Page 1

User Manual

1442 Eddy Current Probe System

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated

Information

Temperature ranges and wire sizes were corrected as appropriate in this manual.

Top ic Pag e

Corrected temperature range 13, 17

Added Speed Measurements section and relocated speed measurement figure 16

Corrected wire size 37, 51

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 5

Table of Contents

Preface

Installation

Measurement Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Configuration Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Driver Installation Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sensor Installation Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Extension Cable Installation Environment . . . . . . . . . . . . . . . . . . . . . 17

Outer Dimensions and Part Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . 17

1442 Sensor Outer Dimensions and Part Nomenclature . . . . . . . . . 17

Extension Cable Outer Dimensions and Part Nomenclature . . . . . 22

Driver Outer Dimensions and Part Nomenclature . . . . . . . . . . . . . . 24

Install the Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mount the Driver on the Housing or Panel . . . . . . . . . . . . . . . . . . . . . 25

Mount the Driver to a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install the Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Use a Sensor Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Use a Stinger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Adjust the Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connect the Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connect the Extension Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connect the Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connect the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Verify the Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Set Gap Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Recommended Specifications for the Monitor Cable . . . . . . . . . . . . . . . . 37

Maintenance and Inspection

Individual Characteristic Data

Chapter 2

Periodic Inspection Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Unit Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshoot the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 3

Characteristic Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Standard Static Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Sensor Temperature Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Driver Temperature Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Static Characteristic Effect Due to Power Source Voltage Variation .

44

Static Characteristic Effect by Target Material . . . . . . . . . . . . . . . . . . 45

Static Characteristic Effect Due to Target Diameter. . . . . . . . . . . . . 46

Static Effect by Target Curved Surface . . . . . . . . . . . . . . . . . . . . . . . . . 47

Static Characteristic Effect Due to Target End Face . . . . . . . . . . . . . 48

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 5

Page 6

Table of Contents

Static Characteristic Effect Due to Side Wall. . . . . . . . . . . . . . . . . . . . 49

Frequency Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Appendix A

Wire the Unit to a Monitor System

Index

Cable Wiring/Laying Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 7

Preface

This manual describes how to install and use the 1442 Series Eddy Current Probe

System.

The 1442 Series eddy current probe system performs non-contact measurement

of the distance between the sensor and the measured object (target), and outputs

a proportional voltage signal. The static component of the measurement is the

"gap," the absolute (DC) distance from the target surface to the probe tip. The

dynamic component of the measurement is the "vibration," the cyclical (AC)

movement of the target toward and away from the probe.

By combining this system with an Allen-Bradley® 1440 or 1444 Series

measurement module, you can measure the vibration of a rotating shaft, its

eccentricity, thrust position and rotating speed. The system is used for

continuous measurement or monitoring of shafts rotating at high speeds, such as

turbines, generators, and compressors.

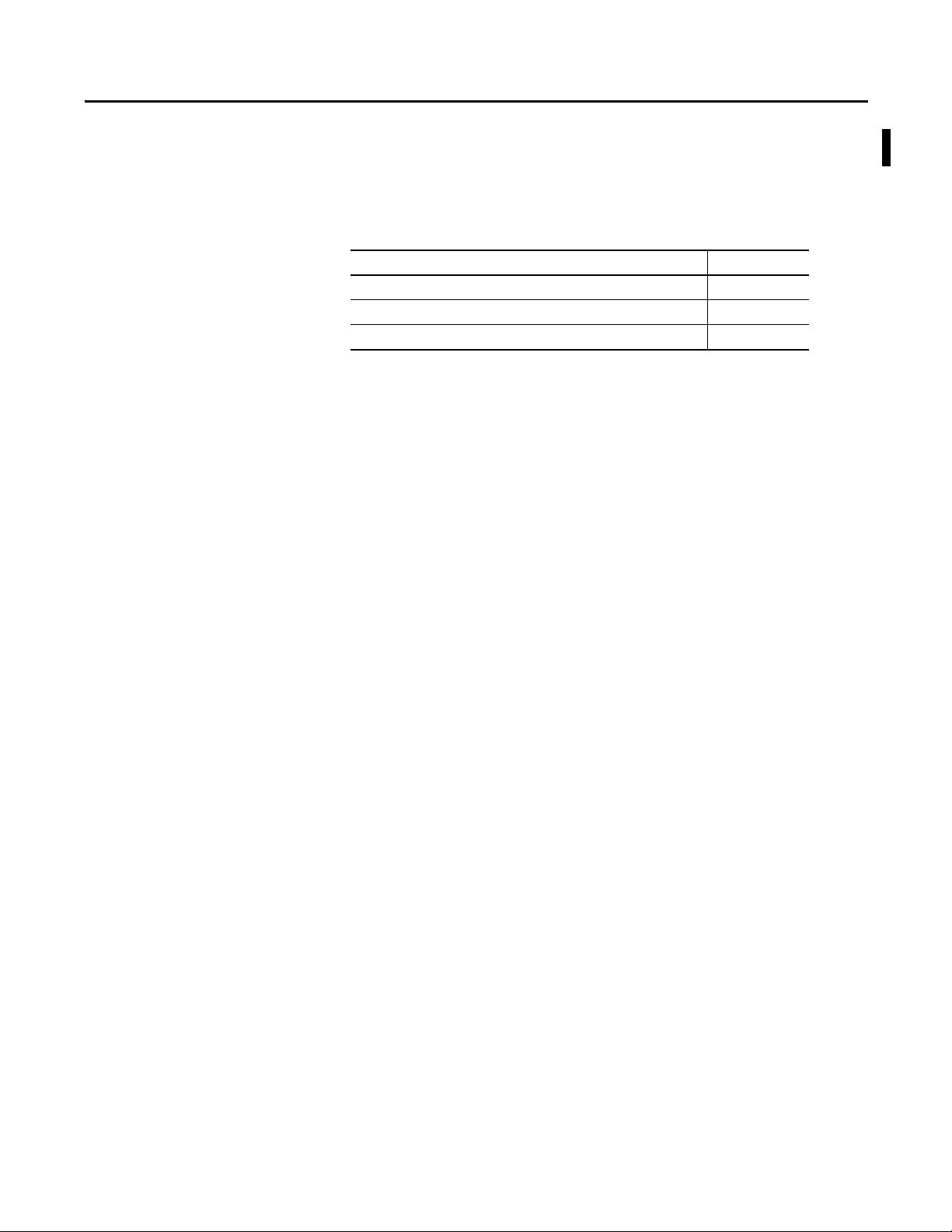

Measurement Principles

The gap between the sensor and the target is found according to the following

principles:

• When an approximately 1 MHz high frequency current is supplied from

the oscillator to the sensor, a high frequency magnetic field is created at the

sensor tip.

• The inter-linkage of the high frequency magnetic flux on the target

induces an eddy current that flows on the target surface.

• When the eddy current flows on the target surface, a magnetic field is

created at the target side, and the sensor impedance changes.

• When this change in output of the oscillator is detected, the distance

versus output voltage is made linear by a linearizer circuit, and the result is

output.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 7

Page 8

Preface

IMPORTANT

You can find the gap between the sensor and the target by measuring the sensor

impedance if the following relationships are identified:

• Relationship between the sensor and the target gap.

• Relationship of the sensor impedance.

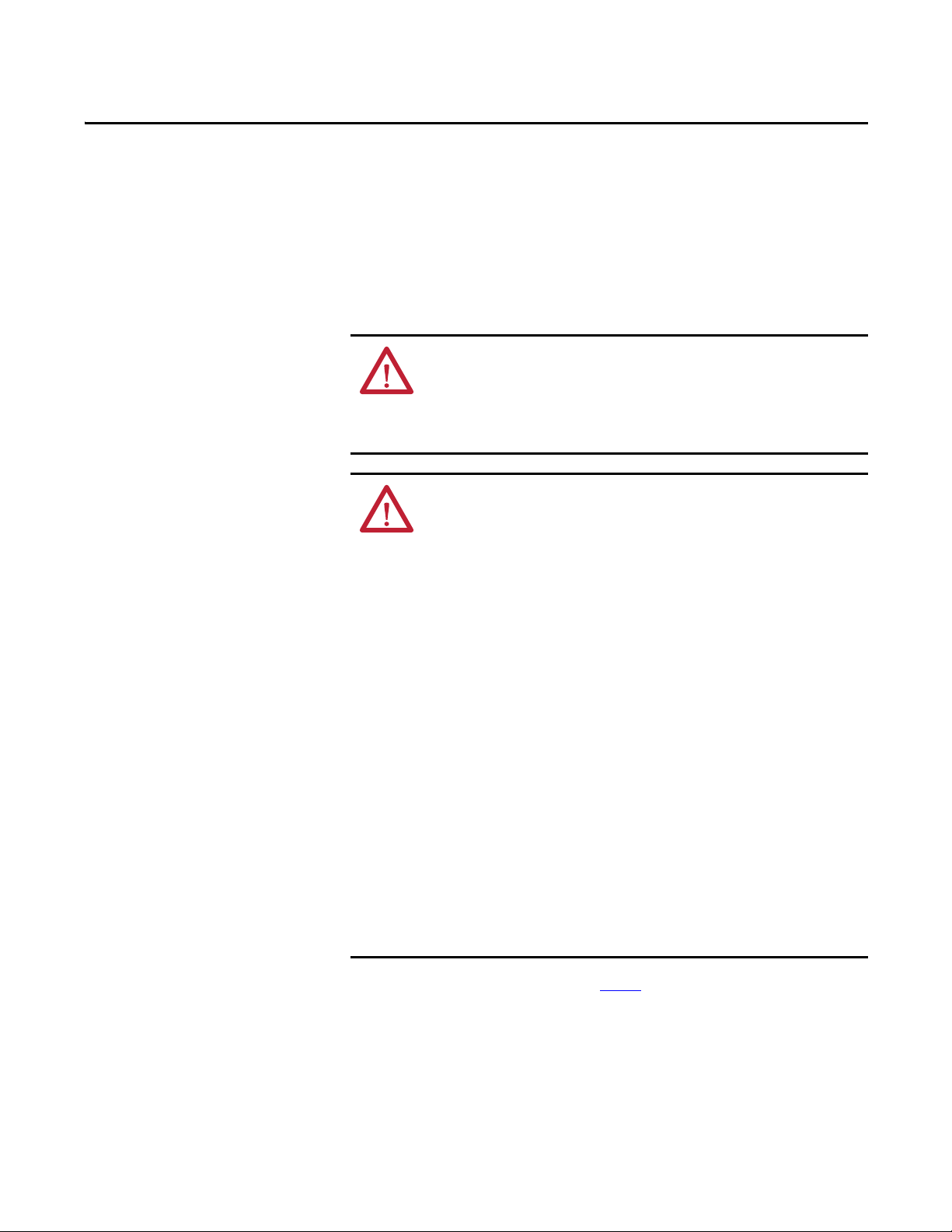

System Configuration Example

This system is designed to fulfill the specifications when used under the following

configuration.

Always combine the components of this system (sensor, extension cable,

and driver) to configure it as follows. If this system is not configured as

shown below, or if the 1442 extension cable is not used in combining the

1442 sensor and driver, the output characteristics will differ dramatically.

Figure 1 - System Configuration Example

Sensor Extension Cable System Cable Length Driver

0.5 m (1.64 ft) + 4.5 m (14.76 ft) = 5.0 m (16.40 ft) → 1442-DR-xx50

1.0 m (3.28 ft) + 4.0 m (13.12 ft) = 5.0 m (16.40 ft) → 1442-DR-xx50

0.5 m (1.64 ft) + 8.5 m (27.89 ft) = 9.0 m (29.53 ft) → 1442-DR-xx90

1.0 m (3.28 ft) + 8.0 m (26.25 ft) = 9.0 m (29.53 ft) → 1442-DR-xx90

(1)

(1) Where xx = appropriate code for probe size.

8 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 9

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

1442 Eddy Current Probe Systems Specifications Technical Data, publication 1442-TD001. Provides specifications for the 1442 Eddy Current Probe System.

Turbine Supervisory Instrumentation System Selection Guide, publication GMSI10-

SG002.

Provides details to help you choose a Turbine Supervisory Instrumentation system.

You can view or download Rockwell Automation publications at http://

www.rockwellautomation.com/literature. To order paper copies of technical

documentation, contact your local Allen-Bradley distributor or Rockwell

Automation sales representative.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 9

Page 10

Preface

Notes:

10 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 11

Chapter 1

TIP

Installation

This chapter describes how to install a 1442 Series Eddy Current Probe System.

ATTENTION: Always ground the system. Never apply power until all

wiring work and connection work has been completed. If this is not

followed, there is a possibility of electrocution.

Installation work, wiring, and connections must be performed by a person

with knowledge in instrumentation.

ATTENTION: Be sure to adhere to the following guidelines:

• Before touching this unit, be sure to touch a metal section near by to

discharge any static electricity. The device can be damaged if exposed to

static electricity from a person’s body.

• Before applying power, make sure that all wiring is properly connected.

There is a possibility of damage to the unit and fire if improperly

connected.

• Install this unit away from motors and relays.

• Install the input/output signal cables away from power system and

control system cables. Noise occurring from the motor or relay can

adversely affect the measurement value. We recommend using separate

wiring ducts.

• Do not pull or bend the sensor cables and extension cables with

excessive force. The conductor in the cable can get cut off.

• The allowable tension of the sensor cables and extension cables is

98.1 N•m (10 kgf•m). The allowable bend radius is as follows:

– Without armored cable: 30 mm (1.18 in.)

– With armored cable: 50 mm (1.97 in.)

• After completing the installation, make sure all connections are correct

and tight before powering the system.

Refer to Appendix A on page 51 for recommended cable wiring, and

installation methods.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 11

Page 12

Chapter 1 Installation

60 mm (2.4 in.)

Installation Environment

Driver Installation Environment

Install the driver in a location that satisfies the following environmental and

installation conditions.

Environmental Conditions

Feature Specification

Ambient temperature Must be in a range of -30…80 °C (-22…176 °F) when devices are operating.

Ambient humidity Must be in a range of 30…95% RH (noncondensing) when devices are operating.

Vibration condition Must be 10 m/s

Air cleanliness We recommend an air dust-particle amount of 0.2 mg/m3 or less.

We recommend an especially low amount of corrosive gasses, such as hydrogen

sulfide, NOx gas, and chlorine, and conductive particles, such as iron dust and

carbon. The allowable amounts of hydrogen sulfide and NOx gas, based on JEIDA29 (1979) Class S1, are shown below.

JEIDA: Japanese Electronic Industry Development Association

2

(1 g) or less at 10…150 Hz.

JEIDA-29 (1979) CLASS S1

Hydrogen sulfide: 0.01 ppm or less, NOx gas: 0.05 ppm or less

(Ambient temperature: 25 °C ± 5 °C (77 °F ± 9 °F), humidity: 40…80%

RH)

Install Conditions

• If there are walls or other obstacles at the cable connection surface of the

driver, make sure to keep spacing as illustrated below. Take care not to bend

the cable excessively.

12 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 13

Installation Chapter 1

• Do not locate above heat emitting objects.

Sensor Installation Environment

Install the sensor at a location that satisfies the following environmental and

installation conditions.

Environmental Conditions

Feature Specification

Ambient temperature ATEX applications must be in a range of -35…80 °C (-31…176 °F) when devices

Ambient humidity Must be in a range of 30…95% RH (noncondensing) when devices are operating.

Vibrational conditions Must be 10 m/s

Air cleanliness We recommend an air dust-particle amount of 0.2 mg/m3 or less.

are operating.

CSA applications must be in a range of -35…85 °C (-31…185 °F) when devices

are operating.

Other applications must be in a range of -35…177 °C (-31…350 °F) when devices

are operating

2

measurement cannot be made.)

We recommend an especially low amount of corrosive gasses, such as hydrogen

sulfide, NOx gas, and chlorine, and conductive particles, such as iron dust and

carbon. The allowable amount sof hydrogen sulfide and NOx gas, based on JEIDA29 (1979) Class S1, are shown below.

JEIDA: Japanese Electronic Industry Development Association

(1 g) or less at 10…150 Hz. (If the sensor vibrates, an accurate

JEIDA-29 (1979) CLASS S1

Hydrogen sulfide: 0.01 ppm or less, NOx gas: 0.05 ppm or less

(Ambient temperature: 25 °C ± 5 °C (77 °F ± 9 °F), humidity: 40…80%

RH)

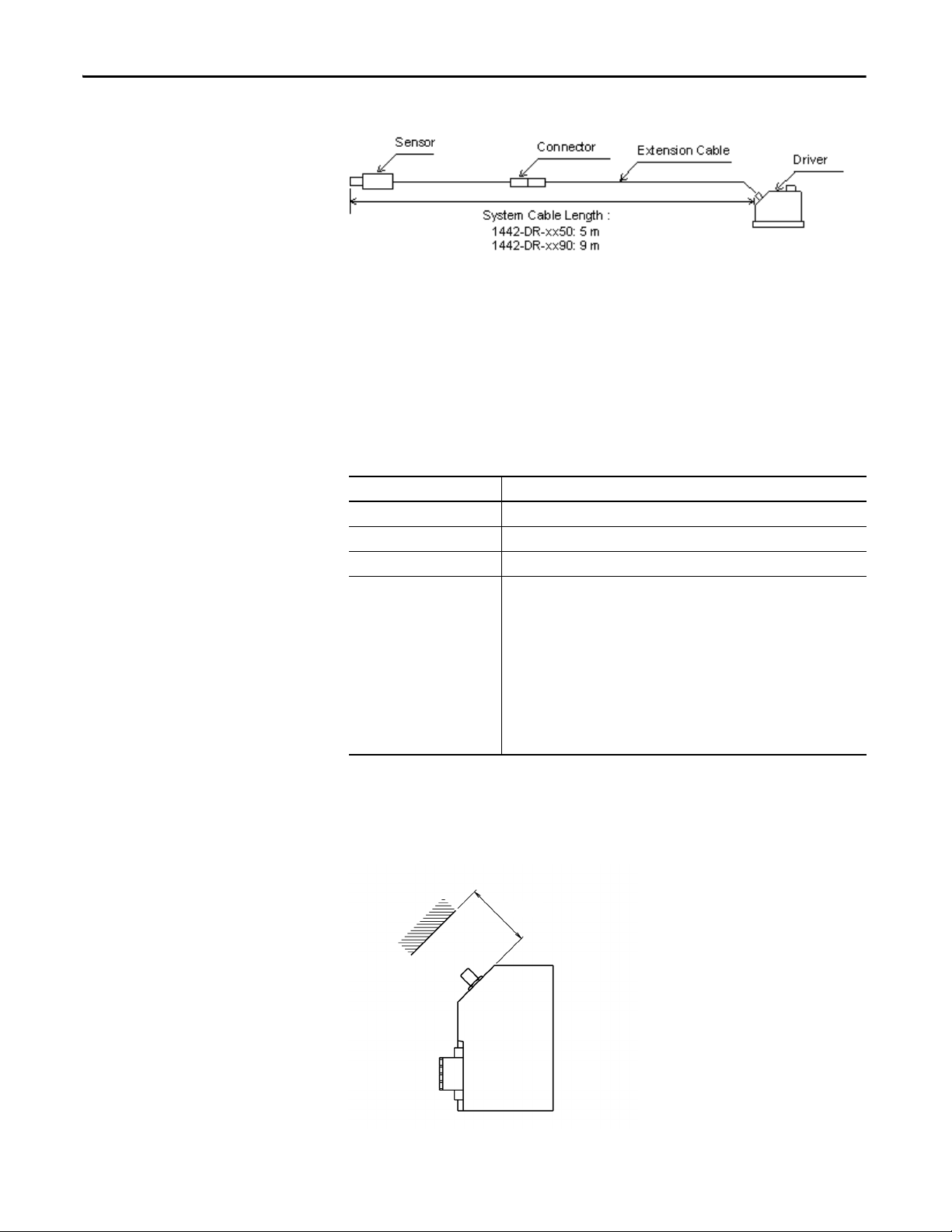

Installation Conditions

• Do not install at a location exposed to rain or other moisture. Moisture can

lead to reduced sensitivity of the sensor, and reduced insulation.

• A target surface area of not less than three times the tip diameter centered

on the sensor is required, as illustrated below.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 13

Page 14

Chapter 1 Installation

40 mm (1.57 in.) or more

40 mm (1.57 in.) or more

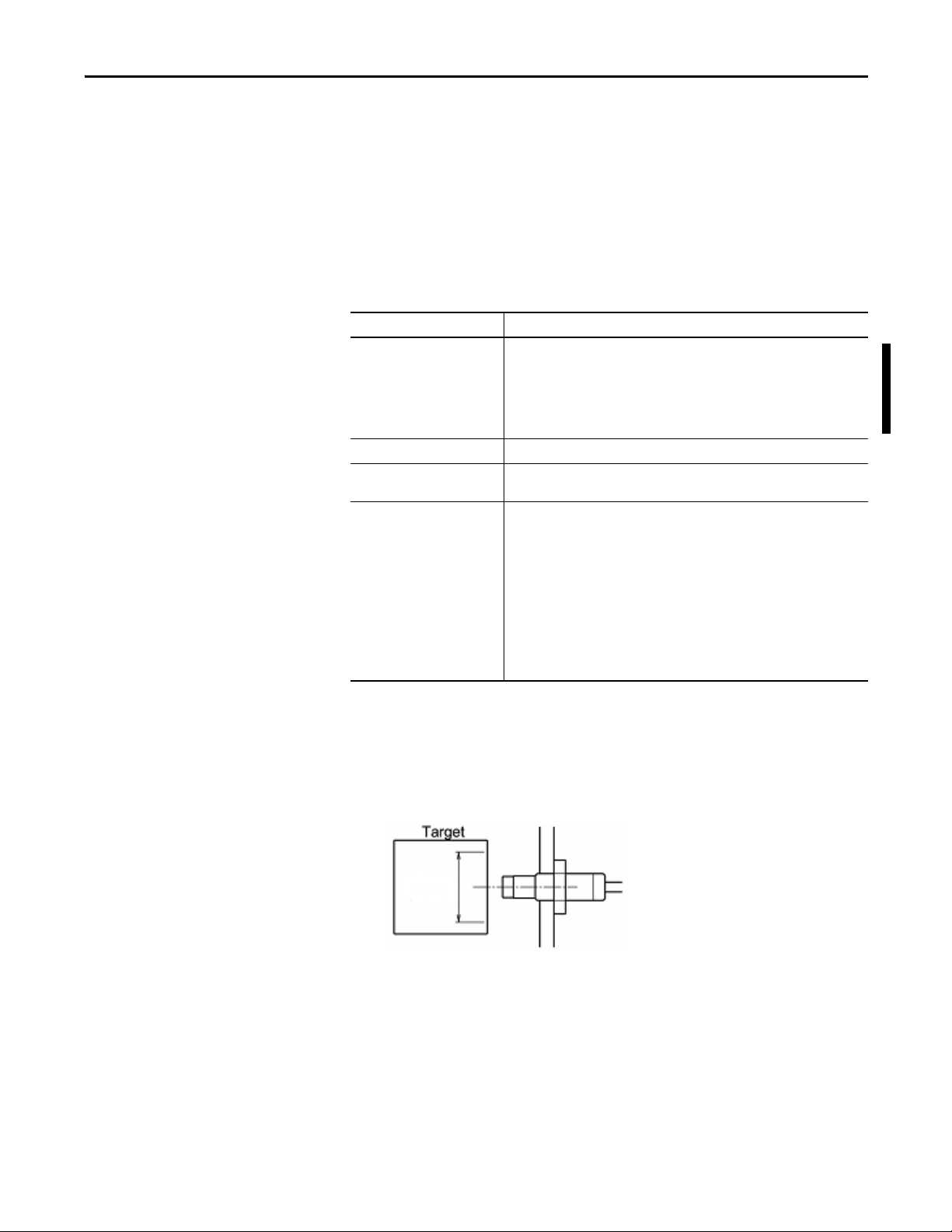

• When placing other sensors next to each other, separate the sensor tops by

not less than 10 times the sensor tip diameter to prevent interference.

• The sensor must be installed on a surface with adequate rigidity that is not

affected by an outside vibration. If the sensor vibrates, an accurate

measurement cannot be taken.

• For shapes and dimensions around the sensor, refer to the installation

examples (1…3) below. If a piece of metal other than the target is near the

sensor, an accurate reading cannot be taken.

If it is unavoidable to install the sensor as illustrated in examples 4…7,

check the characteristics at the attachment completed conditions.

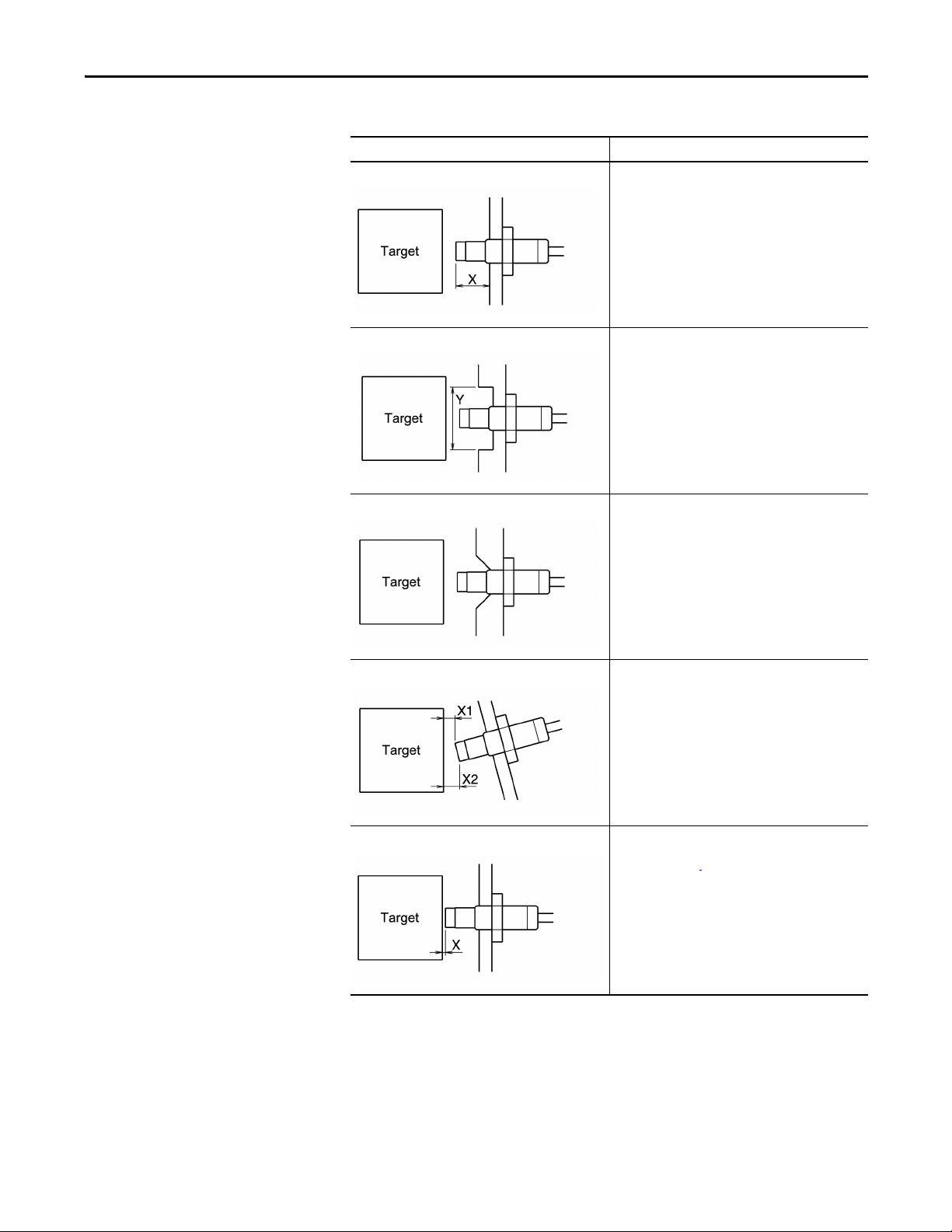

Table 1 - Installation Examples

Example Description

Example 1 (most recommended) Dimension X is to be not less than 1.2 times the tip

Example 2 (recommended) Dimension X is to be not less than 1.2 times the tip

Example 3 (recommended) After constructing as shown in example 2, the area shown

diameter.

diameter

Dimension Y is to be not less than 3 times the tip

diameter.

by the shaded line in the illustration is filled with resin or

other insulating material.

14 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 15

Installation Chapter 1

Table 1 - Installation Examples

Example Description

Example 4 If dimension X is less than 1.2 times the tip diameter, the

measurement will be affected by the attachment plate.

Example 5 If dimension Y is less than 3 times the tip diameter, the

Example 6 If the attachment plate around the sensor top is

Example 7 If the target and the sensor top are not parallel

measurement will be affected by the attachment plate.

chamfered, it will be affected by the attachment plate.

(dimension X1 and X2 are not the same), it will affect the

reading.

Example 8 If dimension X is less than the minimum linear range from

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 15

sensor tip specification for the sensor, the measurement

will not be accurate.

Page 16

Chapter 1 Installation

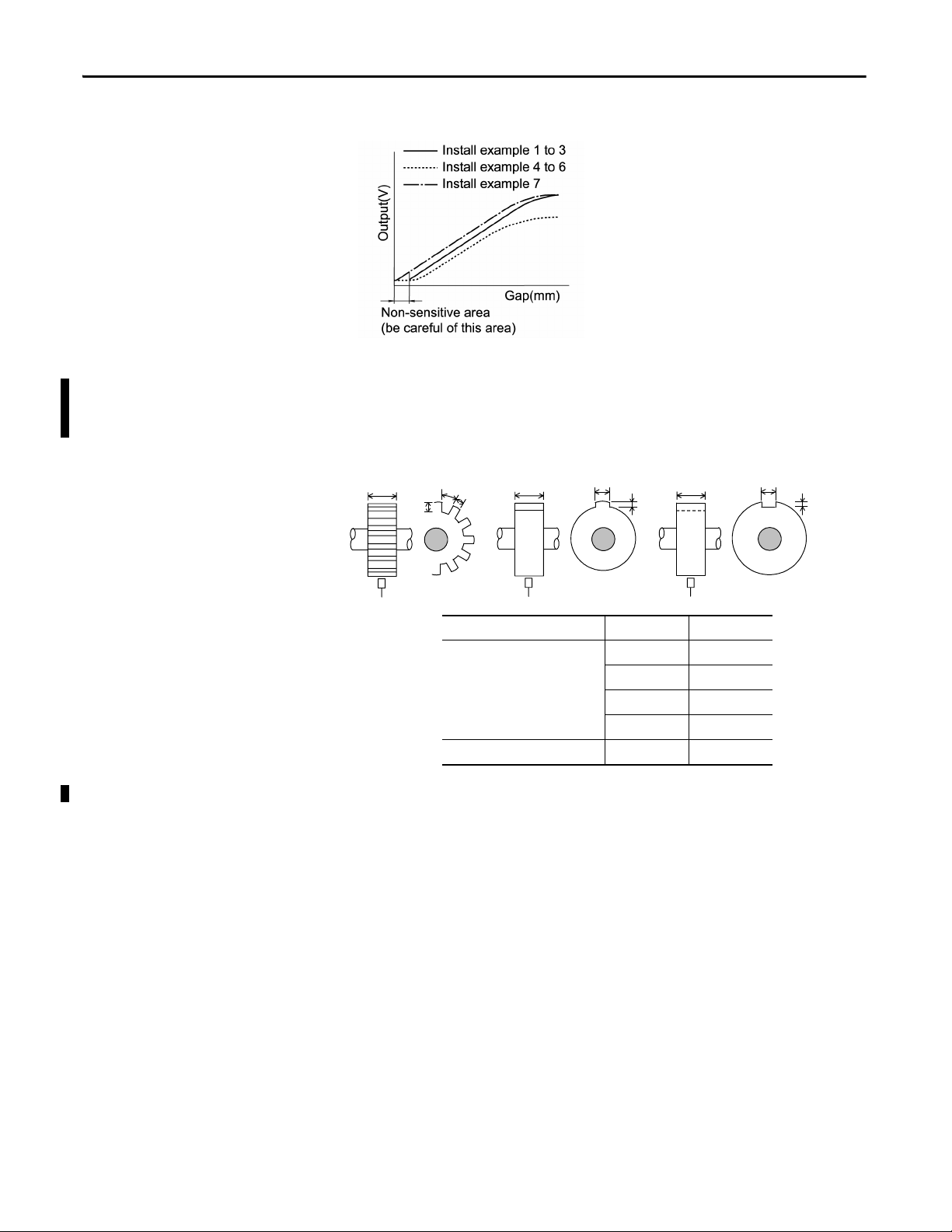

The characteristics of output (V) and gap (mm) are as shown in the graph below.

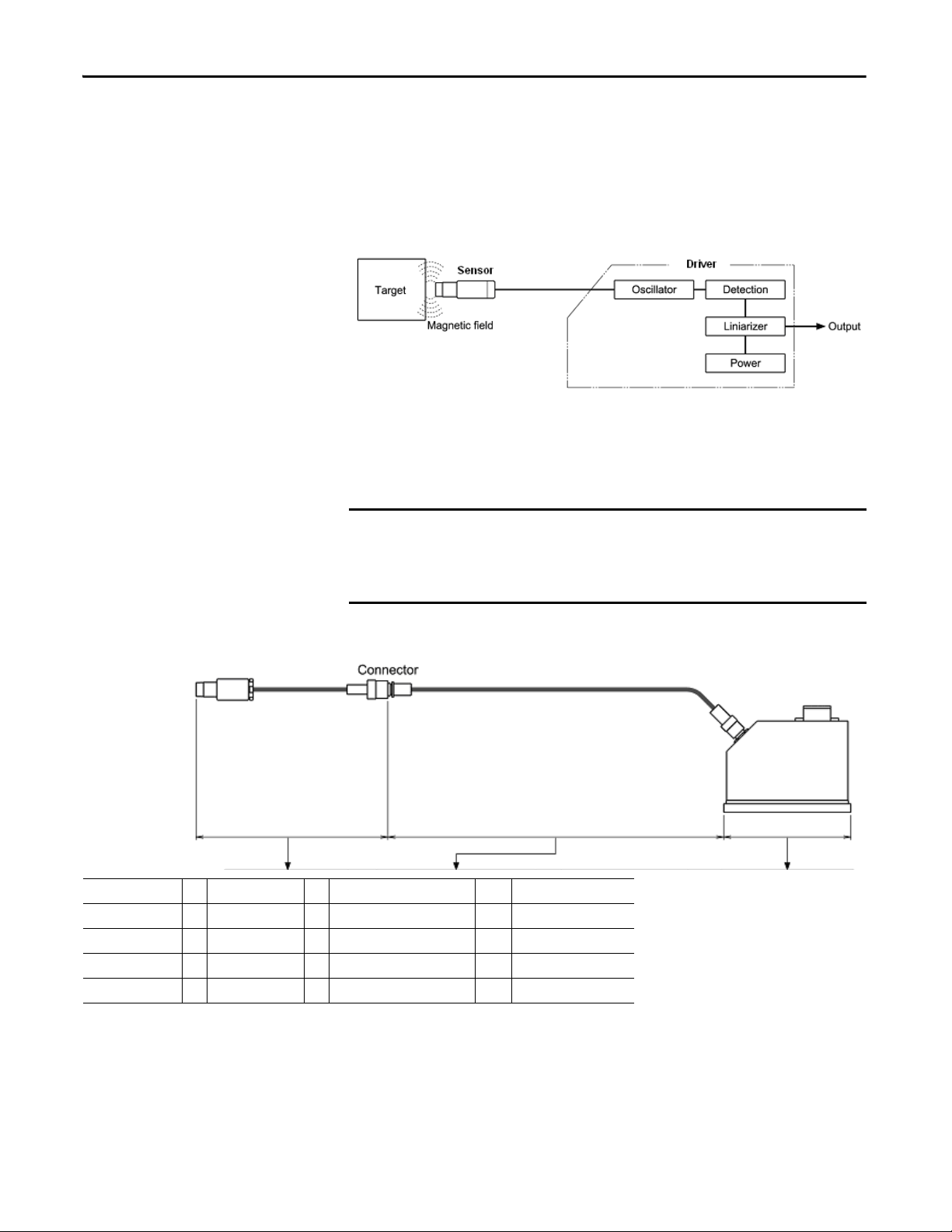

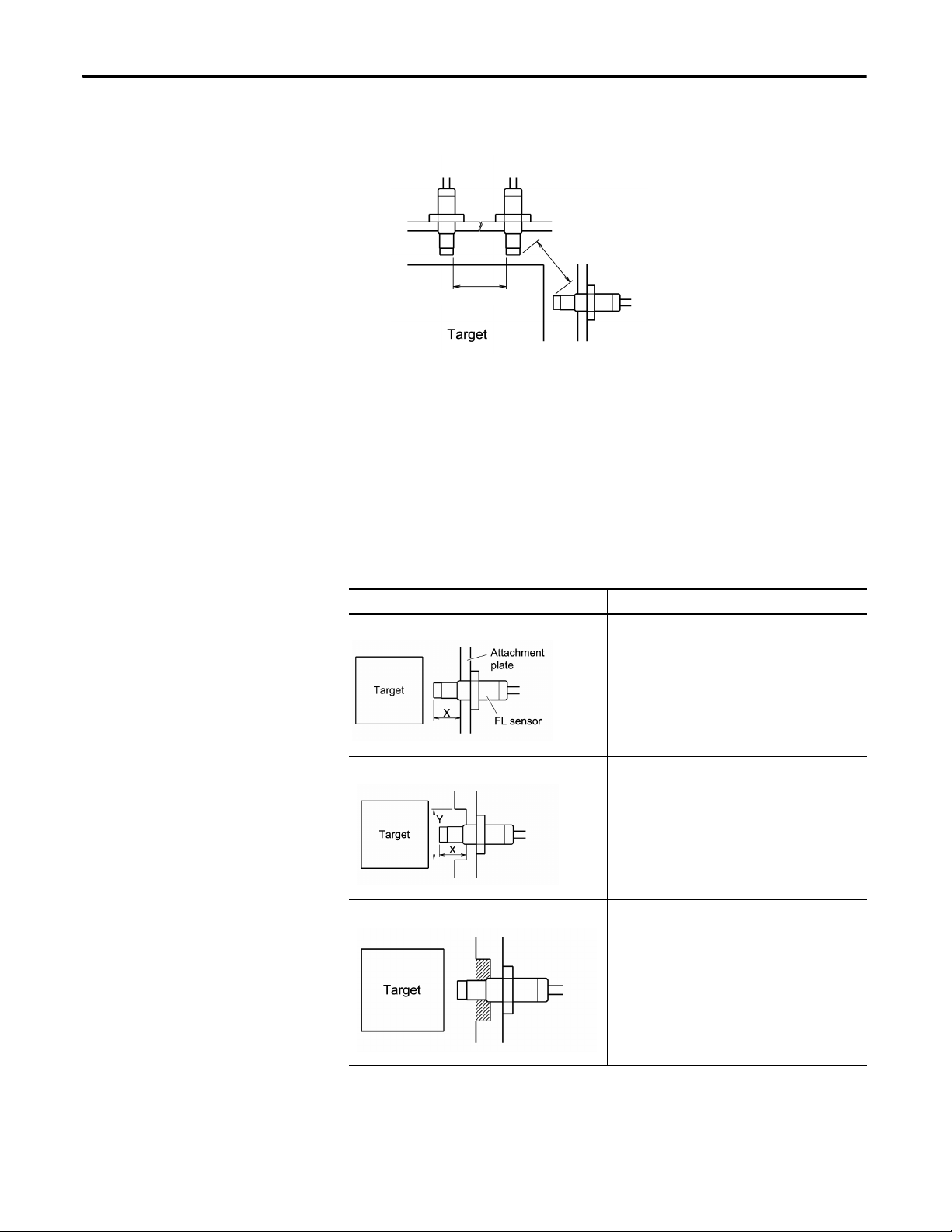

Speed Measurements

Assumes measurements are made with a 5 mm or 8 mm probe.

Figure 2 - Dimension of target (recommended for rotational speed measurement):

D

B

A

C

D D

A

C

B

C

mm mils

Recommended dimension of

target (mm)

A ≥ 6A ≥ 236

B ≥ 7B ≥ 275

C ≥ 2.5 C ≥ 98

D ≥ 15 D ≥ 590

Recommended set gap (mm) 1.0...1.5 39...59

16 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 17

Installation Chapter 1

Extension Cable Installation Environment

Install the extension cable in a location that satisfies the following environmental

and installation conditions.

Feature Specification

Ambient temperature Cable must be in a range of -35…177 °C (-31…350 °F) when devices are

Ambient humidity Must be in a range of 30…95% RH (noncondensing) when devices are operating.

operating.

Connector must be in a range of -35…125 °C

(-31…257 °F) when devices are operating.

ATEX applications must be in a range of -35…80 °C (-31…176 °F) when devices

are operating.

CSA applications must be in a range of -35…85 °C (-31…185 °F) when devices

are operating.

Outer Dimensions and Part Nomenclature

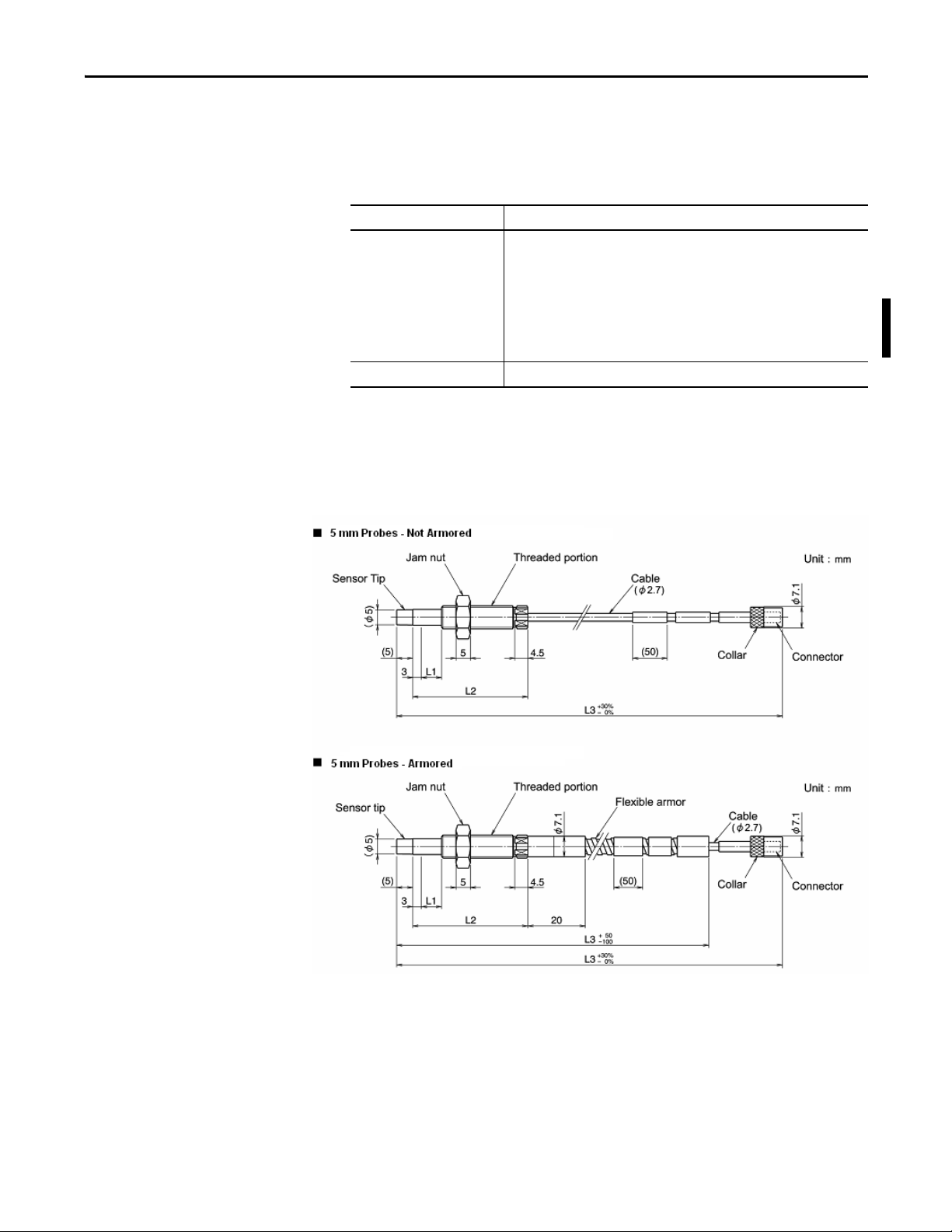

1442 Sensor Outer Dimensions and Part Nomenclature

5 mm Sensor

L1 = Unthreaded length

L2 = Case length

L3 = Cable length

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 17

Page 18

Chapter 1 Installation

8 mm Sensor

L1 = Unthreaded length

L2 = Case length

L3 = Cable length

Reverse 8 mm Sensor

L3 = Cable length

18 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 19

11 mm Probes - Non Armored

L1 = Unthreaded length

L2 = Body length

L3 = Cable length

Installation Chapter 1

11 mm Probes - Armored

L1 = Unthreaded length

L2 = Body length

L3 = Cable length

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 19

Page 20

Chapter 1 Installation

18 mm Probes - Armored

L1 = Unthreaded length

L2 = Body length

L3 = Cable length

25 mm Probes - Armored

L1 = Unthreaded length

L2 = Body length

L3 = Cable length

20 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 21

25 mm Probes - Flange Mount, Armored

2 = 4 holes in flange, 14 mm deep with M6 threads

L3 = Cable length, +30% / -0%

Installation Chapter 1

50 mm Probes - Armored

L2 = Body length

L3 = Cable length

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 21

Page 22

Chapter 1 Installation

Extension Cable Outer Dimensions and Part Nomenclature

5, 8, and 11 mm Probe Extension Cables - Non Armored

5 and 8 mm Probe Extension Cables - Armored

22 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 23

11 mm to 50 mm Probe Extension Cables - Armored

Installation Chapter 1

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 23

Page 24

Chapter 1 Installation

Driver Outer Dimensions and Part Nomenclature

24 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 25

Installation Chapter 1

TIP

Install the Driver

The driver can be installed on a DIN rail, or it can be mounted on a panel or wall

by using the provided adapter.

Mount the Driver on the Housing or Panel

The driver can be directly mounted on the panel.

When attaching to panels or mounts, make sure the surface is strong and

flat.

Attach the driver to the panel mounting plate and affix with the provided four

screws (M4 x 12 mm).

Terminal Arrangement

Ter mina l No. Sign al

1OUTPUT

2COM

3 -24 V

4Shield (COM)

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 25

Page 26

Chapter 1 Installation

TIP

TIP

Mount the Driver to a DIN Rail

The driver can be mounted to a 35 mm DIN rail.

1. Hook the upper tabs on the back of the driver onto the DIN rail.

2. Push the driver into the DIN rail until a click is heard from the slide lock.

Install the Sensor

If the driver does not fit onto the DIN rail well, pull on the slide lock and

push the driver against the DIN rail.

3. Make sure the upper tabs and the slide lock are securely fixed on the DIN

rail.

Remove the driver by pushing down on the slide lock with a flat-blade

screwdriver.

Install according to the conditions described in the Sensor Installation

Environment on page 13.

ATTENTION: Do not drop or otherwise subject the sensor to shock.

The sensor installation instructions comply with API Standard 670.

26 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 27

Installation Chapter 1

Use a Sensor Mounting Bracket

If you need a mounting bracket for the sensor, construct your own mounting

bracket. The mounting bracket can be readily machined at your site. The bracket

must provide a stable, secure, platform that satisfies the conditions described in

the Sensor Installation Environment

When using a sensor mounting bracket, use the following steps to install the

sensor.

1. Attach the sensor mounting bracket to the mount (body), and temporarily

attach with bolts.

on page 13.

Insert the sensor into the sensor mounting brackets screw hole, and adjust

the gap between the sensor top face and the target.

Refer to

Set Gap Voltage on page 35.

2. Tighten the bolts further, and affix the sensor mounting bracket.

3. Retighten the lock nut gain at the specified torque.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 27

Page 28

Chapter 1 Installation

TIP

Figure 3 - Sensor Mounting Bracket Installation Example

Use a Stinger

1442 Series 8-mm reverse-mount probes can be used with commonly available

probe holders. Stingers (also known as sensor sleeve), are provided with the probe

holder. Stingers can also be purchased from probe holder suppliers or can often

be machined locally.

The following instruction is a general guide based on common probe holder

designs. Consult your specific probe holder installation instructions for

additional details.

Install the probe holder and stinger assembly per installation instructions

before mounting the probe onto the stinger.

1. Remove the jam nut of the reverse mount sensor. (Remove at the Jam nut

attachment.)

28 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 29

Installation Chapter 1

2. Attach the sensor to the sensor sleeve.

3. Attach the sensor sleeve to the mounting (machine casing).

4. Adjust the gap between the sensor top face and the target.

Figure 4 - Sensor Sleeve Installation Example

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 29

Page 30

Chapter 1 Installation

TIP

Adjust the Gap

Adjust the gap by using the following procedures.

After completing all wiring connections, you can perform gap adjustment

by using a tester.

Make sure to fully understand the content described in this chapter and

complete all connection work, then perform the gap adjustment by using

the Set Gap Voltage

procedures on page 35.

1. Refer to Standard Static Characteristics on page 41

, and prepare a gap gage

matching the gap to produce the desired characteristics.

Consider the following items for the gap:

• Set the gap so that even when the target is at the nearest point to the

sensor, the target does not come into direct contact with the sensor.

• Set the gap so that it does not go beyond the linear range of the

connection monitor.

2. Being careful not to scratch the sensor top and target surface, insert the gap

gage between the sensor top and target.

3. Adjust the sensor to a position where the gap gage just moves freely, and

affix in place with the jam nut.

4. Tighten the jam nut with the following torque.

Table 2 - Torque Requirements

Sensor Example

1442-PS-05xxM (5 mm metric) 1442-PS-0503M0010N 4 41 35.4

1442-PS-05xxE (5 mm English) 1442-PS-0512E0010N 1.4 15 12.4

1442-PS-08xxM (8 mm metric) 1442-PS-0803M0010N 8.5 87 75.2

1442-PS-08xxE (8 mm English) 1442-PS-0812E0010N 6.8 69 60.2

1442-PS-11xxM (11 mm metric) 1442-PS-1104M0510N 26.1 266 231

1442-PS-11xxE (11 mm English) 1442-PS-1116E0510N 18.6 190 164

1442-PS-18xxM (18 mm metric) 1442-PS-1805M0510A 58.8 600 520

30 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Tightening Torque

N•m kgf-cm lb•in

Page 31

Table 2 - Torque Requirements

Tightening Torque

Sensor Example

1442-PS-18xxE (18 mm English) 1442-PS-1820E0510A 88.2 900 780

1442-PS-25xxM (25 mm metric) 1442-PS-2505M0510A 176 1800 1557

1442-PS-25xxE (25 mm English) 1442-PS-2520E0510A 196 2000 1734

1442-PS-50xxM (50 mm metric) 1442-PS-5005M0010A 176 1800 1557

1442-PS-50xxE (50 mm English) 1442-PS-5020E0010A 196 2000 1734

1442-PR-08xxM (8 mm rev mnt metric) 1442-PR-0803M0505N 8.5 87 75.2

1442-PR-08xxE (8 mm rev mnt English) 1442-PR-0812E0205N 6.8 69 60.2

N•m kgf-cm lb•in

ATTENTION: Make sure to tighten the jam nut at the specified torque.

If tightened with excessive torque, the sensor can be damaged. If the

tightening torque is too small, it can come loose.

Installation Chapter 1

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 31

Page 32

Chapter 1 Installation

TIP

TIP

Connect the Wiring

This section describes the wiring connections for the 1442 Series Eddy Current

Probe system.

The 1442 Series includes color–coded bands on the ends of each component.

The color–coded bands help you identify the length of the extension cable and

the length of the probe so that the total system length (5 or 9 meters) can be

matched to the appropriate driver. When the system is properly "sized," the color

bands for the probe, extension cable, and driver will match.

Table 3 - 1442 Series Color Band Table

Sensor Extension Cable Driver

Cable Length Color Band

Length

0.5 m Yellow 4.0 m Black Blue 5.0 Blue

1.0 m Black 4.5 Yellow Blue 9.0 Red

5.0 m Blue 8.0 Black Red

9.0 m Red 8.5 Yellow Red

Probe End Color

Band

Driver End Color

Band

System Cable

Length

Color

Band

WARNING: Make sure the wiring and connections are performed by a

person with knowledge in instrumentation.

WARNING: Make sure you ground your system. Never apply power until

all wiring and connection work has been completed. If this is not

followed there is a possibility of electrocution.

ATTENTION: Make sure to tighten the collar of the connector by hand.

Using a tool to tighten the collar can damage the connector. If the

installation environment does not allow proper tightening by hand and

there is a possibility that it can come loose, tighten an additional 1/4

turn using pliers after tightening by hand:

• Do not apply excessive force on the screws of the connector. The

connector can be damaged

• Do not cut the sensor or extension cables shorter. It can cause problems,

such as not being able to perform up to specifications.

Make sure that the cable is not twisted when connecting the connectors.

Twisting stress on the cable can slowly loosen the connection.

If a twisting force is applied to the direction where the collar is loosened,

twist the extension cable slightly to the opposite direction of the collar

tightening direction before connecting. Then connect the connector and

tighten the collar.

We recommend that excessive extension cables be stored in the cable

storage box. If it is unavoidable to store inside the driver housing, do not

force excessive cables into the housing.

32 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 33

Installation Chapter 1

TIP

TIP

Connections are performed in the following order.

1. Connect the extension cable (when using the extension cable).

2. Connect the sensor.

3. Connect the XM® module.

4. Verify the connections.

5. Check the gap voltage.

Connect the Extension Cable

Use the following steps to connect the sensor and extension cable.

The connection area of the connector must not be exposed to water or oil. If

water or oil enters the connector, the cable capacity increases, and causes a

loss in sensitivity.

Make sure the color band on the sensor cable matches the color band on the

probe end of the extension cable. See

page 32.

1442 Series Color Band Table on

1. Confirm that there are no foreign objects in the sensor and extension cable

connectors.

Foreign objects in the connector cause faulty connections or faulty

characteristics.

2. Insert the extension cable through the provided insulation sleeve (clear

heat shrink tube).

3. Connect the sensor connector and extension cable connectors, and tighten

the collar by hand.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 33

Page 34

Chapter 1 Installation

TIP

4. Cover the insulation sleeve over the connector.

5. Apply hot air on the insulation sleeve to shrink the insulation sleeve.

ATTENTION: Never use vinyl tape to insulate.

• During extended periods of use or when the connecter temperature

exceeds 80 °C (176 °F), vinyl electrical tape can harden or the adhesive

can deteriorate, leading to a dirty connector and faulty insulation.

• If there is not a spare insulation sleeve available, protect the connector

with a fluorine resin tape. Recommended insulation tape is:

– Manufacturer: Nitto Denko Corporation

– Product Name: Nitoflon adhesive tape (Model Number: NO. 903UL)

• Temperature spec: -60…180 °C (-76…356 °F) 0.08 mm thickness.

Connect the Sensor

Connect the sensor by using the following steps. Connection is performed in the

same manner when using an extension cable.

Make sure the color band on the extension cable matches the color band on

the probe driver. See

1. Confirm that there are no foreign objects in the sensor (or extension cable)

and in the driver sensor input connector.

2. Connect the sensor (or extension cable) connector and the sensor input

connector, and tighten the collar by hand.

1442 Series Color Band Table on page 32.

34 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 35

Installation Chapter 1

Connect the Module

The 1442 sensors can be connected to many different Allen-Bradley 1440 XM

Series or 1444 Dynamix® Series modules. Refer to the appropriate Module User

Manual for wiring requirements and instructions on how to wire the sensor to the

module.

Verify the Connections

Before turning on the power, verify the following connections:

· Be sure that there are no loose terminals, and that all wiring is properly

connected.

· Check that the power line for the power source is connected to

NEGATIVE PWR (-24V) on the measurement module or its terminal

base.

· Be sure that the driver and sensor are installed at locations where the

installation environmental conditions are satisfied.

· Be sure that there are no problems with the driver and sensor installation,

and they are not installed at the following types of locations:

– Locations with high temperatures and high humidity.

– Locations with dust.

– Location exposed to vibration.

– Locations where there are metal objects, other than the target, near the

sensor.

After checking all items, check the set gap voltage values.

Set Gap Voltage

Perform confirmation of set gap voltage to maintain the performance of this unit

when doing the following:

• Supplying power to the unit for the first time

• More than one year has passed from the last confirmation

• The performance of this unit has been reduced due to a problem of some

sort

Follow these steps to check the set gap voltage.

1. Turn on th e p ow er.

2. Allow the unit to warm up for 5 minutes to stabilize the output.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 35

Page 36

Chapter 1 Installation

IMPORTANT

Warm-up is necessary to collect accurate data.

3. Connect the tester (voltmeter) across the Input Signal and Input Common

terminals on the measurement module base and read the voltage.

4. Refer to Standard Static Characteristics on page 41

to make sure that the

desired set gap voltage is indicate

Data indicated in Standard Static Characteristics (on page 41) are measured

for a SCM440 flat target (diameter more than 33 mm). When the target

material or shapes differ, the output characteristics (gain) differ, making it

necessary to compensate with later equipment.

5. If the desired set gap voltage is not attained, readjust the sensor position by

using the following procedure.

a. Loosen the sensor jam nut.

b. Adjust the sensor position so that the desired set gap voltage is

attained.

36 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 37

Installation Chapter 1

TIP

c. After adjustment, tighten the sensor jam nut to the specified torque

value (see table on page 30

).

ATTENTION: Always tighten the lock nut at the specified torque.

The measurement precision described in the specifications will be satisfied

approximately five minutes after turning on the power.

Recommended Specifications for the Monitor Cable

Cable Name Note

CVVS 3 core shielded cable (straight) The CVVS 3 core shield is also recommended in the API Standard 670.

3 line multiple core cable for light elec trical instruments

(individually shielded)

Use a commercially sold cable to connect the probe driver to the monitor. A

CVVS 3 core shielded cable (straight) is recommended, but if it is not available, a

3 line multiple core cable for light electrical instruments (individually shielded)

can be used. Use 0.75 mm

2

…1.25 mm2 (18…16 AWG) cables.

Recommendation: Copper tape shield (core wire; soft copper wire); (Normally,

silver plated braid)

Use conduit pipe (cable rack) for wiring.

Recommendation: Outer shield is aluminum tape, copper tape shield

The multipair cable can contain a mixture of vibration signals and displacement

signals. However, vibration signals for a high amplitude vibration can affect other

vibration signals and displacement signals negatively; and these need to be

wired on a separate cable.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 37

Page 38

Chapter 1 Installation

Notes:

38 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 39

Chapter 2

IMPORTANT

Calibration

(Static characteristic data collection)

The margin for error satisfies the specifications.

(Thrust, Rotations --> sensitivity)

(Vibration, Eccentric --> scale factor)

Verify the installation, reset the gap and/or troubleshoot

the system per this instruction.

Does the system performance satisfy the specifications?

Replacement is recommended.

Continue to use the unit.

Continue to use the unit after adjustment.

Ye s

Ye s

No

No

Maintenance and Inspection

This chapter describes the maintenance and inspection procedures for the unit.

Periodic Inspection Intervals

Unit Life

To maintain performance and secure system stability of the unit, inspect the

system and its mounts for corrosion, properly-tightened or torqued fittings and

connections, and component conditions annually. Check sensor gap settings

annually and at any time measurements become suspect. Refer to Set Gap Voltage

on page 36.

Plan to replace eddy current probe systems approximately every 10 years.

Ten years is a general guideline for replacement. If otherwise undisturbed,

eddy current probe systems deteriorate over time due to temperature and

erosion. The deterioration rate for sensors, extension cables, and drivers

depends on the specific environmental conditions to which each

component is subjected.

The following is a flowchart for determining when a replacement is required.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 39

Page 40

Chapter 2 Maintenance and Inspection

Troubleshoot the Unit

Symptom Possible Cause Recommended Action

Output is 0V DC and does not change. Power is not on. Turn on the power.

Output is approximately -0.7V DC and does not change. The target is beyond the measurement range. Refer to Set Gap Voltage on page 36 to adjust the gap.

Output is approximately -22V DC and does not change. The target is outside the possible measurement range. Refer to Set Gap Voltage on page 36

Use the table below to troubleshoot problems with the unit.

Unit is not connected properly. Refer to Connect the Wiring on page 32

The driver is faulty. Replace the driver.

The sensor failed or the sensor cable is shorted or

disconnected.

The extension cable is shorted or disconnected. Measure the resistance of the extension cable, and if it is

There is a foreign object in the connector. Disconnect the connector, and remove foreign object in

The driver is faulty. Replace the driver.

The driver is faulty. Replace the driver.

unit is wired correctly.

Measure the resistance between the sensor connector,

and if not normal, replace the sensor.

Normal value:

Sensor coil resistance: Approx. 5.5 Ω

Sensor cable resistance: Approx. 0.25 Ω/m

not normal, replace the extension cable.

Normal value:

Center conductor resistance: Approx. 0.25 Ω/m

Outer conduc tor resistance: 0 Ω

Center pin to outer conductor resistan ce: ∞Ω

the connector.

to make sure the

to adjust the gap.

40 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 41

Individual Characteristic Data

Chapter 3

Characteristic Data

This chapter describes static characteristics, temperature characteristics, and

other characteristic data. Use this data to determine the gap.

Standard Static Characteristics

Target material is SCM440 flat face (diameter 15 mm or more).

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 41

Page 42

Chapter 3 Individual Characteristic Data

Sensor Temperature Characteristics

System cable length is 5 m.

42 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 43

Driver Temperature Characteristics

System cable length is 5 m.

Individual Characteristic Data Chapter 3

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 43

Page 44

Chapter 3 Individual Characteristic Data

Static Characteristic Effect Due to Power Source Voltage Variation

44 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 45

Individual Characteristic Data Chapter 3

Static Characteristic Effect by Target Material

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 45

Page 46

Chapter 3 Individual Characteristic Data

Static Characteristic Effect Due to Target Diameter

Target material is SCM440.

46 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 47

Static Effect by Target Curved Surface

Target material is SCM440.

Individual Characteristic Data Chapter 3

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 47

Page 48

Chapter 3 Individual Characteristic Data

Static Characteristic Effect Due to Target End Face

Target material is SCM440.

48 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 49

Static Characteristic Effect Due to Side Wall

Target and side wall material is SCM440.

Individual Characteristic Data Chapter 3

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 49

Page 50

Chapter 3 Individual Characteristic Data

Frequency Characteristics

50 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 51

Appendix A

Wire the Unit to a Monitor System

The 1442 Series Probe System is designed to satisfy the API-670 standard. Any

monitor designed to connect API-670 probes can be used with these sensors.

Consider the following recommendations when wiring the probe driver to a

monitor:

· Use a good quality instrumentation cable with three-conductor stranded

wire and shield.

– Wire must be rated with a maximum capacitance of 60 pF/ft

(197 pF/m) and inductance of 0.3 µH/ft (1 µH/m).

– Use wire with insulation suitable for the environment and with

adequate tensile strength and flexibility for the application.

– Use wire with a foil shield for use in environments where radio

frequency interference (RFI) may be present. Use a wire with a braid

shield for environments where electromagnetic interference (EMI) may

be present.

– Use 0.75…1.25 mm (18…16 AWG) gauge wire.

· Make sure the wire is isolated from power cables and any other wiring that

may be transmitting high-voltage power or control signals.

· Any cable transmitting pulse-type vibration signals such as a phase marker

or speed pulse must be isolated from displacement and vibration signals.

· Run wire within conduit and cable trays and as per any local electrical

codes.

· Do not exceed a wire length of 500 m (546.81 yds). However, limiting the

length to 300 m (328.08 yds) transmits vibration signals in the 0…10 kHz

frequency range with minimal attenuation. When longer lengths are

needed the capacitance of the cable and the desired frequency response of

the system must be considered.

· In most cases, ground the cable shield at only one point, generally at the

monitor.

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 51

Page 52

Appendix A Wire the Unit to a Monitor System

Cable Wiring/Laying Examples

Good Example Bad Example

The following illustrations provide examples on how to wire and lay the cable.

52 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 53

Index

Numerics

1442 driver

dimensions

installation

installation environment

1442 extension cable

connecting

dimensions

1442 reverse mount probe

dimensions

1442 Sensors

connecting

dimensions

installation environment

24

25

12

33

22

18, 19, 20, 21

34

17

13

C

cable wiring 51

examples

51

issues

characteristic data 41

51

D

dimensions 17

din rail mounting

driver installation

din rail mounting

housing mounting

panel mounting 25

driver installation environment

26

25

26

25

12

P

panel mounting 25

S

sensor installation 26

gap adjustment

mounting bracket

stinger 28

sensor installation environment

set gap voltage

specifications

monitor cable

Stingers

28

system configuration example

30

27

35

37

T

troubleshooting 40

W

wiring connections 32

extension cable

sensor

set gap voltage 35

verification

XM module

wiring recommendations 51

33

34

35

35

13

8

G

gap adjustment 30

H

housing mounting 25

I

installation

driver

25

sensor

26

installation environment

driver

12

13

sensor

introduction

7

12

M

maintenance and inspection 39

measuring principles

mounting bracket

7

27

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014 53

Page 54

Index

54 Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Page 55

Page 56

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwi de Lo cato r

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Publication ICM-UM004C-EN-E - February 2014

Supersedes Publication ICM-UM004B-EN-E - April 2013 Copyright © 2014 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...