Page 1

User Manual

Enpac 2500 Data Collector

Catalog Numbers 1441-PEN25 and 1441-PEN25-Z

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, Enpac, Emonitor, Enshare, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Upgrade Options 13

Additional Resources 17

Added safety warnings 20

Setup Screen 30

Data Collection Screen 33

Engineer Mode Menu Screen 37

Setting Up the Enpac 2500 Data Collector 40

Module ICP 42

Using Memory Cards 47

Operating System Update Procedures 50

Bias Check 125

FRF Frequency Response Function Extension Module 287

Specifications 301

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 5

Table of Contents

Preface

The Enpac 2500 Data Collector

Using the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Upgrade Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Enpac 2500 Data Collector and the Emonitor Software . . . . . . . . . . . . . 14

Software Compatibilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

USB and Communication Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using Online Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Help Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 1

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Optical Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Laser Radiation Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parts of the Enpac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Enpac 2500 Diagram and Key Definitions . . . . . . . . . . . . . . . . . . . . . . 21

External Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Strap Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Checking Battery Life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Inserting and Removing the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . 28

Powering on the Enpac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Enpac 2500 Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Set the Date, Time, and Date Format. . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Data Collection Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Help Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Engineer Mode Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

View Settings for Current Measurement Definition . . . . . . . . . . . . . 39

Setting Up the Enpac 2500 Data Collector . . . . . . . . . . . . . . . . . . . . . . . . . 40

Configure the Data Collector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Configure the Data Collection Options . . . . . . . . . . . . . . . . . . . . . . . . 42

Using Memory Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Types of Memory Cards Used with Enpac 2500. . . . . . . . . . . . . . . . . 48

Inserting and Removing a Memory Card . . . . . . . . . . . . . . . . . . . . . . . 48

Operating System Update Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Update the Enpac 2500 Data Collector Operating

System, Firmware Version 3.10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Restarting the Data Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Perform Soft Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 5

Page 6

Table of Contents

Perform Hard Restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Adding Applications to the Enpac 2500 Data Collector . . . . . . . . . . . . . 58

Chapter 2

Setting Up Measurements

Measurement Definition Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Measurement Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Measurement Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Measurement Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Setting Up Collection Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Measurement Input Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Measurement Window Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Measurement Signal Detection Types . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Measurement Maximum Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Measurement Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Number and Type of Averages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Order Normalization for Orders Track Spectrum . . . . . . . . . . . . . . . 73

Using Frequency Items for the Diagnostic Frequency Cursor. . . . . 74

Setting Up Speed References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Setting Up Measurement Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Magnitude Measurement Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Magnitude and Phase Measurements at Orders. . . . . . . . . . . . . . . . . . 79

Numeric (process) Measurement Definitions . . . . . . . . . . . . . . . . . . . 82

Spectrum Measurement Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Time Waveform Measurement Definitions . . . . . . . . . . . . . . . . . . . . . 87

Voltage Measurement Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Combining Measurement Definitions for a Location . . . . . . . . . . . . 91

Setting Up Tri-axial Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Setting Up Alarms, Lists, and Inspection Codes. . . . . . . . . . . . . . . . . . . . . 93

Alarms and the Data Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Lists and the Data Collector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Inspection Codes and the Data Collector. . . . . . . . . . . . . . . . . . . . . . . 94

Chapter 3

Loading and Unloading

6 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Setting Up for Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Set Up the Current Data Collector in Emonitor . . . . . . . . . . . . . . . . 96

Set Up Computer Communication Options in Emonitor. . . . . . . . 99

Set Up the Data Collector for Communication . . . . . . . . . . . . . . . . 100

Connecting the Data Collector and Computer (RS-232) . . . . . . . 100

Using the USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Using a PCMCIA Card Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Loading Lists to the Data Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Preparing the Data Collector before Loading . . . . . . . . . . . . . . . . . . 104

Initializing the Data Collector before Loading . . . . . . . . . . . . . . . . . 105

Loading Inspection Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Loading Frequency Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Overriding the Collect on Alarm Setting . . . . . . . . . . . . . . . . . . . . . . 108

Page 7

Collecting and Reviewing Data

Table of Contents

Selecting the List(s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Loading Selected Lists to the Data Collector . . . . . . . . . . . . . . . . . . . 109

Displaying the Data Collector Driver Version Number . . . . . . . . . 110

Unloading Lists from the Data Collector. . . . . . . . . . . . . . . . . . . . . . . . . . 111

Unloading Lists in Emonitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Unloading Multiple Measurements Points in Emonitor. . . . . . . . . 112

Unloading Unscheduled (off route) Data from the

Enpac 2500 Data Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Unloading Measurements using Smart Unscheduled Mode . . . . . 113

Automatically Printing Reports after Unloading . . . . . . . . . . . . . . . 115

Chapter 4

Preparing for Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Connect a Transducer to the Data Collector. . . . . . . . . . . . . . . . . . . 118

Select the Data Collection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Collecting Route Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Select a Route . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Move through a List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Start Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Bias Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Select Inspection Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Manually Enter a Numeric Measurement. . . . . . . . . . . . . . . . . . . . . . 125

Collect a Process DC Voltage Measurement . . . . . . . . . . . . . . . . . . . 126

Collect a Magnitude Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Collect a Spectrum Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Collect a Time Waveform Measurement . . . . . . . . . . . . . . . . . . . . . . 132

Collect Magnitude and Phase Measurements at Orders . . . . . . . . . 133

Collect Multiple Measurements for a Point . . . . . . . . . . . . . . . . . . . . 135

Collecting Offroute Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Methods for Collecting Offroute Data . . . . . . . . . . . . . . . . . . . . . . . . 136

Collect Offroute Data using a Pre-defined Measurement. . . . . . . . 137

Create and Collect a User-defined Point. . . . . . . . . . . . . . . . . . . . . . . 139

Storing Unscheduled Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Changing Display View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Reviewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Review Route Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Review Offroute Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Use Diagnostic Frequency Cursors with a Spectrum . . . . . . . . . . . . 153

Review Waterfall Spectra Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Delete a Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Capturing Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Print Reports and Plots by Using the Emonitor Software . . . . . . . 155

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 7

Page 8

Table of Contents

Chapter 5

Multi-channel Measurements

Predictive Maintenance Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Orbit Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Understanding an Orbit Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Set Up Orbit Measurements Definitions in

the Emonitor Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Set Up Offroute Orbit Measurements. . . . . . . . . . . . . . . . . . . . . . . . . 163

Collect Orbit Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Review Orbit Data Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Cross Channel Phase Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Phase Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Multi-channel Cursor, Display Expand, and

Full Scale Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Set Up Cross Channel Phase Measurement Definitions in the

Emonitor Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Set Up an Offroute Cross Channel Phase Measurement . . . . . . . . 174

Collect a Cross Channel Phase Measurement . . . . . . . . . . . . . . . . . . 176

Review Cross Channel Phase Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Two-channel Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Set Up Two-channel Measurement Definitions in

the Emonitor Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Collect an Offroute Two-channel Measurement . . . . . . . . . . . . . . . 181

Magnitude and Phase Offroute Measurement . . . . . . . . . . . . . . . . . . . . . 184

Installing Optional Extension

Modules

Bump Test Application

Balancing Application

Chapter 6

Install Optional Extension Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Uninstall an Extension Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Manage Extension Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Chapter 7

Overview of the Bump Test Application . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Setting Up and Collecting Bump Test Measurements . . . . . . . . . . . . . . 194

Setting Up Bump Test Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 194

Collecting Bump Test Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 197

Saving a Bump Test Setup and Measurement . . . . . . . . . . . . . . . . . . 198

Recalling a Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Reviewing Bump Test Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Backing Up and Deleting Bump Test Files . . . . . . . . . . . . . . . . . . . . . . . . 202

Backing Up Bump Test Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Deleting a Bump Test Measurement and Setup . . . . . . . . . . . . . . . . 204

Chapter 8

Overview of Balancing Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Setting Up the Balancing Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Balance Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

8 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 9

Table of Contents

Advanced Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

One Plane Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Taking the Initial Vibration Measurement. . . . . . . . . . . . . . . . . . . . . 213

Adding the Trial Weight and Taking a Measurement. . . . . . . . . . . 214

Adding the Correction Weight and Taking a

Residual Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Two Plane Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Taking the Initial Vibration Measurement. . . . . . . . . . . . . . . . . . . . . 220

Adding the Trial Weight and Taking a Measurement in Plane 1 . 222

Adding the Trial Weight and Taking a Measurement in Plane 2 . 225

Adding the Correction Weights and

Taking a Residual Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Moving Around in a Balance Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Reviewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Vibration Summary Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Weights Summary Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Combining Weights Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Capturing and Printing the Summary Tables . . . . . . . . . . . . . . . . . . 234

Saving and Reloading a Balance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Saving a Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Reloading a Balance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Time Recorder Application

Run Up/Coast Down Application

Chapter 9

Overview of the Time Recorder Application. . . . . . . . . . . . . . . . . . . . . . . 237

Setting Up and Collecting Time Recorder Measurements . . . . . . . . . . 238

Setting Up Time Recorder Measurements . . . . . . . . . . . . . . . . . . . . . 238

Recorder Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Previewing the Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Recording the Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Saving a Time Recorder Setup and Measurement. . . . . . . . . . . . . . . 242

Recalling a Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Reviewing Time Recorder Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 246

Capturing and Printing the Review Data Screen. . . . . . . . . . . . . . . . 247

Backing Up and Deleting Time Recorder Files. . . . . . . . . . . . . . . . . . . . . 248

Backing Up Time Recorder Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Copying Time Recorder Files to the Host Computer . . . . . . . . . . . 249

Deleting a Time Recorder Measurement and Setup. . . . . . . . . . . . . 250

Chapter 10

Overview of the Run Up/Coast Down Application . . . . . . . . . . . . . . . . 253

Setting Up Run Up/Coast Down Measurements . . . . . . . . . . . . . . . . . . 255

Collecting Run Up/Coast Down Measurements. . . . . . . . . . . . . . . . . . . 257

Run Up/Coast Down Status Indicators . . . . . . . . . . . . . . . . . . . . . . . 257

Collecting and Analyzing Run Up/Coast Down . . . . . . . . . . . . . . . 257

Displaying Measurements Using a Bode Plot . . . . . . . . . . . . . . . . . . . . . . 260

Setting Up the Bode Plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 9

Page 10

Table of Contents

Displaying the Bode Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Displaying Measurements Using a Nyquist Plot. . . . . . . . . . . . . . . . . . . . 263

Setting Up the Nyquist Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Displaying the Nyquist Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Displaying Measurements in Table Format . . . . . . . . . . . . . . . . . . . . . . . . 266

Setting Up the Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Displaying the Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Displaying Measurements Using a Waterfall. . . . . . . . . . . . . . . . . . . . . . . 269

Setting Up the Waterfall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Displaying the Waterfall Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Displaying Measurements Using a Spectrogram. . . . . . . . . . . . . . . . . . . . 274

Setting Up the Spectrogram Plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Displaying the Spectrogram Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Saving Run Up/Coast Down Measurements. . . . . . . . . . . . . . . . . . . . . . . 277

Recalling a Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Reviewing Run Up/Coast Down Measurements . . . . . . . . . . . . . . . . . . . 280

Deleting Run Up/Coast Down Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Chapter 11

FRF Frequency Response Function

Extension Module

Newtons Law and Apparent Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Setting Up an FRF Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Test Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Avoid Bad Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

FRF Module Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

FRF Analysis Set-up Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Collect FRF Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Field Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Saving, Reviewing, and Deleting FRF Measurements . . . . . . . . . . . . . . . 297

Save an FRF Test Setup and Measurement. . . . . . . . . . . . . . . . . . . . . 297

Importing to ODS Analysis Software.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Appendix A

Specifications Appendix B

Frequently Asked Questions and

Answers

Setting Up Measurement Definitions in Emonitor . . . . . . . . . . . . . . . . . 303

How do I set up measurement definitions?. . . . . . . . . . . . . . . . . . . . . 303

Why do unsupported selections appear in Emonitor? . . . . . . . . . . . 303

Why can’t I edit the measurement definitions units?. . . . . . . . . . . . 304

Loading Lists to the Enpac 2500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

I think I lost some data. What happened?. . . . . . . . . . . . . . . . . . . . . . 304

Why won’t Emonitor load a list to the Enpac 2500? . . . . . . . . . . . . 305

Why does Emonitor rebuild the Quickload files? . . . . . . . . . . . . . . . 305

How do I load a list to the PCMCIA card? . . . . . . . . . . . . . . . . . . . . 305

How do I tell when loading or unloading is done? . . . . . . . . . . . . . . 305

Collecting Data with the Enpac 2500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Why does the Enpac 2500 seem to skip

measurements at a location? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

10 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 11

Accessories

Glossary

Table of Contents

Why wont the Enpac 2500 combine magnitude and

phase or manual entry measurements at a location? . . . . . . . . . 306

What does the USER (eus) units mean? . . . . . . . . . . . . . . . . . . . . . . . 307

Why are the alarms in the Enpac 2500 not what I selected?. . . . . . 307

Why aren't inspection codes available for a list? . . . . . . . . . . . . . . . . 307

How can I reduce the ranging time required during collection? . . 308

Unloading Data from the Enpac 2500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

How do I unload data from more than one list? . . . . . . . . . . . . . . . . 308

How do I clear data from lists after unloading? . . . . . . . . . . . . . . . . . 308

How do I print reports after unloading data?. . . . . . . . . . . . . . . . . . . 308

Analyzing Data in Emonitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Why does the magnitude reading not correspond to the

calculated overall value? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Appendix C

Upgrade Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Cables and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Index

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 11

Page 12

Table of Contents

Notes:

12 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 13

Preface

The content in this manual is based on the following firmware revision and

software version.

• Enpac® 2500 data collector, firmware revision 3.10

• Emonitor® software, version 3.4

Using the Manual

Upgrade Options

This manual covers the Enpac 2500 data collector module which is used for

predictive maintenance using noise and vibration analysis. It describes also how

to use the Emonitor software to load and unload lists.

When using the Enpac 2500 data collector, you can do the following:

• Create lists of measurement definitions.

• Load lists from Emonitor into the data collector.

• Use a 40 Khz fmax, Route and Offroute.

• Collect magnitude, process, spectrum, time, and phase data.

• View selected alarms.

• Select inspection codes to store with a measurement.

• Define and collect unscheduled measurements

• Unload the data from the data collector directly into the Emonitor

database.

• View the high resolution, up to 12,800 lines on the data collector.

These are the upgrade options for the Enpac 2500 data collector:

• 1441-PEN25-MOD-2CH 2 - Channel Upgrade Kit

Two Channel application allows for advanced use of orbits, cross channel

phase, and simultaneous data collection in route and off route collection.

• 1441-PEN25-MOD-BMP - Bump Test

A bump test (or hammer test) determines the natural frequencies of a

machine or a structure.

• 1441-PEN25-KIT-BAL - Balancing

Balancing application resolves single-plane, two-plane, and static-couple

balances with high precision.

• 1441-PEN25-MFRF - Frequency Response Function

The FRF test lets you determine the natural frequencies of a machine as

well as sophisticated information about the frequency response of the

structure being tested.

• 1441-PEN25-MOD-REC - Time Recorder

The Time Recorder test uses a the instrument as a data recorder for realtime data acquisition and analysis.

• 1441-PEN25-MOD-RUCD - Run Up Coast Down

The RUCD test records and analyzes data from intermittent events and

transient vibration signals from non-steady state machines.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 13

Page 14

Preface

TIP

Enpac 2500 Data Collector and the Emonitor Software

Software Compatibilities

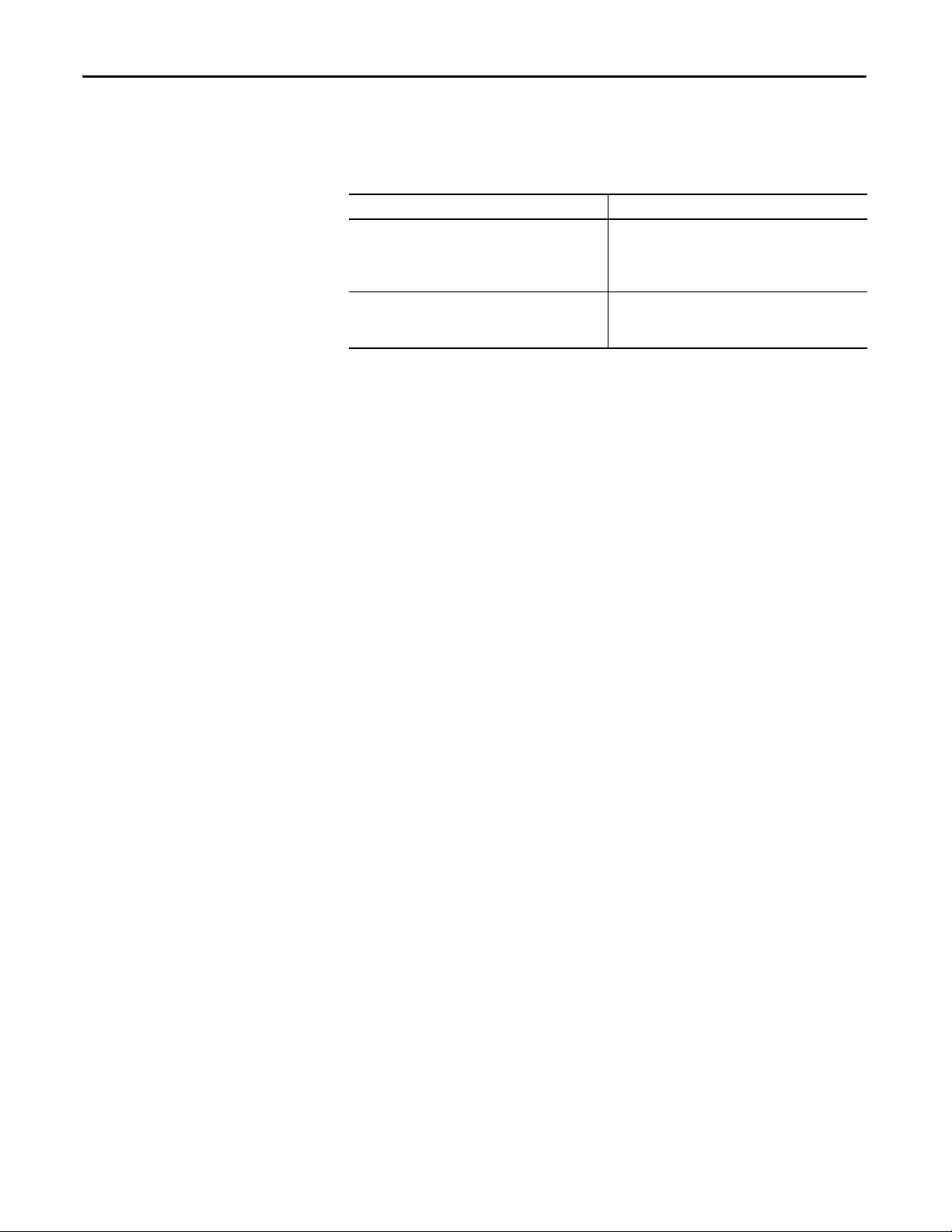

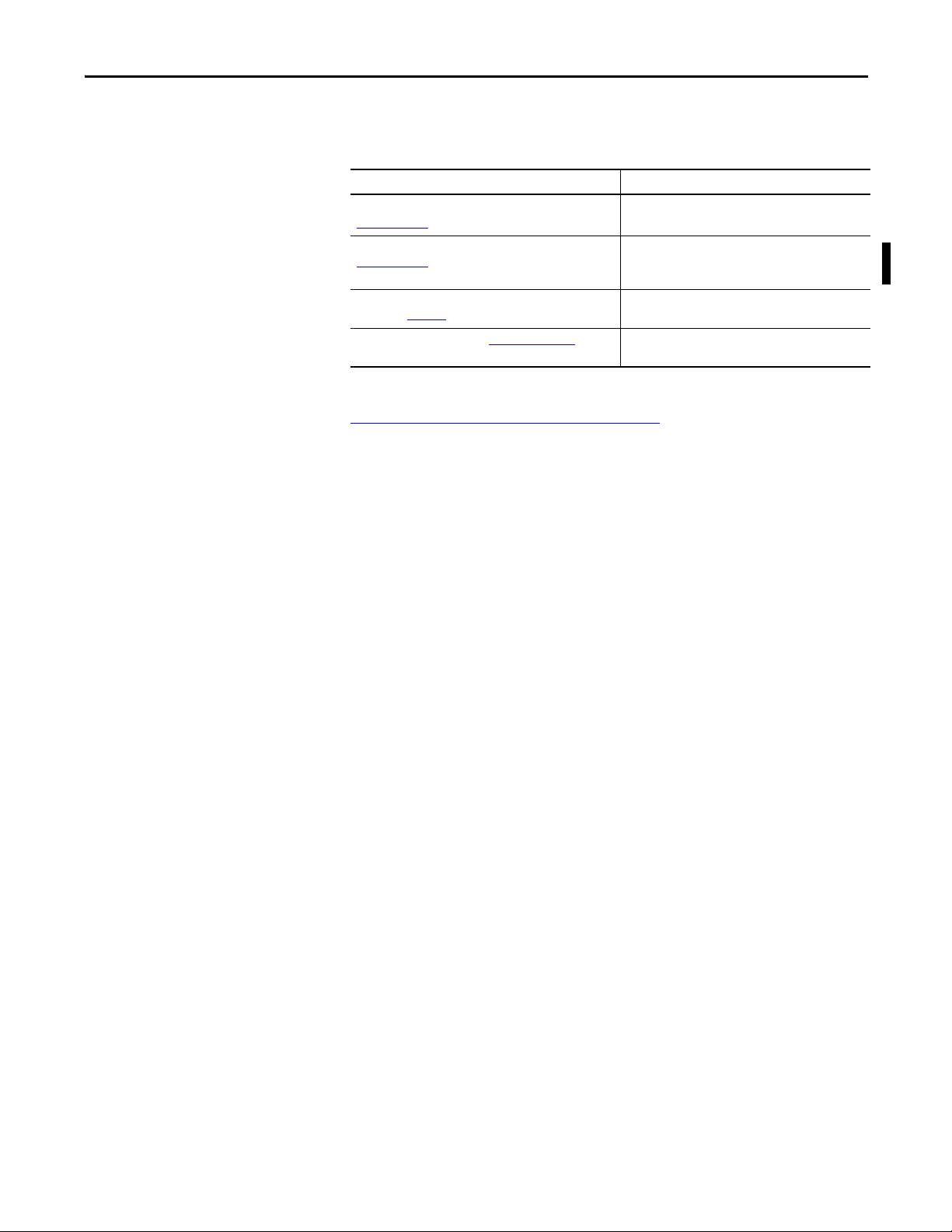

The terminology in the data collector and the software differ in several ways.

This table illustrates the differences.

Table 1 - Terminology Differences

Enpac 2500 Terminology Emonitor Terminology

Offroute

Measurements that are taken but are not downloaded on

to the instrument from Emonitor.

These measurements can be upload to Emonitor.

Route

The Enpac 2500 data collector uses the term route to refer

to a list loaded in the data collector.

Unscheduled measurements

Measurements that are not defined in the list of

measurements downloaded by Emonitor.

These measurements are unscheduled.

List

The Emonitor software uses the term `list for an ordered

set of measurement definitions.

The Enpac 2500 data collector requires the following software versions.

USB and Communication Software

These are the supported communication software versions.

• USB communication with Microsoft Windows 2000 and Windows XP is

supported using Microsoft ActiveSync software version 4.5 or greater

• USB communication with Microsoft Windows 7 is supported using

Microsoft Mobile Device Center

• Microsoft Windows 7 32 bit and/or Microsoft Windows 7 64 bit are

supported

Document Conventions

Operating System

• Microsoft Windows 2000 (SP4) with ActiveSync software

• Microsoft Windows XP (SP3) with ActiveSync software

• Microsoft Windows 7 with Mobile Device Center software

Microsoft Windows Mobile Device Center replaces ActiveSync for Windows

Vista, and Microsoft Windows 7. Windows Mobile Device Center offers device

management and data synchronization between a Windows Mobile-based

device and a computer. For Windows XP or earlier operating systems, you must

use Microsoft ActiveSync.

These are document conventions used in this manual.

• The Enpac 2500 data collector is referred to as a data collector and an

instrument in this manual.

• The different versions of the Emonitor software are Enterprise, Factory,

and Workstation. These are all are referred to as the Emonitor software in

this manual.

14 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 15

Preface

Using Online Help

The Emonitor software and the Enpac 2500 data collector each include online

help:

• Emonitor Online Help

The Emonitor online help is available from the Emonitor Help menu or by

pressing F1.

• Enpac 2500 Online Help

The Enpac 2500 data collector online help is available from any screen

where the Help function appears. Press F1 (Help) to access the online help.

On some screens that do not display the Help function, pressing Shift(0)

provides access also to the Help.

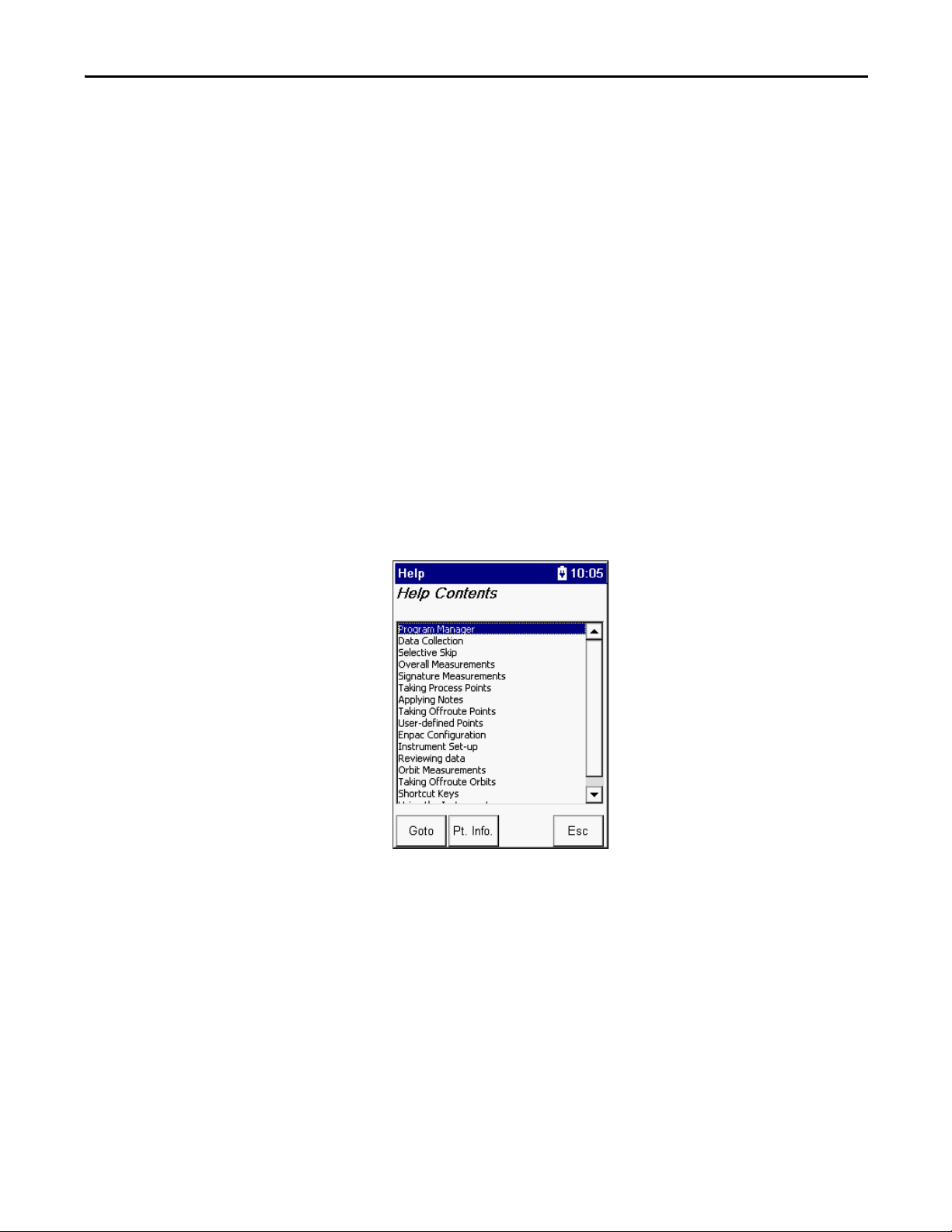

Help Screen

Press F1 (Help) to access online help from any screen where the Help function is

displayed on the screen.

1. Press F1 (Help) to access the online help.

The Help Contents screen appears.

2. Select the topic for which you want to view and press F1 (Goto).

3. When you are finished viewing the topic, press F1 (Contents) to return to

the Help Contents screen or press F4 (Esc) to exit the online help.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 15

Page 16

Preface

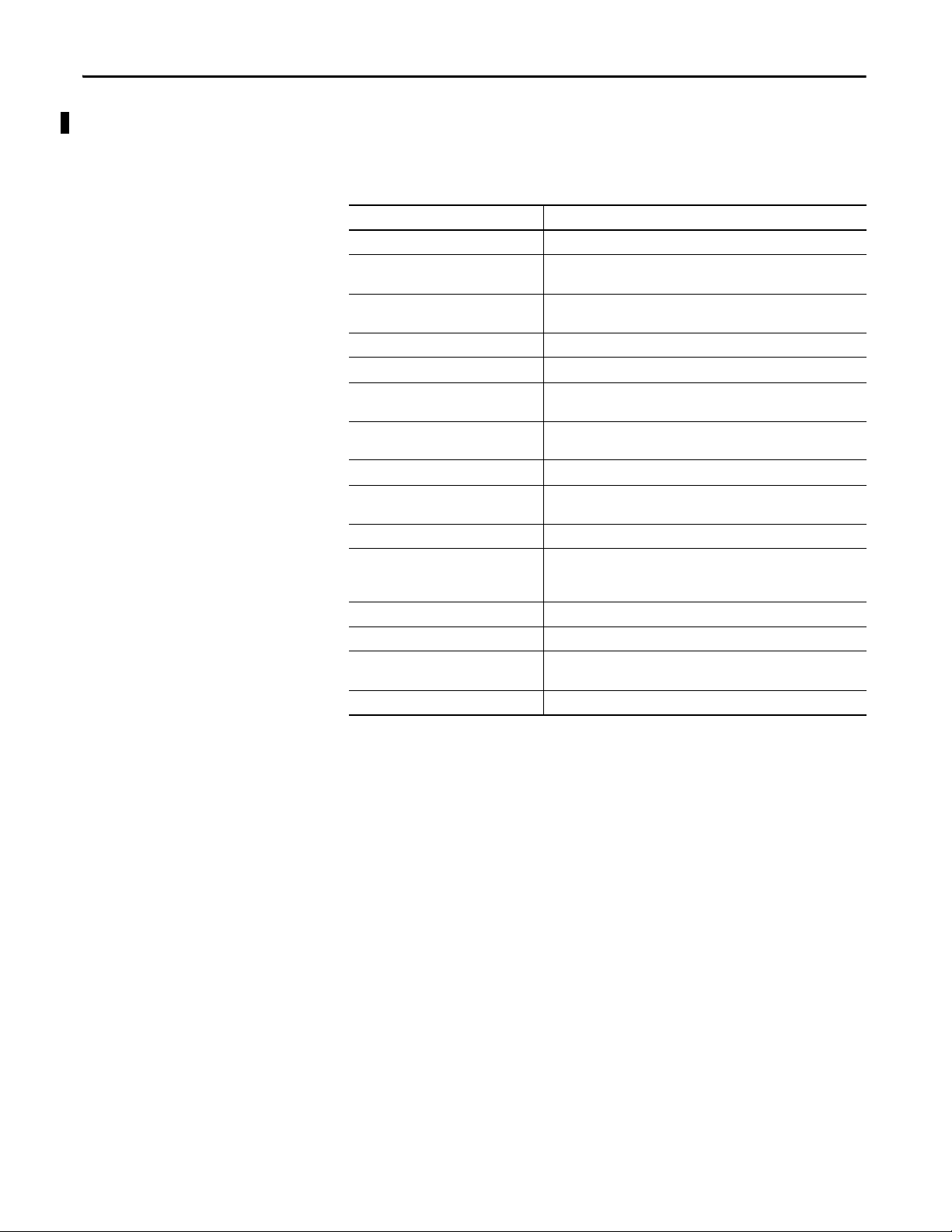

Organization

To help you navigate through this manual, it is organized in chapters based on

these tasks and topics.

Section Description

Preface Contains an overview of the manual.

Chapter 1, The Enpac 2500 Describes the Enpac 2500 data collector and covers the basic operations

Chapter 2, Setting up Measurements Describes setting up measurement definitions in Emonitor for use with

Chapter 3, Loading and Unloading Describes loading lists and unloading data.

Chapter 4, Collecting and Reviewing Data Describes the tasks associated with collecting data including list data.

Chapter 5, Multi-channel Measurements Shows you how to set up and collect dual channel, cross channel phase,

Chapter 6, Balancing Application Describes methods used for performing one- or two-plane balancing by

Chapter 7, Time Recording Application Describes how to set up and collect time recording measurements.

Chapter 8, Bump Test Application Describes the tasks needed to set up and collec t bump test

Chapter 9, Run Up/Coast Down Application Describes recording and analyzing run up/coast down measurements.

Chapter 10, FRF Frequency Response

Function Extension Module

Appendix A, Specifications Lists the technical specifications for the Enpac 2500 data collector.

Appendix B, Frequently Asked Questions Contains answers to frequently asked questions.

Appendix C, Accessories Provides a current list of accessories available for the Enpac 2500 data

Glossary Definitions of terms.

and configuration of the data collector.

the data collector. It also explains lists, inspection codes, and alarms.

and orbit measurements.

using the data collector coupled with a speed measuring device.

measurements.

Describes how to determine the natural frequencies where resonances

occur, as well as capturing data about the frequency response of the

structure being tested.

collector. For definitions of terms used in this Guide.

Document Conventions

There are several document conventions used in this manual, including the

following:

• The Enpac 2500 is referred to as Enpac, instrument, unit, or data collector

throughout this manual.

• The different versions of Emonitor (Enshare®, Odyssey Deluxe, and

Odyssey Basic) are referred to as Emonitor throughout this manual.

• Emonitor uses the term ‘list’ for an ordered set of measurement

definitions. The Enpac uses the term ‘route’ to refer to a list loaded in the

Enpac. This manual uses the two terms interchangeably.

16 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 17

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

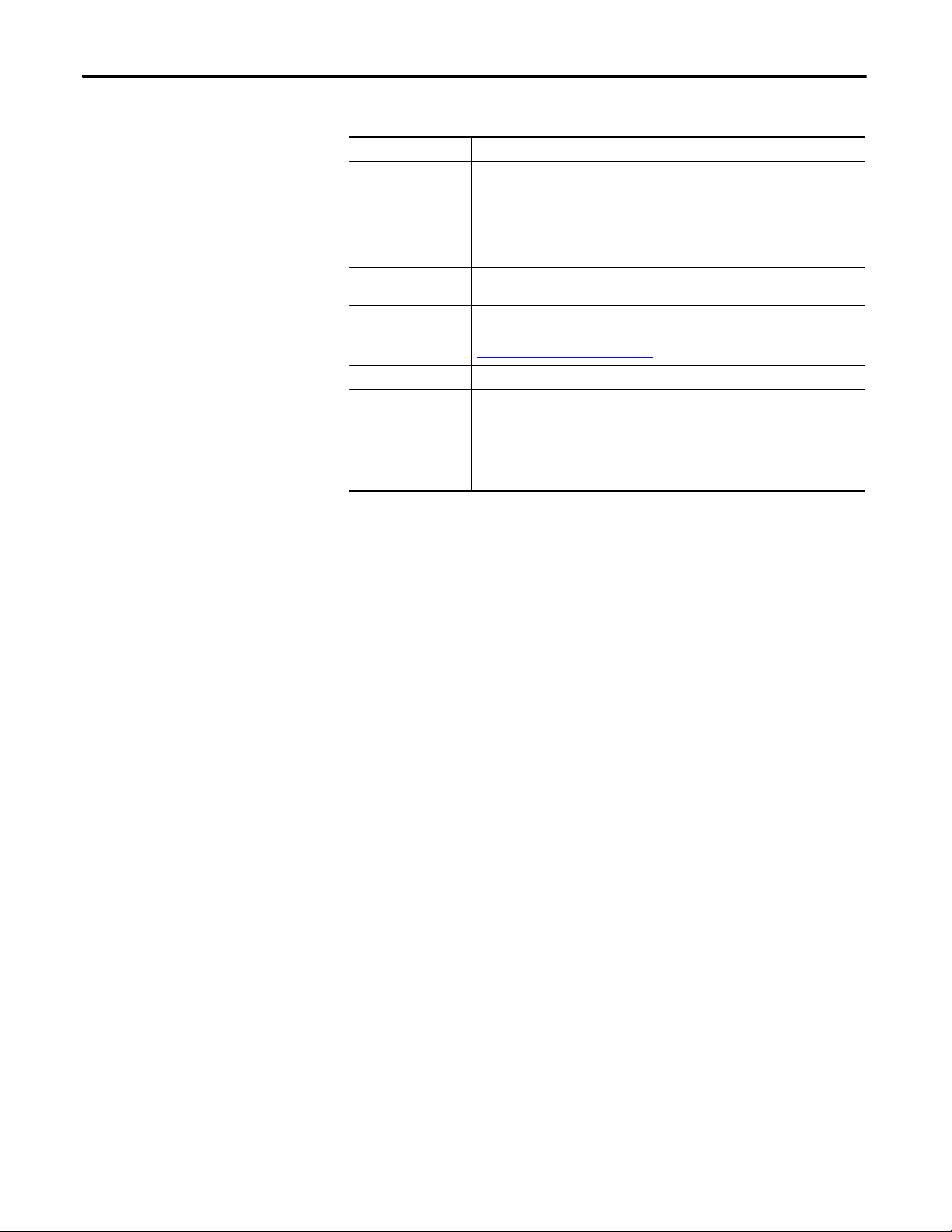

Resource Description

Emonitor Users Guide, publication

EMONTR-UM001

Enpac 2500 Data Collector Release Notes, publication

GMSI10-RN004B

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com

Describes data management for predictive

maintenance services.

Provides important information on the latest updates,

for example, firmware, certifications, warnings, and

hardware changes for the data collector.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 17

Page 18

Preface

Notes:

18 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 19

Chapter 1

The Enpac 2500 Data Collector

This chapter describes the Enpac 2500 in detail and covers the basic operations

and configuration of the data collector.

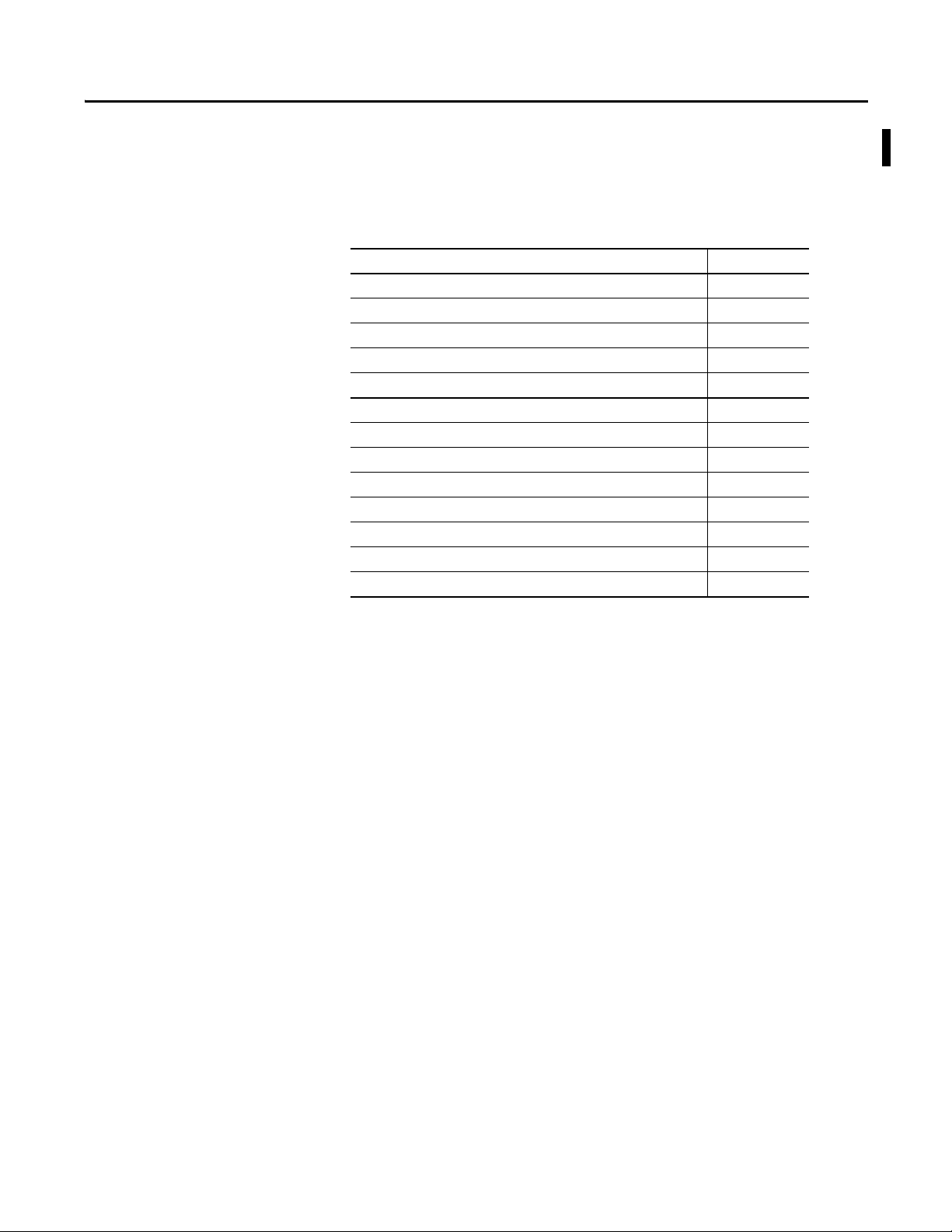

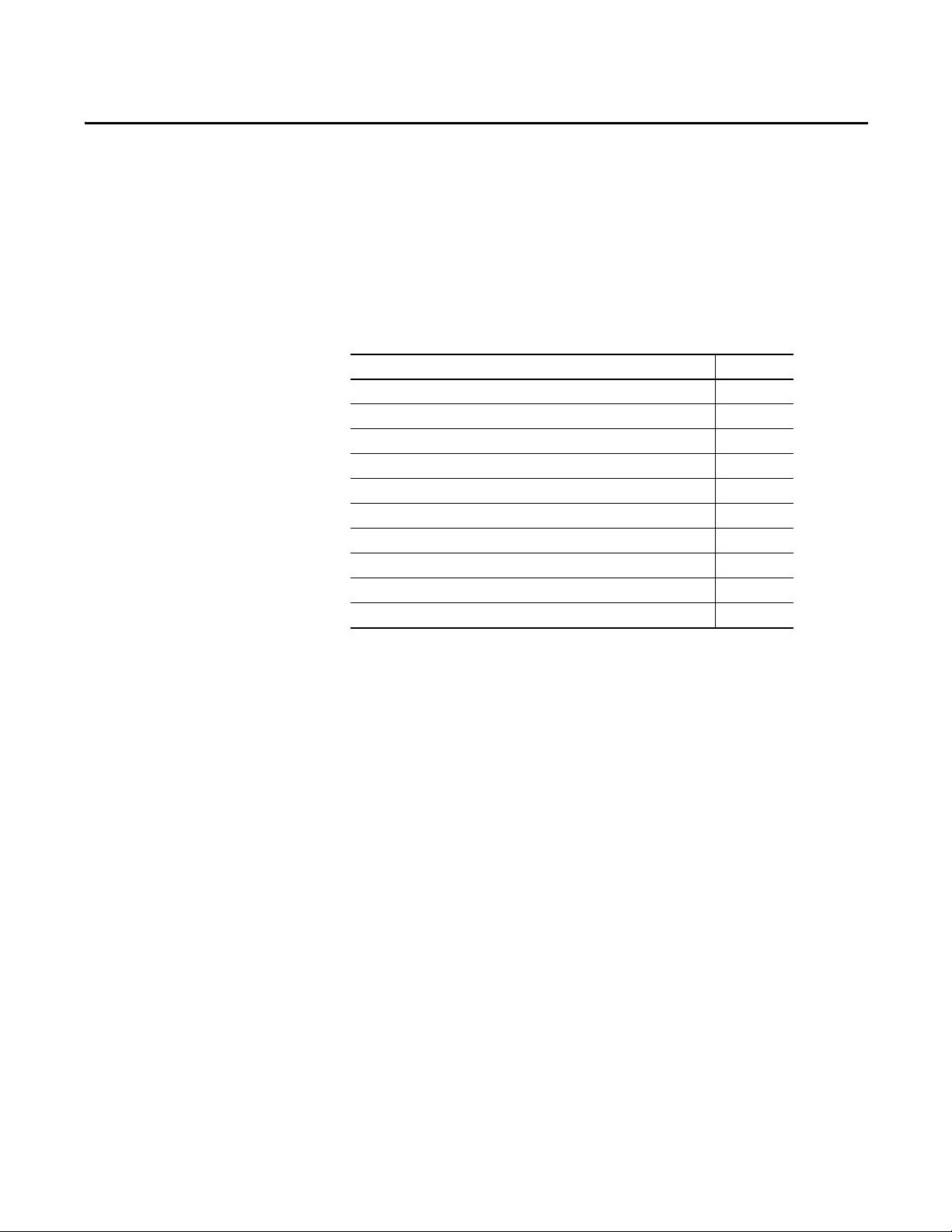

Top ic Pa ge

Safety Information 20

Parts of the Enpac 21

Battery Pack 26

Powering on t he Enpa c 29

Enpac 2500 Screens 29

Data Collection Screen 33

Setting Up the Enpac 2500 Data Collector 40

Using Memory Cards 47

Operating System Update Procedures 50

Adding Applications to the Enpac 2500 Data Collector 59

The combination of the Enpac 2500 data collector with Emonitor software

provides a complete package for predictive maintenance by using noise and

vibration analysis. The Enpac can also be used for a variety of other applications,

such as Balancing or Bearing Analysis.

A predictive maintenance program helps you decide when equipment needs to be

serviced or replaced. Part of a complete predictive maintenance program includes

vibration monitoring. Emonitor and the Enpac 2500 allow you to perform

vibration analysis by collecting data samples.

With the combination of predictive maintenance software and the Enpac 2500,

you can:

• Create lists of measurement definitions for data collection.

• Load lists from Emonitor into the Enpac 2500.

• Collect magnitude, process, spectrum, time, and phase data.

• View selected alarms with the data. The Enpac 2500 alerts you when a

measurement exceeds an alarm.

• Select inspection codes to store with a measurement, documenting the

condition of the machine.

• Unload the data from the Enpac 2500 directly into the Emonitor database,

along with any inspection codes and unscheduled measurements.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 19

Page 20

Chapter 1 The Enpac 2500 Data Collector

IMPORTANT

In addition, Emonitor can optimize your data collection by combining

measurement definitions at a location. For example, Emonitor could combine

two magnitude and one spectrum measurement definitions so that the list

appears to contain only a single measurement. This allows you to collect all three

measurements at one time, minimizing the time you spend collecting data.

The Enpac 2500 is a two-channel, real-time Fast Fourier Transformer (FFT)

analyzer and data collector for predictive maintenance and machinery vibration

diagnostics. It is capable of measuring, processing, displaying and storing a wide

range of analysis functions. It can operate as a stand-alone instrument or you can

download your measurements to your software application for program analysis.

Safety Information

Be aware of these safety precautions.

Avoid Water

The Enpac 2500 data collector is splash and dust resistant. However, avoid

direct contact with water, wet surfaces, or condensing humidity. Keep this

instrument away from wet locations, for example, laundry, wet basements,

swimming pools.

If the data collector subject to these conditions, adverse operation may result.

Before you use it, let the instrument dry thoroughly before operating.

ATT EN TI ON : To avoid damage or injury, place the Enpac 2500 data collector on

a solid stable surface when not in use and do not place any heavy objects on it.

Use only the accessories recommended by Rockwell Automation. Keep liquids

and foreign objects away from the instrument, and never operate it if any liquid

or foreign object has entered it.

Optical Ports

ATTENTION: When the laser on the data collector is active, viewing the laser

beam can expose your eyes beyond the maximum permissible exposure

recommendations and cause harm.

Laser Radiation Ports

ATTENTION: Class 1 laser product. Laser radiation is present when the system is

open and interlocks bypassed. Only trained and qualified personnel should be

allowed to install, replace, or service the instrument.

20 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 21

The Enpac 2500 Data Collector Chapter 1

READ/OK Key

Arrow Keys

ON/OFF

Numeric Keys

+/-

Decimal

0 or Shift

READ/OK Key

Funct ion Keys

(F1 to F4)

Parts of the Enpac

This section describes the basic components of the Enpac 2500 including key

definitions, hardware connections and status indicators. If you are already

familiar with the components of the data collector, you may want to skip this

section.

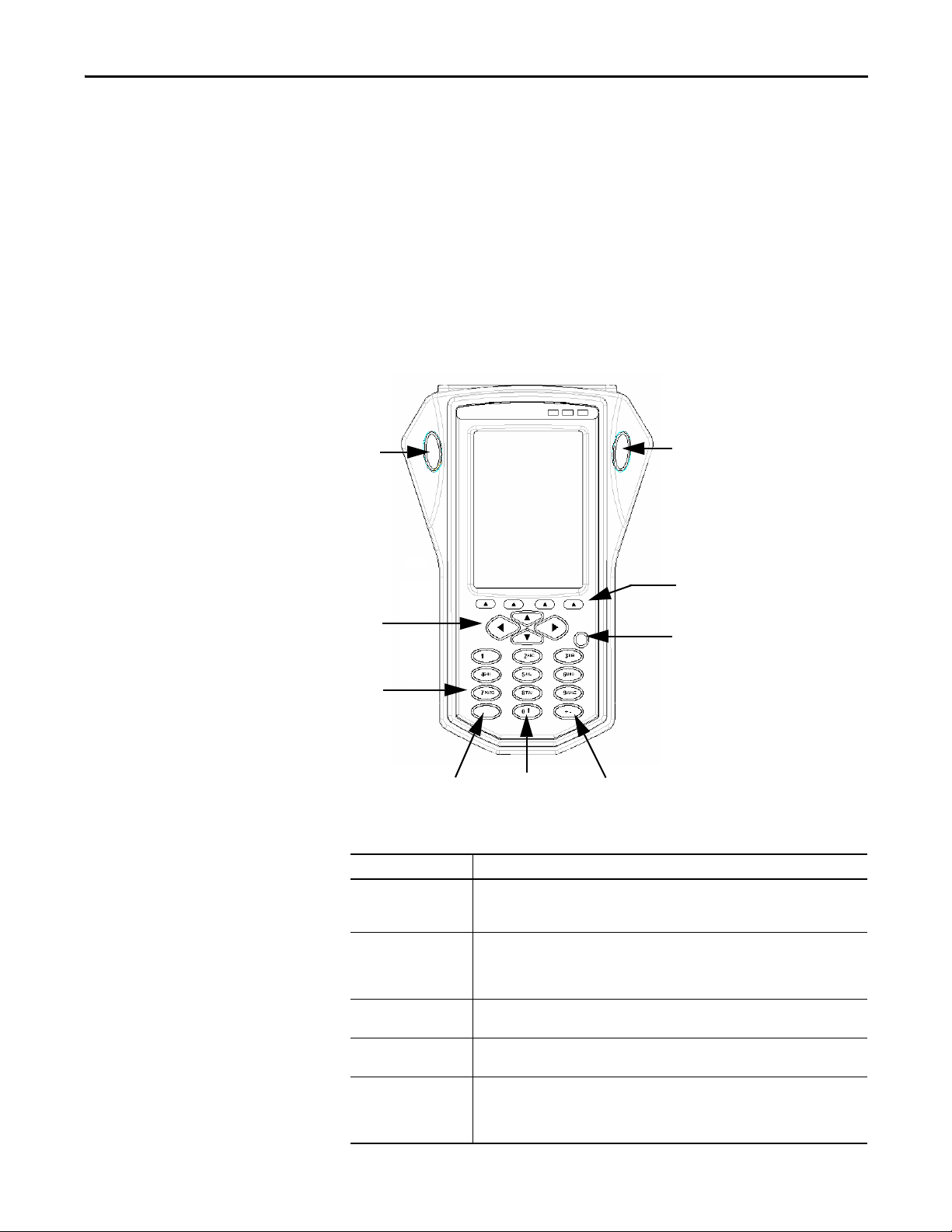

Enpac 2500 Diagram and Key Definitions

This is a diagram of the Enpac 2500 data collector showing the keys used for

operation.

Figure 1 - Diagram of the Enpac 2500

Table 2 - Key Definitions

Keys Definition

Read/OK The READ/OK key starts collecting data for the current point or accepts the current

Function Keys Below the display are four function keys referred throughout this manual as F1, F2, F3,

Up Arrow • Moves to the previous field or menu selection.

Down Arrow • Moves to the next field or menu selection.

Left Arrow • Displays the previous screen of information if there is more than one screen (for

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 21

measurement. There are two keys so you can use the data collector with either your left or

right hand.

and F4. The function keys change depending on the current state of the data collector. The

data collector displays the current function of the keys in the display above the key. When

no text appears above a function key, the key is inactive in the current window.

• Decreases the Y-axis scaling in a signature plot.

• Increases the Y-axis scaling in a signature plot.

example, selecting a point in the Data Collection screen).

• Closes the menu selection on the Setup and Instrument Configuration screens.

• Moves the signature cursor to the left.

Page 22

Chapter 1 The Enpac 2500 Data Collector

Table 2 - Key Definitions

Keys Definition

Right Arrow • Displays the next screen of information if there is more than one screen (for example,

selecting a point in the Data Collection screen).

• Opens the menu selection on the Setup and Instrument Configuration screens.

• Moves the signature cursor to the right.

ON/OFF The ON/OFF key turns the data collector on and off. To turn the data collector off, press and

hold the ON/OFF key for one second.

Numeric The numeric keys allow you to enter numeric values or move to the appropriate menu

selection on the Main Menu screen.

Decimal The Decimal (.) key allows you check the status of the battery, or enter a decimal point in a

numeric field.

Refer to Checking Battery Life on page 27 for more information.

+/- The +/- key allows you to expand or compress a signature plot on the screen.

0 The 0 key acts as a `Shift‘ key that has multiple uses depending on the current operation.

• In a Setup screen numeric input field, the key acts as a zero.

• In Setup screens, the key moves the selection to the first parameter when you are not

in an input field.

• In all other screens, pressing and holding the key displays alternate functions for the

function keys.

22 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 23

The Enpac 2500 Data Collector Chapter 1

IrDA Window, is not

supported.

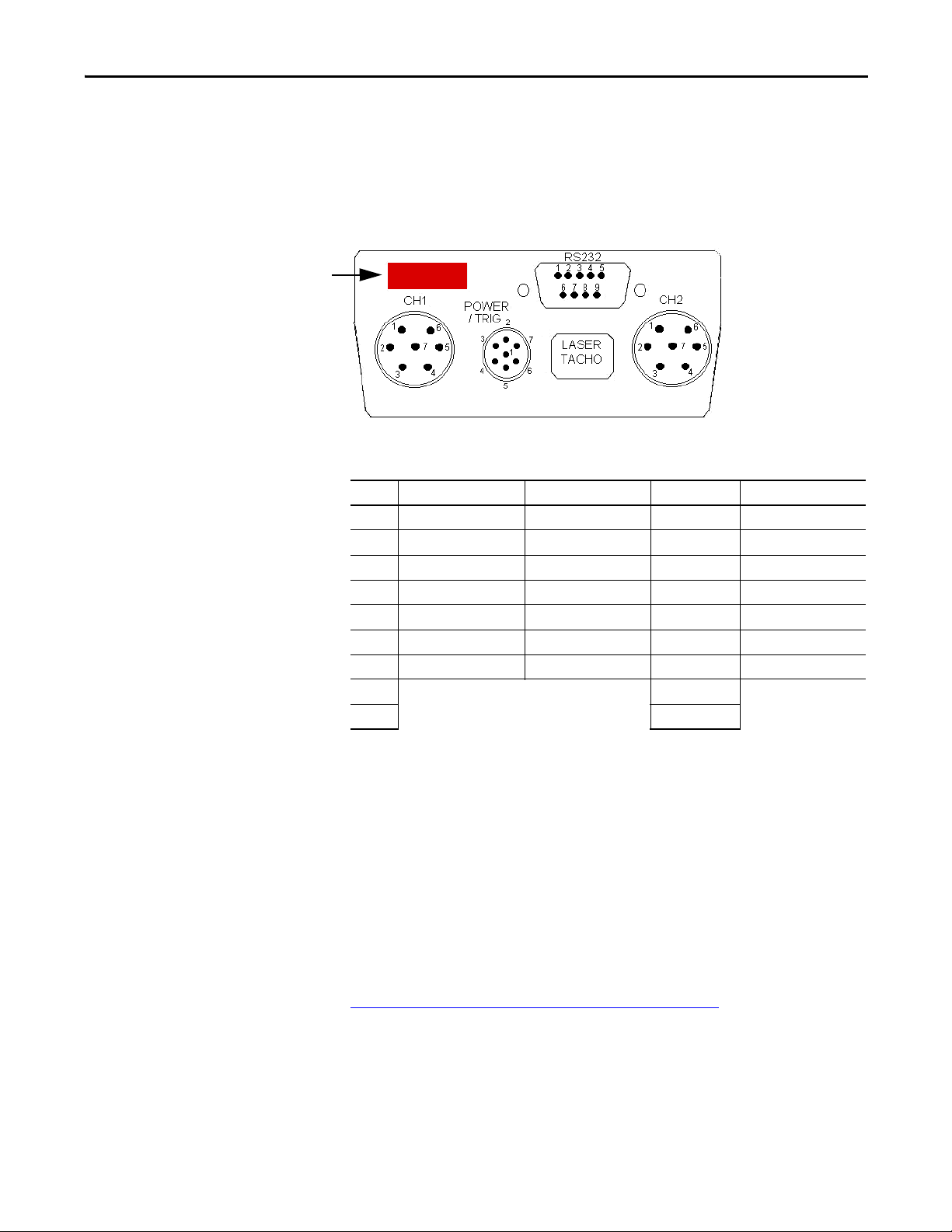

External Connections

The external hardware connections for communications and data collection are

located on the top panel of the Enpac 2500, as illustrated in this figure.

Figure 2 - External Hardware Connections

Table 3 - Pin Assignments

Pin No. CH 1 CH 2 RS-232 POWER/TRIG

1 N/C N/C N/C USBV

2 CHANNEL X CHANNEL Y TxD-OUT USB+

3 CHANNEL Z N/C RxD-IN USB4 STO RE/FIRE STO RE/FIRE DT R-OUT DIGITAL GND

5 ANALOG GND ANALOG GND DIGITAL GND EXT-DC-IN

6 CHANNEL Y N/C N/C EXT-TRIG-IN

7 N/C N/C CTS-IN +5V-TACHO-OUT

8RTS-OUT

9+5V

CH1 / CH2 Inputs

Signal inputs are made through the LEMO connectors marked CH1 and CH2

on the top of the Enpac.

The maximum measurement range is ±40 V while the minimum full-scale range

voltage available is ±10 mV (peak). The inputs are protected against high voltage

transients, but sustained over-voltage input levels must be avoided. Voltage can be

DC or AC coupled, while the third option, Accel (ICP), is available for direct

connection of integrated circuit piezoelectric transducers. These settings are

specified in the Emonitor software.

Refer to

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 23

Setting Up Measurement Definitions on page 78.

Page 24

Chapter 1 The Enpac 2500 Data Collector

External power

adapter

USB cable

In line socket

POWER / TRIG / USB

This socket connects the Enpac to either an external trigger, power adapter or

USB interface. The external trigger enables synchronization of the data

acquisition process to external events, such as tachometer inputs for rotational

synchronization for balancing applications, or for order normalization of

frequency spectrum. The trigger pulse can also be used to collect running speeds

of machinery. The pin assignment for the trigger is shown in Pin Assignments

page 23.

The external power adapter can be used to charge the internal battery. This can

be connected to the Enpac by connecting the DC output of the mains power

supply to the in line socket of the USB Power Splitter cable (Cat. No. 1441PEN25-COMS-US). Then connect the Fischer plug into the Power socket on

top of the Enpac. Only the provided transformer may be used. Any other supply

may cause permanent damage to the data collector.

A USB interface is also provided via the POWER/TRIG connector and the USB

Power Splitter cable. The interface is configured as a Client to allow automatic

connection to a PC through Microsoft ActiveSync™ software. This interface

allows you to copy files and transfer data from the data collector to your PC.

on

Refer to

Figure 3 - USB Power Splitter Cable

Installing ActiveSync on page 103.

RS-232 Interface

Data can also be transferred between the Enpac and your computer over an

RS-232 interface. The RS-232 interface is provided via a 9-way (Plug) Dconnector on the top of the Enpac 2500 data collector. The cable catalog number

is 1441-PEN25-COMS-RS.

24 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 25

The Enpac 2500 Data Collector Chapter 1

Red

Amber

Green

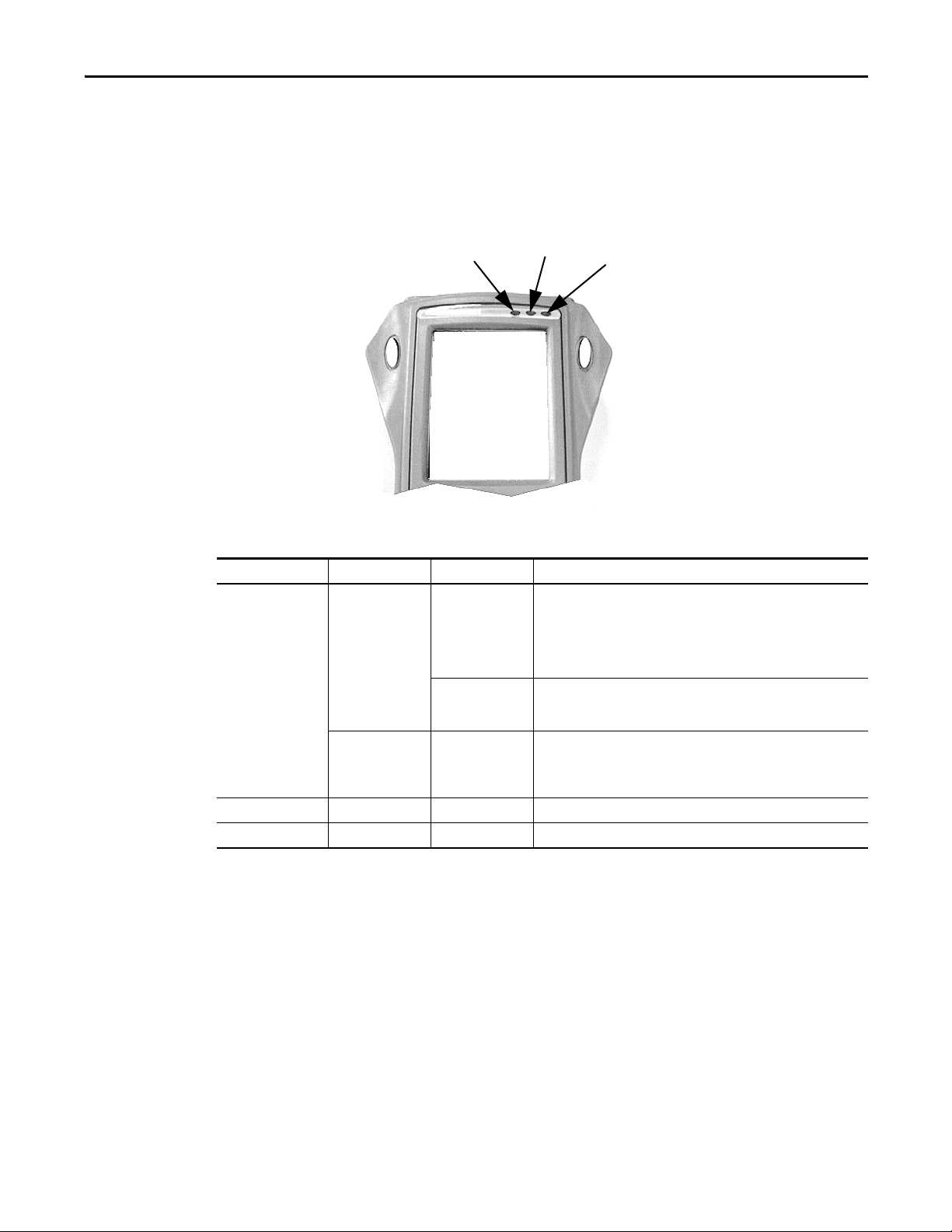

Status Indicators

The Enpac 2500 has three status indicators located in the upper-right side of the

Enpac nameplate.

Figure 4 - Status Indicators

Table 4 - Stat us In dicators

Status Indicators Operation State Definition

Red Charging Battery Flashing When first connected to the power adapter, the Enpac 2500 tests the

condition of the main battery. Within 30 seconds, the status indicators

should go to a solid state. If the status indicators continues to flash, the unit

has diagnosed a fault in the main battery and it will not charge the battery.

The problem may be that the cell temperature is too high or there is a fault

with the battery.

Solid The main battery is OK. The power adapter is connected to the Enpac 2500

and charging the main battery. The battery will be maintained by a trickle

charge from the power adapter for as long as it remains attached to the unit.

Data Collection Solid • An alarm condition has been set.

• Input signal is out of range.

• ICP Fail is active.

• The power adapter is connected to the Enpac 2500.

Amber Data Collection Solid Acquisition sub-system is settling.

Green Data Collection Solid Input signal is stable and data is ready to be stored.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 25

Page 26

Chapter 1 The Enpac 2500 Data Collector

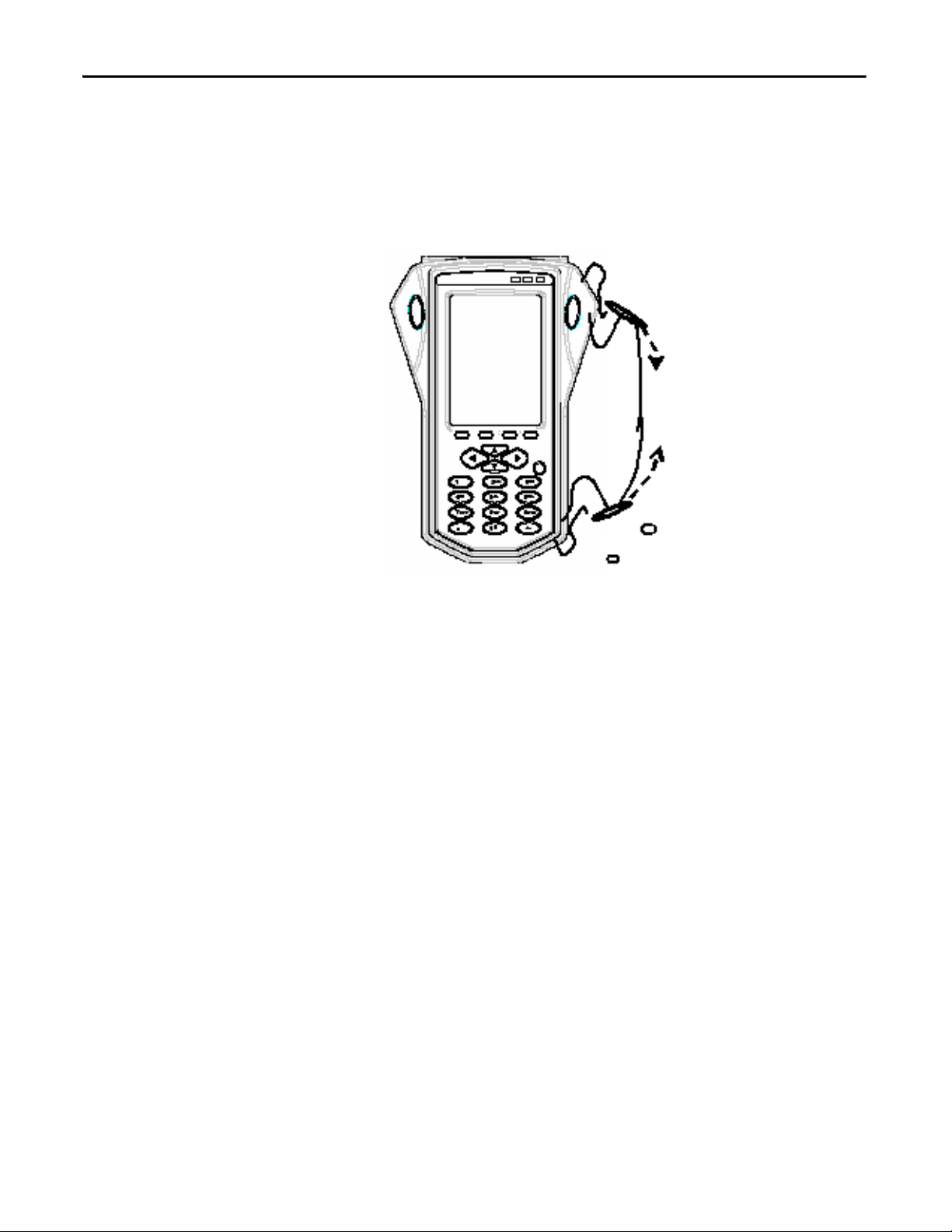

Strap Attachment

The strap can be fitted to either the left or right side of the Enpac 2500.

1. Feed the ends of the strap through the top and bottom corner pillars as

shown in the illustration below.

Battery Pack

2. Loop the ends of the strap through the buckles and adjust the tightness to

suit.

The Enpac 2500 data collector can be powered either from its own internal

Lithium Ion battery or by connecting the DC output of the mains power supply

to the in line socket of the USB Power Splitter cable. Then connect the Fischer

plug into the Power socket on top of the Enpac. The Enpac also has an internal

backup battery which maintains the system settings should the battery become

discharged or removed while the unit is not being powered by an external DC

supply.

This section describes how to check the battery level information and remove the

battery pack from the data collector. The Enpac battery pack is located on the

underside of the Enpac.

26 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 27

The Enpac 2500 Data Collector Chapter 1

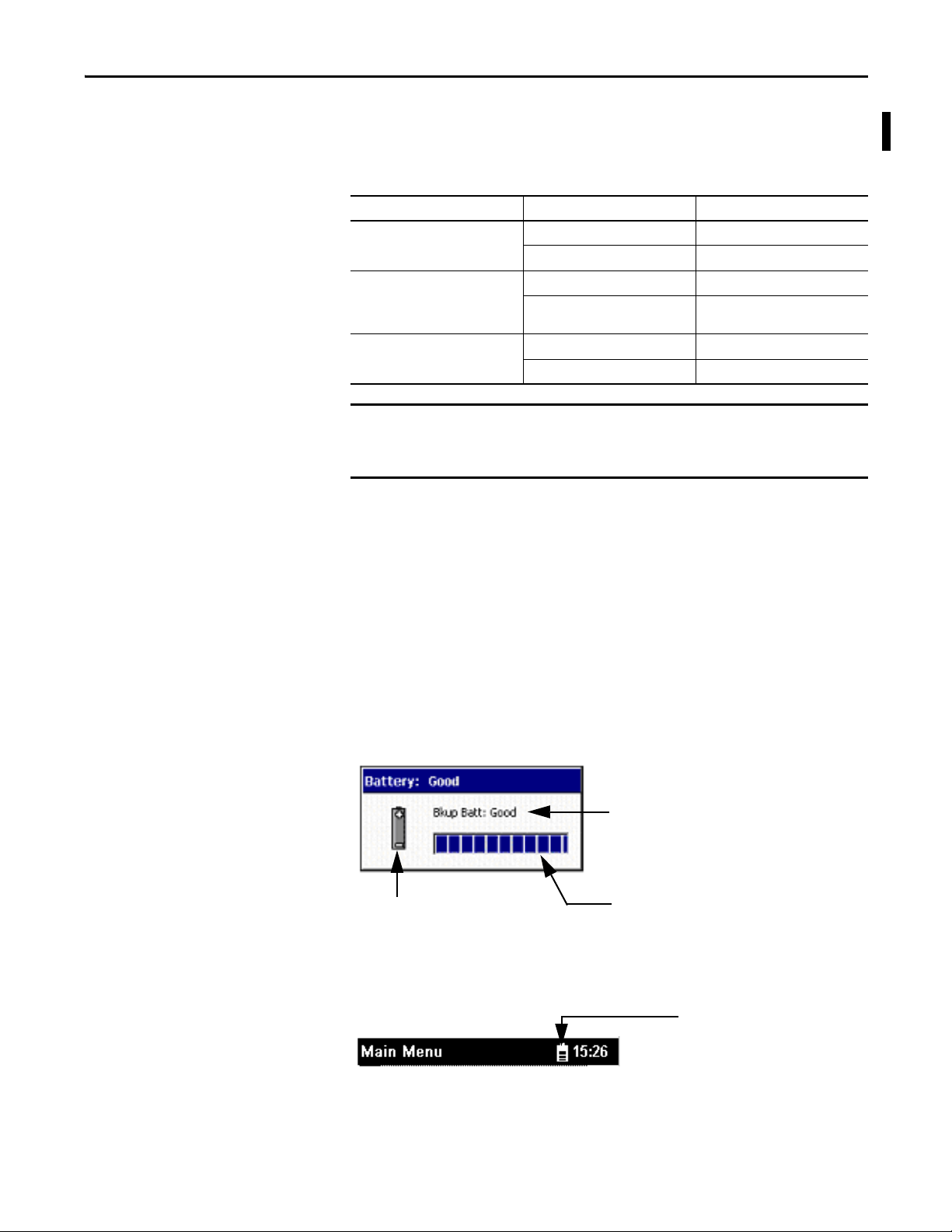

IMPORTANT

The condition of the internal

backup battery.

Main battery indicator bar

gauge.

Indicates the unit is operating under

internal battery. This changes to a plug

when under Mains power.

battery status indicator

This table shows the typical battery life for the lithium ion battery, assuming the

battery is properly charged.

Table 5 - Battery capacity

Mode State Typical Battery Life

On (Windows CE) Performing typical data collection 8 hours minimum

Idle mode 14 hours minimum

Off Main battery & backup battery 14 days minimum

Main battery removed & instrument

running on backup battery

Main Battery Charge Time 100% 5 hours

70% 3 hours

2 days minimum

If the main battery is allowed to discharge completely, the instrument will

behave as if it has experienced a hardware reset. When you reapply power,

the current date, time and status information will be lost.

Checking Battery Life

You can check the status of the battery in the Enpac 2500 by pressing the Decimal

(.) key. (This function is available on most screens.)

The Battery Status dialog reports the status of the internal battery and the

condition of the units backup battery. The backup battery charges while the unit

is connected to the external DC power adapter or when the unit is powered on by

using the internal battery.

Figure 5 - Battery Status Dialog

The battery status is also displayed in the upper-right corner of the caption bar.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 27

Page 28

Chapter 1 The Enpac 2500 Data Collector

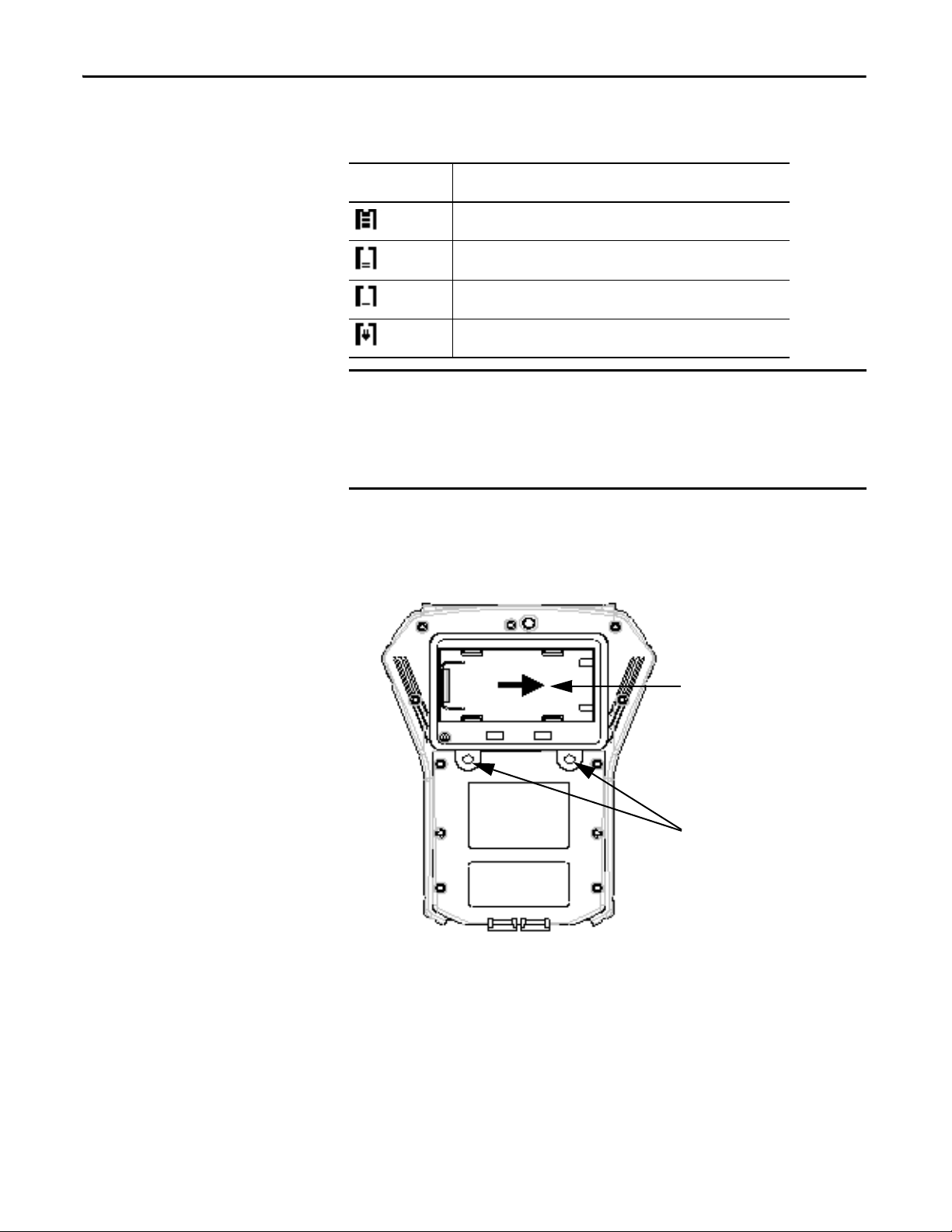

IMPORTANT

TIP

Release screws to access battery

pack.

Once battery cover is removed,

slide cell to left and lift out.

This table shows battery status icons relative strength of the battery.

Table 6 - Battery status icons

Battery Icon Meaning

Battery status is good (>30% life remaining)

Battery status is low (>10% life remaining)

Battery status is very low (<10% life remaining)

Battery charging

The Enpac 2500 will automatically notify you when the battery status is

30% or lower. To clear the notification, press the Decimal (.) key. The

notification will periodically appear until the battery is recharged or the

power adapter is attached.

When the battery status is 10% or lower, communications is prohibited.

Inserting and Removing the Battery Pack

1. Using a flat head screwdriver, remove the quick release screws (underside

of the data collector).

2. Remove the battery cover.

The Enpac has a safety switch positioned under the plate of the

battery compartment. When you remove this cover, the data

collector shuts down (as if the ON/OFF key was pressed.)

3. Slide the cell to the left and lift it out from the data collector.

The battery is inserted into the data collector by following this process in

28 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

reverse order.

Page 29

The Enpac 2500 Data Collector Chapter 1

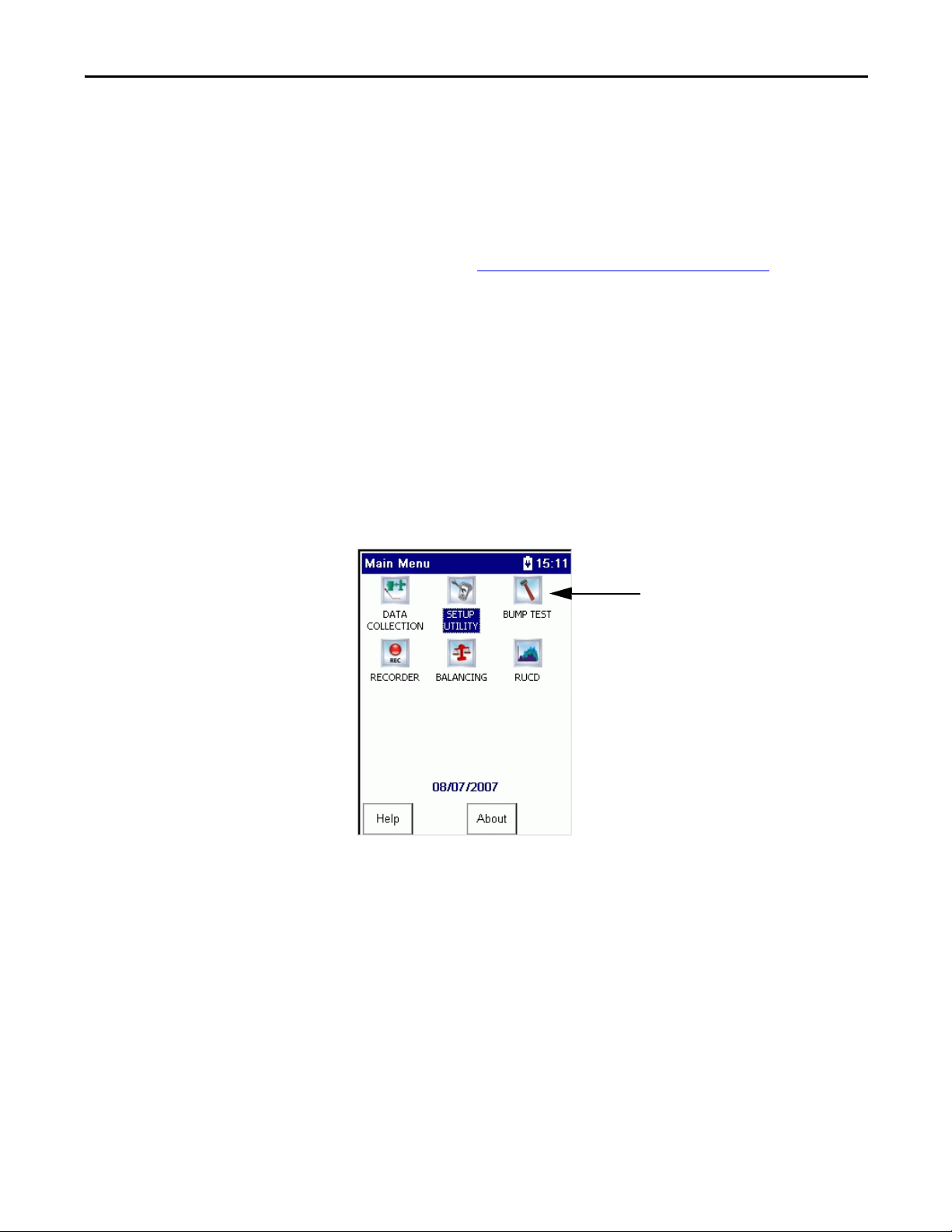

TIP

Bump Test, Balancing, Recorder

and RUCD are optional

applications.

Powering on the Enpac

Enpac 2500 Screens

The ON/OFF key powers the Enpac 2500 on and off. A single press of the key

powers on the data collector. However, to power off the Enpac 2500, press the

ON/OFF key for a period of one second. The Enpac 2500 resumes operation at

the last screen you viewed when you powered off the unit.

The first time you power on the Enpac 2500 or following a reset, the

Instrument Setup screen automatically appears in the display.

Refer to

Set the Date, Time, and Date Format on page 32.

This section introduces you to the main screens that appear when operating the

Enpac 2500. There are many other screens that appear while operating the Enpac

2500. These screen are described with the operation.

Main Menu

The Main Menu allows you to navigate to the different programs in the Enpac

2500. Each option in the Main Menu allows you to complete different tasks, such

as collecting data, defining the setup options, and reviewing data.

To make a selection from the Main Menu, highlight the option by using the

arrow keys and press either of the READ/OK keys.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 29

Page 30

Chapter 1 The Enpac 2500 Data Collector

The Main Menu includes these standard options.

•Data Collection - The Data Collection option allows you to collect both

route and unscheduled (off route) data. It also allows you to view any data

stored in Enpac 2500. The data can be viewed on the screen by using the

RS-232 interface.

Refer to

Data Collection Screen on page 33 for more information.

•Setup Utility - The Setup option allows you to set up global options for

collecting data.

Refer to

Setup Screen on page 30 for more information.

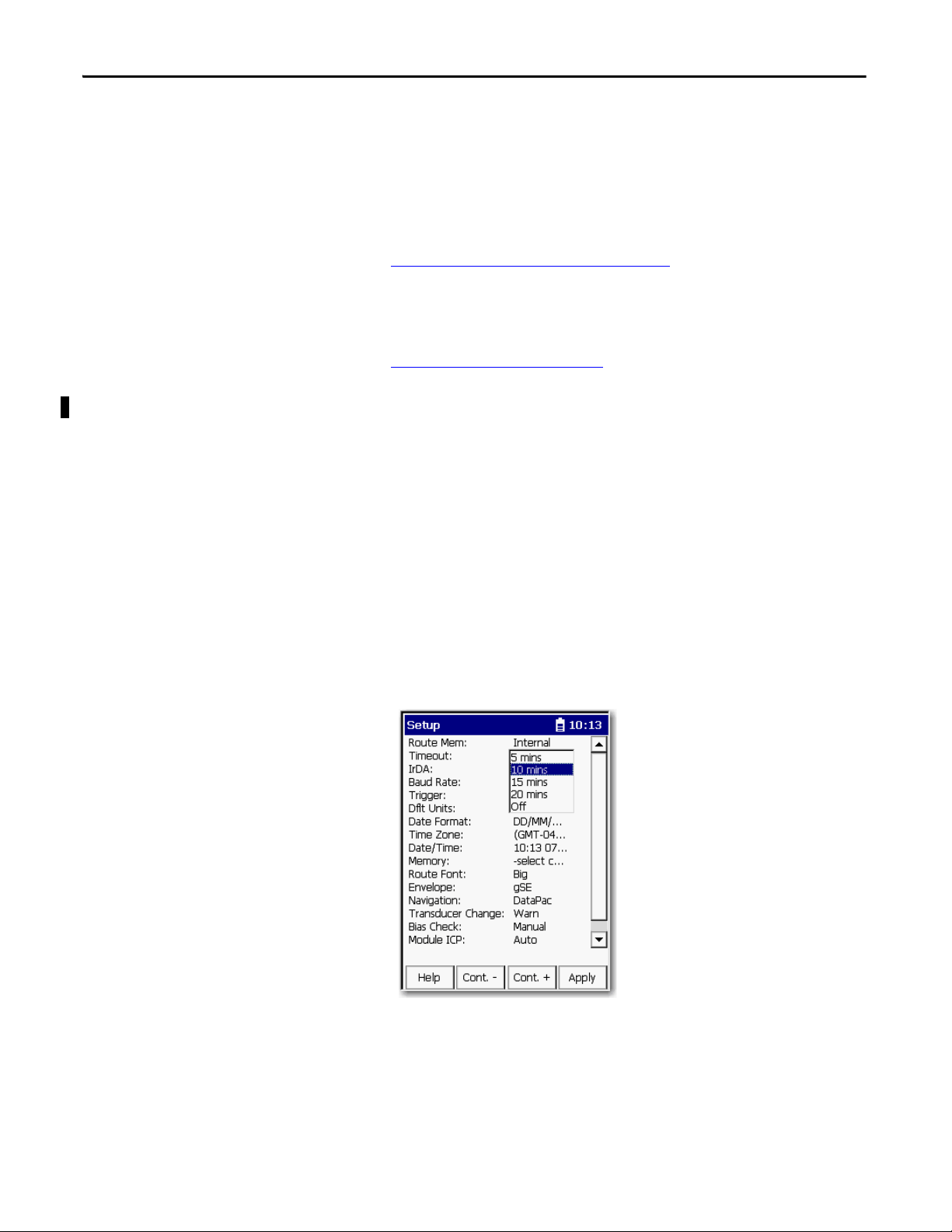

Setup Screen

The Setup screen allows you to set up global options for the Enpac 2500,

including date and time. The Enpac 2500 displays the Setup screen when you

first power on the instrument or after you reboot or hardware reset the Enpac

2500. You can also access this screen by selecting Setup Utility from the Main

Menu.

Follow these steps to edit an option.

1. Use the up or down arrow keys to select the parameter.

2. Press the right arrow key to open a list of choices.

This is an example of the timeout list of options.

3. Select the choice by pressing the arrow keys or type in a value using the

numeric key pad.

4. Press the left arrow key to make your selection.

5. Press 0 to display the additional options on the Setup dialog box.

30 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 31

The Enpac 2500 Data Collector Chapter 1

The Extension Manager and Calibration buttons appear.

The Extension Manager lists the option extension modules installed on

the data collector.

Refer to

Install Optional Extension Modules on page 189.

When you are finished, press F4 (Apply) to return to the Main Menu.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 31

Page 32

Chapter 1 The Enpac 2500 Data Collector

TIP

Set the Date, Time, and Date Format

The Enpac 2500 data collector keeps the current date format, date, and time even

when the instrument is powered off. However, there may be times when you need

to change these settings. For example, after restarting or resetting the Enpac 2500,

the date and time get set to 00:00:00.

Follow these steps to set the date, time, and select a date format.

1. Select Setup Utility from the Main Menu and press Enter.

The Setup screen appears.

On powering on the Enpac 2500 data collector for the first time or

after a restart or hardware reset, the Setup screen automatically

appears.

2. To change the format of the date, highlight Date Format and press the

Right arrow key to display the format choices.

3. Select the appropriate format and press the Left arrow key to save your

choice.

4. To change the date and time, highlight Date/Time and press the Right

arrow key to open the date and time window.

5. Enter the current time and date.

6. When you get to the Year field, press the Right arrow key to save your

entry.

7. When you are finished, press Enter to return to the Main Menu.

32 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 33

The Enpac 2500 Data Collector Chapter 1

Displays the instrument configuration

screen, which lets you access global

data collection settings.

If you press 0, the Help button appears

in the next level of function keys.

Data Collection Screen

The Data Collection screen allows you to navigate around the Routes loaded in

the data collector, collect and store route and off route data, and edit the data

collection options.

It also allows you to navigate through the stored data and to review previously

collected route and off route data.

When you select Data Collection from the Main Menu, the Route Manager

screen appears. All of the routes that you download from Emonitor to the data

collector appear on the Route Manager screen.

Follow these steps to open a Route.

1. Select the route and press Enter.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 33

Page 34

Chapter 1 The Enpac 2500 Data Collector

To highlight an item, press the

Up or Down arrow key.

To view previously collected

route dat a.

Collect and review Offroute data.

Displays the Instrument

Configuration screen.

Backlight adjustments

The information for the first point taken appears.

To access four additional functions for the Data Collection screen, press 0.

Follow these steps to move around in the Data Collection screen.

1. Select the hierarchy level, for example, Plant, Train, Machine, and

Location.

The Enpac 2500 supports up to six hierarchy levels for each point. These

levels are defined by the structure of the Route database in the Emonitor

software. The number and labels of these levels vary according to the way

your Route database was set up.

2. Display the next screen of information, for example, a list of location

measurement points, press the Right arrow key.

34 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 35

The Select Location screen appears.

TIP

Use the Up and Down arrow keys

to highlight the point.

The Selection screen does not appear if you set the route

Navigation mode to `DataPac’ in the Setup Utility menu. Instead,

the Enpac 2500 data collector automatically moves to the next

point in the route when you press the Right arrow.

The Enpac 2500 Data Collector Chapter 1

Task Action

Select an item. Highlight the item and press the Left arrow key.

Leave the screen without selecting an item. F4 (Esc)

Start collecting data. Enter

Review previously collected route data. F1 (Review)

Collect and review Offroute data. F2 (Offroute)

See Collecting and Reviewing Data on page 119

for more information.

3. To select an item, highlight the item and press the LEFT ARROW key.

To leave the screen without selecting an item, press F4 (Esc).

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 35

Page 36

Chapter 1 The Enpac 2500 Data Collector

4. To start collecting data, press READ/OK.

5. To review previously collected route data, press F1 (Review).

6. To collect and review off route data, press F2 (Offroute).

7. When you are finished in the Data Collection screen, press F4 (Esc) to

return to the Main Menu.

Refer to Collecting and Reviewing Data on page 119

collecting and reviewing data.

for more information about

36 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 37

The Enpac 2500 Data Collector Chapter 1

To highlight a topic, press the UP or

DOWN ARROW key.

Help Screen

Online help is available from any screen where the Help function is displayed on

the screen.

1. Press F1 (Help) to access the online help. The Help Contents screen

appears.

2. Highlight the topic for which you want to view and press F1 (Goto).

3. When you are finished viewing the topic, press F1 (Contents) to return to

the Help Contents screen or press F4 (Esc) to exit the online help.

Engineer Mode Menu Screen

The Engineer Mode Menu screen allows you to perform various maintenance

operations such as resetting the unit to the default settings, or loading an

operating system to the data collector. The Engineer Mode Menu can only be

initiated manually.

To initiate the Engineer Mode Menu, perform a hardware reset and hold down

the RIGHT and LEFT ARROW keys.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 37

Page 38

Chapter 1 The Enpac 2500 Data Collector

Option 4 is not supported in the Enpac 2500.

Figure 6 - Engineer Mode Menu Screen

The Engineer Mode Menu provides you the following options. To select one of

the options, press the respective numeric key.

1. Force Clean Boot - During a normal boot sequence, the unit will

automatically update the registry contents into Flash memory so that any

changes are permanently stored. Select this option to bypass the normal

boot sequence and revert back to a ‘clean or default setup.

2. Download Image from Serial - Select this option to install a new

operating system onto the unit over the RS-232 serial interface. The

WinSerDL utility is required with this option.

Refer to

Operating System Update Procedures on page 50.

3. Download Image from PCMCIA - Select this option to install a new

operating system onto the unit using a PCMCIA ATA Flash card (FAT

format).

4. Touch Recalibration - This option is not supported in the Enpac 2500.

5. Exit and Launch CE - Select this option to exit the Engineer Mode Menu

and launch the Windows CE operating system.

38 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 39

The Enpac 2500 Data Collector Chapter 1

TIP

View Settings for Current Measurement Definition

You can review the measurement definitions for the current active measurement

point from the online help.

1. Press F1 (Help) to access the online help.

The Help Contents screen appears.

On some screens, Help is located on the second set of functions, press

(shift) to display F1 (Help).

2. Press F2 (Pt. Info.) to view the measurement definition.

The Current Point Info screen appears.

3. When you are finished, press F4 (Esc) to exit the online help or press F1

(Contents) to return to the Help Contents screen.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 39

Page 40

Chapter 1 The Enpac 2500 Data Collector

For the Route data to be accurately

time based, you must set the date and

time before leaving this screen.

Setting Up the Enpac 2500 Data Collector

Before you begin to take readings, you need to configure the instrument

parameters by using the Setup Utility, Instrument Configuration and Data

Collection screens.

Configure the Data Collector

By using the Setup Utility, you can configure the global options for your data

collector.

Follow these steps to configure the data collector.

1. Select Setup Utility from the Main Menu and press Enter.

The Setup screen appears.

2. Review the default values and edit if necessary.

3. When finished, press F4 (Apply) to return to the Main Menu.

40 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 41

The Enpac 2500 Data Collector Chapter 1

Table 7 - Setup Screen Parameter Descriptions

Parameter Description Value

Route Mem Sets the location where the loaded route data is stored. Internal (default)

Storage Card

Timeout The number of minutes the Enpac 2500 can remain idle before it shuts itself off to

conserve battery power.

Press On/Off to reactivate the instrument following a timeout. The instrument returns to

the point in the program where it was when it shut off. No stored data will be lost.

Trigger Sets the Phase/Order input trigger synchronization:

• Laser Tach enables the internal Laser Tachometer when a Phase or Order

measurement is collected.

• External uses the trigger input from the POWER/USB/TRIGGER connector as the

trigger source.

• RS-232 transfers data can also be transferred between the data collector and your

computer.

Dflt Units Defines the units of measurement for Offroute standard velocity measurements.

Important: Used only* for Offroute standard velocity measurements.

Date Format The format of the date displayed in the Enpac 2500. MM/DD/YYY Y (default)

Time Zone Sets the time zone.

Only used when using ActiveSync software data synchronization. The time zone on the

instrument must match the time zone on the computer. If you are not using ActiveSync

software then the time zone setting has no effect.

Important: Always set your instrument to the correct time zone or your files will not be

in sync by time zone.

Date/Time Displays the date and time in the format you select in the Date and Time parameters. Current data and time

Memory Configures the memory:

• Select cmd to exit this field without selecting an option.

• Delete all routes and data from memory.

• Initialize formats the memory. Deletes all files from memory including any route files

and directories.

Important: These commands are performed on the memory location as set by Route

Memory.

Route Font You can select the font size for the Route. Big or Small

Envelope The type of envelope to use for high frequency and rolling element bearing analysis.

Determines which pre-defined measurement you can use to collect Offroute data.

Navigation Determines how the instrument navigates through the routes in the Data Collection

screens when the Right arrow key is pressed:

• Enpac- The instrument displays a Selection screen from which you select the item

you want to collect or review.

• DataPac - The instrument functions like a dataPAC 1500 in that it automatically

advances to the next point in the route.

Transducer Change Notification of a transducer change.

If set to Warn, a prompt appears on the screen warning you of the transducer change.

Off (default)

5 min

10 min

15 min

20 min

External (default)

Laser Tach

RS-232

English (ips) (default)

Metric (mm/s)

DD/MM/YYY Y

YYYY/MM/DD

List of 30 time zones

Select cmd (default)

Delete all routes

Initialize

gSE (default), collects an Offroute gSE point.

ESP, collects an Offroute ESP point

Enpac

DataPac (default)

Warn (defa ult)

Do not warn

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 41

Page 42

Chapter 1 The Enpac 2500 Data Collector

Table 7 - Setup Screen Parameter Descriptions

Parameter Description Value

Bias Check The bias of the transducer before taking the measurement. Manual (default)

Automatic

Module ICP The Module ICP option allows the manual control of turning off/on ICP power to

transducers in application modules.

Language Sets the language for the user inter face. Chinese

Never

Always

Auto

English

Francais

Deutsch

Italiano

Portuguese (Brasil)

Russkiy

Espanol (Spain, traditional)

Configure the Data Collection Options

The data collection options affect the measurement, the data collection process,

and how the data displays on the Enpac 2500. The instrument stores the data

collection settings even when the instrument is powered off. However, you

should check these options each time you start data collection.

Follow these steps to download a Route onto the data collector by using the

Emonitor software.

1. Using the Route Manager, select an appropriate route and press Enter.

The Data Collection screen appears.

2. Press 0 (Shift) to display the Config function.

42 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Page 43

The Enpac 2500 Data Collector Chapter 1

The Config function should remain on the screen for approximately three

seconds after releasing the 0 key.

3. Press F4 (Config) to display the data collection options.

The Instrument Configuration screen appears.

4. Review the default values and edit if necessary.

5. When you are finished, press F4 (Apply) to return to the Data Collection

screen.

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012 43

Page 44

Chapter 1 The Enpac 2500 Data Collector

Value Description

On Default

The display is updated only when the data collector has collected and averaged all the data.

For example, if the number of averages is set to 20, then data is displayed only when 20 blocks have been collected and

averaged. There is no progress indication during data collection, only a `Collecting data... message.

This speeds up the data collection of the spect ra by using the percent overlap specified in Emonitor. The interim averages

are not displayed.

Off The display is updated as often as possible while the data collector is collecting and averaging the data. For example, if

the number of averages is set to 20, then data might be displayed for averages 1, 6, 12, 18, and 20. The averages that are

displayed depends on the Fmax and number of lines selected. If each block is acquired very quickly then only the first

and last updates may be seen. Data can be stored at any time once the spectrum has been displayed.

Important: The Off option applies only to spectral averaging, not time synchronous averaging. This means it has no

effect on Phase points or other time synchronous averaged measurements.

Value Description

On The instrument automatically accepts both the overall and signature measurements and proceeds to the next point in

the list.

The overall measurement is accepted based on an algorithm. The algorithm is based on a percent fluctuation over a

period of time (seconds).

If the overall stays with the % specified by Percent for the number of seconds specified with Time, the overall magnitude

is accepted.

You must press Enter to accept the overall measurement, and then press Enter again to accept the signature

measurement.

Off Default

Value Description

On The instrument automatically moves forward to the next point in the list after

collecting data for the current point. No spectrum is displayed.

Off Default

The instrument displays a spectrum after collecting data for the current point.

Table 8 - Instrument Configuration Parameters

Parameter Description Value

Freq. Units The frequency units for displaying spectra/FFT data in the data collector.

This parameter is initially set to the default frequency (Hz or CPM) in

Emonitor when you load a list.

Fast Averaging Sets the averaging display and overlap processing.

Hz: displays spectra in Hertz, cycles per second.

CPM (default): displays spectra in cycles per minute.

Orders: spectra in orders of the operating speed.

This is used only when order normalized or phase data is collected by

using a tachometer or strobe to trigger data collection.

Auto Store Controls the number of key presses required to accept data.

Time The number of seconds that the input signal must be steady for Auto

Percent The fluctuation percent for Auto Store to occur. 30% (default)

Auto Advance Determines whether the Enpac 2500 automatically moves forward to the next point in the list after collecting data for the current point.

44 Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Store to occur.

2 s (default)

This parameter is used only when Auto Store is set to On.

This parameter is used only when Auto Store is set to On.