Page 1

Instructions

(For 6180 Industrial Computers)

This document shows how to remove or install a floppy disk drive or

CD ROM drive in the accessory drive bay of the 6180 Industrial

Computer. Instructions for operation of a CD ROM drive are

provided along with floppy and CD ROM drive specifications. For

additional information on mounting brackets and covers, refer to the

6180 Industrial Computer Accessory Mounting Brackets and Covers

publication.

Safety Precautions

Internal 6180 Computer components may be damaged by

Electrostatic Discharge (ESD). Make sure you wear a grounding

strap whenever handling circuit boards, memory modules or other

internal components.

ATTENTION: Wear a wrist strap (well grounded)

and perform work in a static safe environment.

!

Also observe the following precautions:

• Always handle the drive by its metal frame.

• Always store a drive in an anti-static bag when it is not installed.

• Avoid touching the cable connectors.

• Never disconnect or connect a drive with the power

turned on.

If you are installing or removing a CD ROM drive, the following

precautions apply.

!

Electrostatic discharge can damage the 6180 Computer

and components.

ATTENTION: The CD ROM contains a laser system.

To ensure proper use of this product, please read this

instruction manual carefully and retain for future

reference. Should the unit ever require maintenance,

contact an authorized service location.

Use of controls, adjustments or the performance of

procedures other than those specified may result in

hazardous radiation exposure.

To prevent direct exposure to laser beam, do not open

the enclosure.

Page 2

Removeable Media2

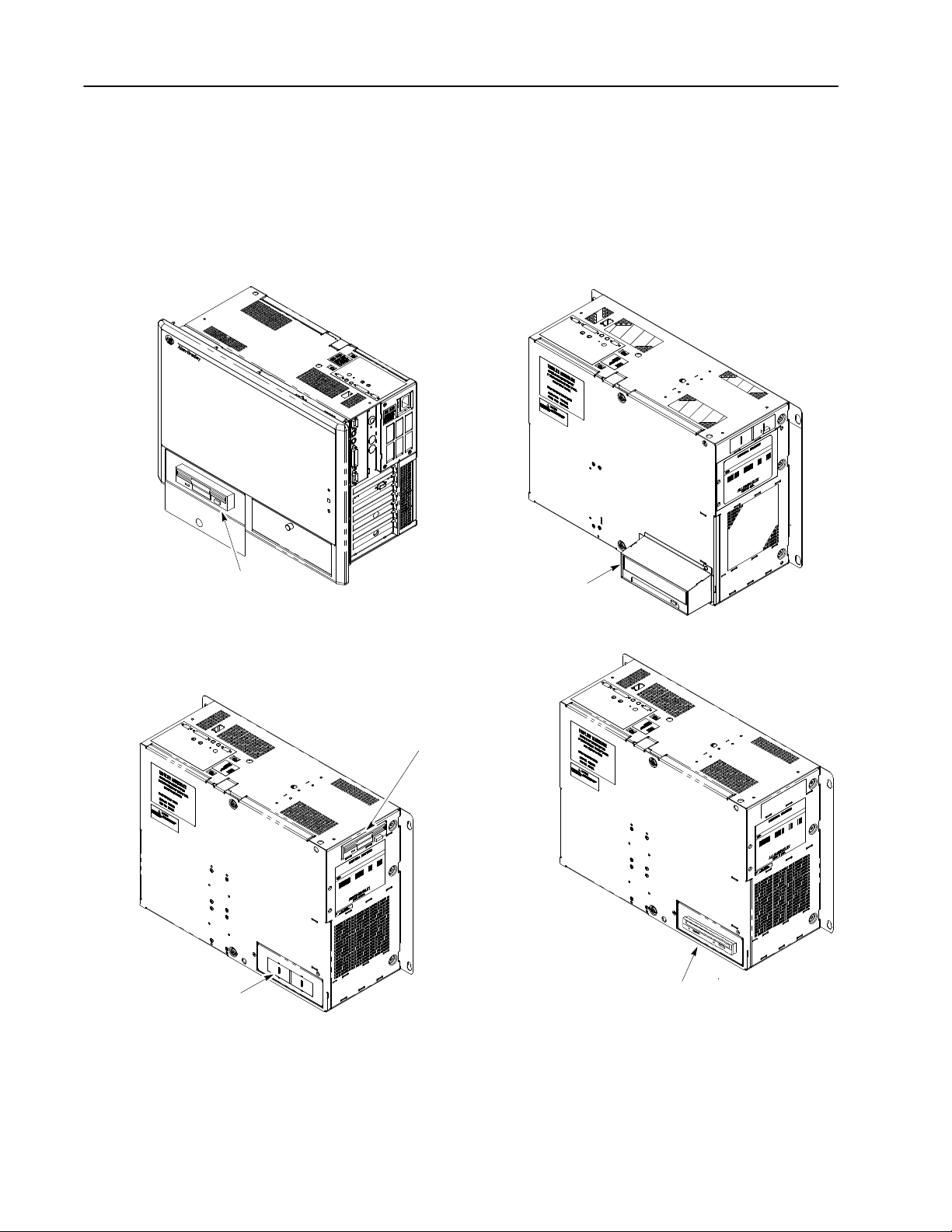

Mounting Options

Front Mounting

(Floppy or CD ROM Drive)

Both the Floppy and CD ROM drives may be front or rear mounted.

With an optional mounting bracket, the floppy drive may also be

mounted in the side facing upper bay (refer to installation

instructions provided with bracket). The following figure shows the

methods of mounting a drive. The front mounting option is not

available for the non-display, metal bezel versions of the 6180

Computer.

Rear Mounting

(CD ROM Drive)

Shown with Cover (6189-RCDBRKT)

Accessory Drive Panel

Knockout for Rear Mounting

Upper Bay Mounting

(Floppy Drive)

Requires a mounting bracket (Catalog No.

6189-UBFDBRKT)

Instructions are provided with bracket.

Rear Mounting

(Floppy Drive)

Page 3

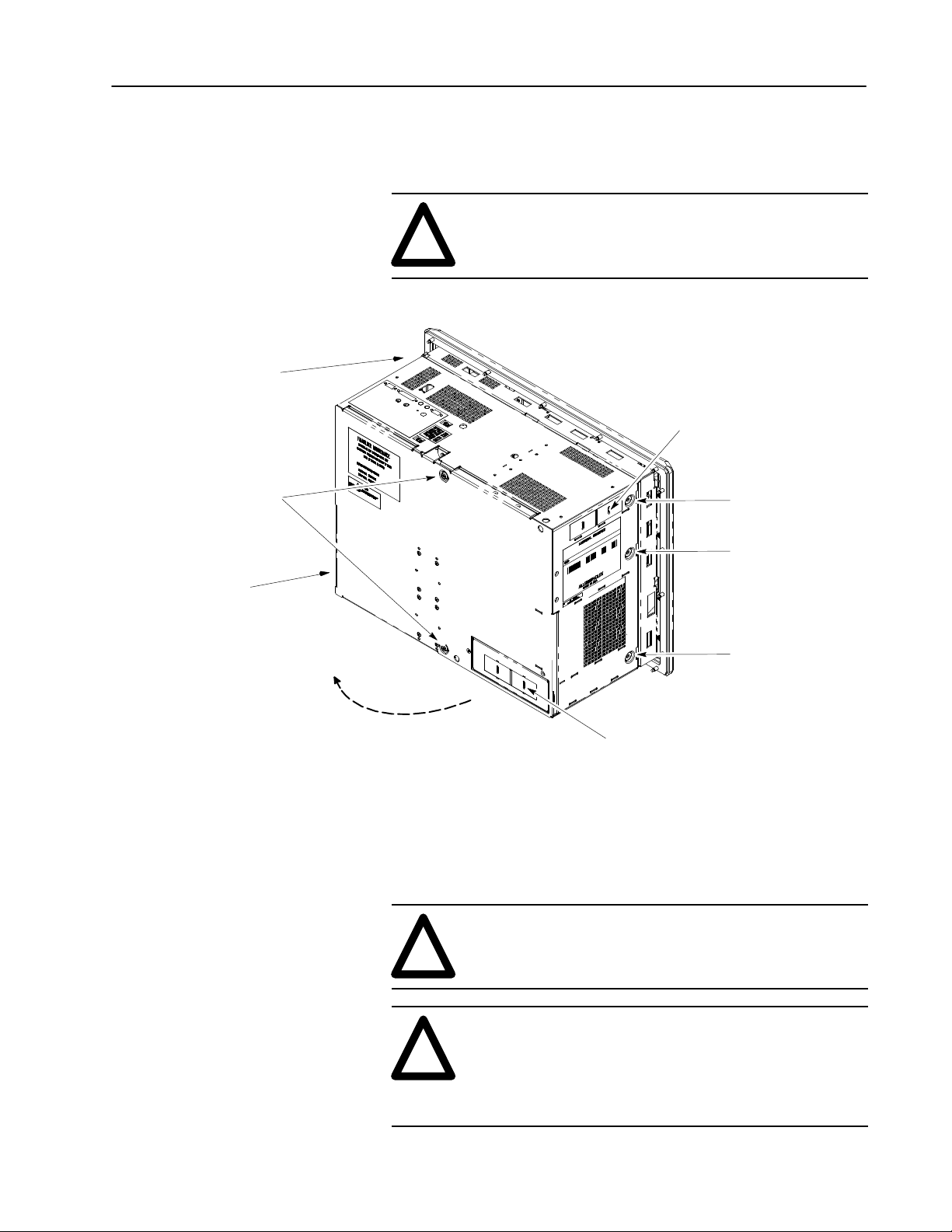

Front Bezel

Hinge On This Side

Back Panel

Retaining Screws

Removeable Media 3

To remove a front or rear facing drive:

1. Disconnect power from the 6180 Computer.

ATTENTION: Disconnect all power before

adding/removing components. Failure to disconnect

!

2. Remove the back panel.

power could result in severe electrical shock or damage

to the 6180 Computer.

Chassis Knockout

For Upper Bay Mounting

Back Panel

Chassis Swings Away

From Bezel

3. To remove the drive, it may be helpful to swing the chassis away

from the front bezel. Remove the three latching screws that

secure the front bezel. Note the following precautions before

swinging the chassis away from the bezel.

!

Front Bezel

Latching Screws (3)

Cover Knockout

for Rear Mounting of Drive

ATTENTION: Remove all cables from the the side

panel connectors. Failure to remove cables may cause

damage to the cables and connectors.

ATTENTION: If the 6180 Computer is installed with

mounting clips, the mounting clips on the hinge side

!

will interfere with the opening of the hinge. Remove

the mounting clips on the hinge side before swinging

chassis away from the bezel. Failure to remove clips

may damage clips and the chassis.

Page 4

Removeable Media4

4. From the bottom of the chassis (under the accessory drive),

remove the 4 screws that secure the accessory drive/ bracket

assembly.

Accessory Drive /

Bracket Assembly

Mounting Screws (4)

6180 Computer

(Bottom View)

5. The sequence of the following steps depends on whether the drive

is mounted to the rear or front:

• If mounted for front access, do step 6 then step 7.

• If mounted for rear access, do step 7 then step 6.

6. Disconnect the ribbon cable connector and power cable connector

from the drive.

Floppy or CD ROM Drive

Mounting Bracket

Not Illustrated

Power Connector

Ribbon Cable

7. Remove the accessory drive / bracket assembly through the back

of the chassis.

Page 5

Floppy Drive Bracket

(Catalog No. 6189-LBFDBRKT)

Removeable Media 5

8. If you are removing a floppy drive, remove the screws which

secure the floppy drive to the bracket. CD ROM drives do not

have a bracket and are mounted directly to the chassis.

Drive Mounting Screws (4)

Floppy Drive

To install a front or rear facing drive:

1. If installing a floppy drive, secure the floppy drive to the floppy

drive bracket. The CD ROM drive does not require a bracket.

2. Position the CD ROM or floppy drive / bracket assembly into the

chassis.

3. Connect the cable connectors to the drive. Connectors are keyed

so they cannot be installed backwards.

4. Align the CD ROM or floppy drive / bracket with the chassis

mounting holes and secure with the mounting screws:

• front facing CD ROM requires 4 screws

• rear facing CD ROM drive requires 2 screws

5. Swing the chassis back onto the bezel and secure chassis with the

three latching screws.

6. Install the back panel and the accessory drive panel.

Page 6

Removeable Media6

Notes:

You may have to remove the panel knockout (shown on page 2) if

a rear mounted floppy drive was not previously installed.

If you are installing a front facing CD ROM drive, a rear cover

(Catalog No. 6189-FCDBRKT) should be installed on the back

panel.

If you are installing a rear facing CD ROM drive, covers (Catalog

No. 6189-RCDBRKT) should be installed on the front bezel and

rear panel.

For additional information on mounting brackets and covers, refer

to the 6180 Industrial Computer Accessory Mounting Brackets

and Covers publication.

7. Apply power to the 6180 Computer and verify operation of the

drive. You may need to update the BIOS settings, refer to the

Processor Board manual.

CD ROM Emergency Eject

If the eject button will not eject the CD tray, use the following

emergency eject procedure.

1. Turn off the power to the computer and wait approximately 1

minute to allow the CD to stop spinning.

2. Insert a paper clip into the emergency eject hole and push in as

shown below. The tray will open.

Page 7

Removeable Media 7

CD ROM Disk Holders

Floppy Drive Specifications

The disk holders are not required for operation with the 6180

computer. The disk holders retain the CD if the CD ROM drive is

mounted in a vertical orientation. The 6180 computer can only be

mounted in an orientation where the CD ROM drive is in a

horizontal position.

The following table provides operating and technical specifications

for the 1.44MB floppy drive (Catalog No. 6189-FD144/A).

Format 3.5 inch Micro Floppy Disk*

Capacity 1.44MB (IBM Format)

Speed of Rotation 300 RPM

Continuous Speed Variation

Instantaneous Speed Variation

Access Time

Track to Track Slew Rate 3ms

Head Setting Time 15ms (maximum)

Average Access Time 94ms

Motor Start Time 500ms (maximum)

Rotational Latency 100ms (average)

Structure

Track Density 135 Tracks per Inch (TPI)

Number of Cylinders 80

Number of Tracks 160

Read/Write Heads 2

Data Rate 500K Bits/sec

Average Power 1.5 watts (typical)

Supply Voltage

* Use only high density floppy disks

1.5%

3.0%

+5V DC 10%

Page 8

CD ROM Drive Specifications

The following table provides operating and technical specifications

for the CD ROM Drive (Catalog No. 6189-CDROM).

Rotational Speed 6,360 rpm (Max)

Sustained Data Transfer Rate

Mode 1 Approximately 2,400 KBytes/s

Mode 2 Approximately 2,736 KBytes/s

Access Time

Average Random Access Time 100ms (Typical)

Average Random Seek Time 95ms (Typical)

Average Full Stroke Access Time 180ms (Typical)

Supply Voltage

Vibration

Operating

Non Operating

➀

➀

Shock

Operating

Non Operating

➀

➀

Temperature

Operating

Non Operating

➀

The 6180 computer specification for shock and vibration exceeds the

specifications for the CD ROM drive. When a CD ROM drive is installed and

operating, derate the shock and vibration specification for the 6180 computer to the

specifications for the CD ROM drive.

+5V, +12V DC 5%

No Hard Error

5 to 500 Hz 2.45m/s

2

(0.25G) (0-P)

5 to 10 Hz 5mm (P-P)

10 to 500 Hz (1G) (0-P)

No Hard Error

2

14.7 m/s

(1.5G) – Horizontal

2

(0.8G) – Vertical

7.8 m/s

Half Sine Wave 11ms/10s Interval)

Refer to 6180 Computer Specifications

C to 50C (41F to 122F)

5

C to 60C (14F to 140F)

-10

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

world’s leading technology companies.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark

Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia • Ireland •Israel • Italy

Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands •New Zealand • Norway • Pakistan • Peru • Philippines • Poland • Portugal • Puerto

•

Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain • Sweden •Switzerland • T aiwan • Thailand • Turkey

Rico

United Arab Emirates • United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Copyright 1997 Allen-Bradley Company, Inc. Printed in USA

40061-365-01(C)

•

•

•

Loading...

Loading...