Page 1

Quick Start

HMI Interface Board Software Updater and Firmware Download Procedure

Bulletin 7000

Top ic Pa ge

Additional Resources 2

Introduction 3

Download PowerFlex 7000 Software Updater 3

Computer Configuration 6

Point-to-Point Connection (not connected on a network) 6

Connect to a Network Without a DHCP Server 8

Connect to a Network With a DHCP Server 10

Download System Firmware to the HMI Interface Board 12

Select a Drive for System Firmware Download 12

Update Selected Drive 13

Troubleshooting 15

Page 2

HMI Interface Board Software Updater and Firmware Download Procedure

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation.

Resource Description

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification details.

Provides general guidelines for installing a Rockwell Automation industrial system.

You can view or download publications at http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative.

2 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 3

HMI Interface Board Software Updater and Firmware Download Procedure

IMPORTANT

Introduction

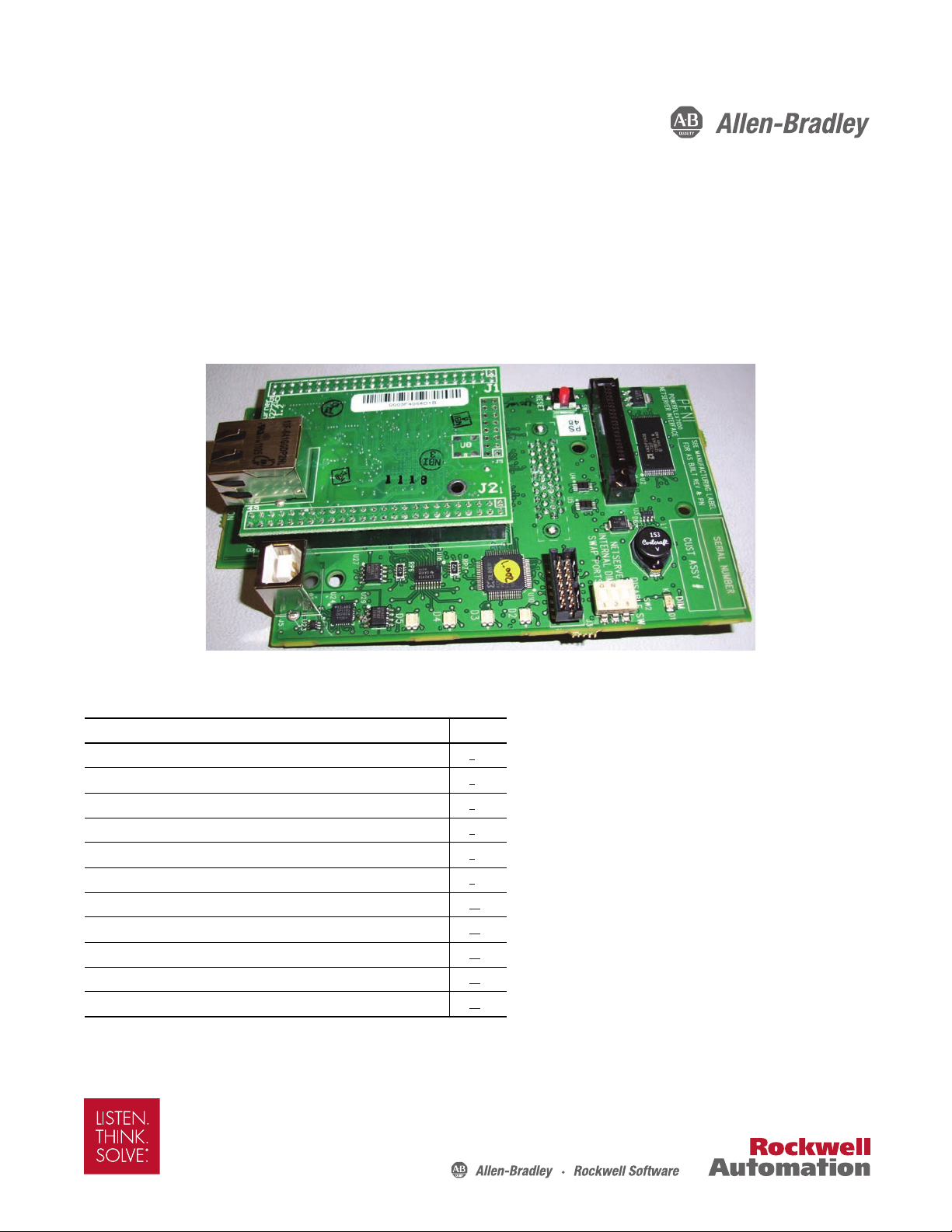

The procedure is only applicable to PowerFlex® 7000 ForGe Drives which utilize the new HMI Interface Board

(Part No. 80190-780-01-R).

The HMI Interface Board Software Updater and Firmware Download Procedure is necessary when:

• Retrofitting existing PowerFlex 7000 ForGe Drive with the new HMI Interface Board, and/or

• Updating PowerFlex 7000 ForGe Drive Firmware and HMI Interface Board Firmware simultaneously with the most

recent firmware versions.

System firmware refers to PowerFlex 7000 ForGe Drive Firmware, the HMI Interface Board Firmware and the SD card generic

content.

When replacing an existing HMI Interface Board, the existing SD card must be placed into the new HMI Interface Board. An

existing SD card contains all the job specific documentation (e.g. user manuals, customer drawings, etc.).

The updater utility does not update this documentation.

Download PowerFlex 7000 Software Updater

Prior to attempting the firmware download, the PowerFlex 7000 Software Updater Utility and associated packages must be

downloaded onto the local hard drive of your computer. This utility allows you to download system firmware.

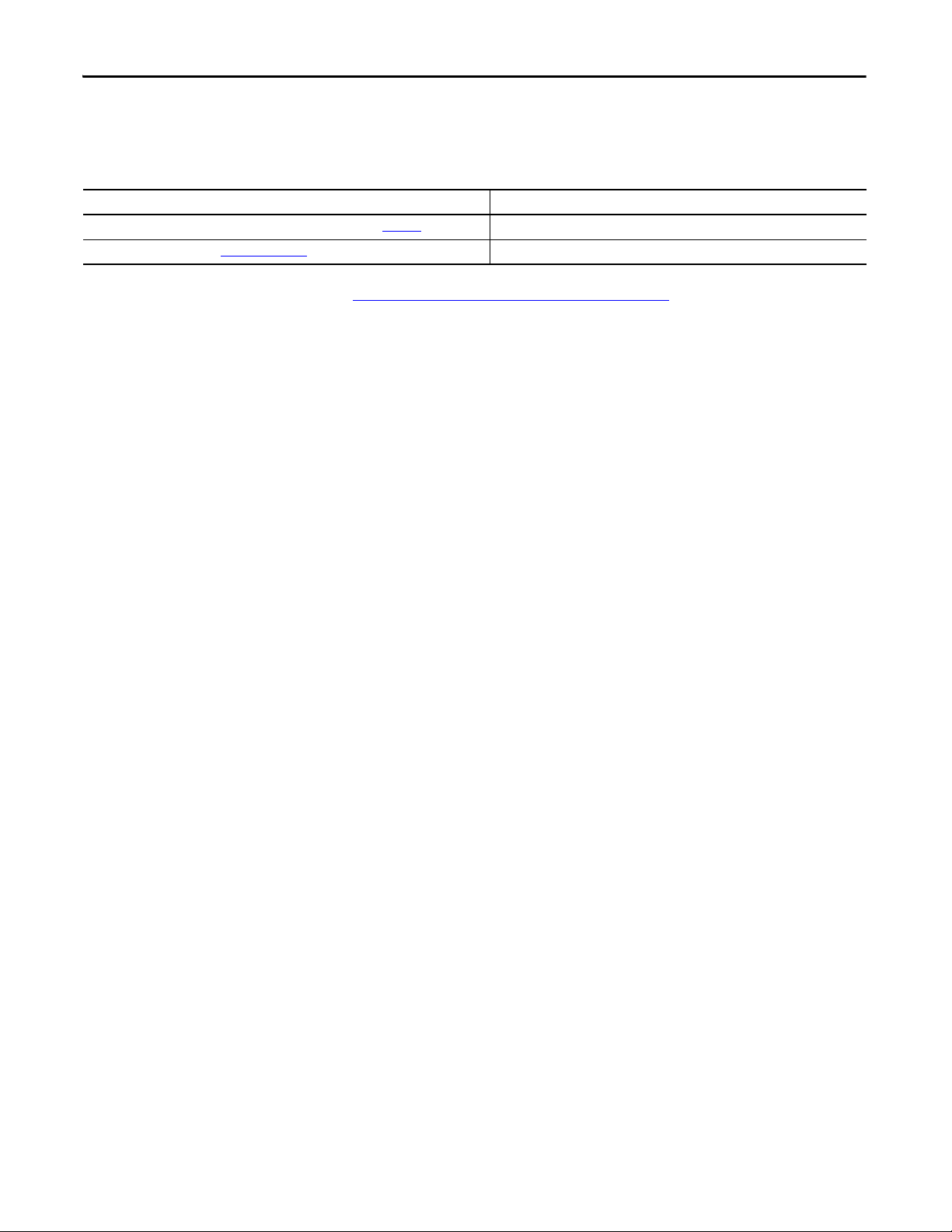

1. Enter the following website to access the Allen-Bradley updates page.

www.ab.com/support/abdrives/webupdate/powerflex7000.html

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 3

Page 4

HMI Interface Board Software Updater and Firmware Download Procedure

IMPORTANT

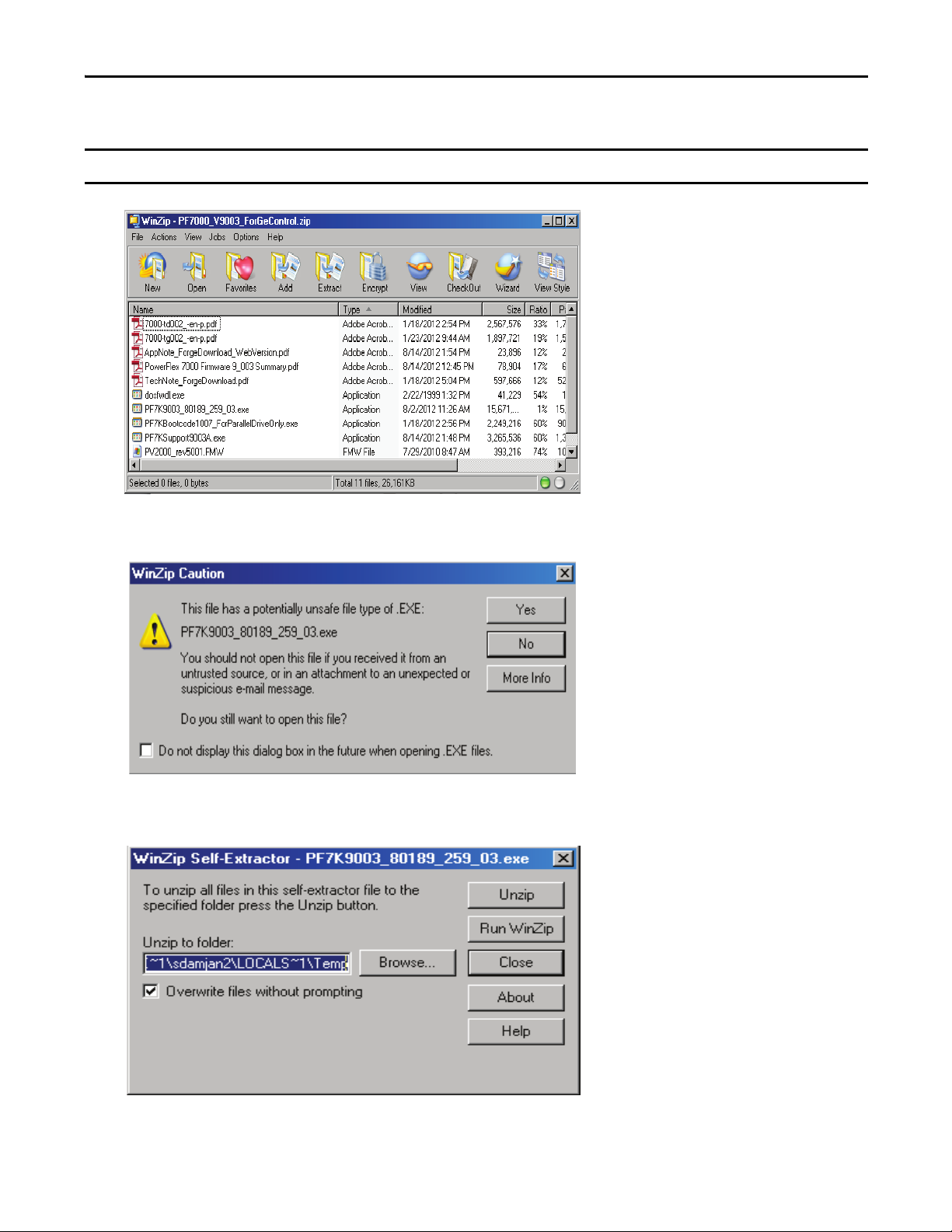

2. Click PowerFlex 7000 ForGe Control>Firmware 9.00_>v9.00_ Firmware and Technical Note.

The version number changes with every firmware release.

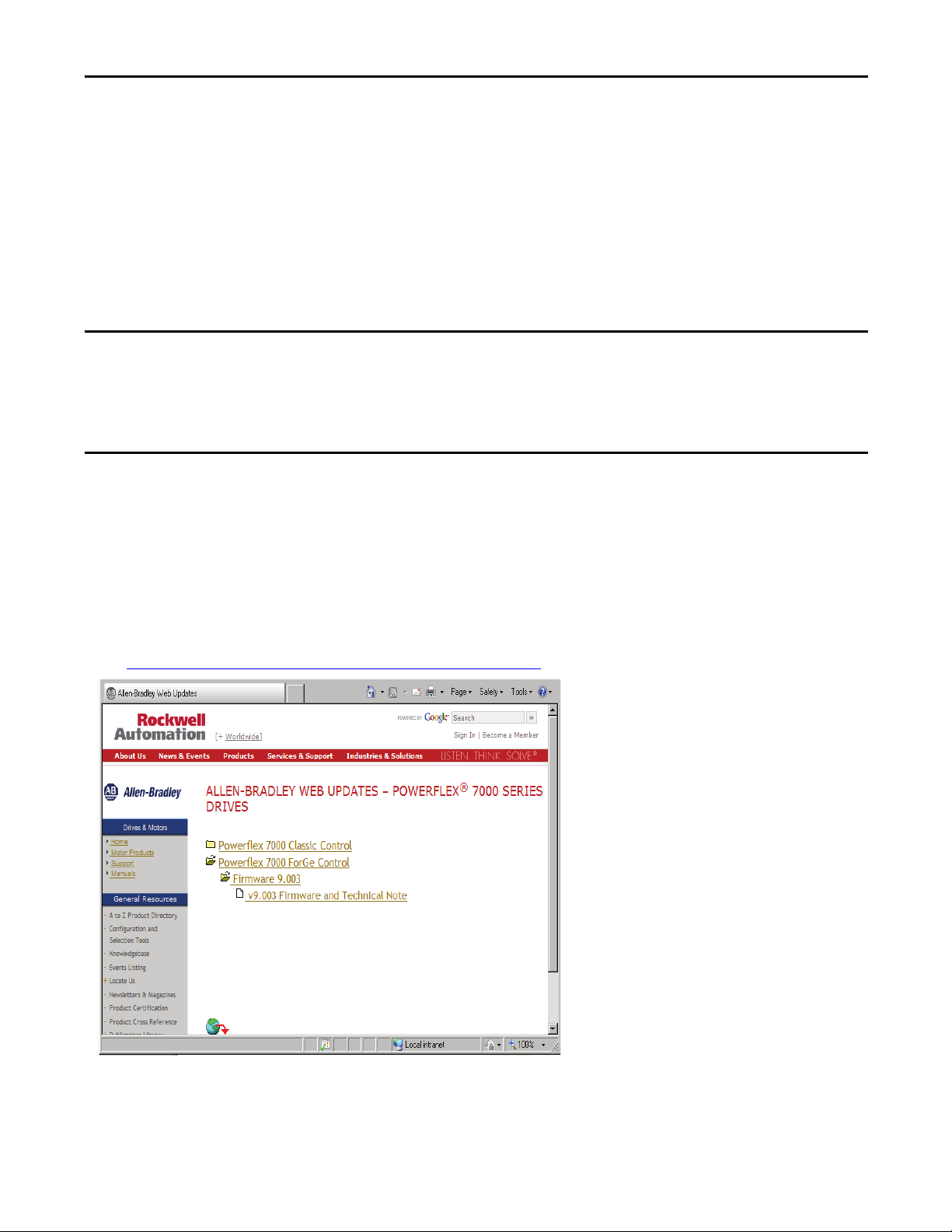

3. Click Save and select Desktop as the destination in the File Download dialog.

4. Click Open in the Download complete dialog.

4 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 5

5. Double-click on PF7K9003_80189_259_03.exe.

IMPORTANT

The file name changes as new firmware revisions become available.

HMI Interface Board Software Updater and Firmware Download Procedure

6. Click Yes to unzip PF7K9003_80189_259_03.exe.

7. Click Browse to select the desired location on the local hard drive to unzip the PF7K9003_80189_259_03.exe (e.g.

Desktop).

8. Click Unzip to extract the file to the selected location.

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 5

Page 6

HMI Interface Board Software Updater and Firmware Download Procedure

IMPORTANT

Computer Configuration

Determine whether the respective HMI Interface Board(s) are not connected to a network, or are connected to a network

with (or without) the DHCP server.

Point-to-Point Connection (not connected on a network)

System firmware is loaded into the HMI Interface Board via a computer using direct (point-to-point) Ethernet connection

to the HMI Interface Board.

This procedure assumes the HMI Interface Board and the computer are not connected to a network. As a result, the

computer static IP address must be configured manually in the computer. This is the simplest method to connect to an

HMI interface board, and is the recommended approach.

The static IP Address of the HMI Interface Board is 169.254.0.10

To have more than one HMI Interface Board (i.e. Drive) connected on the same network with no DHCP Server, all HMI Interface

Boards must be configured with distinct static IP addresses.

This process must occur before the drive is connected to the common network. Failure to do so results in conflicting HMI Interface

Boards with the same IP address.

If the HMI Interface Board has been configured with a different static IP address (other than the default HMI Interface

Board IP Address of 169.254.0.10

the one of the HMI Interface Board). The HMI Interface Board and a computer must both be configured with distinct IP

addresses in order to communicate.

), choose an appropriate laptop or desktop static IP address (an address different from

by default.

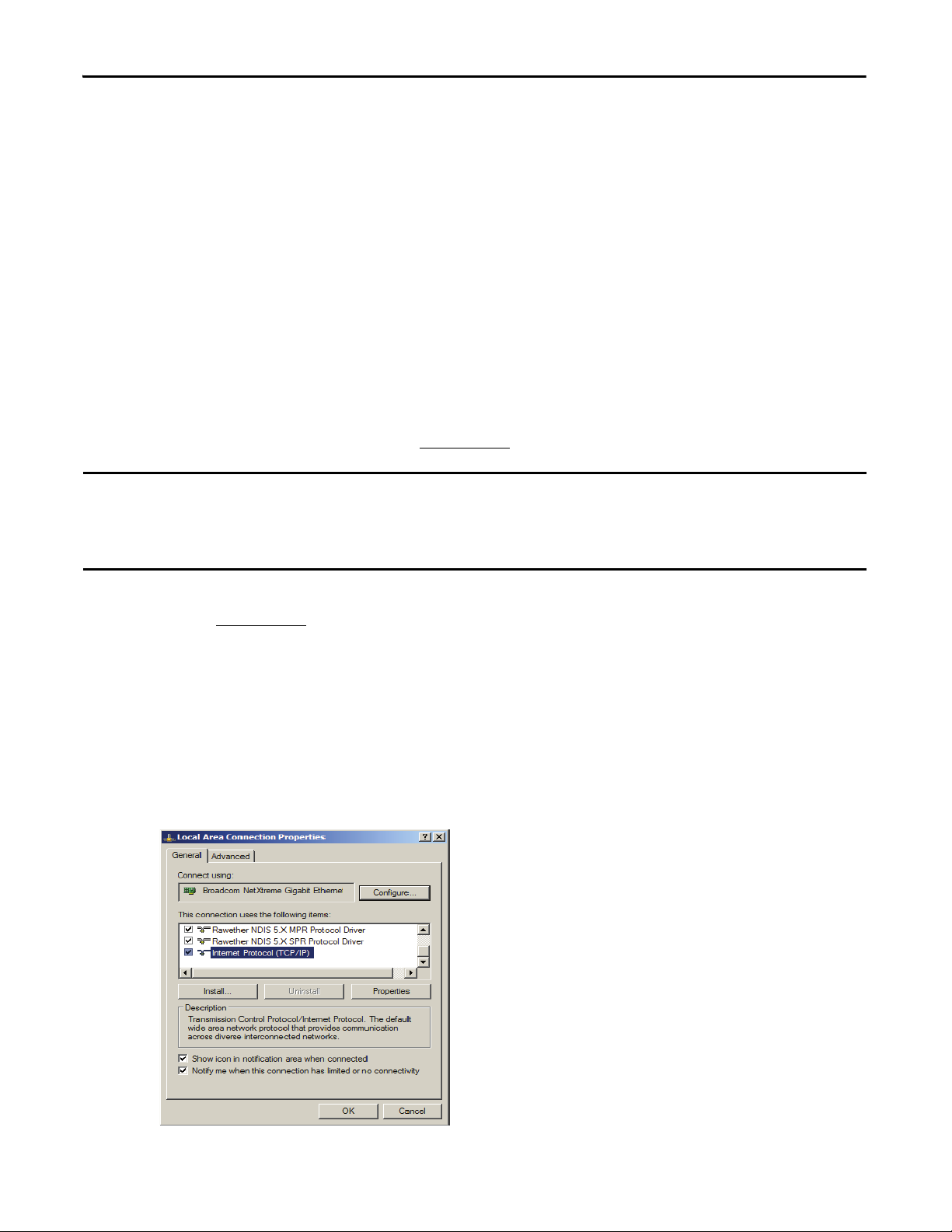

Configure a Static IP Address using Windows XP

1. From the Start menu, click Settings>Network Connections>Local Area Connection.

2. Click the General tab, and click Properties.

3. Under the General tab, scroll down and select Internet Protocol (TCP/IP), and click Properties.

6 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 7

HMI Interface Board Software Updater and Firmware Download Procedure

4. Click Use the following IP address and enter the laptop/desktop’s IP Static Address of 169.254.0.11 (an address

different from the one of the HMI Interface Board).

Enter a Subnet mask of 255.255.0.0. All other entries can be left blank.

5. Press OK on the two open dialogs, and Close on the Local Area Connection Status dialog.

Upon completion, refer to Download System Firmware to the HMI Interface Board

on page 12.

Configure a Static IP Address using Windows 7

1. From the Start menu, select Control Panel>Network and Sharing Center.

2. Click Change Adapter Settings, and double-click Local Area Connection.

3. Under the General tab, click Properties.

4. Under the Networking tab, scroll down and select Internet Protocol Version 4 (TCP/IP). Click Properties.

5. Click Use the following IP address and enter the laptop/desktop’s IP Static Address of 169.254.0.11 (an address

different from the one of the HMI Interface Board).

Enter a Subnet mask of 255.255.0.0. All other entries can be left blank.

6. Click OK on the two open dialogs, and Close on the Local Area Connection Status dialog.

Upon completion, refer to Download System Firmware to the HMI Interface Board

on page 12.

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 7

Page 8

HMI Interface Board Software Updater and Firmware Download Procedure

TIP

Connect to a Network Without a DHCP Server

System firmware is loaded into the HMI Interface Board(s) via a computer using an Ethernet connection.

When the computer is connected to a network without a DHCP Server, the HMI Interface Board(s) and the computer

must be manually configured with distinct static IP addresses.

If the HMI Interface Board(s) has been configured with a different static IP address (other than the default HMI Interface

Board Static IP 169.254.0.10.), choose an appropriate static IP address for the computer (within the same subnet as the

HMI Interface Board(s)).

The HMI Interface Board and the computer must both be configured with distinct IP Addresses in order to communicate.

To have more than one HMI Interface Board connected on the same network where there is no DHCP Server, all HMI Interface

Boards must be configured with distinct Static IP Addresses.

This process must occur before the drive is connected to the common network. Failure to do so results in conflicting HMI Interface

Boards with the same IP address.

Configure a Static IP Address using Windows XP

1. From the Start menu, click Settings>Network Connections>Local Area Connection.

2. Click the General tab, and click Properties.

3. Under the General tab, scroll down and select Internet Protocol (TCP/IP), and click Properties.

8 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 9

HMI Interface Board Software Updater and Firmware Download Procedure

4. Click Use the following IP address and enter the dedicated laptop or desktop static IP address of 169.254.0.11 (an

address different from the one of the HMI Interface Board(s)).

Enter a Subnet mask of 255.255.0.0. All other entries can be left blank.

5. Click OK on the two open dialogs, and click Close on the Local Area Connection Status.

Upon completion, refer to Download System Firmware to the HMI Interface Board

on page 12.

Configure a Static IP Address using Windows 7

1. From the Start menu, select Control Panel>Network and Sharing Center.

2. Click Change Adapter Settings, and double-click Local Area Connection.

3. Under the General tab, click Properties.

4. Under the Networking tab, scroll down and select Internet Protocol Version 4 (TCP/IP), and click Properties.

5. Click Use the following IP address and enter the laptop/desktop’s IP Static Address of 169.254.0.11 (an address

different from the one of the HMI Interface Board).

Enter a Subnet mask of 255.255.0.0. All other entries can be left blank.

6. Click OK on the two open dialogs, and Close on the Local Area Connection Status dialog.

Upon completion, refer to Download System Firmware to the HMI Interface Board

on page 12.

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 9

Page 10

HMI Interface Board Software Updater and Firmware Download Procedure

Connect to a Network With a DHCP Server

System firmware is loaded into the HMI Interface Board via a computer (i.e. laptop or desktop) using an Ethernet

connection. The HMI Interface board and a laptop or desktop must both be configured with distinct IP addresses to

communicate.

When connected to a network with a DHCP Server present, the computer can be configured to automatically receive a

Dynamic IP address.

Configure a Dynamic IP Address using Windows XP

1. From the Start menu, click Settings>Network Connections>Local Area Connection.

2. Click the General tab, and click Properties.

3. Under the General tab, scroll down and select Internet Protocol (TCP/IP), and click Properties.

4. Click Obtain an IP address Automatically. Click OK on the two open dialogs, and Close on the Local Area

Connection Status dialog.

Upon completion, refer to Download System Firmware to the HMI Interface Board

on page 12.

10 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 11

HMI Interface Board Software Updater and Firmware Download Procedure

Configure a Dynamic IP Address using Windows 7

1. From the Start menu, select Control Panel>Network and Sharing Center.

2. Click Change Adapter Settings, and double-click Local Area Connection.

3. Under the General tab, click Properties.

4. Under the Networking tab, scroll down and select Internet Protocol Version 4 (TCP/IP). Click Properties.

5. Click Obtain an IP address Automatically.

6. Click OK on the two open dialogs, and Close on the Local Area Connection Status dialog.

Upon completion, refer to Download System Firmware to the HMI Interface Board

on page 12.

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 11

Page 12

HMI Interface Board Software Updater and Firmware Download Procedure

TIP

IMPORTANT

Download System Firmware to the HMI Interface Board

The information contained within this document is only applicable to PowerFlex 7000 ForGe Drives which utilize the new

HMI Interface Board within the drive.

The PowerFlex 7000 Software Updater Utility is a Rockwell Automation program designed specifically to update system

firmware on PowerFlex 7000 Forge Drives equipped with an HMI Interface Board. The utility can be run on Windows XP,

Windows 7 and Windows CE.

Select a Drive for System Firmware Download

Windows Firewall must be disabled during this process. Re-enable the firewall once this process is completed

1. Double-click 80189-259-03.exe on your desktop.

The file name changes as new Firmware revisions become available.

2. Click Select.

A list of discovered drives opens in a separate window.

12 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 13

HMI Interface Board Software Updater and Firmware Download Procedure

TIP

TIP

3. Select the desired HMI Interface Board (PowerFlex 7000 Forge Drive) from the list.

If the IP address of the drive is known beforehand, enter it in the provided blank fields.

The HMI Interface Board IP is now displayed in the Drive fields.

Update Selected Drive

Once the desired IP address of the drive is either selected or entered, the drive must be placed in Download Mode.

1. Click Internal, and click Update.

The drive may need to be placed in download mode.

2. Click Yes, and enter the appropriate PIN value for the desired access level.

The PIN codes required for the firmware download are the same PIN codes used in the operator interface. Unless changed, the

Advanced PIN is 0 by default. If an incorrect PIN is entered, the update process must be restarted.

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 13

Page 14

HMI Interface Board Software Updater and Firmware Download Procedure

IMPORTANT

TIP

3. Press Enter on the keyboard.

A bar graph shows the progress of the file transfer to the HMI Interface Board. A status window under the Update

button shows information about the update progress.

Once the entire Package has been downloaded, the HMI Interface Board will perform a validation process on the

contents.

Status strings provide information about each step in the process:

• Val ida ting ea ch fi le

• Extracting each file

• Completion status

If any of the contents fails validation, or the drive is not in download mode to accept an included .FFW file, the

entire process will be aborted.

To receive status information from the HMI Interface Board module, UDP port 514 must be permitted by the updating computer’s

firewall.

Press Package to preview the contents of the selected radio button

The Package View dialog shows the generic contents of the SD Card which will be created or updated on the HMI Interface Board.

The PowerFlex 7000 ForGe Drive Firmware and HMI Interface Firmware may also be included in the Package. In this example, the

HMI Interface Board Firmware will be updated, but no update is contained for the Drive Firmware.

14 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 15

HMI Interface Board Software Updater and Firmware Download Procedure

Troubleshooting

1. The PowerFlex 7000 Software Updater uses the following Ethernet ports:

• TCP 20,21 for FTP transfer of files

• UDP 20034 for the discovery process of drives

• UDP 514 for status strings for each step of the update process

To function properly, any firewall that may be utilized must not block these ports, or the firewall temporarily

disabled.

2. If the PC has multiple Ethernet ports (referred to as MultiHoming) and problems are encountered, disable all ports

except the one connected to the drive network.

3. If a Comm Error is encountered while using the PowerFlex 7000 Software Updater during the download operation,

press the Reset button on the HMI Interface Board and try the download process again.

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 15

Page 16

HMI Interface Board Software Updater and Firmware Download Procedure

Notes:

16 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 17

Notes:

HMI Interface Board Software Updater and Firmware Download Procedure

Rockwell Automation Publication 7000-QS002A-EN-P - October 2012 17

Page 18

HMI Interface Board Software Updater and Firmware Download Procedure

Notes:

18 Rockwell Automation Publication 7000-QS002A-EN-P - October 2012

Page 19

Page 20

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

code and links to software service packs, and a MySupport feature that you can customize to make the best use of these

tools. You can also visit our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

information, support chat and forums, software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application notes, sample

for FAQs, technical

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

SM

Te c h C o n n e c t

representative, or visit http://www.rockwellautomation.com/support/

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwi de Lo cato r at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact your local Rockwell

Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Medium Voltage Products, 135 Dundas Street, Cambridge, ON, N1R 5X1 Canada, Tel: (1) 519.740.4100, Fax: (1) 519.623.8930

Online: www.ab.com/mvb

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Publication 7000-QS002A-EN-P - October 2012

, available at http://www.rockwellautomation.com/literature/.

Copyright © 2012 Rockwell Automation, Inc . All rights reserved. Printed in Canada.

Loading...

Loading...