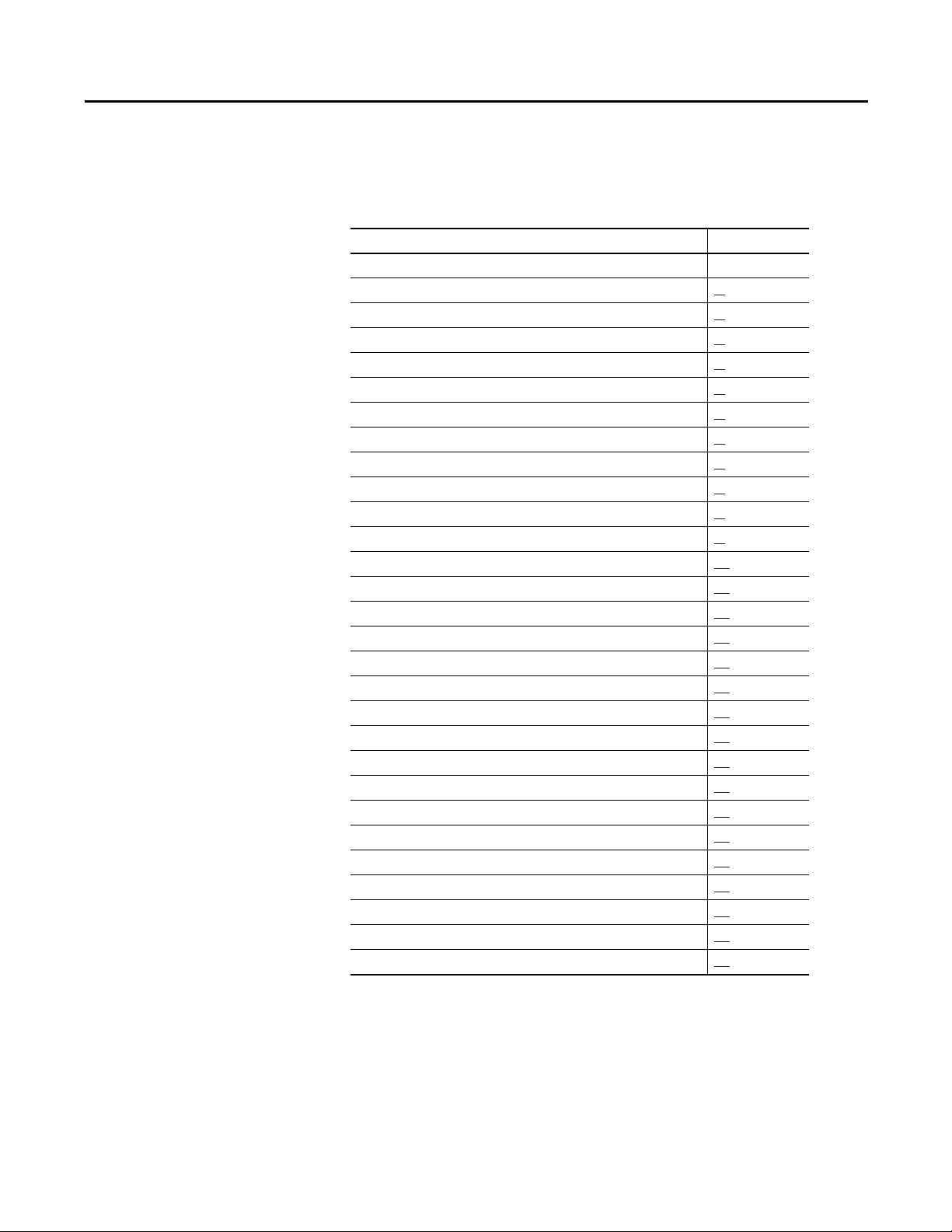

This manual contains new and updated information.

Summary of Changes

New and Updated

Information

This table summarizes the changes made to this revision.

Top ic Pag e

Changed all references of “tachometer” to “encoder” Throughout

Added HPTC information to Topology section 17

Updated Speed Regulator Bandwidth 24

Updated Torque Regulator Bandwidth 24

Inserted Torque Accuracy with HPTC 24

Added Polish to list of available Languages 25

Added “Dual-port Ethernet/IP” to Communications Protocols 25

Replaced Control Overview block diagram 29

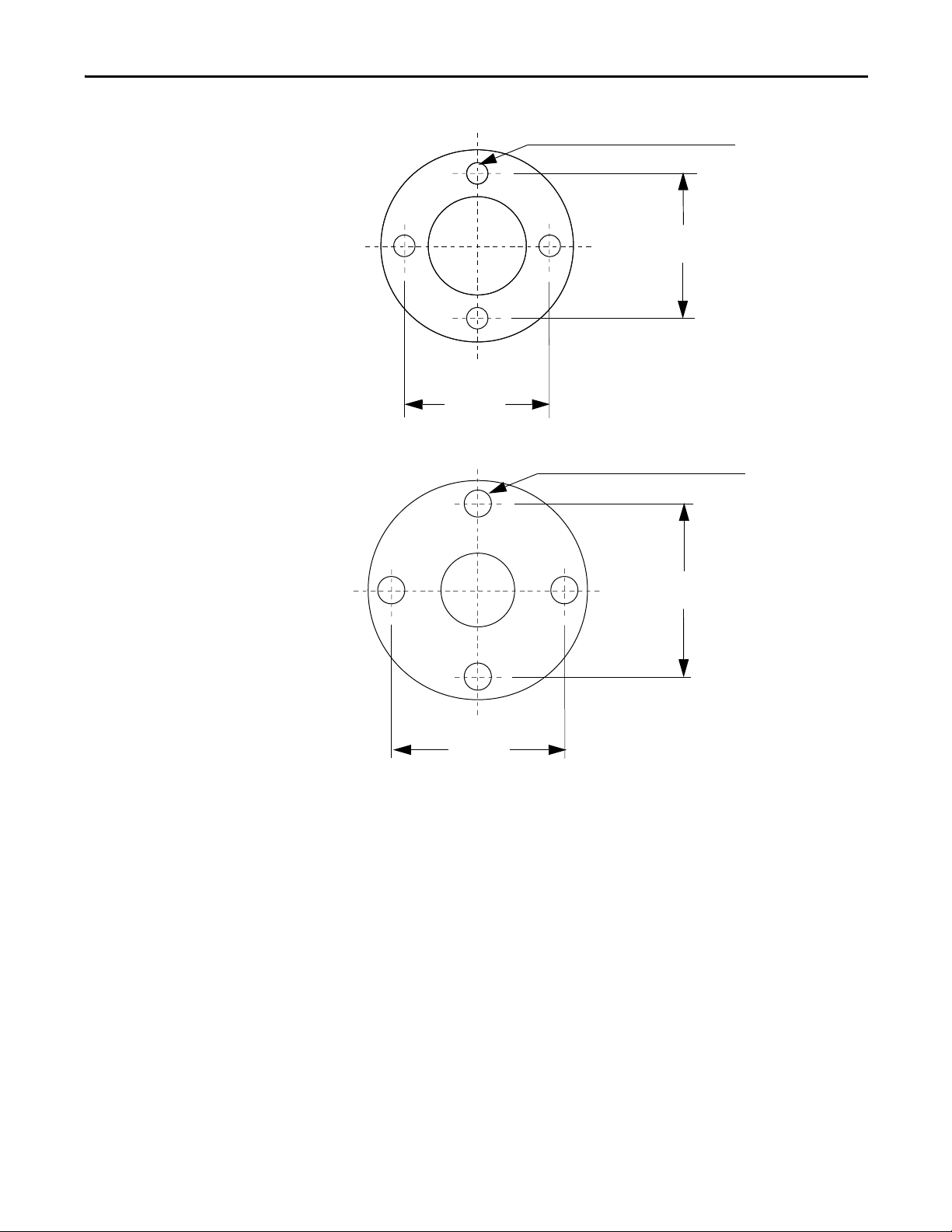

Added “Pipe Materials and Layout” section 76

Added dimensions and torque information to Pipe Flange detail images 77

Inserted “External Piping to the Drive” section 77

Inserted “Controlled Siphon into Open-top Reservoir” section 78

Added Converter Cabinet Components (3300/4160V) image 212

Added Converter Cabinet Components (6600V) image 213

Changed graphic labels for valve locations 217

Changed graphic labels for valve locations 218

Inserted “System Fill and Air Venting” and “Normal Operation” section 218

Replaced Cooling System Overview chart 328

Inserted “Pump Cabinet with Ebara Pumps” image 331

Added “Pump Replacement with Drive Running” section 331

Replaced Pressure Indicator and Switch Locations image 333

Replaced Temperature and Conductivity Sensors image 337

Replaced Deionizer Reservoir Circuit image 338

Inserted “Replacing the Mesh Filters” section 339

Replaced Catalog Number Explanation 411

Updated “When is an Encoder Required?” section and table 414

Replaced Encoder Selection table 415

Added HPTC information to Drive Torque Capabilities table 415

Updated Typical Application Load Torque Profiles 416

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 5

Overview of Drive

Table of Contents

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Liquid Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Benefits of Liquid Cooling Include: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Benefits of the 7000L “C” Frame Liquid-cooled Drive: . . . . . . . . . . 16

Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

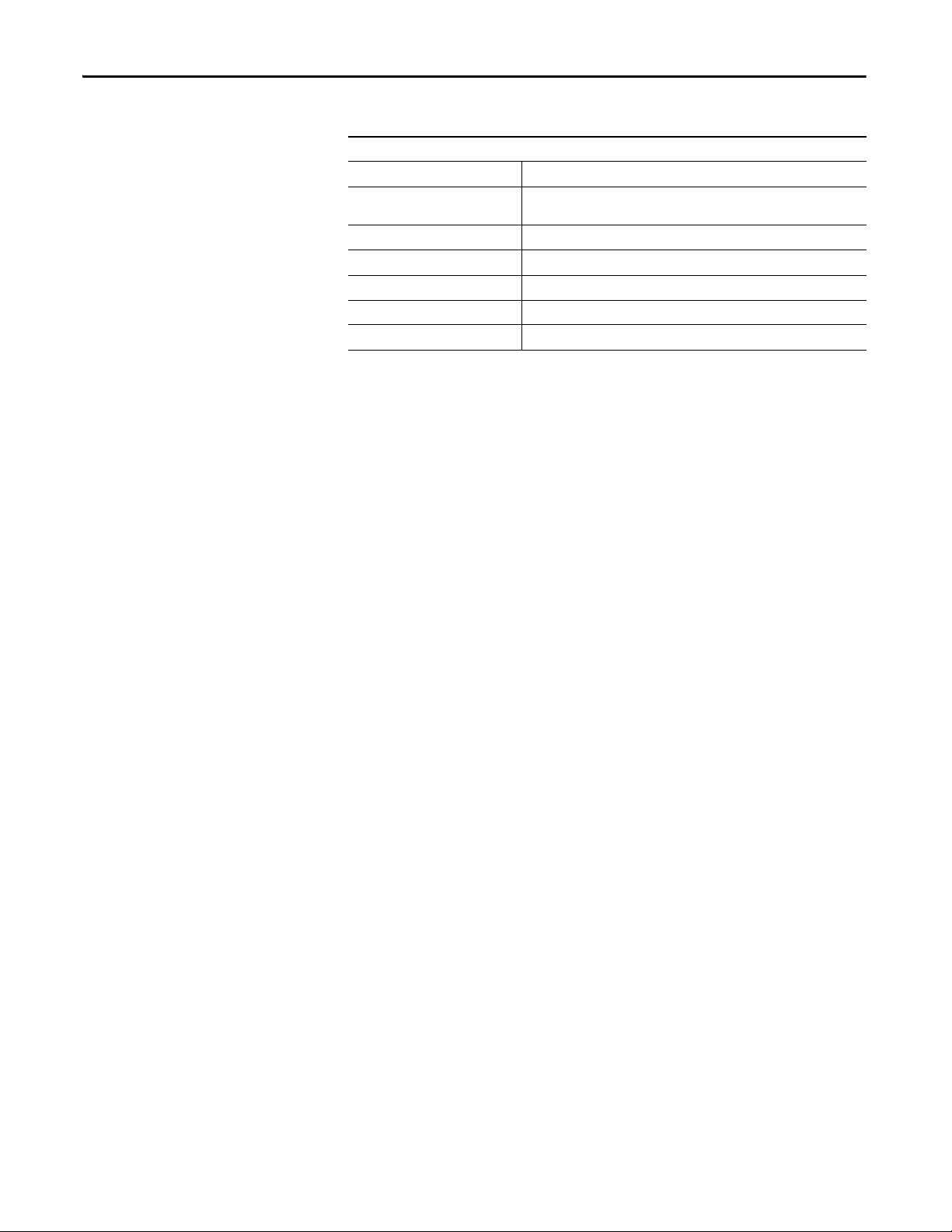

Rectifier Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

18 Pulse Rectifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Active Front End (AFE Rectifier). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

“Direct-to-Drive” Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Motor Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SGCT Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Simplified Electrical Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Direct Vector Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Control Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Drive Installation

Chapter 2

Safety and Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transportation and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Overhead Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Rod or Pipe Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Fork Lift Trucks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Siting of the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Site Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

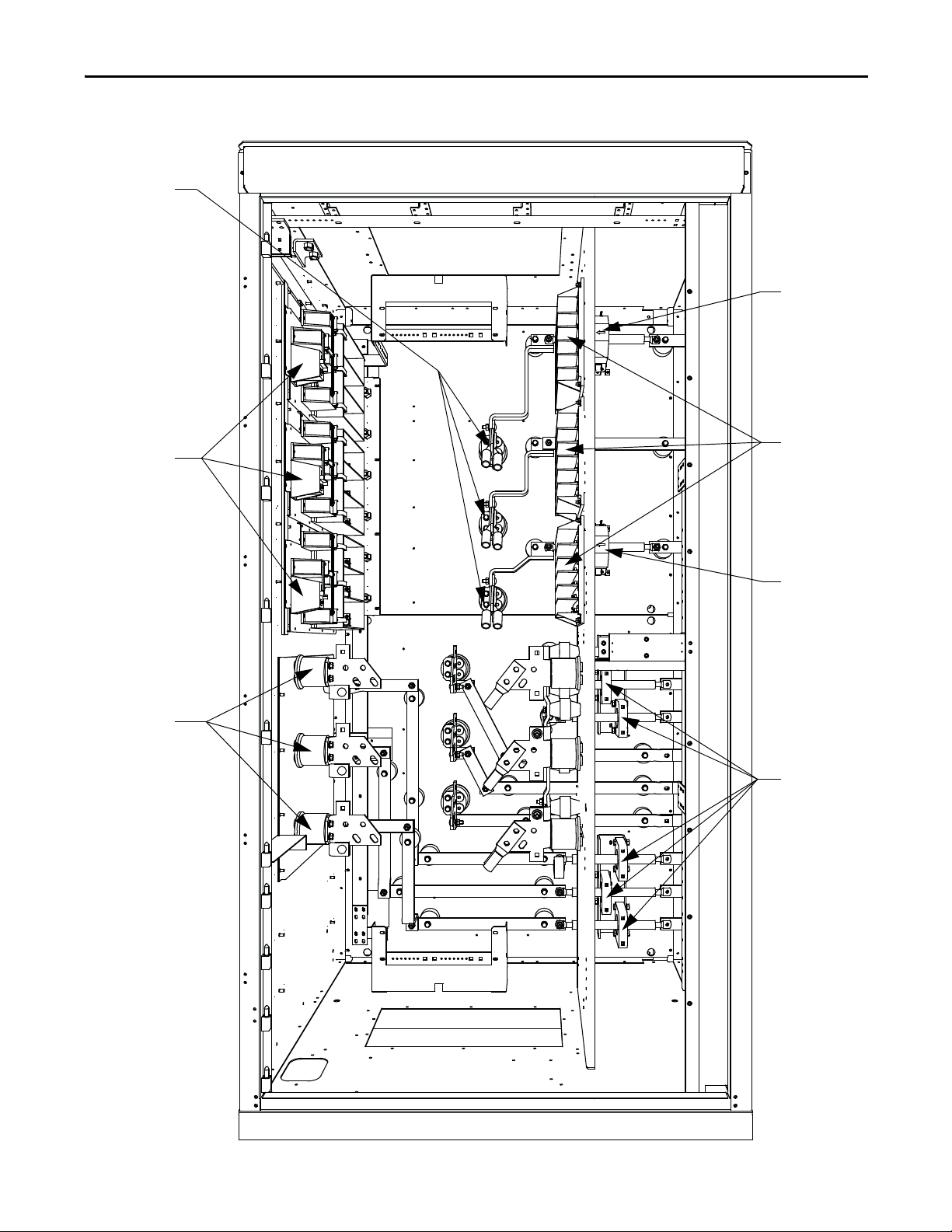

Joining Shipping Splits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connect the Sections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Tools Required (not supplied). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Install CPVC Piping Splices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connect Power: M+, L+, M-, L- Power Bus . . . . . . . . . . . . . . . . . . . . 42

Control Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removal of DC Link Choke Turnbuckle Supports . . . . . . . . . . . . . 54

Removal of Lifting Angles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Shock Indication Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installation of Exhaust Air Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Internally mounted fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Externally mounted fans and fan hood . . . . . . . . . . . . . . . . . . . . . . . . . 58

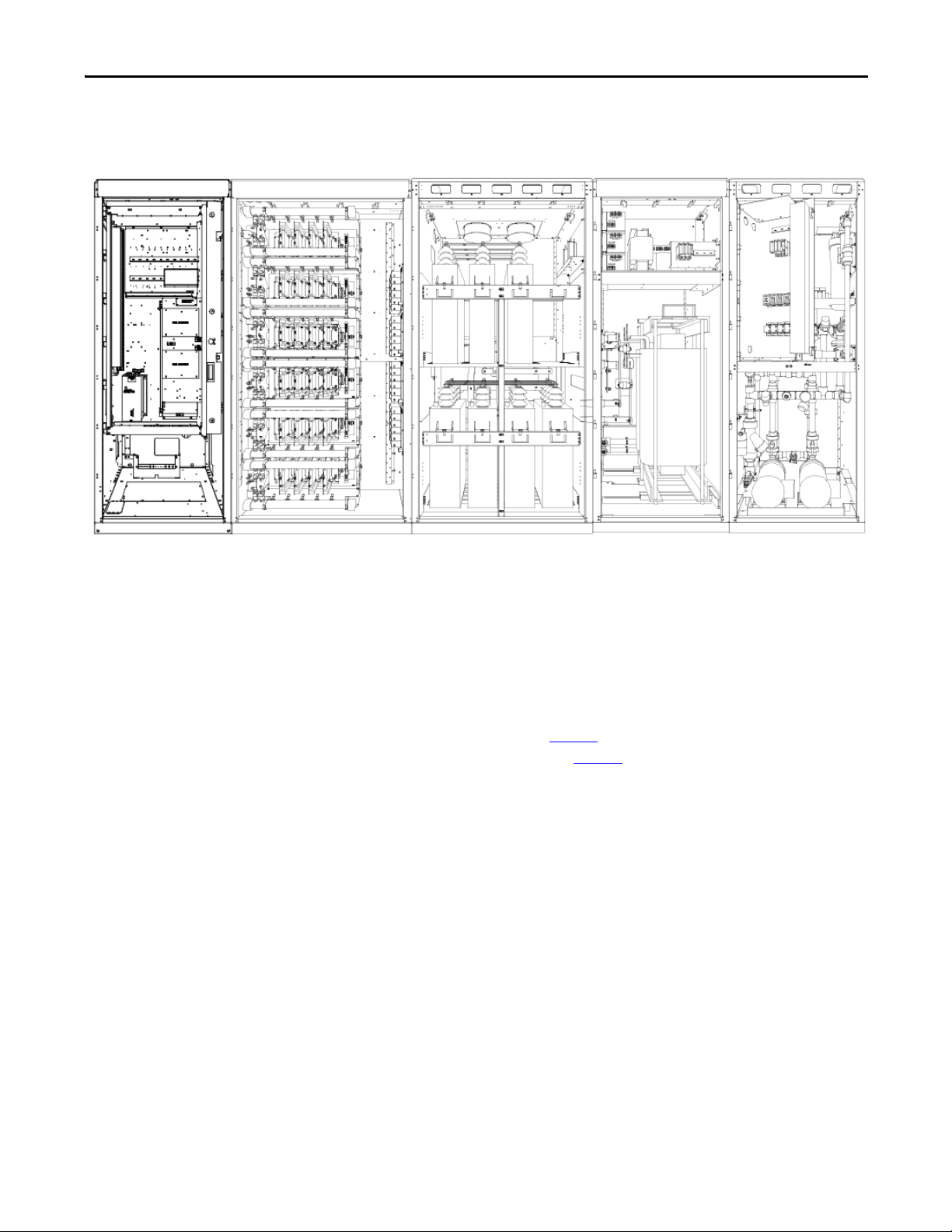

Typical PowerFlex 7000L Drive Structure Layout. . . . . . . . . . . . . . . 59

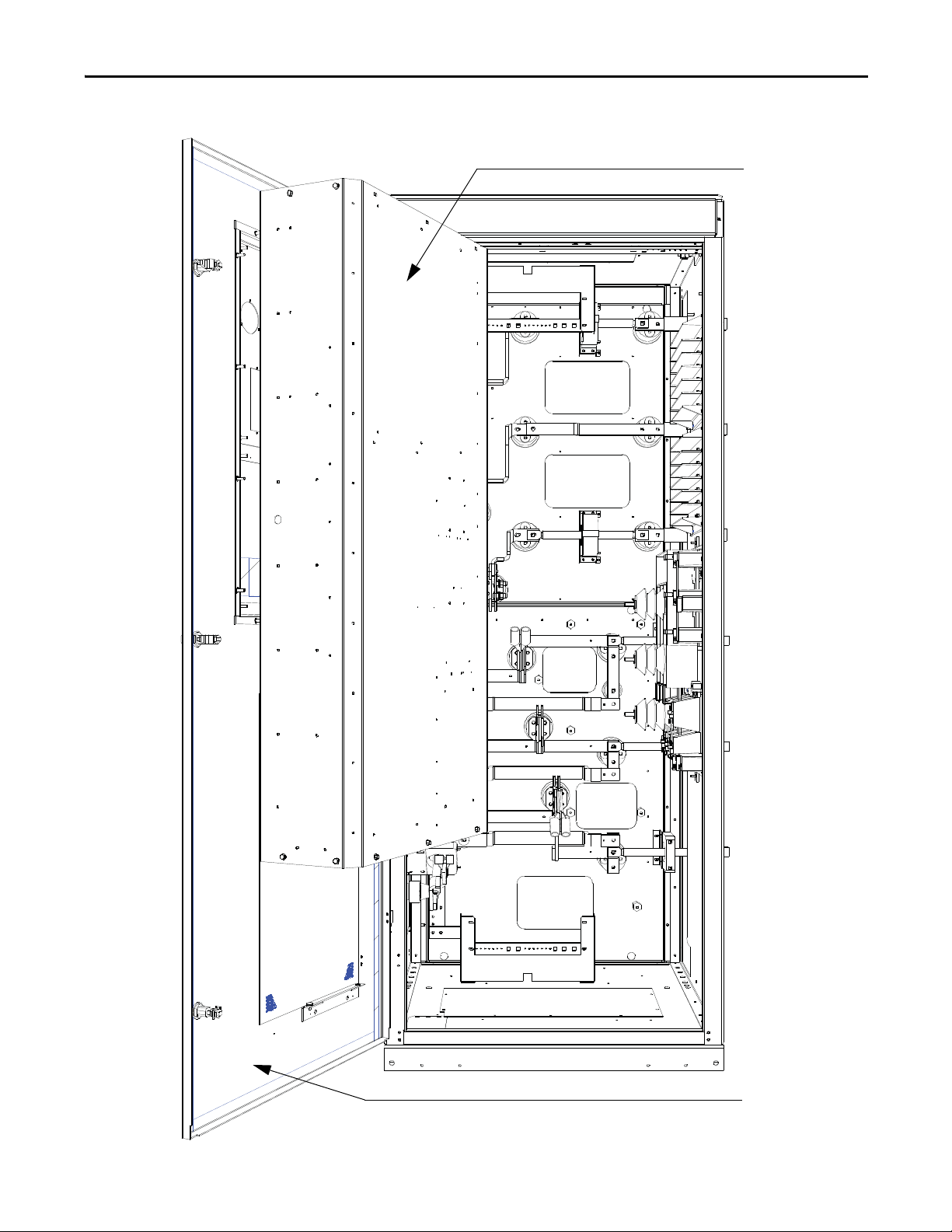

Control/Cabling Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 5

Page 6

Table of Contents

IEC Component and Device Designation . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Power Wiring Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Cable Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Power Cabling Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Access the Customer Power Cable Terminations: . . . . . . . . . . . . . . . 71

Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Incoming Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Liquid Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

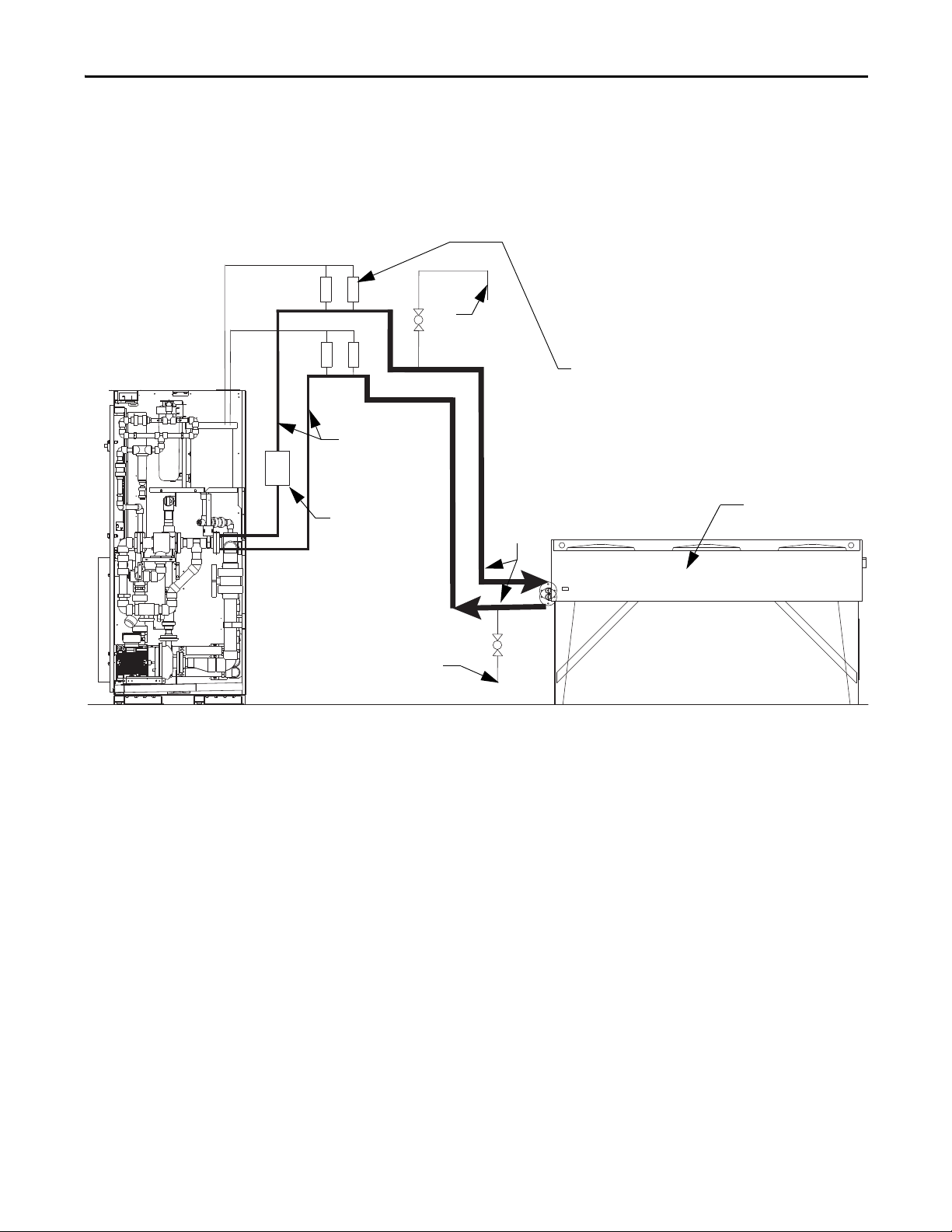

Liquid-to-Air Heat Exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Pipe Materials and Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

External Piping to the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

External Piping Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Controlled Siphon into Open-top Reservoir . . . . . . . . . . . . . . . . . . . . . . . . 78

Liquid-to-Liquid Heat Exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Power and Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Control Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Encoder Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Information Regarding Termination of Customer Cables . . . . . . . . 86

Grounding Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Grounding Guidelines and Practices for Drive Signal and Safety

Grounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Grounding Requirements and Grounding Specification for

Customers and Power Integrators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Identification of Types of Electrical Supplies – Grounded and

Ungrounded Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Ground Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Interlocking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 3

Operator Interface

6 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Function (Softkeys) Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Cursor (Selection) Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Data Entry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

What is a Screen?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Information Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

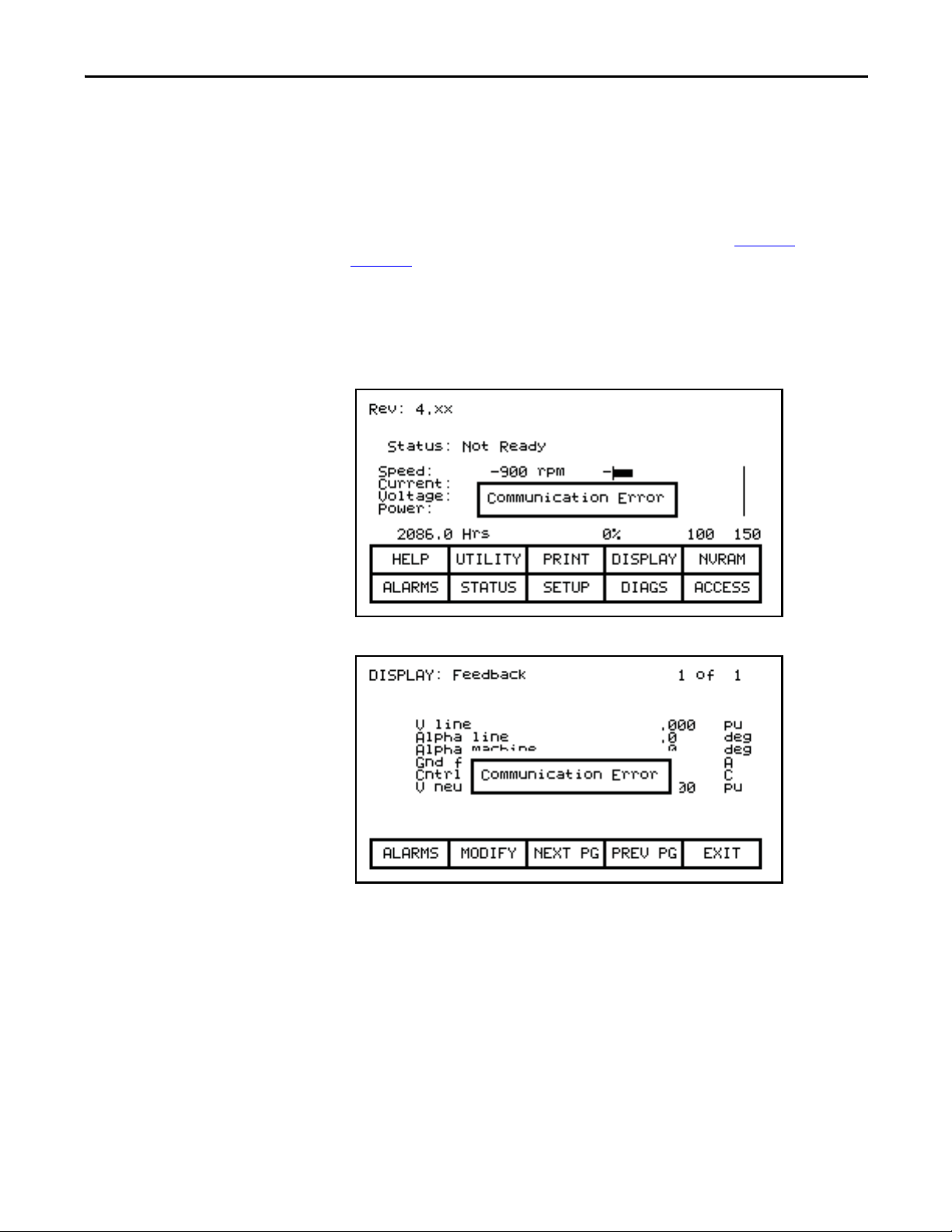

Accessing/Writing to Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Communication Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Languange Changing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

General Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Operator Interface Power-up Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Top Level Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

How To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Page 7

Table of Contents

Obtain Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Related Topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Help on Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Modify Operator Interface Operation (Utility) . . . . . . . . . . . . . . . . . . . . 102

Changing Backlight Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Changing Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Setting Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Setting Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Selecting Meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Viewing Revision Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Transfer Data in Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Picking an Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Select a Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Via Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Via Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Via Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Edit Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Configure the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Enter/Modify an Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Drive Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Modify Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Numerical Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Enumerated Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Bit Encoded Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Analog Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Fault Masks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

User Definable External Text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

XIO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Message Prompting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Store/Retrieve Configuration (NVRAM) . . . . . . . . . . . . . . . . . . . . . 135

Initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Display Parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Custom Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

View Drive Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

View and Reset Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Help for Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Request Printouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Perform Diagnostic Trending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Assigning a Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Setting the Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Defining Sample Rate and Positioning . . . . . . . . . . . . . . . . . . . . . . . . 146

Starting the Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Flash Memory Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 7

Page 8

Table of Contents

Format Flash Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

View a Directory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Select a Filename . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Enter a Filename. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Loading Programs (Firmware). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Parameter Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Upload to Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Download from Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Upload to Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Download from Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Parameter File Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Loading Language Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

System Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Advanced Screen Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Communications Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Protocol Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Print Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Memory Dump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Database Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Operator Interface Menu Hierarchy Chart . . . . . . . . . . . . . . . . . . . . . . . . 162

What Does It Show? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

How Do You Read It? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

PCMCIA Memory Card Installation Data . . . . . . . . . . . . . . . . . . . . . . . . 167

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Installing the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Commissioning

Chapter 4

Start-up Commissioning Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Drive Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Commissioning the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Pre-Commissioning Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

PowerFlex 7000 ‘C’ Frame Pre-Commissioning Checklist . . . . . . . . . . 171

Receiving and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Installation / Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Drive Line-up Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Cooling System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Commissioning Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Recommended Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 175

Technical Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

PowerFlex 7000 “C” Frame Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

PowerFlex 7000 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Additional Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Resources Required to Complete Drive Commissioning . . . . . . . . . . . . 176

8 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 9

Table of Contents

Important Note for Commissioning Engineer . . . . . . . . . . . . . . . . . . . . . 177

Key Steps to Commissioning a PowerFlex 7000 Drive. . . . . . . . . . . . . . 178

PowerFlex 7000 “C” Frame Commissioning Datasheets . . . . . . . . . . . . 179

PowerFlex 7000 “C” Frame Drive Commissioning Checklist . . . . . . . 180

Drive Application Review. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Rockwell Automation Drive Line-up Drawings . . . . . . . . . . . . . . . . 183

Electrical System One-line Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Verify One-line Diagram on Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Inspect Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Safety Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Lockout Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Step Down Transformer Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Fuse and O/L Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Installation Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Inspect for Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Inspect Cabinets for Debris . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Protective Barriers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Component Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Information on Splice Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Power Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Liquid-Cooling Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Service Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Why this Information is Needed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Customer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Control Power Off Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Interlocking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Resistance Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

SGCT Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

SGCT Anode-to-Cathode Resistance . . . . . . . . . . . . . . . . . . . . . . . . . 198

Snubber Resistance (SGCT Device). . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Snubber Capacitance (SGCT Device). . . . . . . . . . . . . . . . . . . . . . . . . 200

SCR Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

SCR Anode-to-Cathode Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

SCR Sharing Resistance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

SCR Gate-to-cathode Resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Snubber Resistance (SCR Device) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Snubber Capacitance (SCR Device). . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Control Power Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Three-Phase Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Three-Phase Input / Single Phase Input . . . . . . . . . . . . . . . . . . . . . . . 207

Power Supply Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Circuit Board Healthy Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Control Power Transformer (CPT). . . . . . . . . . . . . . . . . . . . . . . . . . . 208

AC/DC Converter (PS1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

DC/DC Converter (PS2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

SGCT Power Supplies (IGDPS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 9

Page 10

Table of Contents

IGDPS Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Commissioning the Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Heat Exchanger Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Pumping Cabinet Control Power Checks. . . . . . . . . . . . . . . . . . . . . . 216

System Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

System Fill and Air Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Gating Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Gating Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

SCR Firing Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

SGCT Firing Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

System Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Start/Stop Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Analog I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Configurable Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

18 Pulse Phasing Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Line Terminal Resistance Measurements . . . . . . . . . . . . . . . . . . . . . . 232

Application of Medium Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Input Phasing Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

DC Current Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

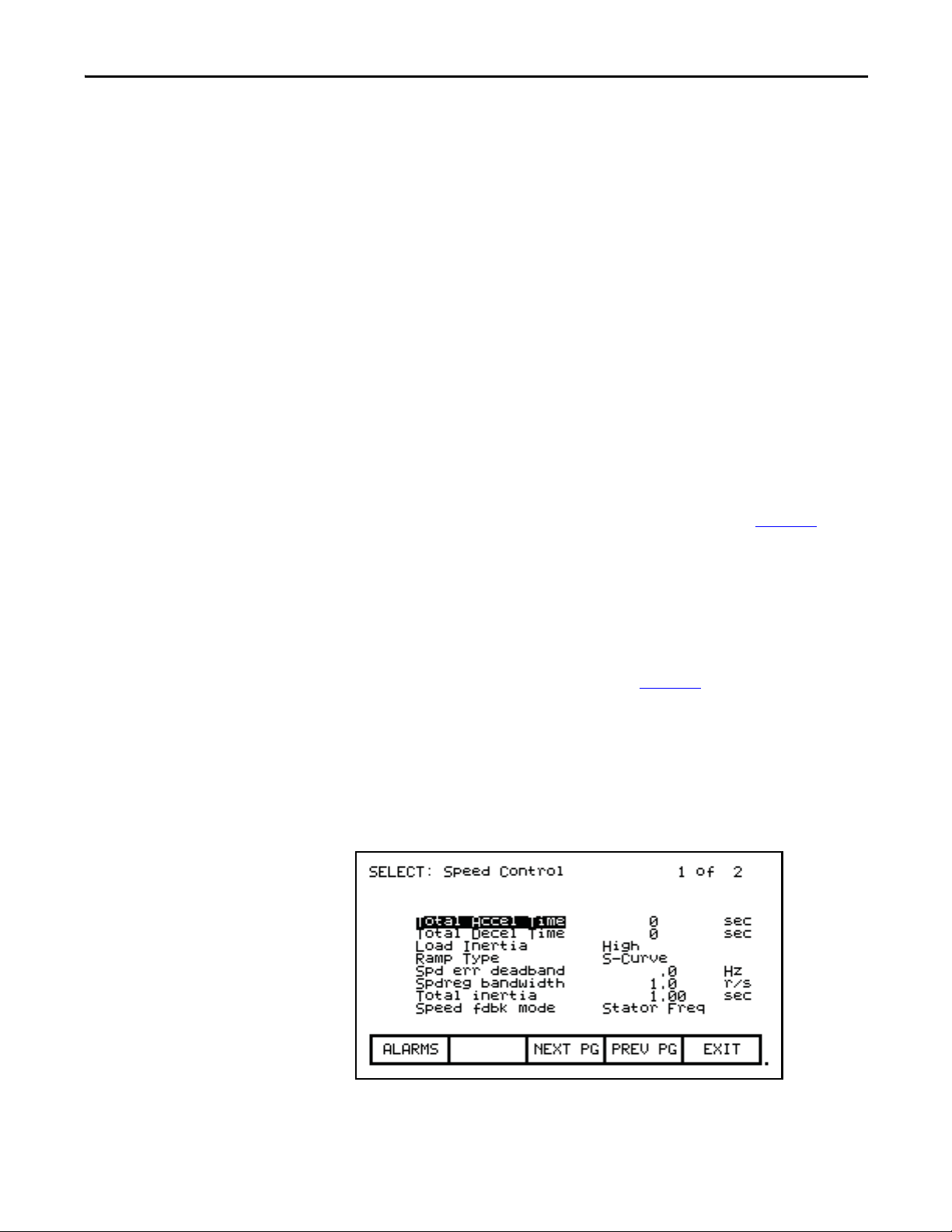

Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

1. Rectifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

2. Motor Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

3. FluxSpeed Regulator [INDUCTION MOTORS] . . . . . . . . . . . 244

4. FluxSpeed Regulator [SYNCHRONOUS MOTORS] . . . . . . . 249

Running the Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Motor Starting Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Reaching Specific Load Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Capturing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Drive Input Voltage Phasing Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Summary: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Harmonic Analysis

(required for AFE drives only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Summary: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

DC Current Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Summary:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Load Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Synchronous Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

10 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 11

Chapter 5

Table of Contents

Component Definition and

Maintenance

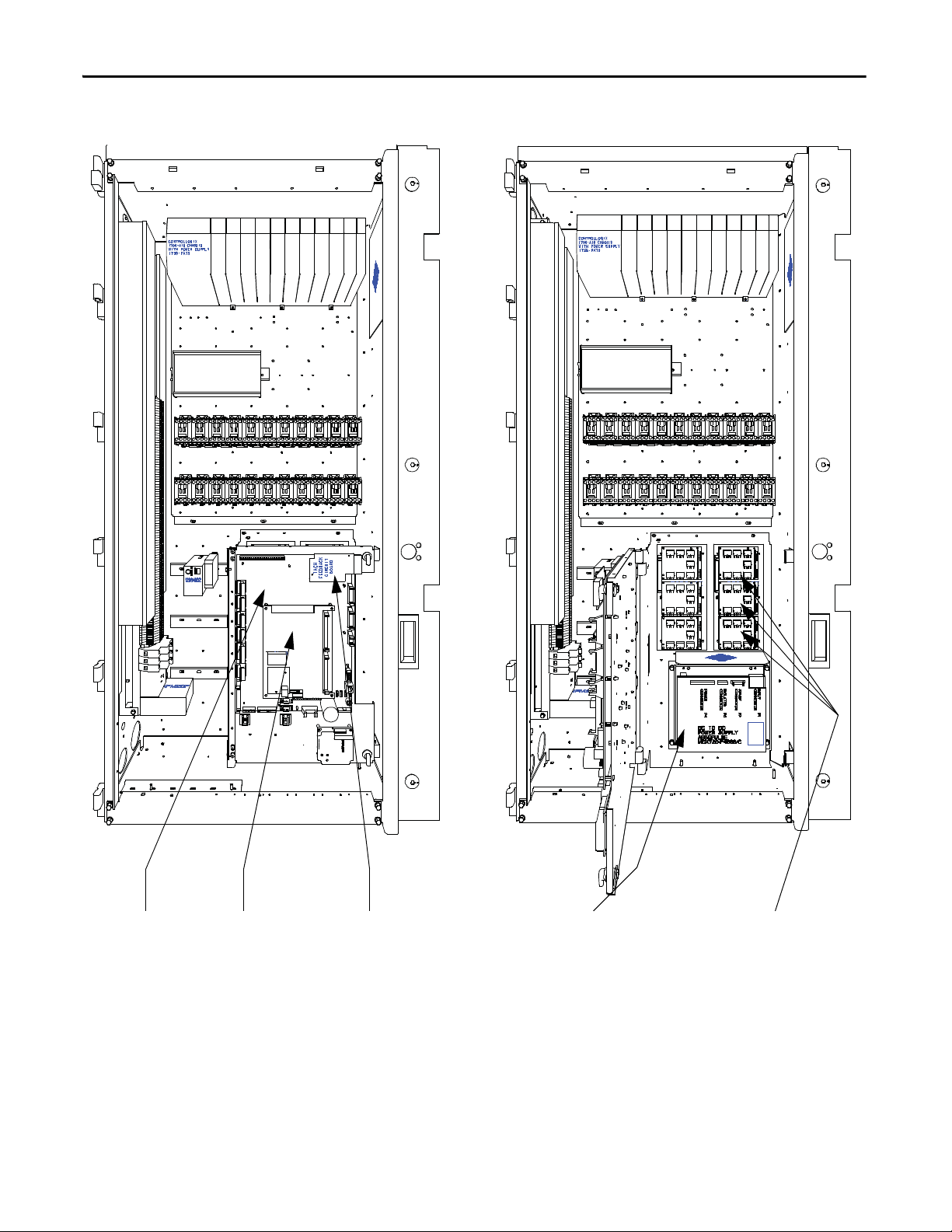

Control / Cabling Cabinet Components. . . . . . . . . . . . . . . . . . . . . . . . . . 266

Voltage-Sensing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Voltage-Sensing Circuit Board Assembly Replacement . . . . . . . . . . . . . 269

Input Transient Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Transient Suppression Network (TSN) . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

MOV Suppressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

MOV Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Transient Suppression Network Fuse Replacement . . . . . . . . . . . . . . . . 273

Metal-Oxide Varistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Surge Arresters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Surge Arrester Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Field Test and Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Output Grounding Network Capacitor Replacement . . . . . . . . . . . . . . 278

Ground Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Hall Effect Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Current Transformer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

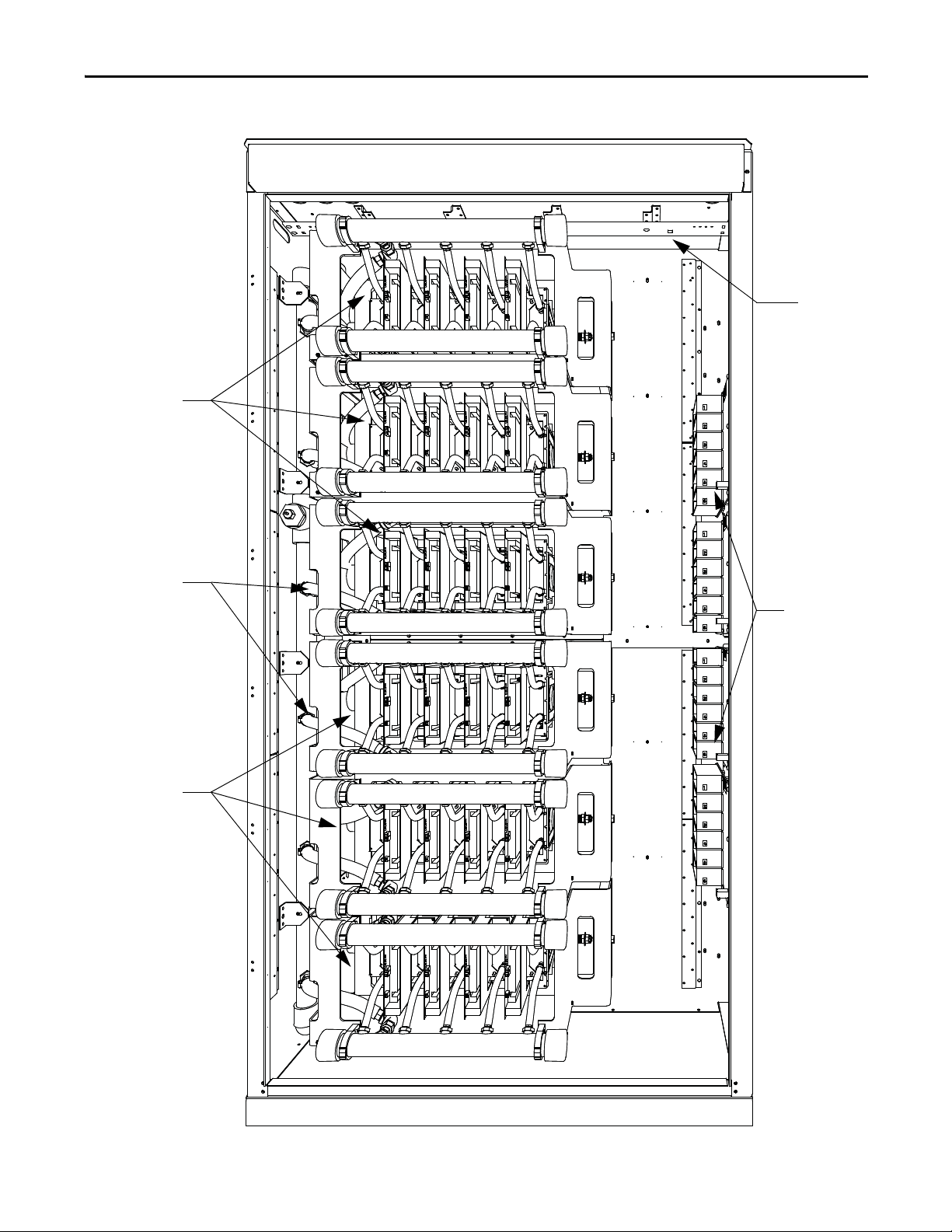

Filter Capacitor Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Filter Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Filter Capacitor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Testing Filter Capacitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

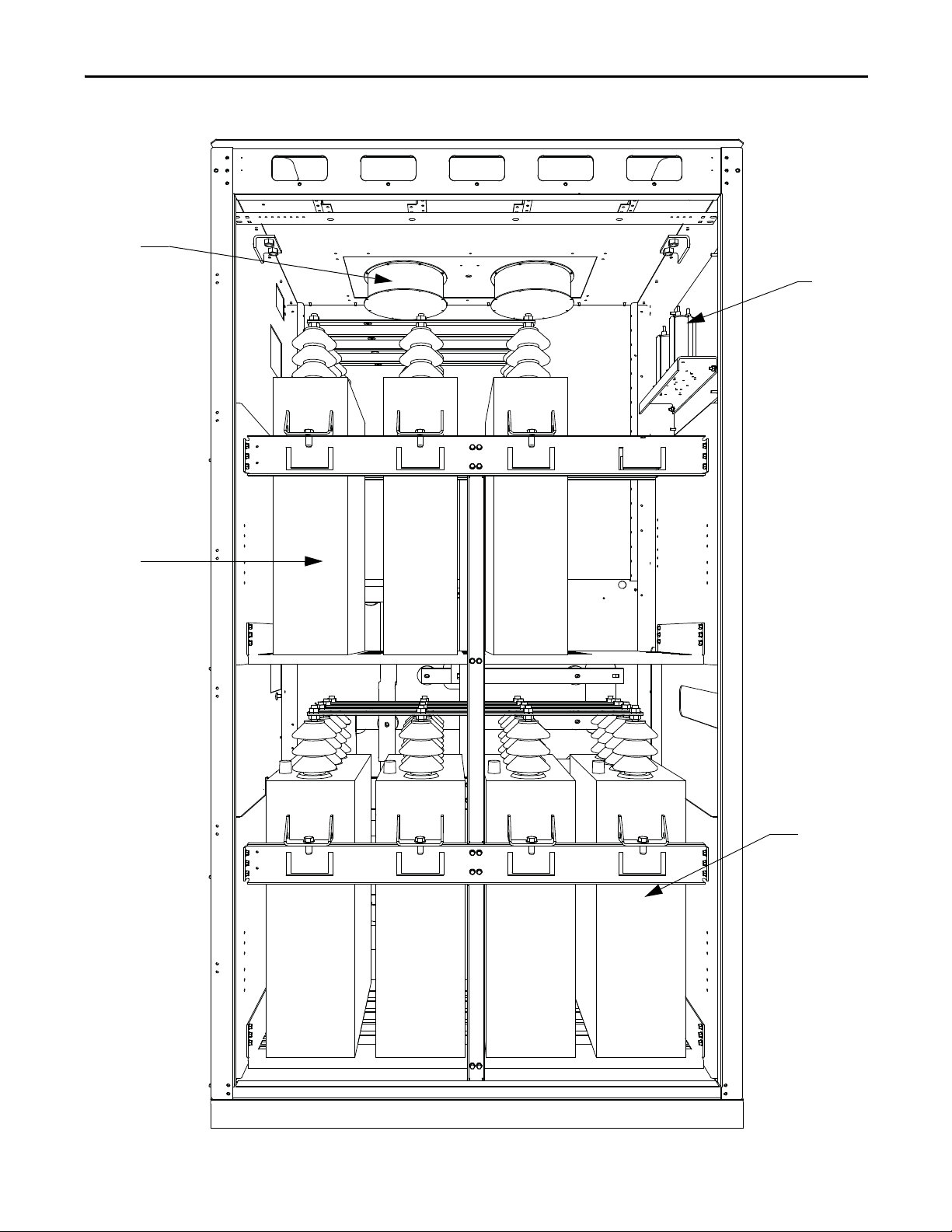

Converter Cabinet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Converter Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

PowerCage™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

SGCT and Snubber Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Checking Clamping Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Clamping Pressure Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Symmetrical Gate Commutated Thyristor Replacement. . . . . . . . . . . . 293

Silicon Controlled Rectifier and SCR Self-Powered Gate Driver Board

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Detachment of Coolant System from PowerCage Modules . . . . . . . . . 299

Reconnecting the Coolant System to a PowerCage Module . . . . . 303

Chill Block Removal and Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Instructions for removing Chill Block assembly . . . . . . . . . . . . . . . . 303

Instructions for inserting Chill Block assembly. . . . . . . . . . . . . . . . . 304

PowerCage Removal and Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Snubber Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Testing Snubber Resistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Sharing Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Testing Sharing Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Snubber and Sharing Resistor Replacement. . . . . . . . . . . . . . . . . . . . . . . . 309

Self-Powered Gate Driver Board – SPGDB. . . . . . . . . . . . . . . . . . . . . . . . 311

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 11

Page 12

Table of Contents

Board Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Test points description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Terminal/connections description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Testing procedure for SCR self-powered gate driver board . . . . . . . . . . 313

Equipment needed: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Procedure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Fiber Optic Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

DC Link Reactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Control Power Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Ride-Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

AC/DC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Terminal / Connections Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 324

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

UPS Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

UPS Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

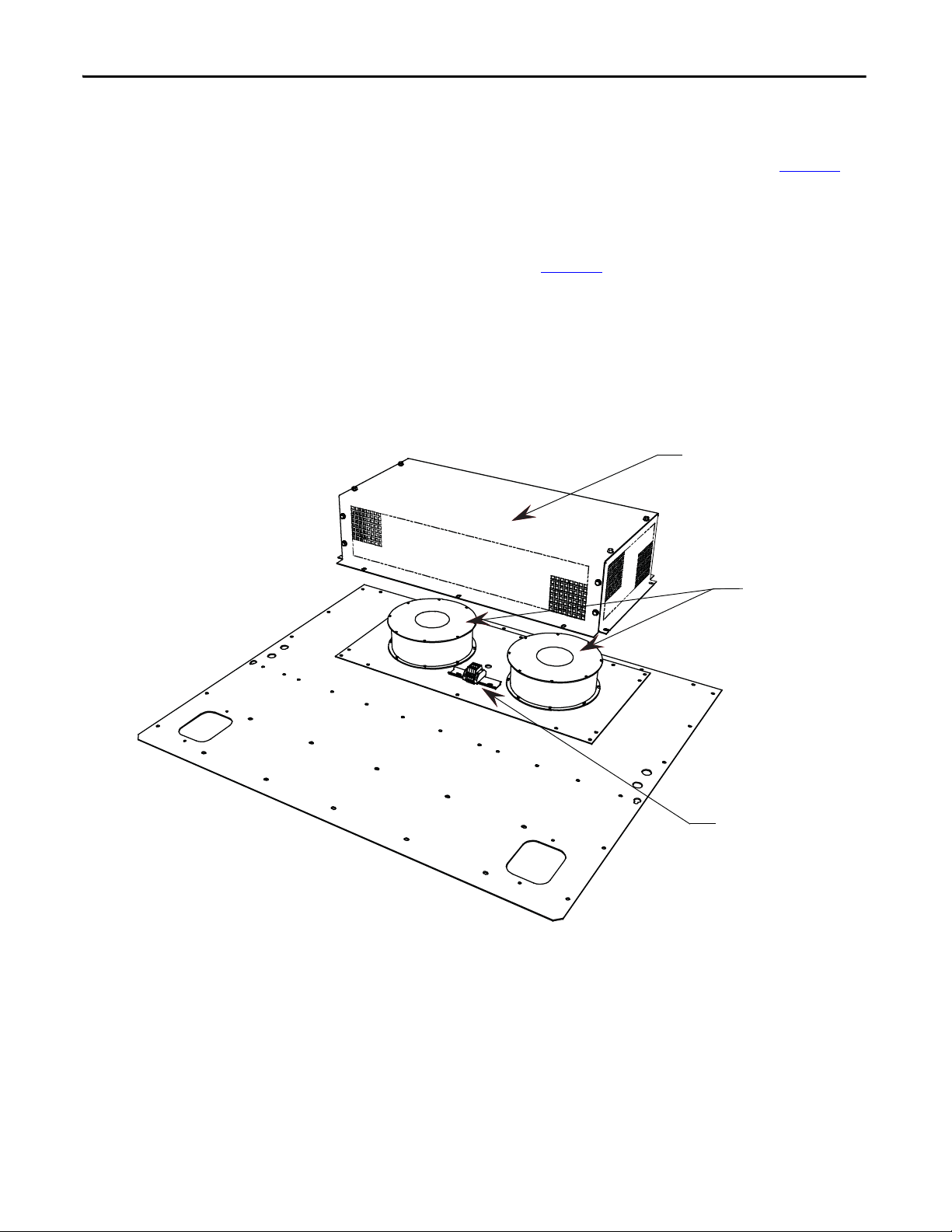

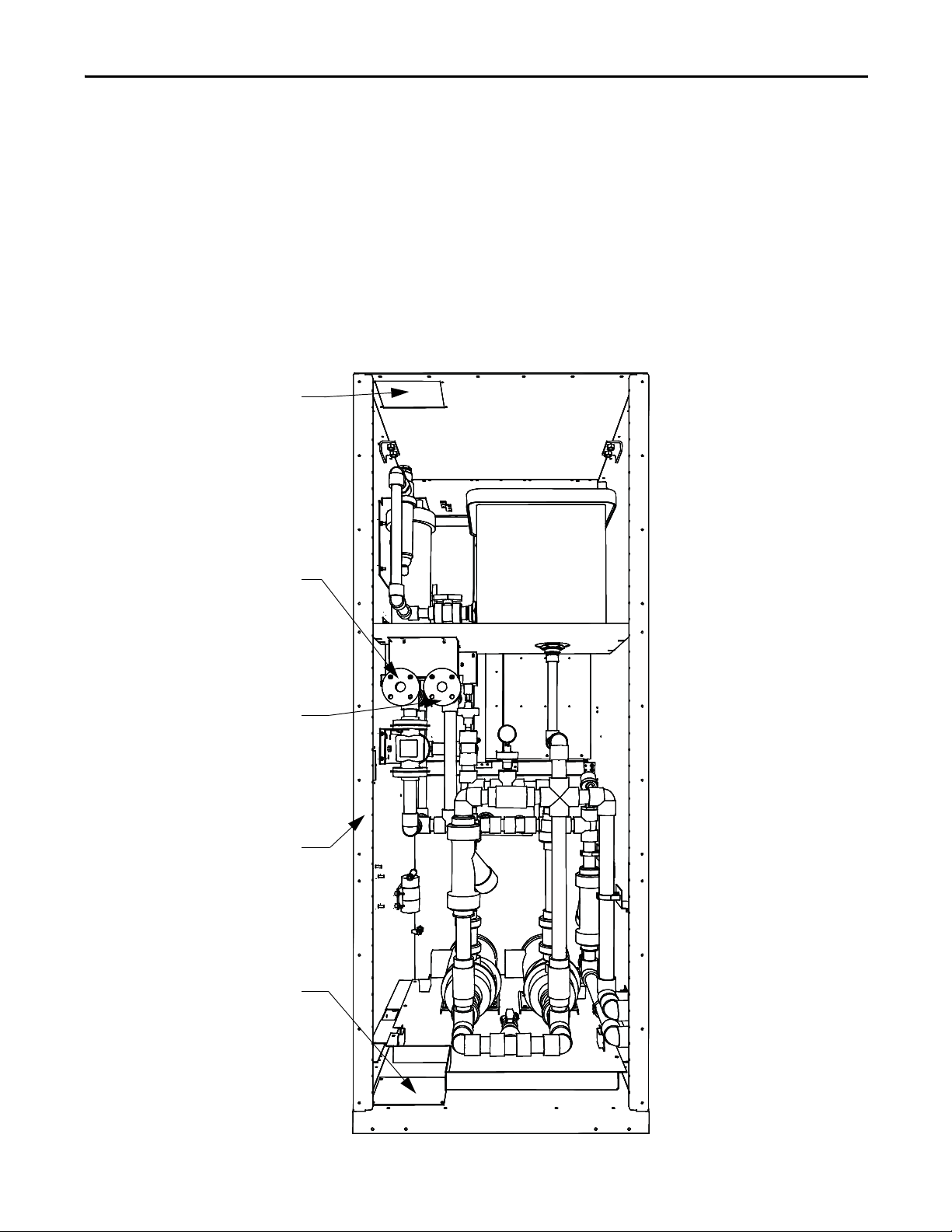

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Cooling Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Chill Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Coolant Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Pump Maintenance and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Pump Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Pump Replacement with Drive Running. . . . . . . . . . . . . . . . . . . . . . . 331

Piping, Tubing and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Non-Return Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Pressure Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Pressure Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Thermostatic Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Thermostatic Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

Repair Instructions - Element Testing . . . . . . . . . . . . . . . . . . . . . . . . . 335

Element Replacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Fluid Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

De-Ionizing Cartridge and Mesh Filter . . . . . . . . . . . . . . . . . . . . . . . . 338

Replacing the Mesh Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Reservoir Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Fluid Top-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Maintaining Coolant Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Leakage Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

System Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Low Voltage Control Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

DC/DC Power SupplyDescription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

12 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 13

Table of Contents

Terminal/Connections Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . 346

Replacement Procedure for DC/DC Power Supply . . . . . . . . . . . . 347

Printed Circuit Board Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

IO Connectors on Control Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Drive Processor Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Drive Processor Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . 351

Instructions to Replace the Drive Processor Module. . . . . . . . . . . . 351

ACB Analog Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Interface Module (IFM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Analog Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Current Loop Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Isolated Process Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Non-Isolated Process Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Auxiliary +24V Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

ACB Analog Control Board Replacement . . . . . . . . . . . . . . . . . . . . . 360

Tachometer Feedback Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Encoder Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Quadrature Encoder Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

Positional Encoder Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Positional Encoder Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

External Input/Output Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

External Input/Output Board Replacement . . . . . . . . . . . . . . . . . . . 368

Optical Interface Boards (OIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Optical Interface Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 370

Optical Interface Base Board (OIBB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Optical Interface Base Board Test Points . . . . . . . . . . . . . . . . . . . . . . 373

Downloading Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

PowerFlex 7000 in Download Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Reloading the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Setting Elapsed Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

Downloading the Terminal Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Using Flash Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

DOSFWDL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

Setting up Diagnostic Trending

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

Diagnostic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Setting up the Trend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Printing (Uploading) Data from the Drive . . . . . . . . . . . . . . . . . . . . . . . . 390

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 390

Creating an empty notepad (.txt) file. . . . . . . . . . . . . . . . . . . . . . . . . . 391

Setting up HyperTerminal Connection . . . . . . . . . . . . . . . . . . . . . . . 393

Uploading the Data from the drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Printing (Uploading) Control Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

Set up HyperTerminal connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 13

Page 14

Table of Contents

Catalog Number Explanation

Printing Control Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Hazardous Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Preventive Maintenance Check List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Operational Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Initial Information Gathering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Physical Checks (NO Medium Voltage and NO Control Power) 406

Control Power Checks (No Medium Voltage) . . . . . . . . . . . . . . . . . 407

Final Power Checks before Restarting . . . . . . . . . . . . . . . . . . . . . . . . . 407

Additional Tasks During Preventive Maintenance. . . . . . . . . . . . . . 408

Final Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Time Estimations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

Tool / Parts / Information Requirements. . . . . . . . . . . . . . . . . . . . . . 409

Appendix A

PowerFlex 7000 Drive Selection Explanation . . . . . . . . . . . . . . . . . . . . . . 413

Service Duty Rating, Continuous Current Rating & Altitude Rating

Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

When is an Encoder Required? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

PowerFlex 7000 Drive Performance (Torque Capabilities). . . . . . . . . . 415

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

Torque Requirements for Threaded

Fasteners

Meggering

Preventative Maintenance Schedule

Appendix B

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

Appendix C

Drive Meggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Meggering the PowerFlex 7000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 421

Equipment Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

Appendix D

PowerFlex 7000 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

I – Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

M – Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

R – Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

C – Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Rv – Review. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

RFB/R – Refurbishment/Replacement . . . . . . . . . . . . . . . . . . . . . . . . 428

14 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 15

Overview of Drive

Chapter 1

Introduction

The PowerFlex® 7000 represents the third generation of medium voltage drives at

Rockwell Automation. The PowerFlex 7000 medium voltage AC drive is part of

the PowerFlex family of AC drive products. The Allen-Bradley PowerFlex® family

of Drives incorporates leading-edge technology, embedded communications, and

significant commonality across multiple platforms, networks, operator interface

programming and hardware. Designed for end users, solution providers and

OEMs, PowerFlex 7000 liquid-cooled drives meet applications ranging from

3000...9000 horsepower (2240...6715 kW).

The PowerFlex 7000L is a general purpose stand alone medium voltage drive that

controls speed, torque, direction, starting, and stopping of standard

asynchronous or synchronous AC motors. It is intended for use on a host of

standard and specialty applications such as fans, pumps, compressors, mixers,

conveyors, kilns, fan-pumps, and test stands. Primary industries for these

applications include petrochemical, cement, mining and metals, forest products,

power generation, and water / waste water.

The PowerFlex 7000L is a global product that adheres to the most common

standards from NEC, IEC, NEMA, UL, and CSA. It is available with the world’s

most common supply voltages at medium voltage, from 2400...6600 volts.

The design focus is on high reliability, ease of use, and lower total cost of

ownership.

(1)

Liquid Cooling

The PowerFlex 7000L “C” Frame liquid-cooled drive utilizes a closed loop

system to cool the converter main power components and the integral DC link

inductor.

Benefits of Liquid Cooling Include:

• Smaller drive dimension compared to air-cooled drives of similar rating

• Higher power rating capability

• Quiet operation in control room

• Low loss rejection to the control room reduces air conditioner loading

• Majority of losses rejected outside the control room via a liquid-to-air or

liquid-to-liquid type heat exchanger

(1) For 2400V and 3300V designs, contact factory.

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 15

Page 16

Chapter 1 Overview of Drive

Benefits of the 7000L “C” Frame Liquid-cooled Drive:

• Completely integrated MV drive package reduces customer installation

costs and start-up time.

• Higher power rating capability (up to 9000 hp / 6715 kW)

• 18 Pulse and AFE rectifiers for low harmonic solutions that meet IEEE

519-1992 Harmonic Guidelines

• Motor friendly current and voltage output waveforms for use with

standard new and existing motors

– Inverter duty motors not required

– Motor temperature derating not required

– No additional dv/dt or peak voltage stress to motor insulation system

– Tested up to 15 kilometers (9.3 miles) cable distance between drive and

motor

• Spacious cable termination cabinet for ease of use by installation

contractor

• Cable termination stabs accommodate:

– 3 cables in / 3 cables out (Direct-to-Drive or AFE rectifier)

– 9 cables in / 3 cables out (18 Pulse)

– Top or bottom entry and exit of line and load cables

• 90% of drive losses are rejected outside the control room

• Integral liquid-cooled DC link inductor reduces overall dimension and

eliminates external interwiring.

• Integral pumping panel includes:

– Line supply c/w disconnect and fusing

– Closed loop coolant system

– Iron and chloride free liquid ethyl-glycol / deionized water mixture

3

– Low conductivity coolant (1-2 micro-Siemens / cm

– Isolated from medium voltage

– Fully serviceable low voltage compartment isolated from medium

voltage power

– Monitors coolant temperature, flow, level, conductivity, and pressure

– Redundant pumping system (optional)

– Automatic pump change over on pump failure

– 1/2 turn valves with quick disconnect couplers for pump replacement

when drive is operating

– Full drip tray to contain any spilled coolant

– Drain and fill pump for convenient filling

– Industrial schedule 80 CPVC piping for pump panel, headers and

manifolds (no condensation possibility)

– Control hardware for cycling of main / redundant cooling pumps and

heat exchanger fans

• “Plug and play” Power Cage concept

– Central location for easy access to all main power components

)

16 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 17

Overview of Drive Chapter 1

2U (X1)

2V (X2)

2W (X3)

SGCT’s

LINE CONVERTER

DC LINK

L+

M+

SGCT’s

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

L-

M-

1U

1V

1W

LR

– Common modular design for rectifier / inverter

– Same concept as air-cooled drive for front access, easy component

replacement, and no special tools

– 5...10 minutes to replace main power devices

– No need to remove any cooling lines for device replacement

– Reduced manufacturing time for faster delivery and lower cost

•Keyed mechanical interlock

– Interlocked with main disconnect means to prevent unsafe access to

medium voltage section

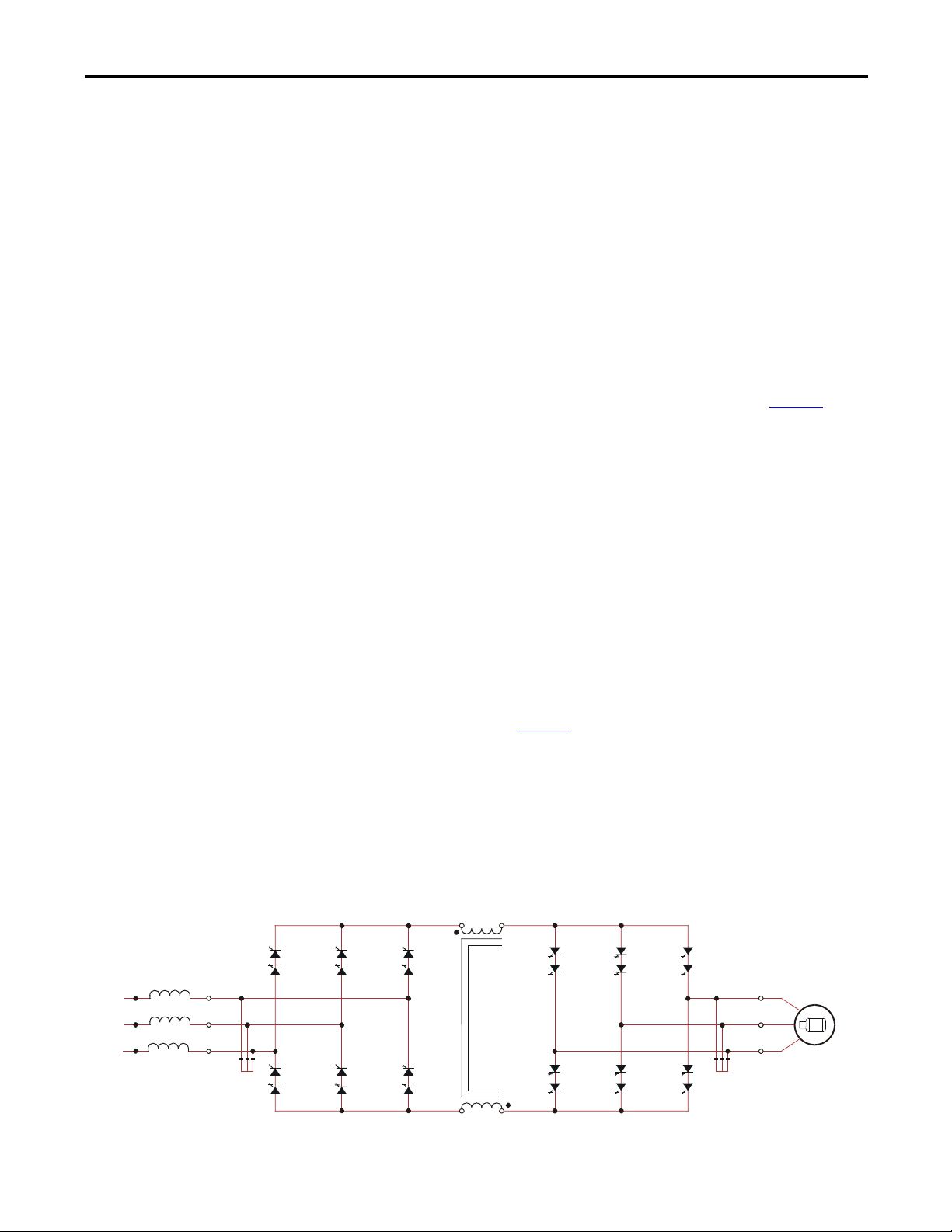

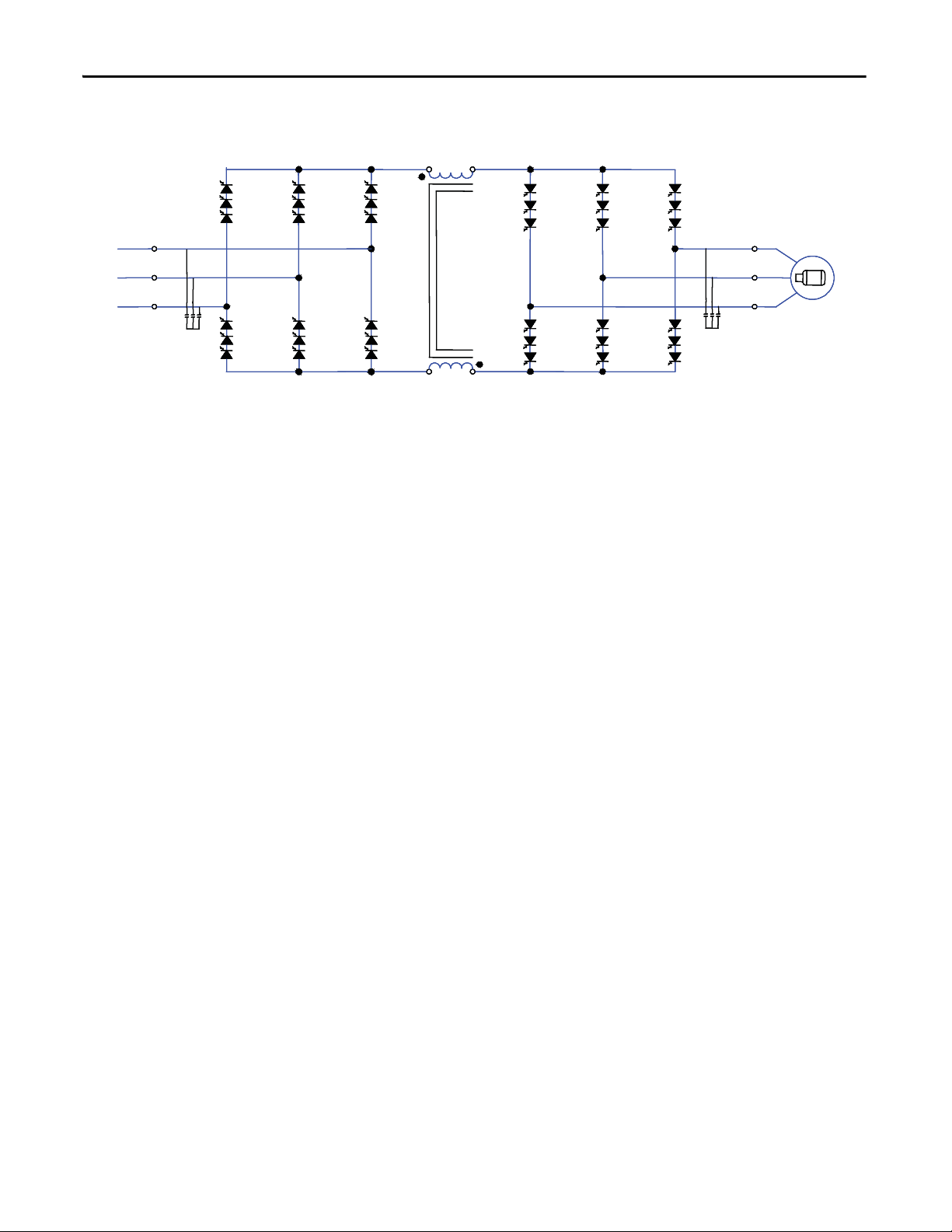

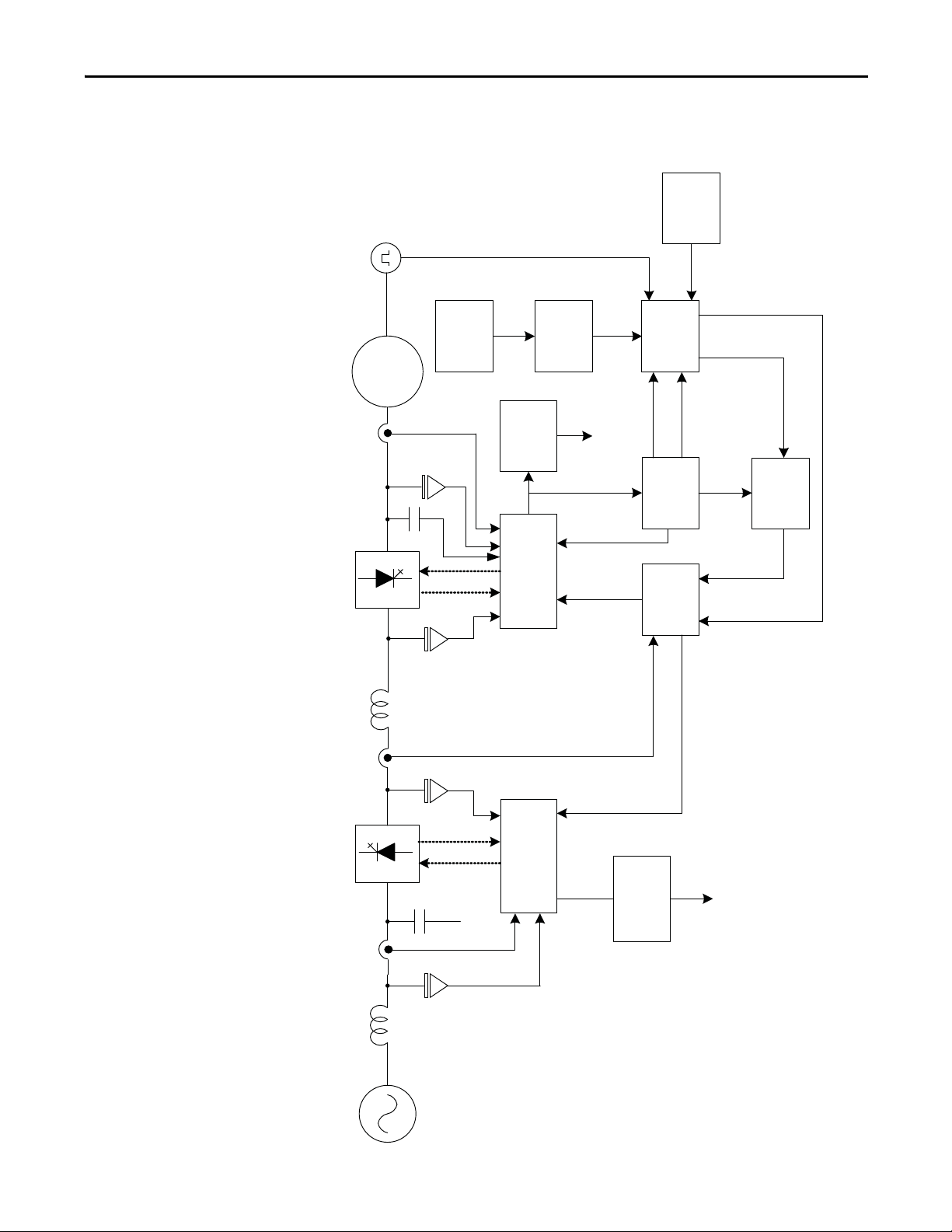

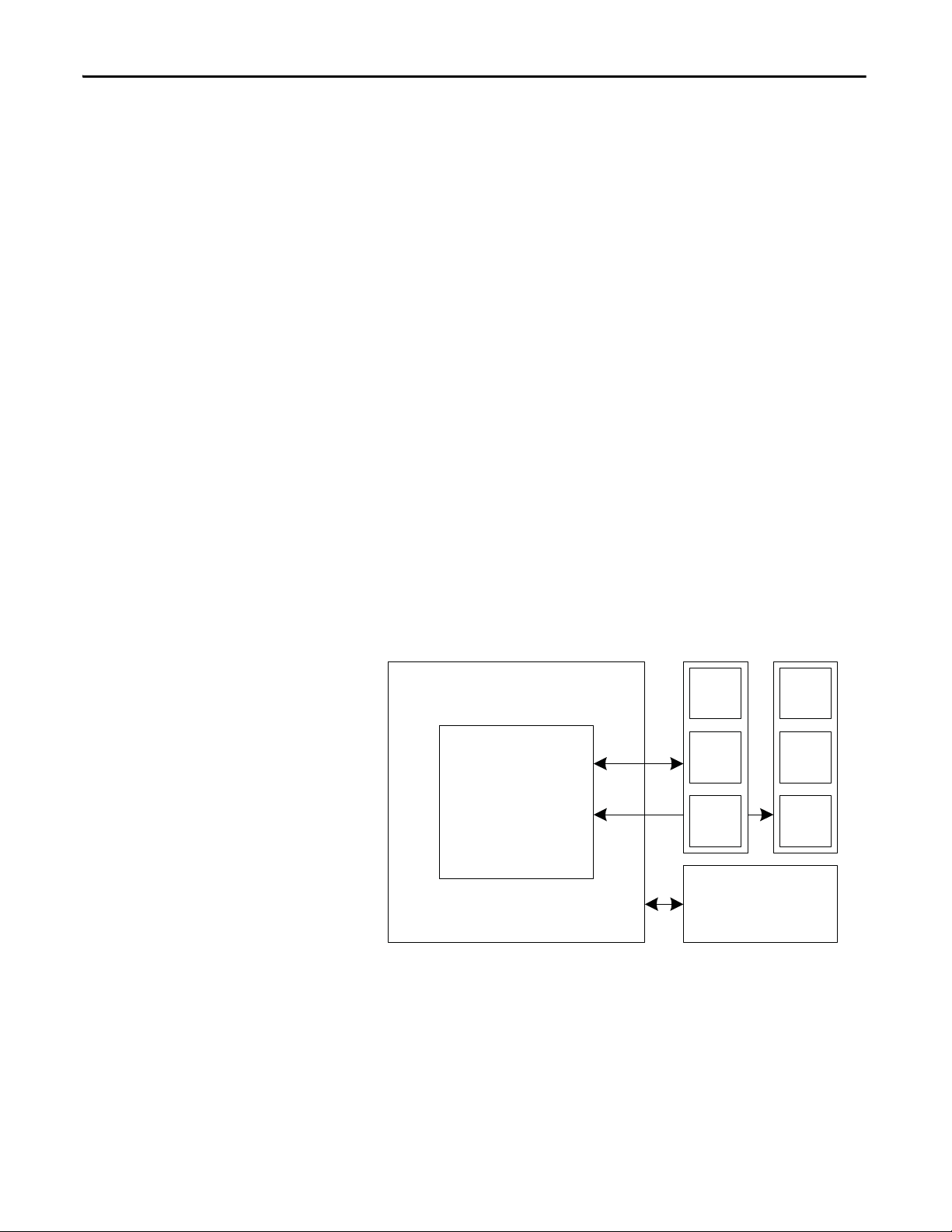

Topology

The PowerFlex 7000L utilizes a Pulse Width Modulated (PWM) – Current

Source Inverter (CSI) for the machine side converter as shown in Figure 1

. This

topology offers a simple, reliable, cost effective power structure that is easy to

apply to a wide voltage and power range. The power semiconductor switches

used are easy-to-series for any medium voltage level. Semiconductor fuses are not

required for the power structure due to the current limiting DC link inductor.

With 6500VPIV rated power semiconductor devices, the number of inverter

components is kept to a minimum. For example, only six inverter switching

devices are required at 2400V, 12 at 3300-4160V, and 18 at 6600V.

The PowerFlex 7000L has the additional benefit of inherent regenerative braking

for applications where the load is overhauling the motor (i.e. downhill conveyors,

etc.), or where high inertia loads (i.e. fans, etc.) need to be slowed down quickly.

Symmetrical Gate Commutated Thyristors (SGCTs) are used for machine

converter switches. Silicon-controlled rectifiers (SCRs) (for 18 Pulse) or SGCTs

(for AFE rectifiers) are used for the line converter switches. An AFE

configuration is shown in Figure 1

.

The PowerFlex 7000L provides a selectable option for enhanced torque control

capabilities and increased dynamic control performance. This High Performance

Torque Control (HPTC) feature delivers 100% torque at zero speed and

provides torque control through zero speed with smooth direction transition.

Figure 1 - AFE Rectifier (4160 Volt)

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 17

Page 18

Chapter 1 Overview of Drive

Line

current

Line-to-line

voltage at PCC

Rectifier Designs

There are two offered designs for the rectifier of the PowerFlex 7000L drive.

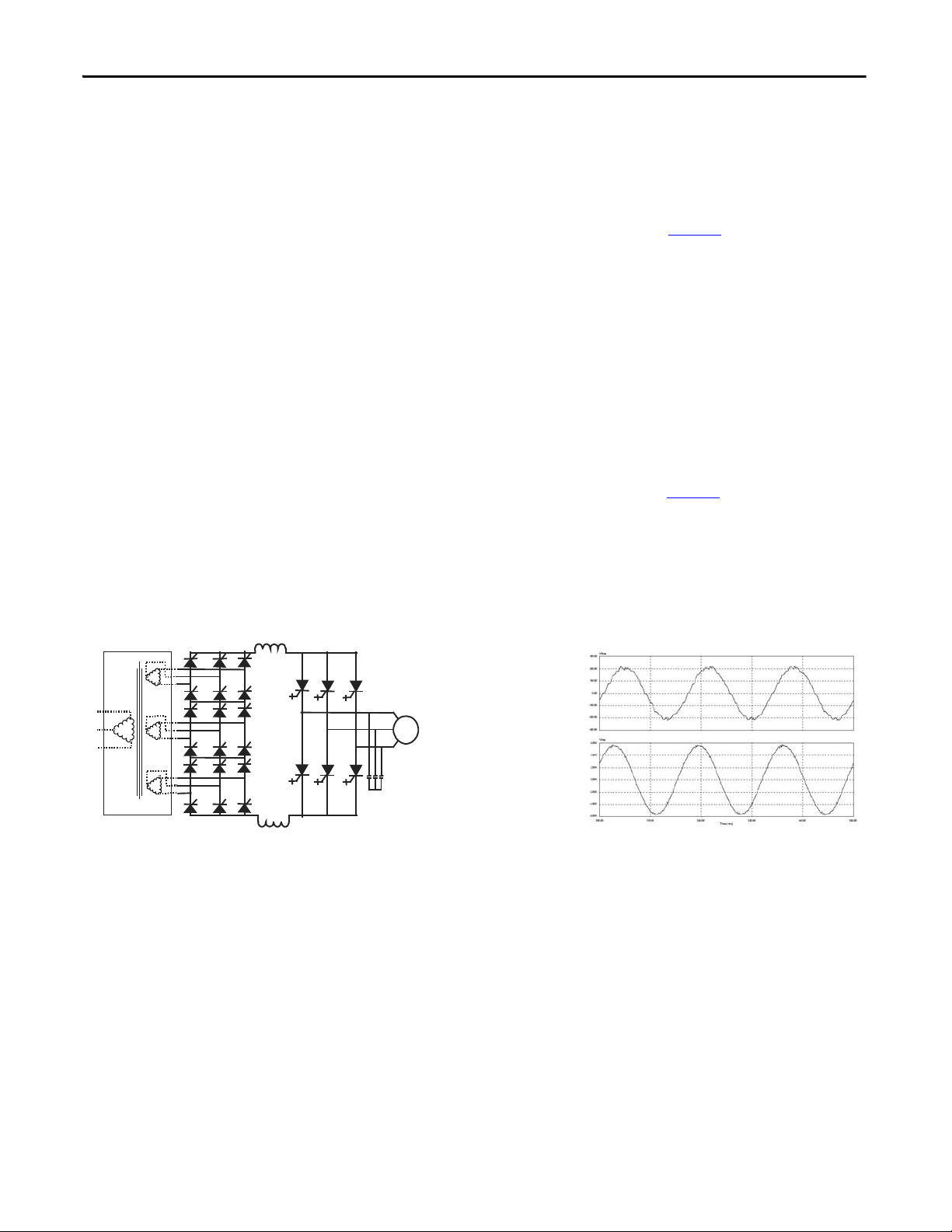

18 Pulse Rectifier

An 18 Pulse phase controlled rectifier is shown in Figure 2. In an 18 Pulse

configuration, the IEEE 519-1992 requirements are met in the majority of cases

without the need for passive filters; however, a multi-winding isolation

transformer is required to mitigate the low order harmonics by phase shifting

principles. The 18 Pulse solution is superior to 6- or 12-pulse offerings in terms of

lowering line side harmonics.

Isolation transformers are available in indoor dry type, cast coil, and outdoor oilfilled designs for maximum flexibility in dealing with floor space, installation

costs, and control room air conditioner loading. (Refer to Specification 80001005, Rectifier Duty Transformers, for more details on transformer requirements

and features.)

Sample line current and voltage are also shown in Figure 2

current is approximately 5.6%, while the THD of line voltage (line-to-line) is

approximately 2.0%. (THD of line voltage is a function of system impedance.)

The 18 Pulse rectifier consists of one master bridge and two slave bridges and will

always have a total of 18 SCR switching devices.

. The THD of line

Figure 2 - 18 Pulse Rectifier and its input waveforms

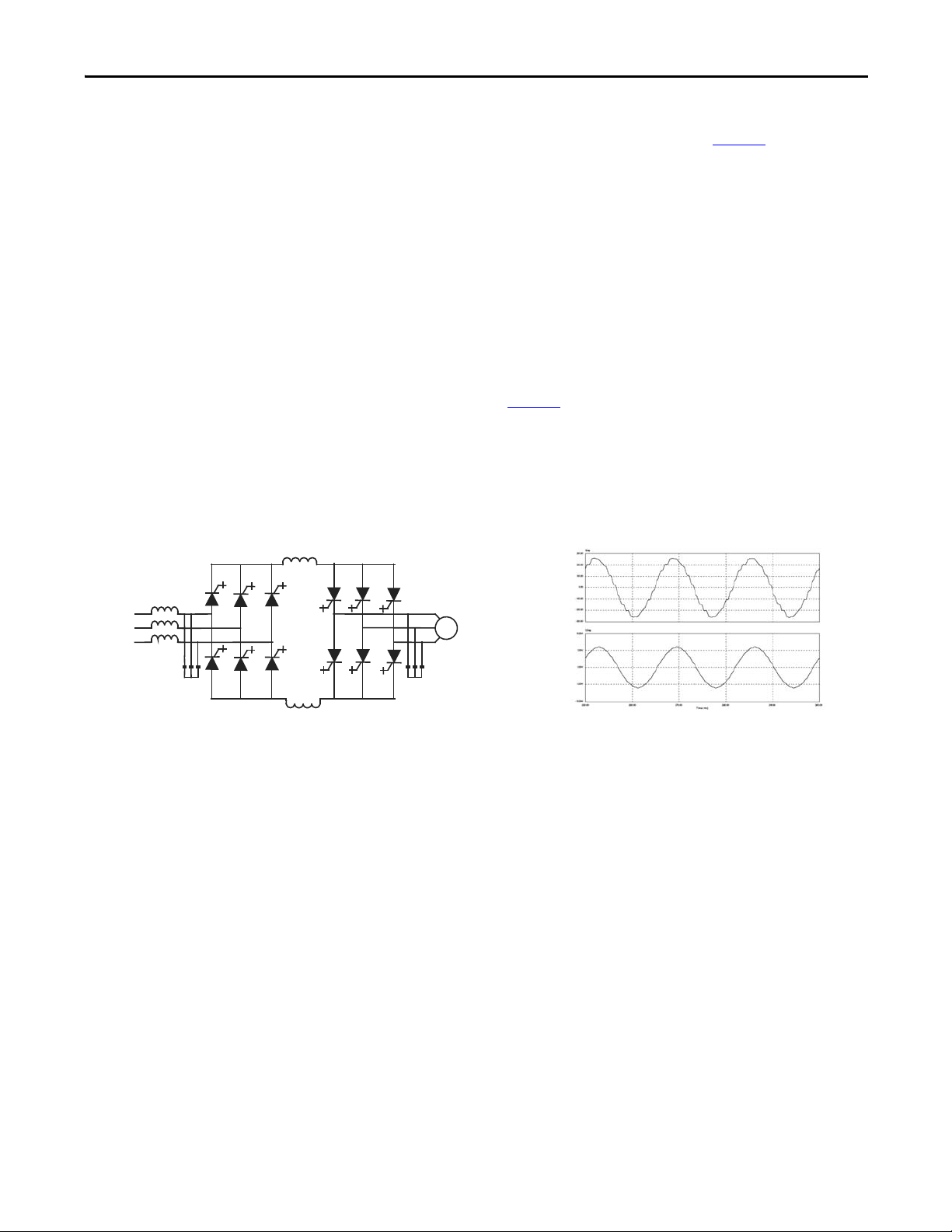

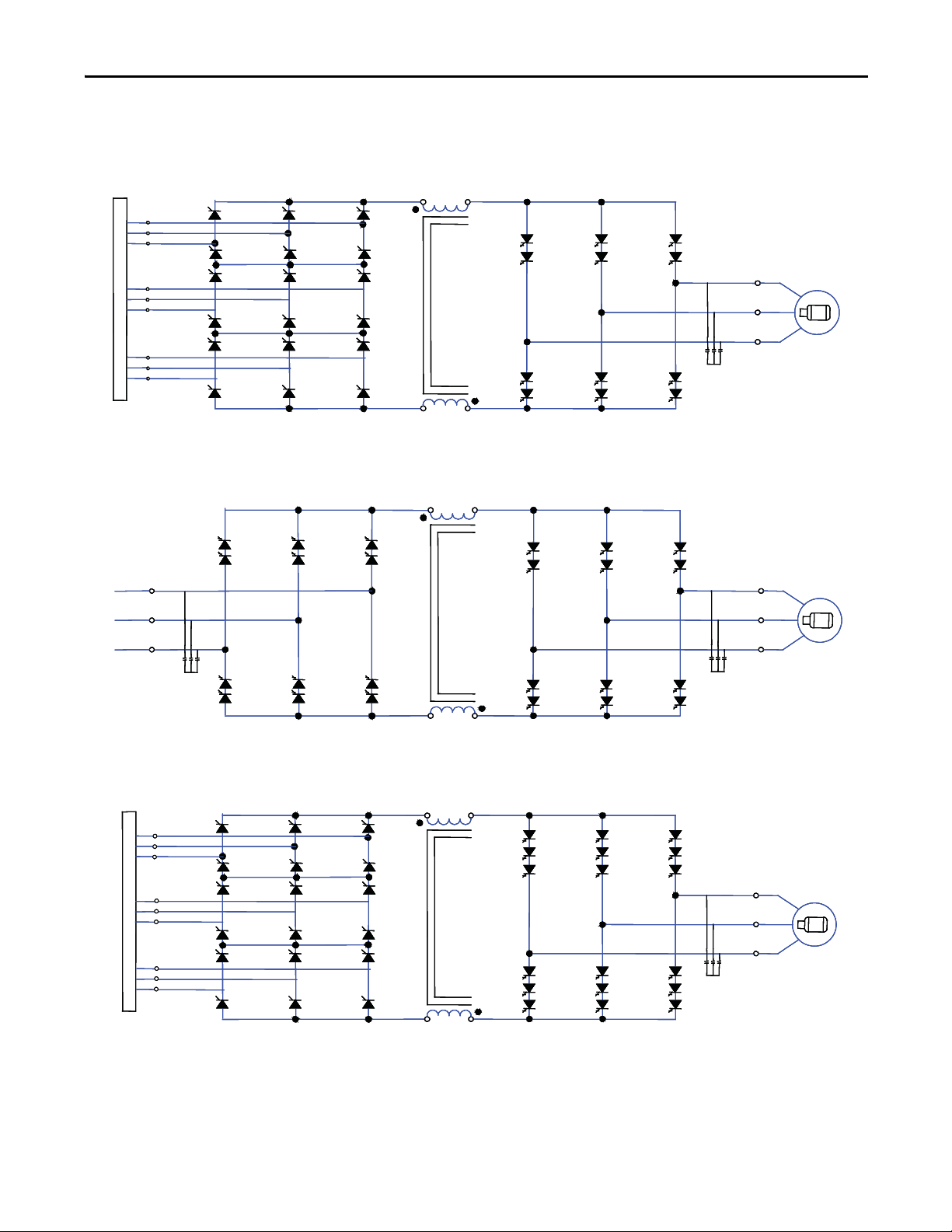

Active Front End (AFE Rectifier)

An active front end (AFE rectifier) suitable for the PowerFlex 7000L topology is

also commonly called a PWM rectifier. This is particularly attractive since it does

not require an isolation transformer to meet IEEE 519-1992. Most available

technologies in today’s MV market require a multi-winding transformer to

mitigate the unwanted harmonics by phase shifting the transformer secondary

windings. Depending on the topology, the transformer can have up to 15 sets of

secondary windings. Elimination of the isolation transformer reduces capital and

installation costs, saves on valuable floor space, and increases overall system

efficiency.

18 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 19

Overview of Drive Chapter 1

Line

current

Line-to-line

voltage at PCC

The AFE rectifier requires a switching pattern that complies with similar rules as

the inverter. The pattern, used for the example shown in Figure 3

, is a 42-pulse

selective harmonic elimination (SHE) pattern, which eliminates the 5th, 7th and

11th harmonics. The integral input capacitors are designed to reduce the current

harmonics of the higher order. The filter transfer function technique is used to

place the filter break frequency in a region where no harmonics are present. This

prevents the excitation of system harmonic frequencies. Other factors that are

considered when designing the filter are the input power factor and the

requirement on Total Harmonic Distortion (THD) of input current and voltage

waveforms.

The AFE rectifier is ideal when a distribution transformer is required to step

down the distribution voltage to match the VFD and motor voltage. The rectifier

input current, the rectifier terminal voltage and the line current and voltage

waveforms are shown in Figure 3

. The line current THD is approximately 4.5%,

while line-to-line voltage THD is approximately 1.5%. (THD of line voltage is a

function of system impedance.) Input power factor with the AFE rectifier is

equal to or greater than 0.98 for the typical speed and load range when applied to

variable torque loads.

Figure 3 - Active rectifier (PWM) and its input current/voltage waveforms

“Direct-to-Drive” Technology

The PowerFlex 7000L with “Direct-to-Drive” technology allows you to:

• connect supply power directly to the drive without an Isolation

Tr a n s f o r m e r

• connect a new or existing motor directly to the drive without extra motor

filtering.

Most Medium Voltage Drive Manufacturers use multi-winding isolation

transformers to mitigate unwanted harmonics by phase shifting the transformer

secondary windings. Depending on the topology, the transformer can have up to

15 sets of secondary windings. The disadvantages to this method are the high

degree of drive and transformer complexity, a very high component count and

many interconnecting cables and connection points. This leads to much higher

maintenance requirements and lower reliability.

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 19

Page 20

Chapter 1 Overview of Drive

Manufacturers also use isolation transformers to protect motors from Common

Mode Voltage stress. When transformers are used they allow the motor neutral

point to be connected to ground, but with this method, the common mode

voltage that would otherwise be impressed on the motor is impressed on the

transformer. The disadvantage to this method is that increased transformer

insulation and increased cable insulation is required between the transformer and

the drive so it can withstand the common mode voltage stress.

Rather than use an Isolation Transformer, the “Direct-to-Drive” Active Front

End uses the semiconductor switching pattern to reduce line current harmonics

to levels that comply to the world’s most accepted harmonic standards. The

Active Front End is the best method of harmonic cancellation because it does not

suffer from complexity and high component count like multi-pulse drive

topologies do.

“Direct-to-Drive” technology produces virtually no common mode voltage so it

is suitable for new or existing motors and imposes no stress on the drive input.

The advantage of “Direct-to-Drive” technology over an Isolation Transformer is

that no extra insulation is required in the motor, in the motor cables or in the line

cables.

In addition to mitigating Common Mode Voltage, “Direct-to-Drive” technology

mitigates dv/dt or Reflected Wave Voltage Stress on motors.

The simplicity of its design results in a lower initial capital investment, lower

operating cost, lower installation cost and lower maintenance cost relative to

drives that require isolation transformers.

The PowerFlex 7000L with “Direct-to-Drive” technology is typically smaller and

lighter than drive technologies that use Isolation Transformers. Isolation

Transformers represent 30 to 50% of a drive system size and 50 to 70% of the

system’s weight. This means that there is no interwiring between drive and

transformer (for external transformer configurations). This makes the PowerFlex

7000L the simplest to install.

20 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 21

Overview of Drive Chapter 1

200.00

100.00

0.00

-100.00

-200.00

-300.00

10.00K

7.50K

5.00K

2.50K

0.00K

-2.50K

-5.00K

-7.50K

-10.00K

100.00

110.00

120.00 130.00

)

140.00

150.00

Arms

Vrms

Motor

Current

Motor

Voltage

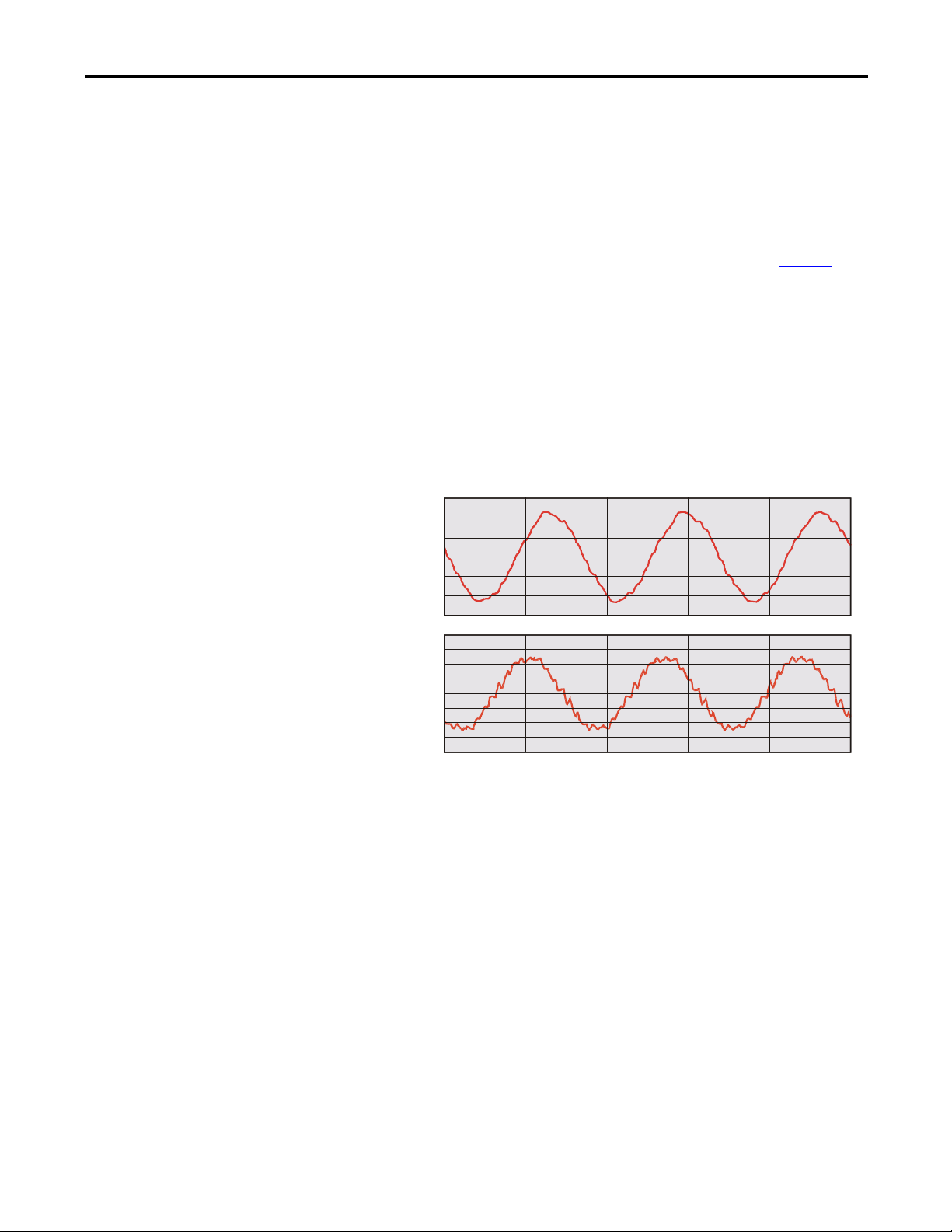

Motor Compatibility

The PowerFlex 7000L achieves near sinusoidal current and voltage waveforms to

the motor, resulting in no significant additional heating or insulation stress.

Temperature rise in the motor connected to the VFD is typically 3°C (5.5°F)

higher compared to across the line operation. Dv/dt in the voltage waveform is

less than 10 volts / microsecond. The peak voltage that the motor insulation will

see is the rated motor RMS voltage divided by 0.707. Reflected wave and dv/dt

issues often associated with VSI (voltage source inverter) drives are a non-issue

with the PowerFlex 7000L. Typical motor waveforms are shown in Figure 4

.

These motor friendly waveforms are achieved by utilizing a selective harmonic

elimination (SHE) pattern in the inverter to eliminate major order harmonics, in

conjunction with a small output capacitor (integral to the drive) to eliminate

harmonics at higher speeds.

Standard motors are compatible without derating, even on retrofit applications.

Motor cable distance is virtually unlimited. This technology has been tested,

controlling motors up to 15 km (9.3 miles) away from the drive.

Figure 4 - Motor waveforms @ full load, full speed

300.00

TIME (ms

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 21

Page 22

Chapter 1 Overview of Drive

SGCT Features and Benefits

An SGCT is a Symmetrical Gate Commutated Thyristor with an integrated gate

drive. Positioning the gate drive close to the SGCT as shown in Figure 5

low inductance path that provides more efficient and uniform gating of the

device. As a result, the device is better suited than a conventional GTO to handle

the fluctuating levels of voltage and current while it is switching on and off during

gating.

An SGCT has similar characteristics to an IGCT (used on some VSI drives),

including low conduction and switching losses, low failure rate, and double sided

cooling for low thermal stress. However, the SGCT achieves voltage blocking

capability in both forward and reverse directions up to 6500 volts by a NPT

(N

on-Punch-Through) structure and nearly symmetrical pnp transistor in the

wafer, while the current is unidirectional. Unlike many VSI topologies that use

IGBTs, the semiconductors used in the PowerFlex 7000L feature a non-rupture,

non-arc failure mode. In the unlikely event of a device failure, the fault would be

contained within the device.

Implementing SGCTs in the PowerFlex 7000L “B” Frame results in significant

advantages including:

1. Simplification of the snubber design and a reduction in the size of the

snubber capacitor by a factor of 10.

, creates a

2. Operation at a higher switching frequency (420-540 Hz), hence reducing

the size of passive components (DC link inductor and motor filter cap) by

50%.

3. Improving performance of the drive.

4. Reduction of component count, hence improving reliability, cost, and size

of the drive.

5. Fail safe failure mode (non-rupture).

Figure 5 - SGCT with integrated gate drive (left) and unit cell structure (right)

22 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 23

Specifications

Overview of Drive Chapter 1

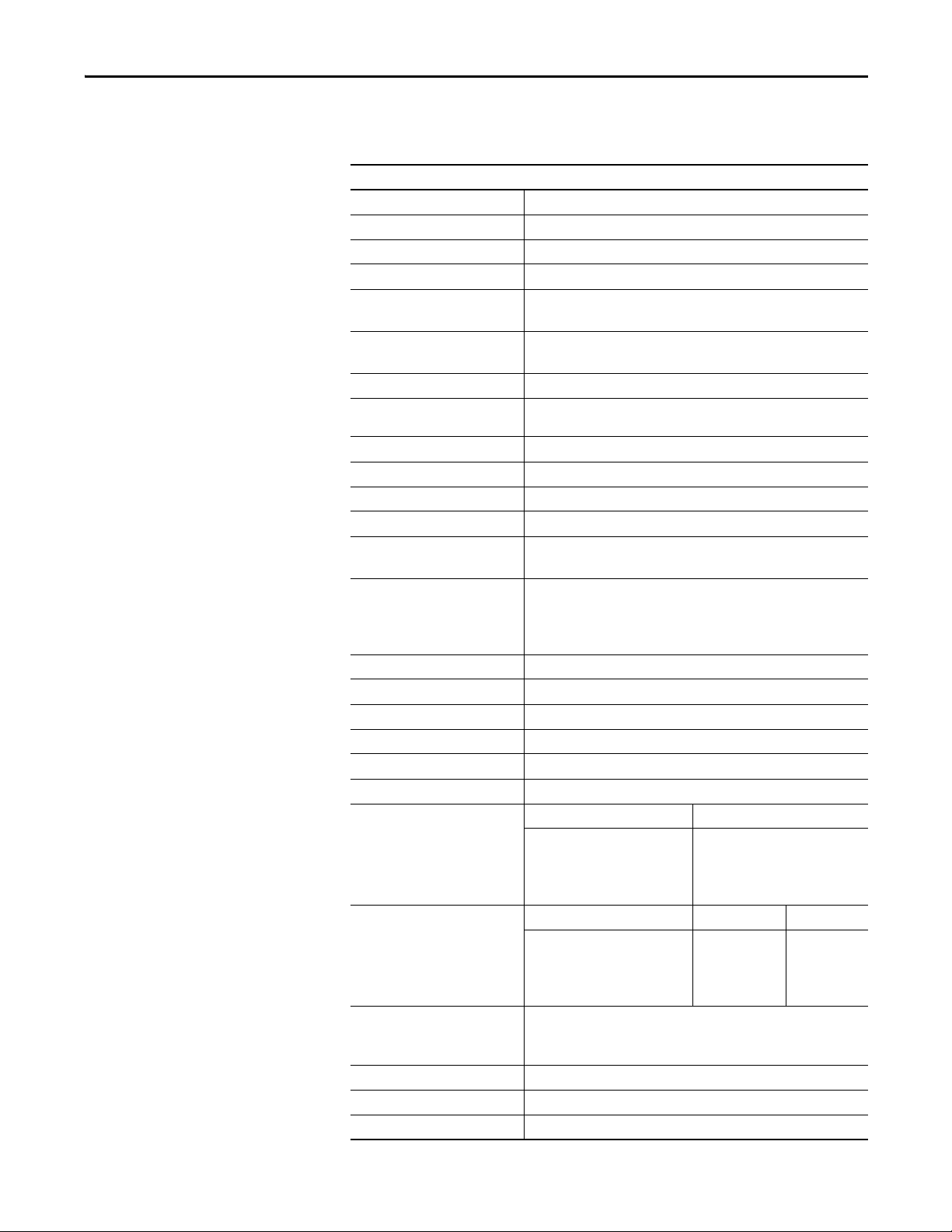

Table 1 - General Design Specifications

Description

Motor Type Induction or Synchronous

Input Voltage Rating 2400V, 3300V, 4160V, 6600V

Input Voltage Tolerance ± 10% of Nominal

Volt age Sag

Control Power Loss Ride-through 5 Cycles (Std)

Input Protection

Input Frequency 50/60 Hz, +/- 0.2%

Power Bus Input Short-circuit

Current Withstand (2400…6600V

Basic Impulse Level

Power Bus Design Copper - Tin plated

Ground Bus Copper - Tin plated 6 x 51 mm (¼ x 2 in.)

Customer Control Wire Way Separate and Isolated

Input Power Circuit Protection

Output Voltage 0…2400V

Inverter Design PWM

Inverter Switch SGCT

Inverter Switch Failure Mode Non-rupture, Non-arc

Inverter Switch Failure Rate (FIT) 100 per 1 Billion Hours Operation

Inverter Switch Cooling Double Sided, Low Thermal Stress

Inverter Switching Frequency 420…440 Hz

Number of Inverter SGCTs Voltage SGCTs (per phase)

Inverter PIV Rating

(Peak Inverse Voltage)

Rectifier Designs Direct-to-Drive (transformerless AFE rectifier)

Rectifier Switch SCR (18 Pulse), SGCT (AFE Rectifier)

Rectifier Switch Failure Mode Non-rupture, Non-arc

Rectifier Switch Failure Rate (FIT) 50 (SGCT) 100 (SCR) per 1 Billion Hours Operation

(1)

-30%

> 5 Cycles (Optional UPS)

(2)

Surge Arrestors (AFE/D irect-to-D rive)

Metal Oxide Varistor (MOV) (18 Pulse)

25 kA RMS SYM, 5 Cycle

(3)

)

(4)

45 kV (0…1000 m)

(5)

Vacuum Contactor with Fused Isolating Switch

or Circuit Breaker

0…3300V

0…4160V

0…6000V, 0…6300V, 0…6600V

2400V

3300V

4160V

6600V

2

4

4

6

Voltage PIV (each device) Total PIV

2400V

3300V

4160V

6600V

6500V

6500V

6500V

6500V

AFE with separate isolation transformer

18 Pulse with separate isolation transformer

6500V

13,000V

13,000V

19,500V

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014 23

Page 24

Chapter 1 Overview of Drive

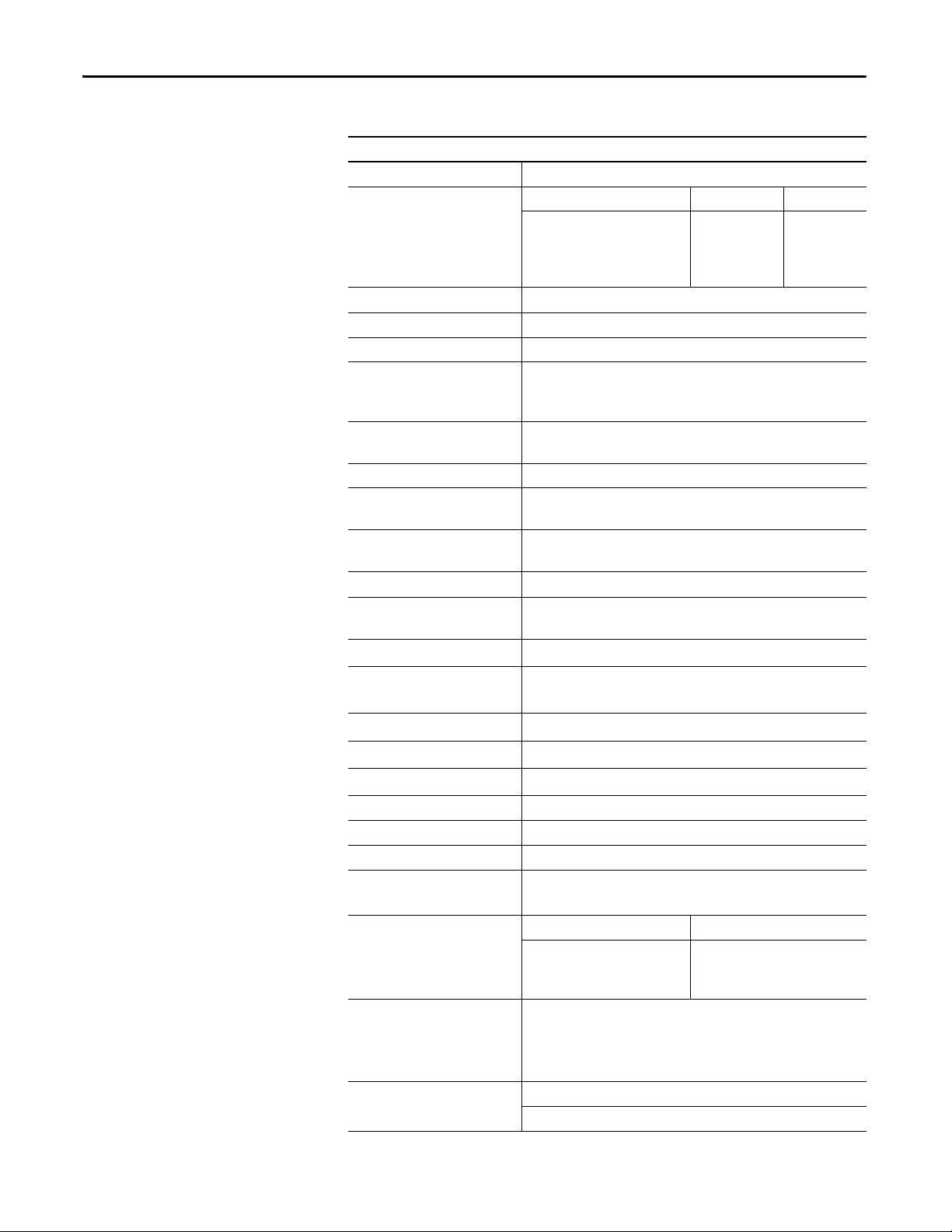

Table 1 - General Design Specifications (Continued)

Description

Rectifier Switch Cooling Double Sided, Low Thermal Stress

Number of Rectifier Devices per phase Voltage AFE 18 Pu lse

2400V

3300V

4160V

6600V

Output Current THD (1st…49th)< 5%

Output Waveform to Motor Sinusoidal Current / Voltage

Medium Voltage Isolation Fiber Optic

Modulation techniques Selective Harmonic Elimination (SHE)

Synchronous Trapezoidal PWM

Asynchronous or Synchronous SVM (Space Vector Modulation)

Control Method Digital Sensorless Direct Vector

Full Vec tor Control with Encoder Feedback (Option al)

Tuning Method Auto Tuning via Setup Wizard

Speed Regulator Bandwidth 1...10 rad/s with standard control

1...20 rad/s with HPTC (optional)

Torque Regulator Bandwidth 15...50 rad/s with standard control

80...100 rad/s with HPTC (optional)

Torque Accuracy with HPTC (optional) +/- 5%

Speed Regulation

Acceleration/Deceleration Range

Acceleration/Deceleration Ramp

Rates

S Ramp Rate

Critical Speed Avoidance

Stall Protection

Load Los s Detecti on Adjust able level, delay, speed set points

Control Mode Speed or Torque

Current Limit Adjustable in Motoring and Regenerative

Output Frequency Range 0.2...75 Hz (Standard)

Service Duty Rating Normal Duty Heavy Duty

Typical VFD Efficiency > 97.5% (AFE)

Input Power Fac tor AFE Rectifier

0.1% without Encoder Feedback

0.01...0.02% with Encoder Feedback

Independent Accel/Decel – 4 x 30 s

4 x Independent Accel/Decel

Independent Accel/Decel – 2 x 999 s

3 x Independent with Adjustable bandwidth

Adjustable time delay

75 Hz...85Hz (Optional - need specific Motor Filter Capacitor [MFC])

110% Overload for 1 min. every 10

min.

(Variable Torque Load)

> 98% (18 Pulse)

Contact Factory for Guaranteed Efficiency

of Specific Drive Rating

0.95 minimum, 10...100% Load

2

4

4

6

150% Overload for 1 min. every 10

min.

(Consta nt To rque Load)

6

6

6

6

24 Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Page 25

Overview of Drive Chapter 1

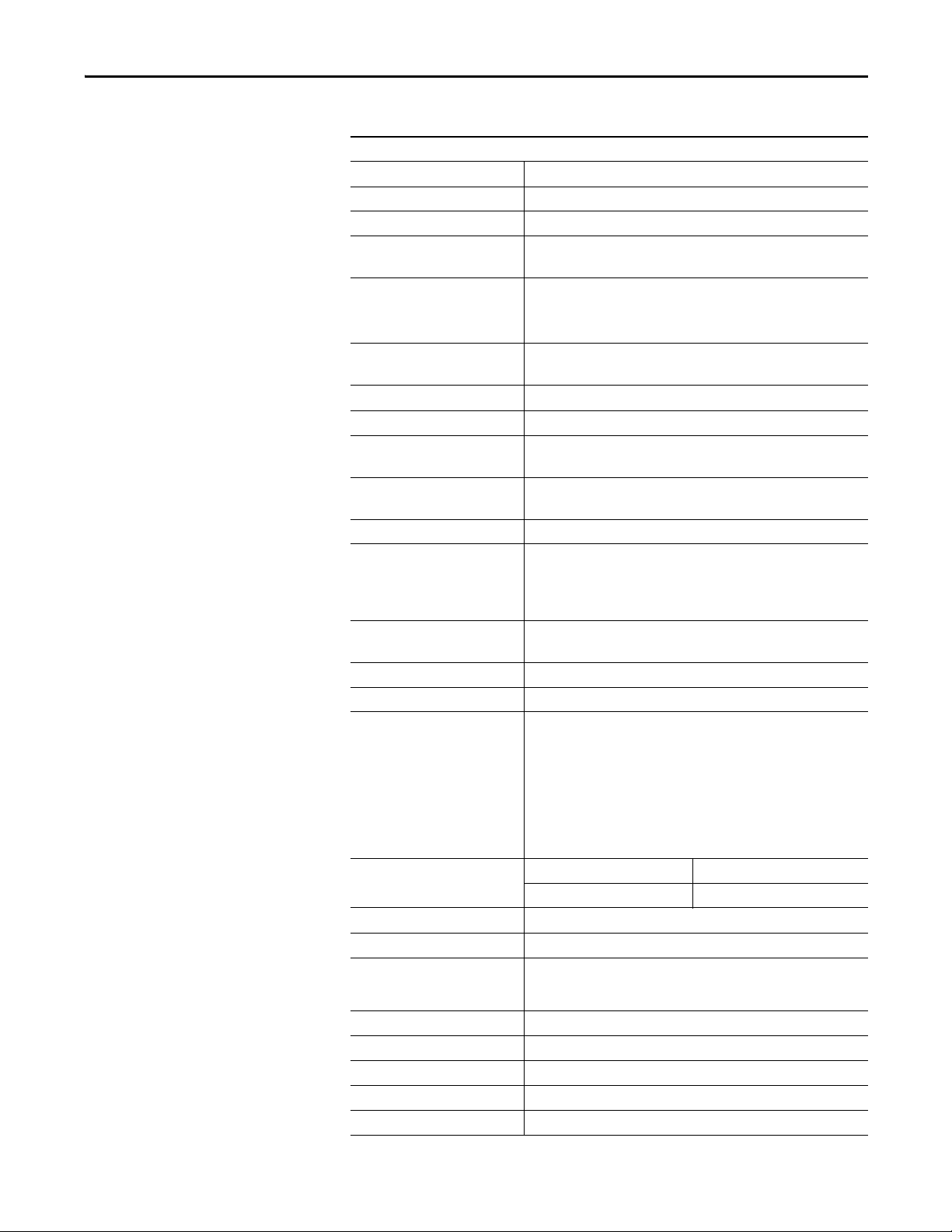

Table 1 - General Design Specifications (Continued)

Description

IEEE 519 Harmonic Guidelines

VFD Noise Level < 85 dB (A)) per OSHA Standard 3074

Regenerative Braking Capability Inherent – No Additional Hardware or Software Required

Flying Start Capability Yes – Able to Start into and Control a Spinning Load in Forward or Reverse

Operator Interface 10” Color Touchscreen – Cat# 2711P-T10C4A9 (VAC)

Languages English, French, Spanish, Por tuguese, German, Chinese, Italian, Russian, and

Control Power 220/240V or 110/120V, Single phase - 50/60 Hz (20 A)

External I/O 16 Digital Inputs, 16 Digital Outputs

External Input Ratings 50…60 Hz AC or DC

External Output Ratings 50…60 Hz AC or DC

Analog Inputs Three Isolated, 4…20 mA or 0…10V (250 Ω)

Analog Resolution Analog input 12 Bit (4…20 mA)

Analog Outputs One Isolated, Eight Non-isolated,

Communication Interface Ethernet IP/DPI

Scan Time Internal DPI – 2 ms min., 4 ms max.

Communications Protocols

(Opti onal)

Enclosure NEMA 1 (standard) IP21 (IEC)

Lifting Device Standard / Removable

Mounting Arrangement Mounting Sill Channels

Structure Finish Epoxy Powder – Paint

Interlocking Key provision for customer input Disconnecting Device

Corrosion Protection Unpainted Parts (Zinc Plated / Bronze Chromate)

Ambient Temperature 0…40 °C (32…104 °F) / 0…50 °C (32…122 °F) - optional

Fiber Optic Interface Rec tifier – Inverter – Cabinet (Warning / Trip)

Door Filter Painted Defuser with Matted Filter Media

(6)

IEEE 519 - 1992 Compliant

Direction

Built-in PDF viewer

Redesigned PanelView Plus 6 Logic Module with 512 Mb of memory

Polis h

120…240V – 1 mA

30…260V – 1 A

Internal parameter 32 Bit resolution

Serial Communication 16 Bit resolution (.1Hz)

(Digital Speed Reference)

4…20 mA or 0…10V (600 Ω)

DeviceNet ControlNet

Ethernet I/P Lon Works

Dual-port Ethernet I/P Can Open

Profibus RS485 HVAC

Modbus RS485 DF1

Interbus RS232 DF1

USB