Page 1

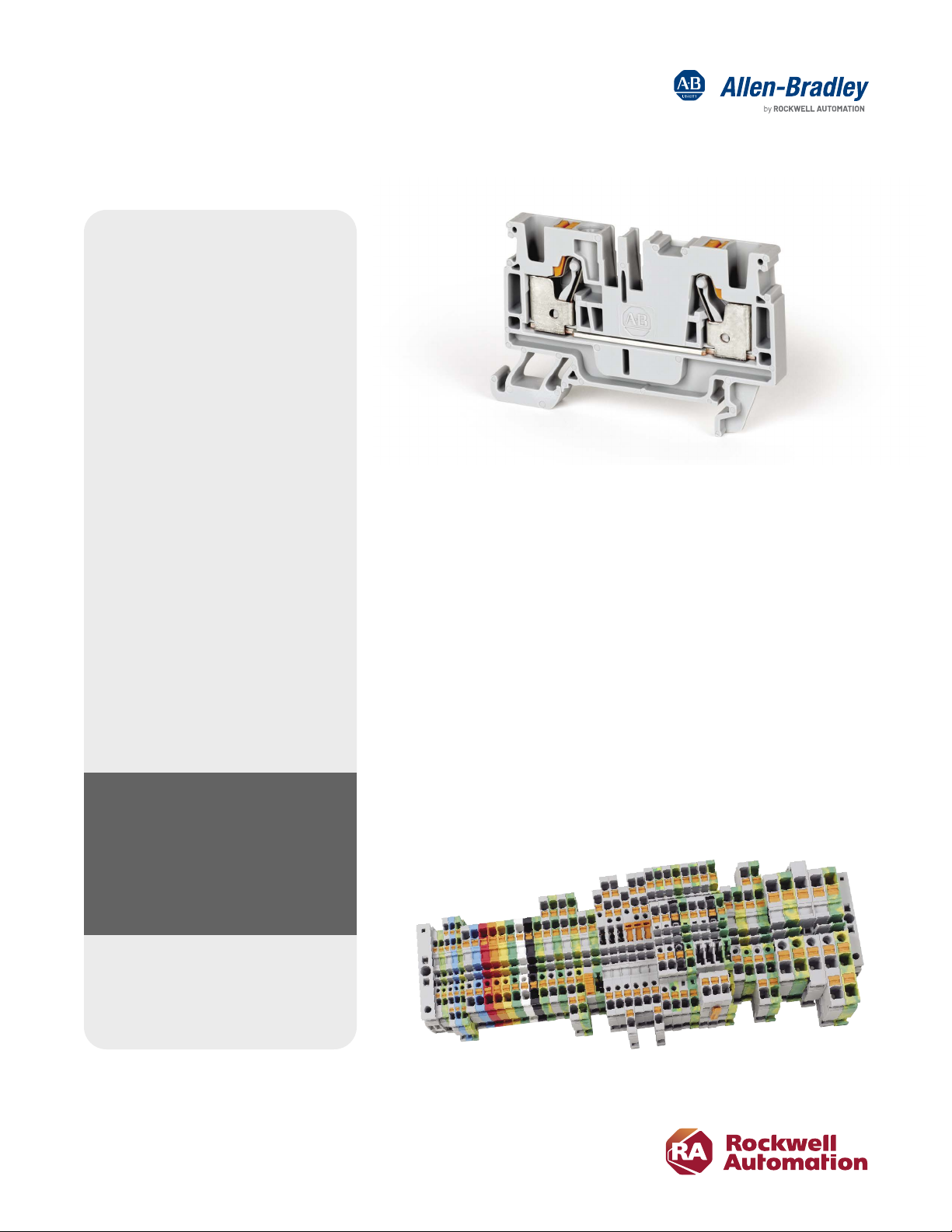

Bulletin 1492-P Push-in Terminal Blocks

Dramatic Time Savings and Improved Reliability

Features and Benets

• ONE-hand, ONE-second insertion

• No strand breakage or turned

back strands

• Low insertion force

• No retightening

• Easy-to-see terminals from the front

• Universally-located test points for fast

inspection and easy commissioning

• Plastic actuators for shock prevention

• Application-driven designs (power

distribution and sensor/signal blocks)

• No torque values needed to install

or double check

• Quick reference guide for easy

ferrule selection

• Marker areas located on the front and

sides with only four marker card types

needed for the entire product line

This innovative push-in connection technology oers dramatic time

savings by creating wiring eciency. The 1492-P Push-in terminal blocks

provide improved wiring accuracy and reliability insuring a quality

connection that requires no double checking.

When using an automated ferrule machine, installation can be up

to 65 percent faster than screw-type terminal block connections –

a 26 second savings per terminal block. That’s a saving of over seven

hours for every 1,000 terminal blocks connected. Not only is productivity

vastly increased, but the resulting connections eliminate the vibration

failure mode of screw terminals. The push-in connections signicantly

exceed UL pull-out standards.

65% reduction in labor –

saving over seven hours per

1,000 terminal blocks installed

Bulletin 1492-P Push-in terminal blocks oer panel builders, OEMs, and

other high-volume users cost-savings – not only in the form of increased

wiring speed, but also through eliminating connection adjustments and

torque-checking of screws. They are available in a wide range of standard

and application specic oerings, including a unique control power

distribution terminal block.

Page 2

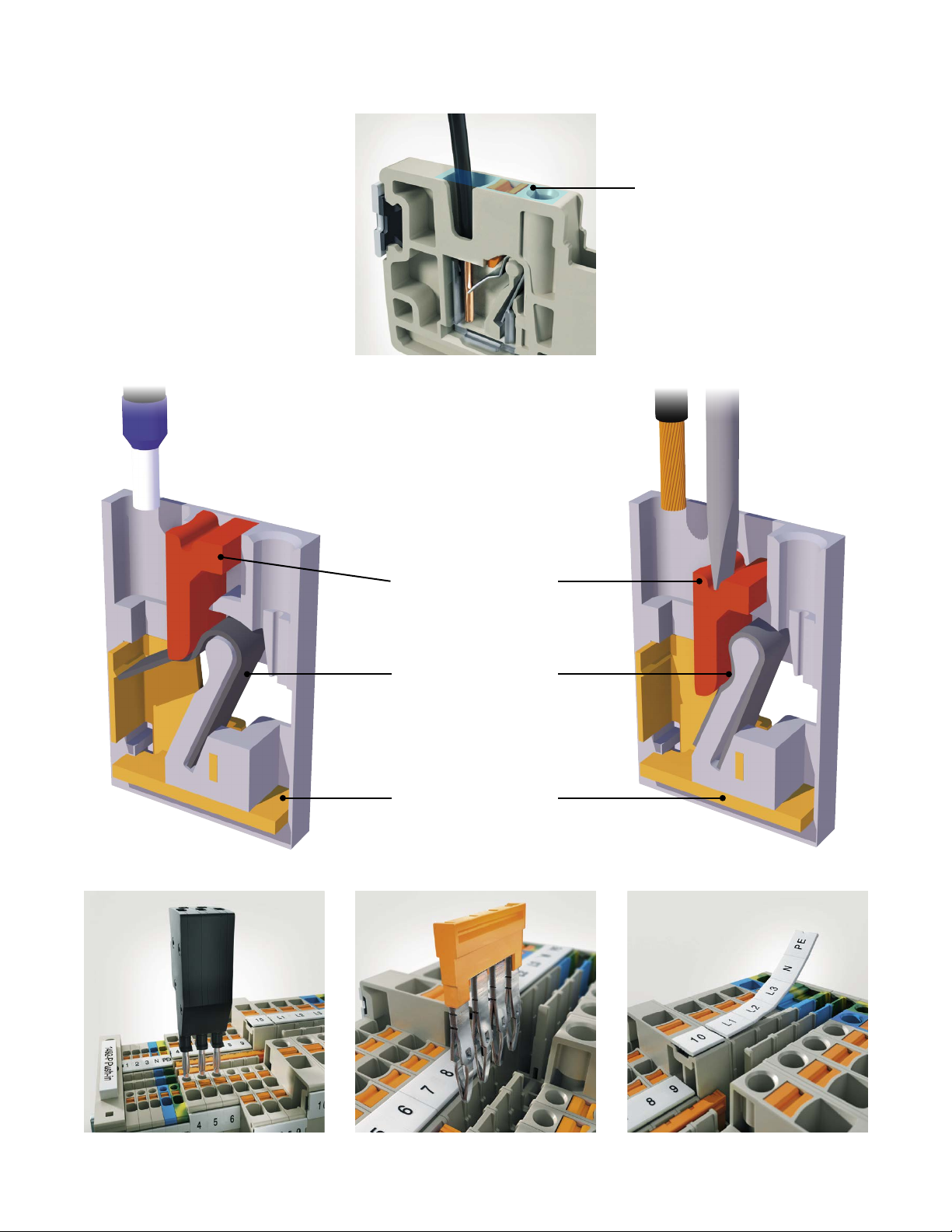

Push-in Technology

Approximate area

shown cut away below

Solid and ferrule:

Direct insertion

without tools

Stranded:

Press actuator

to open clamp

then insert wire

Actuators allow

insertion and removal

of all wire types

Steel clamp holds

wire onto current

bar connection

Copper for conductive

components

Easy verication testing with individual terminal test points. Multiple distribution congurations available with

two isolated jumper channels.

Compatible with Allen-Bradley ClearMultiprint,™

ClearPlot® and ClearMark™ marking systems.

Page 3

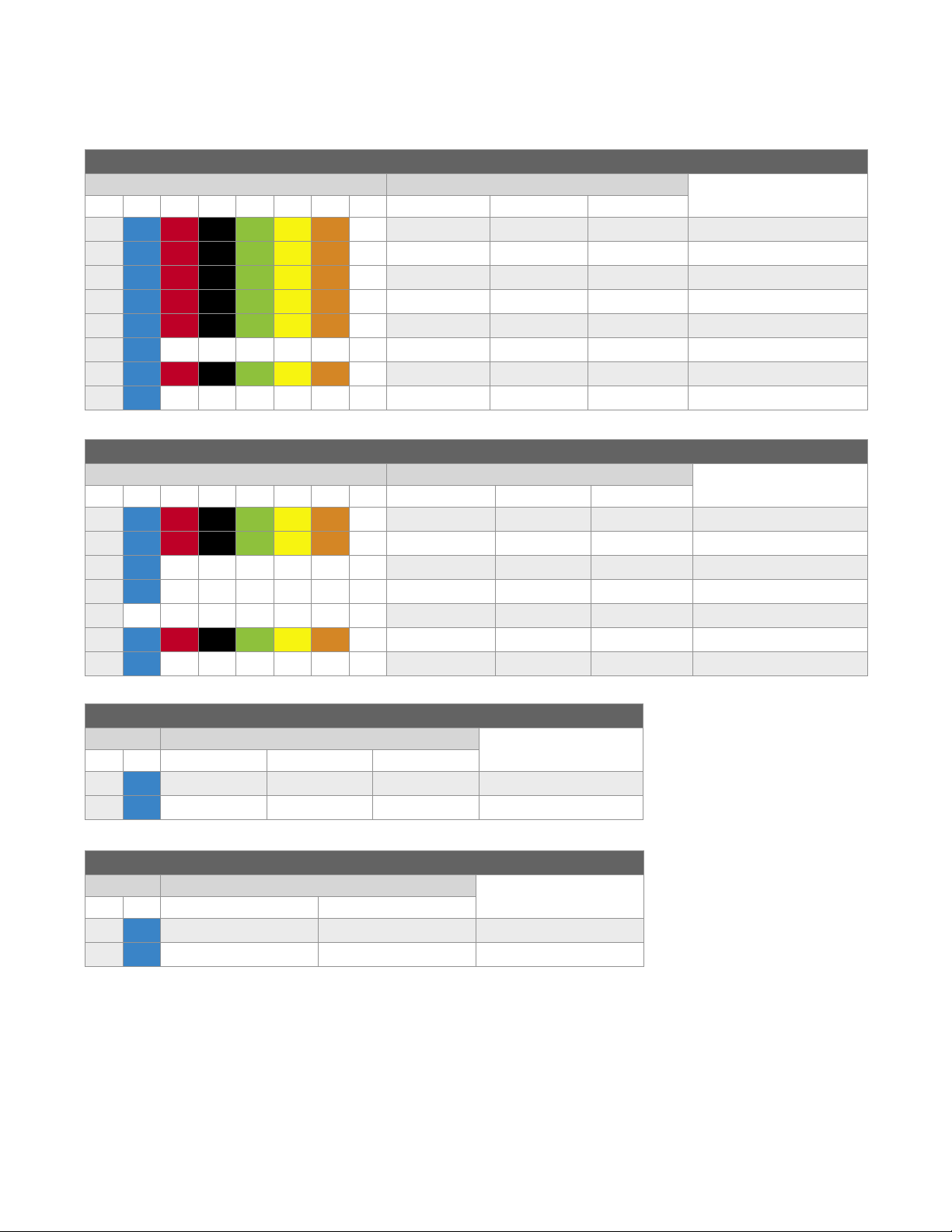

Oerings

A wide range of product and accessories are available, with eight colors and accepting wire sizes from 6-28 AWG

Universal / Standard Terminal Blocks

Single Level Feed-Through

(1)

Color

-B -RE -BL -G -Y -OR -W 2 Wire 3 Wire 4 Wire

Catalog Number

1492-P2 1492-P2T 1492-P2Q 26-14 AWG (1.5 mm2)

1492-P3 1492-P3T 1492-P3Q 28-12 AWG (2.5 mm2)

1492-P4 1492-P4T 1492-P4Q 26-10 AWG (4.0 mm2)

1492-P6 1492-P6T 22-8 AWG (6.0 mm2)

1492-P10 20-6 AWG (10.0 mm2)

– – – – – – 1492-P10T 20-6 AWG (10.0 mm2)

1492-P16 18-6 AWG (16.0 mm2)

– – – – – – 1492-P16T 18-6 AWG (16.0 mm2)

Multiple Level Feed-Through

(1)

Color

-B -RE -BL -G -Y -OR -W Double Level Three Level Four Level

Catalog Number

1492-PD3 28-12 AWG (2.5 mm2)

1492-PD3C

(3)

– – – – – – 1492-PT3 28-12 AWG (2.5 mm2)

– – – – – – 1492-PT3C

– – – – – – – 1492-PQ3

1492-PD4 26-10 AWG (4.0 mm2)

– – – – – – 1492-PD4C

(3)

(2)

(2)

Wire Range

(Rated Cross Section)

Wire Range

(Rated Cross Section)

28-12 AWG (2.5 mm2)

(3)

28-12 AWG (2.5 mm2)

(4)

28-12 AWG (2.5 mm2)

26-10 AWG (4.0 mm2)

Disconnect

(1)

Color

-B 2 Wire 3 Wire 4 Wire

Catalog Number

(2)

Wire Range

(Rated Cross Section)

1492-PKD3 1492-PKD3T 1492-PKD3Q 28-12 AWG (2.5 mm)

1492-PKD4 26-10 AWG (4.0 mm2)

Flex Plug-in

(1)

Color

-B Single Level Double Level

Catalog Number

(2)

Wire Range

(Rated Cross Section)

1492-P31P 1492-PD32P 28-12 AWG (2.5 mm2)

1492-PD32PC

(1) Available in gre y as the standard co lor. To order oth er colors add a sux t o the catalog numbe r. For exam ple, the catalog nu mber would be

1492-P3-B for a blue 1492-P3 termi nal block.

(2) Ground ing terminal bloc ks available in all siz es. To order a grouding te rminal block add a “G” to th e catalog number.

For examp le, the catalog numb er would be 1492-PG4Q for a gr ounding version o f 1492-P4Q.

(3) The “C” in the cata log number design ates a commoning bar m eaning the upper and l ower circuits are c onnected.

(4) The 1492-PQ3 includes a si ngle ground conne ction on the lowes t level.

(3)

28-12 AWG (2.5 mm2)

Page 4

Oerings

Accessory Plug-in

(1)

Color

2 Wire 3 Wire 4 Wire

Catalog Number

Wire Range

(Rated Cross Section)

1492-P3P 1492-P3PT 1492-P3PQ 28-12 AWG (2.5 mm2)

Fuse

Color Catalog Number

Voltage Rating

Non-Indicating

600V AC/DC 10…36V AC/DC 30…70V AC/DC 60…150V AC/DC 100…250V AC/DC

With LED for Blown Fuse Indication

1492-PFB4 1492-PFB424 1492-PFB448 1492-PFB4120 1492-PFB4250 26-10 AWG (4.0 mm2)

(1) Available in gre y as the standard co lor. To order oth er colors add a sux t o the catalog numbe r. For exam ple, the catalog nu mber would be

1492-P3-B for a blue 1492-P3 termi nal block.

(2) Ground ing terminal bloc ks available in all siz es. To order a grouding te rminal block add a “G” to th e catalog number.

For examp le, the catalog numb er would be 1492-PG4Q for a gr ounding version o f 1492-P4Q.

(3) The “C” in the cata log number design ates a commoning bar m eaning the upper and l ower circuits are c onnected.

(4) The 1492-PQ3 includes a si ngle ground conne ction on the lowes t level.

Universal/Standard Distribution Blocks

Fuse

Wire Range

(Rated Cross Section)

The 1492-P6D and 1492-P16D feed-in terminal blocks allow power to be distributed to the output terminal blocks.

Use center jumpers to connect to the output terminal blocks as shown.

1492-CJP2-*

1492-P6D

1492-P2

* Available in multiple pole versions.

1492-P3

1492-CJP2-*

1492-CJP3-*

1492-P2

1492-P16 D

1492-P3

1492-P16 D

1492-P4

1492-CJP3-*

1492-CJP4-*

1492-P6

1492-CJP6 -*

Page 5

Control Power Distribution Blocks

Colored actuators make it easy

to distinguish between the

positive and negative potentials

Up to 6 connection

points on the output

distribution terminals

3

Power is

distributed

to output

distribution

terminals

Block Type

Standard 1492-P6PD2S-1B

Standard 1492-P6PD2S-1RE

with Grounding

Standard 1492-P6PD2E-6B

Standard 1492-P6PD2E-6RE

Standard 1492-P6PD2S-1B1RE

with Grounding

Standard 1492-P6PD2E-3B3RE

1

Power is

supplied

to feed-in

terminals

2

Using

jumpers

Catalog Number

Start (Feed-in) End (Output)

(1)

(1)

(3)

(3)

1492-PG6PD2S

1492-P6PD2S-1RE1G

(1)

(1)

(1)

(2)

(2)

(2)

Wire Range

(Rated Cross Section)

22-8 AWG (6.0 mm2)

22-8 AWG (6.0 mm2)

22-8 AWG (6.0 mm2)

26-14 AWG (1.5 mm2)

26-14 AWG (1.5 mm2)

22-8 AWG (6.0 mm2)

22-8 AWG (6.0 mm2)

26-14 AWG (1.5 mm2)

Catalog Number

Block Type

Standard 1492-P10PD3S-1B

Standard 1492-P10PD3S-1RE

with Grounding

(3)

Start (Feed-in) End (Output)

(1)

(1)

1492-PG10PD3S

(1)

Standard 1492-P10PD3E-5B

Standard 1492-P10PD3E-5RE

Standard 1492-P10PD3S-1B1RE

with Grounding

(3)

1492-P10PD3S-1RE1G

(2)

(2)

Standard 1492-P10PD3E-2B2RE

(1) Shape/Size Cong uration #1: (+/-) on separate te rminal blocks

(2) Shape/Size Co nguration #2: (+/-) integrated into a s ingle terminal blo ck

(3) Not grounde d to the Din Rail. This is a f unctional ear th ground that allow s you ground the minu s potential of the powe r supply to 0 V.

Wire Range

(Rated Cross Section)

20-6 AWG (10.0 mm2)

20-6 AWG (10.0 mm2)

20-6 AWG (10.0 mm2)

(1)

(1)

28-12 AWG (2.5 mm2)

28-12 AWG (2.5 mm2)

20-6 AWG (10.0 mm2)

20-6 AWG (10.0 mm2)

(2)

28-12 AWG (2.5 mm2)

Page 6

Control Power Distribution Blocks

1492-P10PD4E-KD

Block Type

Start (Feed-in) End (Output)

Standard 1492-P10PD4S-1B

Standard 1492-P10PD4S-1RE

with Grounding

(3)

1492-PG10PD4S

1492-P10PD4E-FB* 1492-P 10PD4 E-1B1FB*

Catalog Number

(1)

(1)

(1)

Standard 1492-P10PD4E-1B

Standard 1492-P10PD4E-1RE

Standard 1492-P10PD4E-KD

Standard 1492-P10PD4E-FB

Standard 1492-P10PD4E-FB24

Standard 1492-P10PD4E-FB48

Standard 1492-P10PD4E-FB120

Standard 1492-P10PD4E-FB250

Standard 1492-P10PD4S-1B1RE

with Grounding

(3)

1492-P10PD4S-1RE1G

(2)

(2)

Standard 1492-P10PD4E-1B1FB

Standard 1492-P10PD4E-1B1FB24

Standard 1492- P10PD4E-1B1FB48

Standard 1492-P10PD4E-1B1FB120

Standard 1492-P10PD4E-1B1FB250

(1)

(1)(4 )

(1)( 5)

(1)

(1)( 6)

(1)( 6)

(1)( 6)

(1)( 6)

(2)(5)

(2)(6)

(2)(6)

(2)(6)

(2)(6)

Wire Range

(Rated Cross Section)

20-6 AWG (10.0 mm2)

20-6 AWG (10.0 mm2)

20-6 AWG (10.0 mm2)

26-10 AWG (4.0 mm2)

26-10 AWG (4.0 mm2)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

20-6 AWG (10.0 mm)

20-6 AWG (10.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

26-10 AWG (4.0 mm)

(1) Shape/Size Cong uration #1: (+/-) on separate te rminal blocks

(2) Shape/Size Co nguration #2: (+/-) integrated into a s ingle terminal blo ck

(3) Not grounde d to the Din Rail. This is a f unctional ear th ground that allow s you ground the minu s potential of the powe r supply to 0 V.

(4) Includes knife disconnect/isolation

(5) Includes non indicating fuse holder

(6) Includes LED indicating fuse holder

* Available in n on-indicatin g and LED indicating . LED indicating is ava ilable in 24, 48, 120 and 250V AC/DC .

Page 7

Sensor/Signal Blocks

Sensor

Signal

+

–

Signal

–

Signal

PE

–

Actuator

Actuator

(1)

(2)

Signal 1

Signal 2

+

–

Sensor

(3)

Signal

+

–

PE

Colored ac tuators make

it easy to di stinguish

between the positive

and negative potentials.

Sensor

(1) Shape/Size Conguration #1 (2) Shape/Size Conguration #2

Sensor/Signal

Catalog Number

Block Type

Standard 1492-PS2-2

with Grounding 1492-PSG2-3

(1) Shape/Size Cong uration #1: (+/-) on separate te rminal blocks

(2) Shape/Size Co nguration #2: (+/-) integrated into a s ingle terminal blo ck

(3) Not grounde d to the Din Rail. This is a f unctional ear th ground that allow s you ground the minu s potential of the powe r supply to 0 V.

2 Circuit 3 Circuit 4 Circuit

(1)

1492-PS2-3

(1)

(1)

1492-PS2-4

1492-PSG2-4

Accessories

Plug End BarrierCenter Jumpers

(3) Shape/Size Conguration #3

(Rated Cross Section)

(2)

(3)

26-14 AWG (1.5 mm2)

26-14 AWG (1.5 mm2)

Plug Coding Element

Wire Range

Test Plugs

Plug Locking

Element

Plug Protective

Plugs (Start, Middle, End)

Cover

End Barriers

Page 8

Ferrule

Ferrules allow a stranded wire to act as a solid wire, so it can

be inserted into the push-in terminal blocks without tools.

Various hand-held or automated crimp tools are available,

depending on the volume of terminations needed.

In addition to the dramatic productivity advantages when

ferrules are used with push-in terminal blocks, they also

provide enhanced connection integrity and safety.

For specic information on which Panduit ferrules to use

with individual Bulletin 1492-P Push-in Terminal Blocks,

consult Appendix sections in Publication 1492-TD017.

Specications

A cylind rical tube of tin -coated copper (wi th or without an

insulated c ollar) that can be cri mped onto the end of a wi re.

UL/CSA Voltage Rating

UL/CSA Current Rating 10…62 A

Wire Range (Rated Cross Section)*

Density

Housing Temperature Range

Material Flammability Rating UL94 V0

Colors

Certications CE, UL, CSA, ATEX, IECEX, DNV GL

* North A merican wire rang e per NEC Table 310-16 using 75 °C and 90 °C stran ded Copper wire.

600V AC/DC,

300V AC/DC,

150V AC/D C

#28…6 AWG

(1.5…16 mm2)

87…2 5 p cs/ ft

(285…83 pcs/m)

-76 …+266 ° F

(- 60 …+130 °C)

Standard: Grey

Grounding Block: Green/Yellow

Available in some products:

Red, Blue, Black, Green, Yellow,

Orange and White

Connect with us.

Allen-Bradley, ClearMark, ClearMultiprint, ClearPlot and Expanding human possibility are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1492-PP014B-EN-P – May 2020 | Supersedes Publication 1492-PP014A-EN-P – April 2018

Copyright © 2020 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...