Page 1

Integrated Display Computers

User Manual

Catalog Numbers

6181P-12NSXPH, 6181P-12NPXPH,

6181P-12TSXPH, 6181P-12TPXPH,

6181P-12TPXPHDC, 6181P-15NSXPH,

6181P-15NPXPH, 6181P-15TSXPH,

6181P-15TPXPH, 6181P-15TPXPHSS,

6181P-17NSXPH, 6181P-17NPXPH, 6181P-17TSXPH,

6181P-17TPXPH, 6181P-17TPXPHSS,

6181P-2PXPH, 6181P-2PXPH

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local

Rockwell Automation sales office or online at http://literature.rockwellautomation.com

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability

for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Rockwell Automation, Allen-Bradley, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

The information below summarizes the changes made to this manual

since the last revision.

Revision bars, as shown in the margin, identify updated information.

These are the changes for this version of the document.

Topic Page

Added revised wording for proper grounding. 17, 27

3Publication 6181P-UM001G-EN-P - July 2008 3

Page 4

Summary of Changes

4 Publication 6181P-UM001G-EN-P - July 2008

Page 5

System Features

Installation

Table of Contents

Preface

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Accessories and Replacement Parts . . . . . . . . . . . . . . . . . . . 10

Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Multilingual User Interface CD Pack. . . . . . . . . . . . . . . . . . . 11

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2

Chapter Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

European Union Compliance. . . . . . . . . . . . . . . . . . . . . . . . 15

Environment and Enclosure Information . . . . . . . . . . . . . . . 16

Installation Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mounting Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Panel Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Bench or Tabletop Mounting. . . . . . . . . . . . . . . . . . . . . . . . 21

Product Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connect a Keyboard and Mouse . . . . . . . . . . . . . . . . . . . . . 25

Connect AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connect the DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connect to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 3

Operation

Chapter Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operating Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operator Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Start the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Reset the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Install Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Universal Serial Bus (USB) Ports . . . . . . . . . . . . . . . . . . . . . 30

Chapter 4

Replace System Components

5Publication 6181P-UM001G-EN-P - July 2008 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Accessories and Replacement Parts . . . . . . . . . . . . . . . . . . . 31

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Electrostatic Discharge (ESD). . . . . . . . . . . . . . . . . . . . . . . . 31

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Remove the Back Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Page 6

Table of Contents

System Troubleshooting

Maintenance

Install or Remove Add-In Cards . . . . . . . . . . . . . . . . . . . . . . 33

Replace the Floppy Drive (1500P and 1700P) . . . . . . . . . . . . 40

Replace the Floppy or Optical Disc Drive (1200P) . . . . . . . . 42

Replace the Optical Disc Drive (1500P and 1700P) . . . . . . . . 45

Add or Remove the Memory Module . . . . . . . . . . . . . . . . . . 47

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Hardware Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting Checklists . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter 6

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Clean the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replace the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Backlight Assembly Disposal . . . . . . . . . . . . . . . . . . . . . . . . 55

Ship or Transport the Product . . . . . . . . . . . . . . . . . . . . . . . 55

Index

Appendix A - Specifications

Appendix B - Use the Touchscreen

Appendix C - Upgrade to a New BIOS

Appendix D - Solid State Drive

6 Publication 6181P-UM001G-EN-P - July 2008

Page 7

Preface

Read this preface to familiarize yourself with the rest of the manual.

The preface covers:

• Who should use this manual

• The purpose of the manual

• Additional resources

Intended Audience

Purpose of This Manual

Additional Resources

Use this manual if you are responsible for installing, using or

troubleshooting the Integrated Display Computers.

This manual is a user guide for the Integrated Display Computers. It

gives an overview of the system and describes procedures to:

• Install the computer

• Make computer connections

• Configure the computer

• Troubleshoot the computer

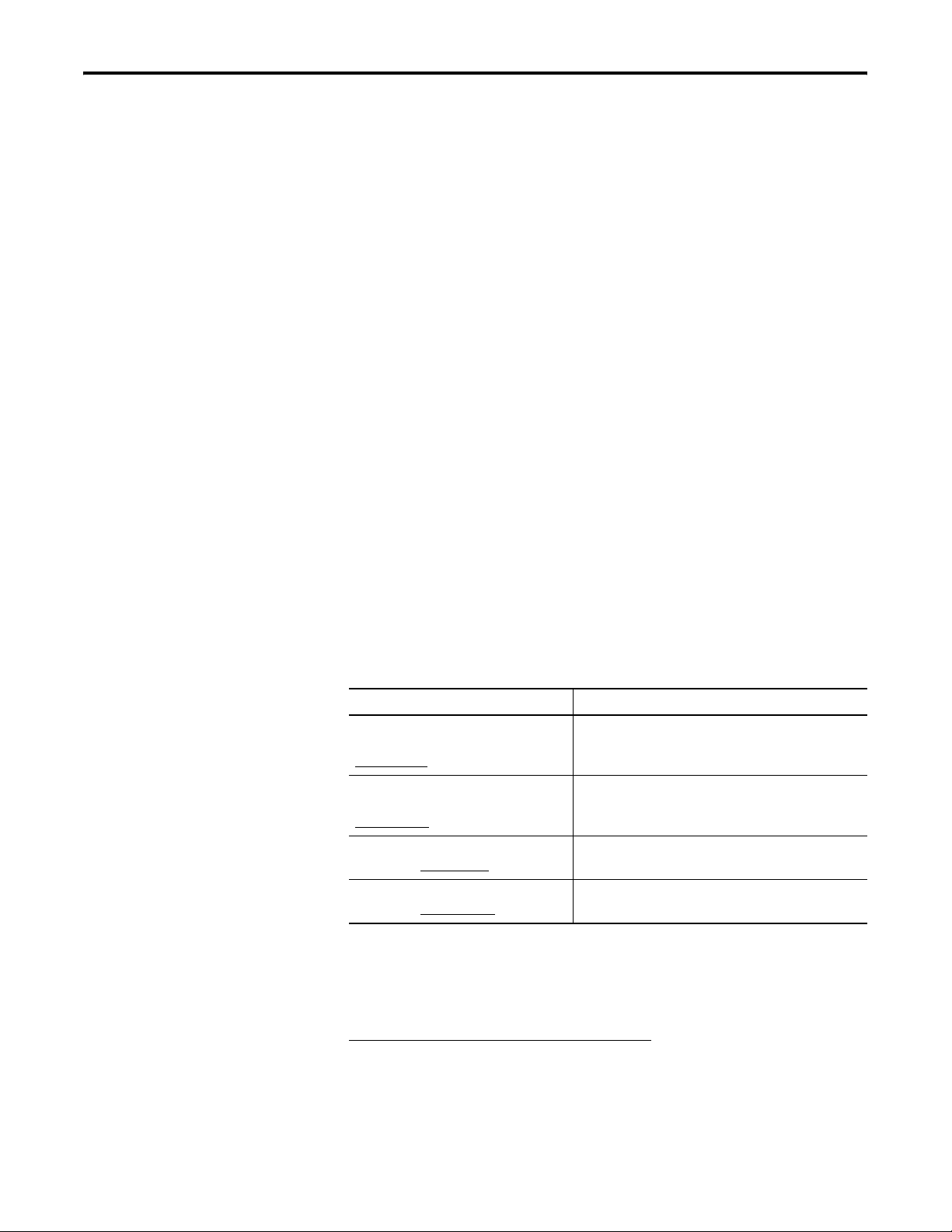

For additional information on the 6181P, 6181F, 6181H, and 6183H

computers, refer to these publications.

Resource Description

6181P Integrated Display Computers

Installation Instructions, publication

6181P-IN001

6181H Integrated Display Computers

Installation Instructions, publication

6181H-IN001

Cloning Utility Technical Data,

publication 6000-TD001

.

.

.

Provides procedures on how to install the

computer and make connections to the

workstation.

Provides procedures on how to install the

computer and make connections to the computer.

Provides information on how to create and restore

a backup image of your computer’s hard disk drive.

1200P Integrated Display Computers,

publication 6183H-IN001

.

Provides procedures on how to install the

computer and make connections to the computer.

These publications are on the Accessories/Cloning CD, which ships

with your computer.

You can view or download publications at

http://literature.rockwell.automation.com

. To order paper copies of

technical documentation, contact your local Rockwell Automation

distributor or sales representative.

Publication 6181P-UM001G-EN-P - July 2008 7

Page 8

Appendix 2

8 Publication 6181P-UM001G-EN-P - July 2008

Page 9

System Features

Chapter

1

Chapter Objectives

Overview

This chapter provides an overview of the computers including:

• Product options

• Accessories

• Operating systems

• Features

• Accessories

• Parts List

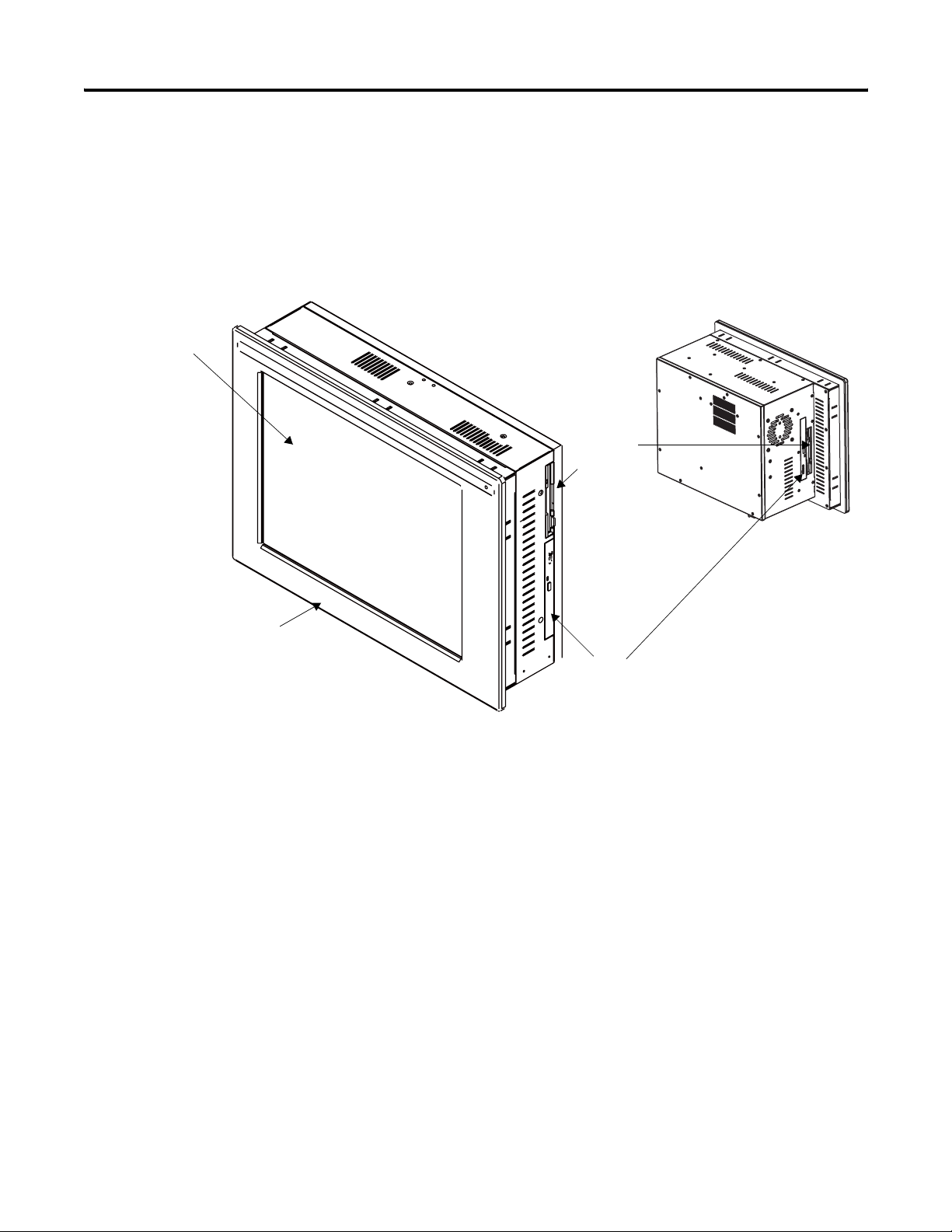

The Integrated Display computers feature 12.1, 15, and 17-inch

displays with a resistive touch screen option. When panel space is

limited, the 12.1 inch model provides product information within a

small space. For operations where it is important to view every aspect

of a process, the 15 and 17-inch displays provide the necessary detail.

These panel-mounted computers combine an industrially hardened

monitor and computer in a single machine, providing computing

power for visual interface, maintenance, and basic information

applications. Because there are no external monitor cables or separate

component mounting requirements, system integration is simplified.

The computers provide serial and Ethernet communication ports.

9Publication 6181P-UM001G-EN-P - July 2008 9

Page 10

Chapter 1 System Features

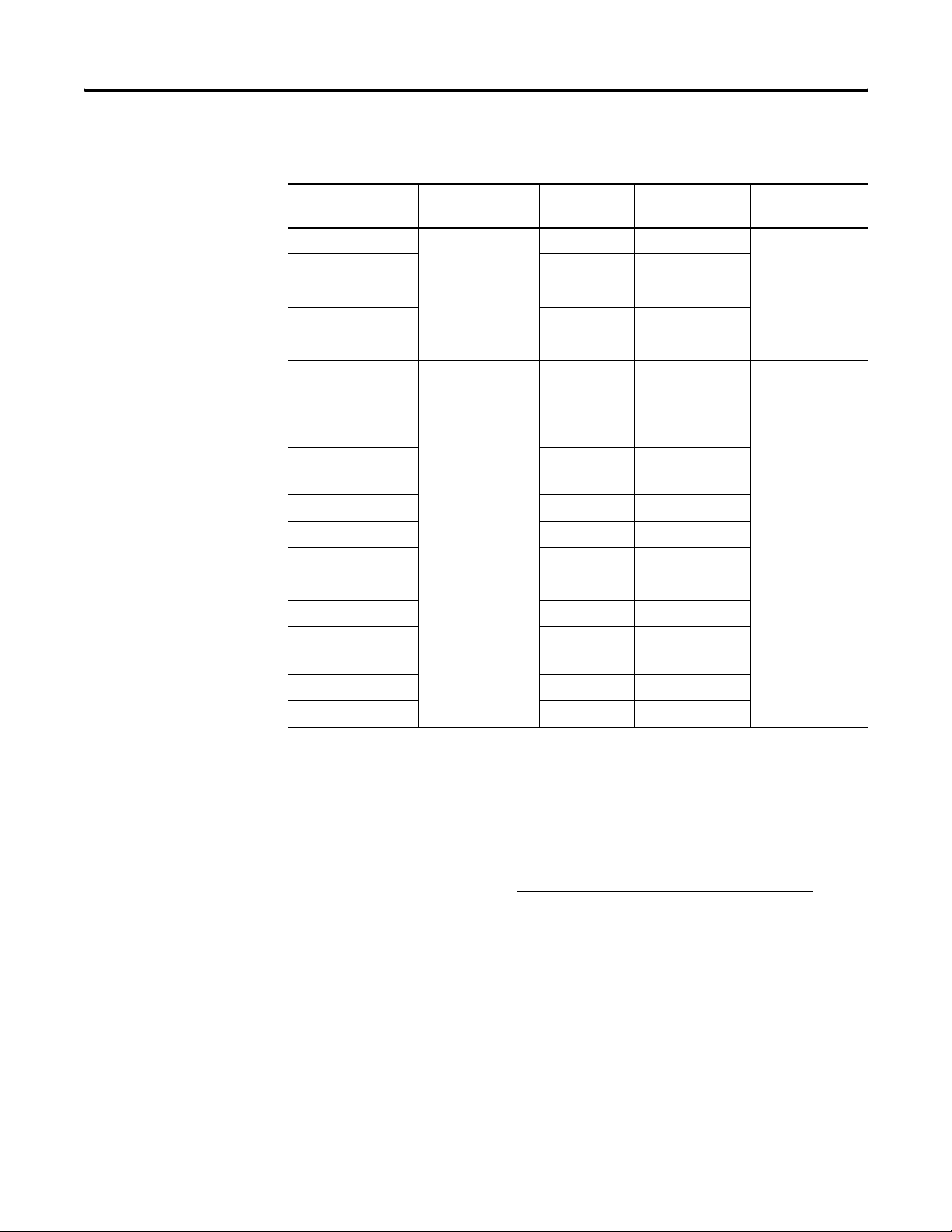

Product Options

Cat. No.

(1)

6181P-12TSXPH

Model

Display

Size

Touchscreen Performance

Yes Standard

6181P-12TPXPH Yes Performance

12 in

6181P-12NSXPH No Standard

1200P

6181P-12NPXPH No Performance

6181P-2PXPH No No Performance

6181F-15TPXPH

Yes Performance Windows XP for

6181P-15TSXPH Yes Standard

6181P-15TPXPH

6181P-15TPXPHSS

1500P 15 in

(2)

Yes Performance

6181P-15NSXPH No Standard

6181P-15NPXPH No Performance

6181H-15TSXPH Yes Standard

6181P-17NP2KH

No Performance

6181P-17TSXPH Yes Standard

6181P-17TPXPH

6181P-17TPXPHSS

1700P 17 in

(2)

Yes Performance

Operating

System

Windows XP

Embedded

Systems

Windows XP

Windows XP

Accessories and Replacement Parts

6181P-17NSXPH No Standard

6181P-17NPXPH No Performance

(1)

The computers are available with the Windows XP or Windows 2000 operating system. Replace XP with 2K in the catalog

number to order a computer with Windows 2000.

(2)

Catalog numbers ending in SS have a stainless steel bezel.

You can view a current list of accessories at the Rockwell Automation

Allen-Bradley website http://www.ab.com/industrialcomputers

.

10 Publication 6181P-UM001G-EN-P - July 2008

Page 11

System Features Chapter 1

Operating Systems

The computers are shipped with one of these operating systems:

• Windows 2000 Professional, Service Pack 4 with Update

Rollup 1

• Windows XP Professional, Service Pack 2b

No operating system updates have been applied to the factory image

beyond the service packs.

For your convenience, the I386 source directory for Microsoft

Windows is on the system drive of your computer off the root

directory, C:\I386. This allows for easy removal and addition of

Windows components.

Computers with rotating-media hard drives include a recovery

partition on the system drive containing the original factory image.

You can use the supplied System Accessories/Cloning CD to restore

the operating system from the recovery partition, create a new

recovery image, and create bootable external recovery media.

Refer to the Cloning Utility documentation, publication 6000-TD001

for instructions. You can view or download publications at

http://literature.rockwellautomation.com

.

,

Multilingual User Interface CD Pack

Computers with solid state drives have been customized to

accommodate the unique properties of the solid state drive. Some of

the pre-installed customizations include:

• no paging file.

• system restore set to zero and disabled.

• DLLCACHE directory emptied.

Computers with solid state hard drives do not contain a recovery

partition. If additional drive space is required, copy the I386 directory

to external media; then delete the I386 directory from C:\I386, which

is approximately 400 MB.

To obtain the original factory image on bootable external recovery

media, which also includes the I386 source directory, contact your

local technical support center.

The Microsoft Multilingual User Interface (MUI) CD Pack contains a

collection of different language sets that can be installed into the

operating system. MUI packs are available for all Windows XP

operating systems and provide a localized start menu and system

icons support.

The instructions for installing MUI languages on your computer are

supplied with the MUI CD Pack.

Publication 6181P-UM001G-EN-P - July 2008 11

Page 12

Chapter 1 System Features

Features

LCD Display

(with or without

optional touchscreen)

The illustrations show the major features and controls of the

computers.

Top and Side View

1500P and 1700P

Floppy Disk

Drive

1200P

Bezel with Clip Mounting

Optical Disc Drive

12 Publication 6181P-UM001G-EN-P - July 2008

Page 13

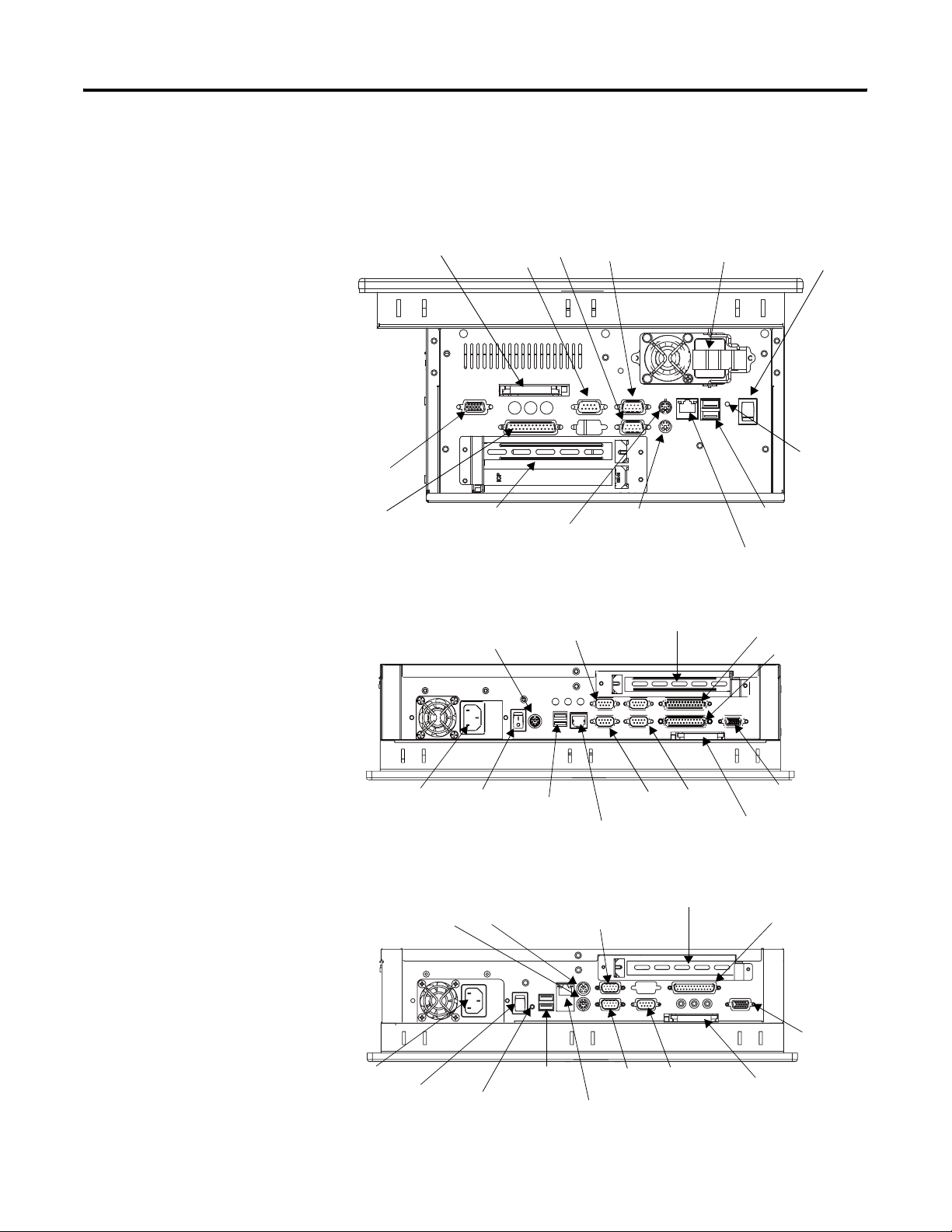

1200P

Bottom View

Compact Flash Expansion Slot

VGA Port

COM4

COM1

COM2

System Features Chapter 1

DC Power Input

Power Switch

Reset

Button

Printer

1500P and 1700P Series A

Keyboard/Pointing Device Ports

AC Power Input

1500P and 1700P Series B

PS/2 Keyboard Port

PCI Expansion Slot

Power Switch

PS/2 Mouse Port

PS/2 Mouse Port

PS/2 Keyboard Port

COM4

2 USB Ports

Ethernet Connector (RJ45)

COM1

PCI Expansion Slot

COM1

2 USB Ports

Ethernet 10/100 Connector (RJ45)

Printer 2

COM2

Compact Flash Expansion Slot

PCI Expansion Slot

Printer 1

VGA Port

Printer

VGA Port

AC Power Input

Power Switch

Publication 6181P-UM001G-EN-P - July 2008 13

Reset

Button

2 USB Ports

Ethernet Connector (RJ45)

COM2

COM4

Compact Flash Expansion Slot

Page 14

Chapter 1 System Features

Before You Begin

Before unpacking the product, inspect the shipping carton for

damage. If damage is visible, immediately contact the shipper and

request assistance. Otherwise, proceed with unpacking.

Keep the original packing material in case you need to return the

product for repair or transport it to another location. Use both the

inner and outer packing cartons to ensure adequate protection for a

unit returned for service.

Parts List

Your computer ships with these items:

• System Accessories/Cloning CD

• Support CD

• Microsoft Multilingual User Interface (MUI) CD Pack

This CD pack is not included with computers containing

solid-state hard drive or computers with the Windows 2000

operating system.

• Mounting clips, except for the 1200P Non-display computer

• Power cord, AC (when appropriate)

• PS/2 Y-adapter cable for keyboard and mouse connection

(supplied with all 6181P Series A and 6181H 1500P Series B

computers)

• Installation guide and cutout template

14 Publication 6181P-UM001G-EN-P - July 2008

Page 15

Installation

Chapter

2

Chapter Objective

European Union Compliance

This chapter describes how to install your computer in a panel and

how to make connections. It covers the following topics:

• European Union Directive Compliance

• Environment and enclosures

• Installation considerations

• Mounting clearances

• Mounting the computer in a panel

• Mounting the computer on a bench or tabletop

• Product dimensions

• Connect a keyboard or mouse

• Connect AC or DC power

• Connect to a network

This product meets the European Union Directive requirements when

installed within the European Union or EEA regions and has the CE

mark. A copy of the Declaration of Conformity is available at the

Rockwell Automation / Allen-Bradley website:

www.ab.com/certification.

ATTENTION

ATTENTION

This product is intended to operate in an industrial or control

room environment, which utilizes some form of power isolation

from the public low voltage mains. Some computer

configurations may not comply with the EN 61000-3-2

Harmonic Emissions standard as specified by the EMC Directive

of the European Union. Obtain permission from the local power

authority before connecting any computer configuration that

draws more than 75 watts of AC power directly from the public

mains.

To comply with EN 55024, the Ethernet port LAN cable must be

less than 30 m (98.42 ft) long, and it must only be used indoors

(i.e., not exit the building at any point). All other I/O cables must

be less than 3 m (9.842 ft) long, and must only be used indoors.

15Publication 6181P-UM001G-EN-P - July 2008 15

Page 16

Chapter 2 Installation

Environment and Enclosure Information

Review the information on enclosures and environments before

installing the product.

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

industrial environment, in overvoltage Category II applications (as

defined in IEC publication 60664-1), at altitudes up to 2000 meters

(6562 feet) without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11. Without

appropriate precautions, there may be potential difficulties

ensuring electromagnetic compatibility in other environments due

to conducted as well as radiated disturbance.

Operating the capacitive touchscreen version in a high noise

environment may cause the touchscreen to respond slowly to touch

inputs, or may cause the position of the screen cursor to drift.

This equipment is supplied as ‘open type’ equipment. UL

recognized and hazardous location equipment must be mounted in

an enclosure that is suitably designed or rated for those specific

environmental conditions that will be present, and designed to

prevent personal injury resulting from accessibility to live parts. UL

Listed equipment need not be mounted inside another enclosure in

ordinary (non-hazardous) locations if NEMA Type and IEC ratings

are not required, but the mounting method must limit the tilt of the

product to +/- 30° from vertical. Examples include articulated arm,

table-top stand, or other means having sufficient mechanical

stability. The mounting means must be firmly attached to the

supporting surface using screws, bolts, or clamps so the product

cannot tip. These units ship with a gasketed bezel to meet

specified NEMA and IEC ratings only when mounted in a panel or

enclosure with an equivalent rating. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings required to comply with certain product

safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, for

additional installation requirements, Allen-Bradley publication

1770-4.1.

• NEMA Standards publication 250 and IEC publication 60529, as

applicable, for explanations of the degrees of protection

provided by different types of enclosure.

16 Publication 6181P-UM001G-EN-P - July 2008

Page 17

Installation Chapter 2

Installation Considerations

Follow these guidelines to make sure your product provides safe and

reliable service.

• The installation site must have sufficient power.

ATTENTION

To maintain an electrically safe installation, the product must

be connected to Earth ground when installed. Follow the

appropriate grounding requirements associated with your

specific product type as described in this installation document.

• The enclosure must have sufficient space around air inlets and

outlets to provide the circulation necessary for cooling. Never let

air passages to become obstructed.

• The ambient air temperature must not exceed the maximum

operating temperature. Consider heat produced by other devices

in the enclosure. You may need to provide a fan, heat

exchanger, or air conditioner to meet this condition.

TIP

Hot air rises. The temperature at the top of the enclosure is

often higher than the temperature in other parts of the

enclosure, especially if air is not circulating.

IMPORTANT

The product can operate at a range of extremes. However, the

life span of any electronic device is shortened if you

continuously operate the product at its highest rated

temperature.

• The humidity of the ambient air must not exceed specified

limits. In very dry environments, static charges build up readily.

Proper grounding of the equipment through the AC power cord

helps to reduce static discharges, which may cause shocks and

damage electronic components.

• The enclosure or cover must remain in place at all times during

operation. The cover provides protection against high voltages

inside the product and inhibits radio-frequency emissions that

might interfere with other equipment.

Publication 6181P-UM001G-EN-P - July 2008 17

Page 18

Chapter 2 Installation

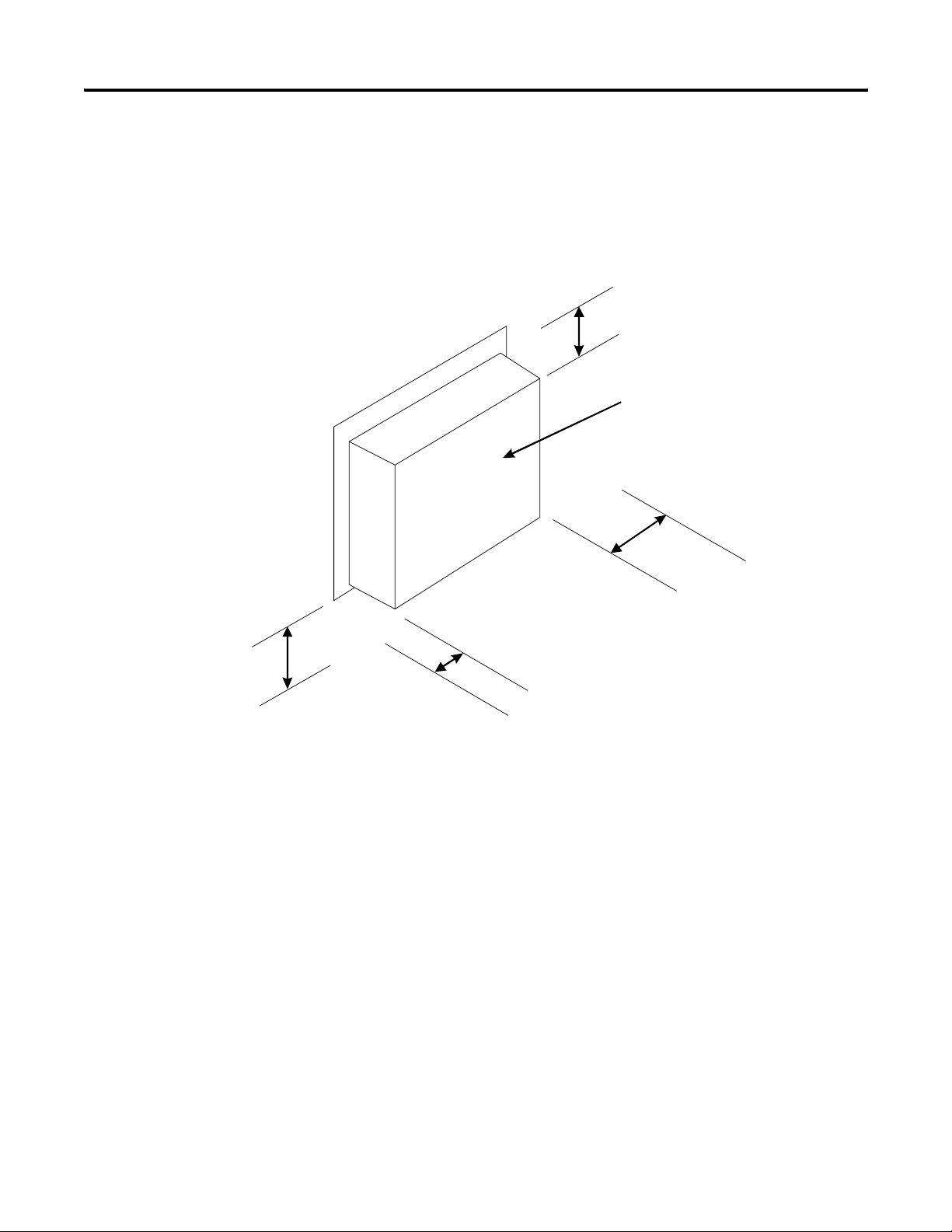

Mounting Clearances

Allow adequate space around the computer for mounting, air flow,

connections, and maintenance. Do not operate the computer in an

enclosure by using the minimum clearances unless adequate

ventilation or other cooling methods are used to lower the

temperature within the enclosure.

Top Clearance:

50 mm (2 in.)

Back Clearance:

50 mm (2 in.)

Left Side Clearance:

1500P/1700P = 50 mm (2 in.)

1200P = 127 mm (5 in.) for

air flow and drive access

Bottom Clearance:

102 mm (4 in) for air flow

and connections

Right Side Clearance:

1200P = 50 mm (2 in.)

1500P/1700P = 127 mm (5 in.) for

air flow and drive access

18 Publication 6181P-UM001G-EN-P - July 2008

Page 19

Installation Chapter 2

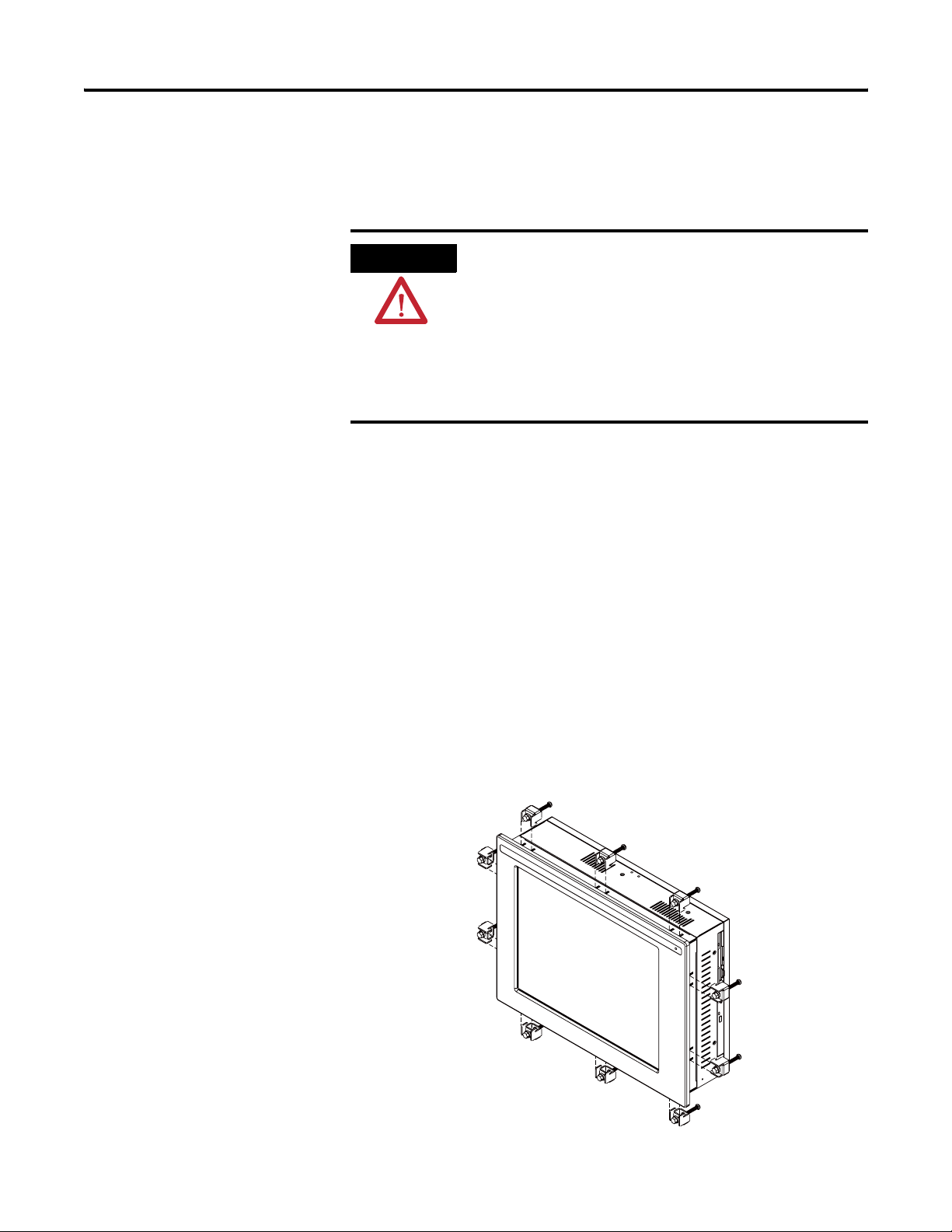

Panel Mounting

Install the computers by using mounting clips. Before installation,

review:

• Tools required.

• Panel mounting guidelines.

• Panel cutout dimensions.

• Product dimensions.

Tools Required

The following tools are required for product installation:

• Panel cutout tools

• #2 Phillips screwdriver

Mounting Guidelines

Observe these guidelines when installing the unit in a panel.

• Confirm that there is adequate space behind the panel. A

cabinet with a minimum depth of 127 mm (5.0 in.) is sufficient.

• Cut supporting panels to specifications before installation. Take

precautions so metal cuttings do not enter components already

installed in panel.

• Supporting panels must be at least 14 gauge to ensure proper

sealing against water and dust and to provide proper support.

The mounting hardware supplied accommodates panels up to

6.25 mm (0.25 in.) thick.

ATTENTION

Failure to follow these guidelines may result in personal injury

or damage to the panel components.

Panel Cutout Dimensions

Computer Model Cutout Dimensions (HxW)

1200P 254.0 x 324.0 mm (10.0 x 12.76 in.)

1500P 285.0 x 386.6 mm (11.24 x 15.22 in.)

1700P 329.5 x 424.0 mm (12.97 x 16.69 in.)

Publication 6181P-UM001G-EN-P - July 2008 19

Page 20

Chapter 2 Installation

Mount the Computer in a Panel

Mounting clips secure the computer to the panel.

ATTENTION

Remove all electrical power from the panel before making

cutout.

Make sure the area around the panel cutout is clear.

Take precautions so metal cuttings do not enter components

already installed in panel.

Failure to follow these warnings may result in personal injury or

damage to the panel components.

Follow these steps to mount the computer in a panel.

1. Remove power from the panel.

2. Cut an opening in the panel using the appropriate panel cutout

dimensions.

3. Make sure the sealing gasket is properly positioned on the

computer.

This gasket forms a compression type seal. Do not use sealing

compounds.

4. Place the computer in the panel cutout.

5. Slide the mounting clips into the slots on the top, bottom, and

sides of the computer.

20 Publication 6181P-UM001G-EN-P - July 2008

Page 21

Installation Chapter 2

6. Gradually tighten the clips, one at a time, around the bezel by

using the specified sequence.

The sequence begins with the center clips and continues to the

corner clips. Repeat this process at least three times until the

clips are hand-tight and the gasket is compressed uniformly

against the panel.

1109

Bench or Tabletop Mounting

5

Torque Sequence

4

278

3

6

7. Tighten the mounting clips to a torque of 1.4 Nm (12 lb-in) by

using the sequence in step 6.

Do not overtighten.

ATTENTION

Tighten the mounting clips to the specified torque to provide a

proper seal and prevent damage to the product. Rockwell

Automation assumes no responsibility for water or chemical

damage to the product or other equipment within the enclosure

because of improper installation.

You can mount the 1500P or 1700P computer on a benchtop or

tabletop arm by using an optional adapter. The back of the computer

has four mounting points that are VESA 100 mm standard.

Cat. No. Description

6189V-MBA Bench/tabletop adapter for 1500P and 1700P

Publication 6181P-UM001G-EN-P - July 2008 21

Page 22

Chapter 2 Installation

Mounting Guidelines

Observe these guidelines when installing the computer on an arm:

• The mounting surface must be strong enough to support both

the computer and the mounting hardware.

• The mounting arm must be strong enough to support the

computer. The arm must meet VESA FPMPMI 100 mm standards.

• The mounting location must provide clearance for mounting and

positioning the adjustable unit and routing cables.

• Per UL Listing restrictions, the product must be mounted with a

tilt of +/- 30° or less from vertical.

Mount the Computer on a Bench or Tabletop

1. Mount the arm to the benchtop or tabletop using screws, bolts,

or clamps so the computer cannot tip.

2. Place the computer over the arm, and insert four M4 x 0.7

screws through the arm brackets and into the back cover of the

computer.

3. Tighten the screws.

22 Publication 6181P-UM001G-EN-P - July 2008

Page 23

Installation Chapter 2

Product Dimensions

Product dimensions for each version of the computer are given in

Dimensions are mm (in.).

1200P Integrated Display Computer

320 [12.60]

281 [11.079]

349 [13.75]

279 [10.99]

8.00 [0.31]

175.9 [6.93]

251 [9.89]

1200P Non-Display Computer

281 [11.079]

343 [13.51]

317.5 [12.51]

240 [9.46]

190.5 [7.51]

144.9 [5.70]

2 (.078)

239.1 [9.41]

Publication 6181P-UM001G-EN-P - July 2008 23

Page 24

Chapter 2 Installation

1500P Integrated Display Computer

383.60 [15.10]

13.20 [0.52]

309.00 [12.17]

410.00 [16.14]

1700P Integrated Display Computer

422.00 [16.61]

8.00 [0.31]

282.60 [11.13]

99.9 [3.93]

14.0 [0.52]

356.00 [14.02]

452.00 [17.80]

8.00 [0.31]

101.6 [4.00]

328.00 [12.91]

24 Publication 6181P-UM001G-EN-P - July 2008

Page 25

Installation Chapter 2

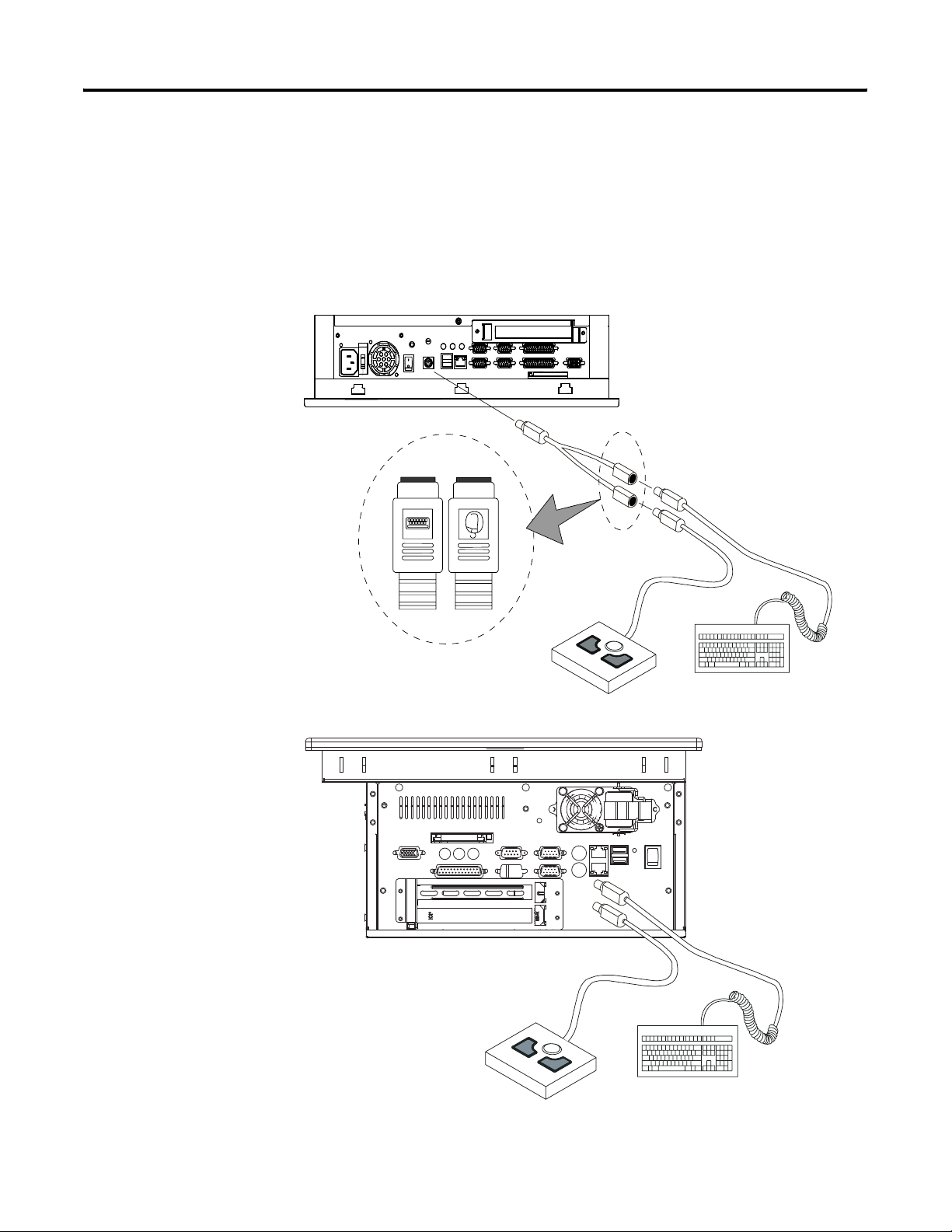

Connect a Keyboard and Mouse

1500P - Series A

1500P - 6181H Series A and B

1700P - Series A

You can connect a keyboard to the PS/2 port on the bottom of the

computer. You can connect both a keyboard and mouse to this port

by using the Y-adapter cable that ships with the 6181P Series A

computers.

The 6181P Series B computers have separate PS/2 ports for the

keyboard and mouse.

1200P - Series B and C

1500P - Series B and C

1700P - Series B and C

Publication 6181P-UM001G-EN-P - July 2008 25

Page 26

Chapter 2 Installation

Connect AC Power

A standard IEC 320 power cord provides power to the computer. The

power supply input accepts 120/240V ac. The power supply is

autoswitching.

1200P Only:

You may need to remove the AC retainer clip

before installing the unit in a panel cutout.

Reattach the clip after installing the unit.

ATTENTION

Connect the AC power cord to a power source with an earth

ground to prevent electrical shock. Failure to follow this

warning could result in electrical shock.

The computer circuit should have its own disconnect. Use an

uninterruptible power source (UPS) to protect against

unexpected power failure or power surges.

Always shut down the operating system before removing

power to minimize performance degradation and operating

system failures.

26 Publication 6181P-UM001G-EN-P - July 2008

Page 27

Installation Chapter 2

Connect the DC Power

The 1200P computers with an integrated 24V DC power supply

support these electrical ratings:

• 18 to 32V DC (24V DC nominal)

• 6.3 A at 24V DC

The power supply is internally protected against reverse polarity.

ATTENTION

Use a Class 2/SELV (Safety Extra-Low Voltage) isolated and

ungrounded power supply as input power to the computer. This

power source provides protection so that under normal and

single fault conditions, the voltage between the conductors and

Functional Earth/Protective Earth does not exceed a safe value.

To connect DC power follow these steps.

1. Secure the DC power wires to the terminal block screws.

2. Secure the ground wire to the GND terminal block screw.

3. Apply 24V DC power to the computer.

GND (safety ground)

V- (DC negative)

ATTENTION

V- V+

V+ (DC positive)

GND (safety ground alternate connection)

Connect the product to earth ground using a 1.31 mm

(16 AWG) or larger external wire.

The ground wire should have green insulation with a yellow

stripe for easy identification.

2

Publication 6181P-UM001G-EN-P - July 2008 27

Page 28

Chapter 2 Installation

Connect to the Network

The computers connect to the Ethernet network using CAT5 or CAT5E

twisted pair Ethernet cabling with RJ45 connectors. The computers

support 10/100 Mbps network communication.

IMPORTANT

To prevent performance degradation of Ethernet

communication, do not subject the computer or cables to

extreme radiated or conducted high-frequency noise.

Proper cable routing and power conditioning is required to

ensure reliable Ethernet communication in industrial

environments. Rockwell Automation recommends that you

route all Ethernet cabling through dedicated metal conduits.

Installing ferrite bead filters at cable ends may also improve

reliability.

28 Publication 6181P-UM001G-EN-P - July 2008

Page 29

Operation

Chapter

3

Chapter Objective

Operating Guidelines

This chapter covers the following topics:

• General operating guidelines

• Operator access to computer

• Booting the system

• Resetting the system

• Installing drivers

• Universal serial bus (USB) ports

Follow these operating guidelines for your computer.

• Avoid turning the system on and off frequently.

• Always use the proper power down procedures as required by

your operating system, such as the Shut Down command in

Microsoft Windows. Failure to do so can result in performance

degradation and eventual system damage.

• Do not operate the computer with the covers removed. An

electrical shock hazard exists. Removing the covers will disrupt

air flow and may result in overheating. All covers are required to

maintain EMI shield.

• To avoid dust and other airborne contamination infiltrating the

product when mounted in a suitable enclosure, the door to the

enclosure must be closed at all times during operation. The door

should be open for routine maintenance only.

ATTENTION

Operator Access

29Publication 6181P-UM001G-EN-P - July 2008 29

Operator access is limited to the front panel of the computer. This

includes the display and touchscreen. Access to components behind

the panel in which the computer is installed is restricted to authorized

and properly trained personnel.

After shutting the system off, do not move the computer, or turn

it back on again, until the hard drive comes to a complete stop,

which takes about 30 seconds.

Page 30

Chapter 3 Operation

Start the System

Reset the System

Apply power to the system. The computer performs a Power On Self

Test (POST). The processor board, memory, keyboard, and certain

peripheral devices are tested.

The system displays the progress of the POST and initialization of

accessory devices. The computer displays the startup dialogs for the

operating system that is installed.

If your system does not boot up, or you notice other problems, refer

to the System Troubleshooting chapter.

To reset the computer, press Ctrl+Alt+Delete on the attached keyboard

and follow the operating system instructions.

After resetting, the computer begins the Power On Self Test (POST).

During a reset, the computer:

• clears RAM.

• starts the POST.

• initializes peripheral devices, such as drives and printers.

• loads the operating system (if installed).

Install Drivers

Universal Serial Bus (USB) Ports

The operating system usually selects the best device driver settings.

However, you may want to ensure fully optimized performance by

manually installing the device drivers included with your system.

Refer to the Readme files on the supplied accessory CD for details on

the latest device drivers and installation procedures.

The Universal Serial Bus (USB) is an external bus standard that

supports data transfer rates up to 480 Mbps (480 million bits per

second). You can connect multiple peripheral devices to the USB

ports, such as a mouse, modem, and keyboard. USB also supports

Plug-and-Play installation and hot plugging.

For information on installing or using USB, refer to the documentation

for your USB peripheral device.

TIP

Many USB devices only work with Windows XP or Windows

2000, because these operating systems have native USB

drivers. Make sure the selected USB peripheral has software

drivers available for your target operating system.

30 Publication 6181P-UM001G-EN-P - July 2008

Page 31

Replace System Components

Chapter

4

Chapter Objectives

Accessories and Replacement Parts

Safety Precautions

This chapter provides safety precautions and procedures to:

• remove the back cover.

• required tools.

• install or remove add-in cards using the PCI Expansion Kit

(6189V-2PCI15).

• replace the floppy drive (1500P and 1700P).

• replace the floppy or optical disc drive (1200P).

• replace the optical disk drive (1500P and 1700P).

• replace the memory modules.

You can view a current list of accessories at the Rockwell Automation

Allen-Bradley website http://www.ab.com/industrialcomputers

The computers contain line voltages. Disconnect all power to the

computer before you install or remove system components.

.

ATTENTION

Disconnect all power from the computer before removing

components. Failure to disconnect power could result in severe

electrical shock or damage to the computer.

Electrostatic Discharge (ESD)

ATTENTION

31Publication 6181P-UM001G-EN-P - July 2008 31

Electrostatic discharge (ESD) can damage the computer and

components. Make sure you work in a static-safe environment

and wear a grounding strap whenever handling circuit boards,

power supply, memory modules or other internal components.

Page 32

Chapter 4 Replace System Components

Required Tools

Remove the Back Cover

Use a #2 Phillips screwdriver for all screws. Using the wrong size tool

may cause damage to the screw head.

To maintain, install, or upgrade computer components, you must first

remove the cover.

ATTENTION

Follow these steps to remove the back cover.

1. Disconnect power from the computer.

2. Remove the screws that secure the back cover.

3. Lift the cover from the chassis.

Failure to follow proper safety precautions could result in

severe electrical shock and/or damage to the computer.

1200P

1500P/1700P

4. To reinstall the back cover, position the back cover over the

chassis and fasten with the screws.

32 Publication 6181P-UM001G-EN-P - July 2008

Page 33

Replace System Components Chapter 4

Install or Remove Add-In Cards

You can install PCI-compatible cards in the computer’s PCI slot. This

section shows how to install and remove cards using the PCI

Expansion Slot Kit (6189V-2PCI15).

IMPORTANT

ATTENTION

ATTENTION

The PCI Expansion Slot Kit is not required if you are installing

only one PCI card. The procedure to install one card is similar.

Failure to follow proper safety precautions could result in

severe electrical shock and/or damage to the computer.

Add-in cards are sensitive to ESD and require careful handling.

Hold cards only by the edges. Do not touch connectors,

components, or circuits. After removing a card, place it on a

flat, static-free surface, component side up. Do not slide the

card over any surface.

Install an Add-in Card

Follow these steps to install an add-in card.

1. Disconnect power from the computer.

2. Remove the back cover.

3. Remove the slot cover bracket (two screws).

Screws

Slot Cover Bracket

Publication 6181P-UM001G-EN-P - July 2008 33

Page 34

Chapter 4 Replace System Components

4. Remove the one-slot riser board (two screws).

PCI Riser Board

5. Add riser bracket (A) to the chassis by using six, M3x6 panhead

screws.

Riser Bracket (A)

34 Publication 6181P-UM001G-EN-P - July 2008

Page 35

Replace System Components Chapter 4

6. Add riser bracket (B) to riser bracket (A) by using seven, M3x6

flat head screws.

Riser Bracket (B)

Riser Bracket (A)

7. Add the center support to the chassis by using three screws

(two - M3x6 flat head, one - M3x6 pan head).

Center Support

Riser Bracket (B)

Riser Bracket (A)

Publication 6181P-UM001G-EN-P - July 2008 35

Page 36

Chapter 4 Replace System Components

8. Add the riser board using the two screws from step 4.

PCI Riser Board

Center Support

Riser Bracket (B)

Riser Bracket (A)

• The slot cover bracket attaches to the chassis with or without

PCI cards.

• If installing PCI cards at this time, follow steps 9a - c.

• If not installing PCI cards, attach the slot cover bracket to the

chassis as shown in step 9c.

a. Attach PCI cards to the slot cover bracket.

Slot Cover Bracket

b. Connect PCI cards to the riser board.

PCI Cards

PCI Riser Board

36 Publication 6181P-UM001G-EN-P - July 2008

Page 37

Replace System Components Chapter 4

c. Fasten the slot cover bracket to the chassis by using four,

M3x6 panhead screws.

9. If installing the expansion kit on a Series A computer, you may

discard the replacement air duct and proceed to step 10.

If installing the expansion kit on a Series B computer, you must

replace the air duct that provides cooling air to the processor.

a. Remove the existing air duct from the back cover of the

chassis by removing the three screws.

b. Attach the replacement air duct to the back cover of the

chassis by using the same three screws.

c. Set the opening of the duct to its full-open position, if

possible.

If the installed PCI cards interfere with the fully-opened duct,

then adjust the duct to a lesser opened position to eliminate

the interference.

Publication 6181P-UM001G-EN-P - July 2008 37

Page 38

Chapter 4 Replace System Components

10. Reinstall the back cover over the chassis by using the screws

from step 2.

38 Publication 6181P-UM001G-EN-P - July 2008

Page 39

Replace System Components Chapter 4

Remove an Add-in Card

Follow these steps to remove an add-in card.

1. Disconnect power from the computer.

2. Remove the back cover.

3. Remove the two screws securing the slot cover bracket to the

chassis.

4. Remove the two screws at the top of the PCI riser board.

5. As a single unit, remove the PCI riser board, add-in card, and

slot cover bracket from the PCI slot on the CPU board.

6. Remove the screw securing the slot cover bracket to the add-in

card.

7. Pull the add-in card free of the slot on the PCI riser board.

Store the card in an anti-static wrapper.

8. Install a slot cover over the open slot on the slot cover bracket

and secure with a screw from step 6.

9. Press the PCI riser board into the PCI slot on the CPU board.

10. Replace the two screws at the top of the PCI riser board from

step 4.

11. Secure the slot cover bracket to the chassis with two screws

from step 3.

12. Reinstall the back cover.

Publication 6181P-UM001G-EN-P - July 2008 39

Page 40

Chapter 4 Replace System Components

Replace the Floppy Drive (1500P and 1700P)

Follow these precautions when working with the floppy drive.

• Do not touch internal components unnecessarily.

• Always handle the floppy drive by its metal frame.

• Store the floppy drive in an anti-static bag when it is not

installed.

• Never disconnect or install a floppy drive with the power on.

ATTENTION

ATTENTION

Failure to follow proper safety precautions could result in

severe electrical shock and/or damage to the computer.

Mechanical shock will damage a floppy drive. Do not drop or

bump the drive.

Remove the Floppy Disk Drive

Follow these steps to remove the floppy disk drive.

1. Disconnect power from the computer.

2. Remove the back cover.

3. Remove the hard drive.

Do not disconnect the HDD cables.

IMPORTANT

Note the location and orientation of all cables before you

remove the existing power supply and cabling, so that you can

reattach them correctly.

40 Publication 6181P-UM001G-EN-P - July 2008

Page 41

Replace System Components Chapter 4

4. Remove the screw(s) that fasten the floppy drive bracket to the

chassis.

1500P and 1700P

Floppy Drive

Floppy Drive

bracket

Floppy Adapter

5. Slide the floppy drive and bracket and lift the floppy drive out

door-first.

6. Disconnect the flat cable at the floppy drive.

7. Remove the four screws securing the floppy drive to the bracket.

8. Remove the floppy drive.

Install the Floppy Disk Drive

Follow these steps to install the floppy disk drive.

1. Fasten the floppy disk drive to the floppy disk drive bracket

with four screws.

2. Connect the flat cable to the floppy disk drive.

3. Insert the floppy disk drive and bracket into the chassis

adapter-end first and slide it into position within the chassis.

4. Fasten the floppy disk drive and bracket to the chassis with the

bracket screw.

5. Apply glue to prevent separation.

6. Reinstall the hard disk drive.

7. Reinstall the back cover.

Publication 6181P-UM001G-EN-P - July 2008 41

Page 42

Chapter 4 Replace System Components

Replace the Floppy or Optical Disc Drive (1200P)

Follow these precautions when working with the floppy or optical

disc drive.

• Do not touch internal components unnecessarily.

• Always handle the drive by its metal frame.

• Store the drive in an anti-static bag when it is not installed.

• Never disconnect or install a drive with the power on.

ATTENTION

ATTENTION

Failure to follow proper safety precautions could result in

severe electrical shock and/or damage to the computer.

Mechanical shock can damage an optical disk drive. Do not

drop or bump the drive.

42 Publication 6181P-UM001G-EN-P - July 2008

Page 43

Replace System Components Chapter 4

Remove the Drive

Follow these steps to remove the drive.

1. Disconnect power from the computer.

2. Carefully separate the display head from the back chassis by

removing the 12 perimeter screws.

3. Disconnect cables between the display and back chassis as

necessary and set the back chassis aside.

4. Remove the floppy or optical disc drive bay by removing the

four screws holding the bracket to the inner shelf.

5. Carefully pull out the drive bay assembly.

6. Disconnect the data, power and audio cables from the assembly.

IMPORTANT

Note the location and orientation of all cables before you

remove the existing power supply and cabling, so that you can

reattach them correctly.

7. For either floppy or optical disc drive removal; disconnect and

remove the drive adapter board from the drive.

Be careful with the delicate ribbon cable on the floppy disk

drive.

Publication 6181P-UM001G-EN-P - July 2008 43

Page 44

Chapter 4 Replace System Components

8. Remove the screws securing the drive to the bay and carefully

pull out the drive.

1200P

Spacer

Drive

Drive Brackets

Drive Adapter

Install the Drive

Follow these steps to install the drive.

1. Fasten the drive to the bay.

2. Connect the drive adapter board to the drive.

Use care with the delicate ribbon cable on the floppy disk drive.

3. Connect the data, power, and audio cables to the drive bay

assembly.

4. Carefully replace the drive bay assembly.

5. Fasten the drive bay bracket to the inner shelf with four screws.

6. Connect the cables between the display and back chassis as

necessary.

7. Carefully reattach the display head to the back chassis using the

12 perimeter screws.

44 Publication 6181P-UM001G-EN-P - July 2008

Page 45

Replace System Components Chapter 4

Replace the Optical Disc Drive (1500P and 1700P)

Follow these precautions when working with the floppy or optical

disk drive.

• Do not touch internal components unnecessarily.

• Always handle the drive by its metal frame.

• Store the drive in an anti-static bag when it is not installed.

• Never disconnect or install a drive with the power on.

ATTENTION

ATTENTION

Failure to follow proper safety precautions could result in

severe electrical shock and/or damage to the computer.

Mechanical shock can damage an optical disc drive. Do not

drop or bump the drive.

Remove the Drive

Follow these steps to remove the drive.

1. Disconnect power from the computer.

2. Remove the back cover.

3. Disconnect the power supply, audio cable, and ribbon cable

from the adapter printed circuit board.

IMPORTANT

4. Remove the two screws that fasten the drive assembly to the

chassis.

5. Lift the drive assembly out of the chassis.

6. Remove the four screws that fasten the drive brackets to the

drive and remove the brackets from the drive.

Note the location and orientation of all cables before you

remove the existing power supply and cabling, so that you can

reattach them correctly.

Publication 6181P-UM001G-EN-P - July 2008 45

Page 46

Chapter 4 Replace System Components

7. Remove the two screws and spacers that fasten the adapter to

the drive and remove the adapter from the drive.

1500P and 1700P

Drive

Drive Brackets

Drive Adapter

Spacer

Install the Drive

Follow these steps to install the drive.

1. Fasten the drive to the drive brackets with four screws.

2. Fasten the drive to the drive adapter with two screws and

spacers.

3. Gently slide the assembly back into the chassis.

4. Fasten the drive assembly to the chassis with three screws.

5. Connect the power supply, audio cable, and ribbon cables to

the drive.

6. Apply glue to ribbon cable and audio cable to avoid separation.

7. Reinstall the back cover.

46 Publication 6181P-UM001G-EN-P - July 2008

Page 47

Replace System Components Chapter 4

Add or Remove the Memory Module

The CPU board in the computer has two sockets. Each socket

supports a Dual In-Line Memory Module (DIMM).

For a current list of memory modules available for your computer,

refer to the Rockwell Automation Allen-Bradley website

http://www.ab.com/industrialcomputers

TIP

It is recommended that you use only qualified Allen-Bradley

parts.

.

Guidelines for Replacing Memory

When adding memory to the CPU board, follow these guidelines.

• Always handle the memory cards by the ends not by the

memory module contacts.

• Store memory in a sealed anti-static bag when it is not installed.

• Never install or remove memory with the power turned on.

ATTENTION

Failure to follow proper safety precautions could result in

severe electrical shock and/or damage to the computer.

ATTENTION

Electrostatic Discharge (ESD) can damage the computer and

components. Make sure you work in a static-safe environment

and wear a grounding strap whenever handling circuit boards,

power supply, memory modules or other internal components.

Publication 6181P-UM001G-EN-P - July 2008 47

Page 48

Chapter 4 Replace System Components

48 Publication 6181P-UM001G-EN-P - July 2008

Page 49

System Troubleshooting

Chapter

5

Chapter Objectives

Hardware Diagnostics

This chapter describes the most common operating problems, the

probable causes, and recommended corrective actions. It includes:

• Hardware diagnostics

• Troubleshooting procedures

• Troubleshooting checklists

The computer monitors:

• Voltage ranges

• Temperature requirements

• Chassis fan speed

Perform this procedure to determine which of these thresholds has

been exceeded.

1. Shut down the computer by using the appropriate method for

your operating system.

2. Apply power to the computer.

3. Press and hold the Delete (DEL) key to enter BIOS Setup.

The BIOS Setup Menu appears.

4. Press the down arrow key to select the PC Health Status menu

for series A or Hardware Monitor Setup menu for series B & C.

49Publication 6181P-UM001G-EN-P - July 2008 49

Page 50

Chapter 5 System Troubleshooting

Troubleshooting Procedure

Follow this procedure to identify and isolate a problem.

1. Shut down the computer’s operating system using the

appropriate method for your operating system.

2. Disconnect the power to the computer.

3. Disconnect peripheral devices such as a printer or external

drive.

4. Connect the keyboard and mouse, if used.

5. Check the video connections if using an external monitor.

6. If the system normally boots from the hard drive, make sure a

disk is not in the floppy drive.

7. Connect power to the computer.

On powerup, monitor the Power On Self Test (POST). One of

three events will occur.

• The computer completes the bootup process.

• An error message displays to indicate a non-fatal fault. You

may have to acknowledge the message before the startup

process continues.

• The bootup process terminates if a fatal error occurs.

8. If the system boots up, isolate the problem by connecting

peripheral devices one at a time until the problem occurs.

If the problem is with a specific software package, or driver,

reinstall the software.

9. If the problem is not related specifically to a software installation

or peripheral device, refer to the troubleshooting checklists.

50 Publication 6181P-UM001G-EN-P - July 2008

Page 51

System Troubleshooting Chapter 5

Troubleshooting Checklists

Use the following checklists to test or verify items.

Problems During Start-up

• Are all connections secure?

• Are the device drivers installed?

• Are the jumpers on any add-in boards correctly positioned?

• Is the hard drive formatted and recognized correctly in the

BIOS?

• Is the RAM memory properly installed? You may want to reinstall

it to ensure a good connection.

• Is the IDE cable from the hard drive properly connected? You

may want to see if the system will boot from a floppy disk.

• Is BIOS properly configured? Select ’Load Optimal Default’ in

the CMOS setup procedure. This will restore the BIOS settings to

the original factory settings.

Problems After Start-up

• If you are running a software package, reinstall the software.

• If the problem is intermittent, you may have a loose connection.

Check all connections including any PCI cards. Check that the

memory module (DIMM) is fully installed.

• Does your system have a computer virus? Run anti-virus

software.

• Try clearing CMOS by removing and reinstalling the battery (on

backplane) and running BIOS Setup.

• Although the computer has a regulated and protected power

supply, a transient voltage in the power line or peripheral cable

may cause a flickering display, unexpected reboots, or a locked

up system. If so, exit the application and start over.

• Is the IDE cable from the hard drive properly connected? You

may want to see if the system will boot from a floppy drive.

• Is the system overheating? Verify that all the fans (CPU, Chassis,

power supply) are working.

• Verify that the ambient air temperature is <50 °C (122 °F).

• Check for proper clearance around the computer to verify

adequate air flow.

Publication 6181P-UM001G-EN-P - July 2008 51

Page 52

Chapter 5 System Troubleshooting

Problems Running the New Software

• Does the software have a hardware requirement that is not

present?

• Are you using an authorized copy of the software? Some copies

of software will not work without proper activation.

• Did the software install correctly? Reinstall the software.

• Are you following the software’s instructions? Refer to the

software vendor’s user manual.

• If the new software installed system software (DLL files) or

device drivers, reapply the current Service Pack (release) of the

operating system. Refer to Chapter 3 on Operation.

Problems with the Add-in Card

• Is the board installed and configured correctly? Recheck jumper

and other configuration settings.

• Are any cables incorrectly installed?

Problems with the Display

• Are the display contrast and brightness controls properly

adjusted? Refer to the operating system containing the video

driver for setup functions.

• Is the monitor compatible with the selected video mode? Try

setting to the native resolution. See Appendix A for

Specifications.

Problems with the Display on an External Monitor

Series A

You can use an external monitor for a temporary connection or for

diagnostics. Using an external monitor for normal operation may

result in problems such as characters not displaying.

Series B

While the external display is configurable after Windows starts, it is

best to have the display connected and turned on when the computer

boots up.

52 Publication 6181P-UM001G-EN-P - July 2008

Page 53

Maintenance

Chapter

6

Chapter Objectives

Clean the Display

This chapter provides information on how to:

• clean the display.

• replace the battery.

• dispose of the backlight assembly.

• ship or transport the computer.

ATTENTION

Follow these steps to clean the display.

1. Disconnect power from the computer at the power source.

2. Using a clean sponge or a soft cloth, clean the display with a

mild soap or detergent.

Use of abrasive cleansers or solvents may damage the display

window. Do not scrub or use brushes.

3. Dry the display with a chamois or moist cellulose sponge to

avoid water spots.

ATTENTION

53Publication 6181P-UM001G-EN-P - July 2008 53

If the computer has a touchscreen, be aware that it is possible

for screen objects to activate during equipment wash-downs if

the computer is turned on.

Page 54

Chapter 6 Maintenance

Remove Paint and Grease

Follow these steps to remove paint and grease.

1. Remove fresh paint splashes and grease before drying by

rubbing lightly with isopropyl alcohol.

2. Perform a final wash with mild soap or detergent solution.

3. Rinse with clean water.

Replace the Battery

ATTENTION

Make sure the isopropyl alcohol does not come in contact with

the equipment labels. Alcohol may cause the label printing to

smear.

The computer contains a lithium battery to maintain CMOS settings

and the real-time clock. The battery is in a battery holder on the

computer’s CPU board. Replace this battery as needed with a

Panasonic battery, part number CR2032, or equivalent.

WARNING

To avoid the danger of explosion, only replace the battery with

part number CR2032 or a recommended equivalent. Dispose of

used batteries according to the manufacturer’s instructions.

The battery life depends on the amount of on-time (time computer is

powered on) per week. The table lists the estimated life of the battery.

On-time Expected Battery Life

0 hours/week 4 years

40 hours/week 5.5 years

80 hours/week 7 years

54 Publication 6181P-UM001G-EN-P - July 2008

Page 55

Backlight Assembly Disposal

ATTENTION

Maintenance Chapter 6

The backlight assembly in this unit contains mercury. At the end

of its life, this equipment should be collected separately from

any unsorted municipal waste.

Ship or Transport the Product

If you need to ship the product via common carrier or otherwise

transport it to another location, you must first uninstall the product

and place it in its original packing material.

ATTENTION

Do not ship or transport the product when it is installed in a

machine, panel or rack. Doing so may cause damage to the

product. You must uninstall the product and place in its original

packing material before shipping. Rockwell Automation is not

responsible for damage incurred to a product that is shipped or

transported while installed in a machine, panel or rack.

Publication 6181P-UM001G-EN-P - July 2008 55

Page 56

Chapter 6 Maintenance

56 Publication 6181P-UM001G-EN-P - July 2008

Page 57

Appendix

Specifications

Display

Type Active Matrix Color TFT

Touchscreen (optional) Resistive antiglare

Display size

1200P

1500P

1700P

Display area (WxH)

1200P

1500P

1700P

Resolution, native

1200P

1500P

1700P

Response time 15 ms (typical)

Mechanical

Weight

1200P

1500P

1700P

Dimensions, overall (HxWxD)

1200P

1500P

1700P

Cutout dimensions (HxW)

1200P

1500P

1700P

Environmental

Temperature, operating 0…50 °C (32…122 °F)

Temperature, storage -20…60 °C (-4…40 °F)

Relative humidity 10…90% without condensation

Shock, operating

Shock, nonoperating

Vibration, operating

Computers without solid state drive

Computers with solid state drive

Vibration, non-operating

Enclosure ratings NEMA Type 1, 12, 4, IP66

(1)

Applies to panel mounted computers only.

(2)

The floppy disk drive and optical disc drive are considered maintenance devices. You should not operate

computers with these devices in environments with the shock and vibration levels listed.

12.1 in.

15 in.

17 in.

246 x 185 mm (9.7 x 7.3 in.)

305 x 229 mm (12 x 9 in.)

338 x 270 mm (13.3 x 10.7 in.)

800 x 600, 256K colors

1024 x 768, 256K colors

1280 x 1024, 16.7M colors

9.2 kg (21 lb)

10 kg (23 lb)

12.6 kg (28 lb)

279 x 349 x 176 mm (10.99 x 13.75 x 6.93 in.)

309 x 410 x 109 mm (12.17 x 16.14 x 4.29 in.)

356 x 452 x 110 mm (14.02 x 17.80 x 4.32 in.)

254 x 324 mm (10.00 x 12.76 in.)

285 x 386.6 mm (11.24 x 15.22 in.)

329.5 x 424 mm (12.97 x 16.69 in.)

15 g (1/2 sine, 11ms)

30 g (1/2 sine, 11 ms)

1.0 g peak (10…500 Hz)

1.5 g peak (10…500 Hz)

2.0 g peak (10…500 Hz)

NEMA Type 4X - stainless steel units only

(1)(2)

(1)

(1)(2)

(1)

(1)

A

Publication 6181P-UM001G-EN-P - July 2008 57

Page 58

Appendix A Specifications

Electrical

Input voltage, ac 90…264V AC autoranging

Line frequency 47…63 Hz

Ground leakage 1.0 uA max. at 1.5KV dc

Power consumption, AC

1200P, 1500P, 1700P

1200P (6181P-2 non-display)

150 VA (1.5 A @ 100V rms, 0.63A @ 240V rms)

140 VA (1.4A @ 100V rms, 0.58A @ 240V rms)

Input voltage, dc

1200P and 1200P (6181P-2 non-display) 18…32V dc

Power consumption, dc

1200P

1200P (6181P-2 non-display)

Certifications

(1)

150 W

140 W

c-UL-us UL 60950 Recognized Component, C-UL 950

Recognized Component, or UL/c-UL Listed when

marked

CE marked for all applicable directives

LVD (73/23/EEC)

EMC (89/336/EEC)

C-Tick Australian Radiocommunications Act

(1)

See http://ab.com for declarations of conformity, certificates, and other certification details.

58 Publication 6181P-UM001G-EN-P - July 2008

Page 59

Appendix

Use the Touchscreen

Computers with the touchscreen option are shipped with the

touchscreen and touchscreen controller installed and connected.

B

Touchscreen Serial Port Usage

Driver Software

For Additional Information

Resistive Touchscreen Technology

The optional touchscreen controller connects internally to the COM3

serial port. The touchscreen is factory configured with the proper

COM3 and touchscreen driver settings, so no user configuration is

required.

The touchscreen driver is already loaded on the computer. The driver

software is also on the accessory CD.

TIP

For more information on setting up or operating a touchscreen or for

future driver upgrades, refer to http://www.ab.com

Resistive touchscreens are activated when you apply pressure to the

touchscreen with your finger. You can operate a resistive touchscreen

while wearing gloves.

If it becomes necessary to reinstall the touchscreen driver, the

touchscreen utility will automatically detect the serial port used

by the touchscreen controller.

.

ATTENTION

Publication 6181P-UM001G-EN-P - July 2008 59

Do not use sharp instruments to activate the touchscreen.

Scratching the surface of the touchscreen could damage the

unit.

Page 60

Appendix B Use the Touchscreen

Calibrate the Touchscreen

The touchscreen supplied with the computer is factory installed and

calibrated.

Follow these steps to recalibrate the touchscreen.

1. Run the touchscreen configuration utility through the

PROGRAMS menu of the operating system.

2. Start the calibration routine offered within the utility.

3. Follow the calibration instructions given on the computer

screen.

60 Publication 6181P-UM001G-EN-P - July 2008

Page 61

Upgrade to a New BIOS

Appendix

C

Introduction

BIOS Update Procedure

If a new BIOS is released to enhance the performance of your

computer, or to correct a defect, you can download the BIOS and

update your computer. Download the BIOS from the Rockwell

Automation Allen-Bradley website at http://www.ab.com

Follow these steps to update the BIOS.

1. Download the BIOS from

http://www.ab.com/industrialcomputers

Locate BIOS under Support Services>Drivers.

2. Load a blank disk in the floppy drive of your computer.

3. Launch the BIOS copy application by double-clicking on the

executable file that you downloaded in the previous step.

The application will copy the BIOS loader to the disk.

4. Boot the computer by using the floppy disk created in the

previous step.

.

.

5. Follow the directions that display on the computer screen to

properly update the BIOS.

Publication 6181P-UM001G-EN-P - July 2008 61

Page 62

Appendix C Upgrade to a New BIOS

62 Publication 6181P-UM001G-EN-P - July 2008

Page 63

Solid State Drive

Appendix

D

Introduction

A reliable means of data storage is a concern in industrial applications

with harsh requirements. Standard rotating media with its spinning

platters and head arms (with temperature limitations) present

obstacles to the reliable storage of data.

Solid state drives (SSD) are a direct replacement for rotating hard

drives on the IDE bus. They are drop-in replacements for their hard

drive counterparts.

Solid state drives offer improvements over the standard hard drive.

• Improved thermal performance

• Higher levels of shock/vibration

• Less power required

• Longer data retention

• No moving parts

The rotating hard drive is susceptible to shock and vibration. This

weakness becomes more apparent as the temperature increases.

Although the solid state drive offer improvements in these areas, you

must consider limitations of other key components within your

systems before choosing to replace hard drives.

The decrease in the cost per megabyte of memory in flash drives is

making the solid state drive a viable alternative, especially in harsh

industrial environments.

Installation

Publication 6181P-UM001G-EN-P - July 2008 63

Use caution when installing or handling a solid state drive. Even

though the solid state drive is typically designed with a case around

the PCB assembly, you must handle the drive with care to prevent

possible electrostatic discharge (ESD) damage.

Follow these guidelines when installing or handling a solid state drive.

• Do not touch the exposed connector; handle by the case.

• Ground yourself whenever possible before handling the solid

state drive.

• Leave the product in its protective ESD bag until the time of

installation.

Page 64

Appendix D Solid State Drive

• The solid state drive installs on the computer’s IDE bus via the

IDE ribbon cable. Pay close attention to connector alignment.

Careless assembly can bend a pin or misalign the connectors,

resulting in hardware damage.

Configuration

Pin 43

Pin 44

The solid state drive is configured for a single drive system, or as a

master in a multiple drive system. The diagram indicates the various

operating configurations.

IMPORTANT

You must power off the drive whenever making a mode change.

IDE Drive Connector Interface

The solid state drive uses a 44-pin (2 mm pitch) connector to attach to

the IDE bus.

Pin 2

Pin 1

A

Mode

C

Settings

D

Master (Factory Default)

64 Publication 6181P-UM001G-EN-P - July 2008

A

B

C

D

A

B

Slave

C

D

Cable Select

A

B

Page 65

Solid State Drive Appendix D

Operation

The solid state drive appears to the system host as a standard rotating

hard drive when powered up. The system host identifies the solid

state drive during powerup and sets the IDE bus speed to reflect the

drives capability:.

• DMA-2 (multiword) or

• PIO-4

In DMA-2 or PIO-4, the maximum IDE bus speed is 16.7 M.

The controller on the solid state drive uses an error correcting code

(ECC) and cyclic redundancy check (CRC) to check for data errors.

The ECC code consists of six bytes per 512 bytes (one sector) and is

stored with the data in flash memory.

Data correction algorithms can prevent data corruption on the drive.

However, they cannot prevent operating system (OS)/file type errors

when the OS breaks large files into smaller (multiple) file transfers.

This results in the host receiving only part of the transfer.

IMPORTANT

Always protect your system against unexpected power

interruptions.

Life Expectancy

Always shutdown your windows application using the Start menu on

the desktop. Whenever possible, use an uninterruptible power source

(UPS) or other power conditioning device to perform a proper

shutdown during unexpected power interruptions.

The limitation of the solid state drive is the finite amount of writes to a

specific memory location. The life expectancy of a solid state drive

varies depending on:

• how often an application writes data to the drive.

• the size of the file written to the drive.

• the amount of available space on the drive that can be used by

the drive’s controller to write data.

• the write/erase cycle limitation the manufacturer specifies.

On the flash drive, the smallest space that can be written to is a sector,

which is 512 bytes. However, the smallest space that can be erased is

a block of memory. Unlike magnetic media, an erase cycle is required

for flash memory before a write can be made. The actual block size

varies depending on the overall capacity of the flash drive, for

example, 63 sectors, or 32 K on a 4 GB drive.

Publication 6181P-UM001G-EN-P - July 2008 65

Page 66

Appendix D Solid State Drive

Wear leveling algorithms in flash memory drives offer an advantage to

the overall throughput of the memory and the life expectancy of the

drive. Wear leveling evenly distributes data that is written to memory

across all free space on the drive. As one block of memory is written

and filled, another is made available for the next data transfer. This

block mapping occurs across all the free space and then starts again at

the initial block. At the same time, the drive’s controller erases blocks

previously used allowing memory to be available for updates without

delaying the write requests from the host CPU.

When a memory cell fails within a specific sector, the entire block

where the sector resides is marked as bad and removed from use. A

new block from the pool of spares replaces the bad block. The

amount of spare blocks within the pool is determined by the size of

the drive memory. The size of the pool typically falls in the range of 1

to 1.5% of the total drive memory space and is set when initially

formatted.

Typical Solid State Drive

Drive SimpleTech 4 GB

Sector 512 bytes

Sectors 8,388,608

Blocks 32,768 (1 block = 131,072 bytes)

Zone 512 blocks (wear level boundary)

Write Cycle Limit 2 million

Free Space 4 GB (OS image + installed applications)

1 Year 8,760 hours

Seconds/Year 31,536,000

Application Example One

An application updates a 100K data file every second on the 4 GB

SimpleTech drive that is approximately half full with the OS image

and application software.

Use this formula to calculate expected life.

(Flashblocks x Write Cycle limit x Drive Freespace) / [(1 block/sec) x (31,536,000sec/yr)]

(32,768 x 2,000,000 x .5) / [ (1 block/sec) x (31,536,000 sec/yr)] = 1039 years

66 Publication 6181P-UM001G-EN-P - July 2008

Page 67

Solid State Drive Appendix D

Application Example Two

The OS is updating its FAT table and root directory twice a second.

This update requires one block of memory (128 K). Every write

regardless of location writes to a single block. In this case, wear

leveling is limited to 1 zone (512 blocks).

Use this formula to calculate expected life:

(Flashblocks x Write cycle limit) / [(2 block/sec) x 31,536,000/yr)]

(512 x 2,000,000) / [(2block/sec) x 31,536,000 sec/yr)] = 16.2 yrs

Normally in a Windows operating environment virtual memory is

used, also known as a ’swap file’ or ’page file’. The OS may read from

and write to this file often in a short period of time. Although the

space used could be small, an entire block of memory is required. On

systems using solid state memory, it is recommended that this feature

be turned off.

Maintenance

Under normal operating conditions, scheduled maintenance is not

required. The integrity of data stored on a solid state drive is good for

up to ten years.

Publication 6181P-UM001G-EN-P - July 2008 67

Page 68