Page 1

Industrial 21" CRT Monitor

(Bullet in 61 58)

Installation and User Manual

Page 2

2 Table of Contents

7

7D

DEOH R

EOH RI

Industrial 21" CRT Monitor.............................................. 3

Description........................................................................... 3

Package Contents................................................................. 4

Dimensions.......................................................................... 5

Installing the 6158 Industrial Monitor ................................... 7

Connecting AC Power.......................................................... 10

Product Options.................................................................... 10

Connecting to a Computer.................................................... 15

Rear Panel Controls and Indicators....................................... 16

Maintenance......................................................................... 18

Allen-Bradley Support ......................................................... 19

Troubleshooting................................................................... 20

Specifications...................................................................... 21

I &RQWH

&RQWHQ

QWV

WV

Important U s er Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. "Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Controls" (Publication SGI-1.1) describes some important

differences between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, Rockwell Automation cannot assume responsibility or liability for actual

use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect to use of the

informat ion, cir cuits, equipment, or s of twar e described in this manu al.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation is prohibite d.

Throughout this manual, we use notes to make you aware of safety considerations.

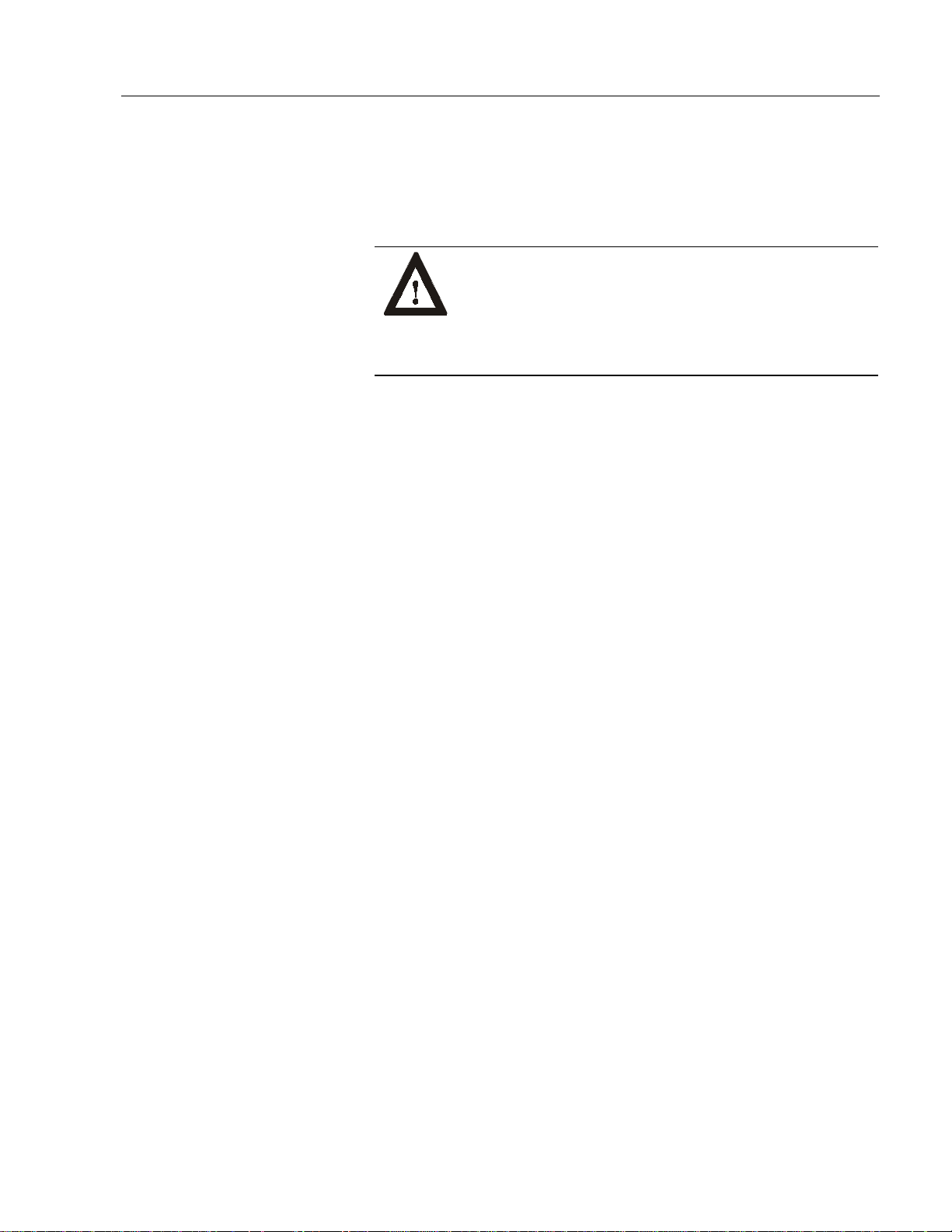

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

Important:

application and understanding of the product.

Identifies information that is espe cially imp ortant for succe ssful

Publication 6158-5.0

Page 3

,QGXVWULDO

,QGXVWULDO

&57 0RQLW

Industrial 21" CRT Monitor 3

&57 0RQLWR

RU

U

Description

The Bulletin 6158 21" Industrial CRT Monitor is a general purpose

monitor suitable for a wide range of industrial computing applications.

ATTENTION: The equipment described in this

document generates, uses, and emits radio frequency

energy. The equipment has been t ested and found to

comply with FCC Rules, Part 15, subpart J, for Class A

computing devices.

The use of non-shielded interface or power cords with

All e n-Bradley indust rial monitor s is prohibited.

ATTENTION: X-ray emissions from these monitors are

typically about 0.05 mR/hr maximum, well below the 0.5

mR/hr maximum rec ommend e d by the US. Departme nt of

Heal th and Human Resour ces an d specif ied i n "Federal

Perf orman ce Standar ds for Television R e ceiv ers", Section

10, Part 1020, Title 21, of the U. S. Code of Regulation

(PL90-620), Vol. 38, No. 198.

These m onitors are equip ped wit h X-ray protection

circuits which cause automatic shutdown of the

equipment i n cas e its X-r ay emissions begin to ap pr oach

Feder al limits .

Publication 6158-5.0

Page 4

4 Industrial 21" CRT Monitor

Package Contents

The monitor shipping carton contains the following items:

Monitor

•

Pa cka g e of mou nt i ng ha r dwa r e

•

AC power cord (optional)

•

Video cable (optional)

•

This user manual

•

A 6158 Industrial Monitor with a touchscreen option is shipped with

these additional items:

Supporting software and manuals

•

RS-232 serial extension cable (optional)

•

Un packing the Unit

Before unpacking a new monitor, inspect the shipping carton for

damage. If damage is visible, immediately contact the shipper and

request assistance. Otherwise, proceed with unpacking.

Note:

Make s ure you keep t he ori ginal packagin g f or the monitor

in case you need to return the monitor for repair.

Publication 6158-5.0

Page 5

Industrial 21" CRT Monitor 5

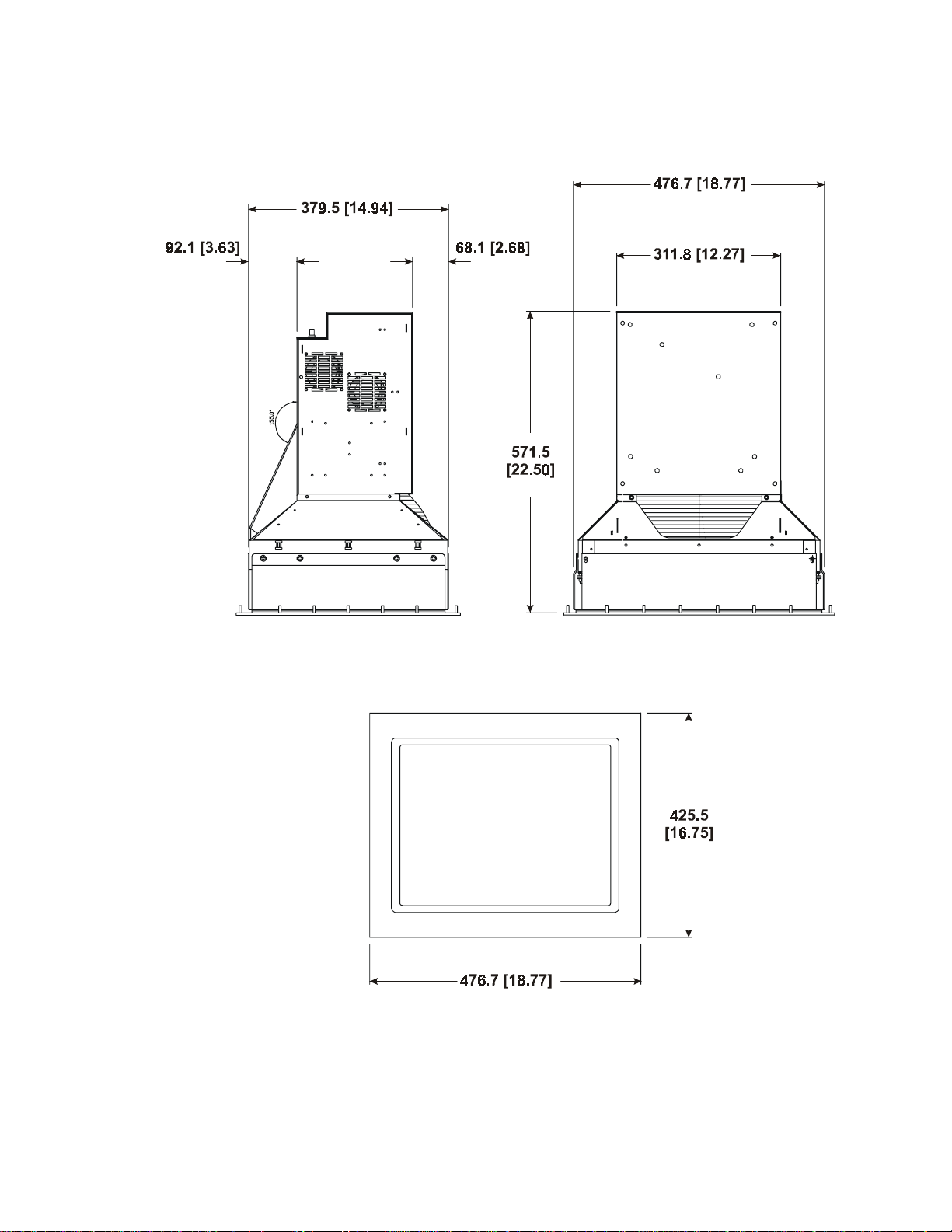

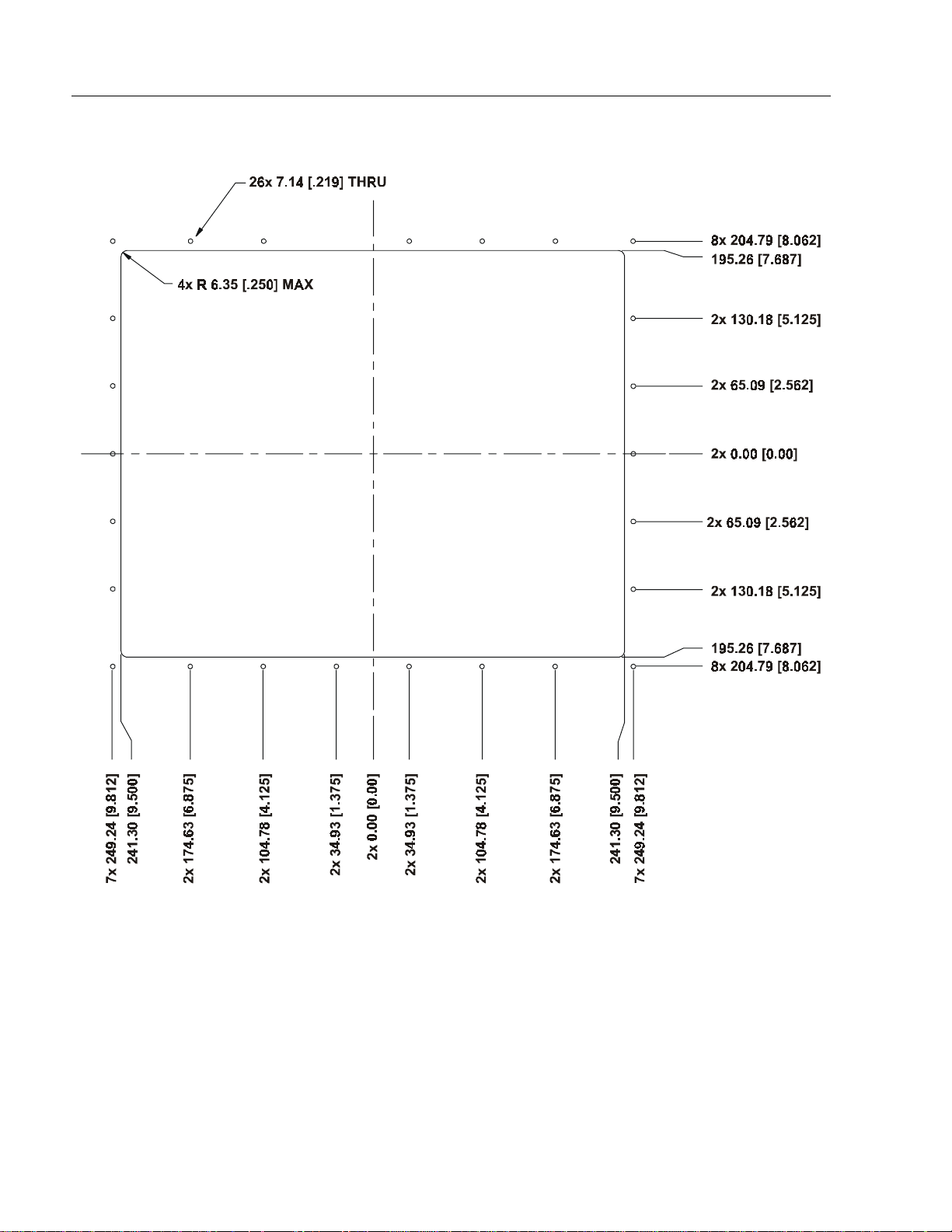

Dimensions

Figure 1

6158 Industrial Monitor - Physical Dimensions

Publication 6158-5.0

Page 6

6 Industrial 21" CRT Monitor

Figure 2

Panel Cutout Dimensions

Publication 6158-5.0

Page 7

Industrial 21" CRT Monitor 7

Installing the 6158 Industrial Monitor

Environmental Considerations

The 6158 Industrial Monitor requires a minimum free air space of 76.2

mm (3 in.) behind and 50.8 mm (2 in.) above and below for proper

cooling. A llen-Bradley I ndustria l Monitors have b e e n de sig ned to

function with out coo l ing fa ns. T herefore, maintenanc e o f f an filters and

access to them n eed not be a concern.

Str ong magnetic fields near the front of the mon i tor outsid e the enclosure

could potentially distort the image over time. This type of image

distortion generally disappears after degaussing occurs. Allen-Bradley

industrial monitors automatically degauss each time AC power is

applied, or whe n the de gauss but ton is press e d.

Note:

The internal degauss will not prevent color impurities

caused by local magnetic fields. Make certain the monitor’s

enclosure is free of residual mag n etism.

Installation Instructions

The 6158 Industrial Monitor has a 9U panel height and is designed to

meet N EMA 4 and NEMA 12 st andards whe n properly installe d.

The panel on which you mount the monitor should be at least 14 gauge

to insure a NEMA 4 seal and proper support for the unit. The mounting

studs attached to the rear of the monitor bezel will accommodate this

minimum thickness panel and panels up to 6.35 mm (0.25 in.) thick.

The monit or may also be bo l ted to the front r ails of EIA standard 19 in.

rack cabinets.

To install the 6158 Industrial Monitor:

1. Confirm that the shipping carton contains a package of 20 10–32

loc k nuts and 20 flat wa shers. You will nee d 18 nut s and washers for

installation.

2. Refer to th e physic al dimension drawings (Figure 1 ) and co nfirm

that there is adequate space behind the panel. Remember to allow

extra space for air circulation.

3. Refer to the pa nel cutout drawing (Figure 2) for dimensions of the

panel cutout and mounting hole locations . Cut and dri ll the panel.

4. Carefully remove the monitor from its packaging. Avoid damaging

the monitor gasket.

Publication 6158-5.0

Page 8

8 Industrial 21" CRT Monitor

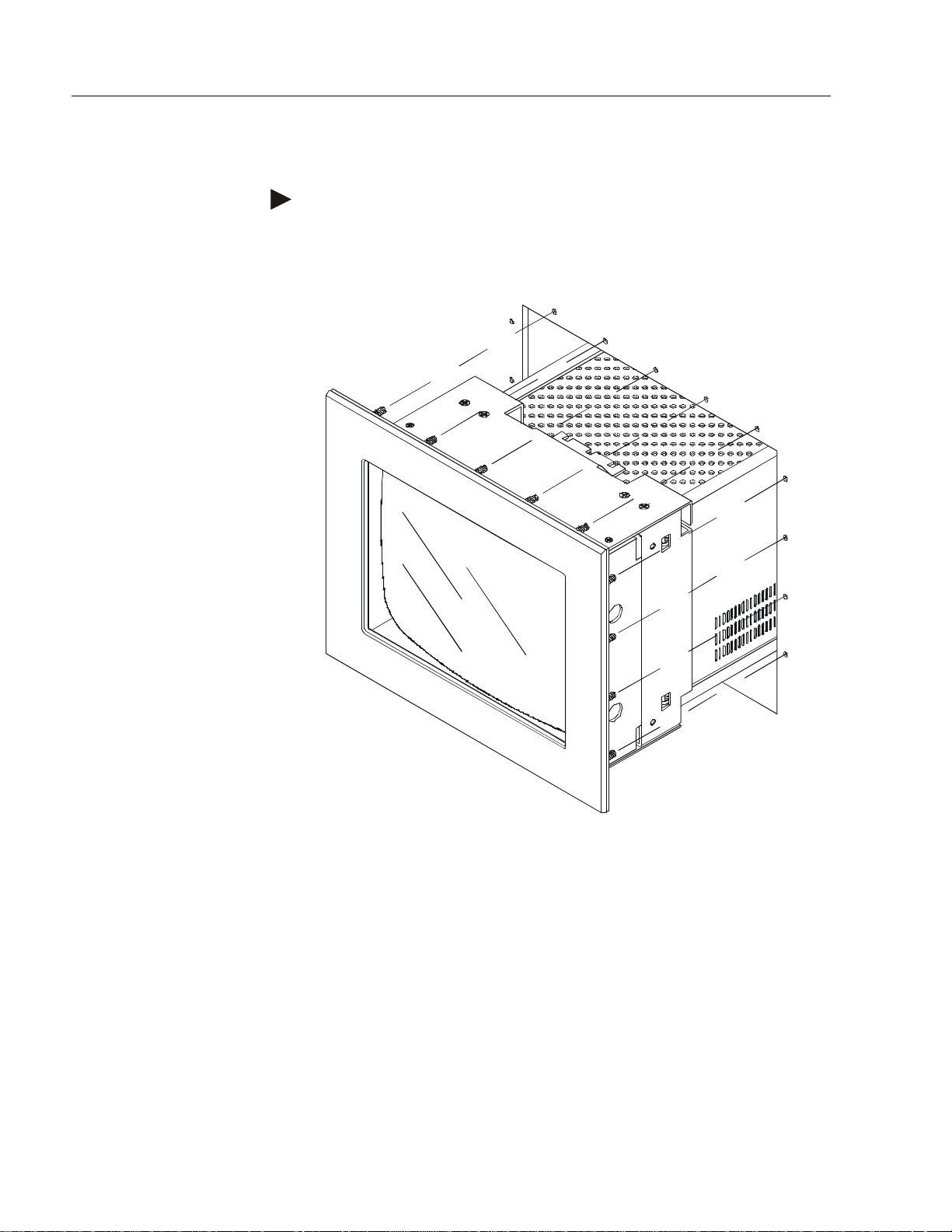

5. Insert the monitor in the panel cutout from the front (Figure 2). Do

not damage the threaded mounting studs as you position the monitor.

Tip: It will be easier to install the monitor if you support it with a shelf

or other support adjusted to the appropriate height.

Figure 3

Generic Panel Mount Diagram

Publication 6158-5.0

Page 9

Industrial 21" CRT Monitor 9

6. Secure the unit with the locknuts and washers provided. Tighten

evenly to 24 inch–pounds of torque.

Important:

To assure a proper seal, be sure to install a washer and nut

on each of the 18 mounting studs.

ATTENTION: Mounting nuts must be tightened to a

torque of 24 inch–pounds to provide panel seal and avoid

pot ential damage. Rock w e ll Automation ass umes no

responsibility for water or chemical damage to the

monitor or other equipment within the enclosure due to

improper installation.

7. Remove the protective adhesive sheet from the screen of the

industrial monitor. The sheet is designed to prevent scratching of the

polycarbonate screen protector or the optional touchscreen during

shipping and ins tallation. It should be remove d before us e.

Publication 6158-5.0

Page 10

10 Industrial 21" CRT Monitor

Connecting AC Power

The 6158 Industrial Monitor requires a single phase power supply

providing 100 to 250V AC at 50 to 60 Hz. Power must be available at a

grounded three–pin outl et located near by. Whenev er poss i ble, c onnec t

the monitor to the same AC source that supplies the computer.

Allen-Bradley monitors automatically adjust to the line voltage and

frequency supplied t o them ( w ithin t he limits sp ec ified) . No switches or

jumpers need to be changed to match the monitor to the voltage supply.

To connect AC power to the monitor:

1. Turn off the mai n switch or breaker.

2. Use the GND point on the rear panel of the monitor to establish a

chassis to earth ground connection. Secure one end of a ground strap

to the GND point. Connect the other end of the ground strap to a

good earth ground.

The ground terminals are M5 screws.

ATTENTION: Chassis ground must be connected for

safe operation of the monitor. The AC receptacle on the

monitor is a 3–wire type with chassis ground pin, and the

mating AC cord supplied is a 3–wire type, designed for

connection to a grounded 3–pin AC outlet. However a

properly grounded AC out let is n ot always a vailab le, a nd

grounding using a 3–wire cord can easily be defeated.

Product Options

If you fail to ground the monitor properly, the setup may

resu lt in p ersona l injury from e lectric al shock or damage

to equipment.

3. Connec t the socket end of the AC power cord to the mat ing

connector on the rear panel of the monitor. Position the power cord

retaining clip attached to the rear panel connector over the cord’s

socket to secure it in place.

4. Connect the plug end of the AC power cord to the mains outlet.

5. Restore AC power to the outlet.

The 6158 Industrial Monitor can be configured with the following

options.

VGA HD-15 or RS-343 BNC video cables

•

touchscreen

•

Publication 6158-5.0

Page 11

Industrial 21" CRT Monitor 11

Video Cables

The monit or ca n be configured with var i ous in dustrial grade v ideo

cables. The standard HD-15 cable is equipped with a conventional HD15 connector at each end.

Figure 4

HD-15 Video Cable Connector

Table A

HD-15 Connector Pin Assignments

Pin Signal Description

1 Red Video Input, analog

2 Green Video Input, analog

3 Blue Video Input, analog

4 ID2 Output, TTL l o w

5 Composite Sync Input, TTL, pulsed

6 Red Video Return

7 Green Video Return

8 Blue Video Return

9 Reserved

10 Ground

11 ID0 Output, TTL low

12 ID1 Output, TTL floating

13 Horizontal Sync Input, TTL, pulsed

14 Vertical Sync Input, TTL, pulsed

15 Reserved

1

Monochrome video generator s should present video to this pin. Composite

sync may be presented to this pin together with green or monochrome video. In

this case, the monitor’s sync selector switch must be set to “Sync on Green.”

1

2

2

With a VGA adapter, the polarizati on of thi s signal, together with the

polarization of the vertical sync signal, vary with the adapter’s operating mode,

as shown in the table below. This mode information is not needed by the

monitor, since it is a variable scan monitor.

Signal Mode 1 Mode 2 Mode 3 Mode 4

H Sync + - - +

V Sync - + - +

Publication 6158-5.0

Page 12

12 Industrial 21" CRT Monitor

Another low noise video interface is the Differential BNC Input

connectors option which accept s red, gree n and blue video signal s (RS –

343 analog signaling) and a separate composite sync signal from the

video source. BNC to BNC cable options are available.

Touchscreen Option

The touchscreen option (6158-xxAxxxxxx) provides an anti-glare

touchscreen system. A software driver provid ed wit h the touchscreen

option allows you to use the touchscreen as a pointing device with many

popular DOS and Windows–based industrial applications. Refer to the

touchscreen documentation for information on installing and using the

touchscreen.

Touchscreen Serial Cable

For units conf i gured with the touchscreen option, a t ouchscreen serial

cable is required. A suitabl e cable can be obtained fro m your Rockwell

Automation sales representative.

The cable provides a communication channel between the touchscreen

controller, which is mounted inside the monitor, and an RS-232-C serial

port on the host computer. The touch controller is provided with power

from the monitor ’s power supply. Accordingly, no external touch power

connections are necessary.

The touch controller is set up to detect the baud rate used by the host. For

additional information on controller configurations, please refer to the

documentation provided with the touch system.

Publication 6158-5.0

Page 13

Industrial 21" CRT Monitor 13

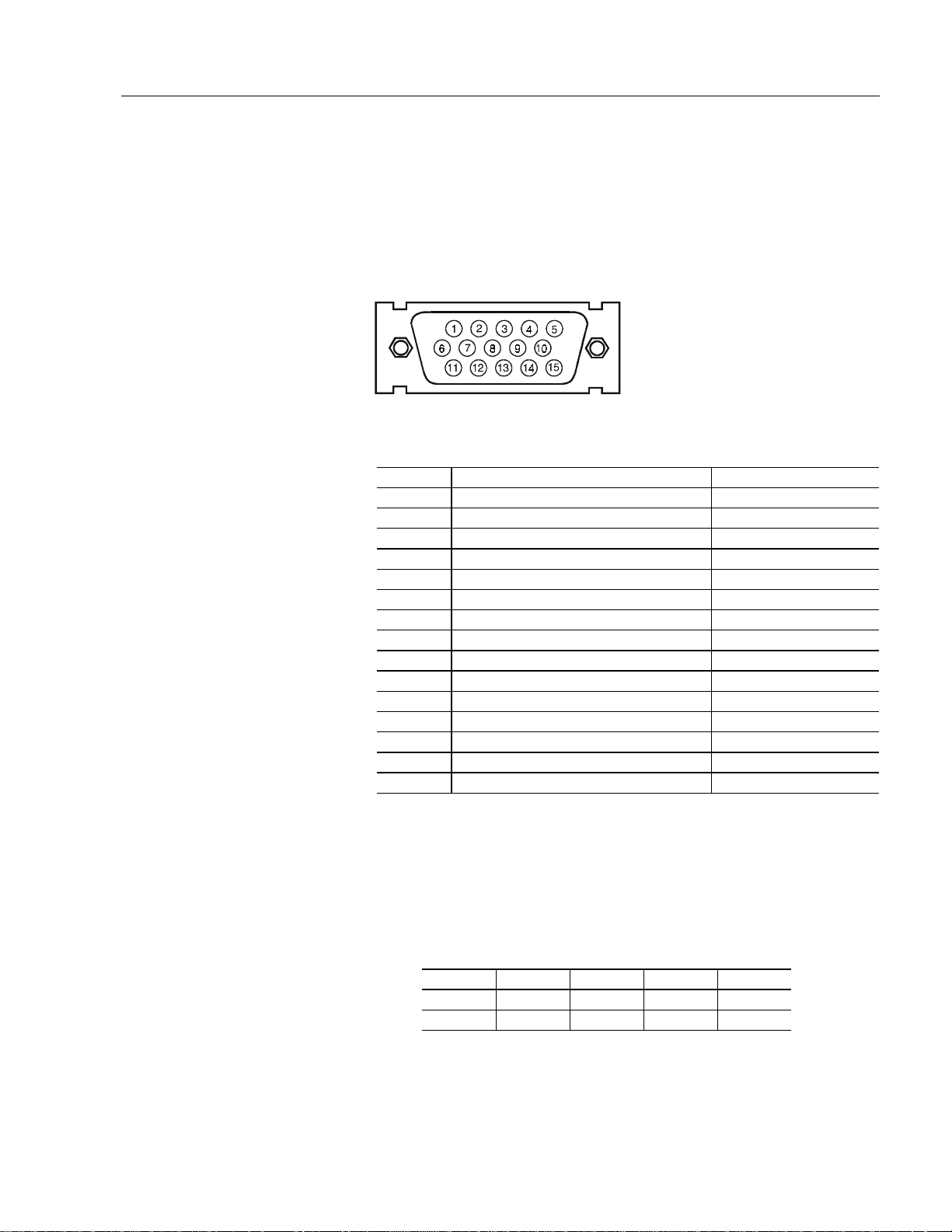

Cable Connectors

The following diagram and table indicate the pin configuration of the

DB9 cable connector and the signals assigned to those pins.

12345

6789

DB9

Monitor Signal Connect to Host DB-9 DB-25

1FG 1 8

2 TX Data (output) RX Data (input) 2 3

3 Not Connected 3 2

4 DSR (input) DTR (output) 4 20

5SG SG 5 7

6 DTR (output) DSR (input) 6 6

7 CTS (input) RTS (output) 7 4

8 RTS (output) CTS (input) 8 5

9 x level RI

VIEW LOOKING INTO

PIN END OF MALE CONNECTOR

SOLDER TERM END OF FEMALE CONNECTOR

OR

Touchscreen Software

Prior to using the touchscreen, you must install the touchscreen driver

software on the host computer and perform a calibration procedure.

Details for installation are covered in the documentation that is provided

with the touchscreen system.

Everything you need to install the touchscreen driver software is

included in th e tou chscreen software packet provid ed wit h the s ystem. It

contains a utility pro gram that makes inst allat ion very eas y. Before

attempting to install the touchscreen software, ensure that the version of

the operating system running on the target machine is compatible with

that required by your particular touchscreen system. There are a few

things the user must know about the touchscreen hardware configuration

of the touch system in order to install the driver properly.

The type and model of touch control ler being used.

•

The COM port in use for the touchscreen. Ensure that the RS-232

•

cable is properly installed between the monitor port and the host’s

COM1 or COM2 port. Note the COM port being used.

The touchscreen controller detects the baud rate of the host’s COM

•

port and automatically adjusts to that rate.

The installation procedure involves transferring driver files from the

diskette supplied with the touch system to the host computer’s hard disk,

and adding instructions to system startup files that will load the drivers

following system boot-up. The installation utility automates the transfer

Publication 6158-5.0

Page 14

14 Industrial 21" CRT Monitor

process and crea tes a special directory on the hard di sk to hold the touch

softwar e. The user may spec ify a directory path name; otherwis e, a

default path name is used. In addition, the utility modifies the system

startup files appropriately.

Touchscreen Calibrati on

After installing the driver software, follow the instructions in the

manufacturer’s documentation provided with the touch system.

ATTENTION: The calibration of the touchscreen will be

invalidated by any subsequ e nt adjustment of th e display

size or position. Insure that the display is properly

adjusted before beginning calibration.

When the touch system is to be used with multiple

applications, and these applications use different video

display modes, the calibration procedure should be

repeated for each mode that is to be used.

Using the Touchscreen with Application Programs

Following the installation of the touch software and calibration, the

touchscreen is ready to use.

Since, in general, the touchscreen emulates a mouse, compatibility issues

can arise in relation to the way the touchscreen emulates mouse buttons,

especially multiple buttons. For a complete discussion of these issues,

and means of reso lving p roblems, s e e the re leva nt sections of the

manufacturer’s documentation.

Polycarbonate Window Option

A polycarbonate window option (6158-xxYxxxxxx) is available for

applications t hat require an added measure of protection f or the monitor

screen.

Publication 6158-5.0

Page 15

Industrial 21" CRT Monitor 15

Connecting to a Computer

Connect the 6158 Industrial Monitor to a computer with the appropriate

video cable. A touchscreen serial cable is required for monitors equipped

with the touchscreen option. To connect your monitor to a computer:

1. Plan the ro ute for the c ables and confirm that the ca bles you have

ordered are long enough for the routing you have chosen.

2. If you are using a standard HD-15 video cable with the monitor,

connect either end of the cable to the 15–pin video input connector.

See the rear panel drawing (Figure 5) to locate the HD-15 connector.

Tighten the captive screws on the cable connector to secure it.

Or

If you are using the optional BNC video interface, connect the ends

of th e BNC vid e o c able to the red, green, blu e and comp osit e s ync

input connectors.

Note:

As the rear panel configurations in Figure 5 indicate,

the monitor is equipped with an HD-15 video

connector. Optionally, it can be equipped with an HD15 connector and four BNC connectors. The HD-15

and the BNC inputs are wired in p arallel an d consti tut e

a single interface.

3. For monitors co nf i gured with the touchscreen option, con nect one

end of the serial t ouc hscreen cable to t h e connector labeled “ AUX1”

on the rear panel of the monitor. Tighten the captive screws to secure

it.

4. Route and secure the cables. In cases where the c able cr o ss es a door

hinge, be sure to leave enough excess cable for a loose fit in all door

positions. The monitor cables are designed to be flexible, so routing

across a hin g e shoul d not r es ult in a pplication failure. The minimu m

recommended bend radius for a video cable is 38 mm (1.5 in.).

5. Connect the standard 15–pin connector end of the video cable to the

computer’s video output connector. Tighten the captive screws on

the cable connector to secure it.

6. Connect the touchscreen cable free end to an appropriate RS–232

communications port on the computer. Tighten the captive screws on

the cable connector to secure it.

7. Coil and secure any extra cable length in a convenient location.

Publication 6158-5.0

Page 16

16 Industrial 21" CRT Monitor

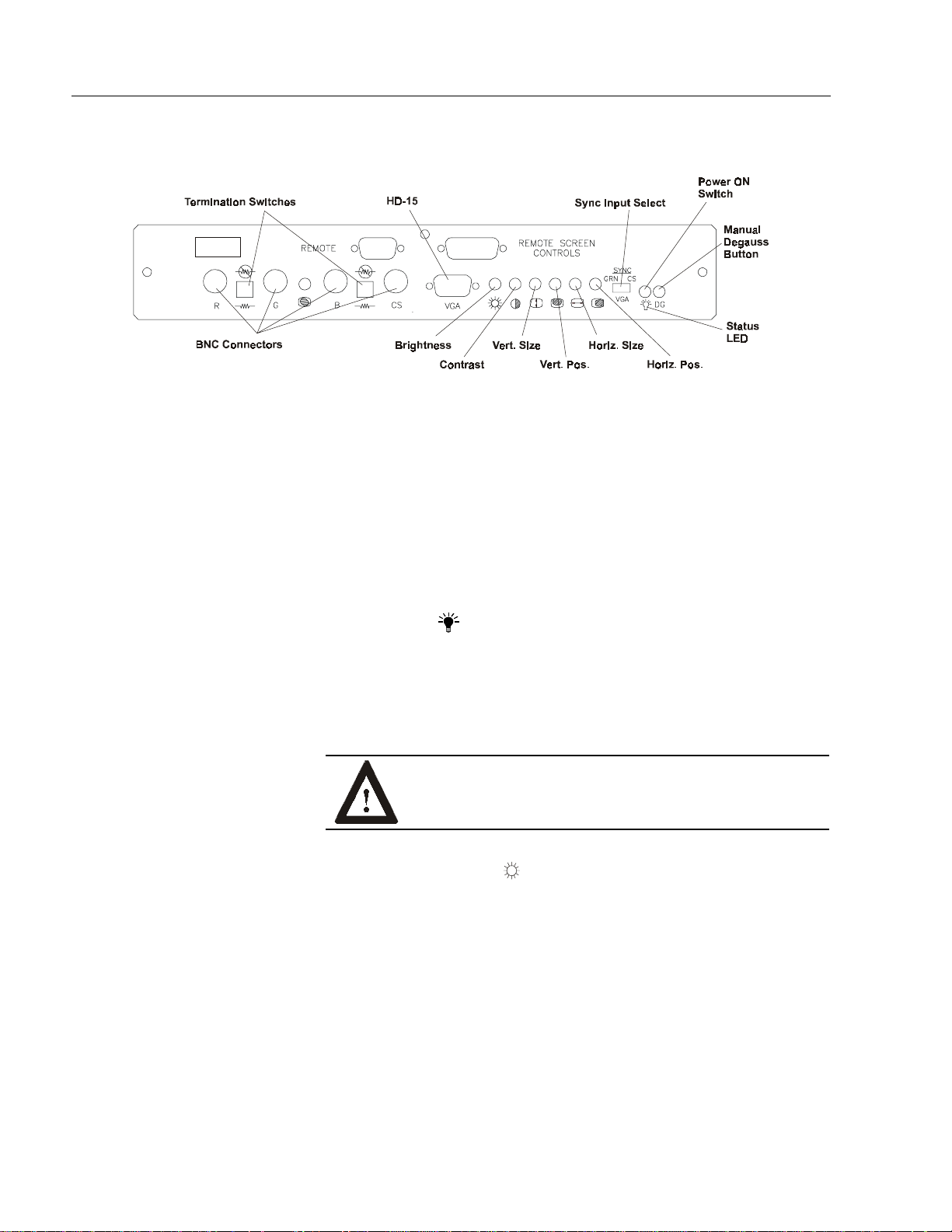

Figure 5

Rea r Panels of M onit or

Rear Panel Controls and Indicators

The rear panel of the 6158 Industrial Monitor contains all of the picture

controls, as well as the power switch and status indicator.

Power Swi tch

Turn on the monitor by pressing the right side of the switch

marked “I”. (Pressing the left side of the switch marked “0” turns the

unit off).

Status LED ( )

When the monitor is powered up and operating correctly, the status

indicator LED (green) will be illuminated. If the light should go out

while the p ower swit ch is in the ”on” pos i tion, a misad just me nt or

malfunct ion has oc c urr e d. Remo ve power immediate ly.

ATTENTION: Do not assume that the monitor is

powered off when the status LED is not lit.

Publication 6158-5.0

Brightness Control ( )

Use the brightness control to adjust the overall intensity of the display.

After allowing the CRT to warm up for at least a minute, adjust for the

least amount of brightness needed to make the display clearly viewable.

Page 17

Industrial 21" CRT Monitor 17

Contrast Control ( )

Use t h e contrast control to vary the differenc e between the d i spla y’s light

and dark el e me nts. With a suitable image displaye d on the sc reen, adjust

th e contrast control to a chieve t he best balanc e between imag e bri ght ness

and fine detail rendition. The optimum setting may vary slightly with

different types of displays and changes in ambient lighting, as well as

individu al taste.

Manual Degaussing Button ( )

The display screen is degaussed automatically each time the monitor is

powered on. This degaussing eliminates color impurities and other

distortions of the display by neut ralizing the eff e c ts of magnet i c fiel ds in

the surrounding environment.

When the unit is left on for a long period, or is repositioned following

power-up, the screen may pick up additional magnetic flux, causing

colors to appear ”blotchy” or otherwise distorted. If this happens,

dega uss t he scre e n manua lly by p ress ing th e d e gaussing bu tto n. For f ull

effectivenes s , allow at least fifteen minutes between manua l degau s s ings.

Shor ter interval s may result in an incompl ete re moval of f lux an d

residual color impurities. If the unit is located near electric transformers,

motors, loudspeakers or other strong magnetic sources, degaussing alone

may not be sufficient to eliminate interference. Try reorienting the unit

relative to the magnetic source or moving the monitor further away.

Vertical Size ( )

Use this control to make the display taller or shorter. Consult the chart

following for recommended display height.

Vertical Position ( )

Use this control to center the display vertically on the screen.

Horizontal Size ( )

Use t h is control t o make the display w ider or narrower. Consult the cha rt

below for recomm e nded d isplay width.

Horizontal Position ( )

Use this control to center the display horizontally on the screen.

Publication 6158-5.0

Page 18

18 Industrial 21" CRT Monitor

Maintenance

Preparation for Shipment

If it is ever necessary to ship the monitor, first remove it from the panel

in which it has been installed, then securely pack it. To remove the

monitor from the panel, reverse the installation procedure that begins on

page 7. Whenever possible, ship the monitor in its original container.

ATTENTION: Never try to ship the monitor while it is

mounted in a panel. Doing so could result in damage t o

the panel or monitor.

Cleanin g in str uction s

Occasionally clean the monitor panel and cabinet with a soft cloth

dampened (not soaked) with a mild household detergent (non-abrasive).

Ensu re tha t air vents a re clea red of dust .

The sc reen may be clean e d with a soft cloth dampen e d with a mild glass

cleaner. Ke ep tur ning a fresh s ide of the cloth toward the scre e n sur f ace

to avoid scratc hing it wi th acc umulated gr it. To minimize the risk of

abrasion, allow the screen to sta nd dry.

Special ca re shou ld be taken when cl eanin g a resistive touc hscr e e n or

polycarbonate shield that is installed over the CRT screen. The surface

can be easily damaged by abrasive and certain chemical cleaners. Never

use alcoholic or ammoniac cleaners.

Replace air filters over fans or heat exchanger intakes periodically to

ensure proper air flow for cooling. (Applicable to units in some industrial

enclosures.)

Publication 6158-5.0

Page 19

Industrial 21" CRT Monitor 19

Allen-Bradley Support

Allen-Bradley offers support services worldwide with over 75

sales/support offices, 512 authorized distributors, and 260 authorized

system integrators located throughout the United States alone, p l us

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

sales and order support

•

product techni c al training

•

warranty support

•

support service agreements

•

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the Troubleshooting section first. Then call

your local Allen-Bradley representative.

Publication 6158-5.0

Page 20

20 Industrial 21" CRT Monitor

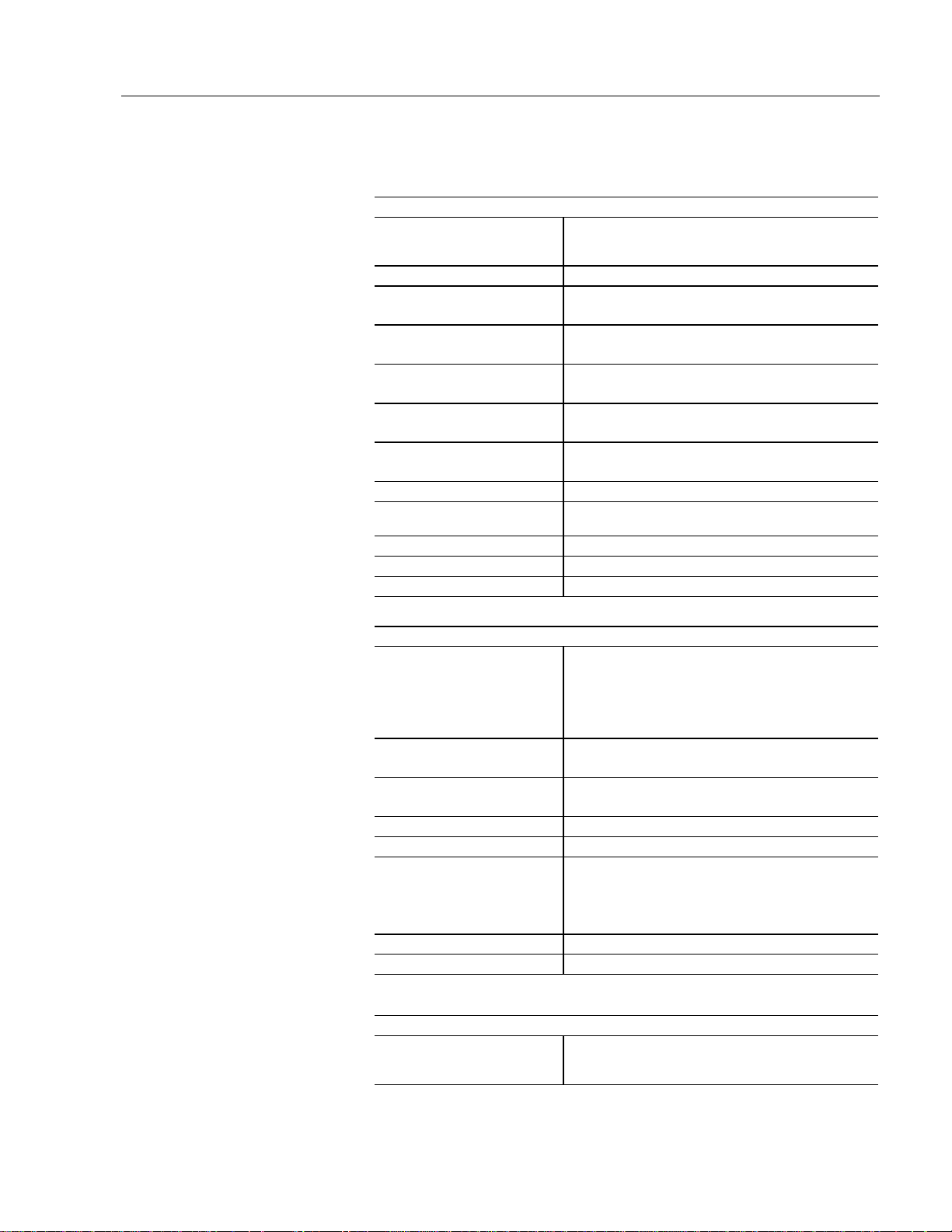

Troubleshooting

The following table can help you identify the potential cause of problems

you may encounter while using the 6158 Industrial Monitor.

Symptom Possible Proble m Action

Status LED does not come on when

power switch is closed.

Status LED is on, but screen is blank. Screen saver activated Disable screen saver by activating an input to

No raster vis i ble even when br ig ht ness

and contrast controls are set full CW.

Raster di m l y vis ib l e wit h br ig htness and

contrast controls set full CW, but no

displ ay pr esent

Display is pr esent, but gar bl ed or r olling. Monitor n ot s ynched to video s ource. Refer to ins t allation inst r uc ti ons .

Display is present and stable, but appears

“wrapp ed” at on e si d e or oth er wise not

properly centered or sized.

Display is present and stable, but missing

some co lor(s)

Display is present and stable, but colors

are not pur e

Display is pr esent, but “jit ters” or is

severely distorted

NOTE: Do not confuse the flicker

associated with an in t erlaced vid eo m od e

with jitter.

Display is present, but “bars” appear

across it.

Power cord not connected. Open power switch. Reconnect power cord at

No power available at AC outlet.

Power cord faulty. Replace power cord.

Monitor f aulty. H ave monitor serviced.

Bright n ess and c ontrast contr ols n ot

proper l y adj us t ed

Monitor ou t of ad jus t ment or fault y H ave m onitor serviced.

Video cable problem

Fault in vid eo s our ce

Fault in mon itor Have moni tor servic ed.

Size and pos it ion controls misadjusted.

Video cable problem Check for proper video cable installation.

Fault in monitor. Have monitor serviced.

Monitor requires degaussing Manually degauss the monitor. Refer to

Interf eri ng external AC or DC m agn et ic

shield

“Nois e” gen erated by oth er equ ip m ent

in the environment is present at the

video inputs

monitor an d at AC out l et . Close power sw itc h.

Test AC outlet by plugging in a lamp or other

known good devic e.

the host system.

Turn brightness and contrast controls CW.

Check for proper installation of video

cable(s). Refer to installation instructions.

Replace suspected faulty cable (s).

Test vid eo s our ce by connect in g to an other

monitor that is known to b e operational.

Check for proper video cable installation.

Replace suspected faulty cable.

Check to ens ure that video s ource is

operating within th e m on it or ’s range.

Adjust c ontrols for pr op er siz e an d p osit ion of

displ ay. R ef er t o op erator instr uc ti ons .

If using BNC inputs, test monitor as follows.

Disconnect sig nal cable(s) corresponding to

the missing color(s). Disconnect signal cable

corresp onding to a disp l ay ed c ol or an d

connect it to the input(s) corre s ponding to the

missi ng color(s). If a missing color reappears,

the signal cable corresponding to that color is

faulty; otherwise, the monitor is faul t y.

Replace suspected faulty cable.

operat or ins tructions .

If possible, reposition the monitor beyond the

proximity of large transformers, motors, bus

bars, etc.

Consult t h e app lication note which disc us ses

method’s of eliminating noise using the

monitor ’s dif f erential inpu ts .

Publication 6158-5.0

Page 21

Specifications

Industrial 21" CRT Monitor 21

Display

CRT Type 21in. diagonal, flat square, 0.28mm, MSP phosphor,

52.3% glass, ARAS coating, INVAR shadow mask,

DAF electron guns, Tension-band implosion protected

Degauss in g Manual and au t om at ic

Image Size (4:3 Aspect) Horizontal 15.3in. (389mm)

Vertical 11.5in. (292mm)

Image Size (5:4 Aspect) Horizontal 14.4in. (365mm)

Vertical 11.5in. (292mm)

Non Linear i t y (CH P M et h od ) Hori z ont al 5% max

Vertical 4% max

Pincus hi on Horiz ont al 3mm max

Vertical 4mm max

Keyston e Horiz ont al 1% max

Vertical 1% max

Regul ati on 2mm max p eak d eviation

Misconvergence 0.3mm max inside ce ntered circle 285mm dia.,

0.4mm m ax ou tside

Lumin ance 30 fL, small wh it e squ are

Lumin ance Uniformi ty Corners at leas t 70% of cent er

CIE coordinates for white x:0.281, y:0.311 (9300K)

Video

Supported Standards IBM VGA (640x480 at 60Hz; VESA 640x480 at

Deflect i on Frequenc i es Horiz ont al Variable: 30kHz to 82kH z

Retrace Times Horizontal 2.8usec min.

Amplifier Bandwidth 150MHz

Black Level Stability Within 1%

Input Signals Video: RGB analog (white level = 0.714V above ref.

Standard Input Connection HD-15 (RGB, HS, VS)

Optional Input Connection HD-15 (RGB, HS, VS) and 4 BNC (RGB, CS)

Operator Controls

Rear Panel Degauss, Brightness, Contra st, H Size, H Position, V

60/72Hz, 800x600 at 56/60/72Hz, 1024x768 at

60/70H z; DEC 10 24 x8 64 at 60Hz, 12 80 x1024 at

66/72Hz; SUN 1152x900 at 67/76Hz; SG/IBM RISC

1280x1 02 4 at 60H z; HP 700 1280 x1 024 at 72Hz, IB M

RISC 1280x1024 at 77Hz

Vertical Variabl e: 40Hz to 80H z

Vertical 0.475msec min

black, in t o 75 Oh ms , dif f er ent ial), Std. Sync : H and V

separate (TTL levels), Sync with BNC Opt.:

Compos ite on green video (0.286V b elow ref. blac k)

or Composite separate (into 75 Ohms differential)

Size, V Position. BNC Option only: Sync Input

Select, RGBS Termination Switches

Publication 6158-5.0

Page 22

22 Industrial 21" CRT Monitor

Environmental

Temperature Operating 0C to 50C

Relati ve Hu midity 10% to 90% n on- condensi ng

Altitude Operating 0 to 10,000 ft (3000m)

Elec trostatic Discharge Operating 8.0KVDC (IEC 801-2, level 3)

Vibration Operating 0.01in. p-p, 5-44Hz sine,

Shock Operating 15g (1/2 sine, 11msec)

X-ray Emissions Designed for compliance with DHHS CFR 21.1020

ELF/VLF Emissions Designed for compliance with MPR-II

Electrical

Line Volt age 90-264VAC

Line Frequency 45- 70Hz

Ground Leakage 1.0 uA max at 1.5KVDC

Power Consumption 135W max

Non-Operating -30C to 65C

Non-Operating 0 to 40,000 ft (12000m )

Non-Operating 20.0KVDC

1.0g peak, 44-500Hz sine

Non-Operating 0.02in. p-p, 5- 4 4H z sin e,

2.0g peak 44-50 0Hz sine

Non-Operating 25g (1/2 sine, 11msec)

Cables

Standard None

Optional US Power Cord (0E2101), 6ft

VGA Cable (0E2003)

Physical

Dimensions 20.5inW x 16.8in.H x 22.5in.D

(514mm x 423mm x 572mm)

Net Weight 70lb (32kg)

Warranty

Standar d 12 months

Option al Extensi ons av ai lable

MTBF

>55,000 hour s at 25C,

Ground B enign

Certification s

UL 1950 Recognized Component,

C-UL 950 R ec og ni z ed C om p onent,

CE97 (89/336/EEC and 73/23/EEC),

FCC Class A

Publication 6158-5.0

Page 23

Industrial 21" CRT Monitor 23

Publication 6158-5.0

Page 24

IBM is a registe red trademark of Inte rn ational Business Machines Corporation.

VGA is a trademar k of International Business Machines Corporation.

PC AT is a trademark of International Business Machines Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Microsoft Windows is a trademark of Microsoft Corporation .

Rockwell A utomation h el ps i ts custom ers receive a superior return on their investment by bringing

together leading brands in industri al aut omation, creating a broad spect rum of easy-t o-i ntegrate

products. T hese are supported by local technical resources availabl e worldwide, a gl obal network of

system s olutions provid ers, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Bolivia • Brazil • Bulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croatia • Cyprus • Czech

Republic • Denmark • Dominican Republic • Ecuador • Egypt • El Salvador • Finland • France • Germany • Ghana • Greece • Guatemala • Honduras • Hong Kong • Hungary

Iceland • India • Indonesia • Iran • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico • Morocco • The Netherlands

New Zealand • Nigeria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia • Saudi Arabia • Singapore

Slovakia • Slovenia • South Africa, Republic of • Spain • Sweden • Switzerland • Taiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates • United Kingdom • United

States • Uruguay • Venezuela

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000, Fax: (1) 414 382-4444

Rockwell Automation European Headquarters, Avenue Hermann Debroux, 46 1160 Brussels, Belgium, Tel: (32) 2 663 06 00, Fax: (32) 2 663 06 40

Rockwell Automation Asia Pacific Headquarters, 27/F Citicorp Centre, 18 Whitfield Road, Causeway Bay, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

World Wide Web: http://www.ab.com

998055-010

Publication 6158-5.0

Copyright 1999 Rockwell Automation Corporation. All rights reserved. Printed in USA.

•

•

•

Loading...

Loading...