Page 1

Technical Data

Original Instructions

1443 Series Accelerometers Specifications

Catalog Numbers 1443-ACC-GP series, 1443-ACC-VO series, 1443-ACC-IS series, 1443-ACC-AT s e r i e s , 1 4 4 3 - A C C - L F - T ,

1443-ACC-HF-T

Top ic Pag e

Sensor Selection Process 4

Shield Wire Isolation Sensor and Cable Selection 8

Sensor Quick Reference 11

Metric and Imperial Mounting 13

Sensors 14

Sensor Certifications and Approvals 42

Accessories 44

Sensor Cross-reference - 1443 Series (New) to 9000 Series (Old) 56

Additional Resources 59

Summary of Changes

Top ic Pa ge

Added new topic ‘API-670 compliance’ 10

Added Important for sensors manufactured earlier than October 2017 10

Added Hall-effect Speed Sensor information to quick reference section 13, 42

Sensitivity changed from (±10%) to (±5%) global change 14

Updated footnote for sensitivity tolerance 14

Updated all Sensor tables frequency ranges with new ranges 14

Exception for sensor compliance for six Accelerometers 16

Page 2

1443 Series Accelerometers Specifications

Permanently Installed

Accelerometers

Sensor Cables to Dynamix™ 1444

Permanently Installed

Accelerometers

Sensor Cables

Switch Box

Sensor to Data Collector Cable

Dynamix™ 2500

Rockwell Automation® 1443 Series Accelerometers are general-purpose sensors that are used to measure vibration on

industrial machinery. The 1443 Series family also includes sensors with these varied capabilities:

• Low frequency, as low as 0.1 Hz or 6 cpm

• High frequency, up to 20 kHz or 1200 kcpm

• Velocity output, internal integrator

• Hazardous area approved

• Dual accelerometer and temperature output

Typical Vibration Measurement Systems

Accelerometers are either permanently mounted or carried from point-to-point in a route-based measurement or analysis

scheme. The entire measurement system, however, can take on various forms, depending on sensor type and the goal of

the monitoring program. The following examples illustrate vibration measurement and monitor systems.

Figure 1 - Dynamix™ System and Permanently Installed Accelerometers

Figure 2 - Portable Data Collector and Permanently Installed Accelerometers

2 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 3

Figure 3 - Portable Data Collector and Accelerometer

Sensor to Dynamix™ 2500

Precision Industrial

Accelerometer with

Magnetic Mounting

Dynamix™ 2500

IMPORTANT All specifications are at room temperature unless otherwise specified.

For certification information, see Declaration of Conformance at rok.auto/certifications

Optional versions have identical specifications and accessories as listed for standard model except where noted. Multiple

options can be used.

1443 Series Accelerometers Specifications

.

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 3

Page 4

1443 Series Accelerometers Specifications

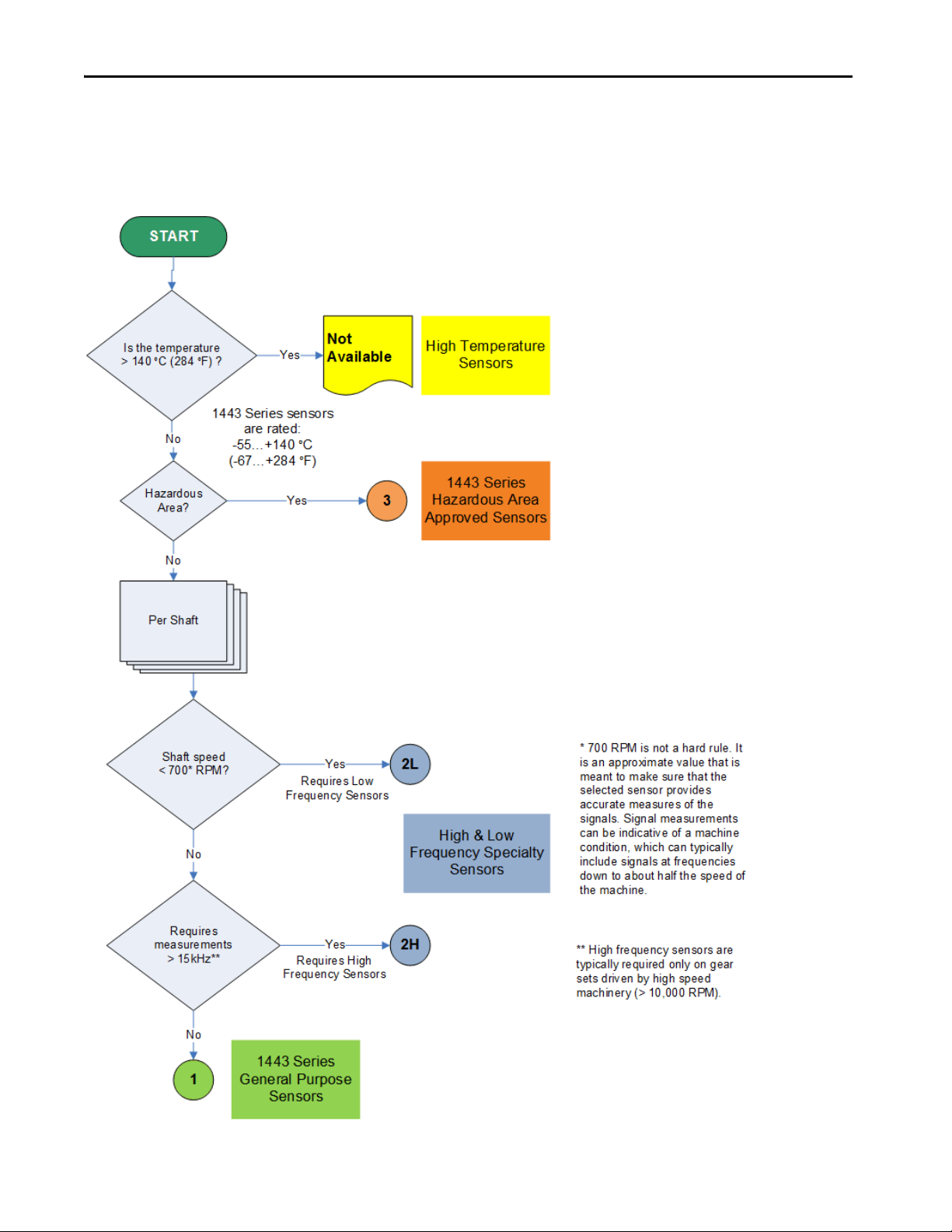

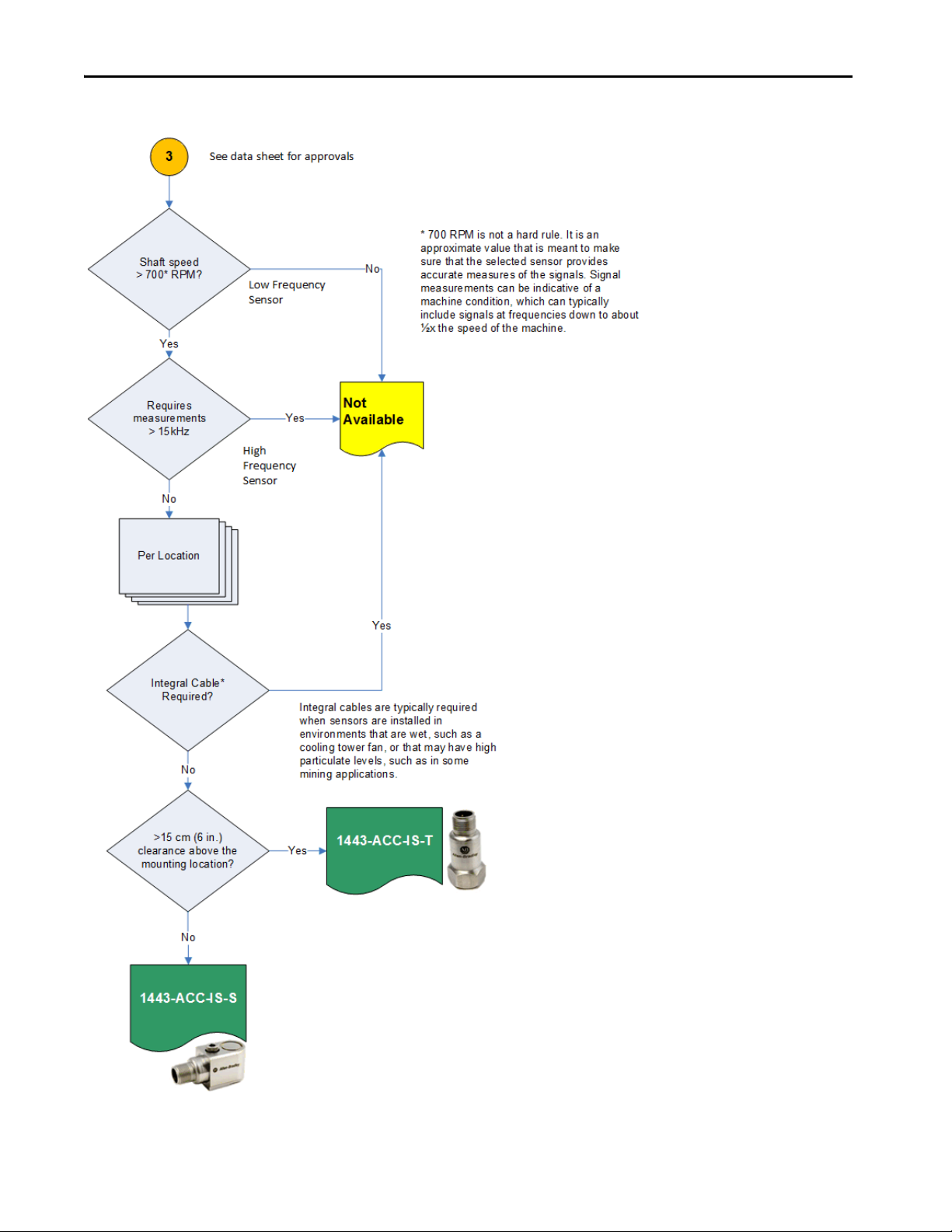

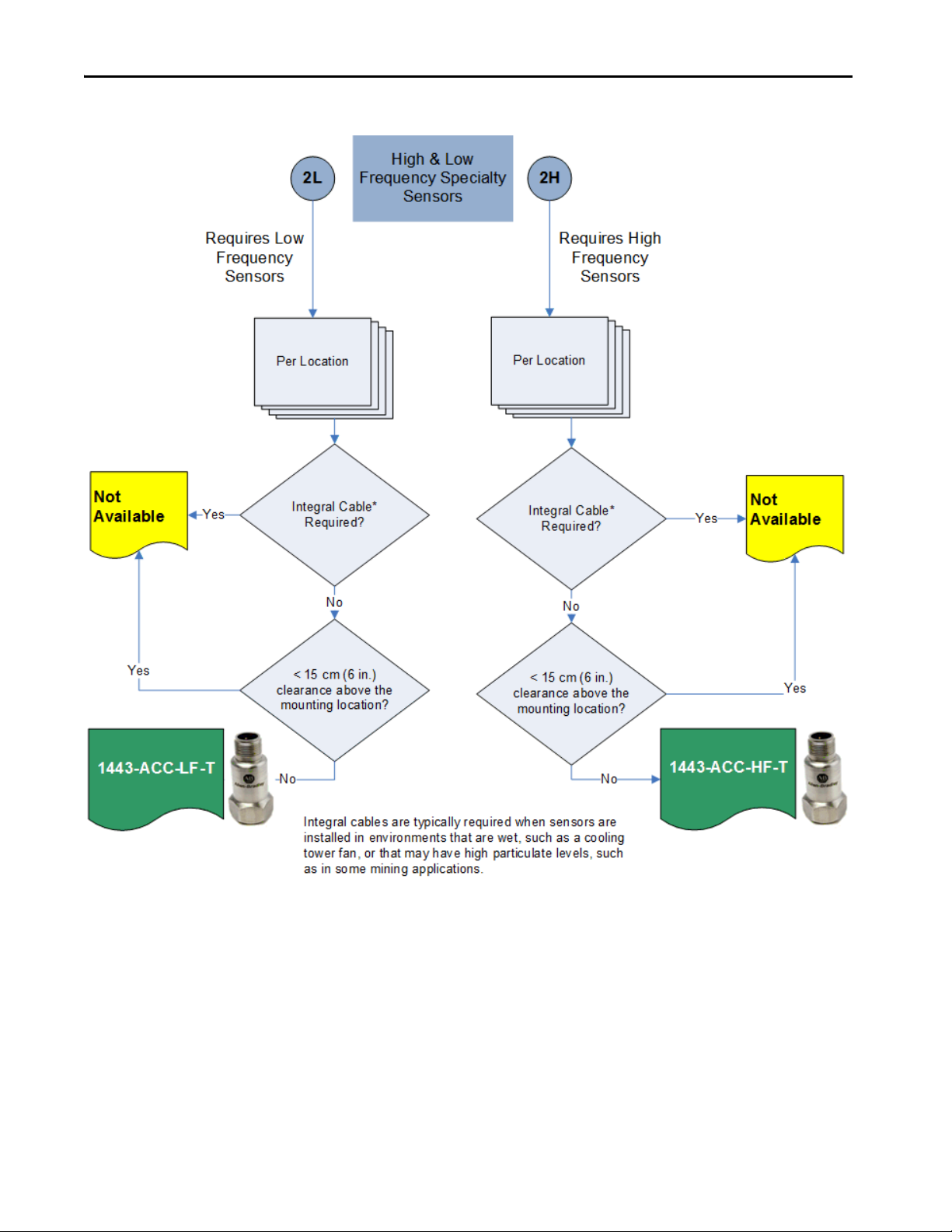

Sensor Selection Process

This flowchart illustrates the process that you can follow to select the appropriate sensor for your application.

Figure 4 - Sensor Selection Flowchart

4 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 5

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 5

Page 6

1443 Series Accelerometers Specifications

6 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 7

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 7

Page 8

1443 Series Accelerometers Specifications

Shield Wire Isolation Sensor and Cable Selection

The 1443 Series include sensor and cable solutions that isolate the shield wire from the sensor or ground the shield wire

to the sensor. For standard sensors, select either shield isolated or shield grounded cables. When a sensor with an integral

cable is required, select a sensor with the shield wire isolated from the sensor or that has its shield wire grounded to the

sensor.

When a shield to sensor isolated solution is required, which is the normal recommended method:

• If a sensor without an integral cable is required, use an accessory cable that has its shield wire isolated from the

sensor connector. Select a cable with ‘IBC’ in its catalog number, for example, 1443-CBL-MS2IBC-32S.

• If a sensor with an integral cable is required, use a sensor with its shield wire isolated from the sensor. Select a

sensor with ‘SI’ in its catalog number, for example, 1443-ACC-GP-T16-SI.

When a shield grounded sensor is required:

• If a sensor without an integral cable is required, use an accessory cable that has its shield wire that is grounded to

the sensor connector. Select a cable with ‘GBC’ in its catalog number, for example, 1443-CBL-MS2GBC-16S.

• If a sensor with an integral cable is required, use a sensor with its shield wire that is grounded to sensor case. Select

a sensor with ‘SC’ in its catalog number, for example, 1443-ACC-GP-T16-SC.

The recommended solution is to connect the shield at the measurement system and leave it isolated at the sensor end. Use

IBC version cables or ‘SI’ version sensors when an integral cable sensor is required. However, when EMI problems are

present or expected, then a shield case grounded solution can prove to be a better design.

When signal noise or interference is a problem or concern, you must understand the source of the problem to resolve it.

Noise can be introduced into signals from accelerometers through these common phenomena:

• Electromagnetic Interference (EMI)

EMI is the introduction of unwanted signals into an electronic device from electromagnetic fields that another

electronic device generated. Televisions, radars, vehicles, variable-frequency drives (VFDs), and other electronic

devices can produce high powered electromagnetic fields. EMI can be introduced into the measurement system via

the signal wiring when that wiring acts as an antenna, which occurs when one end of the wire is ungrounded.

When EMI occurs, it typically results in signals being introduced at discrete frequencies that are related to the

signal source. The impact on measurements is dependent on the magnitude and specific frequency of the signal

that is induced. This occurrence is relative to the measurement systems design signal magnitude and frequency

range and the expected signals that are intended to be measured.

•Ground Loops

In electronics, a ground loop is caused when a device has multiple paths for electricity to flow to ground. In a

measurement system, this scenario commonly occurs when a signal wire is grounded at both ends, with each end

having another potential (resistance) to ground.

The key for accelerometer measurement systems is knowing if the machine case, or bearing housing, to which the

sensor is attached, is grounded or not. While a new machine installation can be isolated, changes are possible over

the life of the machine as wear occurs, maintenance is performed, and other changes are made.

Regardless the source, when present these signals or noise can result in significant error in measurements. The result can

be random and inexplicable machine alarms and trips, erroneous condition assessment / diagnosis, and possible damage

to the instrumentation. If the source of the noise is clear, and there is only one concern, then the corrective action is clear,

depending on the source of the problem, try the following:

8 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 9

1443 Series Accelerometers Specifications

EMI

Ground the shield at both ends of the cable.

• If you tie the shield to the sensor case only, it creates a ground if the structure that the sensor is mounted on is

grounded. If the bearing housing or the machine is isolated from ground, then when you connect the shield to the

case of the sensor cannot ground the shield.

• If the ground potential through the sensor is different than ground potential through the instrumentation ground,

then a ground loop is created. The ground loop that is created can be a worse condition than the EMI problem.

• In most cases, grounding the shield at both ends must be the last resort because ground loop problems can result.

The ground loop problems can create more significant problems than the EMI issue. Make sure that the following

common wiring solutions are considered:

– Use high quality, well shielded, twisted wire cable.

– Route cable runs to avoid obvious / strong sources of EMI such as radio transmission towers, generators,

and transformers.

– If cables are routed through a J-box, make sure that shields are properly connected.

– When routing cables, make sure to cross AC power lines at right angles. Approach AC motors from a right

angle to the motor shaft and do not route wiring alongside a motor.

– At the monitor, connect the shield wires directly to ground - so do not ground it through the instrument.

Ground Loops

Isolate the shield at one end of the cable.

• In most cases, make sure that the shield is not connected to the sensor.

• A special cable or a custom made cable is required for accelerometers with two or three pin

MIL-C-5015 connectors.

• For existing installations, do not assume that the shield is not tied to the sensor case. While not connected to the

sensor case is normal practice in most locations, it doesn't mean that it is that way. Also, if the shield is connected to

the sensor case, it’s possible that the structure the sensor is mounted on has changed in respect to the ground for

other reasons.

• If continuous or intermittent EMI (RFI) sources are present, then when you isolate one end of the shield it creates

an antenna that can result in EMI (RFI) noise problems. An EMI (RFI) issue can be a worse condition than the

ground loop problem.

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 9

Page 10

1443 Series Accelerometers Specifications

API-670 Compliance

All 1443 Series sensors are compliant to the American Petroleum Institute (API) Standard 670, 5th Edition, November

2014, with the following exceptions:

• Side exit sensors have an outside diameter greater than 25 mm (1 in.) as specified by API-670 paragraph 5.2.1.5.

• Calibration frequency is 80 Hz, in accordance with ISO standard 9001-2008, rather than 100 Hz as specified in

API-670 Table 1 note f.

• Only the standard 16 ft cables are nominally 5 m (200 in.) as specified by API-670 paragraph 5.2.2.2.

• Cables do not ship with loose heat-shrink tubing for labeling, as specified by API-670 paragraph 5.2.2.3.

Perhaps the most important attribute of the sensor, per the standard, is its accuracy. The standard specifies accuracy

requirements for accelerometers in the following table.

Table 1 - Machinery Protection System Accuracy Requirements

Accelerometers and Accelerometer Extension Cables

Temperature Accuracy Requirements as a Function of Temperature

Test Range Operating / Storage Range Within Testing Range Outside Testing Range but Within Operating Range

20...30 °C

(68...86 °F)

(1) During the testing o f the accelerometers, the parameter under test is the only parameter that is varied. All other parameters remain constant.

(2) Conditions of test at any one temperature within the testing range, at any single frequency that is not specified but is within the specified frequency range of the transducer.

(3) Frequency response testing conditions, at any one temperature within the testing range, at an excitation amplitude that is not specified but is within the specified amplitude range of the transducer.

(4) Principal axis sensitivity testing conditions (test range), at any one temperature within the testing range set at 100 Hz, at an excitation amplitude that is not specified but is within the specified

amplitude range of the transducer. Operating range at any one temperature within the operating range, at 100 Hz, at an excitation amplitude that is not specified but is within the specified amplitude

range of the transducer.

–55...+120 °C

(–65...+250 °F)

Principal axis sensitivity

Amplitude linearity: 1% from 0.1...50 g peak

Frequency response

referenced to the actual measured principal axis

(4)

sensitivity

(4)

: 100 mV/g ± 5%

(3)

: ±3 dB from 10 Hz to 10 kHz,

(2)

(1)

Principal axis sensitivity

(4)

: 100 mV/g ± 20%

The 1443 Series sensor is ± 5% across the entire operating range of the sensor. This sensor range significantly exceeds the

requirement of only testing within the temperature range. Among sensors advertised as API compliant, this provides a

much more consistent and accurate measurement than most sensors compared to the requirement of just ±20%.

IMPORTANT Sensors manufactured earlier than October 2017 can have sensitivity variances of up to ± 10% across the operating range.

10 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 11

1443 Series Accelerometers Specifications

Sensor Quick Reference

General-purpose Accelerometers

General-purpose industrial accelerometers are recommended for permanent installation onto machinery or route-based

vibration data collection in predictive maintenance and condition-monitoring applications.

Table 2 - General-purpose Accelerometers

Purpose Cat. No Features Page

General-purpose Accelerometer 1443-ACC-GP-T • 100 mV/g

1443-ACC-GP-S • 100 mV/g

General-purpose Accelerometer

(with Integral Cable)

(1) S ensors with the shield wire grounded to the case are non-standard. See Shield Wire Isolation Sensor and Cable Selection on page 8 before ordering.

1443-ACC-GP-T16-SI • Integral ~5 m (16 ft) Cable

1443-ACC-GP-T32-SI • Integral ~10 m (32 ft) Cable

1443-ACC-GP-T16-SC • Integral ~5 m (16 ft) Cable

1443-ACC-GP-T32-SC • Integral ~10 m (32 ft) Cable

• 0.8…19 kHz

•Top Exit

• 0.2…15 kHz

• Side Exit

• 100 mV/g

• 0.8…15 kHz

•Top Exit

• 100 mV/g

• 0.8…15 kHz

•Top Exit

• Shield Case Grounded Cable

• 100 mV/g

• 0.8…15 kHz

•Top Exit

• Shield Case Grounded Cable

• 100 mV/g

• 0.8…15 kHz

•Top Exit

(1)

(1)

14

16

18

20

22

24

Sensors with Integral Cables

Included in the list of 1443 Series general-purpose Accelerometers are variants of the sensor that include integral 4.8 m

(16 ft) and 9.7 m (32 ft) cables. Sensors with an integrated cable are useful in wet or dirty (high particulate) areas.

Low Frequency Accelerometer

The accelerometer combines low-frequency response with high-output sensitivity to obtain the resolution characteristics

and output signal levels necessary for low-frequency measurements and analysis.

Table 3 - Low Frequency Accelerometer

Purpose Cat. No Features Page

Low Frequency Accelerometer 1443-ACC-LF-T • 500 mV/g

• 1.5…10 kHz (5%)

• 0.1…15 kHz (3db)

•Top Exit

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 11

26

Page 12

1443 Series Accelerometers Specifications

High Frequency Accelerometer

When you test, monitor vibrations, and analyze the frequency of machinery where frequencies greater than

approximately 15 kHz, the frequencies must be measured.

Table 4 - High Frequency Accelerometer

Purpose Cat. No Features Page

High Frequency Accelerometer 1443-ACC-HF-T • 50 mV/g

• 0.8…20 kHz

•Top exit

28

Specialty Accelerometers

These sensors are available for applications that require velocity output and temperature output from the sensor.

•Velocity Output

• Acceleration and Temperature

Table 5 - Specialty Accelerometers

Purpose Cat. No Features Page

Velocity Output Accelerometer 1443-ACC-VO-T Output is integrated to velocity

100 mV/ips

2…6 kHz

Output ±50 in/s

Top Exit

Velocity Output Accelerometer 1443-ACC-VO-S Output is integrated to velocit y

100 mV/ips

2…6 kHz

Output ±50 in/s

Side Exit

Combination Acceleration and Temperature 1443-ACC-AT-T 100 mV/g

0.8…15 kHz

10 mV/°C

Top Exit

Combination Acceleration and Temperature 1443-ACC-AT-S 100 mV/g

0.8…15 kHz

10 mV/°C

Side Exit

30

32

34

36

12 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 13

1443 Series Accelerometers Specifications

Intrinsically Safe Accelerometers

Intrinsically safe sensors meet additional requirements for hazardous environments. See specification tables for a list of

certifications.

Table 6 - Intrinsically Safe Accelerometers

Purpose Cat. No Features Page

Hazardous Area Accelerometer 1443-ACC-IS-T • 100 mV/g

• 0.8…15 kHz

•Top Exit

1443-ACC-IS-S • 100 mV/g

• 0.8…15 kHz

• Side Exit

38

40

Hall-effect Speed Sensor

Catalog number EK-44395 is an Airpax Model H1512-005 hall-effect sensor that is designed to generate a steady pulse

train in response to movement of a target surface.

The EK-44395 Hall-effect Speed Sensor outputs a TTL signal that is suitable for use as a direct speed input to the

Dynamix™ 1444-DYN04-01RA monitor. See Ta b l e 2 1

on page 42.

Metric and Imperial Mounting

Sensor mounting accessories are included with the accelerometer, see Supplied Accessories in the specification tables.

Options exist to mount the sensor on the machine end, in either in Metric or Imperial units, as denoted by the ‘Mounting

Thread’ attribute in the following tables for each sensor.

Top exit sensors have a 1/4-28 UNF female thread on the sensor end. Two studs are included, both with one 1/4-28

UNF male end (for the sensor). The other end has either an M8 x 1.25 mm male thread or a 1/4-28 UNF male thread for

mounting on the machine.

Side exit sensors have a through hole. Bolts are included with a machine mounting thread of either M6 x 1.00 mm male

or 1/4-28 UNF male.

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 13

Page 14

1443 Series Accelerometers Specifications

Sensors

1443-ACC-GP-T Accelerometer

General-purpose industrial accelerometers are recommended for permanent installation onto machinery or route-based

vibration data collection in predictive maintenance and condition-monitoring applications.

Table 7 - 1443-ACC-GPT-T Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Measurement range ±785 m/s

Frequency range (±5%)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Resonant frequency, typical 28 kHz 1680 kcpm

Broadband resolution (1…10,000 Hz), typical 2943

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure Rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 2...20 mA 2...20 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 19 x 36 mm 3/4 x 1.42 in.

Weight, approx. 48 g 1.7 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Shear

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin-MIL-C-5015

Electrical connector position Top

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

10.2 mV/(m/s2)100 mV/g

2

±80 g

1.5…10 kHz 90…600,000 cpm

2

μm/s

300 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

Calibration Certificate

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-base d, least-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) Calibration @80 Hz per ISO 9001-200 83

14 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 15

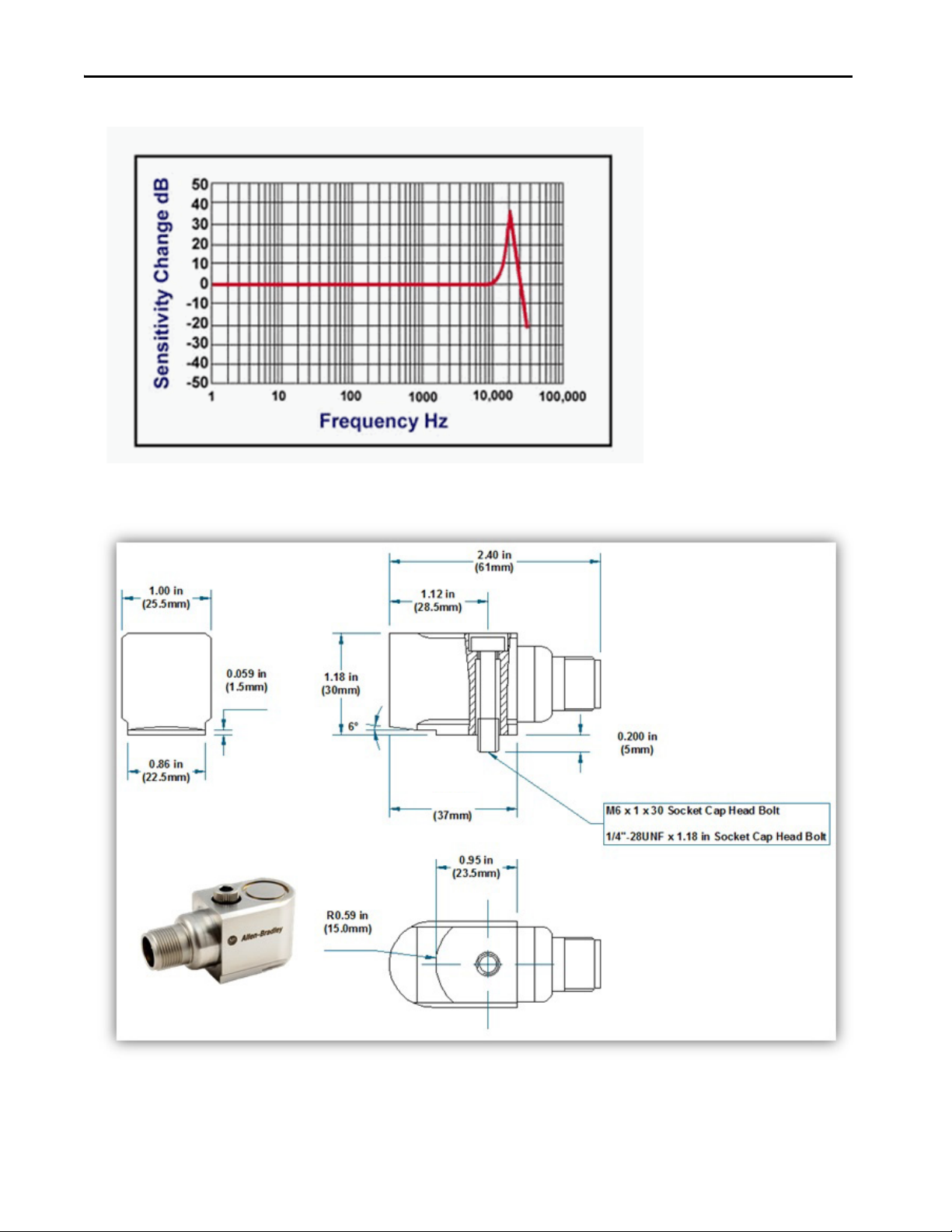

Figure 5 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

in.

Figure 6 - 1443-ACC-GP-T Measurements

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 15

Page 16

1443 Series Accelerometers Specifications

1443-ACC-GP-S Accelerometer

General-purpose industrial accelerometers are recommended for permanent installation onto machinery or route-based

vibration data collection in predictive maintenance and condition-monitoring applications.

Table 8 - 1443-ACC-GP-S Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

(1)

Measurement range ±785 m/s

Frequency range (±5%)

(2)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Resonant frequency, typical 22 kHz 1500 kcpm

Broadband resolution (1…10,000 Hz), typical 491

Non-linearity

(3)

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 2…20 mA 2…20 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 25 x 30 x 35 mm 1 x 1.18 x 1.38 in.

Weight, approx. 170 g 6.0 oz

Mounting thread

(4)

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin-MIL-C-5015

Electrical connector position Side

Supplied Accessories

(5)

10.2 mV/(m/s2) 100 mV/g

2

±80 g

1.5…10 kHz 90…600,000 cpm

2

μm/s

50 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M6 x 1 mm male 1/4-28 UNF male

1443-BLT-125-0

1443-BLT-125-M6

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

16 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 17

Figure 7 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

1.46 in.

Figure 8 - 1443-ACC-GP-S Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 17

Page 18

1443 Series Accelerometers Specifications

1443-ACC-GP-T16-SI Accelerometer

General-purpose industrial accelerometers are recommended for permanent installation onto machinery or route-based

vibration data collection in predictive maintenance and condition-monitoring applications.

Table 9 - 1443-ACC-GP-T16-SI Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Measurement range ±785 m/s

Frequency range (±5%)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Resonant frequency, typical 28 kHz 1680 kcpm

Broadband resolution (1…10,000 Hz), typical 2943

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 0.5…8 mA 0.5…8 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 19 x 36 mm 3/4 x 1.42 in.

Weight, approx. 48 g 1.7 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Top

Cable Length 5 m 16 ft

Cable Type Shielded Silicone

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

10.2 mV/(m/s2) 100 mV/g

2

±80 g

1.2…10 kHz 72…600,000 cpm

2

μm/s

300 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

18 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 19

(4) 1/4-28 UNF has no equivalent in metric units.

16 ft

5 m

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

Figure 9 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

1443 Series Accelerometers Specifications

Figure 10 - 1443-ACC-GP-T16-SI Accelerometer

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 19

Page 20

1443 Series Accelerometers Specifications

1443-ACC-GP-T32-SI Accelerometer

General-purpose industrial accelerometers are recommended for permanent installation onto machinery or route-based

vibration data collection in predictive maintenance and condition-monitoring applications.

Table 10 - 1443-ACC-GP-T32-SI Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Measurement range ±785 m/s

Frequency range (±5%)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Resonant frequency, typical 28 kHz 1680 kcpm

Broadband resolution (1…10,000 Hz), typical 2943

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 0.5…8 mA 0.5…8 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 19 x 36 mm 3/4 x 1.42 in.

Weight, approx. 48 g 1.7 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connec tor Two-pin MIL-C-5015

Electrical connector position Top

Cable Length 10 m 32 ft

Cable Type Shielded Silicone

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

10.2 mV/(m/s2) 100 mV/g

2

±80 g

1.2…10 kHz 72…600,000 cpm

2

μm/s

300 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

20 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 21

Figure 11 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

Figure 12 - 1443-ACC-GP-T32-SI Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 21

Page 22

1443 Series Accelerometers Specifications

1443-ACC-GP-T16-SC Accelerometer

General-purpose industrial accelerometers are recommended for permanent installation onto machinery or route-based

vibration data collection in predictive maintenance and condition-monitoring applications. Sensors with the shield wire

that is grounded to the case are non-standard. See Shield Wire Isolation Sensor and Cable Selection

Table 11 - 1443-ACC-GP-T16-SC Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Measurement range ±785 m/s

Frequency range (±5%)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Resonant frequency, typical 28 kHz 1680 kcpm

Broadband resolution (1…10,000 Hz), typical 2943 μm/s

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s2 pk 5000 g pk

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 0.5…8 mA 0.5…8 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 1010 Ω> 10

Electrical protection 500V 500V

Physical

Size (hex x height) 19 x 36 mm 3/4 x 1.42 in.

Weight, approx. 48 g 1.7 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Top

Cable Length 5 m 16 ft

Cable Type Shielded Silicone

Cable Grounding Shield Case Grounded

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

10.2 mV/(m/s2)100 mV/g

2

±80 g

1.2…10 kHz 72…600,000 cpm

2

300 μg

±1% ±1%

10

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

on page 8 ordering.

(1) S ensitivity tolerance is across the operating temperature range. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

22 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 23

Figure 13 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

Figure 14 - 1443-ACC-GP-T16-SC Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 23

Page 24

1443 Series Accelerometers Specifications

1443-ACC-GP-T32-SC Accelerometer

General-purpose industrial accelerometers are recommended for permanent installation onto machinery or route-based

vibration data collection in predictive maintenance and condition-monitoring applications. Sensors with the shield wire

that is grounded to the case are non-standard. See Shield Wire Isolation Sensor and Cable Selection

Table 12 - 1443-ACC-GP-T32-SC Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Measurement range ±785 m/s

Frequency range (±5%)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Resonant frequency, typical 28 kHz 1680 kcpm

Broadband resolution (1…10,000 Hz), typical 2943 μm/s

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s2 pk 5000 g pk

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 0.5…8 mA 0.5…8 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 1010 Ω> 10

Electrical protection 500V 500V

Physical

Size (hex x height) 19 x 36 mm 3/4 x 1.42 in.

Weight, approx. 48 g 1.7 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Top

Cable Length 10 m 32 ft

Cable Type Shielded Silicone

Cable Grounding Shield Case Grounded

Supplied Accessories

(1) S ensitivity tolerance is across the operating temperature range. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

(1)

(2)

(3)

(4)

(5)

10.2 mV/(m/s2)100 mV/g

2

±80 g

1.2…10 kHz 72…600,000 cpm

2

300 μg

±1% ±1%

10

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

on page 8 ordering.

24 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 25

Figure 15 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

Figure 16 - 1443-ACC-GP-T32-SC Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 25

Page 26

1443 Series Accelerometers Specifications

1443-ACC-LF-T Accelerometer

The accelerometer combines low-frequency response with high-output sensitivity to obtain the resolution characteristics

and output signal levels necessary for low-frequency measurements and analysis.

Table 13 - 1443-ACC-LF-T Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

(1)

Measurement range ±157 m/s

Frequency range (±5%)

(2)

Frequency range (±3 dB) 0.2…15 kHz 12…900,000 cpm

Resonant frequency, typical 25 kHz 1500 kcpm

Broadband resolution (1…10,000 Hz), typical 490

Non-linearity

(3)

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 2…20 mA 2…20 mA

Output impedance <100 Ω <100 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 25 x 40 mm 1 x 1.6 in.

Weight, approx. 110 g 3.9 oz

Mounting thread

(4)

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Top

Supplied Accessories

(5)

51 mV/(m/s2)500 mV/g

2

±16 g

1.2…10 kHz 72…600,000 cpm

2

μm/s

50 μg

±1% ±1%

2

pk 5000 g pk

8

Ω> 10

8

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

26 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 27

Figure 17 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

in.

in.

Figure 18 - 1443-ACC-LF-T Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 27

Page 28

1443 Series Accelerometers Specifications

1443-ACC-HF-T Accelerometer

Table 14 - 1443-ACC-HF-T Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Measurement range ±1570 m/s

Frequency range (±5%)

Frequency range (±3 dB) 0.8…20 kHz 48…1,200,000 cpm

Resonant frequency, typical 28 kHz 1680 kcpm

Broadband resolution (1…10,000 Hz), typical 2943

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28 V DC 18…28 V DC

Constant current excitation 0.5…8 mA 0.5…8 mA

Output impedance <200 Ω <200 Ω

Output bias voltage 10…12 V DC 10…12 V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 19 x19 mm 3/4 x 0.75 in.

Weight, approx. 48 g 1.7 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Shear

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Top

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

51 mV/(m/s2) 50 mV/g

2

±160 g

2…14 kHz 120…840,000 cpm

2

μm/s

300 μg

±1% ±1%

2

pk 5000 g pk

8

Ω> 10

8

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

28 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 29

Figure 19 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

Figure 20 - 1443-ACC-HF-T Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 29

Page 30

1443 Series Accelerometers Specifications

1443-ACC-VO-T Accelerometer

Table 15 - 1443-ACC-VO-T Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Output ±1.27 m/s ±50 in/s

Measurement range Peak ±1000 mm/s ±39.4 in/s

Frequency range (±10%)

Frequency range (±3 dB) 2…6 kHz 120…360,000 cpm

Resonant frequency, typical 22 kHz 1320 kcpm

Broadband resolution (1…10,000 Hz), typical 11.4

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28 V DC 18…28 V DC

Constant current excitation 2…10 mA 2…10 mA

Output impedance <200 Ω <200 Ω

Output bias voltage 10…12 V DC 10…12 V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 25 x 40 mm 1 x 1.6 in.

Weight, approx. 110 g 3.9 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Top

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

4 mV/(mm/s) 100 mV/(in/s)

3.5…4 kHz 210…240,000 cpm

μm/s 450 μin./s

±1% ±1%

2

pk 5000 g pk

8

Ω> 10

8

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

30 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 31

Figure 21 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

in.

in.

Figure 22 - 1443-ACC-VO-T Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 31

Page 32

1443 Series Accelerometers Specifications

1443-ACC-VO-S Accelerometer

Table 16 - 1443-ACC-VO-S Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Output ±1.27 m/s ±50 in/s

Measurement range Peak ±1000 mm/s ±39.4 in/s

Frequency range (±10%)

Frequency range (±3 dB) 2…6 kHz 120…360,000 cpm

Resonant frequency, typical 22 kHz 1320 kcpm

Broadband resolution (1…10,000 Hz), typical 11.4

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28 V DC 18…28 V DC

Constant current excitation 2...10 mA 2...10 mA

Output impedance <200 Ω <200 Ω

Output bias voltage 10…12 V DC 10…12 V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 25 x 35 x 30 mm 1 x 1.4 x 1.2 in

Weight, approx. 170 g 6.0 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Side

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

4 mV/(mm/s) 100 mV/(in/s)

3.5…4 kHz 210…240,000 cpm

μm/s 450 μin./s

±1% ±1%

2

pk 5000 g pk

8

Ω> 10

8

Ω

M6 x 1 mm male 1/4-28 UNF male

1443-BLT-125-0

1443-BLT-125-M6

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

32 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 33

Figure 23 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

1.46 in.

Figure 24 - 1443-ACC-VO-S Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 33

Page 34

1443 Series Accelerometers Specifications

1443-ACC-AT-T Accelerometer

Table 17 - 1443-ACC-AT-T Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

(1)

Sensitivity Temperature 10 mV/°C 5.56mV/°F

Measurement range ±785 m/s

Frequency range (±5%)

(2)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Temperature range 0…100 °C 32…212 °F

Resonant frequency, typical 22 kHz 1320 kcpm

Broadband resolution (1…10,000 Hz), typical 2943

Non-linearity

(3)

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 2…20 mA 2…20 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 25 x 40 mm 1 x 1.6 in.

Weight, approx. 110 g 3.9 oz

Mounting thread

(4)

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Three-pin MIL-C-5015

Electrical connector position Top

Supplied Accessories

(5)

10.2 mV/(m/s2) 100 mV/g

2

±80 g

1.5…10 kHz 90…600,000 cpm

2

μm/s

300 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

34 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 35

Figure 25 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

in.

in.

Figure 26 - 1443-ACC-AT-T Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 35

Page 36

1443 Series Accelerometers Specifications

1443-ACC-AT-S Accelerometer

Table 18 - 1443-ACC-AT-S Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

Sensitivity Temperature 10 mV/°C 5.56mV/°F

Measurement range ±785 m/s

Frequency range (±5%)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Temperature range 0…100 °C 32…212 °F

Resonant frequency, typical 22 kHz 1320 kcpm

Broadband resolution (1…10,000 Hz), typical 2943

Non-linearity

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+140 °C -67…+284 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 2…20 mA 2…20 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 25 x 30 x 35mm 1 x 1.18 x 1.38 in

Weight, approx. 170 g 6.0 oz

Mounting thread

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Three-pin MIL-C-5015

Electrical connector position Side

Supplied Accessories

(1)

(2)

(3)

(4)

(5)

10.2 mV/(m/s2) 100 mV/g

2

±80 g

1.5…10 kHz 90…600,000 cpm

2

μm/s

300 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M6 x 1 mm male 1/4-28 UNF male

1443-BLT-125-0

1443-BLT-125-M6

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

36 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 37

Figure 27 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

1.46 in.

Figure 28 - 1443-ACC-AT-S Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 37

Page 38

1443 Series Accelerometers Specifications

1443-ACC-IS-T Accelerometer

Table 19 - 1443-ACC-IS-T Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

(1)

Measurement range ±785 m/s

Frequency range (±5%)

(2)

Frequency range (±3 dB) 0.4…15 kHz 24…900,000 cpm

Resonant frequency, typical 28 kHz 1680 kcpm

Broadband resolution (1…10,000 Hz), typical 2943

Non-linearity

(3)

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+110 °C -67…+230 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation 2…20 mA 2…20 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 19 x36 mm 3/4 x 1.42 in.

Weight, approx. 48 g 1.7 oz

Mounting thread

(4)

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connector Two-pin MIL-C-5015

Electrical connector position Top

Supplied Accessories

(5)

10.2 mV/(m/s2)100 mV/g

2

±80 g

1.5…10 kHz 90…600,000 cpm

2

μm/s

300 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M8 x 1.25 mm male 1/4-28 UNF male

1443-STD-0-0

1443-STD-0-M8

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Sensor is compliant to API Standard 670, 5th Edition. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

38 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 39

Figure 29 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

in.

in.

Figure 30 - 1443-ACC-IS-T Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 39

Page 40

1443 Series Accelerometers Specifications

1443-ACC-IS-S Accelerometer

Table 20 - 1443--ACC-IS-S Accelerometer Specifications

Attribute Value

Performance

Sensitivity (±5%)

(1)

Measurement range ±785 m/s

Frequency range (±5%)

(2)

Frequency range (±3 dB) 0.84…15 kHz 24…900,000 cpm

Resonant frequency, typical 22 kHz 1500 kcpm

Broadband resolution (1…10,000 Hz), typical 491

Non-linearity

(3)

Transverse sensitivity < 5% < 5%

Environmental

Overload limit (shock) 49,050 m/s

Temperature range -55…+110 °C -67…+230 °F

Enclosure rating IP66 to 68, depending upon the cable assembly used. IP66 to 68, depending upon the cable assembly used.

Electrical

Settling time (within 1% of bias) < 2.0 s < 2.0 s

Discharge time constant ≥ 0.5 s ≥ 0.5 s

Excitation voltage 18…28V DC 18…28V DC

Constant current excitation … 2…20 mA

Output impedance <150 Ω <150 Ω

Output bias voltage 10…12V DC 10…12V DC

Electrical isolation (case) > 10

Electrical protection 500V 500V

Physical

Size (hex x height) 25 x 30 x 35 mm 1 x 1.18 x 1.38 in

Weight, approx. 170 g 6.0 oz

Mounting thread

(4)

Mounting torque 8 N•m 6 ft•lb

Sensing element Ceramic

Sensing geometry Compression

Housing material Stainless Steel

Sealing Welded hermetic

Electrical connec tor Two-pin MIL-C-5015

Electrical connector position Side

Supplied Accessories

(5)

10.2 mV/(m/s2) 100 mV/g

2

±80 g

1.5…10 kHz 90…600,000 cpm

2

μm/s

50 μg

±1% ±1%

2

pk 5000 g pk

10

Ω> 10

10

Ω

M6 x 1 mm male 1/4-28 UNF male

1443-BLT-125-0

1443-BLT-125-M6

ICS-3 3 pt calibration

(1) S ensitivity tolerance is across the operating temperature range. Conversion factor 1 g = 9.81 m/s2.

(2) 1 Hz = 60 cpm (cycles per minute).

(3) Zero-based, le ast-squares, straight-line method.

(4) 1/4-28 UNF has no equivalent in metric units.

(5) ICS-3 3 pt calibration 10 Hz, 100 Hz, 1 kHz.

40 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 41

Figure 31 - Sensitivity Change vs. Frequency for the Accelerometer (Same for All 1443 Series)

1.46 in.

Figure 32 - 1443-ACC-IS-S Accelerometer

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 41

Page 42

1443 Series Accelerometers Specifications

Hall-effect Speed Sensor

The EK-44395 Hall-effect Speed Sensor outputs a TTL signal that is suitable for use as a direct speed input to the

Dynamix™ 1444-DYN04-01RA monitor.

The sensor can be used with any 3-wire accelerometer cable, which is listed inTab l e 2 6

Table 21 - EK-44395 Hall-effect Speed Sensor Specifications

Attribute Value

Frequency range Near 0…15 kHz

Power supply voltage 4.5…24V DC

Reverse voltage protection Up to -30V DC

Temperature range -40…+125 °C (-40…+257 °F)

TTL compatible logic 50% ± 30% duty cycle

Housing material 300 series stainless steel

Tar get air gap

01.27…0.508 mm (0.005…0.20 in.) With 20 diametric pitch gear

01.27…1.143 mm (0.005…0.45 in.) With 12 diametric pitch gear

01.27…1.524 mm (0.005…0.60 in.) With 28 diametric pitch gear

on page 51.

Sensor Certifications and Approvals

Table 22 - Sensor Certifications

Certification

Entity Parameters Ui = Vmax = 28V, Ii=lmax=93 mA, PI=0.65 W, CI=1.0 nF, Li=zero

Temperature, ambient, max. Hazardous Area - North America-55 °C…+110 °C (-67…+230 °F)

Temperature Codes For Div 1,2 Groups A-G

Cable Assemblies

For use with 1443-ACC-IS-S

and 1443-ACC-IS-T

Wiring Categor y

(1)

(When Product Is Marked) 1443-ACC-IS-S and 1443-ACC-IS-T

Hazardous Area - ATEX-55 °C…+110 °C (-67…+230 °F)

Hazardous Area - IECEx-55 °C…+110 °C (-67…+230 °F)

T4 (-55…+110 °C) (-67…+230 °F)

T6 (-55…+60 °C) (-67…+140 °F)

For Zone 20, Dust group IIIC

T130 °C (-55…+110 °C) (-67…+230 °F)

T80 °C (-55…+60 °C) (-67…+140 °F)

For Class I Zone 0 gas group IIC

T4 (-55…+110 °C) (-67…+230 °F)

ATEX and IECEx:

For Ex ia IIC

T4 (-55…+110 °C) (-67…+230 °F)

T6 (-55…+60 °C) (-67…+140 °F)

For Ex ia IIIC

T130 °C (-55…+110 °C) (-67…+230 °F)

T80 °C (-55…+60 °C) (-67…+140 °F)

1443-CBL-MS2IBC

1443 -CBL-MS2IBC-50A - tighten to 4 N•m (2.95 lb•ft) , temperature range: -40…+100 °C (-40…+212 °F)

1443-CBL-MS2IBC - rated IP66

1443-CBL-MS2GBC - push on connection, temperature range: -50…+110 °C (-58…+230 °F)

1443-CBL-MS2GBC - rated IP68

1443-CBL must conform with Rockwell Automation® Environmental Specification 970-20-01

(2)

2 - on shielded signal ports

42 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 43

Table 22 - Sensor Certifications (Continued)

Ex European Union 94/9/EC ATEX Directive, compliant with:

EN 60079-0:2010+A11:2013; General Requirements

EN 60079-11:2012 Explosive Atmospheres, Protection `i’

I M1 Ex ia I Ma -55 °C<Ta<+110 °C (-67…+230 °F)

II 1 G Ex ia IIC T4 Ga -55 °C <Ta<+110 °C (-67…+230 °F)

II 1 G Ex ia IIC T6 Ga -55 °C <Ta<+60 °C (-67…+140 °F)

II 1 D Ex ia IIIC T130°C IP65 Da -55 °C <Ta<+110 °C (-67…+230 °F)

II 1 D Ex ia IIIC T80°C IP65 Da -55 °C <Ta<+60 °C (-67…+140 °F)

Baseefa15ATEX0101X

Baseefa15ATEX0100

IECEx IECEx System, compliant with:

IEC 60079-0:2011 Edition 6; General Requirements

IEC 60079-11:2011 Edition 6; Explosive Atmospheres, Protection `i‘

Ex ia I Ma -55 °C<Ta<+110 °C (-67…+230 °F)

Ex ia IIC T4 Ga -55 °C<Ta<+110 °C (-67…+230 °F)

Ex ia IIC T6 Ga -55 °C<Ta<+60 °C (-67…+140 °F)

Ex ia IIIC T130°C IP65 Da -55 °C <Ta<+110 °C (-67…+230 °F)

Ex ia IIIC T80°C IP65 Da -55 °C <Ta<+60 °C (-67…+140 °F)

IECEx BAS 15.0073X

IECEx BAS 15.0072

c-SGS-us SGS Certified Process Control Equipment for Class I, Zone 0

Hazardous Locations, which are certified for US and Canada. See SGS File USTC/15/FAI/01350

AEx, ia, IIC, T4, Ga, -55°C…+110 °C (-67…+230 °F)

c-SGS-us SGS Certified Process Control Equipment for Zone 20

Hazardous Locations, which are certified for US and Canada. See SGS File USTC/15/FAI/01350

AEx, ia, IIIC, T130°C, IP65, Da, -55 °C…+110 °C

AEx, ia, IIIC, T80°C, IP65, Da, -55 °C…+60 °C

c-SGS-us SGS Certified Process Control Equipment for Class I, II, III Division 1, 2 Group A-G

Hazardous Locations, which are certified for US and Canada. See SGS File USTC/15/FAI/01350

T4, -55 °C…+110 °C, IP65

T6, -55 °C…+60 °C

(1) See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other certification details.

(2) Use this conductor c ategory information to plan conduc tor routing. See Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

1443 Series Accelerometers Specifications

.

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 43

Page 44

1443 Series Accelerometers Specifications

Accessories

This section describes the accessories that are available for the sensors.

Cables

These cables are available for the two-pin sensors.

Table 23 - Cables for Two-pin Sensors

Catalog Number Description

1443-CBL-MS2IBC-16S 16 ft of silicone twisted shielded pair cable w/ molded 2-pin mil connector and terminated to blunt cut, shield isolated from the connector

1443-CBL-MS2IBC-32S 32 ft of silicone twisted shielded pair cable w/ molded 2-pin mil connector and terminated to blunt cut, shield isolated from the connector

1443-CBL-MS2IBC-64S 64 ft of silicone twisted shielded pair cable w/ molded 2-pin mil connector and terminated to blunt cut, shield isolated from the connector

1443-CBL-MS2GBC-16S 16 ft of silicone twisted shielded pair cable w/ molded 2-pin mil connector and terminated to blunt cut, shield grounded to the connector

1443-CBL-MS2GBC-32S 32 ft of silicone twisted shielded pair cable w/ molded 2-pin mil connector and terminated to blunt cut, shield grounded to the connector

1443-CBL-MS2GBC-64S 64 ft of silicone twisted shielded pair cable w/ molded 2-pin mil connector and terminated to blunt cut, shield grounded to the connector

1443 -CBL-MS2IBC-50A 50 ft of stainless steel armored jacket over polyurethane twisted shielded pair cable w/ 2-pin mil (AM) connector and terminated to blunt cut,

shield isolated from the connector

(1) Cables with the shield that is grounded to the connector are non-standard. See Shield Wire Isolation Sensor and Cable Selection on page 8 before ordering.

(1)

(1)

(1)

TIP Before selecting a `GBC’ version cable, see Shield Wire Isolation Sensor and Cable Selection on page 8.

44 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 45

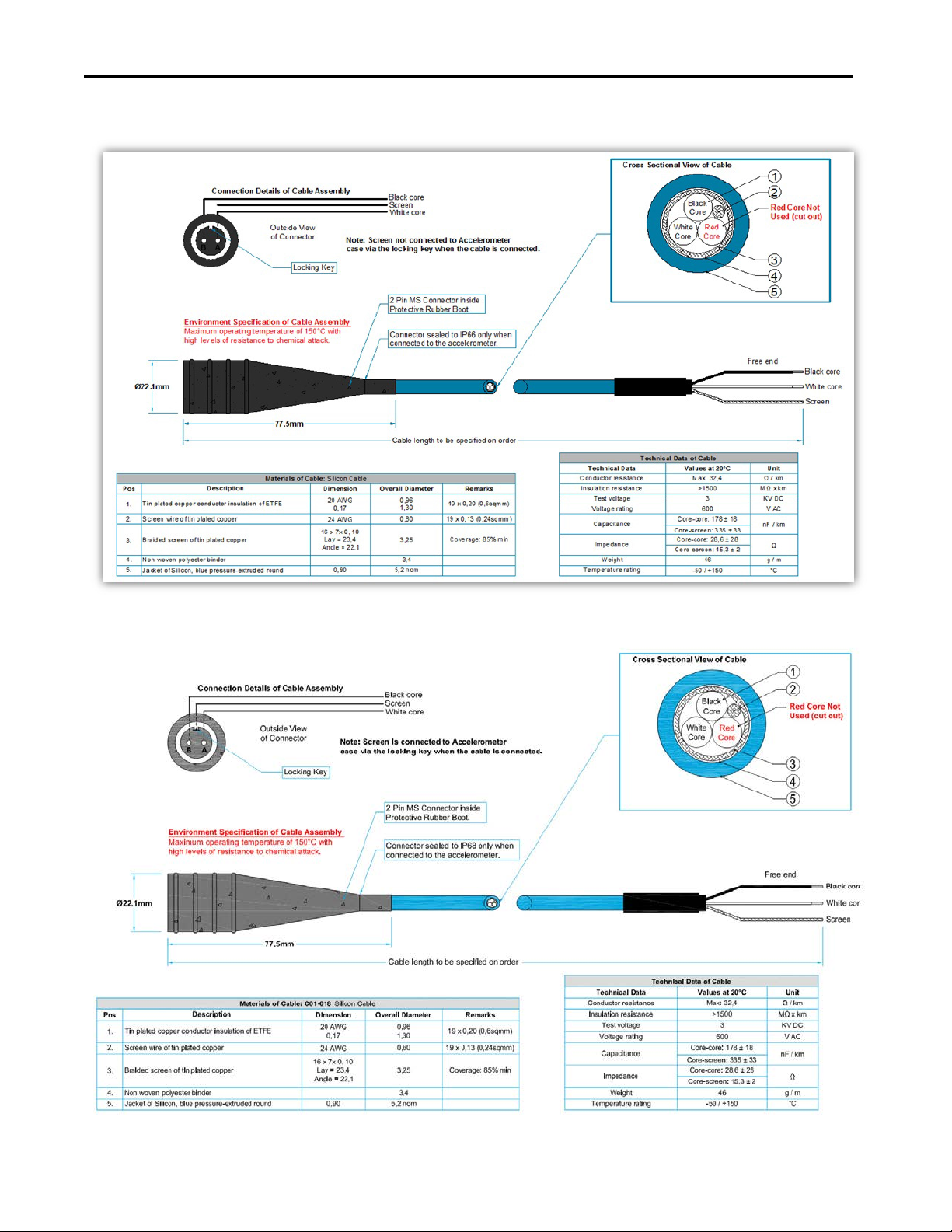

Figure 33 - 1443-CBL-MS2IBC

1443 Series Accelerometers Specifications

Figure 34 - 1443-CBL-MS2GBC

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 45

Page 46

1443 Series Accelerometers Specifications

Figure 35 - 1443 -MS2IBC-50A

46 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 47

1443 Series Accelerometers Specifications

Table 24 - Cables for Three-pin Sensors

Catalog Number Description

1443-CBL-BC3BC-500 Bulk spool of 500 ft of silicone t wisted shielded 3-conductor cable

1443-CBL-MS3IBC-16S 16 ft of silicone twisted shielded 3-conductor cable w/ molded 3-pin mil connector and terminated to blunt cut, shield

isolated from the connector

1443-CBL-MS3IBC-64S 64 ft of silicone twisted shielded 3-conductor cable w/ molded 3-pin mil connector and terminated to blunt cut, shield

isolated from the connector

1443-CBL-MS3IBC-112S 112 ft of silicone twisted shielded 3-conductor cable w/ molded 3-pin mil connector and terminated to blunt cut, shield

isolated from the connector

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 47

Page 48

1443 Series Accelerometers Specifications

Figure 36 - 1443-CBL-BC3BC-500

Figure 37 - 1443-CBL-MS3IBC (All Lengths)

48 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 49

Table 25 - Adapter Cables

Catalog Number Description

1443-CBL-MSILM-6 Coiled data collector sensor cable, Two-pin ms to lemo, top

1443-CBL-MSILM-50 50 ft, data collector balancing cable, Two-pin ms to lemo, top

1443-CBL-LMBNC-1 1 foot, lemo to BNC adapter

Figure 38 - 1443-CBL-MSILM-6

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 49

Page 50

1443 Series Accelerometers Specifications

Figure 39 - 1443-CBL-MSILM-50

Figure 40 - 1443-CBL-LMBNC-1

50 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 51

Connectors

Table 26 - Connectors

Catalog Number Description

1443-CON-MS2-SP Qty 5: silicon boot, splash proof, push on: Two-pin ms, top exit

1443-CON-MS3-SP Qty 5: silicon boot, splash proof, push on: Three-pin ms, top exit

Figure 41 - 1443-CON-MS2-SP & 1443-CON-MS3-SP

Mounting Accessories

Table 27 - Mounting Accessories

Catalog Number Description

1443-MAG-075C-14

1443-MAG-075F-15

1443-MAG-100C-35

1443-MAG-100F-35

1443-MAG-150C-55

1443-MAG-150F-50

1443-STD-0-0 Mounting Stud - 1/4-28 to 1/4-28

1443-STD-0-M8 Mounting Stud - 1/4-28 to M8

1443-BLT-125-M6 Through bolt - M6

1443-BLT-125-0 Through bolt - 1/4-28

1443-PRB-40 Probe tip 4" length, 1/2” hex tapered to point (1/4-28)

1443-PRB-90 Probe tip 9" length with 1/4-28 stud, aluminum

1443-PAD-075-0 Mounting pad 1/4-28

(1) Magnet material: Neodymium-Iron-Boron (NdFeB)

(1)

(1)

(1)

(1)

(1)

(1)

3/4” diameter curved-surface magnet (14 lb pull, 1/4-28)

3/4” diameter flat-surface magnet (15 lb pull, 1/4-28)

1" diameter curved-surface magnet (35 lb pull, 1/4-28)

1" diameter flat-surface magnet (35 lb pull, 1/4-28)

1"-1/2” diameter curved-surface magnet (55 lb pull, 1/4-28)

1"-1/2” diameter flat-surface magnet (50 lb pull, 1/4-28)

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 51

Page 52

1443 Series Accelerometers Specifications

Figure 42 - 1443-MAG (Representative of All Sizes)—Left: Curved Surface, Right: Flat Surface

Figure 43 - 1443-STD-0-0

Figure 44 - 1443-STD-0-M8

TIP Through bolt cannot be used with EK 9000 Series side exit sensors.

52 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 53

Figure 45 - 1443-BLT-125-0

PNPN-

Figure 46 - 1443-BLT-125-M6

1443 Series Accelerometers Specifications

Figure 47 - 1443-PRB-40 / 1443-PRB-90

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 53

Page 54

1443 Series Accelerometers Specifications

Figure 48 - 1443-PAD

Spot-face Tool Kits

Table 28 - Accessory Spot-face Tool Kit

Catalog Number Description

1443-SFT-125-0 Spot-face tool kit for sensor mounting, 1.25" diameter, 1/4-28 pilot, two drill Bits, three taps, tap wrench, hex key, case

1443-SFT-125-M6 Spot-face tool kit for sensor mounting, M6 pilot, two drill Bits, three taps, tap wrench, hex key, case

1443-SFT-125-M8 Spot-face tool kit for sensor mounting, M8 pilot, two drill Bits, three taps, tap wrench, hex key, case

Figure 49 - 1443-SFT-125 (Representative for All)

54 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 55

1443 Series Accelerometers Specifications

Data Collector Sensor Kit

Table 29 - Data Collector Sensor Kit

Catalog Number Description

1443-KIT-DATACLTR0 Includes one 1443-ACC-GP-T Accelerometer, one 1443-CBL-MSILM-6 coiled cable, one 1443-MAG-075F-15 magnet mount

EK 9000 Series Compatibility

1443 Series cables and accessories are compatible with EK 9000 Series sensors except for the side exist sensor through

bolts. Through bolts 1443-BLT-125-M6 and 1443-BLT-125-0 cannot be used with EK 9000 Series sensors.

• For cables, make sure to choose the same type of cable, two pin or three pin, shield isolated (all EK 9000 Series

cables are shield isolated) cable.

• For mounting accessories, make sure to match the thread size.

See the Sensor Cross-reference - 1443 Series (New) to 9000 Series (Old)

sensors.

on page 56, to identify equivalent 1443 Series

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 55

Page 56

1443 Series Accelerometers Specifications

Sensor Cross-reference - 1443 Series (New) to 9000 Series (Old)

The EK Series sensor line is marked Rockwell Automation®. They are legacy products from Entek. The current sensors

are sourced from PCB/IMI in the U.S. Earlier versions of the same sensors were sourced from Wilcoxon Research or were

manufactured by IRD.

The 1443 Series are Allen-Bradley® branded products that are sourced from Hansford Sensors in the UK.

This project simplifies the offering from about 58 EK catalogs, including 26 sensors, to a total of 47 catalogs and just 14

sensors.

TIP The 1443 Series exclude specialty high temperature sensors or proportional output (4-20 mA) “process” sensors. These

capabilities are no longer offered.

Table 30 - Sensor Cross-reference - 1443 Series (New) to 9000 Series (Old)

Sensor Class Catalog Number Replaces

General-purpose 1443-ACC-GP-T EK-43781I

EK-43784I

EK-43792I

1443-ACC-GP-S EK-47086I

EK-47090I

1443-ACC-GP-T16-SI EK-43782I

EK-46255I

1443-ACC-GP-T32-SI EK-43782I

EK-46255I

1443-ACC-GP-T16-SC New

New

1443-ACC-GP-T32-SC New

New

Low Frequency 1443-ACC-LF-T EK-43794I

EK-43795I

EK-43797I

EK-43798I

High Frequency 1443-ACC-HF-T EK-43799I

EK-43800I

Velocity 1443-ACC-VO-T EK-43808I

1443-ACC-VO-S EK-43809I

Hazardous Area 1443-ACC-IS-T EK-43786I

EK-43787

1443-ACC-IS-S EK-43790I

EK-43791I

EK-48965

Accel and Temp 1443-ACC-AT-T New

1443-ACC-AT-S EK-43811I

56 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 57

Table 30 - Sensor Cross-reference - 1443 Series (New) to 9000 Series (Old) (Continued)

Sensor Class Catalog Number Replaces

Cable 1443-CBL-MS2IBC-16S EK-46800I

EK-44134

1443-CBL-MS2IBC-32S EK-46801I

EK-44135

1443-CBL-MS2IBC-64S EK-46802I

EK-44136

1443-CBL-MS3IBC-112S EK-46806I

1443-CBL-MSGBC-16S New

1443-CBL-MSGBC-32S New

1443-CBL-MSGBC-64S New

1443 -CBL-MSIBC-50A New

1443-CBL-BCBC-500 New

1443-CBL-MSILM-6 EK-36960-C-006

EK-36960-S-005

EK-47787

1443-CBL-MSILM-50 EK-36960-S-050

1443-CBL-LMBNC-1 EK-46252

EK-47021

Connector 1443-CON-MS2-SP EK-44144

1443-CON-MS3-SP New

Tool 1443-SFT-125-0 EK-42053

1443-SFT-125-M6 New

1443-SFT-125-M8 New

Kit 1443-KIT-DATACLTR0 EK-45148

1443 Series Accelerometers Specifications

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 57

Page 58

1443 Series Accelerometers Specifications

Table 30 - Sensor Cross-reference - 1443 Series (New) to 9000 Series (Old) (Continued)

Sensor Class Catalog Number Replaces

Mounting 1443-MAG-075C-14 EK-46670

EK-44162

EK-42118

1443-MAG-075F-15 EK-42120

1443-MAG-100C-35 EK-41717

1443-MAG-100F-35 EK-42121

1443-MAG-150C-55 EK-41529

EK-42119

EK-04332

1443-MAG-150F-50 EK-24746

EK-42123

1443-STD-0-0 EK-44151

EK-44152

EK-44153

1443-STD-0-M8 EK-44154

EK-44155

1443-BLT-125-M6 New

1443-BLT-125-0 New

1443-PRB-40 EK-41530

1443-PRB-90 EK-01103

EK-41915

1443-PAD-075-0 EK-44156

You cannot replace all EK sensors with a 1443 Series sensor. The sensors that are listed in this table are no longer offered.

Table 31 - Discontinued EK Sensors

Catalog Number Description

EK-46496 9150HTA High Temperature Accelerometer

EK-48958 9842V Process Accelerometer

EK-48964 9842VCRT Hazardous Process Accelerometer

EK-43805I 9100T High Temperature Accelerometer

EK-43807I 9150HT High Temperature Accelerometer

58 Rockwell Automation Publication 1443-TD001D-EN-P - March 2019

Page 59

1443 Series Accelerometers Specifications

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation®.

Resource Description

Dynamix™ 1443 Series Sensors Product Information, publication 1443-PC001

Dynamix™ 1443 Series Sensors User Manual, publication 1443-UM001

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation® industrial system.

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification details.

Included with hazardous area rated sensors, provides basic environmental, ratings,

and mounting information.

Provides complete information for mounting and cabling 1443 Series sensors.

You can view or download publications at http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation® sales representative.

Rockwell Automation Publication 1443-TD001D-EN-P - March 2019 59

Page 60

Rockwell Automation Support

Use the following resources to access support information.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete the

How Are We Doing? form at http://literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdf

.

Technical Support Center

Knowledgebase Articles, How-to Videos, FAQs, Chat,

User Forums, and Product Notification Updates.

www.rockwellautomation.com/knowledgebase

Local Technical Support Phone Numbers

Locate the phone number for your country. www.rockwellautomation.com/global/support/get-support-

now.page

Direct Dial Codes

Find the Direct Dial Code for your product. Use the

code to route your c all directly to a techni cal support

engineer.

www.rockwellautomation.com/global/suppor t/directdial.page

Literature Library

Installation Instructions, Manuals, Brochures, and

Technical Data.

www.rockwellautomation.com/literature

Product Compatibility and Download Center

(PCDC)

Get help determining how products interact, check

features and capabilities, and find associated

firmware.

www.rockwellautomation.com/global/support/pcdc.page

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation maintains current product environmental information on its webs ite at http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page.

Allen-Bradley, Dynamix, LISTEN. THINK. SOLVE., Rockwell Automation, and Rockwell Software are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Publication 1443-TD001D-EN-P - March 2019

Supersedes Publication 1443-TD001C-EN-P - June 2017 Copyright © 2019 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...