Page 1

Analog I/O Conversion Module

(Cat 1492-CM1771-LA005)

I. Description

This Analog I/O Conversion Module provides for the conversion of (1) 1771, 8 Channel Thermocouple Input

module to be converted to (1) 1756, 6 or 8 Channel Thermocouple Input module and consists of the following:

(1) 1771 Thermocouple Module (8ch) to (1) 1756 Thermocouple Module (8ch)

(1) 1492-CM1771-LA005 (Series B)

(1) Cable: 1492-CONACAB005G8

(1) Conversion Mounting Assembly: 1492-MUA… (Table 1)

(1) 1771 Thermocouple Module (8ch) to (1) 1756 Thermocouple Module (6ch)

(2) Conversion Module: 1492-CM1771-LA005

(1) Cable: 1492-CONACAB005G

(1) Conversion Mounting Assembly: 1492-MUA… (Table 1)

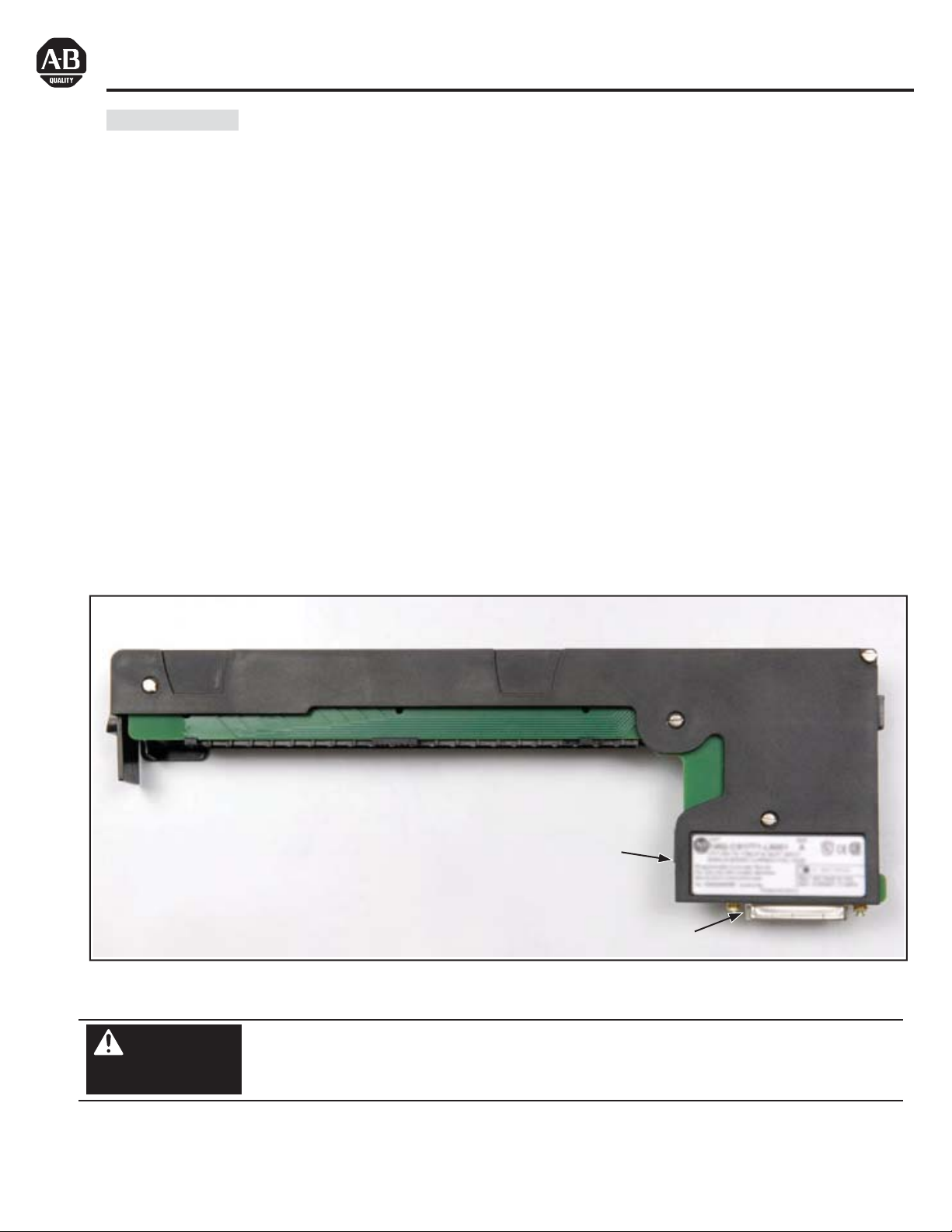

This conversion is accomplished without the removal of any field wires from the existing 1771 Swing Arm. The

existing 1771 Swing Arm fits directly onto the edge connector of the 1492 Conversion Module. On one end of the

1492 Cable is (1) connector for the Conversion Module. On the other end is the Removable Terminal Block (RTB)

for the 1756 I/O module, as shown in the photo below. The I/O signals are routed through the 1492 Conversion

Module and the 1492 Cable to the appropriate terminals on the 1756 I/O module per the Wiring Diagrams in

Section V. As standard, both portions of the 1492 Cables are 0.5M long, but we also offer a 1.0M cable length.

Refer to the footnotes in Table 2 for further details.

WARNING

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN049B-EN-E

Printed in U.S.A.

Conversion Compatibility

and Product I.D. Label

25-Pin Connector for cable 1492-CONACAB005

G

1492-CM1771-LA005 Conversion Module

De-energize and lockout any and all power to all I/O eld devices connected to the A-B 1771 I/O

chassis, and the power to the 1771 I/O chassis itself. Ensure all power is de-energized and locked out

to any device in the control cabinet where the conversion is to be performed. Ensure work is

performed by qualied personnel.

Page 2

II. Installation

The 1492 Conversion Modules must be installed in a 1492 Conversion Mounting Assembly (see Table 1 below). A

complete System Installation Manual ships with the 1492 Conversion Mounting Assembly.

1) Determine the quantity of each type of 1771 I/O modules used in the 1771 I/O Chassis to be converted.

2) Select the applicable 1492 Conversion Modules from Table 2, Section III.

3) Review the Max Slots for I/O and Chassis Width data from the Table 1 below.

4) Select a 1756 I/O Chassis which has enough I/O Slots.

NOTE: (2) I/O slots are required in the 1756 Chassis for conversions where (1) 1771 I/O module converts to (2) 1756 I/O

modules.

5) Select the 1492 Conversion Mounting Assembly which has enough Conversion Module slots.

NOTE: (2) Conversion Module slots are required in the 1492 Conversion Mounting Assembly for conversions where (2)

1771 I/O module convert to (1) 1756 I/O modules.

NOTE: The 1492 Conversion Mounting Assembly has the same Height & Width foot-print as the 1771 Chassis and is

designed to use the same mounting hardware. The combined Depth of the 1492 Conversion Mounting Assembly with the

1756 Chassis mounted on top is 10.25 inches (Controller w/key) or 10.0 inches (Controller w/o key). Dimension drawings

are included in the System Installation Manual that ships with the 1492 Conversion Mounting Assembly.

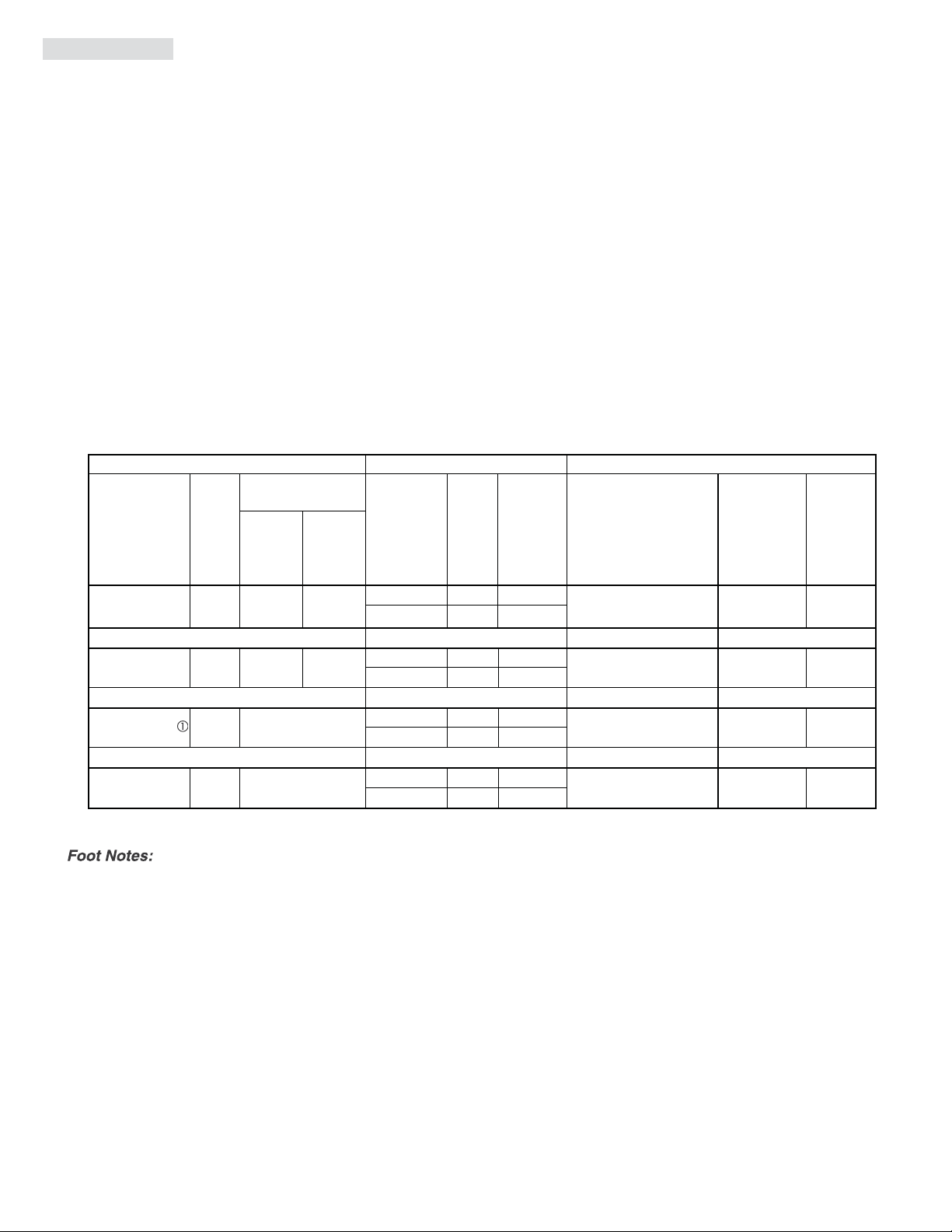

Table 1: Bulletin 1771 to 1756 Chassis Conversion

1771 Chassis 1756 Chassis Conversion Mounting Assembly

Max

Cat. No.

1771-A1B 4 9.01 12.61

1771-A2B 8 14.01 17.61

1771-A3B1

1771-A4B 16 24.01

Slots

for

I/O

12 19.01

Chassis Width

without

Power

Supply

with

Power

Supply

Cat. No.

1756-A4

1756-A7

1756-A7

1756-A10

1756-A10

1756-A13

1756-A13

1756-A17

Max

Slots

Chassis

for

I/O

12 23.15

12 23.15

16 29.06

Width

3 10.35

6 14.49

6 14.49

9 19.02

9 19.02

Max Slots

Cat. No.

1492-MUA1B-A4-A7 4 9.01

1492-MUA2B-A7-A10 8 14.01

1492-MUA3-A10-A13 12 19.01

1492-MUA4-A13-A17 16 24.01

for

Conversion

Modules

Chassis

Width

1771-A3B is not listed as it is used for 19 inch wide instrumentation panels.

Notice that the 1756 Chassis Width sometimes exceeds the 1771 Chassis Width, with or without the Power Supply. The

Cover-Plate of the 1492 Conversion Mounting Assembly allows the 1756 Chassis to be Left justified, Right justified or

Centered. A complete System Installation Manual ships with the 1492 Conversion Mounting Assembly.

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN048B-EN-E

(2)

Page 3

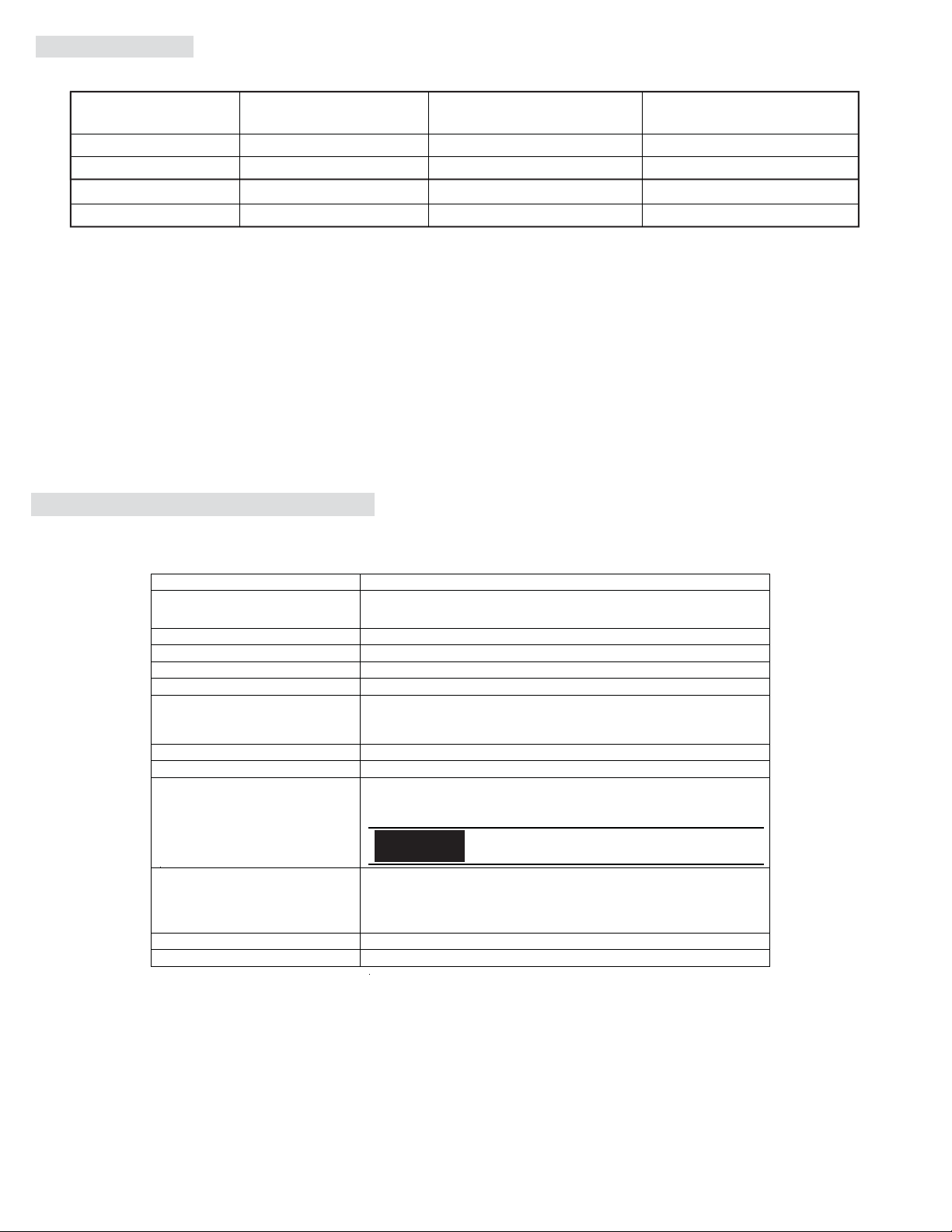

III. Compatibility

es:

1771

1492

Analog I/O Module

Analog I/O Module

1756

1771-IXE 1756-IT6I2 (6 channels) 1492-CM1771-LA005 1492-CONACAB005G

1771-IXHR

1756-IT6I2 (6 channels) 1492-CM1771-LA005 1492-CONACAB005G

1771-IXHR 1756-IRT81I (8 channels) 1492-CM1771-LA005 (B) 1492-CONACAB005G8

1771-IXHR

1756-IRT81I (8 channels) 1492-CM1771-LA005 (B) 1492-CONACAB005G8

t Not

To understand any issues concerning I/O module compatibility, refer to the Installation Manuals for the specific

1771 and 1756 I/O modules involved.

The 3 numbers indicate the length of the 1492 Cable. Recommended cable lengths of 0.5M are shown.

Additional cable lengths are as follows:

1.0M = 1492-CONACAB010G

IV. Conversion Module Specifications

(Operating specifications are when installed in the Conversion System base / cover-plate assembly)

I/O Conversion Module

1492

Cable

Specification Value

Dimensions

Approximate Shipping Weight

Storage Temperature -40 to +85 C (-40 to 185° F)

Operating Temperature 0 to 60 C (32 to 40° F)

Operating Humidity 5 to 95% at 60° C (non-condensing)

Shock

Non-operating

Operating

Operating Vibration 2g at 10 to 500Hz (Agrees with 1756 I/O module specification)

Maximum Operating Voltage 30 Vdc

Max. Module Operating Current

Per Point:

Per Module:

Agency Certifications

Pollution Degree 2

Environmental Rating IP20

11.81 in. (height) x 4.38 in. (depth) x 1.5 in. (width)

300 mm. (height) x 111.25 mm (depth) x 38.1 mm (width)

X g (Y lbs) (includes carton)

50g

30g

2 Amps

12 Amps

NOTICE

NOTICE

UL Classified: Under UL File Number E113724

CSA

CE: compliant for all applicable directives

Refer to the Wiring Diagram(s) for

current limits for a specic congura-

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN048B-EN-E

(3)

Page 4

V. Wiring Diagrams

Conversion: 1771-IXE to 1756-IT6I2

WARNING

Thermocouple

There are several key application considerations and system specications (bottom of drawing) when

using these components (conversion module, cable and input module). Read and understand these

considerations before installation.

Conversion Module

1492-CM1771-LA005

1492-CONACAB005G

+

-

Input 1+ 5

Input 1Input 2+

Input 2-

Input 3+

Input 3Input 4+

Input 4-

Input 5+

Input 5Input 6+

Input 6-

18

17

16

15

14

13

12

11

10

9

T

8

7

6

5

4

3

2

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SH

Orange/Red

White/Red

Black/Red

Blue/White

Green/White

Red/White

Black/White

Blue/Black

Orange/Black

Green/Black

Red/Black

White/Black

Blue

Orange

Cable

6

7

8

9

10

11

12

13

14

15

16

3

4

1756-IT6I2

IN-0

RTN-0

IN-1

RTN-1

IN-2

RTN-2

IN-3

RTN-3

IN-4

RTN-4

IN-5

RTN-5

CJC+

CJC-

1771-WI Swing Arm

From 1771-IXE

Conversion Module Installation and Application Considerations

This Bul. 1492 cable consists of a cable wired to one 1756-IT6I2 RTB. Recommended cable lengths of 0.5M or 1.0M (005=0.5M, 010=1.0M).

SHIELD GROUNDING: In some installations, the field wiring shield was grounded on the 1771 chassis. If this was the case, the installer must

remove these shield connections from the 1771 chassis and they can be connected to the grounding stud on the 1492-CM1771-LA005 module.

The pre-wired cable used between the 1492-CM1771-LA005 module and the 1756-IT6I2 [1492-CONACAB005G] provides a shield ground lug to

ground the shield at the 1756 ControlLogix chassis, this must be connected. Do NOT connect this ground lug to the conversion module grounding

stud.

The 1771-IXE has 8 input channels. The 1756-IT6I2 only has 6 input channels. This module combination can only be used to convert the

signals if 6 or less channels were used on the 1771-IXE.

The 1771-IXE has built CJC (cold junction compensation) into the swing-arm. The conversion module [1492-CM1771-LA005] passes this CJC

signal to the 1756-IT6I2. Ensure that the 1756-IT6I2 is configured for external CJC.

The 1771-IXE input configuration was software configured, as is the 1756-IT6I2. Please ensure the correct configuration in the 1756-IT6I2.

Refer to your 1771-IXE and 1756-IT6I2 Installation and User Manuals for additional information concerning comparisons of module wiring,

features and configuration details. [Reference Doc: 41170-951 (Version 02)]

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN048B-EN-E

(4)

Page 5

V. Wiring Diagrams (Cont’d)

Conversion: 1771-IXHR to 1756-IT6I2

WARNING

Thermocouple

+

-

There are several key application considerations and system specications (bottom of drawing) when

using these components (conversion module, cable and input module). Read and understand these

considerations before installation.

Conversion Module

1492-CM1771-LA005

Cable

1492-CONACAB005G 1756-IT6I2

Input 1+ 5

Input 1Input 2+

Input 2Input 3+

Input 3Input 4+

Input 4-

Input 5+

Input 5Input 6+

Input 6-

18

17

16

15

14

13

12

11

10

9

T

8

7

6

5

4

3

2

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SH

Orange/Red

White/Red

Black/Red

Blue/White

Green/White

Red/White

Black/White

Blue/Black

Orange/Black

Green/Black

Red/Black

White/Black

Blue

Orange

6

7

8

9

10

11

12

13

14

15

16

3

4

IN-0

RTN-0

IN-1

RTN-1

IN-2

RTN-2

IN-3

RTN-3

IN-4

RTN-4

IN-5

RTN-5

CJC+

CJC-

1771-WI Swing Arm

From 1771-IXHR

Conversion Module Installation and Application Considerations

This Bul. 1492 cable consists of a cable wired to one 1756-IT6I2 RTB. Recommended cable lengths of 0.5M or 1.0M (005=0.5M, 010=1.0M).

SHIELD GROUNDING: In some installations, the field wiring shield was grounded on the 1771 chassis. If this was the case, the installer must

remove these shield connections from the 1771 chassis and they can be connected to the grounding stud on the 1492-CM1771-LA005 module.

The pre-wired cable used between the 1492-CM1771-LA005 module and the 1756-IT6I2 [1492-CONACAB005G] provides a shield ground lug to

ground the shield at the 1756 ControlLogix chassis, this must be connected. Do NOT connect this ground lug to the conversion module grounding

stud.

The 1771-IXHR has 8 input channels. The 1756-IT6I2 only has 6 input channels. This module combination can only be used to convert the

signals if 6 or less channels were used on the 1771-IXHR.

The 1771-IXHR has built CJC (cold junction compensation) into the swing-arm. The conversion module [1492-CM1771-LA005] passes this CJC

signal to the 1756-IT6I2. Ensure that the 1756-IT6I2 is configured for external CJC.

The 1771-IXHR input configuration was software configured, as is the 1756-IT6I2. Please ensure the correct configuration in the 1756-IT6I2.

Refer to your 1771-IXHR and 1756-IT6I2 Installation and User Manuals for additional information concerning comparisons of module wiring,

features and configuration details. [Reference Doc: 41171-035 (Version 00)]

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN048B-EN-E

(5)

Page 6

V. Wiring Diagrams (Cont’d)

Conversion: 1771-IXHR (1) to 1756-IRT8I (1)

Thermocouple

+

-

WARNING

In_CH0+

In_CH0In_CH1+

In_CH1In_CH2+

In_CH2In_CH3+

In_CH3-

CJC+

CJC-

In_CH4+

In_CH4In_CH5+

In_CH5In_CH6+

In_CH6-

In_CH7+

In_CH7-

There are several key application considerations and system specifications (bottom of drawing) when using

these components (conversion module, cable and input module). Read and understand these considerations

before installation.

Conversion Module

1492-CM1771-LA005 SER “B”

18

17

16

15

14

13

12

11

10

9

T

8

7

6

5

4

3

2

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1492-CONACAB005G8

Orange/Red

White/Red

Black/Red

Blue/White

Green/White

Red/White

Black/White

Blue/Black

Orange/Black

Green/Black

Red/Black

White/Black

Blue

Orange

Red/Black

White/Black

Blue

Orange

Cable

1756-IRT8I

3

In_CH0+

4

In_CH0-

7

In_CH1+

8

In_CH1-

11

In_CH2+

12

In_CH2-

15

In_CH3+

16

In_CH3-

19

In_CH4+

20

In_CH4-

23

In_CH5+

24

In_CH5-

1

CJC+

2

CJC-

27

In_CH6+

28

In_CH6-

31

In_CH7+

32

In_CH7-

SH

5

6

9

10

13

14

17

1771-WI Swing Arm

From 1771-IXHR

CONVERSION MODULE INSTALLATION AND APPLICATION CONSIDERATIONS

This Bul. 1492 cable consists of a cable wired to one 1756-IRT8I RTB. Recommended cable lengths of

0.5M or 1.0M (005=0.5M, 010=1.0M).

SHIELD GROUNDING: In some installations, the field wiring shield was grounded on the 1771 chassis. If this was

the case, the installer must remove these shield connections from the 1771 chassis and they can be connected

to the grounding stud on the 1492-CM1771-LA005 SER”B” module. The pre-wired cable used between the 1492-CM1771-LA005 SER”B”

module and the 1756-IRT8I [1492-CONACAB005G8] provides a shield ground lug to ground the shield at the 1756

ControlLogix chassis, this must be connected. Do NOT connect this ground lug to the conversion module grounding stud.

The 1771-IXHR has built CJC (cold junction compensation) into the swing-arm. The conversion module [1492-CM1771-LA005 SER”B”]

passes this CJC signal to the 1756-IRT8I. Ensure that the 1756-IRT8I is configured for external CJC.

The 1771-IXHR input configuration was software configured, as is the 1756-IRT8I. Please ensure the correct configuration

in the 1756-IRT8I.

Refer to your 1771-IXHR and 1756-IRT8I Installation and User Manuals for additional information concerning comparisons

of module wiring, features and configuration details.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

18

21

22

25

26

29

30

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN048B-EN-E

Printed in U.S.A.

(6)

Page 7

V. Wiring Diagrams (Cont’d)

Conversion: 1771-IXE (1) to 1756-IRT8I (1)

Thermocouple

+

-

WARNING

There are several key application considerations and system specications (bottom of drawing) when

using these components (conversion module, cable and input module). Read and understand these

considerations before installation.

Conversion Module

Cable

1756-IRT8I

3

In_CH0+

4

In_CH0-

7

In_CH1+

8

In_CH1-

11

In_CH2+

12

In_CH2-

15

In_CH3+

16

In_CH3-

19

In_CH4+

20

In_CH4-

23

In_CH5+

24

In_CH5-

1

CJC+

2

CJC-

27

In_CH6+

28

In_CH6-

31

In_CH7+

32

In_CH7-

In_CH0+

In_CH0In_CH1+

In_CH1In_CH2+

In_CH2In_CH3+

In_CH3-

CJC+

CJC-

In_CH4+

In_CH4In_CH5+

In_CH5In_CH6+

In_CH6-

In_CH7+

In_CH7-

1492-CM1771-LA005 SER “B”

18

17

16

15

14

13

12

11

10

9

T

8

7

6

5

4

3

2

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1492-CONACAB005G8

Orange/Red

White/Red

Black/Red

Blue/White

Green/White

Red/White

Black/White

Blue/Black

Orange/Black

Green/Black

Red/Black

White/Black

Blue

Orange

Red/Black

White/Black

Blue

Orange

SH

5

6

9

10

13

14

17

1771-WI Swing Arm

From 1771-IXE

CONVERSION MODULE INSTALLATION AND APPLICATION CONSIDERATIONS

This Bul. 1492 cable consists of a cable wired to one 1756-IRT8I RTB. Recommended cable lengths of

0.5M or 1.0M (005=0.5M, 010=1.0M).

SHIELD GROUNDING: In some installations, the field wiring shield was grounded on the 1771 chassis. If this was

the case, the installer must remove these shield connections from the 1771 chassis and they can be connected

to the grounding stud on the 1492-CM1771-LA005 SER”B” module. The pre-wired cable used between the 1492-CM1771-LA005 SER”B”

module and the 1756-IRT8I [1492-CONACAB005G8] provides a shield ground lug to ground the shield at the 1756

ControlLogix chassis, this must be connected. Do NOT connect this ground lug to the conversion module grounding stud.

The 1771-IXE has built CJC (cold junction compensation) into the swing-arm. The conversion module [1492-CM1771-LA005 SER”B”]

passes this CJC signal to the 1756-IRT8I. Ensure that the 1756-IRT8I is configured for external CJC.

The 1771-IXE input configuration was software configured, as is the 1756-IRT8I. Please ensure the correct configuration

in the 1756-IRT8I.

Refer to your 1771-IXE and 1756-IRT8I Installation and User Manuals for additional information concerning comparisons

of module wiring, features and configuration details.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

18

21

22

25

26

29

30

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN048B-EN-E

Printed in U.S.A.

(7)

Page 8

PN-114291

DIR 10000060102 (Version 02)

Publication 1492-IN048B-EN-E

Printed in U.S.A.

Loading...

Loading...