Page 1

Bulletin 7000 User Manual

PowerFlex® 7000 Medium Voltage AC Drive Air-Cooled

(“A” Frame)—ForGe Control

(Using PanelView 550)

Publication 7000A-UM151D-EN-P

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface Overview Who should use this Manual .................................................... P-1

What is not in this Manual ....................................................... P-1

Manual Conventions ................................................................ P-2

General Precautions ................................................................. P-3

Who to call for Commissioning ............................................... P-3

Chapter 1 Overview of Drive Introduction .............................................................................. 1-1

Drive Configurations ............................................................... 1-2

Topology .................................................................................. 1-3

Rectifier Designs

Active Front End (AFE) Rectifier .................................... 1-4

“Direct-to-Drive” Technology ................................................ 1-5

Motor Compatibility ................................................................ 1-6

Simplified Electrical Drawings

2400 volt – Active Front End (AFE) Rectifier .................. 1-7

3300/4160 volt – Active Front End (AFE) Rectifier ......... 1-8

6600 volt – Active Front End (AFE) Rectifier .................. 1-9

Operator Interface .................................................................. 1-10

Chapter 2 Drive Installation Safety and Codes ..................................................................... 2-1

General Handling Procedures .................................................. 2-1

Drive Storage ........................................................................... 2-1

Siting of the Drive ................................................................... 2-2

Site Considerations ............................................................ 2-2

Installation ............................................................................... 2-4

Installation of Exhaust Air Hood ...................................... 2-4

Installation of Integral Transformer Cooling Fan ............. 2-8

Neutral Resistor Assembly ............................................... 2-9

Installation of Neutral Resistor Assembly ...................... 2-10

Cabinet Layout and Dimensional Drawings of Drive ............ 2-11

PowerFlex 7000 “A” Frame Dimensional Drawing .............. 2-12

Drive Layout .......................................................................... 2-13

Direct-to-Drive AFE Rectifier Configuration #1 ............ 2-13

AFE Rectifier (Separate Isol. Transformer (Config. #2) ..... 2-14

AFE Rectifier (Integral Isol. Transformer (Config. #3) ....... 2-15

Cabling Cabinet #1 (with Input Starters) .............................. 2-16

Cabling Cabinet #1 (without Input Starters) ......................... 2-17

Cabling Cabinet #2 ............................................................... 2-18

Cabling Cabinet #3 ............................................................... 2-19

Converter Cabinet .................................................................. 2-20

Control/DC Link/Fan Cabinet ............................................... 2-21

Low Voltage Control Tub ...................................................... 2-22

IEC Component and Device Designations ............................ 2-24

Power Wiring Selection ......................................................... 2-24

Cable Insulation .............................................................. 2-25

Wire Group Numbers ...................................................... 2-26

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 4

ii Table of Contents

Chapter 2 Drive Installation

Power Cabling Access ........................................................... 2-27

(cont.)

To access the customer power cable terminations .......... 2-27

Power Connections ................................................................ 2-28

Line/Motor Terminations ................................................ 2-28

Power Cabling Installation Requirements ....................... 2-28

Dimension Views:

Cabling Cabinet for Config. #1 with Input Starter ......... 2-29

Cabling Cabinet for Config. #1 without Input Starter ..... 2-30

Cabling Cabinet for Config. #2 ...................................... 2-31

Cabling Cabinet for Config. #3 ...................................... 2-32

Power and Control Wiring ..................................................... 2-33

Control Cables ................................................................ 2-33

Grounding Practices ............................................................... 2-34

Grounding Guidelines and Practices for Drive Signal

and Safety Grounds ................................................... 2-35

Grounding Requirements and Specifications for

Customer and Power Integrators .............................. 2-36

Identification of Types of Electrical Supplies

– Grounded and Ungrounded Systems ..................... 2-36

Ground Bus ..................................................................... 2-36

Interlocking ............................................................................ 2-37

Chapter 3 Operator Interface Chapter Objectives ................................................................... 3-1

Terminology ............................................................................ 3-1

Overview ................................................................................. 3-3

Keypad .............................................................................. 3-3

Function (Softkeys) Keys ........................................... 3-3

Cursor (Selection) Keys .............................................. 3-4

Data Entry Keys .......................................................... 3-4

What is a Screen? .............................................................. 3-5

Components ................................................................ 3-5

Information Windows ................................................. 3-6

Accessing/Writing to Drive .................................. 3-7

Communication Error ........................................... 3-7

Language Changing ............................................. 3-8

General Operation ....................................................... 3-8

Operator Interface Power-up Sequence ............................. 3-9

Top Level Menu .............................................................. 3-11

How to:

Obtain Help ..................................................................... 3-12

Related Topics .......................................................... 3-12

Help On Help ............................................................ 3-13

Modify Operator Interface Operation (Utility) ............... 3-14

Changing Backlight Delay ........................................ 3-14

Changing Contrast .................................................... 3-15

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 5

Table of Contents iii

Chapter 3 Operator Interface

Setting Time ............................................................. 3-16

(cont.)

Setting Date .............................................................. 3-17

Selecting Meters ....................................................... 3-17

Viewing Revision Levels .......................................... 3-20

Transfer Data in Memory ......................................... 3-21

Picking an Access Level ........................................... 3-21

Select a Parameter ............................................................ 3-22

Via Groups ................................................................ 3-22

Via Name .................................................................. 3-23

Via Code ................................................................... 3-24

Edit Text .......................................................................... 3-26

Configure the Drive ......................................................... 3-28

Enter/Modify an Access Level ................................. 3-28

Drive Set-up .............................................................. 3-32

Language Selection ............................................ 3-33

Modify Parameters ............................................. 3-34

Numerical Value ................................................ 3-34

Enumerated Value .............................................. 3-36

Bit Encoded Value ............................................. 3-37

Analog Ports ....................................................... 3-38

Fault Masks ........................................................ 3-39

User Definable External Text ............................. 3-42

PLC .................................................................... 3-43

XIO ..................................................................... 3-45

Message Prompting .................................................. 3-45

Store/Retrieve Configuration (NVRAM) ................. 3-46

Initialize ............................................................. 3-46

Save .................................................................... 3-47

Load ................................................................... 3-47

Display Parameters .......................................................... 3-48

Custom Group ........................................................... 3-50

View Drive Status ........................................................... 3-51

View and Reset Alarms ................................................... 3-51

Help for Alarms ........................................................ 3-52

Request Printouts ............................................................ 3-53

Loading Programs (Firmware) ........................................ 3-54

Parameter Transfers ........................................................ 3-56

Upload to Operator Interface ............................. 3-57

Download from Operator Interface .................... 3-57

Upload to Memory Card .................................... 3-57

Download from Memory Card ........................... 3-58

Parameter File Format ........................................ 3-58

Loading Language Modules ............................................ 3-59

System Programming ...................................................... 3-60

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 6

iv Table of Contents

Operator Interface Menu Hierarchy Chart

Chapter 3 Operator Interface

What does it show? ......................................................... 3-61

(cont.)

How do you read it? ........................................................ 3-61

Example ........................................................................... 3-62

PowerFlex 7000 “A” Frame Terminal Menu Tree .......... 3-63

PCMCIA Memory Card Installation Data

Description ...................................................................... 3-65

Installing the Memory Card ............................................ 3-65

Cabling Cabinet for Config. #1 (Direct-to-Drive) ................. 4-1

Chapter 4 Component Definition

Cabling Cabinet for Config. #1

and Maintenance

(Direct-to-Drive, optional Input Starter) .......................... 4-2

Cabling Cabinet for Config. #2

(AFE Rectifier with Separate Isolation Transformer) ....... 4-3

Cabling Cabinet for Config. #3

(AFE Rectifier with Integral Isolation Transformer) ....... 4-4

Converter Cabinet Components ............................................... 4-5

Converter Cabinet .................................................................... 4-6

Surge Arresters ....................................................................... 4-6

Description ....................................................................... 4-6

Operation .......................................................................... 4-7

Field Test and Care .......................................................... 4-7

PowerCage™ ........................................................................... 4-8

SGCT and Snubber Circuit .................................................... 4-11

Uniform Clamping Pressure .................................................. 4-12

Checking Clamping Pressure ................................................. 4-13

Clamping Pressure Adjustment ....................................... 4-13

Temperature Sensing ............................................................. 4-14

Symmetrical Gate Commutated Thyristor Replacement ....... 4-15

Snubber Resistors .................................................................. 4-18

Testing Snubber Resistors ............................................... 4-18

Fiber Optic Cabling .............................................................. 4-19

Air Pressure Sensor ................................................................ 4-19

DC Link/Fan/Control Components ........................................ 4-20

Filter Capacitors .............................................................. 4-21

Filter Capacitor Replacement .......................................... 4-22

Testing Filter Capacitors ................................................ 4-23

First Method ............................................................ 4-23

Second Method ........................................................ 4-24

Recommended Digital Multimeters (DMM) .................. 4-27

Fan Replacement ................................................................... 4-28

DC Link Section .............................................................. 4-28

Safety Notes .................................................................... 4-28

Fan Installation ................................................................ 4-29

Top of Integral Isolation Transformer Section ................ 4-29

Top of Integral Line Reactor/Input Starter Section ......... 4-29

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 7

Table of Contents v

Impeller Maintenance (DC Link/Fan Section) ...................... 4-31

Chapter 4 Component Definition

Impeller Removal from Motor Shaft ............................... 4-31

and Maintenance

Safety Notes .................................................................... 4-31

(cont.)

Installation of Impeller Assembly onto Motor Shaft ....... 4-32

Impeller Maintenance ........................................................... 4-34

Isolation Transformer Cooling Fan ................................. 4-34

Inlet Ring Removal and Replacement ................................... 4-34

Safety Notes .................................................................... 4-34

DC Link / Fan Section ..................................................... 4-34

Procedure ......................................................................... 4-34

Top on Integral Isolation Transformer Section ............... 4-35

Replacement of Air Filters ..................................................... 4-35

Procedure ......................................................................... 4-35

Control Power Components ................................................... 4-38

Ride-Through .................................................................. 4-38

AC/DC Power Supply ............................................................ 4-41

Description ...................................................................... 4-41

Location ........................................................................... 4-42

Low Voltage Control Section ................................................ 4-44

DC/DC Power Supply ............................................................ 4-46

Description ...................................................................... 4-46

IO Connectors on Control Boards ........................................ 4-47

Drive Processor Module ........................................................ 4-48

ACB Analog Control Board .................................................. 4-49

Interface Module (IFM) ................................................. 4-50

Analog Inputs and Outputs .............................................. 4-50

External Input/Output Boards ................................................ 4-51

Optical Interface Boards ........................................................ 4-53

Environmental Considerations ............................................... 4-55

Hazardous Materials ........................................................ 4-55

Disposal ........................................................................... 4-57

Appendix A Commissioning Start-up Commissioning Services ........................................... A-1

Drive Commissioning ...................................................... A-1

Appendix B Catalog Number Catalog Number Explanation................................................... B-1

Control Power Transformer Selection ............................... B-2

PowerFlex 7000 Drive Selection Explanation ........................ B-3

When is a Tachometer Required? ........................................... B-4

PowerFlex 7000 Drive Performance ....................................... B-5

Glossary of Terms ................................................................... B-5

Typical Application Load Torque Profiles ............................. B-6

Explanation Supply Voltage, Control Voltage, Frequency and

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 8

vi Table of Contents

Appendix C Torque Requirements Torque Requirements for Threaded Fasteners ........................ C-1

Appendix D Meggering Drive Meggering ..................................................................... D-1

Meggering the PowerFlex 7000A ........................................... D-1

Equipment Required ......................................................... D-2

Procedure .......................................................................... D-2

Preventive Maintenance Check List ....................................... E-1

Appendix E Preventative

Operational Maintenance ........................................................ E-1

Maintenance

Annual Maintenance ............................................................... E-2

Initial Information Gathering ........................................... E-2

Physical Checks (NO Medium Voltage and

NO Control Power) .................................................... E-2

Control Power Checks (NO Medium Voltage) ................ E-4

Final Power Checks before Restarting ............................. E-4

Additional Tasks During Preventive Maintenance .......... E-5

Final Reporting ................................................................. E-5

Time Estimations ............................................................. E-6

Tool / Parts / Information Requirements .......................... E-7

Maintenance Schedule ........................................................... E-8

Preventative Maintenance Service Schedule ......................... E-9

General Notes ...................................................................... E-11

Maintenance of MV Motor Control Equipment ............ E-11

Periodic Inspection ........................................................ E-11

Contamination ............................................................... E-12

High Voltage Testing .................................................... E-12

Maintenance after a Fault Condition ............................. E-12

Part-specific Notes ............................................................... E-13

Cooling Fans ................................................................. E-13

Operating Mechanisms .................................................. E-13

Contacts ......................................................................... E-13

Vacuum Contactors ....................................................... E-13

Power Cable and Control Wire Terminals ................... E-14

Coils ............................................................................. E-14

Batteries ......................................................................... E-14

Pilot Lights .................................................................... E-14

Solid-State Devices ....................................................... E-15

Locking and Interlocking Devices ................................ E-15

Appendix F Specifications Specifications ........................................................................... F-1

Dimensions/Weights ............................................................... F-4

Nominal Power Ratings .......................................................... F-4

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 9

Preface

Overview

Who Should Use This Manual This User Manual is intended for use by personnel familiar with

medium voltage and variable speed solid-state drive equipment. The

manual contains material that will allow the user to operate the drive

system.

What Is Not in this Manual This manual is designed to provide only information specific to the

PowerFlex 7000 “A” Frame drive. Therefore customer specific

topics are not presented. These customer specific topics include:

• Dimensional and Electrical Drawings generated for each

customer specific order. (This manual does provide generic

drawings for illustrative purposes only.)

• Spare Parts Lists compiled for each customer specific order.

(This manual does provide a generic list of possible components

and a description of their characteristics and functionality.)

The above information is provided to the customer during the

Three User Manuals address this product line:

If you have multiple drive types or power ranges, ensure you have

For detailed information on Troubleshooting, Parameters and

For detailed information on receiving and handling for Medium

Reference Manuals (for “A”, “B” and “C” Frame drives) are also

Please note: This manual deals specifically with the PowerFlex 7000

order process cycle.

“A” Frame for lower power air-cooled configurations

(up to approximately 1250 hp/933 kW)

“B” Frame for higher power air-cooled configurations

“C” Frame for all liquid-cooled configurations

the correct manual.

Functional Description for MV variable frequency drives, please

refer to Technical Data publication 7000-TD002_-EN-P.

Voltage variable frequency drive and related equipment, please refer

to General Handling Procedures, publication 7000-IN002_-EN-P.

available. These manuals provide additional technical information

about the drive components. Contact your local Rockwell

Automation Sales office to order copies of these publications.

“A” Frame drive. Information on auxiliary cabinetry or special

components we are contracted to supply with the drive will be

contained within the Service Manual you will receive with your order.

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 10

P-2 Preface

Manual Conventions Symbols are used throughout this manual to indicate specific types

of information.

W A R N I N GW A R N I N G

Warnings tell readers where people may be

hurt if procedures are not followed properly.

A T T E N T I O NA T T E N T I O N

Cautions tell readers where machinery may be

damaged or economic loss can occur if

procedures are not followed properly.

Both of the above could indicate:

• A possible trouble spot

• Tell what causes the trouble spot

• Give the result of an improper action

• Tell the reader how to avoid trouble

S H O C K H A Z A R DS H O C K H A Z A R D

This symbol alerts the user to a potential

electrical shock hazard that exists on a

component or printed circuit board.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 11

Preface P-3

General Precautions

A T T E N T I O NA T T E N T I O N

This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies.

Static control precautions are required when

installing, testing, servicing or repairing this

assembly. Component damage may result if

ESD control procedures are not followed. If

you are not familiar with static control

procedures, reference Allen-Bradley

publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other

applicable ESD protection handbook.

A T T E N T I O NA T T E N T I O N

An incorrectly applied or installed drive can

result in component damage or a reduction in

product life. Wiring or application errors,

such as, undersizing the motor, incorrect or

inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the

system.

A T T E N T I O NA T T E N T I O N

Only personnel familiar with the PowerFlex

7000 Adjustable Speed Drive (ASD) and

associated machinery should plan or

implement the installation, start-up and

subsequent maintenance of the system.

Failure to comply may result in personal

injury and/or equipment damage.

Who to Call for Commissioning Rockwell Automation Medium Voltage Support group is

responsible for Commissioning Support and activities in our product

line.

They may be contacted at 519-740-4100, request Medium Voltage

Support – Project Manager.

The support they offer includes, but is not limited to:

– Quoting and Managing Product On-site Start-ups.

– Quoting and Managing Field Modification projects.

– Quoting and Managing Customer in-house and on-site

product training.

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 12

P-4 Preface

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 13

Chapter 1

Overview of Drive

Introduction The PowerFlex® 7000 represents the third generation of medium

voltage drives from Rockwell Automation, and is part of the

PowerFlex family of AC drive products. The Allen-Bradley

PowerFlex® family of Drives incorporates leading-edge technology,

embedded communications, and significant commonality across

multiple platforms, networks, operator interface programming and

hardware.

The PowerFlex 7000 is a general purpose stand alone medium

voltage drive that controls speed, torque, direction, starting, and

stopping of standard induction or synchronous AC motors. It is

intended for use on a host of standard and specialty applications such

as fans, pumps, compressors, mixers, conveyors, kilns, and test

stands. Primary industries for these applications include petrochemical,

cement, mining and metals, forest products, power generation, and

water/waste water.

The PowerFlex 7000 is a global product that adheres to the most

common standards from NEC, IEC, NEMA, UL, and CSA. It is

available with the world’s most common supply voltages at medium

voltage, from 2400-6600 volts.

The design focus is on high reliability, ease of use, and lower total

cost of ownership.

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 14

r

1-2 Overview of Drive

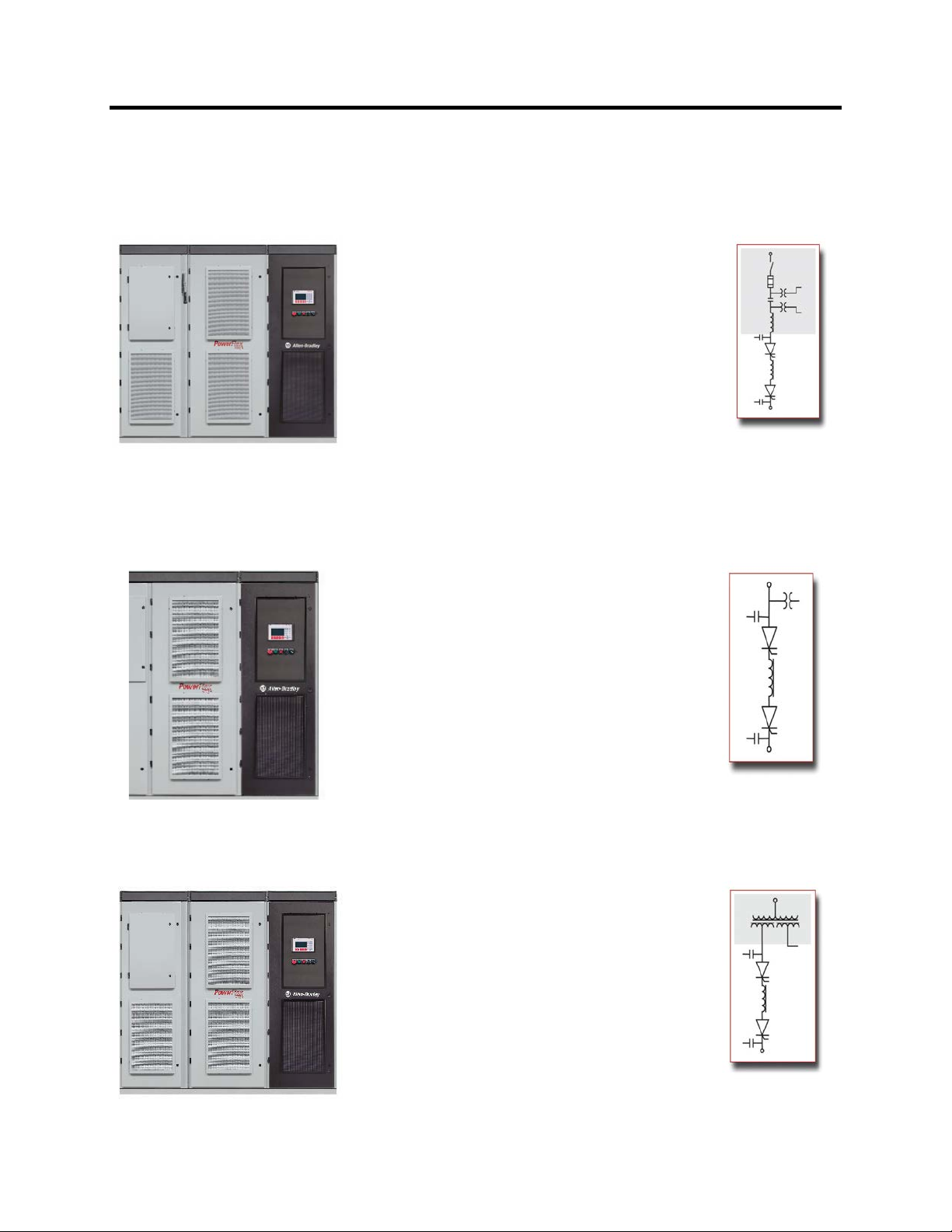

Drive Configurations – PowerFlex 7000 “A” Frame

Configuration #1

Direct-to-Drive

(AFE with DTC DC Link)

Elimination of isolation transformer results in lower

losses and saved space

An integrated system solution for fewer connections

and reduced installation costs

New or existing motors

Small system footprint

3 cables in/3 cables out on entire system for easy

installation

Low line harmonics and high power factor (typical

current THD < 5%, PF > 0.98)

Fan control power and control circuit power

Configuration #2

AFE Rectifier

(Separate isolation transformer)

supplied internally

Input starter optional

Optimum installation flexibility with connection to

indoor or outdoor isolation transformers

Compact packaging for smallest footprint

requirements

New or existing motors

3 cables in/3 cables out for easy installation

Low line harmonics and high power factor (typical

current THD < 5%, PF > 0.98)

Fan control power supplied internally (1-phase

control circuit power supplied by customer,

120V/60 Hz, 110V/50 Hz, 20 amp)

Directto-Drive

(Optional

Input

Starter)

AFE

Rectifier

Configuration #3

AFE Rectifier

(Integral isolation transformer)

An integrated system solution for fewer connections

and reduced installation costs

Small system footprint

New or existing motors

3 cables in/3 cables out for easy installation

Integral cooling fans for VFD and transformer

Low line harmonics and high power factor (typical

current THD < 5%, PF > 0.98)

Fan control power supplied internally (1-phase

control circuit power supplied by customer,

120V/60 Hz, 110V/50 Hz, 20 amp)

Integral

Isolation

Transforme

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 15

Overview of Drive 1-3

L

K

A

Topology

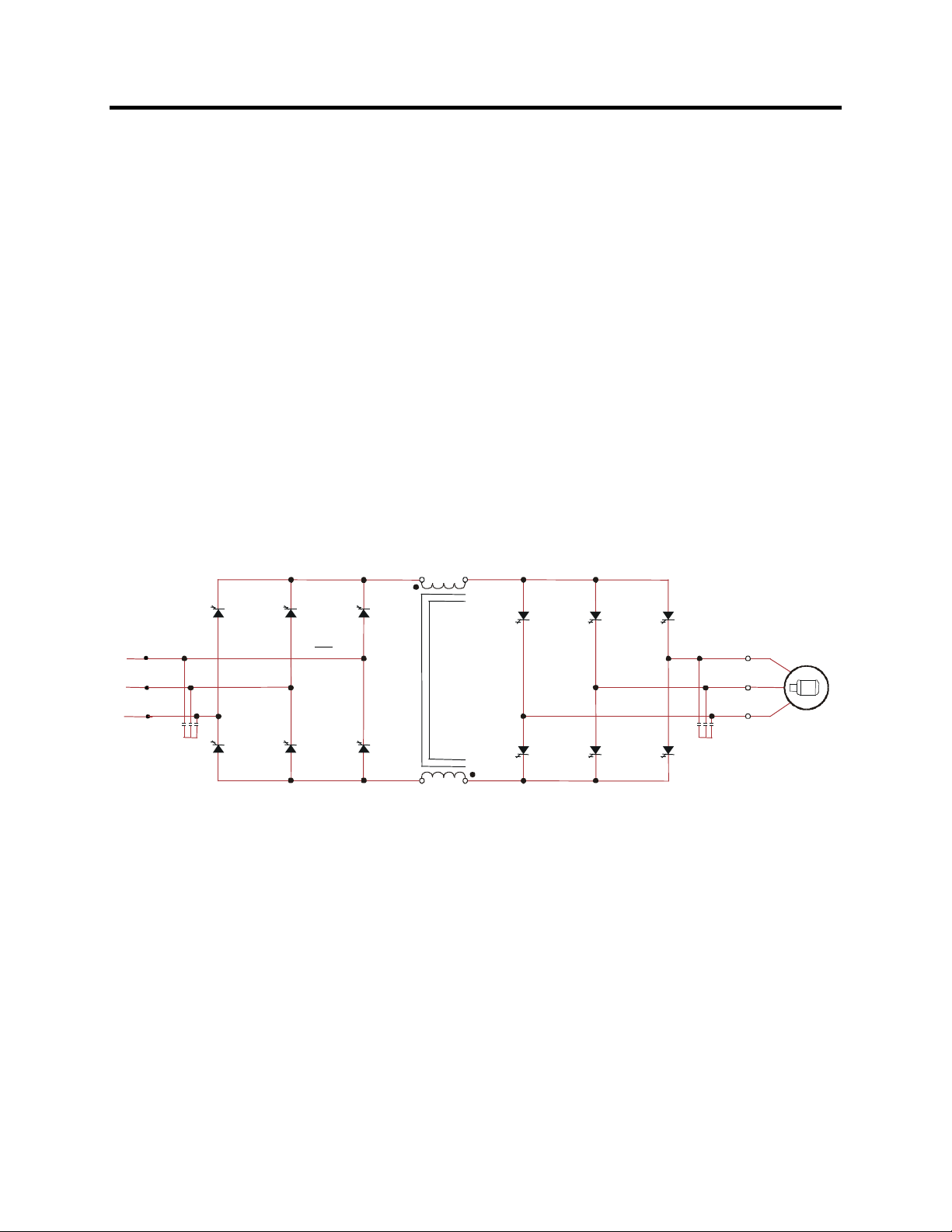

With 6500 volt PIV rated power semiconductor devices, the number

The PowerFlex 7000 has the additional benefit of inherent

The PowerFlex 7000 utilizes a Pulse Width Modulated (PWM) –

Current Source Inverter (CSI) for the machine side converter as shown

in Figure 1.1. This topology offers a simple, reliable, cost-effective

power structure that is easy to apply to a wide voltage and power

range. The power semiconductor switches used are easy-to-series for

any medium voltage level. Semi-conductor fuses are not required for

the power structure due to the current limiting DC link inductor.

of inverter components is kept to a minimum. For example, only six

inverter switching devices are required at 2400V, 12 at 3300-4160V,

and 18 at 6600V.

regenerative braking for applications where the load is overhauling

the motor, or where high inertia loads need to be slowed down

quickly. Symmetrical Gate Commutated Thyristors (SGCTs) are

used for machine converter switches and line converter switches.

M

INE CONVERTER DCLIN

L+

M+

CHINE CONVERTER

2U (X1)

2V (X2)

2W (X3)

SGCTs

L-

M-

SGCTs

U(T1)

V(T2)

W(T3)

Figure 1.1 – PWM-CSI AC Drive

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 16

1-4 Overview of Drive

Rectifier Designs

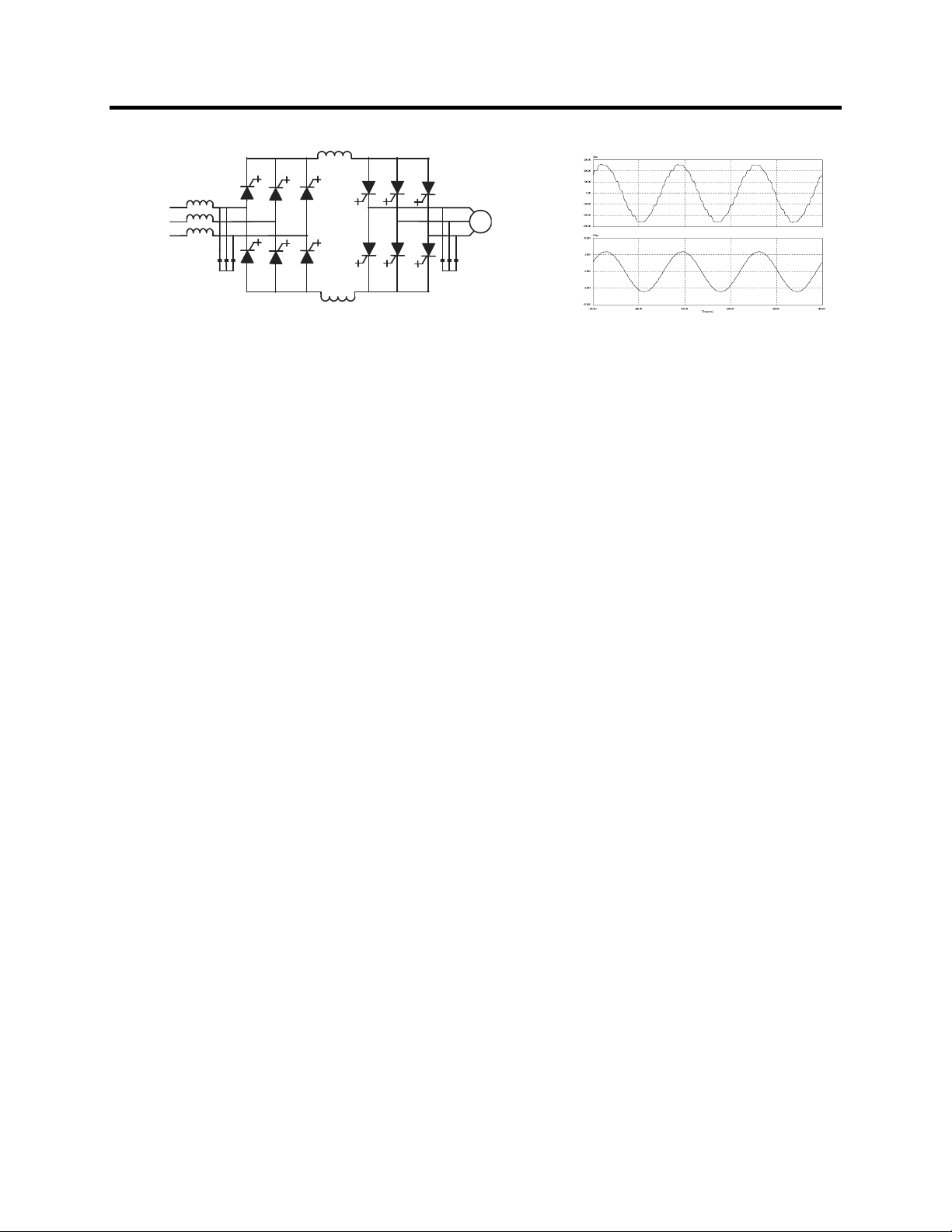

An Active Front-End rectifier is particularly attractive since it does

Many competing technologies in today’s MV market require a multi-

The AFE rectifier requires a switching pattern that complies with

The filter resonant frequency is placed below 300 Hz (for a 60 Hz

The small integral AC line reactor (see Fig. 1.2) provides additional

Active Front-End (AFE) Rectifier

not require an isolation transformer to meet IEEE 519-1992.

winding transformer to mitigate the unwanted harmonics through

cancellation by phase shifting the transformer secondary windings.

Depending on the topology, the transformer can have up to 15 sets of

secondary windings.

Elimination of the isolation transformer reduces capital and

installation costs, saves on valuable floor space, reduces

operating costs and increases overall system efficiency.

similar rules as the inverter. The pattern used for the example shown

in Figure 1.3 is a 42-pulse selective harmonic elimination (SHE)

pattern, which eliminates the 5

th

, 7th and 11th harmonics. The integral

input capacitors are designed to reduce the current harmonics of the

higher order.

system) where no residual harmonics exist. This prevents the

excitation of system harmonic frequencies. Other factors that are

considered when designing the filter are the input power factor and

the requirement on Total Harmonic Distortion (THD) of input

current and voltage waveforms.

filtering and current limiting features to a line side short circuit fault.

The line current and voltage waveforms are also shown in Figure 1.2.

The line current THD is approximately 4.5%, while line-to-line

voltage THD is approximately 1.5%. (THD of line voltage is a

function of system impedance.) Input power factor with the AFE

rectifier is near unity throughout a typical operating speed range for

variable torque loads.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 17

Overview of Drive 1-5

a)

b)

a) Line current

Figure 1.2 – AFE rectifier and its input current/voltage waveforms

b) Line-to-line voltage at PCC

The AFE rectifier can be used in conjunction with a rectifier duty

isolation transformer or with an AC line reactor (as shown in Figure 1.2).

Isolation transformers are available:

1) Integral to the Drive

2) Remote indoor dry type, or

3) Outdoor oil-filled type

This allows for maximum flexibility in dealing with floor space,

installation cost and control room air conditioner loading.

“Direct-to-Drive” Technology Reduce the cost, size and weight of your medium voltage drive

system with the Allen-Bradley PowerFlex 7000 with Direct-to-Drive

technology. This is the first and only technology that allows you to

directly connect a medium voltage drive to utility power without the

requirement of an isolation transformer. Isolation transformers with

multiple secondary windings are required for traditional AC drives to

address line-side harmonic concerns and common mode voltage.

However, typical isolation transformers are large, heavy, costly,

complex and inefficient. Direct-to-Drive technology combines an

Active Front End (AFE) rectifier to dramatically lower line-side

harmonics and a patented DC link inductor to address common mode

voltage at its source. By addressing harmonics and common mode

voltage, the isolation transformer becomes redundant. This reduces

system complexity to maximize uptime and increases system

efficiency to lower operational costs. Exceptional output voltage and

current waveforms, true of our entire product line, make this ideal for

retrofit applications and allow the use of standard motors for new

applications.

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 18

0

A

1-6 Overview of Drive

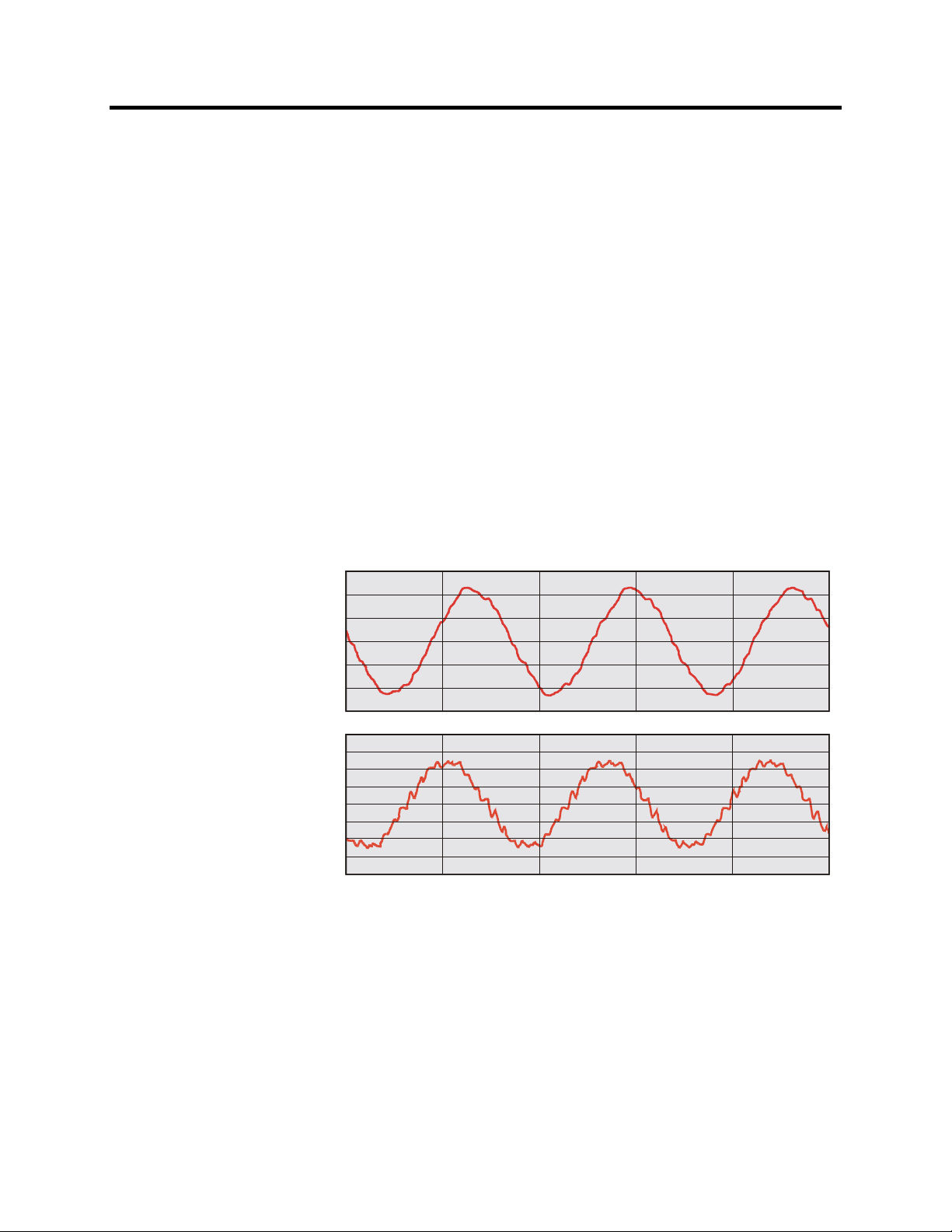

Motor Compatibility The PowerFlex 7000 achieves near sinusoidal current and voltage

waveforms to the motor, resulting in no significant additional heating

or insulation stress. Temperature rise in the motor connected to the

VFD is typically 3 °C (5.4 °F) higher compared to across-the-line

operation. Voltage waveform has dv/dt of less than 10 volts per

microsecond. Reflected wave and dv/dt issues often associated with

VSI (voltage source inverter) drives do not exist with the PowerFlex

7000. Typical motor waveforms are shown in Figure 1.3. These

motor friendly waveforms are achieved by utilizing a selective

harmonic elimination (SHE) pattern in the inverter to eliminate

major order harmonics, in conjunction with a small output capacitor

(integral to the drive) to eliminate harmonics at higher speeds.

Standard motors are compatible without de-rating, even on retrofit

applications.

Motor cable distance is virtually unlimited. This technology is capable

of controlling motors up to 15 km (9.3 miles) away from the drive.

rms

300.00

200.00

100.00

Motor current

Motor voltage

-10.00K

0.00

-100.00

-200.00

-300.00

10.00K

7.50K

5.00K

2.50K

0.00K

-2.50K

-5.00K

-7.50K

Vrms

100.00

110.00

120.00 130.00

TIME (ms)

140.00

150.0

Figure 1.3 – Motor waveform @ full load, full speed

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 19

LIN

ECONVERTERDCLIN

K

M

ACHIN

ECONVERTE

A

1

1

A

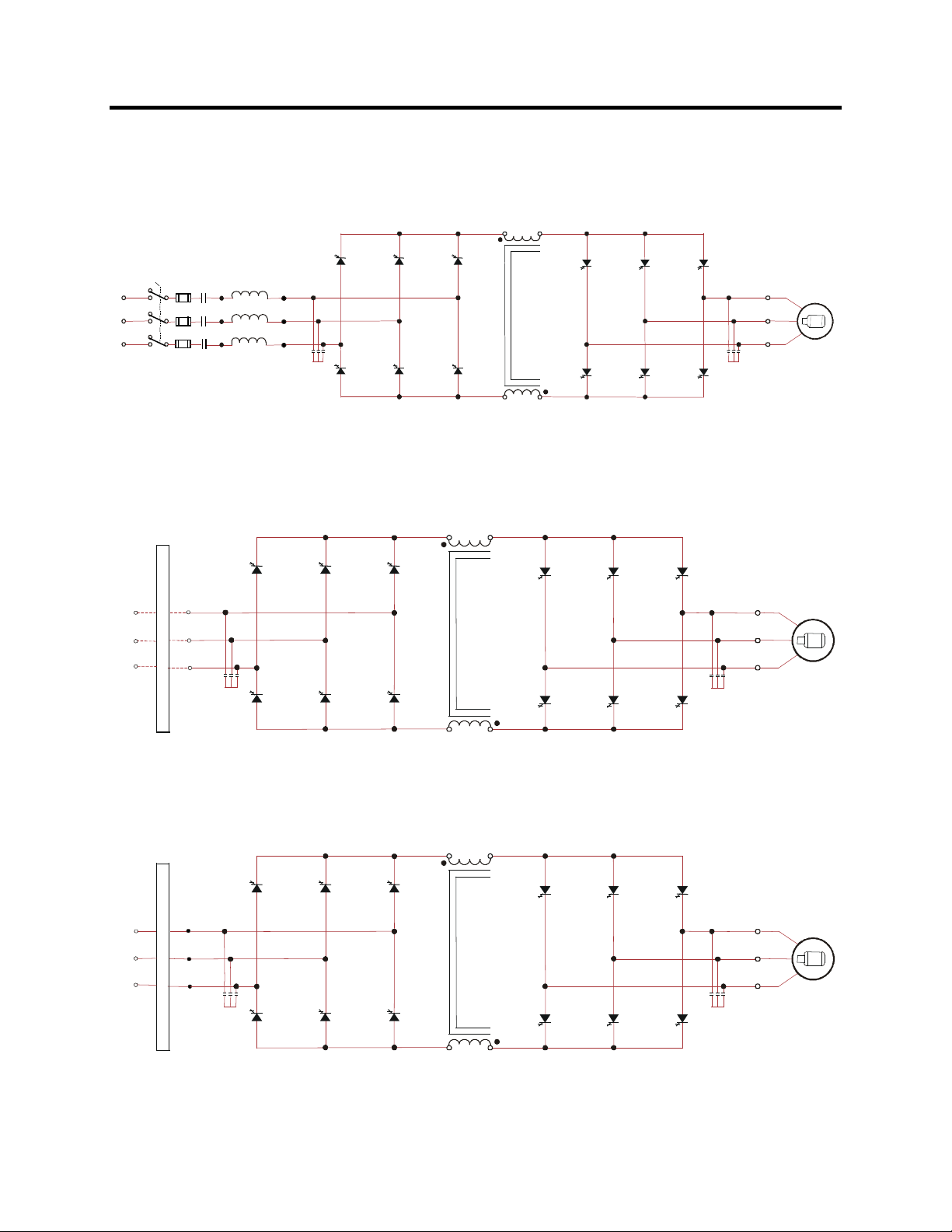

Simplified Electrical Drawings – 2400V with AFE Rectifier

L+

Overview of Drive 1-7

M+

R

SGCTs

L1

L2

L3

LR

L-

M-

2400 Volt – AFE Rectifier, Configuration #1 – Direct-to-Drive

(Configurations without Integral Input Starter are available)

REMOTE

ISTX

1U

1V

W

2U (X1)

2V (X2)

2W (X3)

LINE CONVERTER DC LINK

SGCTs

L+

M+

CHINE CONVERTER

M

SGCTs

SGCTs

U(T1)

V(T2)

W(T3)

U(T1)

V(T2)

W(T3)

L-

M-

2400 Volt – AFE Rectifier, Configuration #2 – Separate Isolation Transformer

INTEGRAL

ISTX

1U

1V

W

2U (X1)

2V (X2)

2W (X3)

LINE CONVERTER DC LINK

SGCTs

L+

M+

L-

M-

CHINE CONVERTER

M

SGCTs

U(T1)

V(T2)

W(T3)

2400 Volt – AFE Rectifier, Configuration #3 – Integral Isolation Transformer

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 20

LIN

ECONVERTERDCLIN

K

M

ACHIN

ECONVERTE

D

C

K

MAC

1

ECONV

ERTERD

C

K

MAC

ECONV

ERTE

1-8 Overview of Drive

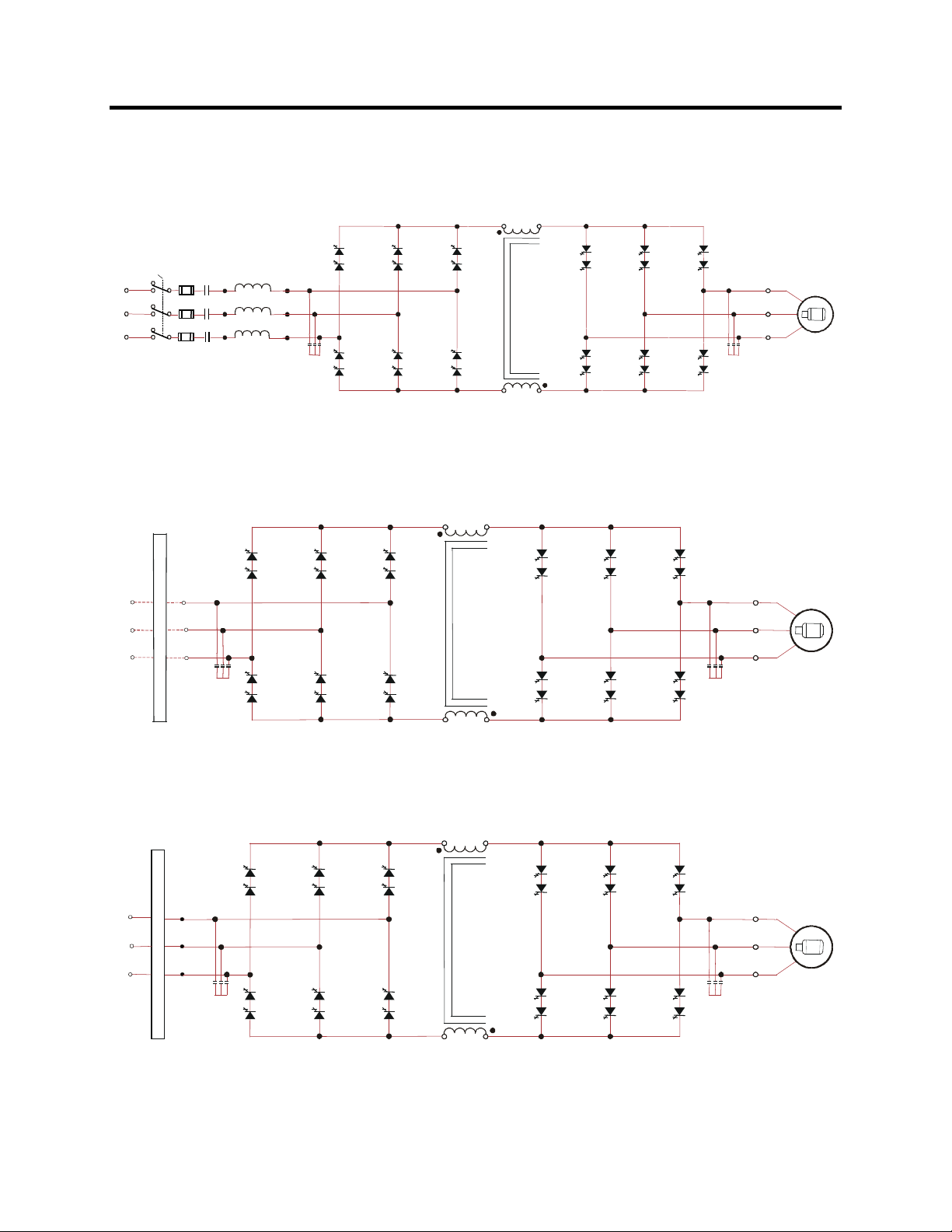

Simplified Electrical Drawings – 3300/4160V with AFE Rectifier

L+

M+

R

SGCTs

L1

L2

L3

LR

L-

M-

SGCTs

3300/4160 Volt – AFE Rectifier, Configuration #1 – Direct-to-Drive

(Configurations without Integral Input Starter are available)

1U

1V

1W

REMOTE

ISTX

2U (X1)

2V (X2)

2W (X3)

LINECONVERTER

SGCTs

LIN

L+

M+

HINECONVERTER

SGCTs

U(T1)

V(T2)

W(T3)

U(T1)

V(T2)

W(T3)

L-

M-

3300/4160 Volt – AFE Rectifier, Configuration #2 – Separate Isolation Transformer

INTEGRAL

ISTX

LIN

SGCTs

1U

1V

W

2U (X1)

2V (X2)

2W (X3)

LIN

L+

M+

L-

M-

SGCTs

HIN

R

U (T1)

V (T2)

W (T3)

3300/4160 Volt – AFE Rectifier, Configuration #3 – Integral Isolation Transformer

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 21

LIN

ECONVERTERDCLIN

K

M

ACHIN

ECONVERTE

D

C

K

MAC

NECONVE

RTERD

CLIN

K

ACHINECONVE

RTE

R

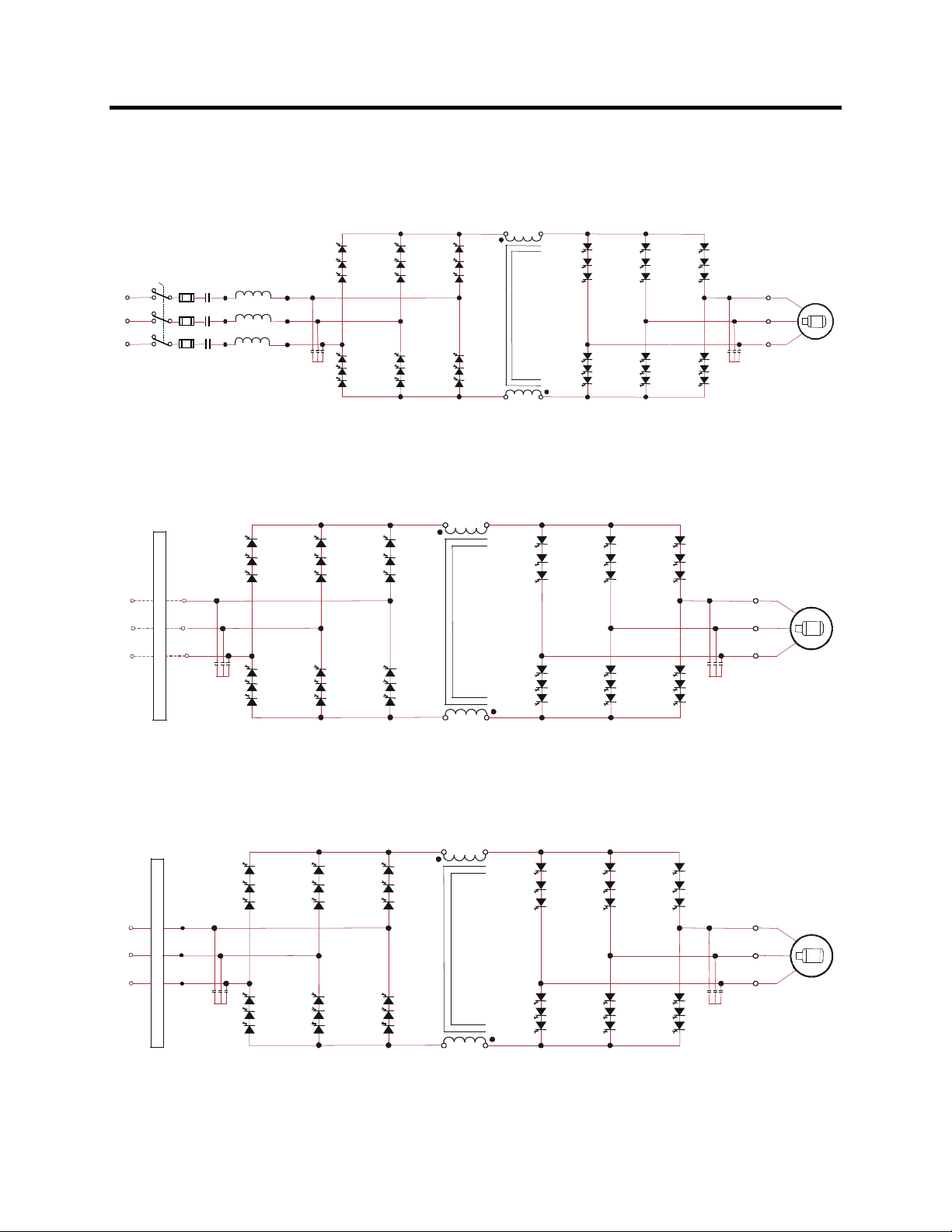

Simplified Electrical Drawings – 6600 V with AFE Rectifier

L+

M+

SGCTs

Overview of Drive 1-9

R

SGCTs

L1

L2

L3

LR

L-

M-

6600 Volt – AFE Rectifier, Configuration #1 – Direct-to-Drive

(Configurations without Integral Input Starter are available)

HINECONVERTER

SGCTs

1U

1V

1W

REMOTE

ISTX

LINECONVERTER

SGCTs

2U (X1)

2V (X2)

2W (X3)

LIN

L+

M+

L-

M-

6600 Volt – AFE Rectifier, Configuration #2 – Separate Isolation Transformer

INTEGRAL

ISTX

LI

SGCTs

L+

M+

M

SGCTs

U(T1)

V(T2)

W(T3)

U (T1)

V(T2)

W(T3)

1U

1V

1W

2U (X1)

2V (X2)

2W (X3)

L-

M-

U(T1)

V(T2)

W(T3)

6600 Volt – AFE Rectifier, Configuration #3 – Integral Isolation Transformer

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 22

1-10 Overview of Drive

Operator Interface

Figure 1.4 – PowerFlex 7000 Operator interface terminal

The operator interface terminal features a 16-line, 40-character, pixel

based LCD display that makes text and graphics easy to read. Bar

chart meters are configurable for common process variables

including speed, voltage and load.

Everything is user friendly about the PowerFlex 7000 operator interface

terminal including the greeting on the opening screen. The terminal

is designed for the greatest ease of use for start-up, monitoring and

troubleshooting. The setup wizard helps the user to set the required

parameter menus by asking questions or prompting selections for

desired operation. Warnings and comments appear complete with

help text to keep the user on the right track. The setup wizard combined

with the auto-tuning feature allows the drive to be tuned to the motor

and load as quickly and accurately as possible, resulting in fast startups, smooth operation, and less down time.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 23

Chapter 2

Drive Installation

Safety and Codes

W A R N I N GW A R N I N G

General Handling Procedures Refer to “General Handling Procedures for PowerFlex 7000 Medium

Voltage Drives”, publication no. 7000-IN002_-EN-P supplied in the

drive shipment (affixed to the drive). Additional copies can be

ordered through your local Rockwell Automation Sales office.

Drive Storage If it is necessary to store the drive, be certain to store in a clean dry

dust free area.

Storage temperature should be maintained between -40°C and 70°C

(-40°F and 185°F). If storage temperature fluctuates or if humidity

exceeds 95%, space heaters should be used to prevent condensation.

The drive should be stored in a heated building having adequate air

circulation. The drive must never be stored outdoors.

The Canadian Electrical Code (CEC), National

Electrical Code (NEC), or local codes outline

provisions for safely installing electrical

equipment. Installation MUST comply with

specifications regarding wire type, conductor

sizes, branch circuit protection and disconnect

devices. Failure to do so may result in personal

injury and/or equipment damage.

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 24

2-2 Drive Installation

Siting of the Drive Site Considerations

The standard environment in which the equipment is designed to

operate is:

• Elevation above sea level less than 1000 meters (3250 feet)

• Ambient air temperature between 0°C (32°F) and 40°C (104°F)

• Relative humidity of the air not to exceed 95% non-condensing

For the equipment to operate in conditions other than those specified

consult the local Rockwell Automation Sales office.

The equipment requires the following site conditions:

(A) Indoor installation only, no dripping water or other fluids

(B) Clean air for cooling requirements

(C) Level floor for anchoring the equipment. Refer to dimension

drawings for the location of the anchoring points.

(D) The room in which the equipment is located must allow for full

opening of the doors of the equipment, typically 1200 mm

(48 inches). Also, allowances have to be made for clearance

for fan removal. This fan allowance must be greater than 700

mm (27.5 inches) above the drive.

or

Dimension drawings can be obtained by contacting the local

Rockwell Automation Sales office. The equipment does not

require rear access for servicing.

(E) Allowance must be made for the stream of cooling air which

exits the drive at the top. The flow of cooling air into and out

the drive must be kept clear and uninhibited.

(F) The room in which the equipment is located must be large

enough to accommodate the thermal losses of the equipment

since air conditioning may be required; the ambient

temperature must not exceed that for which the equipment is

rated. The heat created by the drive is directly proportional to

the power of the motor being driven and the efficiency of

equipment within the room. If thermal load data is required

contact the Rockwell Automation Sales office.

(G) The area in which the drive is located should be free of radio

frequency interference such as encountered with some welding

units. This may cause erroneous fault conditions and shut

down the drive.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 25

Drive Installation 2-3

(H) The equipment must be kept clean. Dust in the equipment

decreases system reliability and inhibits cooling.

(I) Power cable lengths to the motor are virtually unlimited due to

the near sinusoidal voltage and current waveforms. Unlike

voltage source drives, there are no capacitive coupling, dv/dt,

or peak voltage issues that can damage the motor insulation

system. The topology utilized in the PowerFlex 7000 medium

voltage AC drive does not produce dv/dt or peak voltage

problems, and has been tested with motors located up to 15

kilometers from the drive.

(J) Only personnel familiar with the function of the drive should

have access to the equipment.

(K) The drive is designed for front access and should be installed

with adequate and safe clearance to allow for total door

opening. The back of the unit may be placed against a wall

although some customers prefer back access also.

A T T E N T I O NA T T E N T I O N

Generator Note:

A T T E N T I O NA T T E N T I O N

An incorrectly applied or installed drive can

result in component damage or a reduction in

product life. Ambient conditions not within

the specified ranges may result in

malfunction of the drive.

Verify that the load is not turning due to the

process. A freewheeling motor can generate

voltage that will be back-fed to the equipment

being worked on.

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 26

2-4 Drive Installation

Installation When the drive has been placed at its installation area, the lag bolts

that fasten the shipping skid to the drive must be removed. The drive

is moved off the shipping skid and the shipping skid can be

discarded.

Position the drive in its desired location. Verify that the drive is on a

level surface and that the position of the drive will be vertical when

the anchor bolts are installed.

The location of the anchor points is provided with the dimension

drawing of the drive.

Install and tighten the anchor bolts. (M12 or ½” hardware required).

Engineering bolt systems are required for seismic requirements.

Consult factory.

Remove the top lifting angles, retain the hardware.

Install the hardware from the lifting angles in the tapped holes at the

top of drive; this prevents leakage of cooling air as well as keeping

dust out of the equipment.

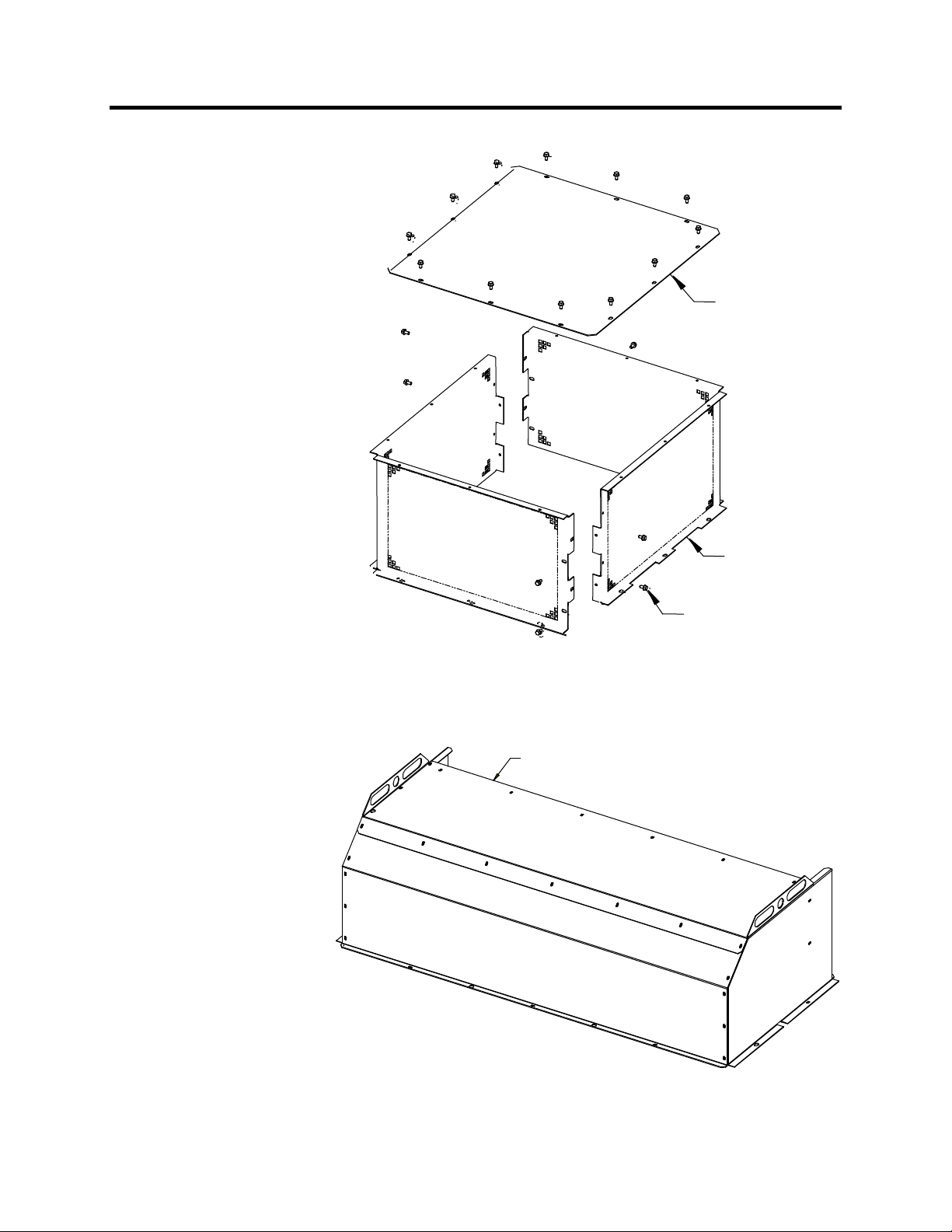

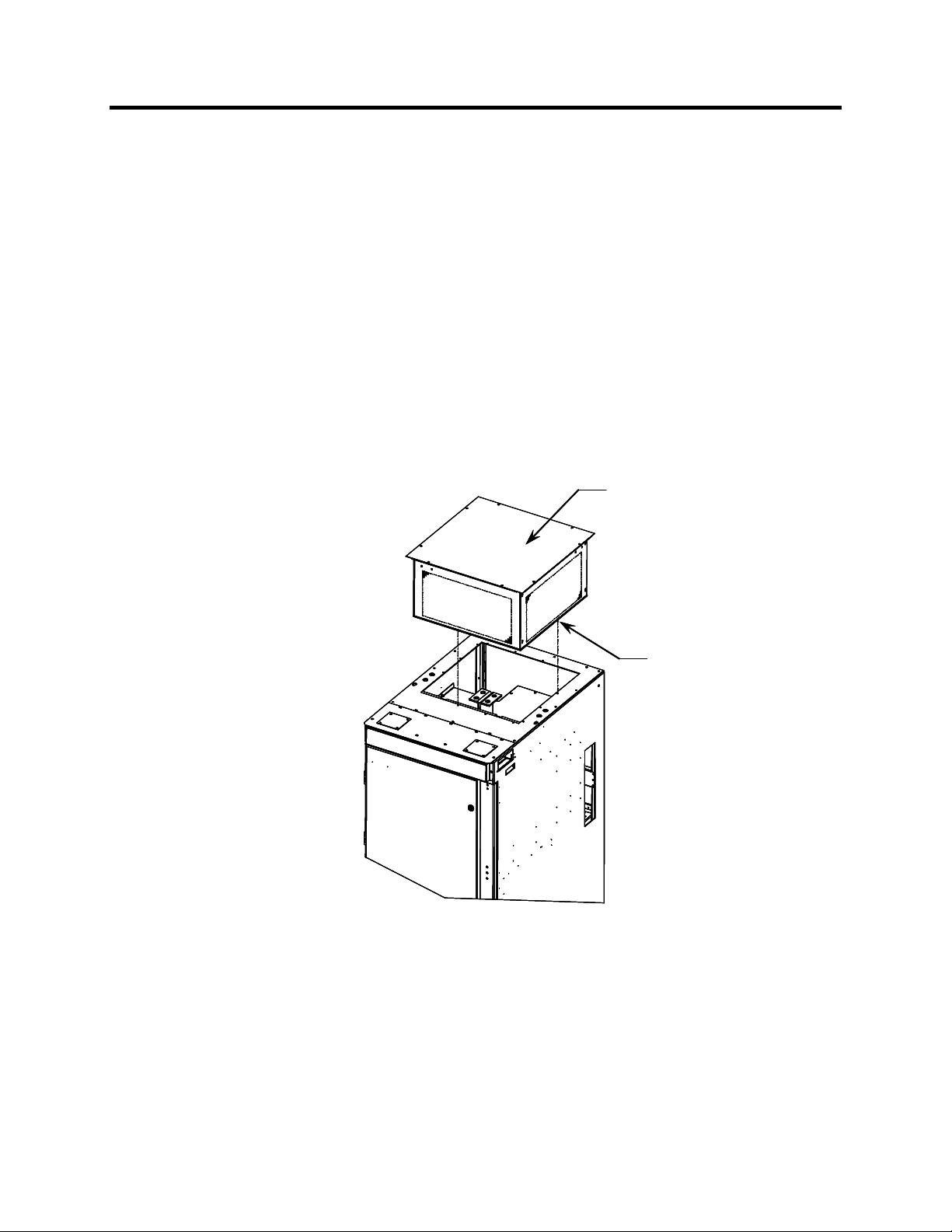

Installation of Exhaust Air Hood

On the top of the cabinet with the cooling fan, a sheet metal exhaust

hood is to be installed. The components to make up the exhaust

hood have been packaged and shipped with the drive. (For drives

with an acoustic hood, the components are shipped assembled. See

Figure 2.2)

The first step is to remove the protective plate covering the fan

opening on the drive. It is a flat cover plate bolted to the top plate.

Remove the bolts and plate and set aside for re-use.

Secondly, loosely assemble the two L-shaped panel components

shipped with the drive as per Figure 2.1.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 27

Drive Installation 2-5

Flat plate

(Quantity = 1)

Figure 2.1 – Fan Hood Assembly

All the components are shipped assembled.

Exhaust hood panels

(Quantity = 2)

M6 thread forming screws

(Quantity = 20)

Figure 2.2 – Acoustic Fan Hood Assembly

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 28

2-6 Drive Installation

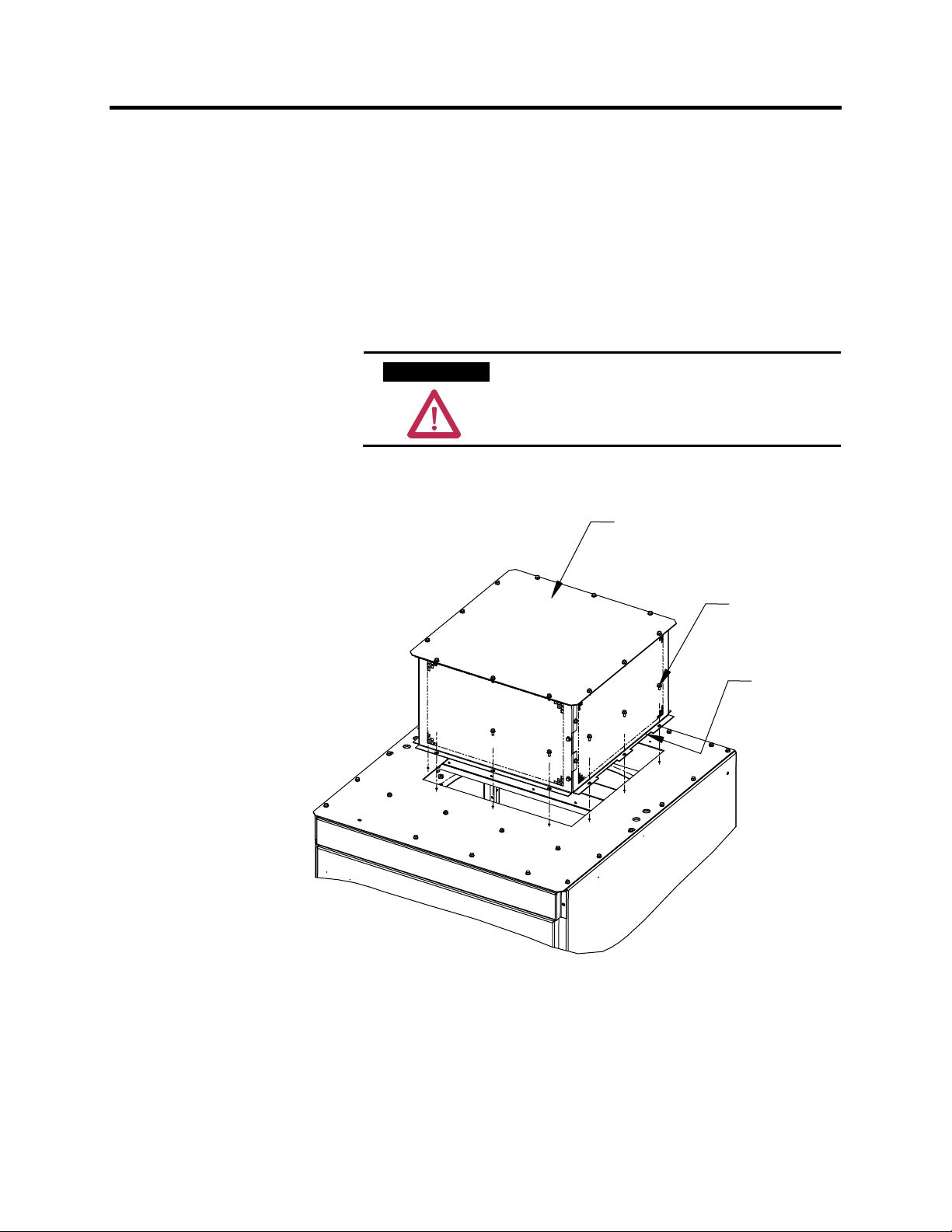

Installation (cont.) Locate the exhaust hood on top of the cabinet per Figure 2.3 and re-

install the original cover plate previously set aside. (Care must be

taken that the notches on the bottom flange are oriented toward the

sides of the drive). Affix assembly to the drive top plate. Tighten all

hardware.

For drives with an acoustic hood (shown in Figure 2.2), locate the

exhaust hood (refer to Figure 2.4).

A T T E N T I O NA T T E N T I O N

Any screws that are accidentally dropped in

the equipment must be retrieved as damage

or injury may occur.

Assembled Exhaust Hood

M6 Screw

(Quantity = 12)

Ensure notch

orientation

to sides

Figure 2.3 – Fan Hood Installation

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 29

w

Drive Installation 2-7

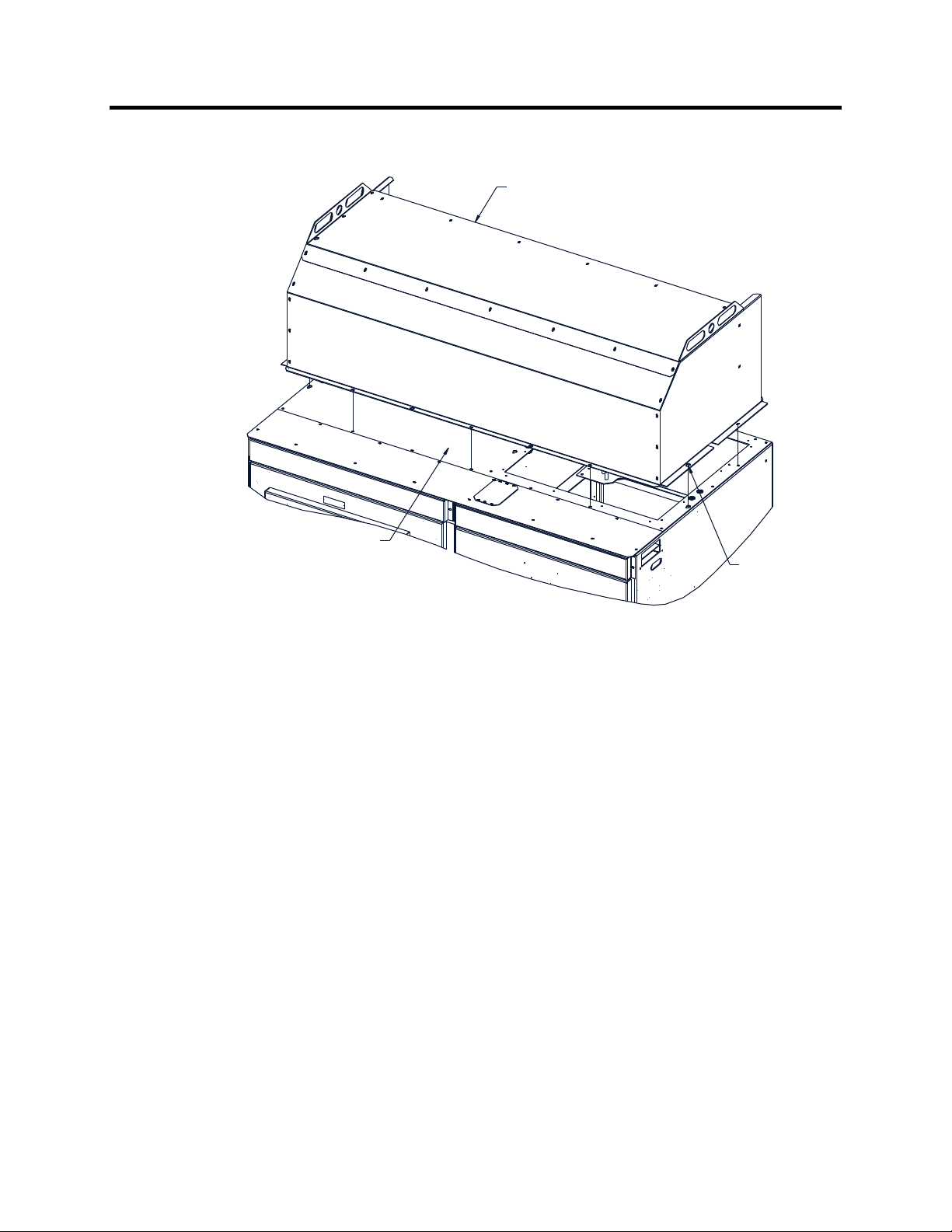

Assembled Acoustic

Exhaust Hood

Top Plate for Converter

and Common Mode Choke/

DC Link Cabinet

Figure 2.4 – Acoustic Fan Hood Installation

M6 Screw.

Remove Existing Scre

and reinsert with Hood.

(Quantity = 11)

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 30

2-8 Drive Installation

Installation (cont.) Installation of Integral Transformer Cooling Fan

1. Remove the protective plate covering the fan opening on the top

of Isolation Transformer cabinet and discard.

2. Locate the cooling fan on top of the cabinet. Position it over the

opening and align the mounting holes and wire harness

connections.

3. Affix the fan to the drive top plate with the M6 thread forming

screws provided.

4. Connect the fan wire harness to fan.

Assembled Exhaust Hood

Assembled Exhaust Hood

M6 Screw

M6 Screw

(Qty = 12)

(Qty = 12)

Figure 2.5 – Fan Installation for Integral Isolation Transformer

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 31

T

T

r

A

Drive Installation 2-9

Neutral Resistor Assembly

op Plate for Neutral

Resistor Housing

Ground Resistor

Hood here

op Plate for Converter

and Common Mode

Choke Cabinet

900 mm Converter –

800 mm Common Mode Choke Cabinet

ttach ground

to top plate

Line Filter

Capacitors

Neutral Resistor Assembly

Refer to Electrical Dra wings

to veri fy cable rating

to connect neutral

resistor assembly.

Motor Filte

Capacitors

Figure 2.6 – Hood Assembly for Neutral Resistor

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 32

2-10 Drive Installation

Assembled Acoustic

Exhaust Hood

Hood Ground Stud

Remove existing screw

and reinsert with Hood.

Ground Exhaust Hood here.

(Use Green M6 Screw)

M6 Screw.

(Quantity = 11)

M6 Screw

(Quantity = 6)

Neutral Resistor Assembly

Top Plate for Converter

and Common Mode

Choke/DC Link Cabinet

Figure 2.7 – Acoustic Hood Assembly for Neutral Resistor

Installation of Neutral Resistor Assembly

(Drives with Common Mode Chokes)

On top of the converter cabinet, a sheet metal enclosure containing

power resistors is to be installed.

1. Locate the resistor assembly on top of the cabinet as shown in

Figure 2.6. (For acoustic hood assembly, refer to Figure 2.7.)

2. Affix the assembly to the top plate using M6 thread forming

screws provided.

3. Remove the top plate of the resistor assembly to permit access to

the wiring connection points.

4. Connect the resistor wiring and per the electrical diagram

provided with the drive, a typical connection diagram is shown

in Figure 2.6. Ensure that the resistor wiring is routed through

the hole having a plastic bushing to protect the wire insulation.

The neutral resistor assembly housing has a ground connection

that is to be connected to the top plate of the drive.

5. Re-install the top plate of the neutral resistor housing.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 33

Drive Installation 2-11

Cabinet Layout and

Dimensional Drawings

of Drive

The following dimension drawing is a sample and may not accurately

detail your drive. It is provided here to give you a general overview

of a typical drive.

The Dimensional Drawings are order specific and will show the

information outlined.

The dimension drawing provides important information for the

installation of the equipment.

The FLOOR PLAN shows:

• the locations for anchoring the equipment to the floor (balloon D)

• size and location of openings for bottom power cable entry

(balloons A and B)

• size and location of openings for bottom control wiring entry

(balloon C)

The ROOF PLAN shows:

• size and location of openings for top power cable entry (balloons

A and B)

• size and location of openings for top control wiring entry

(balloon C)

• minimum aisle clearance in front of equipment (balloon M)

The Front View shows:

• minimum clearance required at top of drive for fan maintenance

(balloon K)

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 34

2-12 Drive Installation

PowerFlex 7000 “A” Frame Dimensional Drawing

SAMPLE

Note: Contact Factory for Seismic Mounting Information.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 35

Drive Installation 2-13

Drive Layout The following diagrams are presented to show the typical layout of

the three main configurations of the PowerFlex 7000 “A” Frame Drive.

Configuration #1

Direct-to-Drive

(AFE with DTC DC Link)

Line Reactor/Starter

Cabling Catinet

Converter Cabinet Control/DC Link/Fan Cabinet

Figure 2.8 – Direct-to-Drive (AFE with DTD DC Link)

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 36

2-14 Drive Installation

Configuration #2

AFE Rectifier

(Separate Isolation Transformer)

Cabling Cabinet Converter Cabinet Control/DC Link/Fan Cabinet

Figure 2.9 – AFE Rectifier (Separate Isolation Transformer)

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 37

Configuration #3

AFE Rectifier

(Integral Isolation Transformer)

Drive Installation 2-15

Isolation Transformer

and Cabling Catinet

Converter Cabinet Control/DC Link/Fan Cabinet

Figure 2.10 – AFE Rectifier (Integral Isolation Transformer)

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 38

C

2-16 Drive Installation

Cabling Cabinet #1 The cabling cabinet of the drive with integral line reactor and input

starter is located in the left-hand section. The mounting and location

of the line reactor and input starter are shown along with customer

cable termination locations. The circulating fans for the cabinet are

Note: This cabinet is also available without integral starter (see

located on top.

Figure 2.13). The width of the cabinet changes as a function of the

drive voltage ratings.

Line Cable Terminations

(behind Disconnect Switch)

Fused Disconnect Switch

ontrol Power Transformer

Motor Cable Terminations

(Hall Effect Sensors behind)

Disconnect Switch Operating Handle

Vacuum Contactor Assembly

Control Power Transformer Fuses

AC Line Reactor

Figure 2.11 – Cabling Cabinet for Configuration #1 with Input Starters

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 39

s

Cabling Cabinet #1

Line Cable

Terminations

Drive Installation 2-17

Low Voltage

Compartment

Hall Effect Sensor

Current

Transformers

Control Power

Transformer Fuses

Motor Cable

Terminations

AC Line Reactor

Figure 2.12 – Cabling Cabinet for Configuration #1 without Input Starters

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 40

r

2-18 Drive Installation

Cabling Cabinet #2

Cabling cabinet #2 is located in the left hand section and shows the

medium voltage area for customer cable terminations, three phase

fan power transformer, and fuse assemblies for transformer.

Low Voltage Wireway

Current Transformer

Line Terminals

Current Transformer

Control Power

Transformer Fuses

Hall Effect Sensor

Motor Cable Terminations

Hall Effect Sensor

Fan Control Power Transforme

Figure 2.13 – Cabling Cabinet for Configuration #2

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 41

Drive Installation 2-19

Bac

F

u

sin

g

Cabling Cabinet #3 The cabling cabinet of the drive with integral isolation transformer is

located in the left-hand section. The mounting and location of the

isolation transformer is shown along with customer cable termination

locations. The cooling fan for the isolation transformer is located on top.

an Ho

Top Cable Entry

and Exit locations

Ground Bus

Hall Effect Sensors

Line Terminals

Load Terminals

Current Transformers

(CT)

Integral Isolation

Transformer

k)

(

Side View Front View

(Front)

Bottom Cable Entry

and Exit locations

Figure 2.14 – Cabling Cabinet for Configuration #3

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 42

2-20 Drive Installation

Converter Cabinet The converter cabinet for all configurations of the PowerFlex 7000

“A” Frame drive is located in the middle section. The mounting and

location of Inverter / rectifier modules are shown along with gate

drive power supplies and voltage sensing modules.

Note: The width of the inverter / rectifier modules changes as a

function of the drive voltage ratings (2400-6600V).

Inverter Modules

Isolated Gate Drive

Power Supplies

(IGDPS)

Rectifier Modules

Voltage Sensing Boards

Figure 2.15 – Major Components of the Converter Cabinet

(3300/4160V version shown)

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 43

Drive Installation 2-21

Control / DC Link / Fan

The control / DC link / fan cabinet for all configurations of the

Cabinet

Note: The control / DC link / fan cabinet has the same layout for all

PowerFlex 7000 “A” Frame drive is located in the right section. The

mounting and location of the DC link inductor, line / load side

capacitors, and main cooling fan are shown behind the low voltage

control tub.

drives at 2400-6600 volt ratings.

Fan

Inlet Ring

DC Link

Inductor

Grounding

Network

Capacitors

Motor Filter

Capacitor

Line Filter Capacitor

Figure 2.16 – Major Components of Control / DC Link / Fan Cabinet

(with low voltage control tub removed)

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 44

y

2-22 Drive Installation

The low voltage control tub is mounted in front of the DC link

Low Voltage Control Tub

(Located in Control / DC Link /

Fan Cabinet)

inductor in DC link / fan cabinet of the drive. Refer to Chapter 6,

Component Definition and Maintenance, for complete content details

of the low voltage section.

Note: The low voltage control tub has the same layout for all

PowerFlex 7000 “A” Frame drive ratings.

AC to DC

Pioneer

Power Suppl

Analog

Control

Board

Drive

Processor

Module

Board

Hinged

Panel

(Closed)

Fiber Optic

Interface

Boards

DC to DC

Power Supply

Hinged Panel (Open)

Figure 2.17 – Location of Low Voltage Control Tub (Pioneer Power Supply)

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 45

y

Drive Installation 2-23

AC to DC

Cosel

Power Suppl

Analog

Control

Board

Drive

Processor

Module

Board

Hinged

Panel

(Closed)

Fiber Optic

Interface

Boards

DC to DC

Power Supply

Hinged Panel (Open)

Figure 2.18 – Location of Low Voltage Control Tub (Cosel Power Supply)

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 46

2-24 Drive Installation

IEC Component and

PowerFlex 7000 electrical drawings use conventions that are based

Device Designations

on IEC (International Electrotechnical Commission) standards, while

remaining basically compatible with North American ANSI

(American National Standards Institute) standards. The symbols

used to identify components on the drawings are international and a

full listing of the symbols is given as part of each PowerFlex 7000

electrical drawing (ED) set. The device designations used on the

drawings and labeling are also listed with explanations on each

drawing set.

Wiring identification uses a source/destination wire number

convention on point to point multi-conductor wiring and in situations

where the system is warranted. The wire-numbering system of

unique, single numbers for multi-drop and point to point wiring

continues to be used for general control and power wiring. Wiring

that connects between the sheets or that ends at one point and starts

at another point on a drawing has an arrow and drawing reference to

indicate the ongoing connection. The drawing reference indicates

the sheet and the X/Y coordinates of the continuation point. The

reference system is explained on a sheet in each drawing set. The

unique wire numbering system serves as confirmation that the

correct wire is being traced from sheet to sheet or across a drawing.

Wires in multi-conductor cables are typically identified by color

rather than by number. The abbreviations used to identify the colors

on the drawings are fully identified on a sheet in the drawing set.

Power Wiring Selection The following tables identify general wire selections that will be

encountered when installing the PowerFlex 7000 “A” Frame drive

line-up.

General Notes:

Adherence to the following recommended field power cabling

insulation levels for medium voltage drives will help to ensure

trouble-free start-up and operation. The cable insulation level must

be increased over that which would be supplied for an Across-theline application with the same rated line to line voltage.

Either shielded or unshielded cable may be used based on the criteria

considered by the distribution system designer. However, NEC

requires shielded cables for installations above 2 kV.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 47

Drive Installation 2-25

Cable Insulation

The cable insulation requirements for the PowerFlex 7000 “A”

Frame drive are given in the tables below.

A T T E N T I O NA T T E N T I O N

Voltage ratings shown in the following

tables are peak line-to-ground. Some cable

manufacturers rate voltage line-to-line RMS.

Ensure the cable meets the rating specified

in the following tables.

Cable Insulation Requirements for AFE Drives with Separate Isolation Transformer

System Voltage (V, RMS)

Cabling from secondary side of Isolation Transformer to input of VFD

Cable Insulation Requirements for “Direct-to-Drive” Technology or Integral

Isolation Transformer

System Voltage (V, RMS)

2400

3000

3300

4160

6000

6300

6600

2400

3000

3300

4160

6000

6300

6600

Cable Insulation Rating (kV)

(Maximum Peak Line-to-Ground)

Machine Side

≥ 4.1 ≥ 2.2

≥ 5.12 ≥ 2.75

≥ 5.63 ≥ 3.0

≥ 7.1 ≥ 3.8

≥ 10.8 ≥ 5.5

≥ 11.4 ≥ 5.8

≥ 11.8 ≥ 6.0

Cable Insulation Rating (kV)

(Maximum Peak Line-to-Ground)

Line Side Machine Side

≥ 2.2 ≥ 2.2

≥ 2.75 ≥ 2.75

≥ 3.0 ≥ 3.0

≥ 3.8 ≥ 3.8

≥ 5.5 ≥ 5.5

≥ 5.8 ≥ 5.8

≥ 6.0 ≥ 6.0

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 48

A

2-26 Drive Installation

The following table identifies general wire categories that will be encountered when installing the

PowerFlex 7000 “A” Frame Drive. Each category has an associated wire group number that is used in the

following sections to identify the wire to be used. Application and signal examples along with the

recommended type of cable for each group are provided. A matrix providing the recommended minimum

spacing between different wire groups run in the same tray or separate conduit is also provided.

For Tray: Recommended spacing between different wire groups in the same tray.

Wire

Category

Power

Control

Signal

Wire

Group

Application

1

2

3

4

5

6

AC Power

(> 600V AC)

AC Power

(TO 600V AC)

115V AC

or 115V DC

Logic

115V AC

Between

Power

24V AC

or 24V DC

Logic

Analog Signals

DC Supplies

Digital

(Low Speed)

Digital

(High Speed)

Signal

Example

2.3 kV, 3∅

AC Lines

480V, 3∅

Relay Logic

PLC I/O

Power Supplies

Instruments

PLC I/O

5-24V DC

Supplies

Power Supplies

TTL Logic Level

Pulse Train

Input

Tachometer

PLC

Communications

Recommended

Cable

Per IEC / NEC

Local Codes and

Application

Requirements

Per IEC / NEC

Local Codes and

Application

Requirements

Per IEC / NEC

Local Codes and

Application

Requirements

Per IEC / NEC

Local Codes and

Application

Requirements

Belden 8760

Belden 8770

Belden 9460

Belden 8760

Belden 9460

Belden 9463

Belden 8760 - 18 AWG, twisted pair, shielded

Belden 8770 - 18 AWG, 3-conductor, shielded

Belden 9460 - 18 AWG, twisted pair, shielded

Belden 9463 - 24 AWG, twisted pair, shielded

Note 1: Steel conduit or cable tray may be used for all PowerFlex 7000 “A” Frame Drive power or control wiring, and steel conduit is required for all PowerFlex

7000 “A” Frame Drive signal wiring. All input and output power wiring, control wiring or conduit should be brought through the drive conduit entry holes of the

enclosure. Use appropriate connectors to maintain the environmental rating of the enclosure. The steel conduit is REQUIRED for all control and signal circuits,

when the drive is installed in European Union countries. The connection of the conduit to the enclosure shall be on full 360 degree and the ground bond at the

junction shall be less than 0.1 ohms. In EU countries this is a usual practice to install the control and signal wiring.

Note 2: Spacing between wire groups is the recommended minimum for parallel runs of 61 m (200 feet) or less.

Note 3: The customer is responsible for the grounding of shields. On drives shipped after November 28/02, the shields are removed from the drive boards. On

drives shipped prior to November 28/02, all shields are connected at the drive end and these connections must be removed before grounding the shield at the

customer end of the cable. Shields for cables from one enclosure to another must be grounded only at the source end cabinet. If splicing of shielded cables is

required, the shield must remain continuous and insulated from ground.

Note 4: AC and DC circuits must be run in separate conduits or trays.

Note 5: Voltage drop in motor leads may adversely affect motor starting and running performance. Installation and application requirements may dictate that

larger wire sizes than indicated in IEC / NEC guidelines are used.

Table 2.A – Wire Group Numbers

For Conduit: Recommended spacing for wire groups in separate conduit – mm (inches).

Wire

Group

In

Tray

Between

Conduit

In

Tray

Between

Conduit

In

Tray

Between

Conduit

In

Tray

Conduit

Power 1 Power 2 Control3 Control4 Signal5 Signal

228.6

(9.00)

228.6

(9.00)

228.6

(9.00)

228.6

(9.00)

ll signal wiring must be run in separate steel conduit.

A wire tray is not suitable.

The minimum spacing between conduits containing different

wire groups is 76.2 mm (3 inches).

228.6

(9.00)

Between Conduit

228.6

(9.00)

Between Conduit

152.4

(6.00)

Between Conduit

152.4

(6.00)

Between Conduit

228.6

(9.00)

76.2 (3.00)

152.4

(6.00)

76.2 (3.00)

228.6

(9.00)

76.2 (3.00)

152.4

(6.00)

76.2 (3.00)

228.6

(9.00)

152.4

(6.00)

152.4

(6.00)

228.6

(9.00)

6

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 49

Drive Installation 2-27

The wire sizes must be selected individually, observing all applicable

safety and CEC, IEC or NEC regulations. The minimum permissible

wire size does not necessarily result in the best operating economy.

The minimum recommended size for the wires between the drive and

the motor is the same as that used with an across-the-line starter.

The distance between the drive and motor may affect the size of the

conductors used.

Consult the wiring diagrams and appropriate CEC, IEC or NEC

regulations to determine correct power wiring. If assistance is

needed, contact your local Rockwell Automation Sales Office.

Power Cabling Access The drive is built with provision for either the top or bottom power

cable entry.

Cable access plates are provided on the top and bottom plates of the

connection cabinet identified by the customer specific dimension

drawing (DD).

To access the customer power cable terminations

Cable connections are located behind the medium voltage door of the

Connection/Cabling cabinet. Location of power terminals for

various drive configurations are as indicated in Figures 2.21, 2.19

and 2.22.

In the case of the cabling cabinet with starter, the removal of internal

barriers and duct covers located on the left side of the cabinet may be

required to facilitate the routing of line cables. This can be

accomplished by removing the hardware securing the barrier/cover

and sliding it toward the front of the cabinet for removal. In addition

the fan housing and cover plate (if already installed) located on the

top of the cabinet must be removed to allow routing and termination

of line cables. All barriers/covers must be replaced, by reversing the

above sequence, before applying medium voltage.

The installer is responsible for modifying the power cable access

plates to suit their requirements.

Note that appropriate connectors must be used to maintain the

environmental rating of the enclosure.

7000 “A” Frame 7000A-UM151D-EN-P – March 2013

Page 50

2-28 Drive Installation

Power Connections The installer must ensure that interlocking with the upstream power

source has been installed and is functioning.

The installer is responsible for ensuring that power connections are

made to the equipment in accordance with local electrical codes.

The drive is supplied with provision for cable lugs. The power

terminals are identified as follows:

• Drives with Connection to remote transformers: 2U, 2V, 2W

• Motor Connections: U, V, W

Line/Motor Terminations

• Drives with integral transformers: 1U, 1V, 1W

• Drives with integral line reactor and input starter: L1, L2, L3

• Drives with integral line reactor, no input starter: 1U, 1V, 1W

Power Cabling Installation Requirements

To determine cable distance from top or bottom of input cabinet to

termination points, refer to Figures 2.21, 2.19 and 2.22.

The installer is responsible for ensuring that power connections are

made with appropriate torque. (Refer to Appendix B "Torque

Requirements" in back of manual.)

The drive is supplied with provision for grounding of cable shields

and stress cones near the power terminals.

7000A-UM151D-EN-P – March 2013 7000 “A” Frame

Page 51

Drive Installation 2-29

411.9 [16.22]

284.9 [11.22]

157.9 [6.22]

L1