Page 1

Digital I/O Conversion Module

(Cat 1492-CM1771-LD009F)

I. Description

This Digital I/O Conversion Module provides for the conversion of (1) 1771, 32 point I/O modules to be converted to

(1) 1756, 32 point I/O module and consists of the following:

(1) 1771 Module (32pt) to (1) 1756 Module (32pt)

(2) Conversion Module: 1492-CM1771-LD009F

(1) Cable: 1492-CONCAB005Z (Table 2, Section III)

(1) Conversion Mounting Assembly: 1492-MUA… (Table 1, Section II)

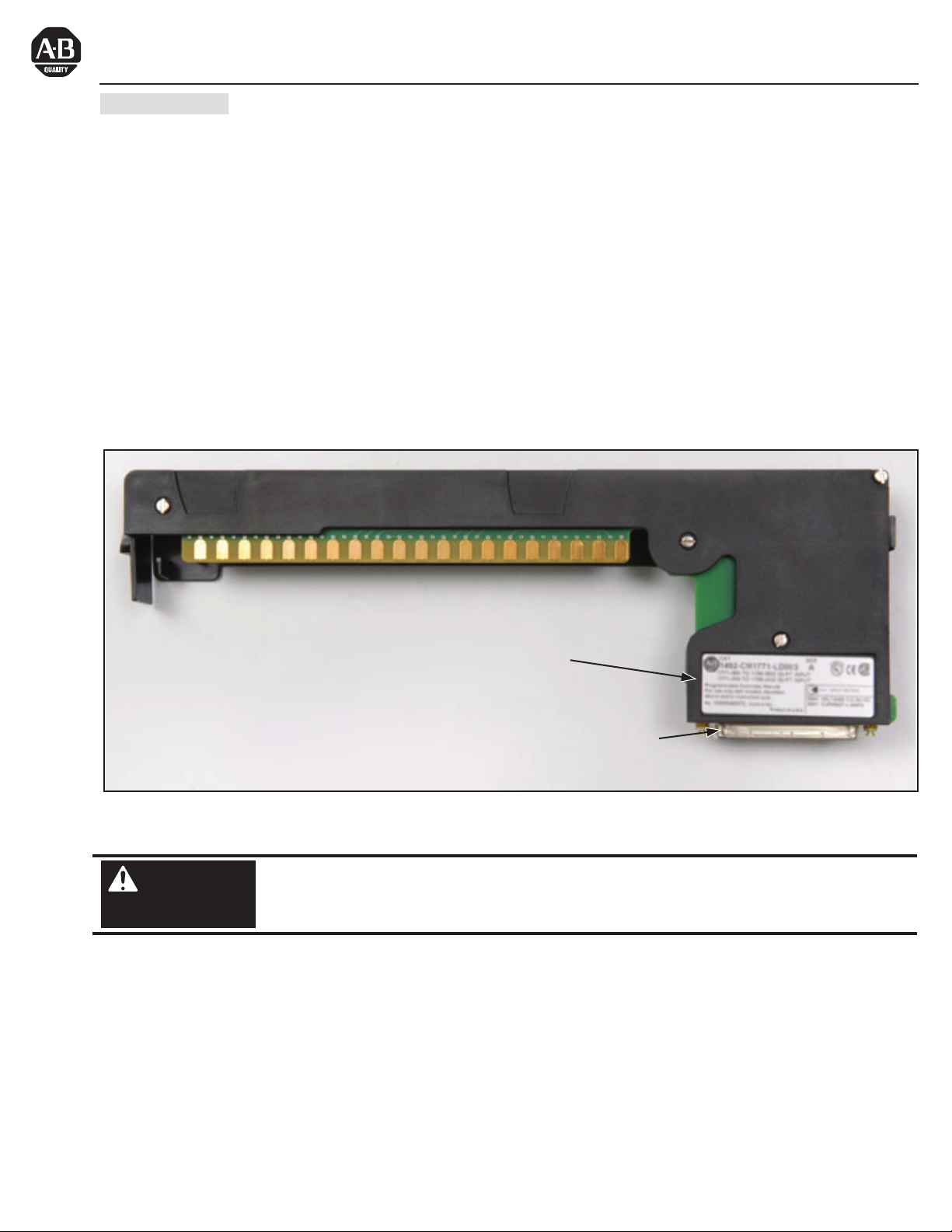

This conversion is accomplished without the removal of any field wires from the existing 1771 Swing Arm. The existing 1771 Swing Arm fits directly onto the edge connector of the 1492 Conversion Module. On one end of the 1492

Cable is (1) connector for the Conversion Module. On the other end is the Removable Terminal Block (RTB) for the

1756 I/O module, as shown in the photo below. The I/O signals are routed through the 1492 Conversion Module and

the 1492 Cable to the appropriate terminals on the 1756 I/O module per the Wiring Diagrams in Section V. As standard, both portions of the 1492 Cables are 0.5M long, but we also offer a 1.0M cable length. Refer to the footnotes in

Table 2, Section III for further details.

WARNING

Conversion Compatibility and

Product I.D. Label

37-Pin Connector for cable 1492-CONCAB

1492-CM1771-LD009F Conversion Module

De-energize and lockout any and all power to all I/O field devices connected to the A-B 1771 I/O chassis,

and the power to the 1771 I/O chassis itself. Ensure all power is de-energized and locked out to any

device in the control cabinet where the conversion is to be performed. Ensure work is performed by

qualified personnel.

Z

PN-114281

DIR 10000060092 (Version 01)

Publication 1492-IN039B-EN-E

Printed in U.S.A.

Page 2

II. Installation

The 1492 Conversion Modules must be installed in a 1492 Conversion Mounting Assembly (see Table 1 below). A

complete System Installation Manual ships with the 1492 Conversion Mounting Assembly.

1) Determine the quantity of each type of 1771 I/O modules used in the 1771 I/O Chassis to be converted.

2) Select the applicable 1492 Conversion Modules from Table 2, Section III.

3) Review the Max Slots for I/O and Chassis Width data from the Table 1 below.

4) Select a 1756 I/O Chassis which has enough I/O Slots.

NOTE: (2) I/O slots are required in the 1756 Chassis for conversions where (1) 1771 I/O module converts to (2) 1756 I/O

modules.

5) Select the 1492 Conversion Mounting Assembly which has enough Conversion Module slots.

NOTE: (2) Conversion Module slots are required in the 1492 Conversion Mounting Assembly for conversions where (2)

1771 I/O module convert to (1) 1756 I/O modules.

NOTE: The 1492 Conversion Mounting Assembly has the same Height & Width foot-print as the 1771 Chassis and is

designed to use the same mounting hardware. The combined Depth of the 1492 Conversion Mounting Assembly with the

1756 Chassis mounted on top is 10.25 inches (Controller w/key) or 10.0 inches (Controller w/o key). Dimension drawings

are included in the System Installation Manual that ships with the 1492 Conversion Mounting Assembly.

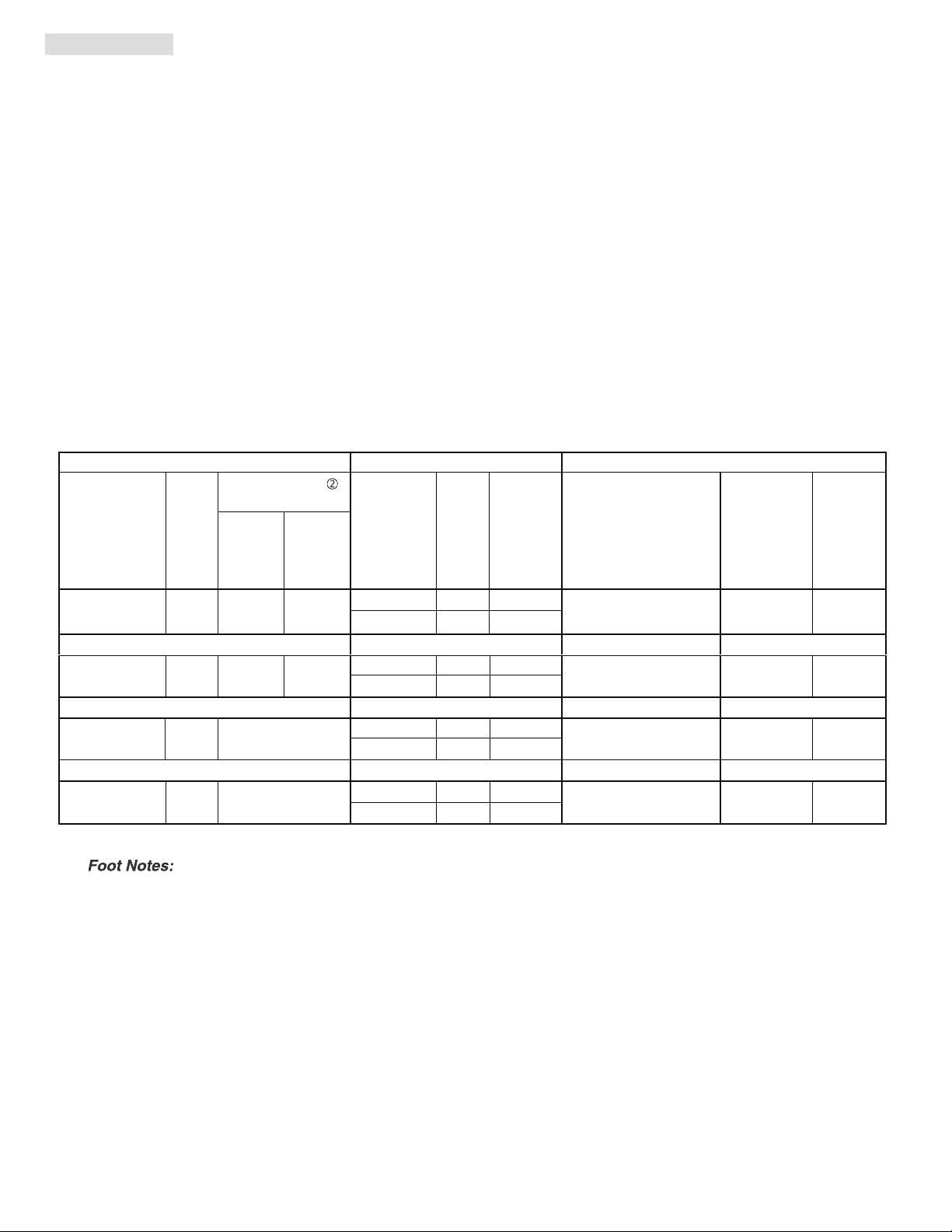

Table 1: Bulletin 1771 to 1756 Chassis Conversion

1771 Chassis 1756 Chassis Conversion Mounting Assembly

Max

Cat. No.

1771-A1B 4 9.01 12.61

1771-A2B 8 14.01 17.61

1771-A3B1 12 19.01

1771-A4B 16 24.01

Slots

for

I/O

Chassis Width

without

Power

Supply

with

Power

Supply

Cat. No.

1756-A4

1756-A7

1756-A7

1756-A10

1756-A10

1756-A13

1756-A13

1756-A17

Max

Slots

Chassis

for

I/O

3 10.35

6 14.49

6 14.49

9 19.02

9 19.02

12 23.15

12 23.15

16 29.06

Width

Cat. No.

1492-MUA1B-A4-A7 4 9.01

1492-MUA2B-A7-A10 8 14.01

1492-MUA3-A10-A13 12 19.01

1492-MUA4-A13-A17 16 24.01

Max Slots

for

Conversion

Modules

1771-A3B is not listed as it is used for 19 inch wide instrumentation panels.

Notice that the 1756 Chassis Width sometimes exceeds the 1771 Chassis Width, with or without the Power

Supply. The Cover-Plate of the 1492 Conversion Mounting Assembly allows the 1756 Chassis to be Left justified,

Right justified or Centered. A complete System Installation Manual ships with the 1492 Conversion Mounting

Assembly.

Chassis

Width

PN-114281

DIR 10000060092 (Version 01)

Publication 1492-IN039B-EN-E

(2)

Page 3

III. Compatiblity

Table 2: Bulletin 1771 to 1756 Conversion Modules and Cables

1771

Digital I/O Module

Digital I/O Module

1756

Conversion Module

1771-OBN 1756-OB32 1492-CONCAB005Z1492-CM1771-LD009F

Foot Notes:

To understand any issues concerning I/O module compatibility, refer to the Installation Manuals for the specific

1771 and 1756 I/O modules involved.

The 3 numbers indicate the cable length of each portion of the 1492 Cable. Recommended cable lengths of 0.5M

re shown. Additional cable lengths are as follows:

1.0M = 1492-CONCAB010Z

To maintain the functionality of the 1771-OBN module the Conversion Module provides 4 mechanical fuses, 1 for

each DC+. Refer to the Wiring Diagram for further details.

IV. Conversion Module Specifications

(Operating specifications are when installed in the Conversion System base / cover-plate assembly)

Specification

Dimensions

Approximate Shipping Weight

Storage Temperature -40 to +85°C (-40 to +185°F)

Operating Temperature

Operating Humidity

Shock

Non-operating

Operating

Operating Vibration

Maximum Operating Voltage 32 Vdc

Max. Module Operating Current

Per Point:

Per Module:

Fusing

Agency Certifications

Pollution Degree

Environmental Rating

11.81 in. (height) x 4.38 in. (depth) x 1.5 in. (width)

300 mm. (height) x 111.25 mm (depth) x 38.1 mm (width)

246.9 g (0.54 lbs) (includes carton)

0 to 60°C (32 to 140°F)

5 to 95% at 60°C (non-condensing)

50g

30g

2g at 10 to 500Hz (Agrees with 1756 I/O module specifications)

2 Amps

6 Amps

NOTICE

Refer to the Wiring Diagram(s) for

current limits for a specific configuration.

Four, 4 Amps (maximum current based on conversion components)

UL Classified: Under UL File Number E113724

CSA

CE: compliant for all applicable directives

2

IP20

1492

Value

1492

Cable

PN-114281

DIR 10000060092 (Version 01)

Publication 1492-IN039B-EN-E

(3)

Page 4

V. Wiring Diagrams

Conversion: 1771-OBN to 1756-OB32

WARNING

+

-

There are several key application considerations and system specifications (bottom of drawing) when

using these components (conversion module, cable and input module). Read and understand these

considerations before installation.

Cable

1756-OB32

18

DC-0(+)

36

DC-1(+)

1

OUT-0

19

OUT-16

2

OUT-1

20

OUT-17

3

OUT-2

21

OUT-18

4

OUT-3

22

OUT-19

5

OUT-4

23

OUT-20

6

OUT-5

24

OUT-21

7

OUT-6

25

OUT-22

8

OUT-7

26

OUT-23

9

OUT-8

27

OUT-24

10

OUT-9

28

OUT-25

11

OUT-10

29

OUT-26

12

OUT-11

30

OUT-27

13

OUT-12

31

OUT-28

14

OUT-13

32

OUT-29

15

OUT-14

33

OUT-30

16

OUT-15

34

OUT-31

17

RTN OUT-0

35

RTN OUT-1

LOAD

10-30V dc(0)

10-30V dc(1)

10-30V dc(2)

10-30V dc(3)

Output 00

Output 00

Output 01

Output 01

Output 02

Output 02

Output 03

Output 03

Output 04

Output 04

Output 05

Output 05

Output 06

Output 06

Output 07

Output 07

Output 10

Output 10

Output 11

Output 11

Output 12

Output 12

Output 13

Output 13

Output 14

Output 14

Output 15

Output 15

Output 16

Output 16

Output 17

Output 17

Common 0

Common 1

Common 2

Common 3

Conversion Module

1492-CM1771-LD009F

1

11

21

31

2

22

3

23

4

24

5

25

6

26

7

27

8

28

9

29

12

32

13

33

14

34

15

35

16

36

17

37

18

38

19

39

10

20

30

40

1492-CONCAB005Z

Black

1

White

2

Red

3

Green

4

Orange

5

Blue

6

7

White/Black

8

Red/Black

9

Green/Black

10

Orange/Black

Blue/Black

11

Black/White

12

Red/White

13

Green/White

14

Blue/White

15

16

Black/Red

17

White/Red

18

Orange/Red

19

Blue/Red

20

Red/Green

21

Orange/Green

22

Black/White/Red

23

White/Black/Red

24

Red/Black/White

Green/Black/White

25

Orange/Black/White

26

27

Blue/Black/White

Black/Red/Green

28

White/Red/Orange

29

Red/Black/Green

30

31

Green/Black/Orange

Orange/Black/Green

32

33

Blue/White/Orange

34

Black/White/Orange

White/Red/Orange

35

36

Orange/White/Blue

37

White/Red/Blue

1771-WN Swing Arm

From 1771-OBN

Conversion Module Installation and Application Considerations

The 1771-OBN module output current limits versus 1756-OB32 limits are as follows:

1771-OBN 1756-OB32w/1492-CONCAB005Z

a) Current/Point 0.5A 0.35A @ 60˚C

b) Current/Module 8A 6A @ 60˚C

c) Surge Current/Point 2A for 10ms 1A for 10ms

The 1771-OBN has four (4) 4A, 250V rectifier fuses. The 1756-OB32 is NOT fused, as such four (4) 2AG fuse clips and 4A

fuses are provided on the 1492-CM1771-LD009F conversion module.

The 1492-CONAB005Z is limited to 3A per pin.

The 1771-OBN has 4 groups (allowing 4 separate power supplies) and the 1756-OB32 has 2 groups. This module/cable

combination ties Groups 0 & 1 from the 1771-OBN to Group 0 on the 1756-OB32 and Groups 2 & 3 from the 1771-OBN to

Group 1 on the 1756-OB32. Field wiring modification must be made to accommodate this if multiple supplies were used.

If 4 supplies were used, 2 must be removed.

Refer to your 1771-OBN and 1756-OB32 Installation Manual wiring schematics and diagrams for more details. Ensure

1756 output module ratings are not exceeded. [Reference Doc: 41170-938 (Version 01)]

PN-114281

DIR 10000060092 (Version 01)

Publication 1492-IN039B-EN-E

(4)

Page 5

VI. Fuse Installation and Replacement

The 1492-CM1771-LD009F conversion module has four (4) mechanical fuse holders with fuses located on the circuit

board inside the modules plastic case. The following explains how to replace the fuses.

1) Remove the 4 screws that hold both halves of the conversion module case together (refer to the following

Figure A).

2) Disassemble both case halves so you can access the module’s circuit board. Remove and replace the fuse or

FIGURE A

fuses (refer to the below Figure B).

Four Fuse Holders and Fuses

FIGURE B

3) Reassemble the two case halves to the circuit board and replace the four screws that hold the case together

(Do NOT over torque the screws (Maximum torque is 5.0 in-lbs.)

NOTES:

1) For module operation a fuse must be inserted into the fuse holder

2) Physical Fuse Size: 2AG

3) Possible Fuse Supplier: LittelFuse (Part Number: 225004P)

4) Maximum Fuse Current rating based on Conversion System Components: 4.0 Amps

PN-114281

DIR 10000060092 (Version 01)

Publication 1492-IN039B-EN-E

(5)

Page 6

PN-114281

DIR 10000060092 (Version 01)

Publication 1492-IN039B-EN-E

Printed in U.S.A.

Loading...

Loading...