Page 1

User Manual

PowerFlex® 7000 Medium Voltage AC Drive Air-Cooled

(“B” Frame)—ForGe Control

Publication 7000-UM202B-EN-P

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

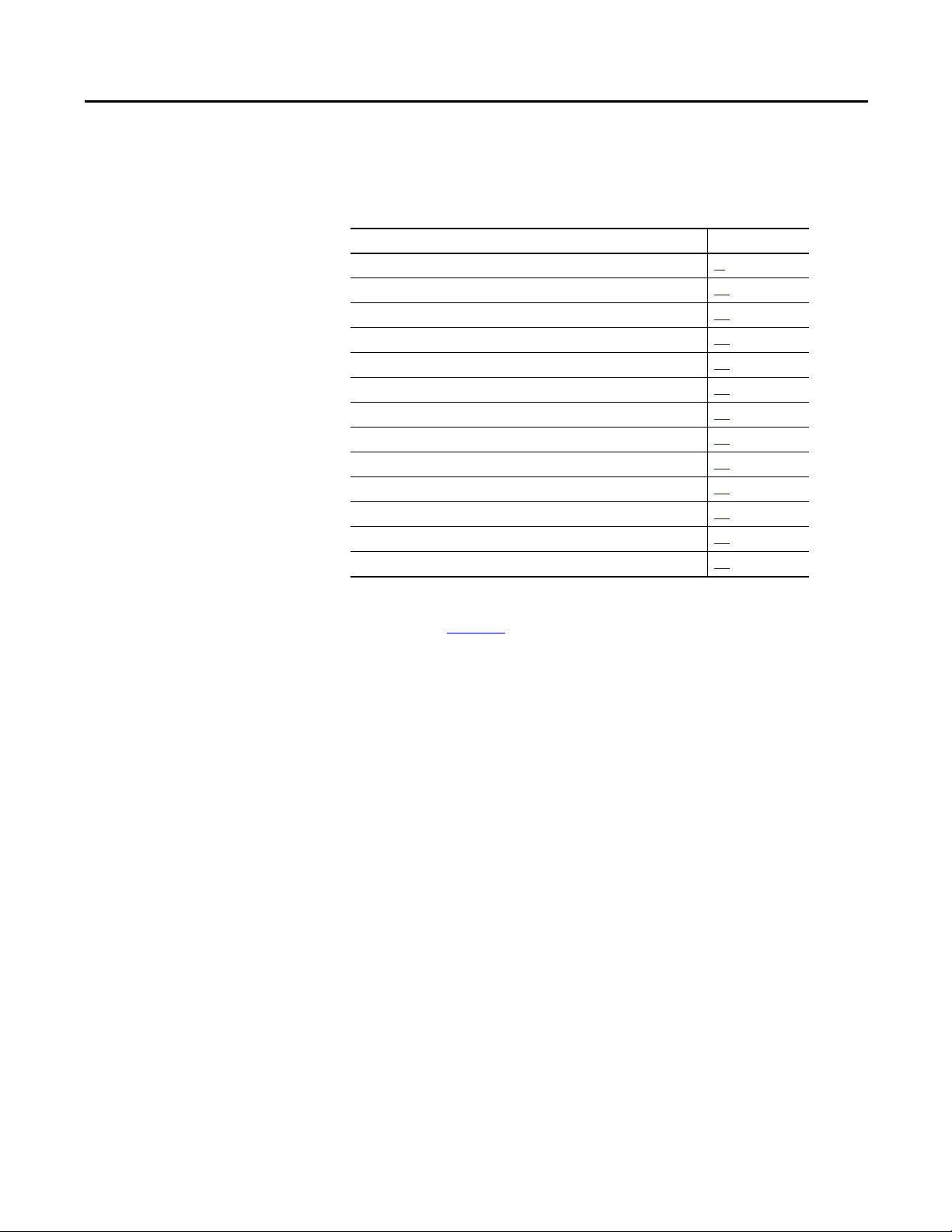

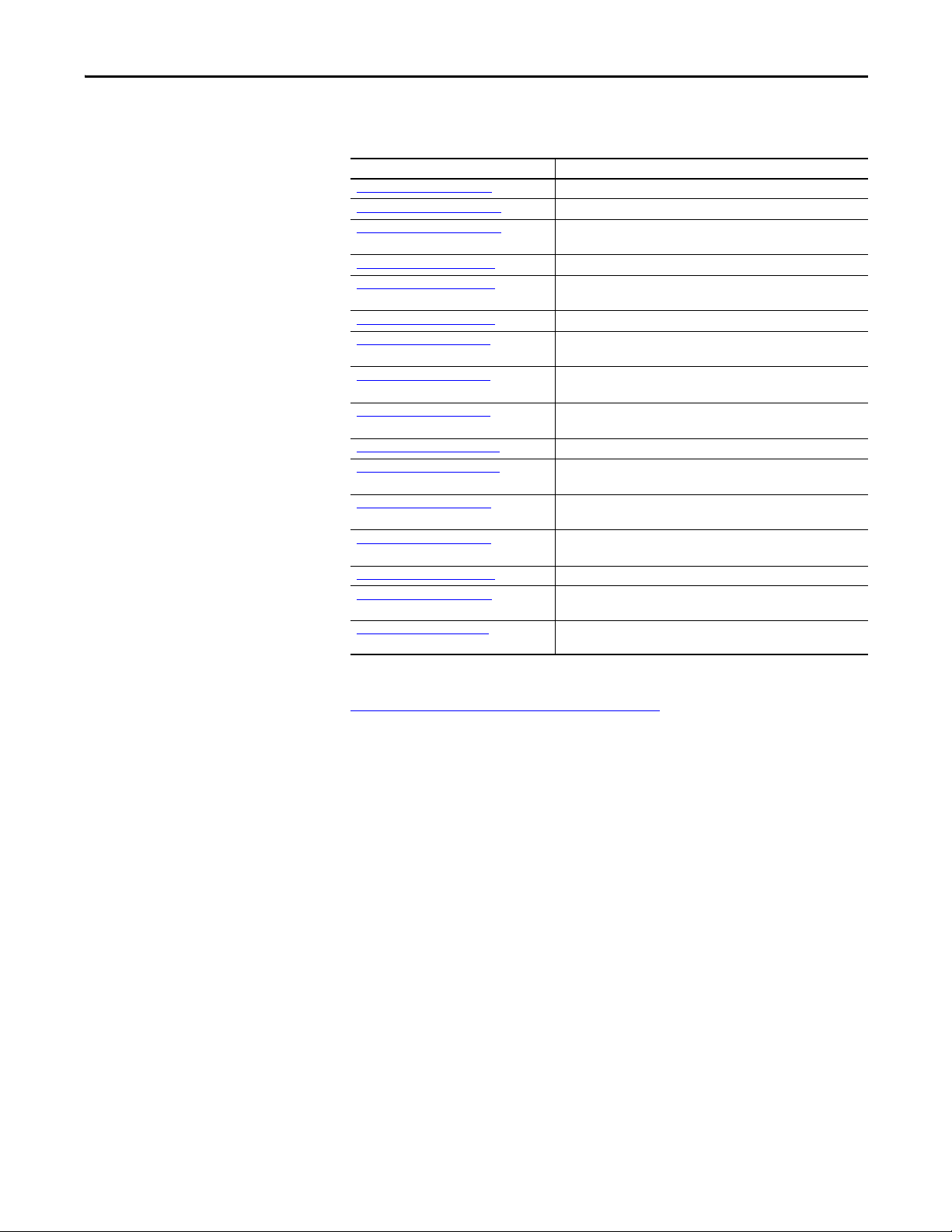

This manual contains new and updated information.

Summary of Changes

New and Updated

Information

This table summarizes the changes made to this revision.

Top ic Pag e

Added HPTC information to Topology section 13

Added additional SPS test harness warning 103

Added minimum gap measurement and image to Fan Installation section 119

Updated Catalog Number Explanation 169

Updated “When to use an Encoder?” section and table 201

Replaced Encoder Selection table 202

Added HPTC information to Drive Torque Capabilities table 202

Updated Typical Application Load Torque Profiles 203

Updated Speed Regulator Bandwidth 206

Updated Torque Regulator Bandwidth 206

Inserted Torque Accuracy with HPTC 206

Added Polish to list of available Languages 207

Added “Dual-port Ethernet/IP” to Communications Protocols 208

Changes made to this manual for previous revisions are included in the History

of Changes on page 209

.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 5

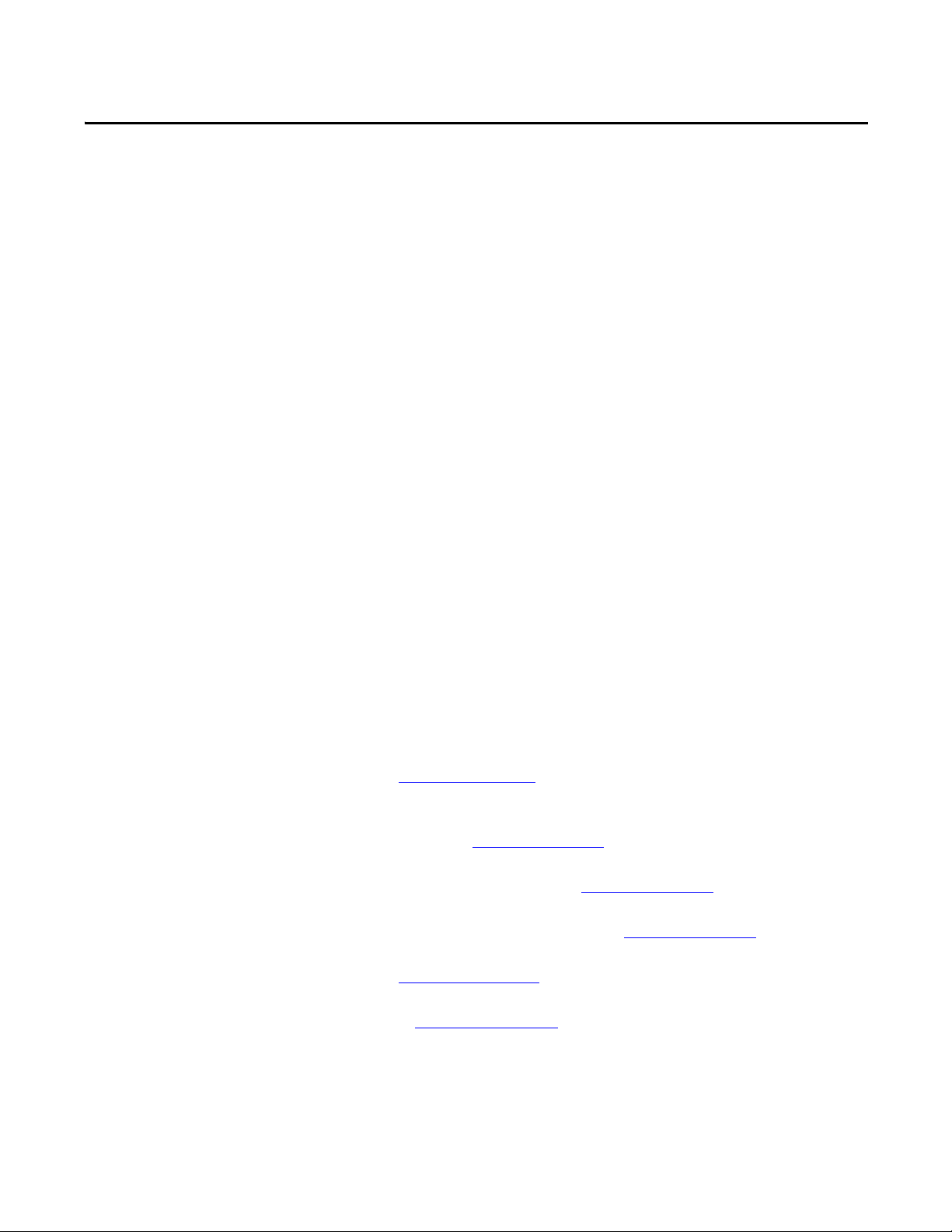

Important User Information

Table of Contents

Chapter 1

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What Is Not in this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Commissioning Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2

PowerFlex 7000 Overview

Component Definition and

Maintenance

Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rectifier Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooling Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Motor Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Simplified Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2400V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3300/4160V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6600V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Basic Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3

Control Power Off Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Interlocking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control / Cabling Cabinet Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Voltage-Sensing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Replacing the Voltage-Sensing Circuit Board Assembly. . . . . . . . . . 34

Input Transient Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Transient Suppression Network (TSN) . . . . . . . . . . . . . . . . . . . . . . . . 35

Surge Arresters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Filter Capacitor Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Filter Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Replacing Filter Capacitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Testing Filter Capacitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Converter Cabinet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

PowerCage™ Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Resistance Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

SGCT and Snubber Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

SGCT Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

SGCT Anode-to-Cathode (Sharing) Resistance. . . . . . . . . . . . . . . . . 64

Snubber Resistance (SGCT Device). . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Snubber Capacitance (SGCT Device). . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing the SGCT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Replacing Snubber and Sharing Resistor. . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing Snubber Capacitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Replacing Sharing Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 5

Page 6

Table of Contents

Silicon Controlled Rectifier PowerCages . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

SCR Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

SCR Anode-to-Cathode Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

SCR Sharing Resistance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

SCR Gate-to-Cathode Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Snubber Resistance (SCR Device). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Snubber Capacitance (SCR Device) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing SCR and SCR Self-Powered Gate Driver

Boards (SPGDB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Uniform Clamping Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Checking Clamping Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Clamping Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Temperature Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Replacing the Thermal Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Replacing Heat Sinks/Heat Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Replacing Heat Sinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Replacing Heat Pipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

PowerCage Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replacing PowerCage Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Removing the PowerCage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Self-Powered SGCT Power Supply - SPS . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Board Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Test Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Testing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Self-Powered Gate Driver Board – SPGDB . . . . . . . . . . . . . . . . . . . . . . . . 104

Board Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Test Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Terminal/Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Testing Procedure for SCR Self-Powered Gate Driver Board . . . . . . . . 106

Testing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Fiber Optic Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Air Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Replacing the Air Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

DC Link and Fan Cabinet Components . . . . . . . . . . . . . . . . . . . . . . . . . . 111

DC Link Reactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Removing and Replacing Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

117

Fan Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Impeller Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Impeller Removal from Motor Shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Installing Impeller Assembly onto Motor Shaft. . . . . . . . . . . . . . . . . 120

Replacing Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Control Power Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Ride-Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

AC/DC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Terminal / Connections Descriptions (Pioneer Power Supply) . . 128

Terminal / Connections Descriptions (Cosel Power Supply) . . . . 129

6 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 7

Table of Contents

Output Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Power Supply Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

UPS Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Replacing the UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Low Voltage Control Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

DC/DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Terminal/Connections Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . 138

Replacing a DC/DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Drive Processor Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Replacing the Drive Processor Module . . . . . . . . . . . . . . . . . . . . . . . . 142

Analog Control Board (ACB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Interface Module (IFM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Analog Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Current Loop Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Isolated Process Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Non-Isolated Process Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Auxiliary +24V Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Replacing the ACB Analog Control Board . . . . . . . . . . . . . . . . . . . . 152

Encoder Feedback Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Encoder Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

20B-ENC-1 & 20B-ENC-1-MX3 Encoder Interface . . . . . . . . . . . 153

80190-759-01, 80190-759-02 Universal Encoder Interface . . . . . 154

Quadrature Encoder Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Positional Encoder Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

External Input/Output Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Replacing the External Input/Output Board. . . . . . . . . . . . . . . . . . . 160

Optical Interface Boards (OIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Replacing the Optical Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . 162

Optical Interface Base Board Test Points . . . . . . . . . . . . . . . . . . . . . . 165

Catalog Number Explanation

Preventative Maintenance Schedule

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 7

Appendix A

PowerFlex 7000 Drive Selection Explanation. . . . . . . . . . . . . . . . . . . . . . 168

Service Duty Rating, Continuous Current Rating and

Altitude Rating Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Appendix B

Preventative Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Operational Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Initial Information Gathering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Physical Checks (NO Medium Voltage and NO Control Power) 170

Control Power Checks (No Medium Voltage) . . . . . . . . . . . . . . . . . 171

Final Power Checks before Restarting . . . . . . . . . . . . . . . . . . . . . . . . . 172

Additional Tasks During Preventive Maintenance . . . . . . . . . . . . . 172

Final Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Page 8

Table of Contents

Torque Requirements

Time Estimations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Tool / Parts / Information Requirements. . . . . . . . . . . . . . . . . . . . . . 174

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

PowerFlex 7000 Preventative Maintenance Schedule . . . . . . . . . . . . . . . 177

Appendix C

Torque Requirements for Threaded Fasteners . . . . . . . . . . . . . . . . . . . . . 179

Appendix D

Meggering

Line & Load Cable Sizes

Environmental Considerations

Drive Meggering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Meggering the PowerFlex 7000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Meggering Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Required Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Appendix E

Max. Line Cable Sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Max. Load Cable Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Appendix F

Air Quality Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Hazardous Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Capacitor Dielectric Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Lithium Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chromate Plating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

In Case Of Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Appendix G

Encoder Use and Torque Capabilities

When to use an Encoder? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

PowerFlex 7000 Drive Performance (Torque Capabilities). . . . . . . . . . 198

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Appendix H

Specifications

“B” Frame Drive Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Index

8 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 9

Chapter 1

Important User Information

This document provides procedural information for managing daily or recurring

tasks involving the PowerFlex 7000 medium voltage “B” Frame drives (heat sink

and heat pipe models).

Who Should Use This Manual

What Is Not in this Manual

This manual is intended for use by personnel familiar with medium voltage and

solid-state variable speed drive equipment. The manual contains material that

enables regular operation and maintenance of the drive system.

This manual provides information specific to maintaining the PowerFlex 7000

“B” Frame drive. It does not include topics such as:

• Physically transporting or siting the drive cabinetry

• Installing or commissioning procedures

• Dimensional and electrical drawings generated for each customer’s order

• Spare parts lists compiled for each customer’s order

Please refer to the following documents for additional product detail or

instruction relating to PowerFlex 7000 “B” Frame drives:

• Drive-specific Technical Data: additional troubleshooting, parameters,

and specification information for MV variable frequency drives

(7000-TD002_-EN-P

• Transportation and Handling Procedures: receiving and handling

instructions for Medium Voltage variable frequency drive and related

equipment (7000-IN008_-EN-P

• Installation Guide: detailed installation and pre-commissioning

procedures and information (7000-IN007_-EN-P

• Commissioning Guide: required procedures and checklists for Rockwell

Automation field service engineers (7000-IN006_-EN-P

• Operator Interface Guide: HMI Offering with Enhanced Functionality

(7000-UM201_-EN-P

• For drives equipped with the PanelView 550 HMI,

see 7000-UM151_-EN-P.

)

)

)

)

)

Rockwell Automation provides the site- and installation-specific electrical and

design information for each drive during the order process cycle. If they are not

available on site with the drive, contact Rockwell Automation.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 9

Page 10

Chapter 1 Important User Information

If you have multiple drive types or power ranges, ensure you have the correct

documentation for each specific PowerFlex 7000 product:

• “A” Frame for lower power air-cooled configurations (up to approximately

1250 hp/933 kW)

• “B” Frame for higher-power, air-cooled configurations (standard or heat

pipe models)

• “C” Frame for all liquid-cooled configurations

General Precautions

Commissioning Support

ATT EN TI ON : This drive contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference Allen-Bradley publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other applicable ESD protection handbook.

ATT EN TI ON : An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or application errors, such as,

undersizing the motor, incorrect or inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the system.

ATT EN TI ON : Only personnel familiar with the PowerFlex 7000 Adjustable

Speed Drive (ASD) and associated machinery should plan or implement the

installation, start-up and subsequent maintenance of the system. Failure to

comply may result in personal injury and/or equipment damage.

After installation, Rockwell Automation Medium Voltage Support is responsible

for commissioning support and activities in the PowerFlex 7000 product line.

Phone: 519-740-4790

Option 1 for technical and option 4 for commissioning questions

MVSupport_technical@ra.rockwell.com or

MVSupport_services@ra.rockwell.com

Rockwell Automation support includes, but is not limited to:

• quoting and managing product on-site start-ups

• quoting and managing field modification projects

• quoting and managing customer in-house and on-site product training

10 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 11

Important User Information Chapter 1

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Publication 7000-PP002_-EN-P

Publication 7000A-UM150_-EN-P PowerFlex 7000 Medium Voltage AC Drive (A Frame) - Classic Control

Publication 7000A-UM151_-EN-P

Publication 7000-UM150_-EN-P PowerFlex 7000 Medium Voltage AC Drive (B Frame) - Classic Control

Publication 7000-UM151_-EN-P PowerFlex 7000 Medium Voltage AC Drive (B Frame) - ForGe Control

Publication 7000-UM202_-EN-P PowerFlex 7000 Medium Voltage AC Drive (B Frame) - ForGe Control

Publication 7000-IN006_-EN-P PowerFlex 7000 Medium Voltage AC Drive (B Frame) Commissioning -

Publication 7000-IN007_-EN-P PowerFlex 7000 Medium Voltage AC Drive (B Frame) Installation -

Publication 7000-IN008_-EN-P

Publication 7000L-UM301_-EN-P

Publication 7000L-UM302_-EN-P

Publication 7000-TD001_-EN-P

Publication 7000-TD002_-EN-P PowerFlex 7000 Medium Voltage AC Drive (Firmware Version 9.xxx) -

Publication 7000-UM201_-EN-P

Publication 7000-QS002_-EN-P

Publication 7000-IN010B-EN-P Handling, Inspection, and Storage of Medium Voltage Line Filter

PowerFlex 7000 Air-Cooled Drives

PowerFlex 7000 Medium Voltage AC Drive (A Frame) - ForGe Control

(Using PanelView 550)

(Using PanelView 500)

ForGe Co ntrol

ForGe Co ntrol

PowerFlex 7000 Medium Voltage AC Drive (B Frame) Trans. & Handling

- ForGe Control

PowerFlex 7000 Medium Voltage AC Drive (C Frame) - ForGe Control

PowerFlex 7000 Medium Voltage AC Drive (C Frame) - ForGe Control

(Marine)

PowerFlex 7000 Medium Voltage AC Drive (Firmware Version 6.xxx) -

Classic Control

ForGe Co ntrol

PowerFlex 7000 HMI Offering with Enhanced Functionality

HMI Interface Board Software Updater and Firmware Download

Procedure

Capacitors

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 11

Page 12

Chapter 1 Important User Information

Notes:

12 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 13

Chapter 2

PowerFlex 7000 Overview

The PowerFlex 7000 is a general purpose, stand-alone, medium voltage drive that

controls speed, torque, direction, starting and stopping of standard asynchronous

or synchronous AC motors. It works on numerous standard and specialty

applications such as fans, pumps, compressors, mixers, conveyors, kilns, fanpumps, and test stands in industries such as petrochemical, cement, mining and

metals, forest products, power generation, and water/waste water.

The PowerFlex 7000 meets most common standards from the National Electrical

Code (NEC), International Electrotechnical Commission (IEC), National

Electrical Manufacturers Association (NEMA), Underwriters Laboratories

(UL), and Canadian Standards Association (CSA). It is available with the world’s

most common supply voltages at medium voltage, from 2400...6600V.

Topology

The design focus is on high reliability, ease of use, and lower total cost of

ownership.

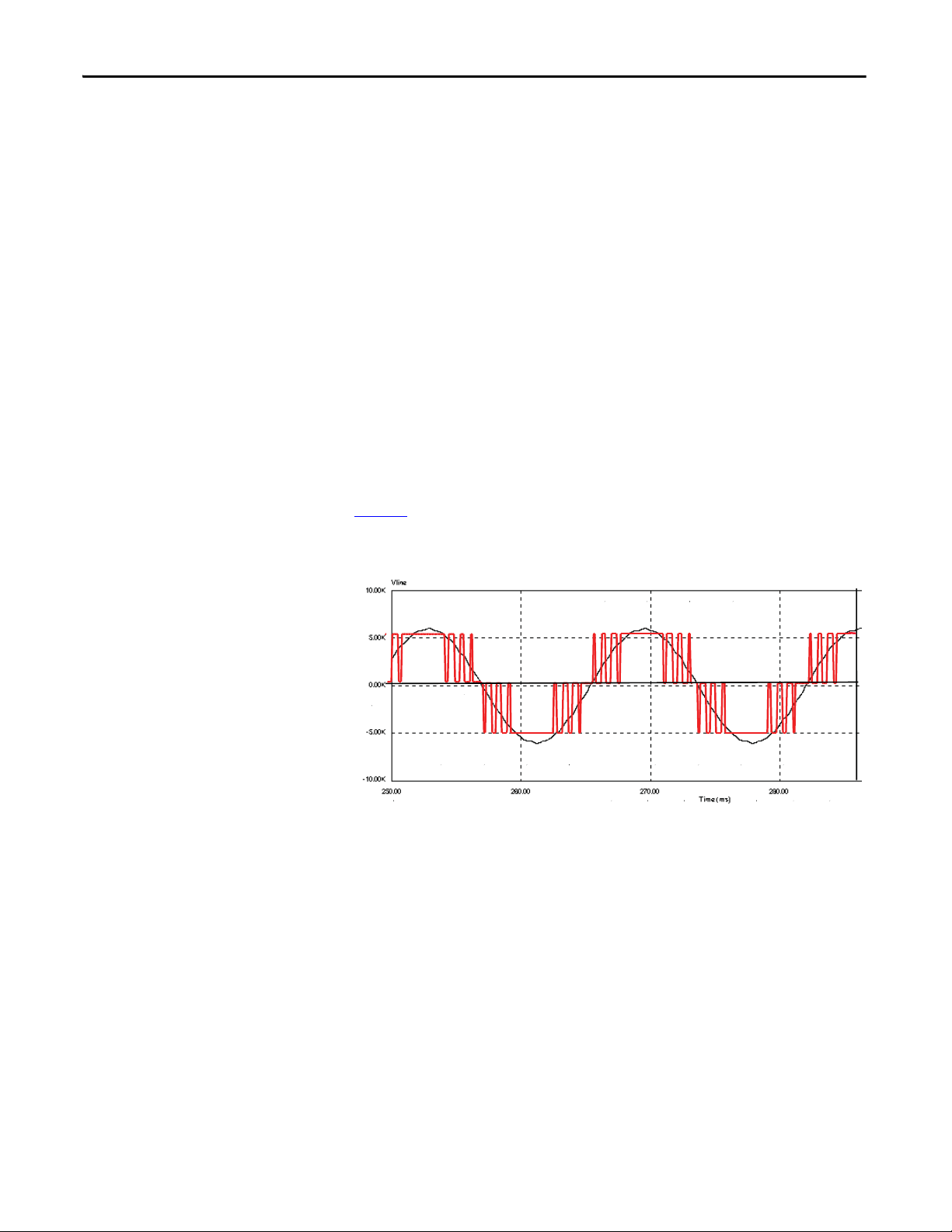

The PowerFlex 7000 uses a Pulse Width Modulated (PWM) – Current Source

Inverter (CSI) topology. This topology applies to a wide voltage and power

range. The power semiconductor switches used are easy-to-series for any medium

voltage level. Semiconductor fuses are not required for the power structure due to

the current limiting DC link inductor.

With 6500V PIV rated power semiconductor devices, the number of inverter

components is minimal. For example, only six inverter switching devices are

required at 2400V, 12 at 3300...4160V, and 18 at 6600V.

The PowerFlex 7000 also provides inherent regenerative braking for applications

where the load is overhauling the motor (e.g. downhill conveyors, etc.), or where

high inertia loads (e.g. fans, etc.) are quickly slowed down. The drive uses

Symmetrical Gate Commutated Thyristors (SGCTs) for machine converter

switches, SGCTs (for Active Front-end [AFE] rectifier configurations) for the

line converter switches and Silicon-controlled Rectifiers (SCRs) (for 18 Pulse

rectifier configurations).

The PowerFlex 7000 provides a selectable option for enhanced torque control

capabilities and increased dynamic control performance. This High Performance

Torque Control (HPTC) feature delivers 100% torque at zero speed and

provides torque control through zero speed with smooth direction transition.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 13

Page 14

Chapter 2 PowerFlex 7000 Overview

Rectifier Designs

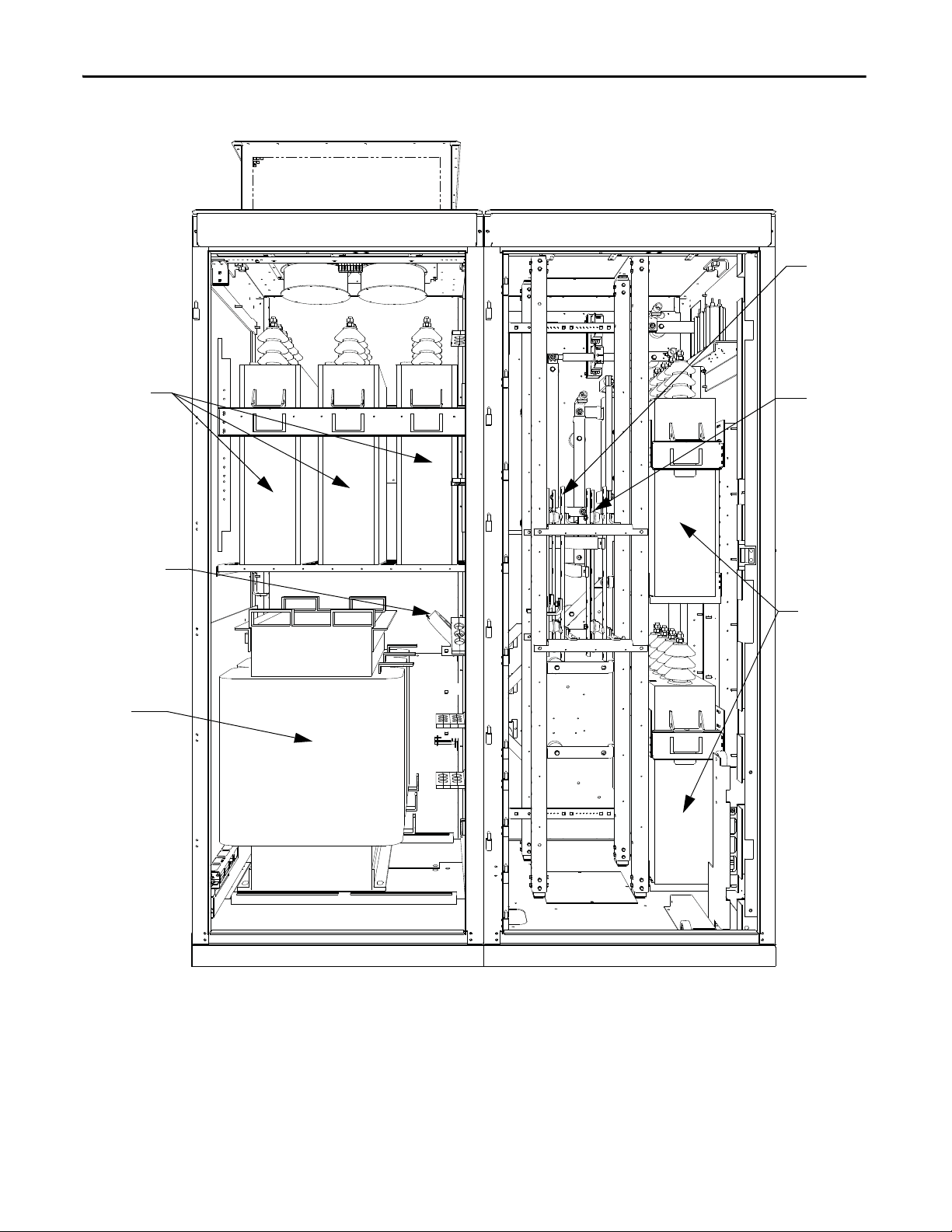

Configurations

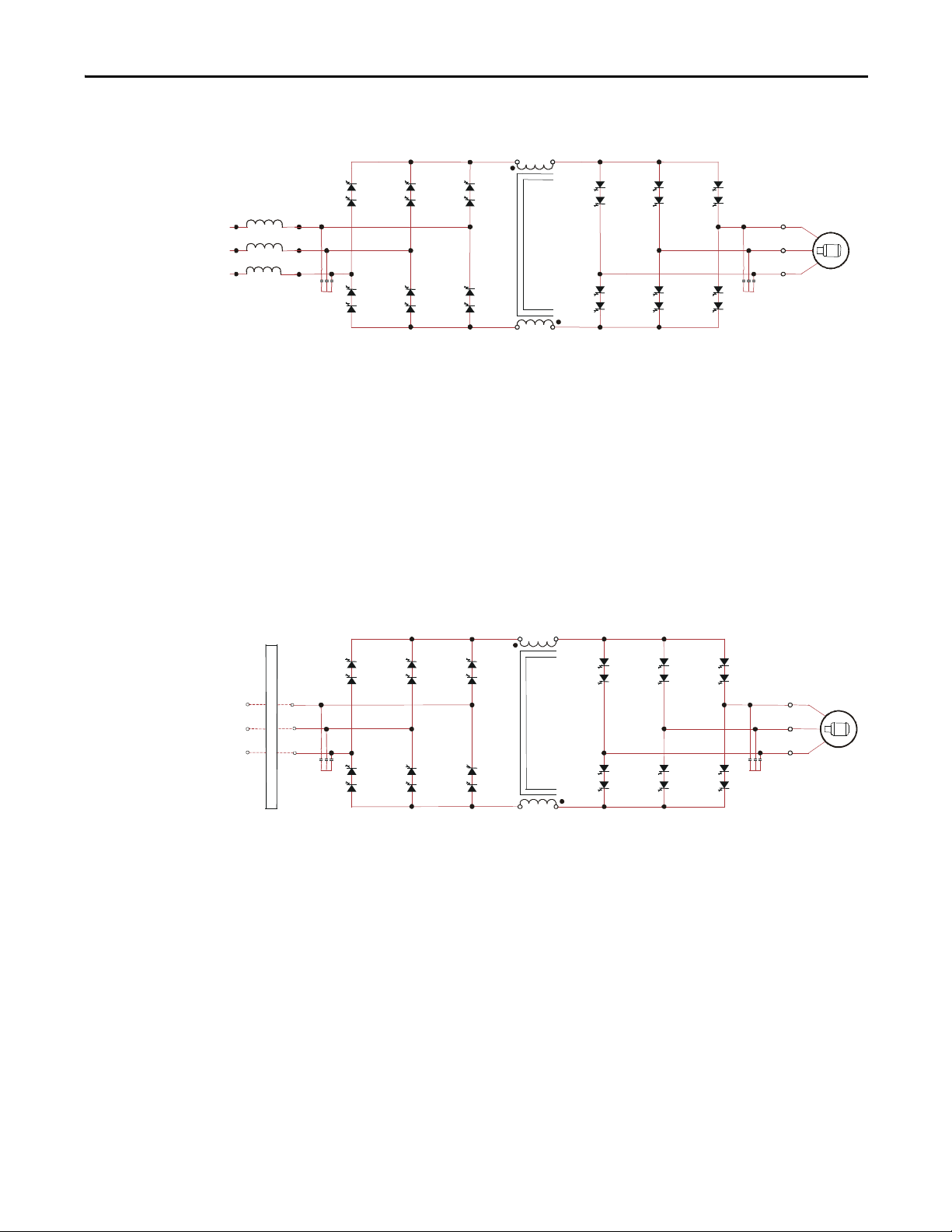

The PowerFlex 7000 offers three rectifier configurations for "B" Frame drives:

• Direct-to-Drive (AFE rectifier with integral line reactor and Common

Mode Choke)

• AFE rectifier with separate isolation transformer

• 18 Pulse rectifier with separate isolation transformer

Direct-to-Drive

Direct-to-DriveTM technology does not require an isolation transformer or

multiple rectifier bridges as in Voltage Source Inverter (VSI) topologies offered

by others. The approach is completely different. Instead of multiple

uncontrolled rectifiers, a single AFE rectifier bridge is supplied. The rectifier

semiconductors used are SGCTs. Unlike the diodes used in VSI rectifier bridges,

SGCTs are turned on and off by a gating signal. A PWM gating algorithm

controls the firing of the rectifier devices, very similar to the control philosophy

of the inverter. The gating algorithm uses a specific 42 pulse switching pattern

(Figure 1

and 11th harmonic orders.

Figure 1 - Typical PWM switching pattern, line voltage waveform

) called Selective Harmonic Elimination (SHE) to mitigate the 5th, 7th,

A small integral line reactor and capacitor addresses the high harmonic orders

(13th and above) and provides virtually sinusoidal input voltage and current

waveforms back to the distribution system. This delivers excellent line-side

harmonic and power factor performance to meet IEEE 519-1992 requirements

and other global harmonic standards in virtually all cases, while still providing a

simple, robust power structure that maximizes uptime by minimizing the number

of discrete components and the number of interconnections required.

A Common Mode Choke (CMC) mitigates the common mode voltage seen at

the motor terminals, so standard (non-inverter duty rated) motors and motor

cables can be used, making this technology ideal for retrofitting existing motor

applications.

14 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 15

PowerFlex 7000 Overview Chapter 2

SGCTs

LINE CONVERTER

OMMON MODE CHOKE

C

L+

M+

SGCTs

MACHINE CONVERTER

U(T1)

V(T2)

W(T3)

L-

M-

LR

SGCTs

LINE CONVERTER DC LINK

L+

M+

SGCTs

MACHINE CONVERTER

U(T1)

V (T2)

W(T3)

L-

M-

2U (X1)

2V (X2)

2W (X3)

1U

1V

1W

ISTXISTX

REMOTE

Figure 2 - 3300/4160V Direct-to-Drive (transformerless AFE rectifier)

AFE Rectifier with Separate Isolation Transformer

For applications when the line voltage is higher than the motor voltage, a

transformer is required for voltage matching. In this case, providing an AFE

rectifier with a separate isolation transformer is ideal (indoor and outdoor

transformer versions are offered). The isolation transformer provides the input

impedance (replaces the requirement for an integral line reactor) and addresses

the common mode voltage (replaces the requirement for a CMC that is supplied

in the Direct-to-Drive rectifier configuration). However, the AFE rectifier, its

operation, and advantages are the same as the Direct-to-Drive configuration.

Figure 3 - 3300/4160 AFE Rectifier with separate isolation transformer

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 15

Page 16

Chapter 2 PowerFlex 7000 Overview

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

REMOTE

1U

1V

1W

18 Pulse Rectifier with Separate Isolation Transformer

For high power constant torque applications and/or when the line voltage is

higher than the motor voltage, a transformer is required for voltage matching

(indoor and outdoor transformer options are available). The 18 Pulse rectifier

uses SCRs instead of the SGCTs used for an AFE rectifier. When used for high

power constant torque applications, the 18 Pulse rectifier has lower losses than

the AFE rectifier, making it ideal for the highest power requirements. The 18

Pulse isolation transformer provides the required input impedance and addresses

common mode voltage just like the separate isolation transformer used with the

AFE rectifier. However, instead of a PWM rectifier switching pattern and a

single rectifier bridge, the 18 Pulse configuration mitigates line side harmonics

through harmonic current cancellation in the isolation transformer phase shifted

secondary windings. The inverter is the same configuration for all available

rectifier options.

Figure 4 - 3300/4160V 18 Pulse rectifier with Separate Isolation Transformer

DC LINK

DC LINK

Cooling Technology

These VFDs are supplied with heat sinks for most configurations and heat pipes

for the highest-power AFE configurations. While both configurations draw heat

away from the semiconductors, heat pipes are bigger, more efficient, and require

larger fans and airflow.

Information and graphics in this manual show both configurations.

16 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 17

PowerFlex 7000 Overview Chapter 2

300.00

200.00

100.00

0.00

-100.00

-200.00

-300.00

10.00K

7.50K

5.00K

2.50K

0.00K

-2.50K

-5.00K

-7.50K

-10.00K

100.00

110.00

120.00 130.00

140.00

150.00

Vrms

CURRENT

VOLTAGE

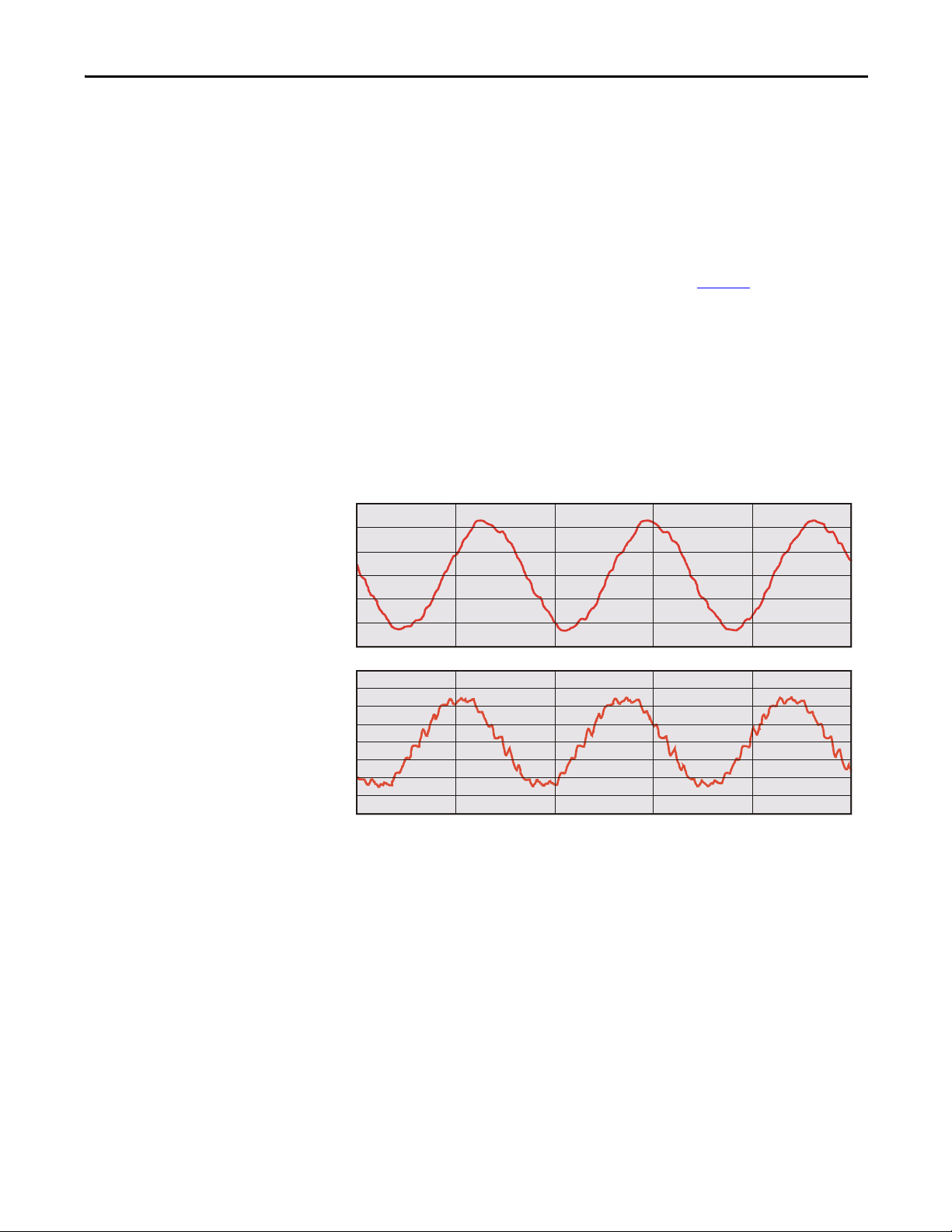

Motor Compatibility

The PowerFlex 7000 achieves near-sinusoidal current and voltage waveforms to

the motor, resulting in no significant additional heating or insulation stress.

Temperature rise in the motor connected to the VFD is typically 3 °C (5.5 °F)

higher compared to across-the-line operation. Voltage waveform has dv/dt of less

than 50 V/

µs. The peak voltage across the motor insulation is the rated motor

RMS voltage divided by 0.707.

Reflected wave and dv/dt issues often associated with voltage source inverter

(VSI) drives are a non-issue with the PowerFlex 7000. Figure 5

shows typical

motor waveforms. The drive uses a selective harmonic elimination (SHE) pattern

in the inverter to eliminate major order harmonics, plus a small output capacitor

(integral to the drive) to eliminate harmonics at higher speeds.

Standard motors are compatible without de-rating, even on retrofit applications.

Motor cable distance is virtually unlimited. Rockwell Automation has tested this

technology for controlling motors up to 15 km (9.3 mi) away from the drive.

Figure 5 - Motor waveforms @ full load, full speed

Arms

TIME (ms)

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 17

Page 18

Chapter 2 PowerFlex 7000 Overview

SGCTs

LINE CONVERTER

L+

M+

SGCTs

MACHINE CONVERTER

U(T1)

V(T2)

W(T3)

L-

M-

LR

OMMON MODE CHOKE

C

SGCTs

LINE CONVERTER DC LINK

L+

M+

SGCTs

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

L-

M-

2U (X1)

2V (X2)

2W (X3)

1U

1V

1W

ISTXISTX

REMOTE

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

1U

1V

1W

REMOTE

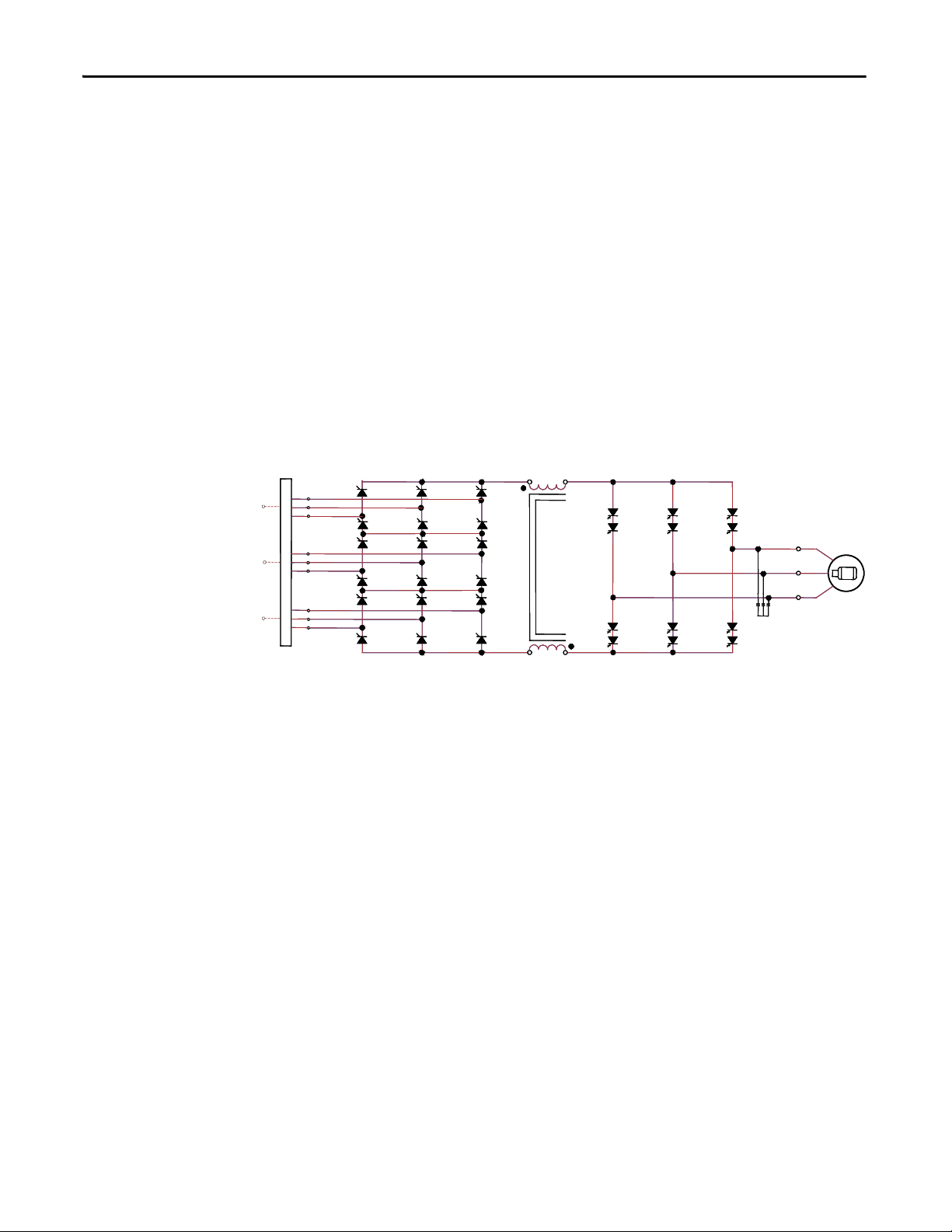

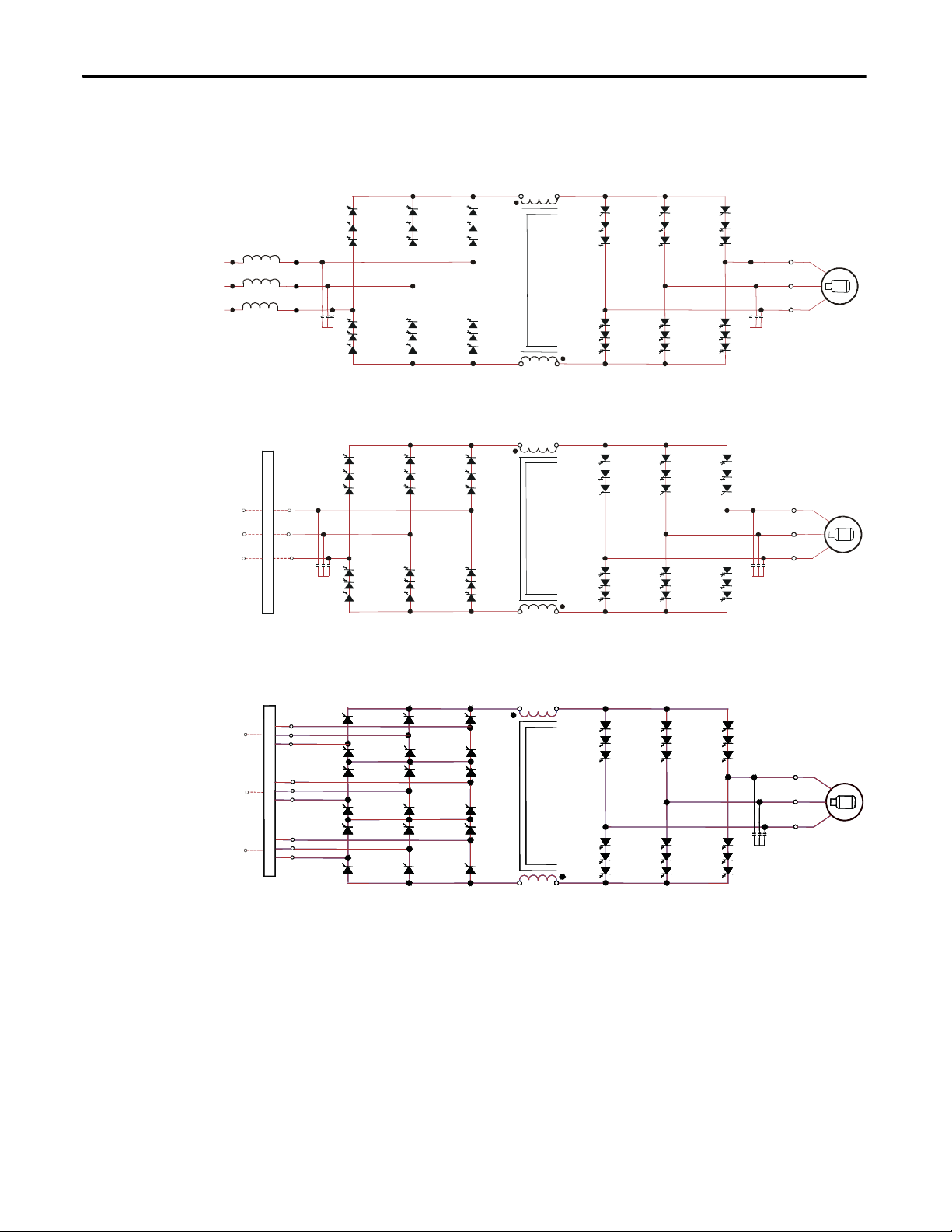

Simplified Electrical Diagrams

2400V

Figure 6 - 2400V – Direct-to-Drive (transformerless AFE rectifier)

Figure 7 - 2400V – AFE Rectifier with Separate Isolation Transformer

Figure 8 - 2400V – 18 Pulse Rectifier with Separate Isolation Transformer

DC LINK

DC LINK

18 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 19

PowerFlex 7000 Overview Chapter 2

SGCTs

LINE CONVERTER

L+

M+

SGCTs

MACHINE CONVERTER

U(T1)

V(T2)

W(T3)

L-

M-

LR

OMMON MODE CHOKE

C

SGCTs

LINE CONVERTER DC LINK

L+

M+

SGCTs

MACHINE CONVERTER

U(T1)

V (T2)

W(T3)

L-

M-

2U (X1)

2V (X2)

2W (X3)

1U

1V

1W

ISTXISTX

REMOTE

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

REMOTE

1U

1V

1W

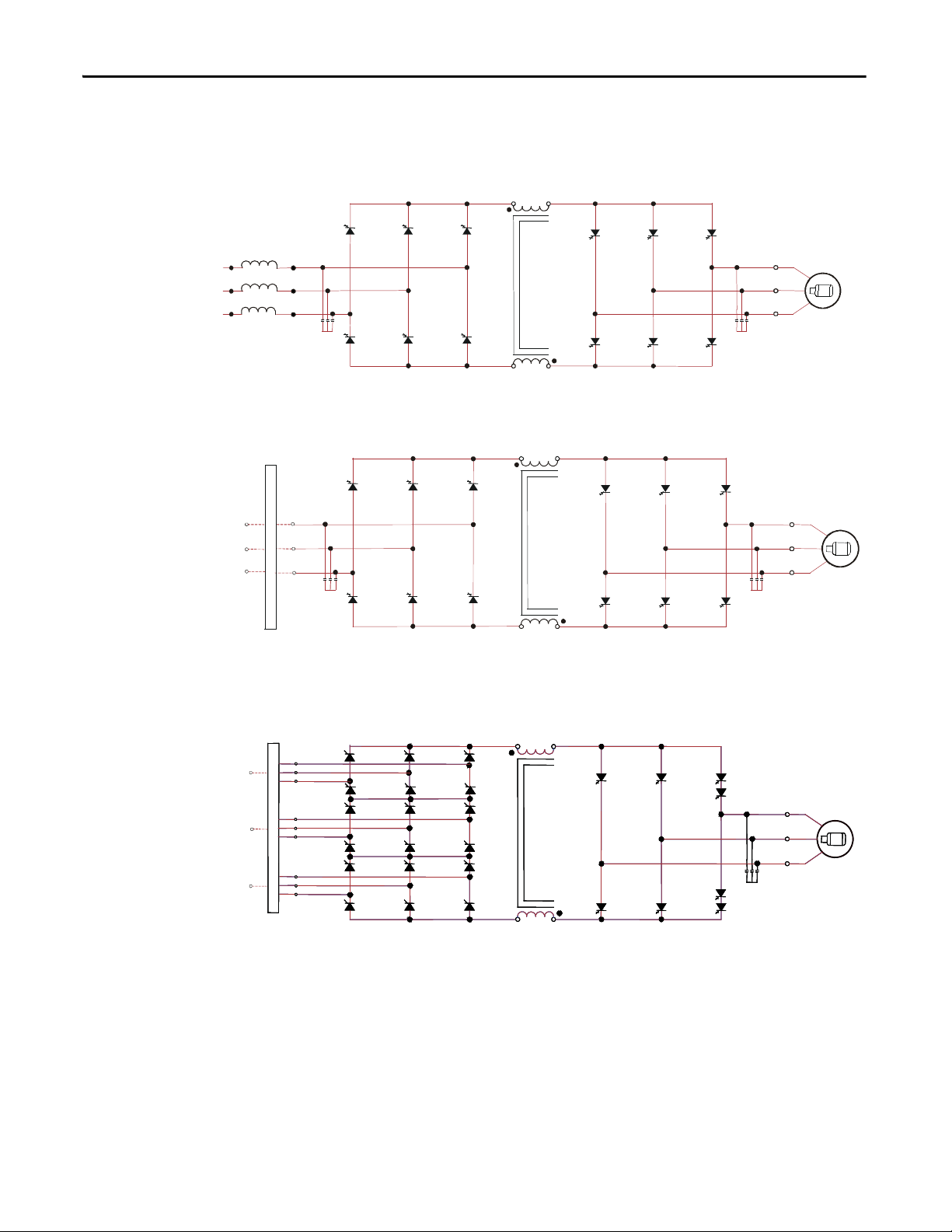

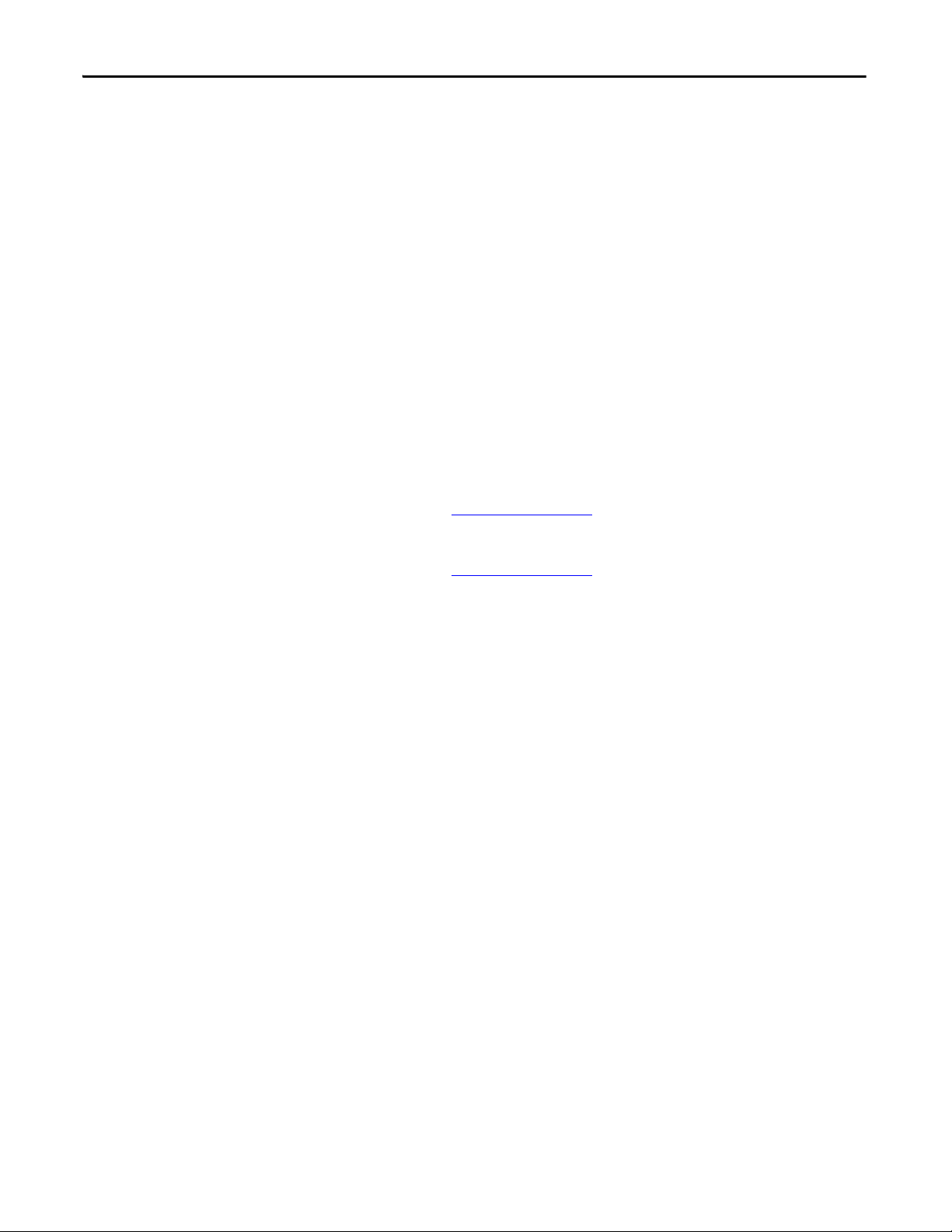

3300/4160V

Figure 9 - 3300/4160V – Direct-to-Drive (transformerless AFE rectifier)

Figure 10 - 3300/4160V – AFE Rectifier with Separate Isolation Transformer

Figure 11 - 3300/4160V – 18 Pulse Rectifier with Separate Isolation Transformer

DC LINK

DC LINK

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 19

Page 20

Chapter 2 PowerFlex 7000 Overview

SGCTs

L+

M+

SGCTs

U(T1)

V(T2)

W(T3)

L-

M-

LR

OMMON MODE CHOKE

C

SGCTs

LINE CONVERTER DC LINK

L+

M+

SGCTs

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

L-

M-

2U (X1)

2V (X2)

2W (X3)

1U

1V

1W

ISTXISTX

REMOTE

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

LINE CONVERTER

L- M-

L+ M+

MACHINE CONVERTER

U (T1)

V (T2)

W (T3)

4U (Z1)

4V (Z2)

4W (Z3)

ISTX

SCRs

3U (Y1)

3V (Y2)

3W (Y3)

2U (X1)

2V (X2)

2W (X3)

SGCTs

1U

1V

1W

REMOTE

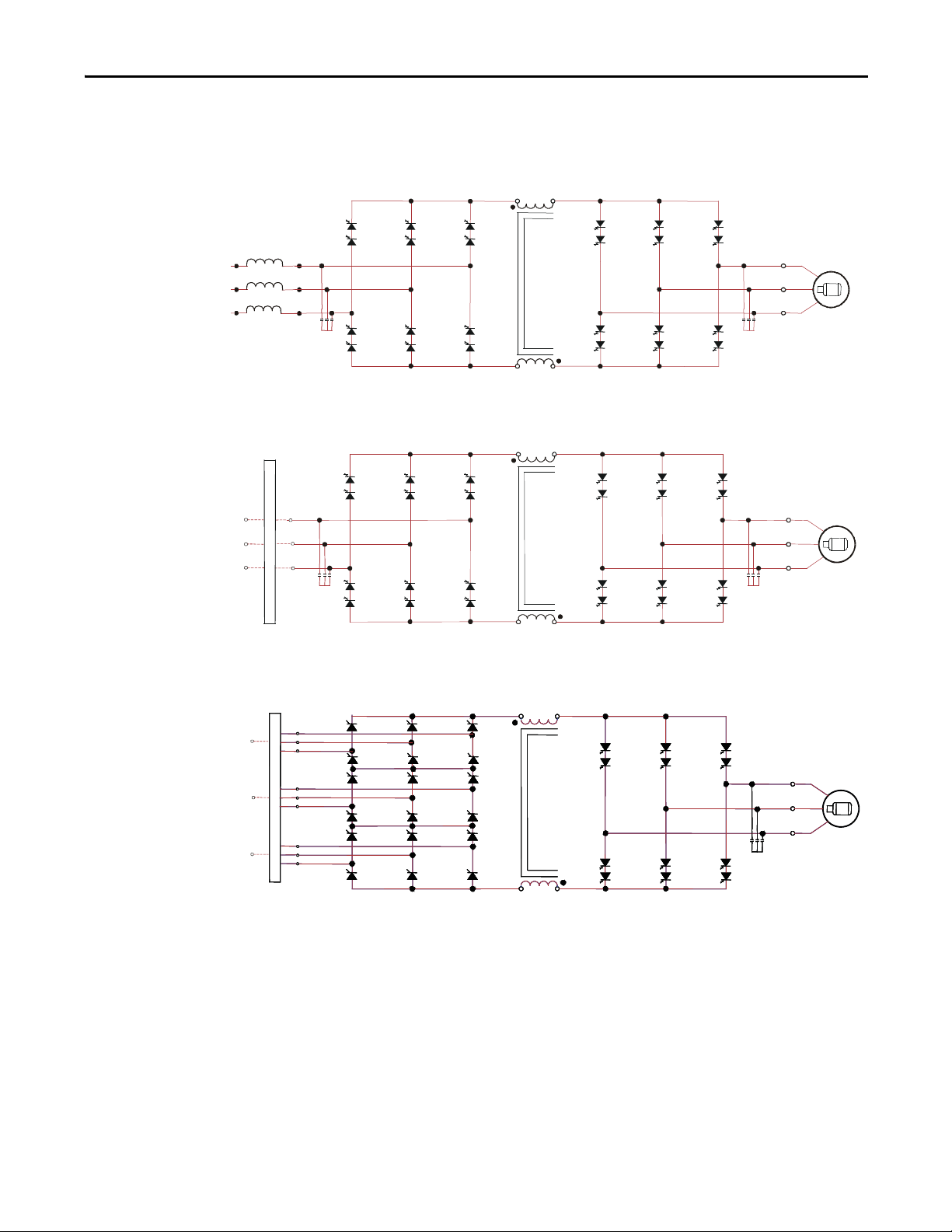

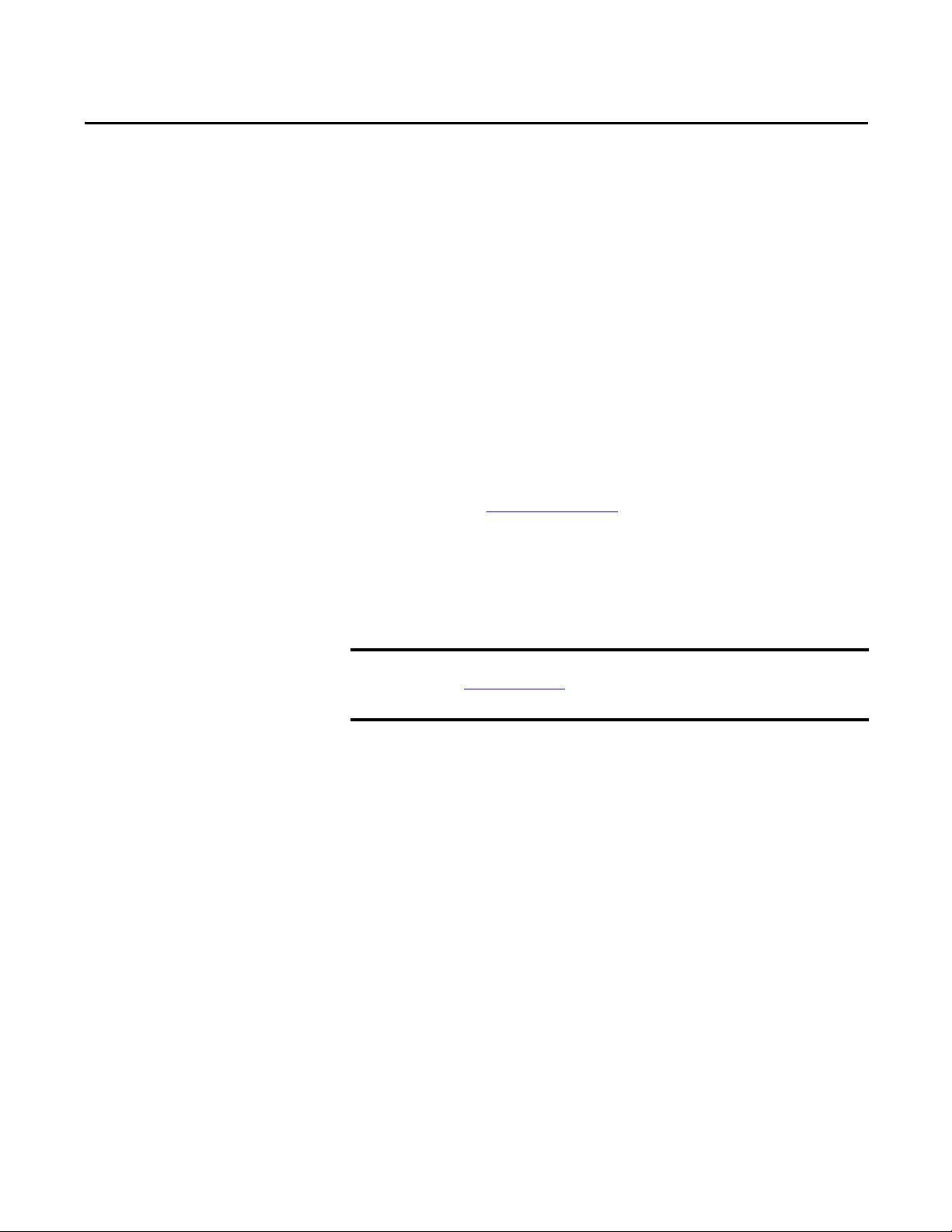

6600V

Figure 12 - 6600V – Direct-to-Drive (transformerless AFE rectifier)

LINE CONVERTER

Figure 13 - 6600V – AFE Rectifier with Separate Isolation Transformer

MACHINE CONVERTER

Figure 14 - 6600V - 18 Pulse Rectifier with Separate Isolation Transformer

DC LINK

DC LINK

20 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 21

PowerFlex 7000 Overview Chapter 2

Operator Interface

The HMI Interface Board is an HMI-enabling device for the PowerFlex 7000

drive. It allows the user to acquire all the necessary executable tools,

documentation and reports required to commission, troubleshoot and maintain

the drive.

Via the HMI Interface Board, the user can choose the style and size of the desired

Windows-based operator terminal to interact with the drive (e.g. PanelView CE

terminal, laptop, or desktop computer). The HMI Interface Board removes past

issues with compatibility between the drive and configuration tools, as all the

necessary tools are acquired from the drive.

The HMI Interface Board is well suited for applications that require remote

placement of the operator terminal and remote maintenance.

Figure 15 - Operator Interface

Basic Configurations

There are three basic configurations for the HMI.

Remote-mounted HMI

The HMI is not mounted in the traditional location on the low voltage door of

the Variable Frequency Drive (VFD). A remote mounting plate, complete with

E-Stop push button, and HMI is supplied loose for the customer to mount

wherever desired. The HMI connects to the VFD via a hardwired Ethernet cable.

There is no significant functional distance limitation.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 21

Page 22

Chapter 2 PowerFlex 7000 Overview

This is ideal for non-PLC users wanting to control and monitor remotely (e.g. at

the driven machine, control room, etc.). Also ideal for customers having policies

in place to control access to medium voltage equipment and the associated

requirements of PPE when using the operator interface at the VFD, etc.

Locally-mounted HMI

Similar to the previously offered PanelView 550, the HMI is mounted on the LV

door of the VFD. There is also a service access port (RJ-45 connector) on the LV

door.

No HMI supplied

A service access port (RJ-45 connector) is located on the LV door of the VFD.

Customers use their own laptop as the HMI. All programs required to use the

laptop as the HMI are stored in the VFD. Their laptop is connected to the VFD

via a hardwired Ethernet cable, when required. This is ideal for unmanned sites,

where a dedicated HMI is not required.

See Publication 7000-UM201_-EN-P

HMI.

See Publication 7000-UM151_-EN-P

drives using the PanelView 550 HMI.

for detailed instruction for the

for detailed instruction for “B” Frame

22 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 23

Chapter 3

IMPORTANT

Component Definition and Maintenance

This section provides an overview of the control components and cabling of your

PowerFlex 7000 “B” Frame drive. It also details a number of regular or recurring

maintenance tasks that will keep your drive in peak operating condition.

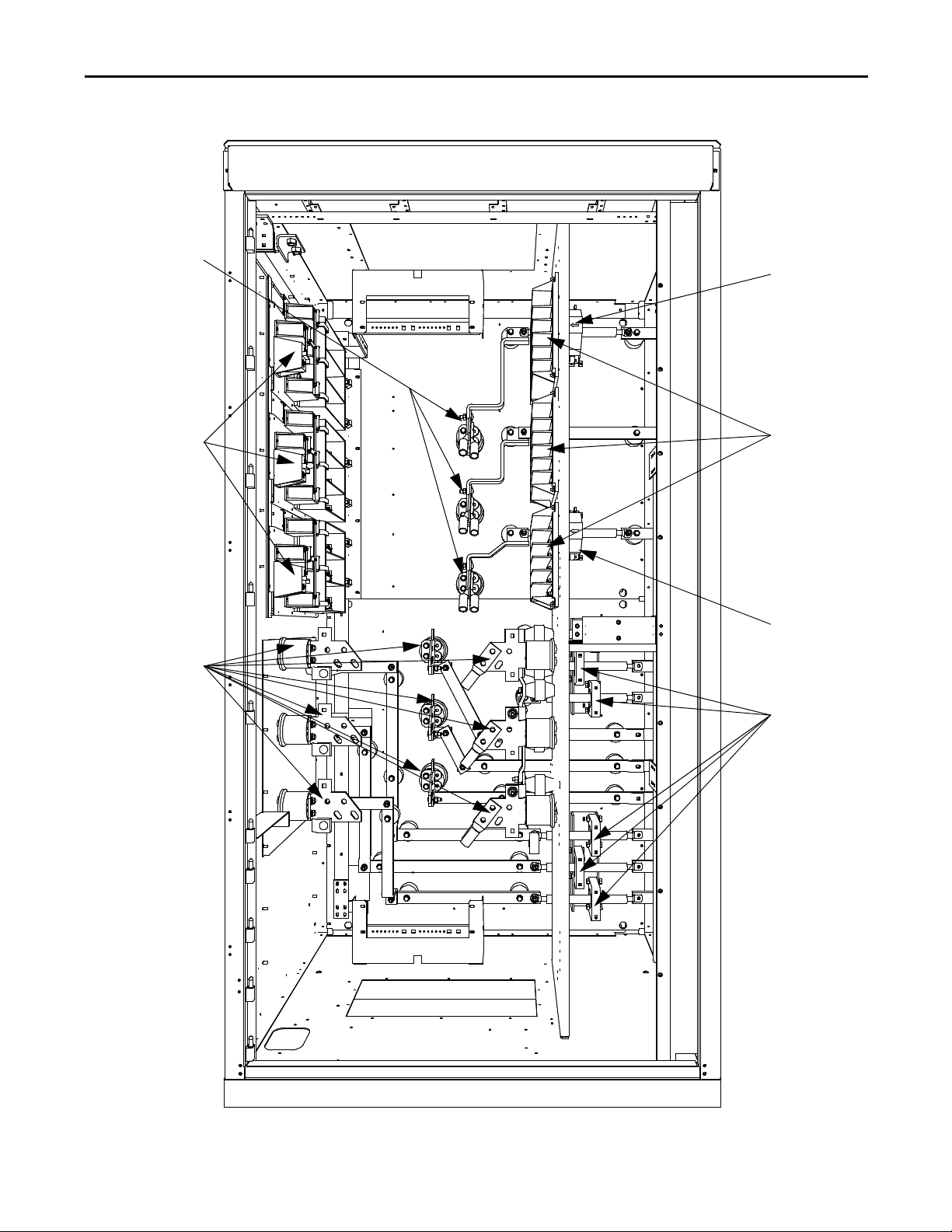

The following illustrations identify the control components and cabling of your

drives. Where appropriate, separate diagrams and instructions are available for

both the heat sink and the heat pipe “B” Frame models.

For information regarding power wiring and cabling connections (as might be

necessary for routine maintenance) refer to the PowerFlex 7000 “B” Frame

Installation Manual (7000-IN007_-EN-P

).

Control Power Off Tests

Perform the following checks before applying control power to the drive.

Rockwell Automation recommends that you complete these checks in the

sequence they are presented here.

This section is also available in the PowerFlex “B” Frame Commissioning Guide

(7000-IN006_-EN-P

drive testing.

); refer to that document for additional information on

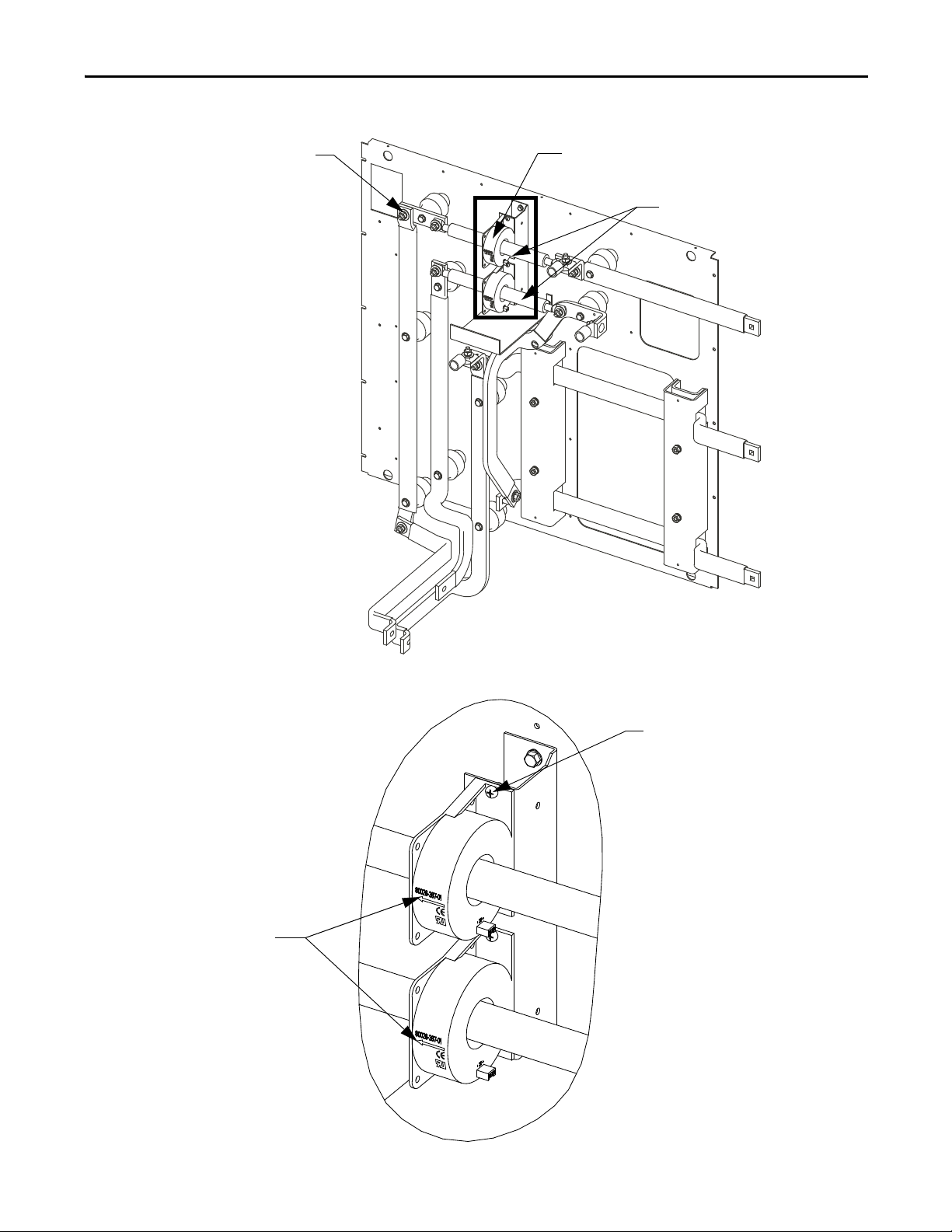

Interlocking

When the input contactor option is purchased, a key interlock is provided to

prevent access to the medium voltage compartments of the drive unless the input

isolation switch is locked in the open position.

Where the input switching device is provided by others, Rockwell Automation

will provide a key interlock on the medium voltage compartment of the drive,

and a matching interlock for installation by others on the upstream device. The

interlock shall be installed in a manner that ensures the power to the drive is off

and the drive is electrically isolated whenever the key is freed.

Although Key interlocks shipped with all medium voltage equipment are aligned

in the factory, they often move out of position during shipping or are often

misaligned when the cabinet is set down on an uneven floor. The following

instructions will assist the field engineers in quickly and accurately aligning the

deadbolt key interlock with its counterpart.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 23

Page 24

Chapter 3 Component Definition and Maintenance

ATT EN TI ON : Servicing energized industrial control equipment can be

hazardous. Severe injury or death can result from electrical shock, burn, or

unintended actuation of control equipment. Hazardous voltages may exist in

the cabinet even with the circuit breaker in the off position. Recommended

practice is to disconnect or lock out control equipment from power sources, and

confirm discharge of stored energy in capacitors. If it is necessary to work in the

vicinity of energized equipment, the safety related work practices of NFPA 70E,

Electrical Safety requirements for Employee Work places, must be followed.

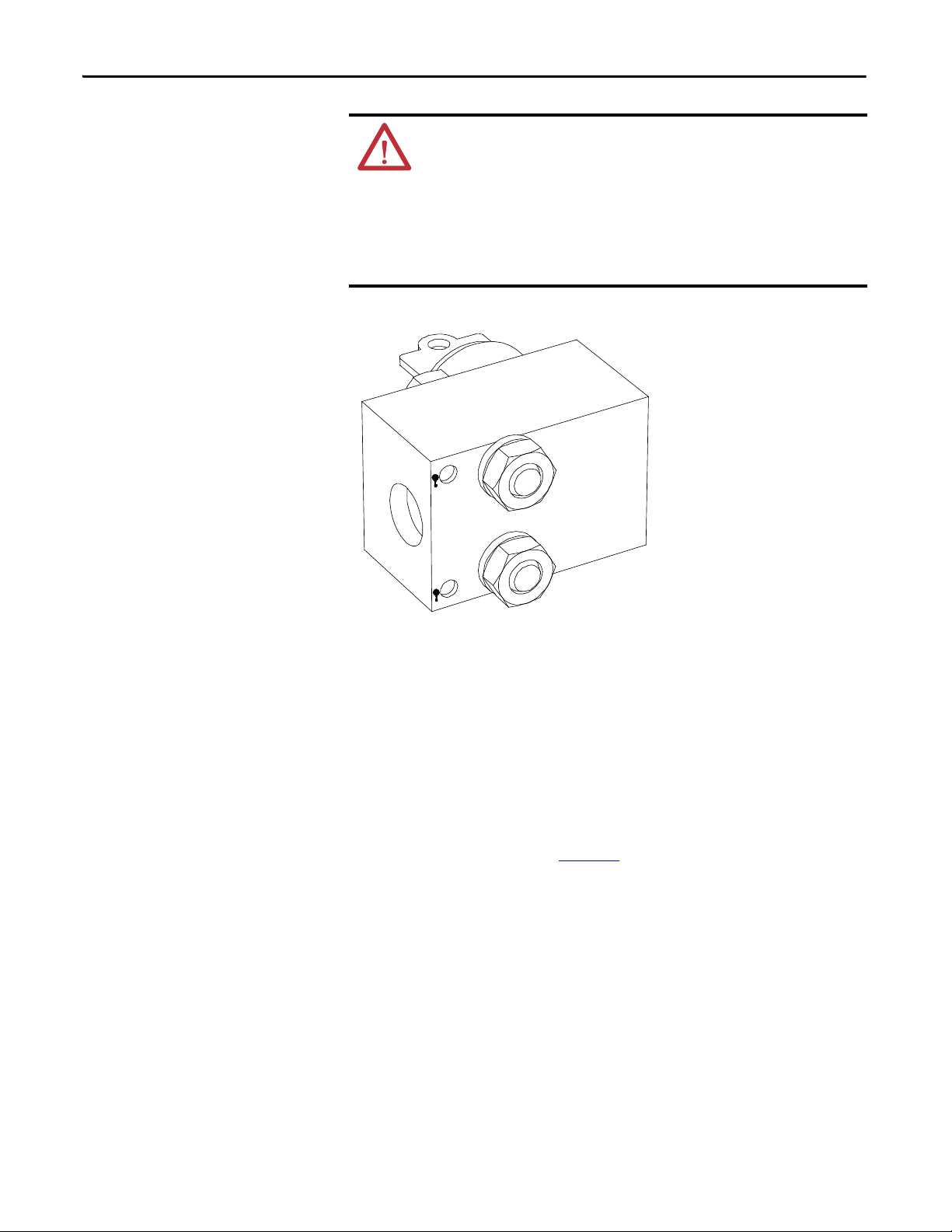

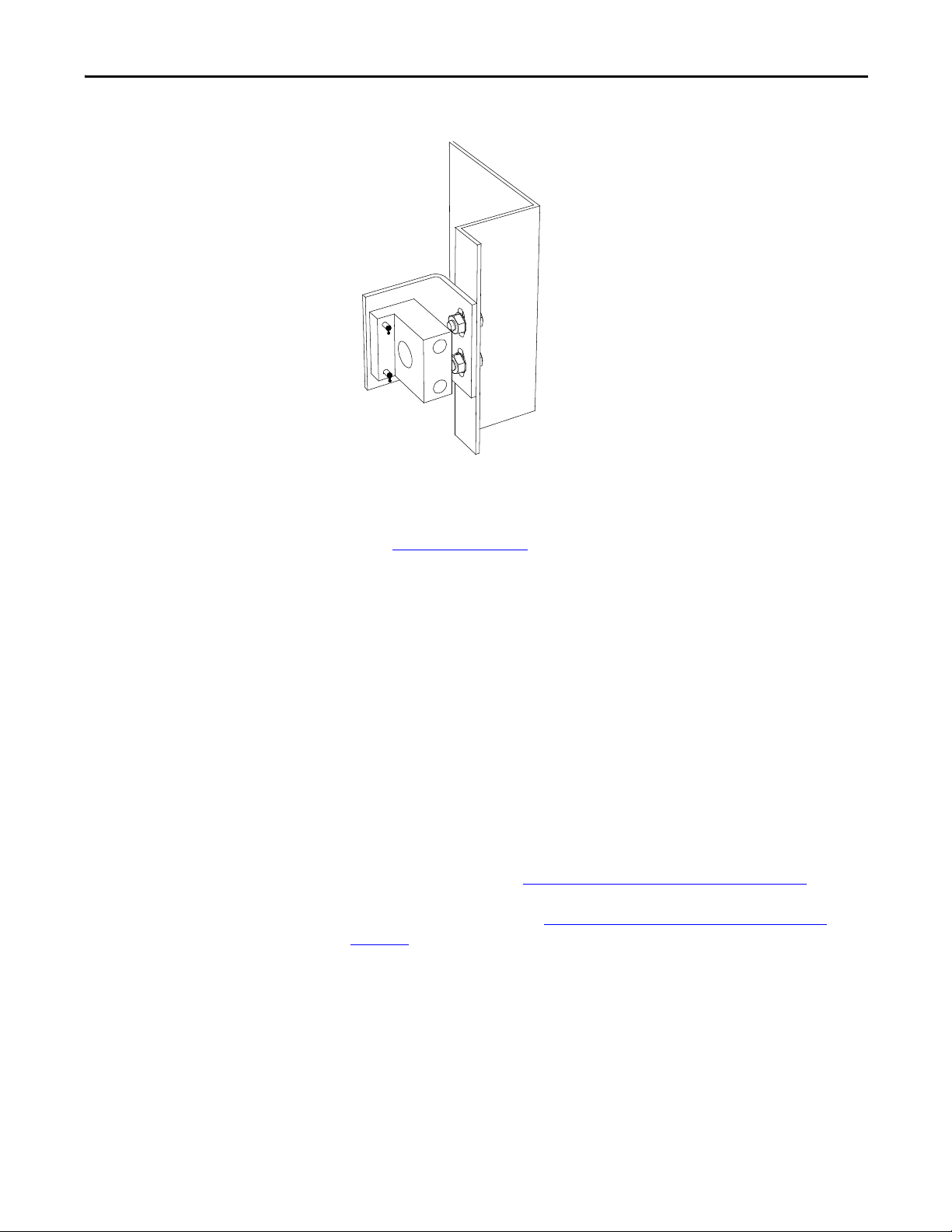

Figure 16 - Deadbolt assembly mounted to door

1. Lock out and isolate the drive from medium voltage. Verify with a hot

stick that there is no medium voltage present.

2. Determine that the key interlock is correctly aligned by securely bolting

the medium voltage doors of the cabinet closed and removing the key from

the lock. The key should turn easily; if any force is required to turn the key,

the deadbolt alignment requires adjustment.

3. Open the doors of the cabinet and inspect the key assembly. Place high

visibility grease on the pins of the deadbolt counterpart. The factory

recommends using yellow torque sealant, however if it is unavailable

almost any grease will do (Figure 17

).

24 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 25

Component Definition and Maintenance Chapter 3

Figure 17 - Deadbolt counterpart mounted to cabinet

4. Bolt the cabinet door closed so the pins on the dead bolt counterpart make

contact with the deadbolt assembly. Doing so should leave two marks of

torque sealant or grease on the assembly where the pins made contact (see

Figure 16 on page 24

).

Control / Cabling Cabinet Components

5. Slightly loosen the adjustment bolts on the counterpart and make the

necessary movements on the counterpart to ensure that the pins align with

the landing plates on the deadbolt assembly. As the amount of counterpart

movement required is an estimate, it may take a couple attempts to

properly align the assembly.

6. Clean the torque seal/grease from the key interlock once finished aligning

the counterpart.

Once properly aligned, the key should turn freely when the cabinet door is fully

bolted shut. If the key does not function when the door is tightly bolted closed,

adjustments will have to be made to the depth of the counterpart. This can be

done by adding shims on the landing plate where the counterpart is mounted.

For converter cabinets, see Converter Cabinet Components on page 50.

For DC link/fan cabinets, see DC Link and Fan Cabinet Components

page 111.

on

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 25

Page 26

Chapter 3 Component Definition and Maintenance

Grounding Network (For use

with Isolation Transformer)

or

Ground Filter (For use with

Line Reactor)

Motor Filter Capacitors

Hall Effect Sensors

Sensing Boards

Line Terminals

Motor Terminals

Current Transformers

Surge Arresters

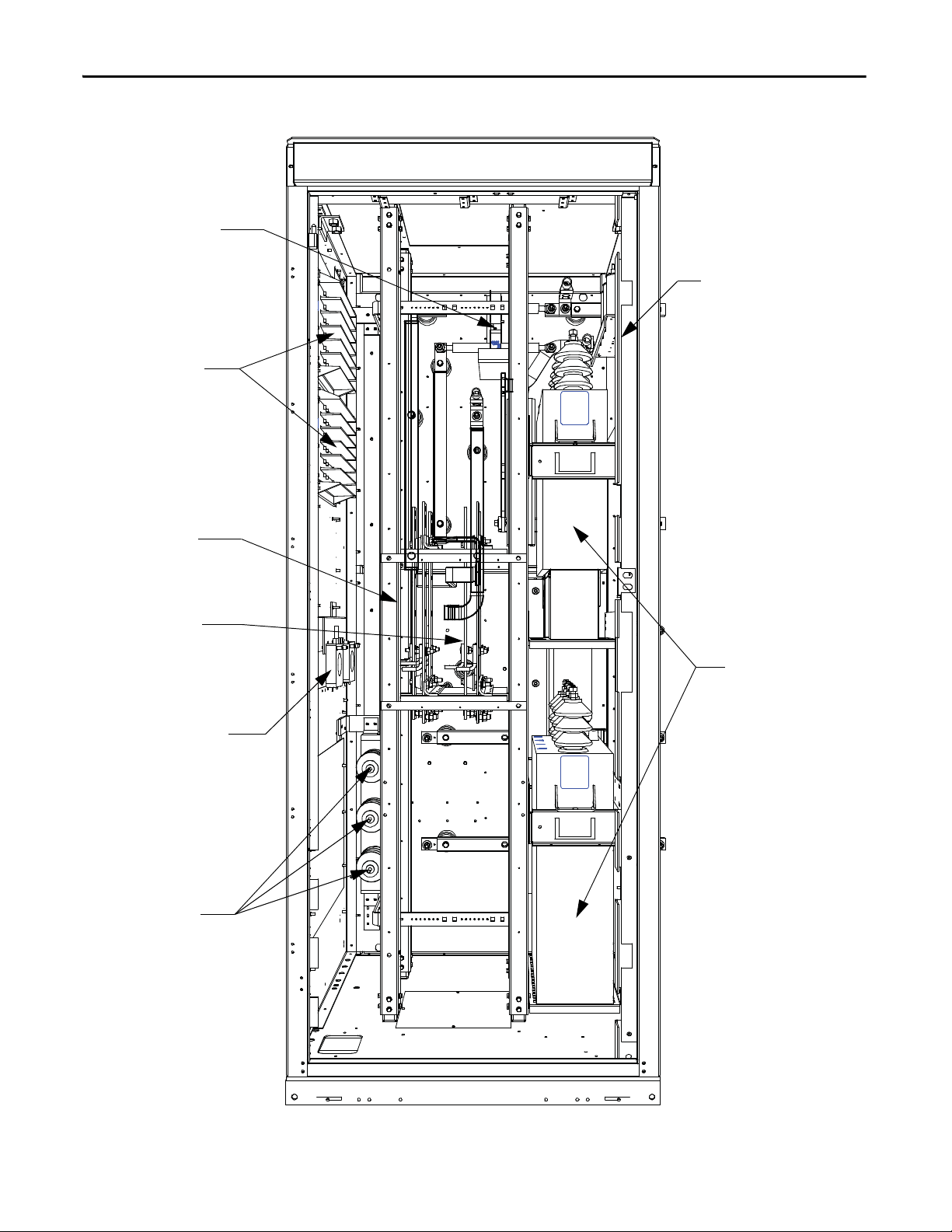

Figure 18 - Cabling cabinet for AFE rectifier (heat sink model)

26 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 27

Grounding Network (For use

with Isolation Transformer)

or

Ground Filter (For use with

Line Reactor)

Surge Arresters

Voltage Sensing Boards

Line Terminals

Current Transfo rmers

Zero Sequence Current

Transformer (used with

Line Reactor)

Motor Terminals

Hall Effect Current

Sensors

Component Definition and Maintenance Chapter 3

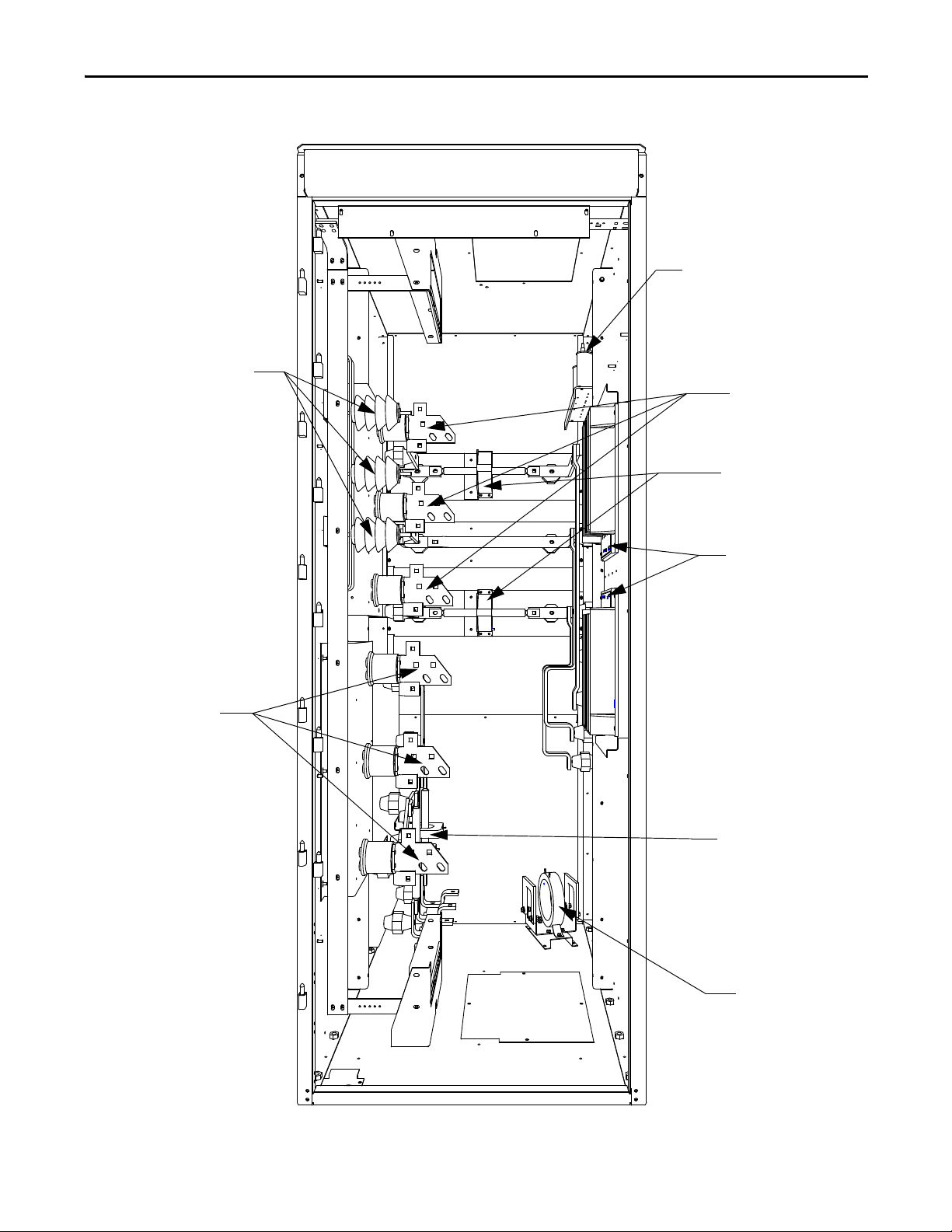

Figure 19 - Cabling cabinet for AFE rectifier (heat pipe model)

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 27

Page 28

Chapter 3 Component Definition and Maintenance

Surge Arrestors

Zero Sequence

Curren t

Transformer

Current Transformer

Grounding Filter (for

use with Line Reactor)

Hall Effect Current

Sensors

Voltage Sensing Boards

Motor Terminals

Line Terminals

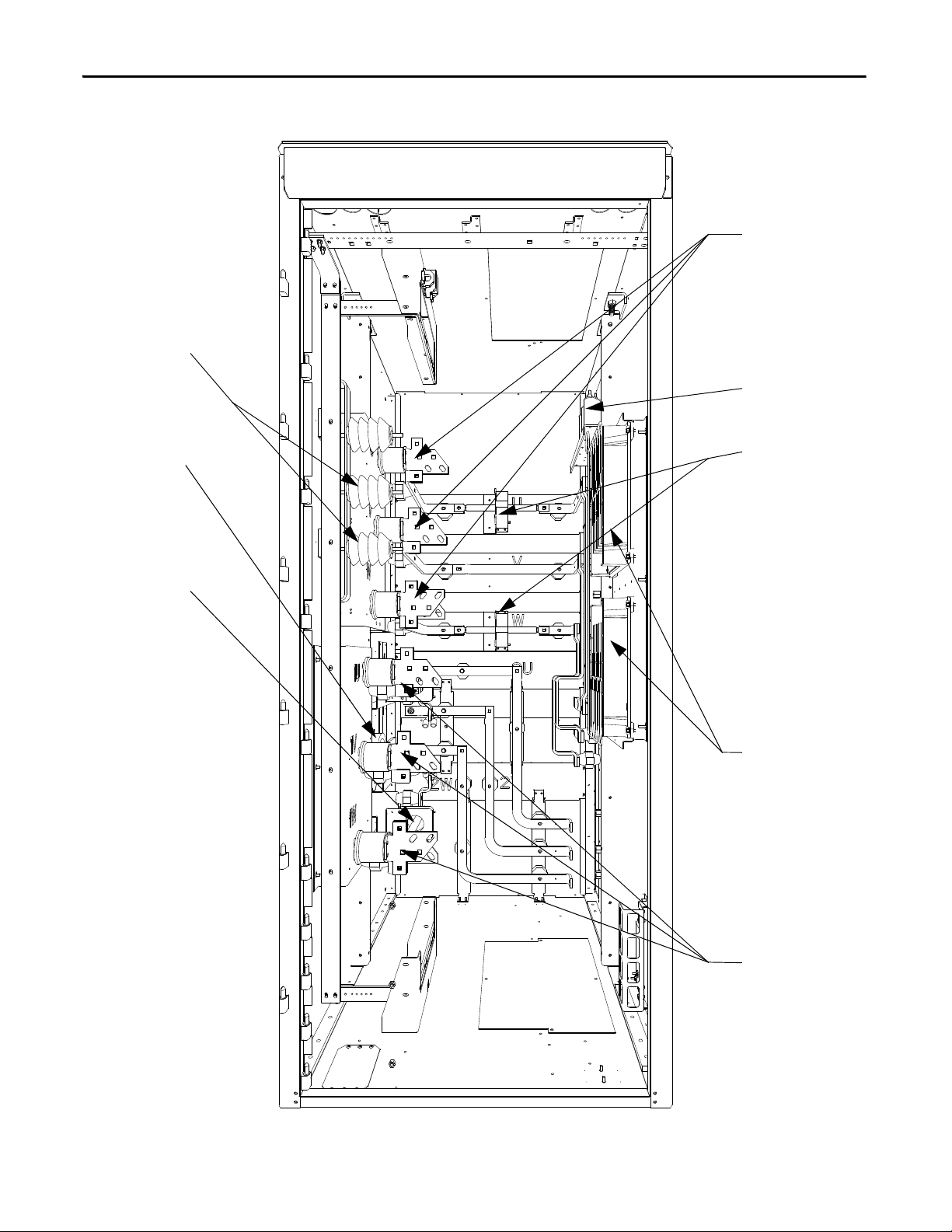

Figure 20 - Cabling Cabinet for AFE Rectifier (6600V heat pipe model)

28 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 29

Component Definition and Maintenance Chapter 3

Hall Effect Sensor

Vol tag e Se nsi ng

Boards

Hall Effect Sensor

Curren t

Tra ns fo rm er s

Motor Terminals

Tra ns ie nt

Suppression

Network

Line Terminals

Figure 21 - Cabling cabinet for 18 Pulse rectifier (motor filter capacitors not shown)

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 29

Page 30

Chapter 3 Component Definition and Maintenance

Line Filter

Capacitors

Zero Sequence

Current

Transformer

(if supplied)

Line

Reactor

Line

Terminals

Motor

Terminals

Motor Filter

Capacitor s

Figure 22 - AC line reactor cabinet with connection cabinet (heat sink model)

30 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 31

Fans

Resistors

Line Reactor

Line Reactor Baffle

Component Definition and Maintenance Chapter 3

Figure 23 - AC Line Reactor Cabinet (6600V heat pipe model)

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 31

Page 32

Chapter 3 Component Definition and Maintenance

Fans

Line Filter

Capacitors

Line Reactor Baffle

Line Reactor

Resistors

Motor Filter

Capacitors

Figure 24 - AC Line Reactor with connection cabinet (heat pipe model)

32 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 33

Component Definition and Maintenance Chapter 3

Voltage-Sensing Assembly

The voltage-sensing assembly consists of the voltage sensing board and the

mounting plate. The voltage sensing board has six independent channels that

convert voltages as high as 10,800V (7.2kV x 1.5 pu) down to low voltage levels

that the PowerFlex 7000 control logic (i.e. Signal Conditioning Board - SCB) can

use. To measure up to twelve independent voltage channels, link two assemblies

together, with one assembly acting as the master assembly and the second as the

slave assembly. In linked assemblies, the master assembly sends the twelve voltage

signals to the SCB board. For drives requiring the synchronous transfer option,

use one additional module.

This assembly uses a separate connector to output the transfer voltages directly to

the SCB board.

The following table shows the input voltage ranges for each input terminal on the

voltage-sensing board. There are four separate inputs taps for each independent

channel. This assembly operates at a nominal input voltage of up to 7200V with a

continuous 40% overvoltage. The output voltages scale to provide almost 10V

peak for a 140% input voltage at the high end of each of the voltage ranges.

Each channel has four taps that provide a range of input voltages and software to

provide a given amount of gain, so that 140% will correspond to the maximum

numerical value of the analogue to digital converter.

Nominal input voltage range

Tap Voltage Range

D 800...1449V

C 1450...2499V

B 2500...4799V

A 4800...7200V

ATT EN TI ON : Reconnect the grounds on the voltage sensing boards. Failure to

do so may result in injury, death or damage to equipment.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 33

Page 34

Chapter 3 Component Definition and Maintenance

Replacing the Voltage-Sensing Circuit Board Assembly

The number of sensing boards is dependent upon the drive rectifier

configuration.

1. Verify there is no power to the equipment.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the sensing board. Verify that all circuits are voltage-free, using a

hot stick or appropriate high voltage-measuring device. Failure to do so may

result in injury or death.

2. Mark the position of the ribbon cables and wires.

3. Remove the screws and lift the ring lugs from the terminals to remove the

wires.

4. Release the locking mechanism located on each side of the ribbon cable

connector and pull the ribbon cable straight out to prevent bending the

pins.

5. Remove the four nuts and washers that secure the assembly to the studs

welded to the frame.

6. Remove the old VSB and replace with the new VSB on the studs, using the

existing hardware to secure the assembly. Do not over-torque the

connections or you may break the studs.

7. Replace ring lugs on terminals. Plug in ribbon cables making sure that

cables are positioned properly and fitting is secure (locking mechanism is

engaged).

8. For personnel and equipment safety, ensure both grounding connections

are re-connected to the sensing board.

Figure 25 - Sensing board with mounting hardware placement

34 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 35

Component Definition and Maintenance Chapter 3

Input Transient Protection

The drive provides input transient protection in one of two forms:

• Transient Suppression Network (TSN), or

• Surge arresters

The TSN is optimized for 18 Pulse rectifier designs. Surge arresters are optimized

for AFE and Direct-to-Drive rectifier designs.

Transient Suppression Network (TSN)

The TSN module consists of an assembly of suppressors connected to each of the

three phase input lines and the structure’s ground bus. There are three assemblies

for an 18 Pulse drive.

A transient voltage spike in excess of the semiconductor rating will destroy or

shorten the lifespan of the device. The TSN module suppresses transient

overvoltages on the drive input, and is a standard feature of the drive. The two

basic blocks of the TSN module are the MOV suppressor and the MOV fuse.

MOV Suppressor

The transient suppressors used in the module are heavy-duty metal oxide

varistors (MOVs). Varistors are voltage dependent, nonlinear resistors. They have

symmetrical voltage/current characteristics similar to back-to-back connected

Zener diodes. The varistor has very high resistance below its voltage rating and

appears as an open circuit.

The leakage current through the device would be very small in this region. When

a voltage transient occurs in which the voltage exceeds the ‘knee’ in the curve, the

varistor resistance changes from its high state by several orders of magnitude to a

very low level. The voltage is clamped for a change in current of several orders of

magnitude (Figure 26

).

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 35

Page 36

Chapter 3 Component Definition and Maintenance

10-710-610-510

-4

10

-3

10

-2

10

-1

10010

10

2

10310

4

10

5

10

-8

CURRENT (AMPERES) -log scale

VOLTAGE

(VOLTS)

log scale

High Resistance

Region

Voltage Clamping Region

Short Circuit

Region

Figure 26 - Typical MOV V-I Characteristic Curve

When the MOV clips the voltage transient, the MOV absorbs the transient

energy. The varistor has a limited energ y absorbing capability and there is

insufficient time to conduct heat out of the device. The MOV size depends on

the steady-state voltage rating, the energy in the transient, and the repetition rate

of the transients. A critical element in selecting a MOV for protection is the

impedance in the line supplying the transient. The isolation transformer or the

AC line reactor on the input of the drive provides this impedance, which is why

an impedance level is necessary for these input devices.

MOV Fuse

A medium voltage fuse is in series with each of the Phase MOVs. As seen in

Figure 27 on page 37

, these fuses may reside on either the assembly or remote

from the assembly (on the Line Terminal module). Check the part number on

your module and the information in this documentation to determine which

assembly your drive requires.

The fuses provide overload protection for the conductors feeding the suppression

network (and overturned protection if a short circuit occurs on the downstream

side of the fuse.) These conductors will normally have a much smaller current

carrying capacity than the drive input conductors; they are not protected by the

drive input fuses. The fuses also isolate a failed MOV. Varistors initially fail in a

short-circuited condition. The high follow-through current will open the fuse

and remove the MOV from the circuit.

36 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 37

Component Definition and Maintenance Chapter 3

IMPORTANT

IMPORTANT

U

V

W

Drive Input Power from Line Terminals

Transient Suppression Network

Medium Voltage Input Fuses

Phase MOV Suppressor

Ground MOV Suppressor

The fuses are E-rated, current-limiting fuses with a high interrupting rating.

Because they are current-limiting, they limit both the magnitude and duration of

fault currents. They are small dimension, ferrule-type fuses with a fiberglass body,

and mount in standard fuse clips.

Rockwell Automation selects the fuses sent with the Transient Suppression

Network based on their characteristics (including internal resistance) for

optimum MOV performance and protection. Do not substitute other fuses

without contacting the factory first.

Voltage sensing occurs after the MOV fuse and will detect open fuses in the

drive control as a Master or Slave Undervoltage or Unbalance.

Figure 27 - Simplified wiring diagram

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 37

Page 38

Chapter 3 Component Definition and Maintenance

IMPORTANT

Ground location

Var ist ors

5 kV fuse example

7.2 kV fuse example

Connecting links

Var ist ors

5 kV fuse location

7.2 kV fuse location

Replacing Transient Suppression Network Fuses

Two sizes of fuses (5 kV, 7.2 kV) are available within the TSN located inside the

connection cabinet. The 18 Pulse drive contains three TSNs.

1. Ensure there is no power to the equipment.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

2. Fuses are held in a place with a fuse clip. To remove the fuse pull firmly.

3. To replace the fuse, hold it in position and push firmly until the fuse is

seated within the fuse clip. Install fuses so that the rating is visible.

Replace the fuse with another of the same rating. (See Figure 28 on page 38 for

location.)

Figure 28 - Transient Suppression Network

38 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 39

Component Definition and Maintenance Chapter 3

Replacing Metal-Oxide Varistors

Metal-oxide varistors (MOV) are part of the TSN located within the connection

cabinet.

1. Ensure there is no power to the equipment.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

2. Observe the locations of the connecting links.

3. Detach the connecting links by removing the screws.

4. Using a screwdriver remove the screws at the base.

5. Replace the MOV (polarity is not an issue).

6. Continue by replacing the screws and connecting links.

Each MOV panel is grounded. Ensure that one MOV (see Figure 28 on page 38

for location) connects to the grounding lead.

Surge Arresters

These medium voltage drives use heavy duty distribution class surge arresters for

transient overvoltage protection in the drives with AFE rectifiers. The arresters

are certified as per ANSI/IEEE Std C62.11-1993.

The surge arresters are MOVs, with or without an air gap in series, in sealed

housing. They provide overvoltage protection similar to that of the TSN module.

They differ from the TSN in that fusing is not mandatory for the operation of

surge arresters.

There are three types of surge arresters depending on the voltage class of the

drive:

Drive Voltage 2.4 kV 3.3 kV, 4.16 kV, 4.8 kV 6.0...6.9 kV

Arrester rating (RMS) 3 kV 6 kV 9 kV

Arrester MCOV (RMS) 2.55 5.10 7.65

The most severe temporary overvoltage occurs when one phase is grounded in an

ungrounded system. The full line-to-line voltage applies to the arrester in this

case. The arresters operate under this condition continuously without any

problems as indicated by their Maximum Continuous Operating Voltage

(MCOV) rating.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 39

Page 40

Chapter 3 Component Definition and Maintenance

W

V

Drive Input from Line Terminals

Heavy-duty

Distribution Class

Surge Arrestor

Three Y-connected surge arresters attach to the incoming MV lines. The neutral

point of the arresters connects to the ground bus.

Figure 29 - Surge arresters on incoming MV lines

U

Operation

Arrester operation without a gap is the same as that of MOVs in the TSN.

Depending on design, the arrester may also have a gap. Both gapped and ungapped arresters provide adequate overvoltage protection.

The arresters can withstand most commonly-seen bus transients within their

capability. If there is a harmonic filter on the MV bus connected to the drive, the

filter must satisfy relevant international or local standards, such as IEEE Std

1531— Clause 6.4, to avoid high inrush currents.

The surge arrester is certified as per ANSI/IEEE Std C62.11-1993. Certification

tests include high current short duration tests, low current long duration tests,

and fault current withstand tests. The fault current withstand tests consist of

different combinations of kA and number of cycles, including a 20kA 10-cycle

test, under which the arresters are non-fragmenting without expelling any

internal components.

When the incoming energy exceeds the handling capability of the arrester and

causes arrester failure, the housing splits open to vent without causing damage to

any adjacent components.

40 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 41

Component Definition and Maintenance Chapter 3

Surge Arresters

Replacing the Surge Arrester

1. Isolate and lock out all power to the drive.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

2. Wait a minimum of ten minutes for the drive to discharge stored energy.

3. Observe the location of the connecting leads.

4. Use proper method to ensure the leads are at ground potential. Use

temporary grounding when necessary.

5. Detach the connecting leads.

6. Loosen the bolt that attaches the surge arrester to the ground bus. Remove

the arrester. Remove temporary ground when applicable.

7. Replace the surge arrester with an equivalent one (make sure that the

voltage rating is the same).

8. Connect the leads to the surge arrester.

9. Torque the surge arrester hardware to 28 N•m (21 lb•ft).

Figure 30 - Surge Arresters (heat sink model)

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 41

Page 42

Chapter 3 Component Definition and Maintenance

Surge Arresters

Figure 31 - Surge Arresters (heat pipe model)

When you disconnect the surge arrester from drive, the arrester may retain a small

amount of static charge. As a precautionary measure, install a temporary ground

on the line-end of the arrester and discharge the stored energy. Remove

temporary ground before reinstalling the arrester. To avoid electrical shock when

removing the arrester from service, treat it as fully energized until you disconnect

both the line and ground leads.

Field Test and Care

No field testing is necessary. The arresters do not require special care. At very

dusty sites, however, you should clean the arrester when cleaning the entire drive.

42 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 43

Component Definition and Maintenance Chapter 3

IMPORTANT

Replacing Output Grounding Network Capacitors

PowerFlex 7000 18 Pulse and select AFE drives come with an installed grounding

network.

The number of capacitors varies depending on the system voltage.

1. Isolate and lock out all power to the drive.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

2. Note the position of the leads.

3. Remove the 6.4 mm (¼ in.) hardware and disconnect the leads connected

to the terminals.

4. Four brackets secure the capacitor. Loosen the four screws at the base of

the brackets and lift the capacitor out.

5. Place the new capacitor and tighten the screws securely.

6. Replace the ring lugs and 6.4 mm (¼ in.) hardware (see Figure 31

The maximum torque for the capacitor terminal is 3.4 N•m (30 lb•in).

Figure 32 - Capacitor in grounding network

).

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 43

Page 44

Chapter 3 Component Definition and Maintenance

IMPORTANT

Replacing the Hall Effect Current Sensor (HECS)

1. Isolate and lock out all power to the drive.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

2. Note the location of all wires and the orientation of the HECS. For quick

reference when checking the orientation of the HECS, look for the white

arrow.

The Hall Effect Current Sensor (HECS) and wires must be in the proper

orientation. Note the position before disassembly.

3. Remove the round bus bar. Remove the M10 hardware and slide the bar

out.

4. Remove the output connector. Note the orientation.

5. Remove the four screws on the base of the Hall Effect sensor and remove

the sensor.

6. Insert the new sensor. Orient the arrows as shown in Figure 34

.

7. Slide the bus bar back into place and secure with the M10 hardware.

8. Replace the output connector, noting the correct orientation.

44 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

Page 45

Component Definition and Maintenance Chapter 3

Bus Bar

Hall Effect

Current Sensor

M10 Hardware

Base H ardware

Arrows must be

oriented properly

Figure 33 - Hall Effect Current Sensor located within cabinet

Figure 34 - Hall Effect Current Sensor (detail)

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 45

Page 46

Chapter 3 Component Definition and Maintenance

IMPORTANT

Replacing the Current Transformer (CT)

1. Isolate and lock out all power to the drive.

ATTENTION: To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

2. Note the location of all wires and the orientation of the CT. For quick

reference when checking the orientation of the CT, look for the white dot.

The CT and wires must be in the proper orientation. Note the position before

disassembly.

3. Disconnect the wires.

4. Disassemble the bus bar to remove the CT. Remove the M10 hardware to

slide out the bus bar.

Filter Capacitor Cabinet

5. Remove the four screws located in the base of the CT and remove the CT.

6. Replace the CT, ensuring the proper orientation. Fasten the CT securely

with the four screws in the base

7. Reconnect the ring lugs. Do not overtighten or you will break the threaded

stud. For torque specifications, refer to Torque Requirements for

Threaded Fasteners on page 183. Replace the bus bar and tighten into

place.

Filter Capacitors

All “B” Frame drives use filter capacitors on the motor side. The AFE rectifier

options also include filter capacitors on the line side. Refer to Figure 19 on

page 27 (Cabling Cabinet for AFE Rectifier) and Figure 21 on page 29 (Cabling

Cabinet for 18 Pulse Rectifier).

The filter capacitors are three-phase, oil-filled, four-bushing units. The threephase capacitors are internal single-phase units connected in a Y configuration.

The neutral point of the Y connects to the fourth bushing, which is available to

use as a neutral point voltage measurement or other protection/diagnostics

purposes. The metal cases of the capacitors are grounded through a stud on the

capacitor housing.

The capacitors have internal “bleeding resistors” to discharge the capacitor and

reduce its voltage below 50V in five minutes when disconnected. Figure 35

a typical three-phase capacitor.

46 Rockwell Automation Publication 7000-UM202B-EN-P - June 2014

shows

Page 47

Figure 35 - Motor filter capacitor

IMPORTANT

Component Definition and Maintenance Chapter 3

WARNING: Allow 5...10 minutes for motor capacitors to safely discharge

voltage prior to opening cabinet doors.

Replacing Filter Capacitors

See Publication 7000-IN010_-EN-P, “Handling, Inspection, and Storage of

Medium Voltage Line Filter Capacitors”.

1. Isolate and lock out all power to the drive.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

2. Note the location of all the cables and mark them accordingly.

3. Remove the 4 power connections to the terminals, and the single ground

connector from the drive to the capacitor frame, located at the back top

right corner of the capacitor.

4. Remove the front bracket that holds the capacitor in place. At the rear of

the capacitor, there is no hardware securing the capacitor; it fits into a slot

in the assembly.

5. Remove the capacitor from the drive.

Capacitors can weigh as much as 100 kg (220 lbs). Use two or more people to

remove a capacitor.

Rockwell Automation Publication 7000-UM202B-EN-P - June 2014 47

Page 48

Chapter 3 Component Definition and Maintenance

ATT EN TI ON : The porcelain bushings are extremely fragile and any force applied

to the bushings can damage the seal between the bushing and the body

causing potential leaks or chipping.

6. Install the new capacitor, sliding it back until it fits into the slot. Fasten the

front bracket.

7. Reconnect all the power cables and the ground connection. These use

M14 hardware, but should only be tightened to 30 N•m (22 lb•ft) due to

capacitor mechanical constraints. You may want to fasten these

connections before fully sliding the capacitor into place depending on the

available space.

8. Follow the instruction labels on each capacitor to tighten the terminal

connections.

9. Reinstall the removed sheet metal, and complete one final check to ensure

connections are secure and correct.

Testing Filter Capacitors

There are two ways to test line filter capacitors. Rockwell Automation

recommends the first method as it reduces the chance of re-torque issues because

the capacitors are not disconnected. If the readings are unsatisfactory, the second

method is more accurate, but involves disconnecting and testing them

individually.

First Method

1. Ensure there is no power to the equipment.

ATT EN TI ON : To prevent electrical shock, disconnect the main power before

working on the drive. Verify that all circuits are voltage-free using a hot stick or

appropriate voltage-measuring device. Failure to do so may result in injury or

death.

ATT EN TI ON : Verify the load is not running due to process. A freewheeling

motor can generate voltage that feeds back to the equipment.

2. Follow appropriate safety steps to isolate the equipment from medium

voltage.

3. Verify that there is no voltage present on the capacitor by using a hot stick

or any other appropriate voltage-measuring device.

4. Perform visual inspection to ensure there is no oil leak or bulge in any of