Page 1

Industrial 15" and 12.1"

Flat Panel Monitors

Bulletin 6185-C and Bulletin 6185-B

Installation and User Manual

Page 2

2

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

6185-C and 6185-B Industrial Flat Panel Monitors........... 5

Description .............................................................................. 6

Part Numbers........................................................................... 8

6185-C Monitor Hazardous Locations.................................... 9

Power Indicators...................................................................... 9

Installing Your Monitor ........................................................ 10

Before you Begin..................................................................... 10

Installing Your Monitor........................................................... 12

Making Connections.............................................................. 15

Connecting the Monitor........................................................... 15

Safety Considerations.............................................................. 16

Connecting a Host Video Source............................................. 16

Connecting the Touchscreen Interface (Optional)................... 17

Connecting Power ................................................................... 17

Configuring Video Setup....................................................... 20

Setting Up Your Workstation................................................... 21

Starting the Screen Setup Utility............................................. 24

Adjusting Your Monitor with the OSD.................................... 25

Full Range Dimming Control (Optional 6185-C Only)......... 31

Calibrating the Video Gain...................................................... 33

Performing Routine Maintenance........................................ 34

Cleaning................................................................................... 34

Replacing a Line Cord............................................................. 34

Other Maintenance.................................................................. 34

Troubleshooting and Support............................................... 35

Troubleshooting....................................................................... 35

Allen-Bradley Support ............................................................ 37

Appendix A: Installing Your Monitor in a Rack................ 38

Installing the 6185-C with Optional Rack Adapters................ 38

Appendix B: Monitor Dimensions........................................ 41

6185-C Dimensions................................................................. 41

6185-B Dimensions................................................................. 44

Appendix C: Touchscreen Serial Interface ......................... 46

Description .............................................................................. 46

Setting Up the Touchscreen Interface...................................... 46

Appendix D: Video Cables.................................................... 49

HD-15 V ideo Connector.......................................................... 49

Appendix E: Product Specifications.................................... 50

Publication 6185-5.1

Page 3

3

Important User Information

electromechanical equipment. "Safety Guidelines for the Application, Installation, and Maintenance of Solid State Controls"

(Publication SGI-1.1) describes some important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and because of the wide variety of uses for solid state equipment, all persons responsible for

applying this equip ment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment. The examples and diagrams in this manual are included solely for illustrative purposes. Because

of the many variables and requirements associated with any particular installation, Rockwell Automation cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect to use of the information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation is

prohibited.

Throughout this manual, we use notes to make you aware of safety considerations.

ATTENTION:

lead to personal injury or death, property damage, or economic loss.

Important:

Identifies information that is especially important for successful application and understanding of the product.

Solid state equipment has operational characteristics differing from those of

Identifies information about practices or circumstances th at can

Publication 6185-5.1

Page 4

4

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Publication 6185-5.1

Page 5

6185-C and 6185-B Industrial

6185-C and 6185-B Industrial

6185-C and 6185-B Industrial6185-C and 6185-B Industrial Flat Panel Monitors

Flat Panel Monitors

Flat Panel MonitorsFlat Panel Monitors

This manual provides installation, operation, and maintenance

instructions for the Allen-Bradley 6185-C and 6185-B monitors.

This manual supports the following Rockwell Automation models:

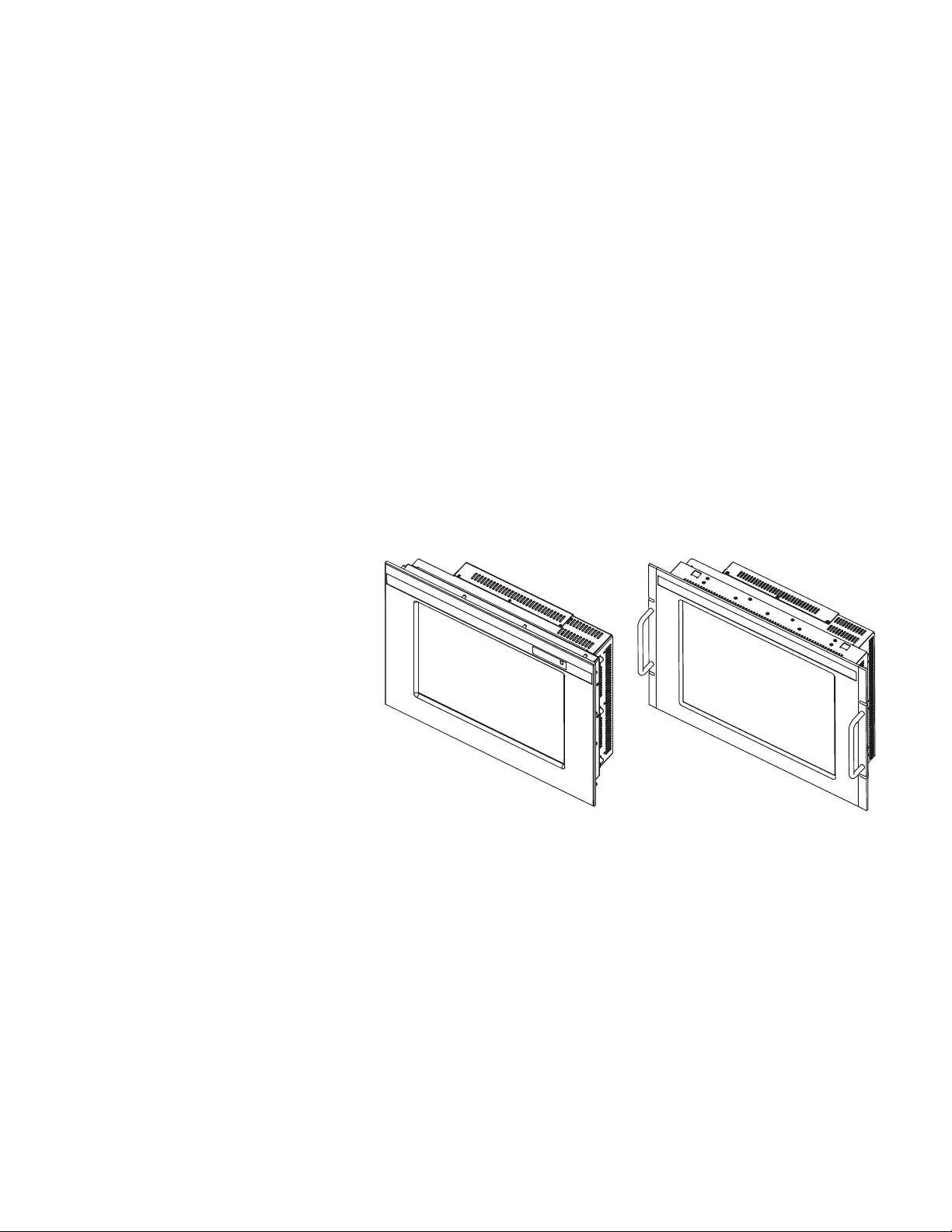

• 15.0” Panel mount (6185-C)

• 12.1” Panel mount (6185-B)

Note:

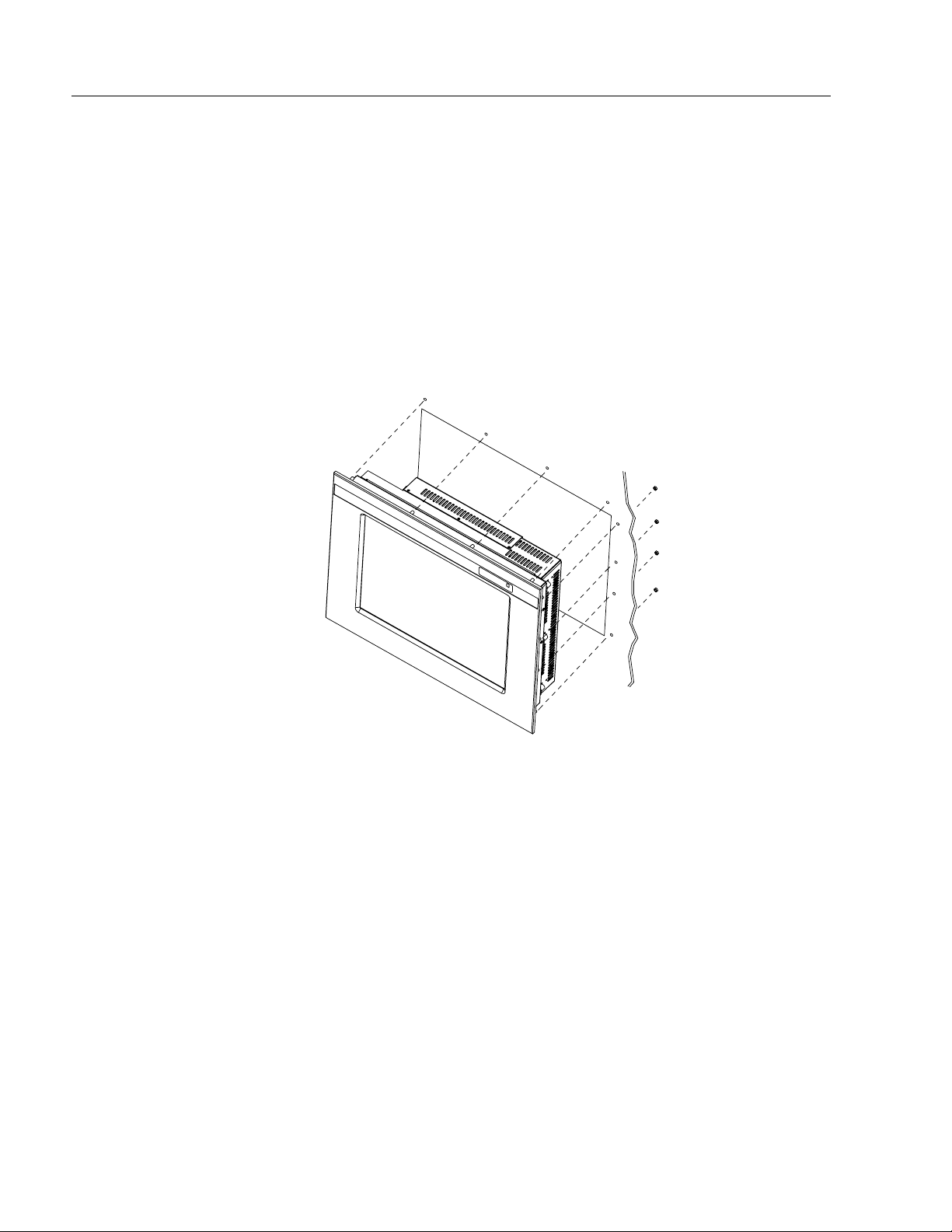

Figure 1

6185-C and 6185-B Panel Mount

If you want to place your monitor into a rack, you can use

the optional rack adapters brackets.

Figure 2

6185-C Panel Mount

with Optional Rack Adapter Brackets

Publication 6185-5.1

Page 6

6

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Description

The 6185-C and 6185-B monitors offer the following:

• 256K color (18-bit) display

• AC or DC power options

• Plug and Play compatible

• 120°H, 100°V viewing angle

Capabilities specific to the 6185-B include the following:

• Bright (250 nits) Active Matrix-TFT 800x600 display

• Video formats supported from 640x480 to 800x600

Capabilities specific to the 6185-C include the following:

• Bright (200 nits) Active Matrix-TFT 1024x768 display

• Video formats supported from 640x480 to 1024x768

• Class 1, Division 2 Hazardous Area Certification

ATTENTION: The equipment described in this

document generates, uses, and emits radio frequency

energy. The equipment has been tested and found to

comply with FCC Rules, Part 15, subpart J, for Class A

computing devices.

The use of non-shielded interface or power cords with

Allen-Bradley industrial monitors is prohibited.

Available Options

The following options are available:

• AC and DC power options

• NEMA 4/12 (IP65/IP53 equivalent) or 4X (stainless steel) front panel

options

• Touchscreen options

• Video cable options

• Power cord options

The following are also available for the 6185-C:

• Full-range dimming

• Rack mount adapter brackets (EIA-19 8U)

Publication 6185-5.1

Page 7

6185-C and 6185-B Industrial Flat Panel Monitors

Package Contents

The shipping cartons contain the following items:

• Monitor

• Screen setup utility on floppy diskette

• Package of mounting hardware

• AC power cord (optional)

• Video cable (optional)

• This user manual

A monitor with a touchscreen option ships with these additional items:

• Supporting software and manuals

• RS-232 serial extension cable (optional)

7

Publication 6185-5.1

Page 8

8

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Part Numbers

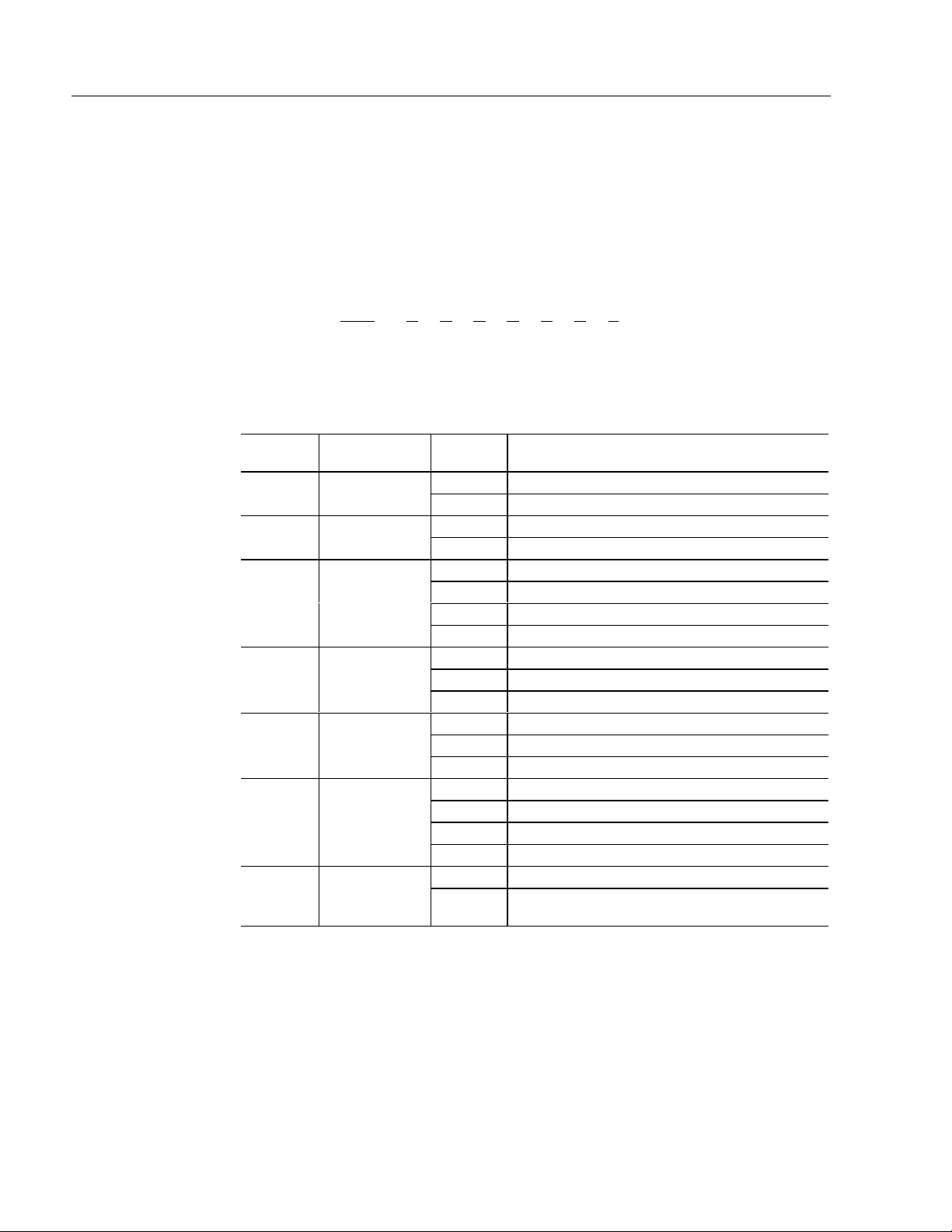

The part number for your particular unit consists of the Bulletin number

(6185) followed by a seven-digit code indicating the size (B or C) and

options on your unit.

Following are explanations of the part numbers for the various models of

monitors.

Example:

6185

1 2345678

Table A

Catalog Number Explanation for 6185-C and 6185-B Monitors

Position Option

Type

4 Touchscreen/

Display Shield

5 Power input

6

7 Touchscreen

External video

cable

serial cable

C A A A A A Z

Option

Letter

B 12.1” Panel Mount Monitor2 Enclosure type

C 15.0” Panel Mount Monitor

A NEMA 4/12 Aluminum Panel3 Front Panel

B NEMA 4X Stainless Steel Panel

A Resistive Polished Touchscreen

C Resistive Antiglare Touchscreen

W Tempered Glass Anti Reflective Display Shield

Z Polycarbonate Polished Display Shield

A 120/240 AC input, USA Power Cord

B 120/240 AC input, No Power Cord

C 24V DC Input

A 6 foot (1.8 meter) HD15-HD15 Cable

B 15 foot (4.6 meter) HD15-HD15 Cable

Z None

A 6 foot (1.8 meter) DE9-DE9 Cable

B 15 foot (4.6 meter) DE9-DE9 Cable

D 6 foot (1.8 meter) DB9-DB25 Cable

Z None

A Full Range Dimming, 6185-C only8 Accessories

R

Rack Mount Adapter Brackets (EIA19-8U),

6185-C only

Category Description

Publication 6185-5.1

Page 9

6185-C and 6185-B Industrial Flat Panel Monitors

9

6185-C Monitor Hazardous Locat io ns

Power Indicators

See the nameplate label on the 6185-C monitor for certifications.

ATTENTION: In Class I, Division 2 hazardous

locations, the panel mount (6185-C) must be wired per

the National Electric Code and/or Canadian Electric code

as it applies to hazardous locations.

A bi-color LED is provided on the front panel to indicate various

operating modes. The following table describes the functions assigned to

each color.

Table B

Power Indicator LED

LED Color Indication

Green (solid) Power ON, video sync detected (normal operation)

Amber (solid) Power ON, loss of video sync or disconnected video

cable

Optional Full Range Dimming is available on 6185-C models. If your

monitor has this option, you will have two LEDs. For more details on

using the Full Range Dimming functionality and reading the LEDs, see

Adjusting the Full Range Dimming Control on page 30.

Publication 6185-5.1

Page 10

10

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Installing Your Monitor

Installing Your Monitor

Installing Your MonitorInstalling Your Monitor

Before you Begin

This section describes how to install the 6185-C and 6185-B.

When installing the monitor, it is important to consider environmental

factors that could affect performance as well as possible effects from

equipment operation on personnel and nearby equipment.

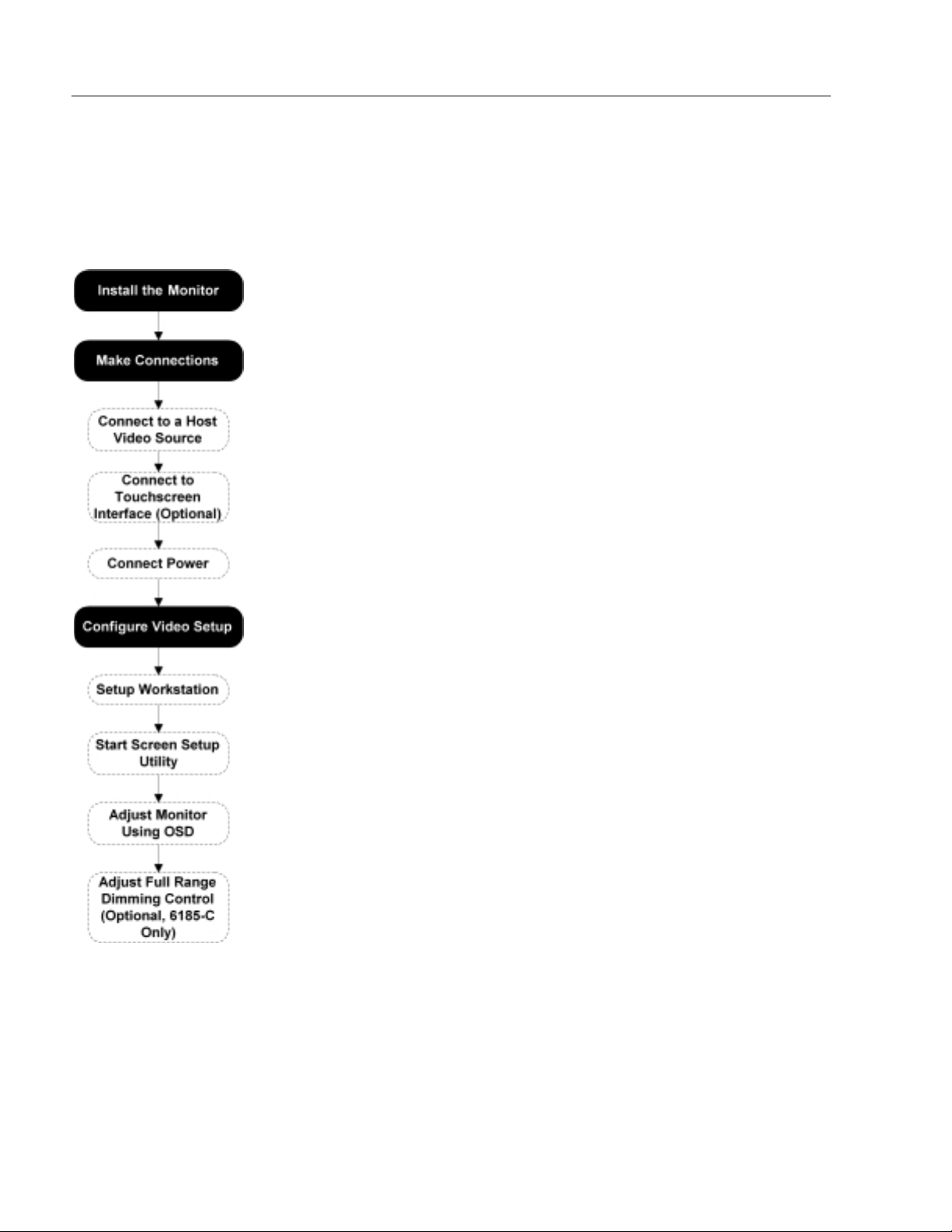

The figure on the left displays the general process to install, connect, and

adjust your monitor.

Installation Guidelines

Following these guidelines will help ensure that the monitor provides

safe and reliable service.

• Ensure that sufficient power is available from a single phase AC

outlet at the site.

• Ensure that sufficient space is available around air inlets and outlets

to provide the circulation necessary for cooling. Never allow air

passages to become obstructed.

• Ensure that the ambient air tempera ture will not exceed the

specified maximum temperature. You may need a user-supplied fan,

heat exchanger , or air condit ion er to m eet thi s condit ion in some

installations.

Publication 6185-5.1

Note:

Important

• Leave the monitor’s enclosure or cover in place at all times during

operation. The cover affords protection against high voltages inside

the monitor and inhibits radio-frequency emissions that might

interfere with other equipment.

• The Federal Communications Commission has prepared a pamphlet

that addresses the problem of radio frequenc y inter ference to radio

Remember that heat rises—many times the temperature at

the top of an enclosure is much higher than the rest of the

enclosure if the air is not circulating.

This monitor is designed to operate at a range of extremes,

:

however it is not good design practice to continuously

operate the monitor at the highest end of the specified

temperature range.

While the product will operate at its highest specified

temperature, the overall life span of any electronic device is

shortened when it operates at its highest rated temperature.

Page 11

Installing Your Monitor

and television reception, which should be consulted in case of

problems with such interference. This publication, “How to Identify

and Resolve Radio/TV Interference Problems” (Stock #004-00000345-4) may be obtained from the US Government Printing Office,

Washington, DC 20402.

• Determine the minimum and maximum ambient humidity for the

monitor by consulting the Appendix E: Product Specifications on

page 50. Ensure that the humidity of the ambient air will not exceed

these limits. In very dry environments, static charges build up very

readily. Proper grounding of the equipment through the AC power

cord can help reduce the likelihood of static discharges, which may

cause shocks and damage electronic components.

11

Publication 6185-5.1

Page 12

12

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Installing Your Monitor

Panel mount monitors are designed to provide protection against water

and dust to NEMA 4 (IP65) and NEMA 12 (IP53) standards.

Slides or shelves are not required because the panel mount monitor is

designed to be supported by the panel in which it is installed.

Note:

Using optional rack adapters, you can install the 6185-C

into a rack. For procedures, skip this section and see

Appendix A: Installing Your Monitor in a Rack on page 38.

Figure 3

Generic Panel Mount Diagram

Publication 6185-5.1

Tools Needed

In addition to the tools required to make the panel cutout, you will need

the following tools:

• 3/8" deep well socket

• ¼" drive extension – 6" or longer

• ¼" drive ratchet or ¼" drive torque ratchet

Page 13

Installing Your Monitor

Panel Mounting Guidelines

Observe the following precautions before installing the unit in a panel:

• Confirm that there is adequate space behind the panel. Remember to

allow extra space (0.5 in. or 12.7 mm behind and on each side) for air

circulation.

− For a 6185-C, a cabinet with a minimum depth of 4.4 in. (112mm)

is sufficient.

− For a 6185-B, a cabinet with a minimum depth of 3.25 in.

(82.6mm) is sufficient.

• Take precautions so that metal cuttings do not enter any components

that are already installed in the panel.

• Supporting panels should be at least 14 gauge to ensure proper

sealing against water and dust and to provide proper support. The

mounting hardware supplied accommodates panels up to 0.25 in.

(6.35 mm) thick.

13

Note:

Supporting panels must be cut and drilled to

specifications before installation.

ATTENTION: Failure to follow these warnings may

result in personal injury or damage to the panel

components.

Before Unpacking the Monitor

Before unpacking a new monitor, inspect the shipping carton for

damage. If damage is visible, immediately contact the shipper and

request assistance. Otherwise, proc eed with unpa ck ing.

Note:

Make sure you keep the original packaging for the monitor

in case you need to return the monitor for repair.

Installing Your Monitor

1. Prepare panel cutout for monitor. Refer to specific cutout drawings

in Appendix B: Monitor Dimensions on page 41.

2. Carefully remove the monitor from its packaging.

Publication 6185-5.1

Page 14

14

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

3. If access to the side of the monitor is not available following

installation, attach the power and video cables to the side of the

monitor at this time. Refer to the figure on Page 15.

4. Install the monitor in the prepared cutout.

5. Install the lock nuts and washers, supplied with the monitor, around

the perimeter of the monitor. Extra lock nuts and washers are

provided.

Note:

Use #10-32 or M5 self-locking nuts for mounting.

ATTENTION: You must apply nuts and washers on all

studs for NEMA 4/12 fluid applications.

6. Tighten all mounting nuts evenly to a torque of 24 inch-pounds.

ATTENTION: Mounting nuts must be tightened to a

torque of 24 inch-pounds to provide panel seal and avoid

potential damage. Rockwell Automation assumes no

responsibility for water or chemical damage to the

monitor or other equipment within the enclosure due to

improper installation.

Publication 6185-5.1

Page 15

Making Connections

Making Connections

Making Connections

Making ConnectionsMaking Connections

15

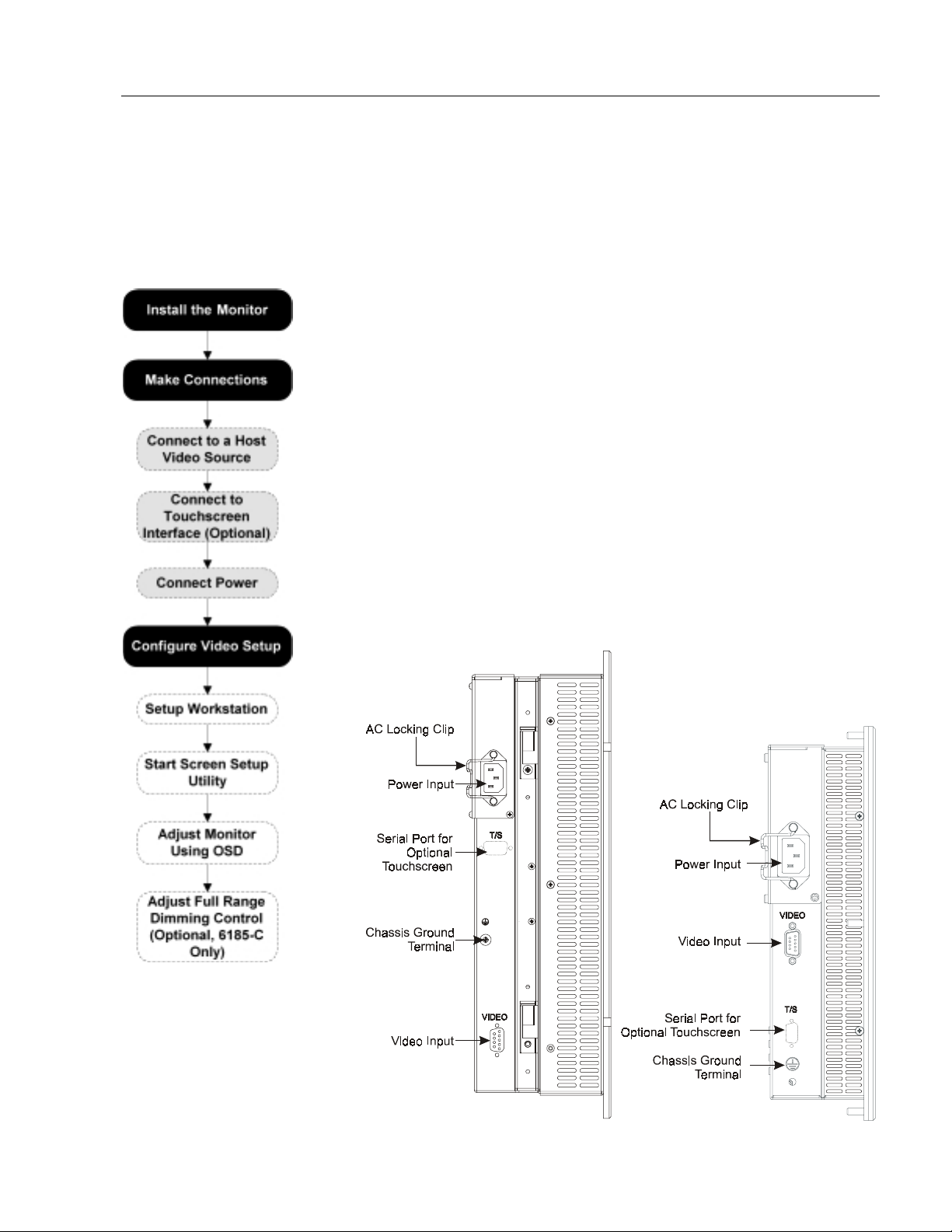

Connecting the Moni tor

Side panels of both the 6185-C and 6185-B monitors have connectors for

attaching cables to accomplish the following:

• Connecting to a host video source (HD-15 VGA connector)

• Connecting to a host touchscreen

• Connecting to AC power (IEC connector) or DC power (terminal

block)

In the figure on the left, the gray shaded areas represent where you are

now in the general process to install, connect, and adjust your monitor.

Monitor Connections

The following figure shows standard configurations for your monitor.

Note:

Figure 4

6185-C and 6185-B Monitor Connections

Some connectors on your monitor may differ slightly

from the following figure.

Publication 6185-5.1

Page 16

16

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Safety Considerations

Connecting a Host Video Source

When connecting the monitor, note the following safety considerations:

ATTENTION: EXPLOSION HAZARD! – Substitution

of components (6185-C) may impair suitability for Class

I, Div. 2.

EXPLOSION HAZARD! – Do not disconnect

equipment (6185-C) unless power has been switched off

or the area is known to be non-hazardous.

The video connection to the host is made through a HD-15 (female)

connector located on the side panel.

Note:

To establish a signal using the HD-15 connector:

1. Obtain a shielded, properly terminated video cable of length as short

as possible. Longer cables (up to approximately 75 feet in some

cases) may be used, provided they are properly constructed. Your

package may include a six-foot or 15-foot video cable, if specified.

For more information on using a HD-15 video cable to

connect to the host computer, see page 49.

2. Connect one end of the cable to the female HD-15 video input

connector on the side panel of the monitor.

3. Connect the other end to the output of any IBM-compatible VGA

adapter or other video generator.

Note:

You may connect the monitor to video generators that

do not conform to VGA standards. The main

requirement is that the generator provides analog RGB

video signals (0.714V above reference black into 75

ohms) and separate horizontal and vertical sync signals.

Publication 6185-5.1

Page 17

Making Connections

17

Connecting the Touchscreen Interface (Optional)

The serial touchscreen interface connection to the host is made through

an RS-232 DE-9 (female) D-shell connector located on the side panel.

The optional touchscreen provides a high-resolution touch input system.

Driver software included with the package allows the touchscreen to

function with many popular DOS and Windows

applications as a pointing device (mouse).

Note:

To connect the touchscreen:

1. For units with the touchscreen option, make sure you have one of the

optional serial cables.

2. Connect one end of the touchscreen serial cable to the T/S port

connector on the side of the monitor.

3. Connect the other end to any communications port on the host

computer.

Refer to Appendix C: Touchscreen Serial Interface on page

46 for additional details on the installation and operation of

the touchscreen.

®

-based industrial

Connecting Power

4. Tighten the captive screws on the cable connector to secure it.

Allen-Bradley monitors can be ordered with either AC or DC power

option.

Connecting AC Power

The 6185-C and 6185-B monitors with an AC power option require a

single-phase power supply providing 85 to 264V AC at 47 to 70 Hz.

Power must be available at a grounded three-pin outlet located nearby.

Whenever possible, connect the monitor to the same AC source that

supplies the computer.

To connect AC power to the monitor:

1. Turn off the main switch or breaker.

2. Use the ground terminal of the monitor to establish a chassis-to-earth

ground connection. The ground terminal is an M5 screw. Secure one

end of a ground strap to the ground terminal. Connect the other end

of the ground strap to a good earth ground.

Publication 6185-5.1

Page 18

18

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

ATTENTION: Chassis ground must be connected for

safe operation of the monitor. The AC receptacle on the

monitor is a 3-wire type with chassis ground pin, and the

mating AC cord supplied is a 3-wire type, designed for

connection to a grounded 3-pin AC outlet. However, a

properly ground AC outlet is not always available, and

grounding using a 3-wire cord can easily be defeated. If

you fail to ground the monitor properly, the setup may

result in personal injury from electrical shock or damage

to the equipment.

3. Connect the socket end of the AC power cord to the mating

connector on the side of the monitor and secure the cord with the

power cord retainer clip. See the figure on page 15.

ATTENTION: EXPLOSION HAZARD! You must

install the power cord retainer clip to ensure safety in

hazardous locations.

Failure to secure the power cord with the retainer clip

could result in hazardous conditions if the power cord is

accidentally disconnected.

ATTENTION: EXPLOSION HAZARD! – Do not

disconnect equipment unless power has been switched off

or the area is known to be non-hazardous.

4. Connect the plug end of the AC power cord to the main outlet.

5. Restore AC power to the outlet.

6. Proceed to Configuring Video Setup on page 20.

Connecting DC Power

The 6185-C and 6185-B monitors with a DC power option require a DC

power supply providing 18 to 32V DC.

To connect DC power to the monitor:

1. Turn off the main switch or breaker.

2. Use the ground terminal on the monitor to establish a chassis-toearth ground connection. The ground terminal is an M5 screw.

Secure one end of a ground strap to the ground terminal. Connect the

other end of the ground strap to a good earth ground.

Publication 6185-5.1

Page 19

Making Connections

ATTENTION: Chassis ground must be connected for

safe operation of the monitor. The DC screw terminals on

the monitor have a chassis ground pin. However, some

DC sources may not provide a proper ground path. If you

fail to ground the monitor properly, the setup may result

in personal injury from electrical shock or damage to the

equipment.

ATTENTION: EXPLOSION HAZARD! – Do not

disconnect equipment unless power has been switched off

or the area is known to be non-hazardous.

3. Route the power wires from your 18-32 VDC power supply and

connect the leads to the DC input terminal block on the monitor as

shown in the following figure. Tighten the screw terminals to ensure

a good connection.

19

Note:

Be sure to follow the labeling on the DC power supply

terminal block to prevent damage to your monitor.

Figure 5 Connecting Power to the Terminal Block

4. Restore DC power.

Publication 6185-5.1

Page 20

20

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Configuring Video Setup

Configuring Video Setup

Configuring Video SetupConfiguring Video Setup

After making the connections, you are ready to setup your monitor.

This section describes how to setup and configure your monitor.

You will need to use the following procedures:

• Setting Up Your Workstation - verifies that your workstation is using

the appropriate settings. See page 21.

• Using the Screen Setup Utility - provides graphical guidelines to use

when adjusting the OSD settings. See page 24.

• Working with the OSD - allows you to physically change the monitor

settings on the monitor. See page 25.

In the figure on the left, the gray shaded areas represent where you are

now in the general process to install, connect, and adjust your monitor.

Importance of Correctly Setting Up the Monitor

If you do not correctly set up the flat panel monitor, the image may

appear correct when you view the Windows Desktop (the screen

displayed initially displayed when Windows starts). However, when you

display an application with certain colors or patterns, you may notice

noisy video or jitter problems at that time.

For example, if the horizontal or vertical position of the display is not

adjusted correctly, one edge of the screen image may extend beyond the

side of the monitor screen.

The horizontal size and clock phase adjustments are especially important

for flat panel monitors. If the horizontal size setting is not properly

adjusted, the screen image may contain vertical shaded bars or the image

may be too wide or too narrow for the screen. If the clock phase setting

is not properly adjusted, the screen image may be “jittery.”

Publication 6185-5.1

Page 21

Configuring Video Setup

Figure 6

Monitor Video Adjustments

You may also need to adjust the brightness or contrast of the screen

image based on the conditions of the location in which the monitor is

installed.

21

Setting Up Your Workstation

Note:

The screen setup utility delivered with this flat panel

monitor is designed to present the "worst case" scenario for

graphic display. It shows a range of colors and presents a

pattern you can use to ensure that the monitor is adjusted

properly.

Note:

Flat panel monitors are not susceptible to magnetic

interference in the same way that CRT monitors are.

However, all monitors are susceptible to ground loop

problems between the computer and the monitor. Ground

loops occur when two or more devices with different

ground potentials are connected with cables and ground

currents flow between. These currents may cause vertical or

horizontal noise bars to move through the display screen.

Verify and change these settings for your workstation using the Windows

Control Panel.

To access monitor settings, select the Start button and select Settings to

access Control Panel. In Control Panel, select Display to access monitor

settings. The options on the Control Panel screens may vary depending

on your video driver.

Selecting the Monitor Type

If you are using Windows 95, Windows 98 or Windows 2000 and your

video card supports it, you should enable your workstation to detect Plug

& Play monitors and select Plug and Play as the monitor type.

Publication 6185-5.1

Page 22

22

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Note:

These monitors use a flat panel display, but they use the

workstation’s analog VGA interface. Because of this, some

setup screens may indicate that the monitor is operating as a

CRT (analog) device, rather than a flat panel (digital)

device.

If your video card does not support Plug and Play, or if you are using

Windows NT, you should the monitor type manually. These settings are:

• Plug and Play Monitor - 6185-C and 6185-B with Plug and Play

enabled system

• Super VGA 1024x768 - 6185-C manual setting

• Super VGA 800x600 - 6185-B manual setting

Depending on if you are using Windows NT, Windows 95 or Windows

98, accessing the settings differ.

Use the following table as a procedure guideline for accessing the

monitor types manually.

Table C

Procedures for Accessing Monitor Type Manually

Windows NT Windows 95 Windows 98

1. Open Control Panel 1. Open Control Panel 1. Open Control Panel

2. Open Display icon 2. Open Display icon 2. Open Display icon

3. Click Settings tab 3. Click Settings tab 3. Click Settings tab

4. Verify Desktop Area

(Resolution)

5. Verify Refresh

Frequency

4. Click Advance

Properties button

5. Click Monitor tab 5. Click Monitor tab

6. Click Change button 6. Click Show all

7. Click Show all

Devices button

8. Verify Manufacturer:

Standard monitor

types

9. Verify Models:

Plug and Play

•

Monitor

Super VGA 800x600

•

Super VGA

•

1024x768

4. Click Advance

Properties button

Devices button

7. Verify Manufacturer:

Standard monitor

types

8. Verify Models:

Plug and Play

•

Monitor

Super VGA 800x600

•

Super VGA

•

1024x768

Publication 6185-5.1

Page 23

Configuring Video Setup

23

Setting Up Video Resolution

Flat panel monitors are fixed resolu tion devices and the image looks best

when operated at their native resolution.

If you switch the resolution of this monitor from the native resolutions,

the display may look slightly distorted due to replication techniques used

to display the full screen. The native resolutions are as follows:

• 1024x768 for 6185-C

• 800x600 for 6185-B

The following table lists the amount of video memory you need to run in

each video mode:

Table D

Video Memory Requirements

Resolution Color Mode Video Memory

640x480 256 colors (8 bit) 0.4 Mb

High color (16 bit color) 0.7 Mb

True Color (24 bit color) 1.0 Mb

800x600 256 colors (8 bit) 0.6 Mb

High color (16 bit color) 1.0 Mb

True Color (24 bit color) 1.5 Mb

1024x768 256 colors (8 bit) 0.9 Mb

High color (16 bit color) 1.7 Mb

True Color (24 bit color) 2.4 Mb

Note:

The 6185-C and 6185-B monitors display up to 256k colors

(18-bit color). Because most workstations only support

8-bit, 16-bit, or 24-bit color, you must operate the monitor

in True Color mode (24-bit color) to use the full color range

of the monitor. The monitor will interpret the colors

correctly.

Verifying Video Refresh Rate

Unlike CRT monitors, there is no benefit to operating a flat panel

monitor at higher vertical refresh rates. It is best to select 60 Hz.

You can verify video refresh rate for your workstation using the

Windows Control Panel.

Publication 6185-5.1

Page 24

24

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Starting the Screen Setup Utility

1. Insert the diskette provided with the monitor in the floppy drive of

the host computer.

Note:

2. Start the screen setup utility using the instructions on the diskette

label.

The following is an example of the screen setup utility.

This utility is designed for 32-bit operating systems

only (Windows 95/98/2000 or Windows NT 4.0 or

greater).

Publication 6185-5.1

Page 25

Configuring Video Setup

25

Adjusting Your Monitor with the OSD

Your monitor is equipped with three controls or pushbuttons on the rear

panel:

• Select

• Up

• Down.

These controls allow you to operate the OSD to adjust and setup your

monitor.

Figure 7

Controls on Back Panel

The following table provides a summary to using the pushbuttons:

Table E

Pushbutton Guidelines

The Select Pushbutton… The Up and Down Pushbuttons…

Starts the OSD. Highlight the option you want.

Selects a highlighted option.

Saves the value and returns to the

previous menu.

Adjust the selected option higher or

lower.

Publication 6185-5.1

Page 26

26

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Working with the OSD

Starting the OSD

1. Press the Select pushbutton to display the OSD.

Verifying Workstation Settings

You changed the settings in Setting Up Your Workstation on page 21.

This procedure verifies your selections.

1. Highlight the System Menu option using the up and down

pushbuttons and press Select.

2. Verify that you are using the desired settings:

• Resolution of 1024x768 for 6185-C or 800x600 for 6185-B

works best

• Vertical refresh rate of 60 or 75Hz.

3. If necessary, change the resolution or video refresh rate for the

workstation using the Windows Control Panel.

Using the Auto-Adjust Feature

Using the auto-adjust feature automatically adjusts the monitor correctly,

often requiring no additional changes.

1. Highlight the Auto Adjust option and press Select.

The monitor attempts to adjust the settings properly based on the

current signal. This process may take up to 20 seconds.

Verifying the Horizontal Size

Verify that the horizontal size is adjusted correctly. You should see

individual lines through the center section of the setup image. See the

figures in this section for detail:

Changing the horizontal size setting adjusts the width of the image on the

monitor from left to right; thus adjusting the sample rate of the monitor

to match the pixel clock rate of the workstation's video card.

1. Highlight the Position option and press Select.

Publication 6185-5.1

2. Highlight the Horizontal Size option and press Select.

3. Adjust the horizontal size until the vertical shaded bars disappear.

Page 27

Configuring Video Setup

Figure 8

Setup Screen Example, Needing Video Adjustments

Figure 9

Setup Screen Example Detail: Horizontal Size Adjustment

27

Note:

If you are running the monitor with a resolution other than

native mode, you will not see individual lines in all cases.

This is a result of the replication techniques used to display

the full image. The native resolutions are as follows:

• 1024x768 for 6185-C

• 800x600 for 6185-B

4. Once you have adjusted the horizontal size until the vertical shaded

bars disappear, then press Select.

Since you have not yet adjusted the clock phase of the monitor, the

lines may appear consistently fuzzy or jittery across the image. You

may need to complete the adjustment process before the vertical

lines are sharp and crisp.

5. Exit the Horizontal Size menu.

Publication 6185-5.1

Page 28

28

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Verifying the Horizontal Position

Verify that the horizontal position is set correctly. The setup image has a

thin white border around the image. It should be visible on the right and

left sides of the screen.

1. Highlight the Horizontal Position option and press Select.

2. Adjust the horizontal screen position so that the white border line is

visible on both sides of the image.

If the horizontal size and position are adjusted correctly, you should

be able to adjust the horizontal position one adjustment to the left or

right and the white border line should move off the edge of the

screen. If this does not occur, you may need to repeat the horizontal

size adjustment step.

3. Exit the Horizontal Position menu.

Verifying the Vertical Position

Verify that the vertical position is set correctly. The setup image has a

thin white border around the image. It should be visible on the top and

bottom sides of the screen.

1. Highlight the Vertical Position option and press Select.

2. Adjust the vertical screen position so that the white border line is

visible on the top and bottom of the image.

3. Exit the Vertical Position menu.

Verifying the Clock Phase

Verify that the clock phase of the monitor is adjusted to best match the

input video signal. An incorrect phase adjustment will show up on screen

as “jitter” or fuzzy lines through the center section of the setup image.

1. Highlight the Clock Phase option and press Select.

2. Adjust the clock phase until the screen image is sharp and there is no

screen “jitter.”

This adjustment selects the best match the video clock rate of the

workstation’s video card

3. Exit the Clock Phase menu.

Publication 6185-5.1

Page 29

Configuring Video Setup

Adjusting the Brightness

Changing the brightness setting adjusts the overall intensity of the

monitor. To obtain the best display, first set the brightness control to the

appropriate setting under the lighting conditions in which the monitor

will be used.

29

Note:

Allow time for the backlight on the monitor to warm up

completely before you adjust the brightness control.

1. Highlight the Brightness option and press Select.

2. Adjust the brightness value to its lowest setting.

3. Adjust the brightness until the black bar at the top of the screen

changes from black to dark gray.

4. Adjust the brightness down until the bar changes back to black. This

is the optimal brightness setting given the current lighting

conditions.

5. Exit the Brightness menu.

Adjusting the Contrast

Changing the contrast setting adjusts the difference between the

monitor's light and dark elements. The optimum setting may vary

slightly with different types of monitors and changes in ambient lighting,

as well as individual taste.

1. Highlight the Contrast option and press Select.

2. Adjust the contrast value up to its highest setting. The gray bars on

the bottom of the screen image change to white.

Adjust the contrast down until the white bar stays white and the first

light gray bar changes back to light gray. The figure below is the

optimal contrast setting given the current lighting conditions.

Figure 10

Contrast Adjustment

3. Exit the Contrast menu.

Publication 6185-5.1

Page 30

30

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

OSD Menu Reference

You can make other adjustments in addition to the most common ones

previously listed. Use the following table as a reference of the available

options on the OSD menu.

OSD Menu Items Description

Basic Adjustment Menu

Image Position Menu

System Menu

Auto-Adjustment Menu Automatically sets up the monitor based on the current video

Exit Menu Closes the screen setup utility.

Brightness Adjusts the overall intensity of the monitor.

Contrast

Color Balance Adjusts the balance of red, green, and blue colors used in the

Clock Phase

Default Settings Returns to the default values. These default values may not be

Horizontal Position Adjusts the location of the image on the monitor from left to right.

Horizontal Size Changes the width of the image on the monitor from left to right.

Vertical Position Adjusts the location of the image on the monitor from top to

Language

OSD Position Changes the location of the screen setup utility with the user

OSD Turn Off Time Changes the timeout period for the screen setup utility (how long

Current Video

Signal

Adjusts the difference between the monitor's light and dark

elements.

display. This will change the overall color temperature of the

monitor.

Adjusts the clock phase of the monitor to best match the video

clock rate of the workstation’s video card.

the same as the ones that were set when you received your

monitor. Allen-Bradley often changes the defaults by lowering the

brightness and increasing the contrast. Also, the phasing will be

different depending on the specific configuration for your monitor.

Adjusts the sample rate of the monitor to match the pixel dock

rate of the workstation's video card. The vertical size is set

automatically by the monitor according to the video signal.

bottom.

Changes the screen setup utility language. Options are English,

French, Italian, German, and Spanish.

interface settings.

before it will automatically disappear if not used).

Changes the monitor functions based on the current video signal.

signal.

Auto Adjust works best on a full screen of data. Results may not

be accurate if image does not go to the edges of the screen. The

Screen Setup utility is an ideal image for Auto Adjustment.

Publication 6185-5.1

Page 31

Configuring Video Setup

31

Full Range Dimming Control (Optional 6185-C Only)

Allen-Bradley provides a full range dimming control option for the

6185-C that allows full range control of image luminance from the front

panel. The full range dimming control option is Accessory option A.

Adjusting the Full Range Dimming Control

The LEDs are present with or without the dimmer control, but the two

buttons that adjust the luminance of the monitor are optional.

Figure 11

Optional Full Range Dimming Control

Note:

The control buttons adjust the luminance of the image, which is not the

same as a brightness setting. Luminance refers to the actual intensity of

the light emitted from the monitor. Brightness refers to the appearance of

the image displayed – a range between dark and dazzling. The backlights

are controlled by the luminance control.

The dimming controls are located on the rear of the monitor

with the optional stainless steel fro nt p ane l.

Publication 6185-5.1

Page 32

32

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

To adjust the luminance of the monitor:

Press and hold either one of the dimmer buttons until the luminance is

adjusted as desired.

• The left dimmer button reduces the lum inanc e and the right but ton

increases it.

• The green LED blinks fast when you first press the button and slows

as you reach the end of the adjustment range.

• When you release the dimmer button for three seco nds, the amber

LED blinks twice to indicate that your changes have been saved and

will be used each time the monitor is powered ON.

To turn off the monitor without turning off the power:

1. Press and hold both buttons for 2 seconds, until the monitor’s

backlight is turned OFF.

2. Press either button to turn the backlight back ON.

Table F

Interpreting the Dimmer LED

Green LED Amber LED Condition

On Off Normal Operation - The monitor is receiving a valid video

signal.

Off On Signal Not Received - The monitor is not receiving a valid

video signal.

On (blinking

slowly)

On (blinking fast

then slow)

Off On (blinking

Off

Off

slowly)

Backlight Off - The monitor is still ON but the backlight is

powered OFF. Hold down both buttons for 2 seconds to

disable the backlight. Press either button to enable the

backlight.

Changing Dimmer Setting - When you are pressing one

of the dimmer buttons, the LED blinks fast and slows

down as you reach the end of the possible dimmer

adjustments in that direction. The light stops blinking

when you stop pressing the button, and the amber LED

blinks twice when the change has been saved. Once a

dimmer setting has been saved, it will be used each time

the display is powered ON.

Calibration Mode - See instructions below.

Publication 6185-5.1

Page 33

Configuring Video Setup

33

Calibrating the Video Gain

Monitors with this a full range dimming control option have a calibration

mode to allow you to compensate for abnormal video signal levels.

Many PC video cards drive the video signal above the .714V as defined

by the VGA standard. You may need to calibrate the video gain if you

see “ghosting” (shadows to the right of the image) or washed out colors.

To calibrate the monitor:

1. Insert the diskette provided with the monitor in the floppy drive of

the host computer.

Note:

The adjustment utility is designed for 32-bit operating

systems only (Windows 95/98/2000 or

Windows NT 4.0 or greater).

2. Start the screen setup utility using the instructions on the diskette

label.

3. Press and hold down both luminance buttons for eight seconds.

Note:

The screen will go blank after two seconds and will

come back on after eight seconds.

The amber LED blinks slowly to indicate that you are in calibration

mode.

4. Use the left luminance button to lower the contrast until the white

bar stays white and the first light gray bar changes back to light gray.

This is the optimal setting for the video gain. (See the figure on

Page 29.)

5. Press and hold down both luminance buttons for two seconds to exit

calibration mode.

The amber light blinks twice when the calibration is complete.

Publication 6185-5.1

Page 34

34

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Performing Routine Maintenance

Performing Routine Maintenance

Performing Routine MaintenancePerforming Routine Maintenance

Cleaning

Replacing a Line Cord

Occasionally clean the display panel and cabinet with a soft cloth

dampened (not soaked) with a mild (non-abrasive) glass cleaner. Keep

turning a fresh side of the cloth toward the screen surface to avoid

scratching it with accumulated grit.

Note:

Special care should be taken when cleaning a touchscreen or

polycarbonate shield that is installed over the screen. Abrasive and

certain chemical cleaners can easily damage the surface.

Note:

To avoid shock and fire hazards, the monitor’s power cord should be

replaced if the insulation becomes broken or if it develops a loose

internal connection.

The solvent should be applied only to the cloth, and not

directly on the monitor screen.

Do not use paper products as they may scratch the surface.

To minimize the risk of abrasion, allow the screen to

stand dry.

For best results cleaning a monitor with the optional,

antireflective tempered glass display shield, a solution of

denatured alcohol is recommended to thoroughly clean the

display. Never use alcoholic or ammoniac cleaners to clean

the polycarbonate shield or a touchscreen.

Other Maintenance

Publication 6185-5.1

ATTENTION: EXPLOSION HAZARD! – Substitution

of components (6185-C) may impair suitability for Class

I, Div. 2 hazardous locations.

Qualified service personnel should perform all maintenance, except for

the power cord replacement described above.

Page 35

Troubleshooting and Support

Troubleshooting and Support

Troubleshooting and Support

Troubleshooting and SupportTroubleshooting and Support

35

Troubleshooting

You can refer to this table to help identify the cause and offer a solution

to a problem. This table lists typical problems you may encounter.

Table G

Troubleshooting Table

Symptom Possible Problem Action

Front panel status LED does not come on.

Screen is blank.

Image is too bright or white. Contrast or luminance control not properly

No image visible even when brightness

control is set full UP.

Image is dim, even with brightness and

contrast controls set full UP.

Image will not adjust.

Image position changes are not saved. Position mode not saved correctly. Reposition the image using the OSD. Wait

Power cord not connected. Connect the power cord.

No power available at outlet. Test outlet by plugging in a lamp or other

Power cord faulty. Replace power cord.

Monitor faulty. Have monitor serviced.

Screen saver activated.

Contrast or luminance control not properly

adjusted. (Luminance control on 6185-C

only.)

Video cable problem. Check for proper installation of video

adjusted.

Monitor is out of adjustment or faulty. Have monitor serviced.

Video cable problem. Check for proper installation of video

Fault in video source. Test video source by connecting to

Fault in monitor. Have monitor serviced.

Video timing outside of range. Use the OSD to adjust the Clock Setting

Not operating in native resolution. When not in native mode black bands

known good device.

Check the status LED using the table

provided on page 9. Disable screen saver

by activating an input to the host system.

Turn brightness or luminance control UP.

cable(s). Refer to installation instruct i ons.

Replace suspected faulty cable(s).

Turn brightness or luminance control

DOWN.

cable(s). Refer to installation instruct i ons.

Replace suspected faulty cable(s).

another monitor that is known to be

operational.

(Page 28). Make sure timing is within

VESA.

appear at the top and bottom of the

screen. The native resolutions are as

follows:

1024x768

•

800x600 for 6185-B

•

5 seconds for the changes to be saved

before you turn off power.

for 6185-C

Publication 6185-5.1

Page 36

36

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Symptom Possible Problem Action

Image is not stable. Monitor is not synched to video source. Refer to installation instructions.

Check for proper video cable installation.

Replace suspected faulty cable.

Check to ensure that video source is

operating within the display’s range. Adjust

the Clock Phase. See page 28.

Image not properly centered or sized. Size and position controls incorrectly

Vertical shaded bars on screen image. Horizontal s i ze not properl y adjusted. Adjust hori zont al s i ze setti ngs. S ee page

Color(s) are missing.

Screen jitter or noisy video.

Slight distortion in text or graphics. Not operating monitor in native resolution. Change the video source to native mode.

Display is present, but “bars” appear

across it or roll through it.

the right of objects on the screen.

adjusted.

Video cable problem.

Fault in monitor. Have monitor serviced.

Monitor clock phase not properly

adjusted.

Video cable problem.

Electrical noise interference from nearby

equipment.

“Noise” generated by other equipment in

the environment is present at the video

inputs.

Ground loop problems between computer

and monitor.

Contrast set too high. Adjust contrast settings. See page 29.Image has blurry streaks or “ghosting” to

Video cable problem. Chec k for proper video cable installation.

Use autp-adjust feature for proper size and

position of image. See page 26.

Reset the horizontal and vertical

positioning using the OSD (Page 28).

Check to ensure that video source is

operating within the monitor’s range.

26.

Check for proper video cable installation.

Replace suspected faulty cable.

Adjust monitor clock phase settings See

page 28.

Check for proper video cable installation.

Replace suspected faulty cable.

Check for proper video cable routing and

installation. Reroute cables or replace

suspected faulty cables.

Check host and monitor grounding.

The native resolutions are as follows:

1024x768 for 6185-C

•

800x600 for 6185-B

•

Consult the application note that

discusses methods of eliminating noise.

Eliminate ground loops by connecting

monitor and computer to the same power

source location or installing an AC

isolation transformer.

Replace suspected faulty cable.

Publication 6185-5.1

Page 37

Troubleshooting and Support

37

Allen-Bradley Support

Allen-Bradley offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• Sales and order support

• Product technical training

• Warranty support

• Support service agreements

Refer to the Rockwell Automation/Allen-Bradley Internet site at

http://www.ab.com for local contact information.

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the Troubleshooting section first. Then call

your local Allen-Bradley representative or contact Allen-Bradley

technical support at (440) 646-5800.

For additional product information and a description of the technical

services available, visit the Rockwell Automation/Allen-Bradley Internet

site listed above.

Publication 6185-5.1

Page 38

38

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Appendix

Appendix AAAA: Installing Your

Appendix Appendix

Monitor in a Rack

Monitor in a Rack

Monitor in a RackMonitor in a Rack

: Installing Your

: Installing Your: Installing Your

Installing the 6185-C with Optional Rack Adapters

You can also install the 6185-C into a rack using optional rack adapters.

The rack adapters are designed for installation in a rack cabinet that

conforms to EIA standards for equipment with 19" (483 mm) wide

panels. The rack adapters option is Accessory option R.

Tools Needed

You will need the following tools:

• EIA panel mounting hardware

• Phillips screwdriver (medium)

6185-C Monitor Rack Mounting Gui delines

Observe the following precautions when installing this unit in a rack:

• The cabinet must be tall enough to accommodate the monitor's panel

height of eight rack units, 14.00" (400 mm), and deep enough to

accommodate the monitor's depth while providing rear clearance for

cabling and air flow. A cabinet with depth of 4.4" (112 mm) is

sufficient.

Publication 6185-5.1

• No slides or shelves are required because the rack mount (6185-C)

monitor is designed to be supported by the panels in which it is

installed.

Page 39

Appendix A: Installing Your Monitor in a Rack

Installing Rack Adapter Brackets on a 6185-C Monitor

1. Carefully remove the monitor from its packaging.

2. Locate four mounting studs on each side of the monitor’s back

enclosure.

3. Install handles onto rack adapter brackets, if required.

4. Install the rack adapter brackets onto the four mounting studs on the

monitor’s back enclosure.

39

5. Secure the rack adapter brackets with the provided nuts for all eight

mounting studs (4 studs for each rack adapter bracket).

Publication 6185-5.1

Page 40

40

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Installing a 6185-C Monitor into a Rack

1. Verify that you have eight rack units (14.0”) available to mount your

monitor.

2. Locate holes in the rack mounting rails corresponding to the holes in

the monitor front panel. Install clip nuts behind the holes in the rails

if threaded rails are not provided.

Note:

The mounting rails that run vertically along the inside

edges of the front opening of an EIA rack cabinet can

be of two types:

• “Wide” rails have holes spaced 0.5"(12.7 mm) and

1.25"(31.8 mm) on centers, in a repeating pattern.

Wide rails are prevalent in Europe.

• “Universal” rails have holes spaced 0.5"(12.7 mm),

0.625"(31.8 mm), and 0.625"(31.8 mm) on centers,

in a repeating pattern. Thus, the universal ra il s have

a hole pattern that contains the wide pattern but

provides an additional hole at the midpoint of the

pattern. Universal rails are most prevalent in the US.

3. Install the monitor into the cabinet from the front.

4. Secure the monitor chassis to the cabinet by installing panelmounting screws through the holes in the monitor’s front panel and

into the rails behind.

Publication 6185-5.1

Page 41

Appendix B: Monitor Dimensions

Appendix

Appendix BBBB: Monitor Dimensions

Appendix Appendix

This section shows the dimensions of the both the 6185-B and 6185-C

monitors. Use this information to ensure you have adequate space to

install the unit and route cables. Units are in mm [inches].

: Monitor Dimensions

: Monitor Dimensions: Monitor Dimensions

41

6185-C Dimensions

Figure 12

6185-C Panel Mounting Cutout

6185-C

Publication 6185-5.1

Page 42

42

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Figure 13

6185-C Dimensions (Front View)

Figure 14

6185-C Dimensions (Side View)

Publication 6185-5.1

Page 43

Appendix B: Monitor Dimensions

Figure 15

6185-C Dimensions (Back View)

43

Publication 6185-5.1

Page 44

44

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

6185-B Dimensions

Figure 16

6185-B Panel Mounting Cutout

6185-B

Publication 6185-5.1

Figure 17

6185-B Dimensions (Front View)

Page 45

Appendix B: Monitor Dimensions

Figure 18

6185-B Dimensions (Side Views)

45

Figure 19

6185-B Dimensions (Back View)

Publication 6185-5.1

Page 46

46

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Appendix

Appendix CCCC: Touchscreen Serial

Appendix Appendix

Interface

Interface

InterfaceInterface

: Touchscreen Serial

: Touchscreen Serial: Touchscreen Serial

Description

All touch controllers are configured by default to provide serial

communications at 9600 baud, 8 data bits, 1 stop bit, no parity.

For Allen-Bradley monitors equipped with touchscreens, a serial

communications cable is required. A suitable cable can be obtained from

Rockwell Automation or you can create one. The cable is a straightwired serial (RS-232) cable with a male DE-9 D-shell connector on the

monitor end.

The cable provides a communications channel between the touchscreen

controller, which is mounted inside the monitor, and an RS-232-C serial

port on the host computer. Because the touch controller obtains power

from the monitor's power supply, no external touch power connections

are necessary.

Software supplied with the touchscreen must be loaded on the host

computer to handle communications with the touch controller over the

channel.

Because the touchscreen emulates a mouse, there may be compatibility

issues involving how the touchscreen emulates mouse buttons, especially

multiple buttons. For a complete discussion of these issues and how to

troubleshoot them, refer to the touchscreen documentation.

Setting Up the Touchscreen Interface

Publication 6185-5.1

This section describes how to set up the touchscreen system. Setup

involves the following:

• Enabling the touchscreen interface

• Installing the software on the host computer that will handle

communications with the touchscreen con troll er

• Performing a calibration

Page 47

Appendix C: Touchscreen Serial Interface

Enabling the Touchscreen Interface

The 6185-C and 6185-B monitors provide a female DE-9 connector on

the side panel. This connector provides the serial interface for the touch

controller.

Interconnecting wiring to the host serial port connection is shown in the

following table.

Table H

Touchscreen Interface

Monitor

(DCE Device) Host (DTE Device)

DE-9 (Female) Signal Description DE-9 (Male) DB-25 (Male)

1 Not Connected (DCD) 1 8

2 Transmit Data (TXD) 2 3

3 Receive Data (RXD) 3 2

4 Data Terminal Ready (DTR) 4 20

5 Common Signal Return (SG) 5 7

6 Not Connected (DSR) 6 6

7 Request To Send (RTS) 7 4

8 Clear To Send (CTS) 8 5

9 Not Connected 9 22

47

Installing the Touchscreen Driver Software

To install the touchscreen driver software correctly, obtain the following

information about the host hardware:

• The COM port in use for the touchscreen. Ensure that the RS-232

cable is properly installed between the monitor port and the host’s

COM port.

• The baud rate at which the controller is operating. You will need to

match the baud rate at the COM port. The controller baud rate is

factory set at 9600.

Note:

Once you have obtained this information, install the software using the

installation disks found in the touchscreen accessory package.

If you are using older touchscreen software, you may be

prompted for the type of touchscreen controller being used.

The 6185-C and 6185-B monitors use the following

controllers:

• Resistive: Elo TouchSystems model E271-2210.

• Capacitive: MicroTouch model SMT-3.

Publication 6185-5.1

Page 48

48

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Note:

Before installation, you may want to check the touchscreen

manufacturer’s site on the World Wide Web for the latest

software drivers. Enter these addresses in your Internet

browser:

• www.elotouch.com for resistive AccuTouch™

touchscreens

• www.microtouch.com for capacitive ClearTek™

touchscreens.

Performing a Calibration

After installing the driv er softw a re, fo llow the ins tru ct ions in the

touchscreen documentation.

Following installation of the touchscreen software and calibration, the

touchscreen is ready to use.

Publication 6185-5.1

Page 49

Appendix D: Video Cables

Appendix

Appendix DDDD: Video Cables

Appendix Appendix

: Video Cables

: Video Cables: Video Cables

You can use a HD-15 connector (all models) or a BNC adapter cable to

connect your monitor to the host computer.

49

HD-15 Video Connector

The HD-15 video cable you use with this monitor is equipped with a

conventional HD-15 connector at each end.

Note:

The following figure is the view looking into the pin end of

the male connector or solder term end of the female

connector.

Figure 20

HD-15 Video Connector

The following table provides the pin numbers and corresponding pin

assignments for the HD-15 video connector with the DDC2B capability:

Table I

Standard HD-15 Video Cable

Monitor (Female) Signal Description Host (Male)

1 Red Video 1

2 Green Video 2

3 Blue Video 3

4 Not Used 4

5 Return 5

6 Red Video Ground 6

7 Green Video Ground 7

8 Blue Video Ground 8

9 Not Used 9

10 Sync Ground 10

11 Not Used 11

12 Bi-Directional Data 12

13 Horizontal Sync 13

14 Vertical Sync (VCLK) 14

15 Data Clock (SCL) 15

Publication 6185-5.1

Page 50

50

Display 6185-C 6185-B

Type Active Matrix Color Thin Film Transistor (TFT) LCD

Backlight

Type

Life Expectancy

Field Replaceable

Nominal Display Area

Diagonal

Horizontal

Vertical

Resolution 1024x768 x RGB pixels, 256K colors 800x600 x RGB pixels, 256K colors

Viewing Angle (CR ≥ 5)

Horizontal (typical)

Vertical (typical)

Luminance (typical) 200 nit, 58 fL (screen overlay option will reduce

Contrast Ratio (typical) 300:1

Response Time 35 msec (typical) 30 msec (typical)

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Appendix

Appendix E: Product

Appendix Appendix

Specifications

Specifications

SpecificationsSpecifications

Cold Cathode Tubes (CCT) (2 bulbs)

50,000 hours (mean for 1/2 brightness point)

Yes

15 in. (380 mm)

12 in. (304 mm)

9.0 in. (228 mm)

+/-60 deg.

+55/-45 deg.

luminance)

: Product

: Product: Product

12.1 in. (308 mm)

9.7 in. (246 mm)

7.3 in. (185 mm)

+/-60 deg.

+55/-45 deg.

250 nit, 73 fL (screen overlay option will reduce

luminance)

Video 6185-C 6185-B

Supported Standards 640x480 at 60Hz and 75Hz

800x600 at 60Hz and 75Hz

1024x768 at 60Hz (native) and 75Hz

Video Input Signal RGB analog (white level = 0.714V above ref. Black, into 75 Ohms

Sync Input Signals H and V separate (TTL levels, positive or negative)

Input Connection HD-15

Controls and Indicators 6185-C 6185-B

Front Panel Bi-color status LED (Green – Power, Amber – No Sync)

Luminance (optional) on 6185-C

Back Panel Access OSD (top button)

Adjust controls through OSD (second and third button)

OSD Menu

Operator Input

Horizontal Size, Vertical Position, Horizontal Position, Contrast, Brightness, Clock Phase,

Language

Touchscreen Option - Resistive touchscreen, with serial controller and DOS and Windows

95/98/2000 drivers. Other OS drivers are available.

640x480 at 60Hz and 75Hz

800x600 at 60Hz and 75Hz

Publication 6185-5.1

Page 51

Appendix E: Product Specifications

Electrical 6185-C 6185-B

Line Voltage 85 to 264VAC, or 18 to 32VDC (optional)

Line Frequency 47-70Hz or DC

Ground Leakage 1.0 uA max at 1.5KVDC

Power Consumption 40W max, 50 VA 25W max, 30 VA

Environmental

Panel Mount Option Rating NEMA 4/12 (built to IP65 or IP53 standards), NEMA 4X optional

Operating Temperature 0C to 50C

Storage Temperature -20C to 60C

Relative Humidity 10% to 85% non-c ondensi ng

Operating Altitude Sea level to 10,000 ft (3048m)

Non-Operating Altitude Sea level to 25,000 ft (7620m)

Operating Electrostatic

Discharge

Non-Operating Electrostatic

Discharge

Operating Shock 20g (1/2 sine, 11 msec)

Non-Operating Shock 30g (1/2 sine, 11 msec)

Operating Vibration 0.015 i n. p-p, 5-53 Hz si ne,

Non-Operating Vibration

8.0K VDC (IEC 801-2, level 3)

20.0K VDC

2.0g peak, 53-640 Hz sine

0.015 in. p-p, 5-53 Hz sine,

2.0g peak, 53-640 Hz sine

51

Physical 6185-C 6185-B

Front Panel Dimensions

(W x H x D)

Rear Chassis Dimensions

(from rear surface of front

panel to back) (W x H x D)

Net Weight 12.0lb (5.4kg)

Shipping Weight 23.0 lb (10. 4kg)

Warranty

Standard 12 months

Optional Extensions available

17.3in. x 14.0in. x 0.25in.

(438mm x 355mm x 6mm)

(without rack adapter brackets)

15.9in. x 11.9in. x 3.9in.

(403mm x 302mm x 99mm)

13.75in. x 11.0in. x 0.25in.

(349mm x 279mm x 6mm)

12.6in. x 9.9in. x 2.75in.

(320mm x 252mm x 70mm)

8.0 lb (3.6kg)

14.5 lb (6.6kg)

Publication 6185-5.1

Page 52

52

Bulletin 6185-C and 6185-B Industrial Flat Panel Monitors

Certifications - Agency

Approvals

LVD (73/23/EEC) EN 60950 (per UL 1950 3rd ed. without D3 dev.)

EMC

(89/336/EEC)

Emissions

Immunity

6185-C 6185-B

UL 1604 Listed UL/C-UL Industrial Flat Panel

Monitor

UL 1950 Recognized Component,

C-UL 950 Recognized Component

UL Listed when mounted in appropriate enclosure

EN 50081-2

EN 50082-2

Australian C-Tick

FCC Class A

No

Publication 6185-5.1

Page 53

Page 54

IBM is a registered trademar k of Internation al Business Mach ines Corporation.

VGA is a trademark of Internati o nal Business M achines Corporation.

PC AT is a trademark of International Business Machines Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Microsoft Windows is a trademark of Micr osoft Corporation.

Microsoft Windows is a trademark of Micr osoft Corporation.

AccuTouch is a trademark of Elo TouchSystems.

ClearTek is a trademark of Microtouch.

Rockwell Automation helps its customers receive a superior return on their investment by bringing

together leading brands in industrial auto mation, creating a broad spectrum of easy-to-integra te

products. These are supported by local technical resources available world wide, a global network of

system solutions providers, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Austra lia • Austria • Bahrain • Belgium • Bolivia • Brazil • Bulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croatia • Cyprus • Czech

Republic • Denmark • Dominican Republic • Ecuador • Egypt • El Salvador • Finland • France • Germany • Ghana • Greece • Guatemala • Honduras • Hong Kong • Hungary

Iceland • India • Indonesia • Iran • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico • Morocco • The Nether lands

New Zealand • Nigeria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia • Saudi Arabia • Singapore

Slovakia • Slovenia • South Africa, Republic of • Spain • Sweden • Switzerland • Taiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates • United Kingdom • United

States • Uruguay • Venezuela

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000, Fax: (1) 414 382-4444

Rockwell Automation European Headquarters, Avenue Hermann Debroux, 46 1160 Brussels, Belgium, Tel: (32) 2 663 06 00, Fax: (32) 2 663 06 40

Rockwell Automation Asia Pacific Headquarters, 27/F Citicorp Centre, 18 Whitfield Road, Causeway Bay, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

World Wide Web: http://www.ab.com

Publication 6185-5.1 – October 2000

Supercedes 6185-5.1 – September 1999

Copyright 2000 Rockwell Automation Corporation. All rights reserved. Printed in USA.

998041-030

•

•

•

Loading...

Loading...