Page 1

User Manual

Run Up Coast Down Extension Module for the

Dynamix 2500 Data Collector

Catalog Number

1441-DYN25-MRUC

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, Emonitor, Dynamix, Enpac, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Installing Optional Extension

Modules

Run Up/Coast Down Extension

Module

Index

Optional Extension Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1

Install an Extension Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Uninstall Extension Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Manage Extension Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Extension Module Battery Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2

Set Up Run Up/Coast Down Measurements . . . . . . . . . . . . . . . . . . . . . . . 17

Collect Run Up/Coast Down Measurements. . . . . . . . . . . . . . . . . . . . . . . 19

Displaying Measurements by Using a Bode Plot. . . . . . . . . . . . . . . . . . . . . 22

Set Up the Bode Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Display the Bode Plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Displaying Measurements Using a Nyquist Plot. . . . . . . . . . . . . . . . . . . . . 25

Set Up the Nyquist Plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Display the Nyquist Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Displaying Measurements in Table Format . . . . . . . . . . . . . . . . . . . . . . . . . 28

Set Up the Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Display the Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Displaying Measurements Using a Waterfall. . . . . . . . . . . . . . . . . . . . . . . . 31

Set Up the Waterfall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Display the Waterfall Plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Displaying Measurements Using a Spectrogram. . . . . . . . . . . . . . . . . . . . . 36

Set Up the Spectrogram Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Display the Spectrogram Plot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Save Run Up/Coast Down Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 40

Recall a Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Review Run Up/Coast Down Measurements. . . . . . . . . . . . . . . . . . . . . . . 43

Screen Capturing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Delete Run Up/Coast Down Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 3

Page 4

Table of Contents

Notes:

4 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 5

Preface

This manual covers the Dynamix 2500 data collector Run Up Coast Down

(RUCD) extension module.

When using the Dynamix 2500 Data Collector Run Up Coast Down Extension

Module, you can do the following:

• Record and analyze data from intermittent events and transient vibration

signals from non-steady state machines.

• Analyze a machine’s critical speeds and resonant frequencies.

Optional Extension Modules

These are the optional extension modules for the Dynamix 2500 data collector:

• 1441-DYN25-4C, 4-channel Activation

The 4-channel activation lets you take 3- or 4- channel magnitude, time

waveform, spectra, and Offroute measurements.

• 1441-DYN25-MBMP Bump Test

The Bump test (or hammer test) determines the natural frequencies of a

machine or a structure.

• 1441-DYN25-MBAL Balancing

The Balancing test resolves single-plane, two-plane, and static-couple

balances with high precision.

• 1441-DYN25-MFRF Frequency Response Function

The FRF test lets you determine the natural frequencies of a machine as

well as sophisticated information about the frequency response of the

structure being tested.

• 1441-DYN25-MREC Time Recorder

The Time Recorder test uses a the instrument as a data recorder for real-

time data acquisition and analysis.

• 1441-DYN25-MRUC Run Up Coast Down

The RUCD test records and analyzes data from intermittent events and

transient vibration signals from non-steady state machines.

(1)

See Additional Resources on page 6

(1) This is an activation license for the Dynamix 2500 data collector.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 5

for a listing of available publications.

Page 6

Preface

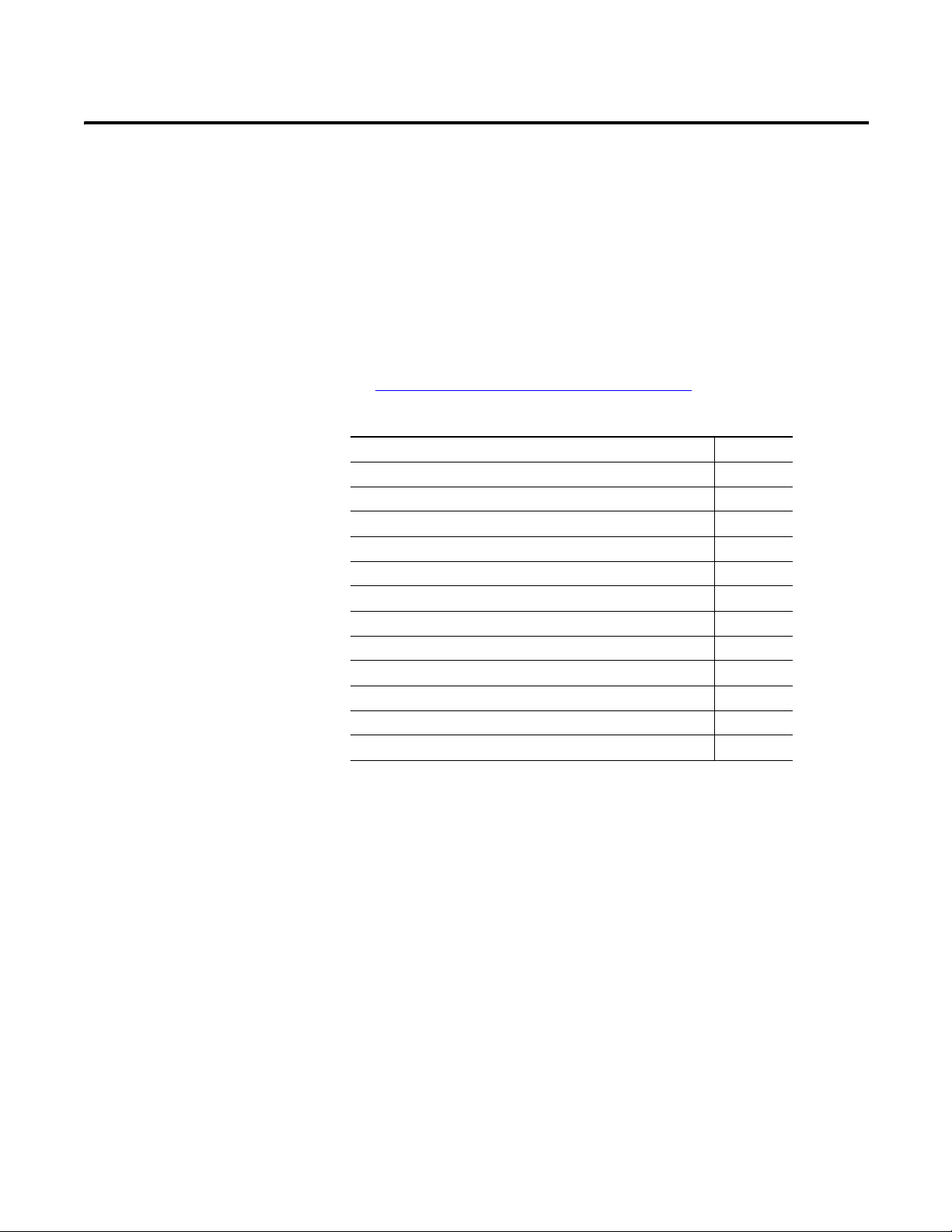

Additional Resources

These documents contain additional information concerning products from

Rockwell Automation.

Resource Description

Dynamix 2500 Data Collector User Manual,

publication 1441-UM001

Dynamix 2500 Data Collector Bump Test Extension

Module User Manual, publication 1441-UM002

Dynamix 2500 Data Collector Frequency Response

Function Extension Module User Manual,

publication 1441-UM003

Dynamix 2500 Data Collector Balancing Extension

Module User Manual, publication 1441-UM004

Dynamix 2500 Data Collector Time Recorder

Extension Module User Manual,

publication 1441-UM005

Emonitor User’s Guide, publication

EMONTR-UM001

Dynamix 2500 Data Collector Kit Release Notes,

publication 1441-RN001

Dynamix 2500 Data Collector Optional Extension

Modules Release Notes, publication 1441-RN002

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, http://www.ab.com

Describes the Dynamix 2500 data collector

which provides predictive maintenance by

using noise and vibration analysis.

Describes how determine natural (or resonant)

frequencies of a machine or structure.

Describes how to determine the natural

frequencies of a machine or structure using

modal hammer.

Describes the direct method to balance your

rotating machinery in one or two planes.

Describes how to use the data collector as a

data recorder for real-time data acquisition,

post processing, and analysis.

Describes data management for predictive

maintenance services.

Provides important information on the latest

updates, for example, firmware, certifications,

warnings, and hardware changes for the data

collector.

Provides important information on how to

install the Optional Extension Modules onto

the Dynamix 2500 data collector.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity,

certificates, and other certification details.

You can view or download publications at http://www.rockwellautomation.com/

literature. To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

6 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 7

Chapter

IMPORTANT

IMPORTANT

1

Installing Optional Extension Modules

The data collector uses the Extension Manager to install and uninstall extension

modules. These extension modules are licensed and ordered separately from the

basic entry level product.

Topic Page

Install an Extension Module 7

Uninstall Extension Modules 9

Manage Extension Modules 12

Extension Module Battery Status Indicators 13

The installation Secure Digital (SD) cards that you receive work with any

Dynamix 2500 data collector. Once you have installed an extension module, the

card is locked so that it can be used only with that instrument.

Install an Extension Module

One installation SD card is required for each instrument that needs to

be upgraded.

You can uninstall extension modules if required. When uninstalling an extension

module, you have the option to free up the license so you can install the extension

module on another instrument. This makes the extension module available to be

transferred between units.

When ever you re-run the OS Loader software, you will re-load only the

main OS firmware. The OS loader will backup licence files and data, but

not the optional extension modules. Once you have updated the OS

firmware, install the latest version of your optional extension modules.

See the Dynamix 2500 Data Collector User Manual, 1441-UM001

more information.

Follow these instructions to install an extension module.

1. Open the base cover at the bottom of the Dynamix 2500 data collector.

2. Place the extension module SD card contact side-up into the unit until it is

firmly seated in place.

, for

3. Close the base cover.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 7

Page 8

Chapter 1 Installing Optional Extension Modules

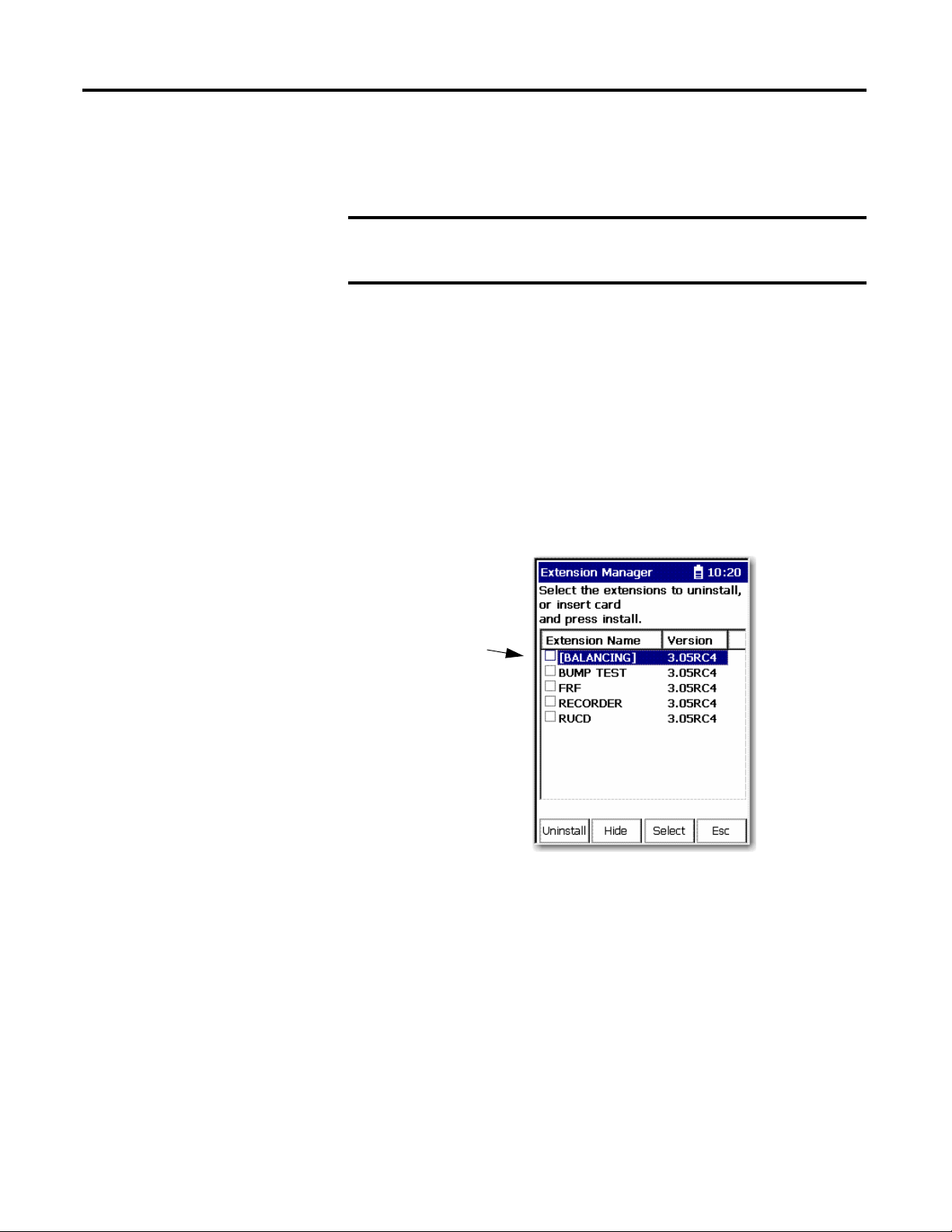

Extension Manager

4. Apply power to the data collector.

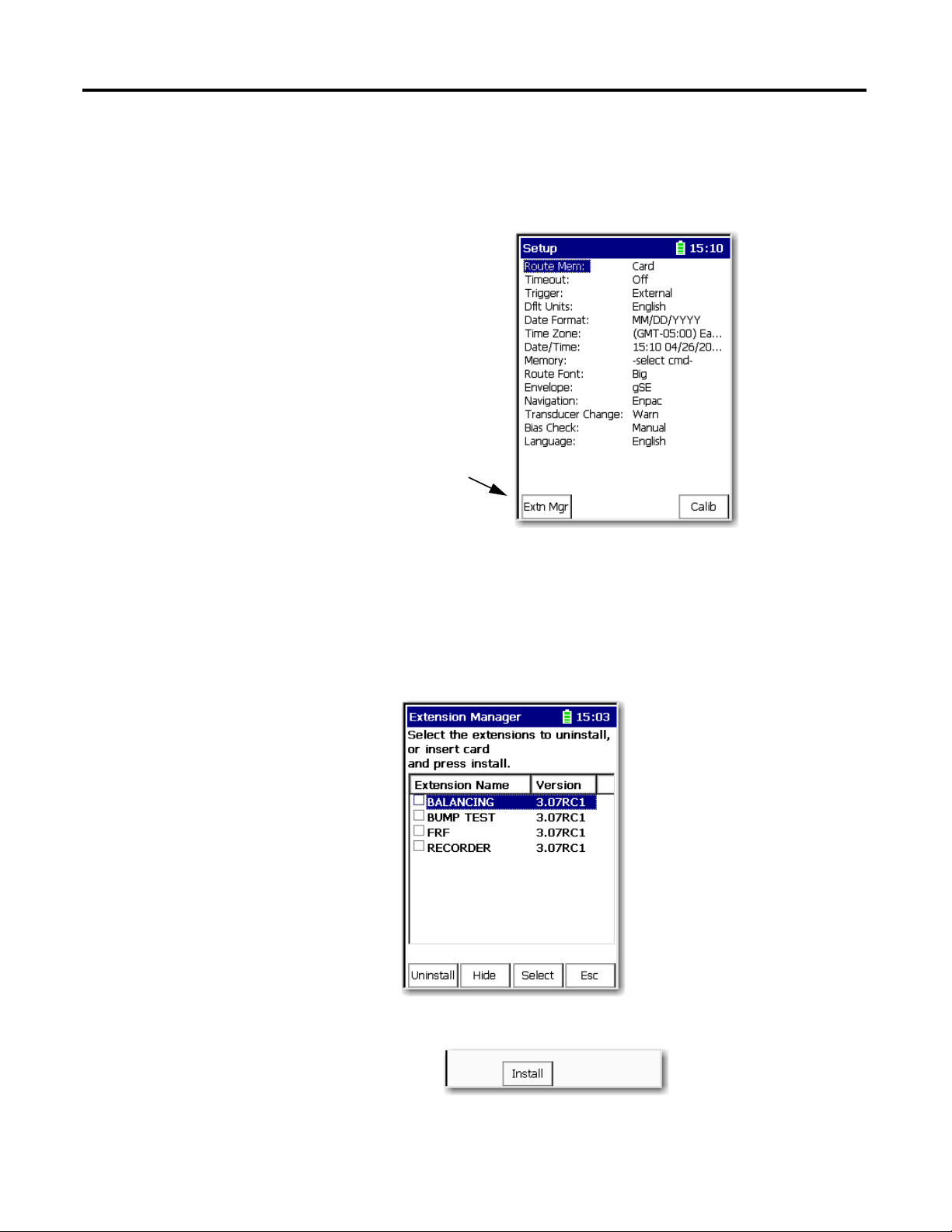

5. From the Main Menu, select Setup Utility and press Enter.

6. Press 0 (Shift) to display the second set of functions.

The Extension Manager function remains on the screen for about

3seconds after releasing 0 (Shift).

7. Press F1 (Extn Mgr).

The Extension Manager screen appears showing the current extension

module installations.

8 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

8. Press 0 (Shift) to display the Install extension function.

9. Press F2 (Install) to install the new extension module.

Page 9

Installing Optional Extension Modules Chapter 1

Extension Manager

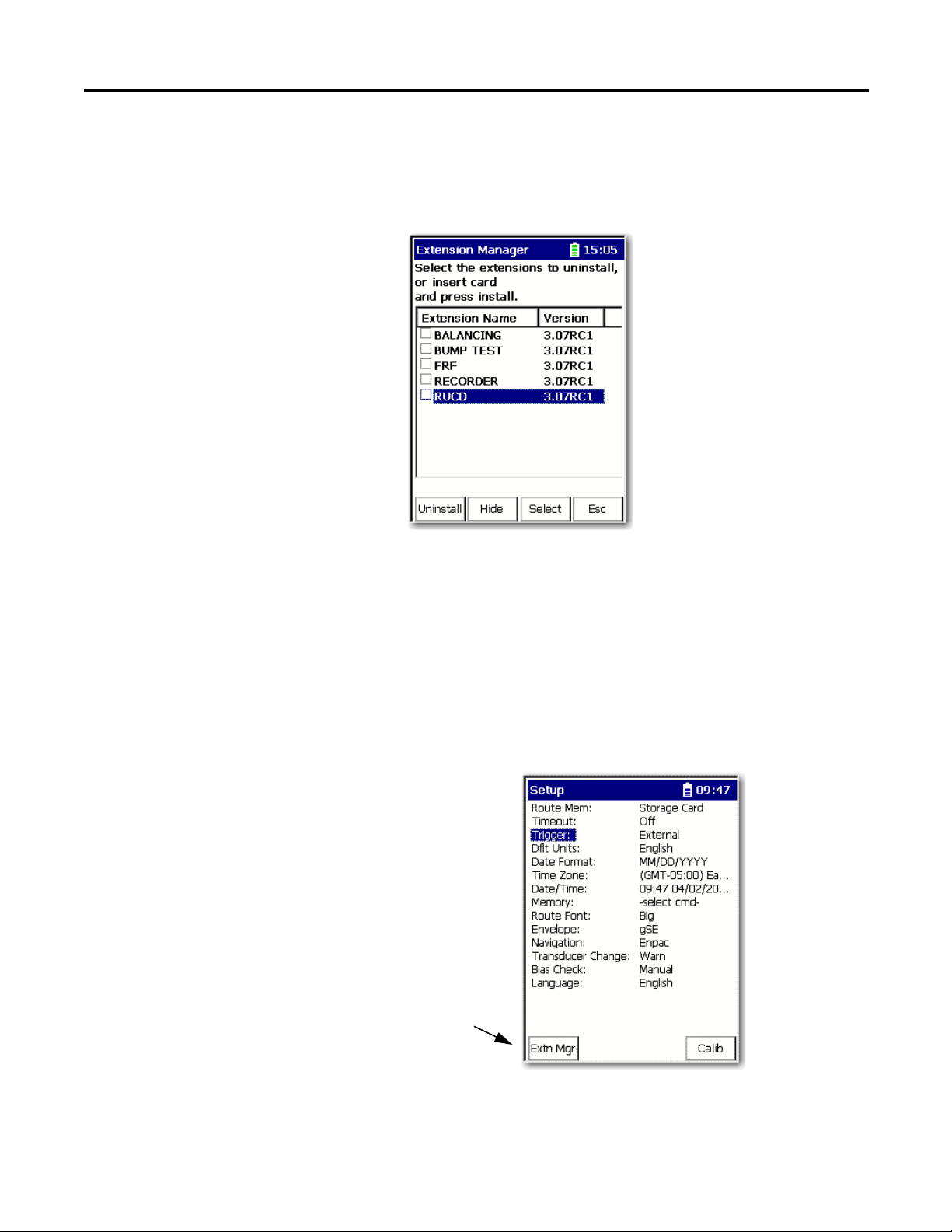

When the installation is complete, a confirmation prompt appears.

10. Press F4 (OK).

The new extension module appears in the list.

Uninstall Extension Modules

11. Press F4 (Esc) to exit the Extension Manager screen.

Follow these instructions to uninstall an extension module.

1. Press 0 (Shift) from the Setup Utility screen to display the Extension

Manager function.

The Extension Manager function remains on the screen for about three

seconds after releasing 0 (Shift).

2. Press F1 (Extn Mgr).

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 9

Page 10

Chapter 1 Installing Optional Extension Modules

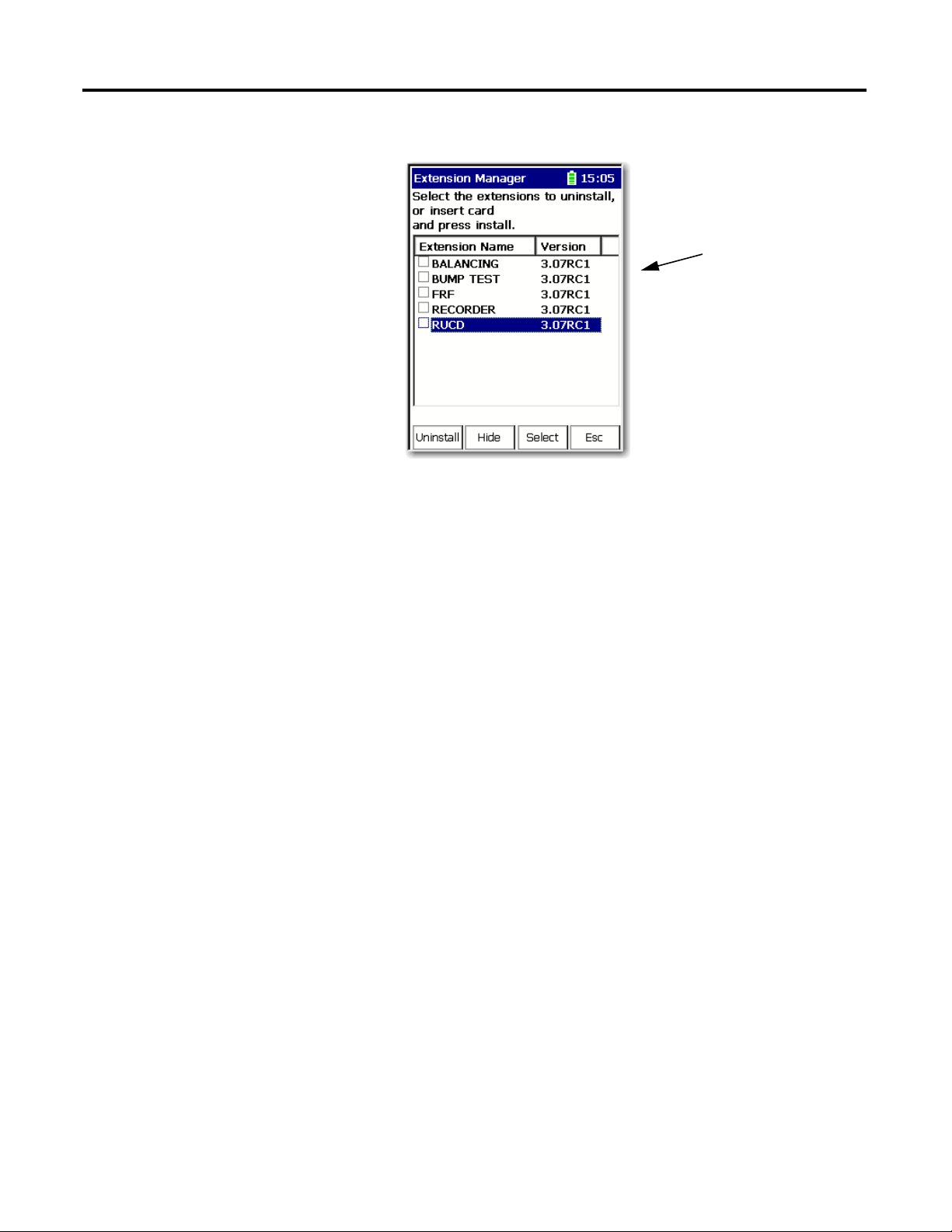

This screen lists the

extension modules

currently installed and the

on the unit.

The Extension Manager screen appears.

3. Select the extension module you want to uninstall and press F3 (Select).

F3 (Select) toggles the selection on and off.

10 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 11

Installing Optional Extension Modules Chapter 1

IMPORTANT

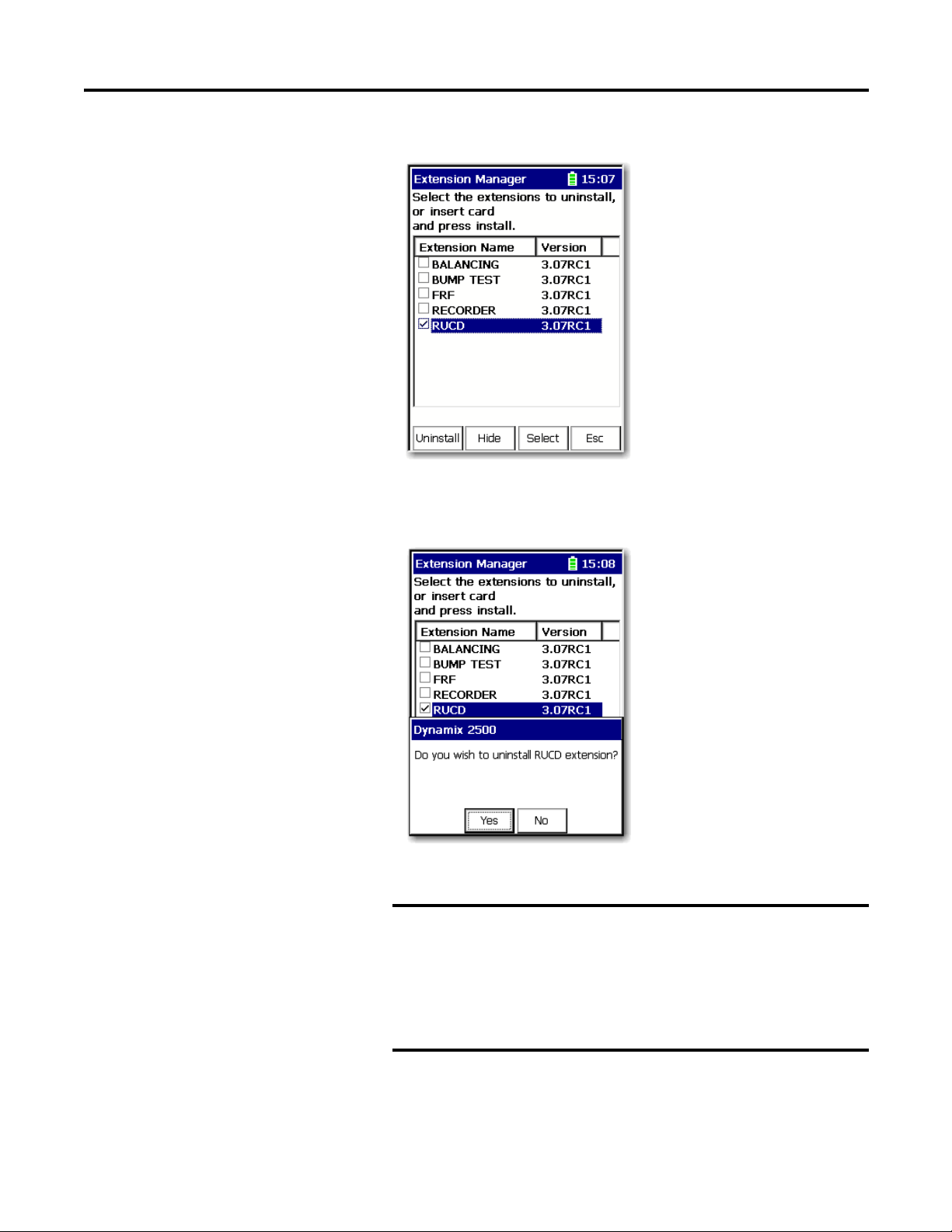

A checkmark appears next to that extension module.

4. Press F1 (Uninstall).

A confirmation message appears.

5. Make sure your installation card is inserted into the instrument.

The extension module is uninstalled and the license on the card is

released so that the card can be used to install the extension

module on another Dynamix 2500 data collector.

If the installation card is not inserted in the instrument and no

card, you are is found or the card does not have the extension

module license for the unit, you are prompted to insert the correct

installation card or continue without freeing the license.

6. Press F2 (Yes) to uninstall the extension module.

7. Press F4 (Esc) to exit the Extension Manager screen.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 11

Page 12

Chapter 1 Installing Optional Extension Modules

IMPORTANT

TIP

The extension modules that

are hidden are shown in

[square brackets].

Manage Extension Modules

The Dynamix 2500 data collector lets you to hide installed extension modules

from the Main Menu. You may need to hide an advanced extension module icon

from an inexperienced user, for example, RUCD and FRF.

Once an extension module is hidden, its icon is not represented on the

Main Menu or displayed in the Dynamix 2500 data collector About

screen.

Follow these instructions to hide or show an extension module icon on the Main

Menu.

1. Press 0 (Shift) on the Setup Utility screen to display the Extension

Manager function.

The Extension Manager function should remain on the screen for

approximately three seconds after releasing 0 (Shift).

2. Press F1 (Extn Mgr).

The Extension Manager screen appears. The Extension Manager displays a

list of installed extensions module.

12 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

The F2 (Hide) toggles between Hide and Show depending if the selected

extension module is hidden or not.

You have to exit and re-enter the Extension Manager after hiding an

extension module to have the Show function appear.

Page 13

Installing Optional Extension Modules Chapter 1

TIP

3. Select the extension module that you want to hide or show and press F2

(Show/Hide).

If you want to show or hide multiple extension modules

simultaneously, select each extension module and press F3

(Select).

A checkbox appears next to each selected extension module. If

you select multiple extension modules and some are hidden

while others are shown, F2 (Show/Hide) reflects the status of the

selected extension module.

4. Press F4 (Esc) to exit the Extension Manager.

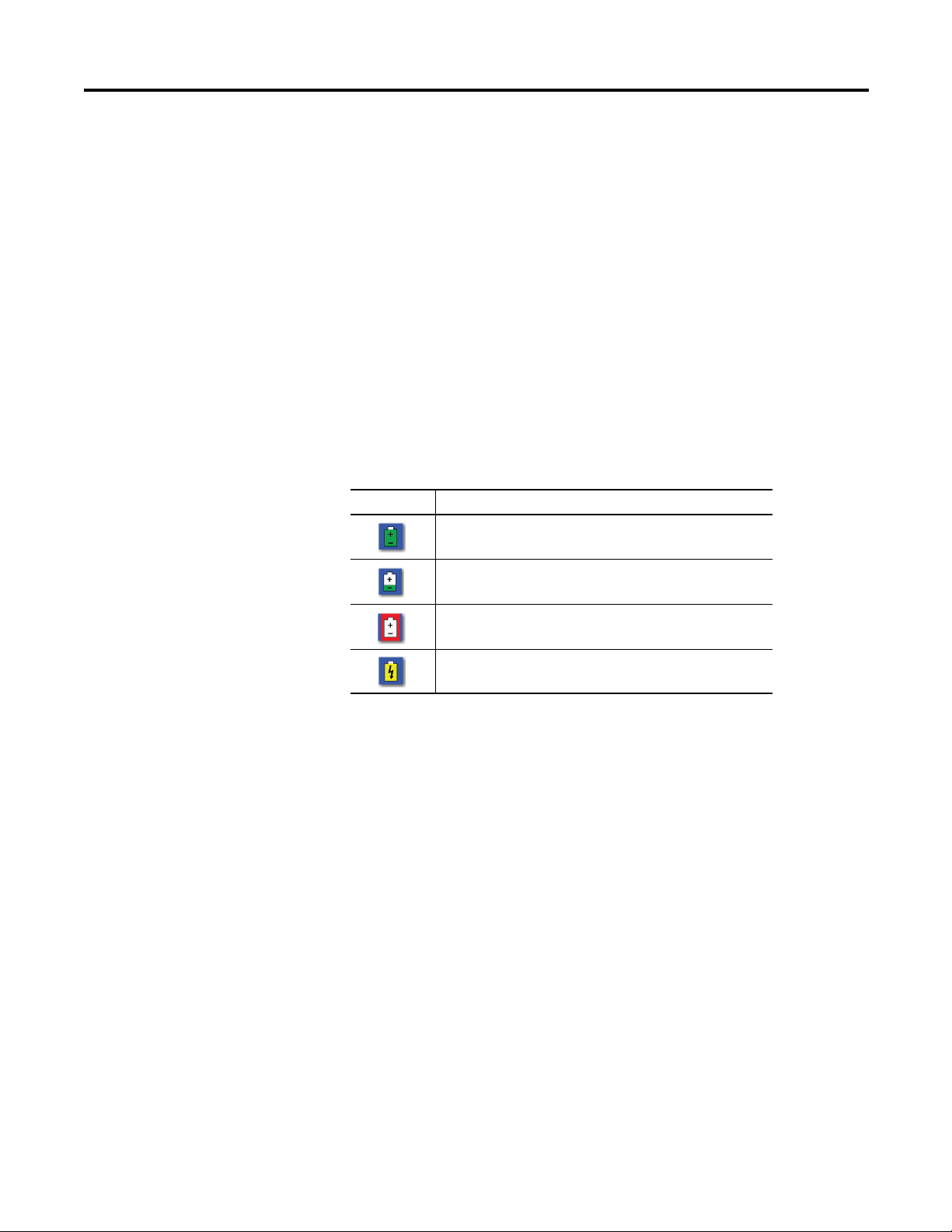

Extension Module Battery Status Indicators

The battery status icons show the strength of the battery.

Table 1 - Extension Module Battery Icon Descriptions

Battery Icon Meaning

Battery status is good: >30% life remaining.

Battery status is low: >10% life remaining.

Battery status is very low: <10% life remaining.

Battery is charging.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 13

Page 14

Chapter 1 Installing Optional Extension Modules

Notes:

14 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 15

Chapter

2

Run Up/Coast Down Extension Module

The Run Up/Coast Down (RUCD) extension module is an optional module for

the Dynamix 2500 data collector. You install the extension module with the

RUCD Secure Digital (SD) card.

See Installing Optional Extension Modules on page 7

instructions.

Topic Page

Set Up Run Up/Coast Down Measurements 17

Collect Run Up/Coast Down Measurements 19

Displaying Measurements by Using a Bode Plot 22

Displaying Measurements Using a Nyquist Plot 25

Displaying Measurements in Table Format 28

Displaying Measurements Using a Waterfall 31

Displaying Measurements Using a Spectrogram 36

Save Run Up/Coast Down Measurements 40

Recall a Setup 41

Review Run Up/Coast Down Measurements 43

Screen Capturing 45

Delete Run Up/Coast Down Files 45

The Run Up/Coast Down extension module lets the data collector record and

analyze data from intermittent events and transient vibration signals from

non-steady state machines.

for installation

The Run Up/Coast Down extension module is used to record and analyze data

from machines where noise or vibration levels are changing with speed or time

such as during a run up (increase in speed), coast down (decrease in speed), or

other applications causing transient phenomena. You use the data to analyze a

machine’s critical speeds and resonant frequencies.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 15

Page 16

Chapter 2 Run Up/Coast Down Extension Module

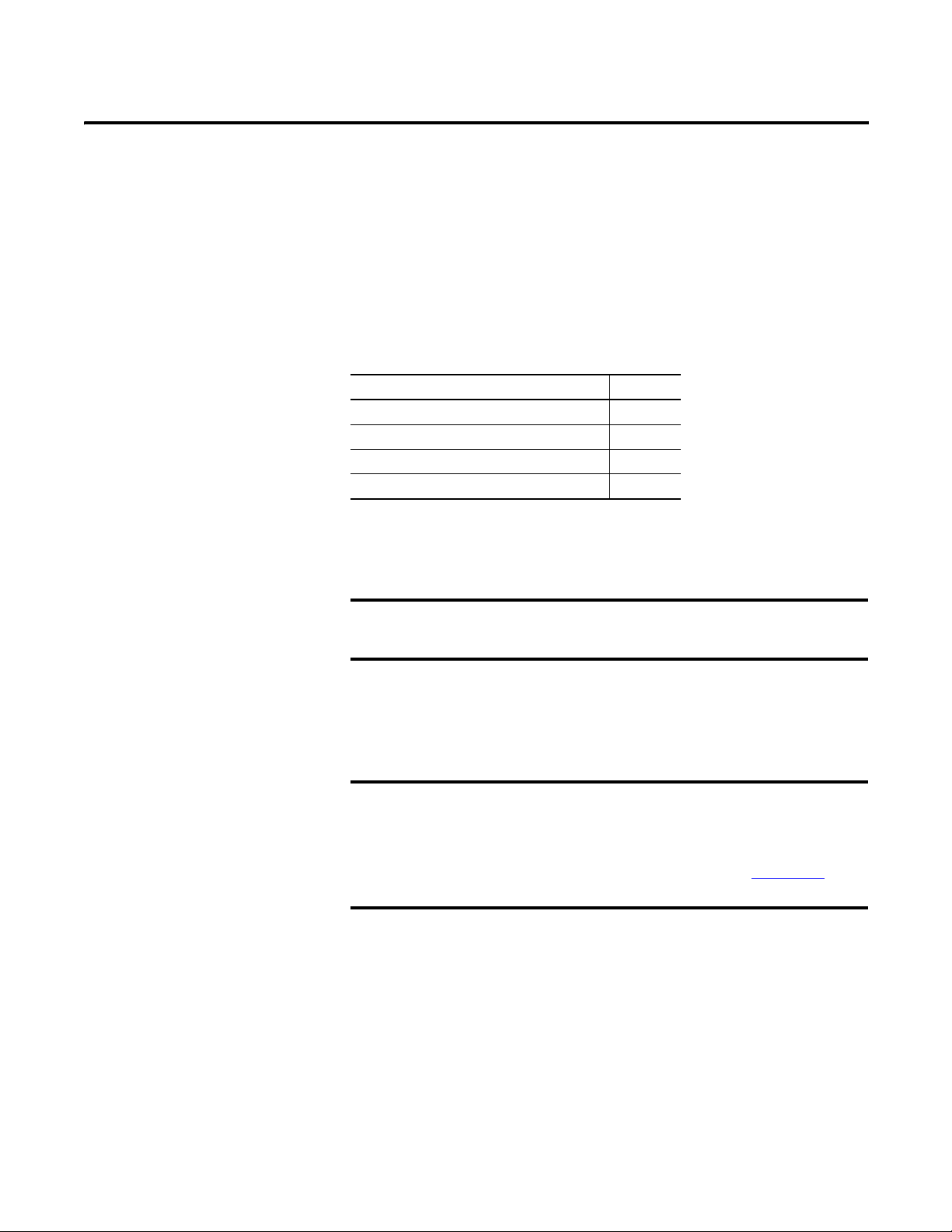

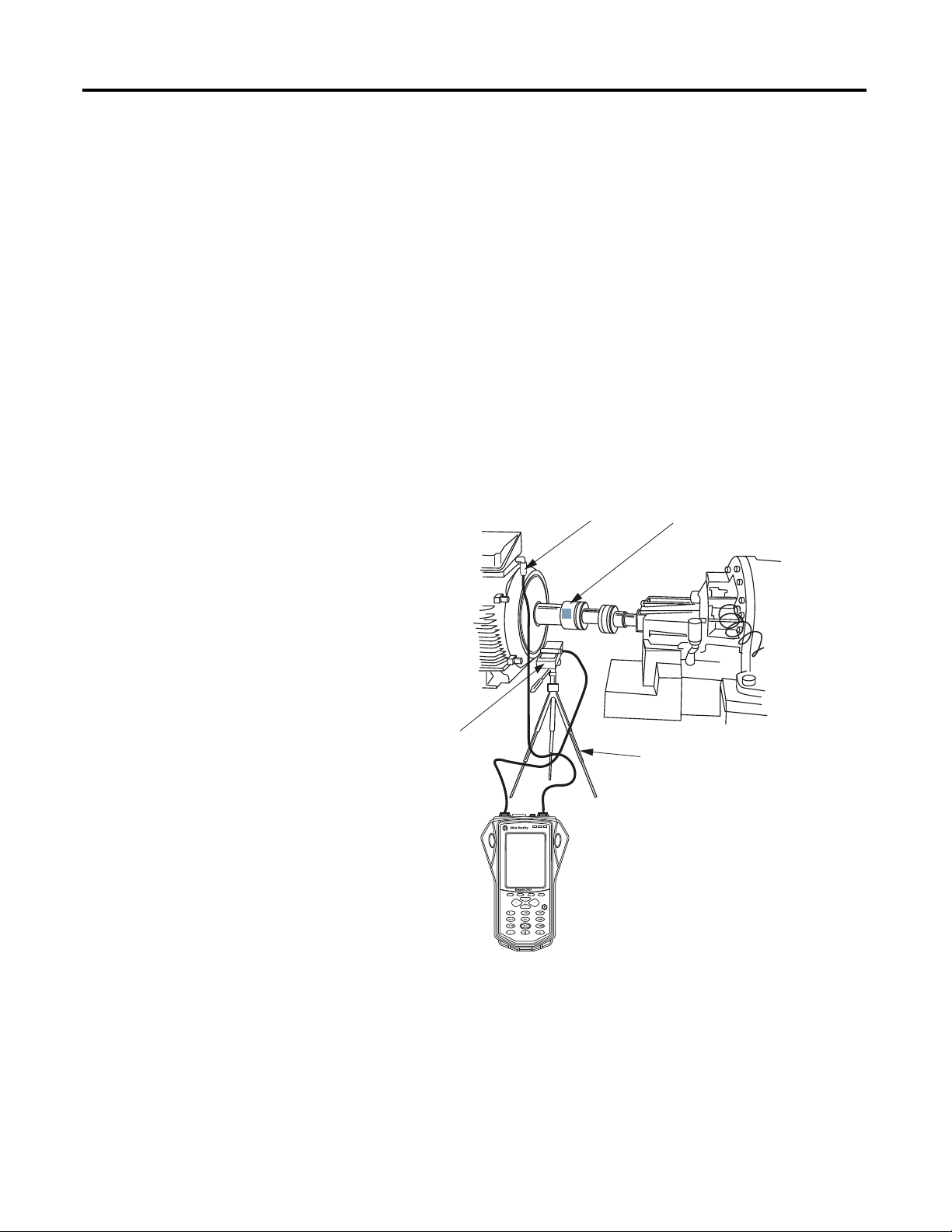

Accelerometer

Tri po d

Tachometer

Reflective Tape

The application acquires a simultaneous noise or vibration signal and a

tachometer signal.

This example setup includes the following:

• Accelerometer attached to connector A of the Dynamix 2500 data

collector

• Optical tachometer signal connected to the POWER/USB/TRIGGER

cable

• Tripod for tachometer signal stability

• Speed reference trigger

• Small piece of reflective tape on the part of the shaft can serve as a reference

trigger or you can simply pass the laser over a notch in the shaft

This graphic illustrates a typical Run Up/Coast Down setup.

Figure 1 - Run Up/Coast Down Setup

The recorded data is saved in the form of a Microsoft .wav time waveform file.

You can analyze this file and viewed in a variety of different formats including:

•Bode Plot

•Nyquist Plot

• Table

•Waterfall

•Spectrogram

16 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

32147-M

Page 17

Run Up/Coast Down Extension Module Chapter 2

Set Up Run Up/Coast Down Measurements

The first step in the Run Up/Coast Down extension module is to setup how the

measurements are taken by the data collector.

1. Select RUCD on the Main Menu and press the Enter.

The RUCD screen appears.

2. Select Setup and press Enter to set up the Run Up/Coast Down

parameters.

The RUCD - Setup screen appears.

3. Select a parameter and press the Right arrow to open a list of values.

4. Select or type the parameter value.

5. Press Left arrow to save your selection.

6. Press F2 (Save) to save the current settings to a file.

See Save Run Up/Coast Down Measurements on page 40

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 17

for details.

Page 18

Chapter 2 Run Up/Coast Down Extension Module

Table 2 - Run Up/Coast Down Setup Parameters

Parameter Description Values/Comments

Transducer Specifies the type of sensor used on Connector A, this is typically

Accel (g).

The specified sensor type determines available options and

engineering units for subsequent setup fields.

Sens (mV/EU) The transducer sensitivity in millivolts (MV) per engineering units

(EU).

Range (EU) The expected maximum amplitude range value for the incoming input

signal.

The range should accommodate for unexpected events. If you are

unsure about the range value, set the range 10 to 20 times higher

than expected.

Max M/c Speed The maximum speed that the shaft will reach in rpm.

This is used with Max No Orders to determine the sampling rate.

Max No Orders The maximum number of shaft orders of interest during analysis.

This is used with Max M/c Speed to determine the sampling rate.

Mode The method for initiating the data collection.

• Runup - The data collection starts when the machine speed

rises above Start Spd.

• Coast down -The data collection starts when the machine

speed falls below Stop Spd.

• Manual - Manually start data collection by pressing F4 (Start).

No tachometer signal is required for this mode.

Use these descriptions to help you configure the parameters in the Run Up/Coast

Down Setup screen.

Accel ICP (g) (default)

Accel (g)

Accel ICP (m/s2)

Accel (m/s2)

Vel ICP (mm/s)

Vel (mm/s)

Vel ICP (ips)

Vel (ips)

Disp (mils)

Disp (µm)

Volts AC

User (EU)

1…2000 (mV/EU)

100 (default)

.1 EU

.2 EU

.5 EU

1 EU

2 EU (default)

5 EU

10 EU

20 EU (default)

50 EU

100 EU

200 EU

500 EU

1000 EU

2000 EU

10…60000 rpm

3600 rpm (default)

1 to 166

32 (default)

Runup (default)

Manual

Coastdown

18 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 19

Run Up/Coast Down Extension Module Chapter 2

Table 2 - Run Up/Coast Down Setup Parameters

Parameter Description Values/Comments

Pulses/Rev The number of tachometer signal pulses per revolution of the

reference shaft.

To acquire a suitable tachometer signal, the tachometer signal must

be approximately 1.5 volts peak-to-peak. The adverse effect of

excessively short tachometer pulse widths can be addressed by

setting the Max No Order to a higher value to increase the sampling

rate.

Start Spd (RPM) Sets the speed at which the unit should start collecting data.

• If Mode is set to Runup, this value must be less than the Stop

Spd.

• If Mode is set to Coast down, this value must be greater than

the Stop Spd.

This parameter is not available if Mode is set to Manual.

Stop Spd (RPM) Sets the speed at which the unit should stop collecting data.

• If Mode is set to Runup, this value must be greater than the

Start Spd.

• If Mode is set to Coast down, this value must be less than Start

Spd.

This parameter is not available if Mode is set to Manual.

Save To Sets the location where data is saved.

Save the data to the SD or PC card if the .wav files will be large. Your

selection affects the maximum recording time.

Max Acq Time (s) The number of seconds to record the time waveform.

This limit applies only if the run up or coast down takes longer than

the time set here.

.1…1000

1 (default)

This number can be a multiple or a non-

integer to accommodate, for example, gear

ratios.

10…3600 rpm

60 rpm (default)

10…3600 rpm

300 rpm (default)

Internal (default)

SD Card

1…1131.65 s

1131.65 s (default)

Collect Run Up/Coast Down Measurements

This section describes the Run Up/Coast Down status indicators and how to

collect Run Up/Coast Down data.

Table 3 - RUCD Status Indicators

Indicator Status Description

Red Solid An overload error (clipping or streaming error) has

occurred during data collection.

Amber Solid An error has occurred during data collection The status

indicator turns off when the error condition disappears.

Green Flashing Green No errors occurred during data collection.

Once you have configured the parameters, you can begin collecting data. The

data is automatically recorded as a .wav file, which can then be analyzed using

several different types of plots.

1. Using the a tachometer cable, connect the reference input device to the

POWER/USB/TRIGGER connector and the transducer to connector A.

2. Align the reference input device (tachometer, optical tachometer, or

strobescope) to capture shaft speed.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 19

Page 20

Chapter 2 Run Up/Coast Down Extension Module

Current Speed of Machine

Current Overall

Vibration Reading

Maximum Acquisition Time in the

Armed State

Remaining Recording Time in the

Acquiring State

Message Area

3. Attach a transducer to the bearing house.

4. Start the machine or stop the machine as needed.

5. From the RUDC Setup screen press F3 (Start).

The RUCD - Taking Data screen appears.

The Dynamix 2500 data collector begins collecting run up or coast down

data based on the parameters you selected. The state of the machine is

indicated on the screen.

State Description

Armed The machine speed has not reached the Start Spd and data collection has

Acquiring The machine speed has reached the Start Spd and data collection has

Error-Clipped An error occurred during data collection. If a sensor’s Range setting is too

not yet started.

At any time during this state, you can press F3 (Start) to manually start

data collection.

started.

At any time during this state, you can press F3 (Stop) to manually stop

data collection.

small to accommodate the signal’s amplitude, a message displays in the

message error.

Press F4 (Back) to return to the RUCD - Setup screen and increase the

Range setting.

Data collection is complete when the specified Stp Speed or Maximum

Acquisition Time is reached, or you press F3 (Stop).

20 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 21

Run Up/Coast Down Extension Module Chapter 2

TIP

The resulting time waveform is recorded as a Microsoft Windows .wav file

and the Acquisition Completed dialog appears on the screen.

If an error occurs during data collection, a message

appears in this dialog box.

6. Press F4 (OK) to continue.

The RUCD - Display Select screen appears.

The Dynamix 2500 data collector provides five different formats for you to

use to view the newly recorded time waveform.

7. Select the format and press F3 (Display).

Format Description

Bode Displays the magnitude and phase over a varying rpm.

See Displaying Measurements by Using a Bode Plot on page 22

Nyquist Displays the selected orders as complex data.

See Displaying Measurements Using a Nyquist Plot on page 25

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 21

.

.

Page 22

Chapter 2 Run Up/Coast Down Extension Module

Format Description

Table Displays the magnitude and phase of selected orders at the varied rpm speeds

Waterfall Displays multiple FFT traces overlaid and offset on one single plot.

Spectrogram Displays multiple FFT traces on one single plot, using color to indicate relative

in a table format.

See Displaying Measurements in Table Format on page 28.

See Displaying Measurements Using a Waterfall on page 31

magnitude.

See Displaying Measurements Using a Spectrogram on page 36

.

.

8. When you are finished analyzing the time waveform, you can save it to a

file.

Displaying Measurements by Using a Bode Plot

See Save Run Up/Coast Down Measurements on page 40

.

The Bode plot is actually two graphs of 1X rpm amplitude and phase as a

function of frequency. The screen shows both plots at the same time. The top

plot shows magnitude versus rpm. The bottom plot shows phase versus rpm.

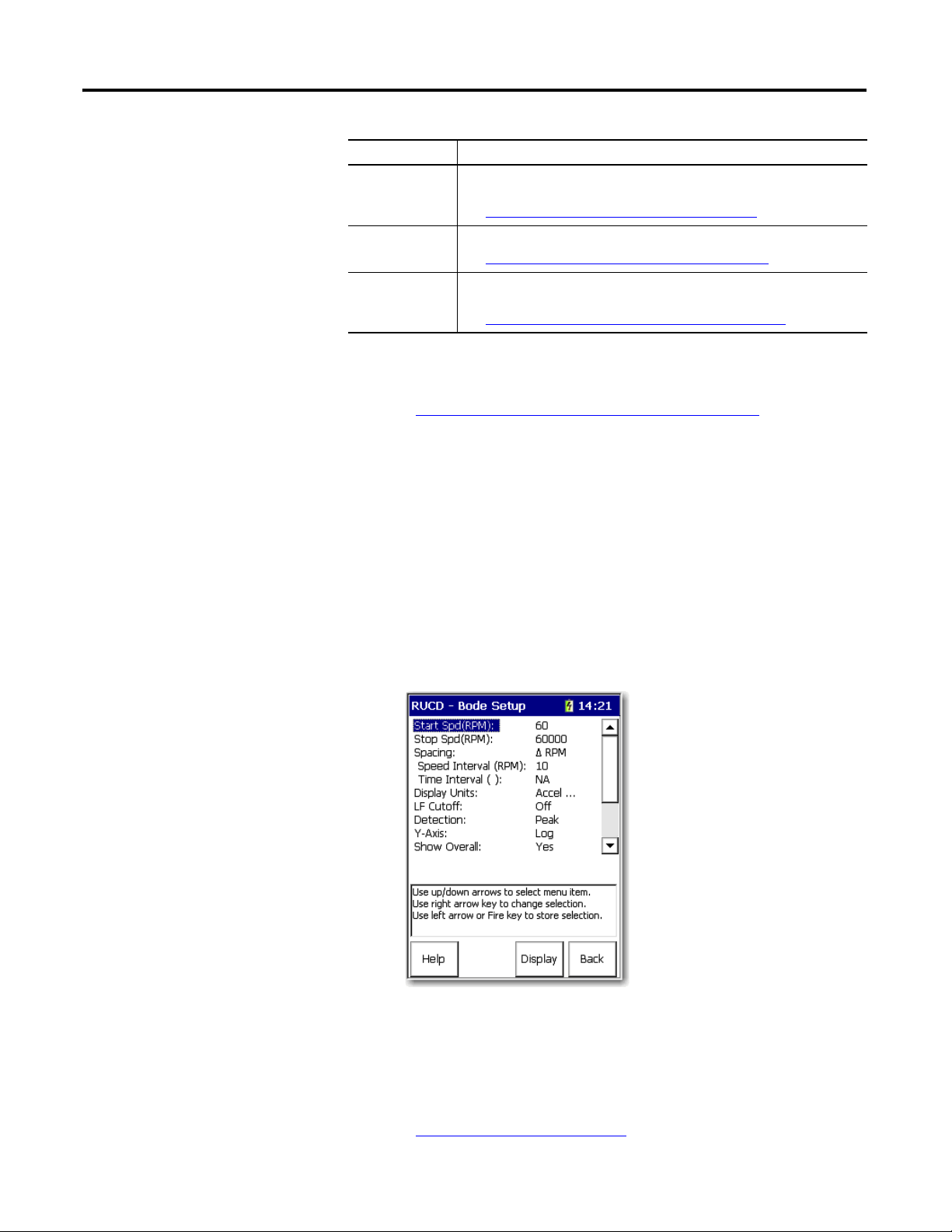

Set Up the Bode Plot

1. Select Bode on the RUCD - Display Select screen and press F3 (Display).

The RUCD - Bode Setup screen appears.

2. Select the parameter and press the Right arrow to open a list of values.

3. Select or type in the parameter value.

4. Press the Left arrow to save your selection.

See Bode Plot Parameters on page 23

22 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

to help you configure the parameters.

Page 23

Run Up/Coast Down Extension Module Chapter 2

5. When you are finished, press F3 (Display) to display the Bode plot.

See Display the Bode Plot on page 24

.

Table 4 - Bode Plot Parameters

Parameter Description Values/Comments

Start Spd (RPM) Sets the start speed of the recorded data for the Bode plot.

This defaults to the Start Spd value set in the RUCD Setup screen. See Table 2

on page 18.

Stop Spd (RPM) Sets the stop speed of the recorded data for the Bode plot.

This defaults to the Stop Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

Spacing Controls the spacing between collected spectra.

•

Δ rpm is a fixed speed change between spectra.

• %

Δ rpm is a percentage speed change between spectra.

•

Δ Time is a fixed time interval between spectra.

•

Δ rpm + Δ Time is a combination of speed and time interval settings. If

speed stops changing then spectra are calculated using the Time Interval

value.

• %

Δ rpm + Δ Time is a combination of speed and time interval settings.

If speed stops changing then spectra are calculated using the Time

Interval value.

Speed Interval (rpm) Sets the speed interval used in calculating FFT spectra.

This parameter not used when Spacing is set to

Time Interval (sec) Sets the time interval used in calculating FFT spectra.

This parameter is not used when Spacing is set to

Display Units Sets the Y-axis units.

The available units depends on the transducer used to collect data.

See Run Up/Coast Down Setup Parameters on page 18.

LF Cutoff Determines whether to apply a low frequency filter (0.3 times the running

Detection Sets the signal detection and scaling display for the Bode plot:

Y-axis Sets the y-axis scaling on the Bode plot:

speed) to the data.

• Peak - Measured RMS value multiplied by the square root of two (1.4142).

• Pk-Pk - Measured RMS value multiplied by two times the square root of

two (2.8284).

• RMS - Root mean squared signal level of the input signal.

• Linear - The plot grid centers are linearly spaced in Y between the centers

of the first and last grid.

• Log - The plot grid centers are logarithmically spaced in Y between the

centers of the first and last grid.

.

Δ Time.

Δ rpm and % Δ rpm.

10…3600 rpm

10…3600 rpm

Δ rpm

%

Δ rpm

Δ Time

Δ rpm + Δ Time

%

Δ rpm + Δ Time

Your selection affects the Speed Interval

and Time Interval settings.

1…240 rpm or % rpm

Enter a value from .001…604800 s

Accel (g)

2

Accel (m/s

Accel (m/s

Vel (mm/s)

Vel (ips)

Disp (mils)

Disp (µm)

Off (default)

On

RMS

Peak (default)

PkPk

Linear (default)

Log

)

2

)

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 23

Page 24

Chapter 2 Run Up/Coast Down Extension Module

TIP

Speed, Magnitude, and Q Factor

at Cursor Location

Active Trace

Table 4 - Bode Plot Parameters

Parameter Description Values/Comments

Show Overall Determines whether to display the overall severity as a trace on the Bode plot. Yes (default)

No

Num Traces Sets the number of traces or order tracks to be displayed on the Bode plot:

• The number of traces available is determined by the Show Overall

parameter.

• Your selection determines the available number of Trace Order

parameters.

Trace Order #1…4 The order numbers to be tracked and displayed on the Bode plot. This value

cannot exceed the Max No Orders value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

.

1 (default)

2

3

4

.001…166 orders

Display the Bode Plot

When you are done setting up the Bode plot parameters, you can process the data

and display the Bode plot by pressing F3 (Display) on the RUCD - Bode Setup

screen.

The larger the .wav file, the longer it takes to process the data

and display the plot.

The top of the display shows magnitude versus rpm. The bottom of the display

shows phase versus rpm:

• To sequence through the traces, press the Up and Down arrows.

The order number of the current trace is displayed in the top left corner of

the screen. To move the cursor along the trace, press the Left and Right

arrows.

24 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 25

Run Up/Coast Down Extension Module Chapter 2

• From the Bode plot you can also display the data in a Table format or

Nyquist plot. To display the data in a table, press 0 (Shift) and F4 (Table).

Displaying Measurements Using a Nyquist Plot

See Display the Table on page 30

• To display the data in a Nyquist plot, press 0 (Shift) and F1 (Nyqst).

See Display the Nyquist Plot on page 27

The Nyquist plot is a polar representation of the amplitude and phase angle as a

function of frequency. Three variables are combined into a single plot in polar

format.

for more information.

for more information.

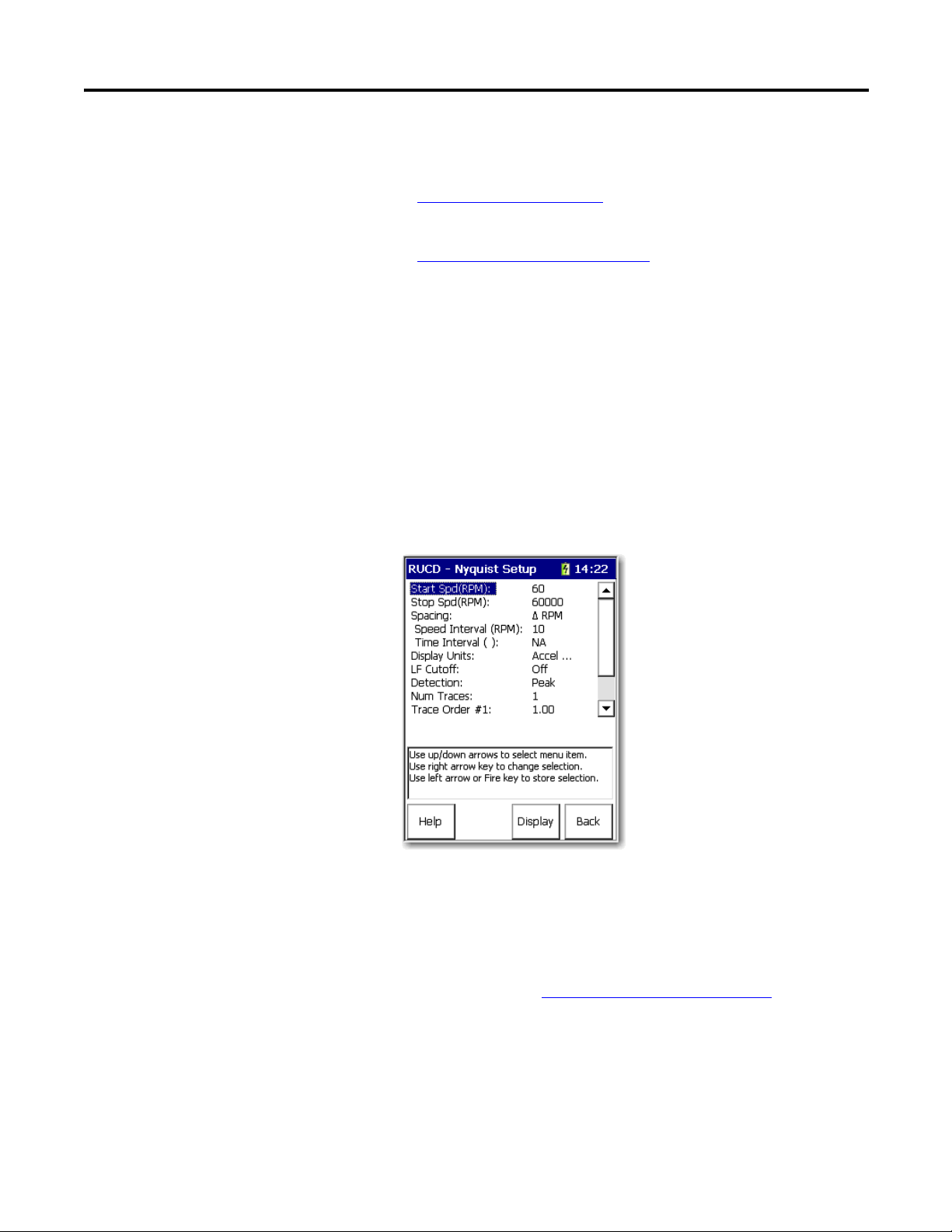

Set Up the Nyquist Plot

1. Select Nyquist on the RUCD - Display Select screen and press F3

(Display).

The RUCD - Nyquist Setup screen appears.

2. Select the option and press the Right arrow to open a list of values.

3. Select or type in a parameter value.

4. Press the Left arrow to save your selection.

Use the descriptions in Nyquist Plot Parameters on page 26

configure the parameters.

5. When you are finished, press F3 (Display) to display the Nyquist plot.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 25

to help you

Page 26

Chapter 2 Run Up/Coast Down Extension Module

See Display the Nyquist Plot on page 27.

Table 5 - Nyquist Plot Parameters

Parameter Name Description Values/Comments

Start Spd (RPM) Sets the start speed of the recorded data for the plot.

This defaults to the Start Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

Stop Spd (RPM) Sets the stop speed of the recorded data for the plot.

This defaults to the Stop Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

Spacing Controls the spacing between collected spectra:

•

Δ rpm is a fixed speed change between spectra.

• %

Δ rpm is a percentage speed change between spectra.

•

Δ Time is a fixed time interval between spectra.

•

Δ rpm + Δ Time is a combination of speed and time interval

settings. If speed stops changing then spectra are calculated using

the Time Interval value.

• %

Δ rpm + Δ Time is a combination of speed and time interval

settings. If speed stops changing then spectra are calculated using

the Time Interval value.

Speed Interval (RPM) Sets the speed interval used in calculating FFT spectra.

This parameter not used when Spacing is set to

Δ Time.

.

.

10…3600 rpm

10…3600 rpm

Δ rpm

Δ rpm

%

Δ Time

Δ rpm + Δ Time

Δ rpm + Δ Time

%

Your selection affects the Speed Interval

and Time Interval settings.

1… 240 rpm or % rpm

Time Interval (sec) Sets the time interval used in calculating FFT spectra.

This parameter is not used when Spacing is set to

Display Units Sets the Y-axis units.

The available units depends on the transducer used to collect data.

See Run Up/Coast Down Setup Parameters on page 18

LF Cutoff Determines whether to apply a low frequency filter (0.3 times the running

speed) to the data.

Detection Sets the signal detection and scaling display for the plot:

• Peak - Measured RMS value multiplied by the square root of two

(1.4142).

• Pk-Pk - Measured RMS value multiplied by two times the square root

of two (2.8284).

• RMS - Root mean squared signal level of the input signal.

Num Traces Sets the number of traces or order tracks to be displayed on the plot.

Your selection determines the available number of Trace Order

parameters.

Trace Order #1-#4 The order numbers to be tracked and displayed on the plot.

This value cannot exceed the Max No Orders value set in the RUCD Setup

screen.

See Run Up/Coast Down Setup Parameters on page 18

Δ RPM and % Δ RPM.

.

.

.001…604800 s

Off

On

RMS

Peak

PkPk

1

2

3

4

.001…166 orders

26 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 27

Run Up/Coast Down Extension Module Chapter 2

TIP

Speed, magnitude, and Q

Factor at Cursor Location

Active Trace

Display the Nyquist Plot

When you are done setting up the plot parameters, you can process the data and

display the Nyquist plot by pressing F3 (Display) on the RUCD - Nyquist Setup

screen.

The larger the .wav file, the longer it takes to process the data

and display the plot.

The display shows the selected orders as complex data with zero degrees along the

positive X-axis and 90 degrees along the positive Y-axis:

• To sequence through the traces, press the Up and Down arrows. The order

number of the current trace is displayed in the top left corner of the screen.

To move the cursor along the trace, press the Left and Right arrows.

• From the Nyquist plot you can display the data in a table or Bode plot,

press 0 (Shift) and F4 (Table).

See Display the Table on page 30

for more information.

• To display the data in a Bode plot, press 0 (Shift) and then F1 (Bode).

See Display the Bode Plot on page 24

for more information.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 27

Page 28

Chapter 2 Run Up/Coast Down Extension Module

Displaying Measurements in Table Format

The magnitude and phase of selected orders at the varied rpm speeds are

displayed in a table.

Set Up the Table

1. Select Table on the RUCD - Display Select screen and press F3 (Display).

The RUCD - Table Setup screen appears.

2. Select a parameter press the Right arrow to open a list of values.

3. Select or type in a parameter value.

4. Press the Left arrow to save your selection.

Use the descriptions in Table Parameter Descriptions on page 28

you configure the parameters.

5. When you are finished, press F4 (Display) to display the table.

See Display the Table on page 30

Table 6 - Table Parameter Descriptions

Parameter Name Description Values/Comments

Start Spd (RPM) Sets the start speed of the recorded data for the table.

This defaults to the Start Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

Stop Spd (RPM) Sets the stop speed of the recorded data for the table.

This defaults to the Stop Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

.

.

.

10…3600 rpm

10…3600 rpm

to help

28 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 29

Run Up/Coast Down Extension Module Chapter 2

Table 6 - Table Parameter Descriptions

Parameter Name Description Values/Comments

Spacing Controls the spacing between collected spectra:

Δ rpm is a fixed speed change between spectra.

•

• %

Δ rpm is a percentage speed change between spectra.

•

Δ Time is a fixed time interval between spectra.

•

Δ rpm + Δ Time is a combination of speed and time interval settings.

If speed stops changing then spectra are calculated using the Time

Interval value.

• %

Δ rpm + Δ Time is a combination of speed and time interval

settings. If speed stops changing then spectra are calculated using the

Time Interval value.

Speed Interval (RPM) Sets the speed interval used in calculating FFT spectra.

This parameter not used when Spacing is set to

Δ Time.

Δ rpm

%

Δ rpm

Δ Time

Δ rpm + Δ Time

%

Δ rpm + Δ Time

Your selection affects the Speed Interval

and Time Interval settings.

1…240 rpm or % rpm

Time Interval (sec) Sets the time interval used in calculating FFT spectra.

This parameter is not used when Spacing is set to

Display Units Sets the Y-axis units.

The available units depends on the transducer used to collect data.

See Run Up/Coast Down Setup Parameters on page 18.

LF Cutoff Determines whether to apply a low frequency filter (0.3 times the running

speed) to the data.

Detection Sets the signal detection and scaling display for the table:

• Peak - Measured RMS value multiplied by the square root of two

(1.4142).

• Pk-Pk - Measured RMS value multiplied by two times the square root of

two (2.8284).

• RMS - Root mean squared signal level of the input signal.

Num Traces Sets the number of traces or order tracks to be displayed in the table.

Your selection determines the available number of Trace Order parameters. 12

Trace Order #1-#4 The order numbers to be tracked and displayed in the table.

This value cannot exceed the Max No Orders value set in the RUCD Setup

screen.

See Run Up/Coast Down Setup Parameters on page 18

Δ RPM and % Δ RPM.

.

.001…604800 s

Off

On

RMS

Peak

PkPk

.001…166 orders

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 29

Page 30

Chapter 2 Run Up/Coast Down Extension Module

Display the Table

When you are done setting up the table parameters, you can process the data and

display the table by pressing F4 (Display) on the RUCD - Table Setup screen.

Up to two orders of the magnitude and phase data set is displayed in the table:

• To scroll through the table, press the Up and Down arrows.

• You can also display the data in a Bode plot. To display the data in a Bode

plot or Nyquist plot, press 0 (Shift) and F4 (Bode).

See Display the Bode Plot on page 24

.

• To display the data in a Nyquist plot, press 0 (Shift) and F1 (Nyquist).

See Display the Nyquist Plot on page 27

.

30 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 31

Run Up/Coast Down Extension Module Chapter 2

Displaying Measurements Using a Waterfall

The Waterfall plot displays the vibration level in relation to the frequencies at

which the vibration occurs. It lets you view several measurements in relationship

to each other.

Set Up the Waterfall

1. Select Waterfall on the RUCD - Display Select screen and press F3

(Display).

The RUCD - Waterfall Setup screen appears.

2. Select the option and press the Right arrow to open a list of values.

3. Select or type in the parameter value.

4. Press the Left arrow to save your selection.

Use the descriptions in Waterfall Plot Parameters on page 31

configure the parameters.

5. When you are finished, press F3 (Display) to display the Waterfall plot.

See Display the Waterfall Plot on page 33

Table 7 - Waterfall Plot Parameters

Parameter Name Description Values/Comments

Start Spd (RPM) Sets the start speed of the recorded data for the plot.

This defaults to the Start Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

Stop Spd (RPM) Sets the stop speed of the recorded data for the plot.

This defaults to the Stop Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

.

.

.

10…3600 rpm

10…3600 rpm

to help you

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 31

Page 32

Chapter 2 Run Up/Coast Down Extension Module

Table 7 - Waterfall Plot Parameters

Parameter Name Description Values/Comments

Spacing Controls the spacing between collected spectra:

• Δ rpm is a fixed speed change between spectra.

• %

Δ rpm is a percentage speed change between spectra.

•

Δ Time is a fixed time interval between spectra.

•

Δ rpm + Δ Time is a combination of speed and time interval settings. If

speed stops changing then spectra are calculated using the Time Interval

value.

• %

Δ rpm + Δ Time is a combination of speed and time interval settings.

If speed stops changing then spectra are calculated using the Time

Interval value.

Speed Interval (RPM) Sets the speed interval used in calculating FFT spectra.

This parameter not used when Spacing is set to

Time Interval (sec) Sets the time interval used in calculating FFT spectra.

This parameter is not used when Spacing is set to

Display Units Sets the Y-axis units.

The available units depends on the transducer used to collect data.

See Run Up/Coast Down Setup Parameters on page 18.

Detection Sets the signal detection and scaling display for the plot:

• Peak - Measured RMS value multiplied by the square root of two (1.4142).

• Pk-Pk - Measured RMS value multiplied by two times the square root of

two (2.8284).

• RMS - Root mean squared signal level of the input signal.

Lines The number of lines (bins) of resolution for the FFT spectra. The larger the

number of lines, the better the frequency resolution of the measured data in the

spectra. Similarly, the higher the number of lines, the longer it takes to display

the spectra in the plot.

X-axis Sets the x-axis frequency units for displaying spectra/FFT data:

• Hz - Displays spectra in Hertz, cycles per second.

• CPM - Displays spectra in cycles per minute.

• Orders - Displays spectra in orders of the operating speed.

Δ Time.

Δ RPM and % Δ RPM.

Δ rpm

%

Δ rpm

Δ Time

Δ rpm + Δ Time

%

Δ rpm + Δ Time

Your selection affects the Speed Interval

and Time Interval settings.

1…240 rpm

.001…604800 s

RMS

Peak

PkPk

100

200

400

800

1600

3200

6400

12800

Hz

CPM

Orders

Freq. Range (EU) The maximum frequency for the measurement.

The frequency range is determined by the X-axis parameter.

32 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Your selection affects the Freq Range and

LF Cutoff parameters.

10…2000 Hz

600…120000 CPM

.001…166 Orders

Page 33

Run Up/Coast Down Extension Module Chapter 2

TIP

Table 7 - Waterfall Plot Parameters

Parameter Name Description Values/Comments

LF Cutoff (EU) Sets a low frequency cutoff filter to remove noise from the analysis.

The available options are determined by the X-axis selection.

Off

21.6 CPM

66 CPM

120 CPM

600 CPM

4200 CPM

.36 Hz

1.1 Hz

2 Hz

10 Hz

70 Hz

Display the Waterfall Plot

When you are finished setting up the plot parameters, you can process the

spectral data by pressing F3 (Display) on the RUCD - Waterfall Setup screen.

The larger the .wav file, the longer it takes to process the data

and display the plot.

Optimize the Waterfall Plot

Additional parameters display on the screen letting you to control how the

spectra appear in the waterfall plot.

1. Select the option and press the Right arrow to open a list of values.

2. Select or type in a parameter value.

3. Press the Left arrow to save your selection.

Use the descriptions in Waterfall Plot Setup Parameters on page 34

to help

you configure the parameters.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 33

Page 34

Chapter 2 Run Up/Coast Down Extension Module

TIP

4. When you are finished and ready to display the waterfall plot, press F3

(Display).

Table 8 - Waterfall Plot Setup Parameters

Parameter Name Description Values/Comments

Z-axis Controls the spacing between the collected spectra.

• RPM- FFTs spaced depending on the rpm at which they were recorded.

• Timestamp- FFTs spaced depending on the time the data was recorded.

• Even Spacing- FFTs spaced evenly along the Z-axis.

No. Spectra Controls the number of spectra to display on the waterfall plot. The spectra

are displayed as follows:

• The first spectrum is always displayed.

• The last spectrum is always displayed.

• The other spectra (No. Spectra minus first and last spectrum) are evenly

distributed on the plot.

Trace Offset Sets the angle of the Z-axis on the plot.

Trace Height Controls the height of the spectra on the plot. Small

Disp. Order Controls the order in which to display the spectra.

• Forward- Display spectra from oldest (front of the waterfall) to newest

(rear of the waterfall).

• Reverse- Display spectra from newest (front of the waterfall) to oldest

(rear of the waterfall).

Blanking Eliminates the display of data below a certain level on the Y-axis. This setting

helps clarify the presence of machine orders or structural frequencies.

RPM

Tim estam p

Even Spacing

2…60 spectra

0

° (C)

22.5

° (C)

45

° (C)

Medium

Large

Forward

Reverse

0%…25%

View the Waterfall Plot

After setting up the Waterfall spectra, press F3 (Display) on the Waterfall Display

Setup screen.

At the bottom of the waterfall plot is a display area that indicates the active

spectrum, and provides information (number of spacing of spectra, speed) on

how the spectra are displayed in the waterfall plot.

If more than sixty spectra were collected, the ticks along the

line indicate which spectra were selected to be displayed.

See No. Spectra on page 34

Cursor Movement

Use the Up and Down arrows to sequence through the displayed spectra. The

active spectrum displays in green. The zero positions of the X and Y-axis move to

34 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

for more information.

Page 35

Run Up/Coast Down Extension Module Chapter 2

TIP

TIP

Frequency and

Magnitude at Cursor

Position

Speed, Time, or Data

Collection Number of

Rear Spectrum

Number and Spacing of Spectra

Speed

Active Spectrum

be relative to the active spectrum. Use the Left and Right arrows to move the

cursor on the active spectrum.

Press P to quickly move the cursor to the next significant peak.

Z-axis Zoom

The Z-axis zoom lets you to zoom in around the current trace. The display area

updates to indicate the number and position of the spectra displayed on the

screen. The zoom capability is only available when the No. Spectra parameter is

set to a number less than the number of extracted spectra.

See No. Spectra on page 34

To use the Z-axis zoom feature, press 0 (Shift) and the +/- key. Repeat this key

sequence to continue zooming in. After the highest zoom level is reached, the

above procedure will cause you to zoom out.

There are more zoom levels available when there are fewer

spectra displayed in the plot.

for more information.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 35

Page 36

Chapter 2 Run Up/Coast Down Extension Module

Displaying Measurements Using a Spectrogram

The Spectrogram plot is a three-dimensional color intensity plot displaying the

amplitude of spectral components as a function of both time and frequency.

Typically the horizontal and vertical axes correspond to time and frequency. The

intensity corresponds to amplitude.

Set Up the Spectrogram Plot

Follow these instructions to setup the plot.

1. Select Spectrogram on the RUCD - Display Select screen and press F3

(Display).

The RUCD - Spectrogram Setup screen appears.

2. Select a parameter and press the Right arrow to open a list of parameters.

3. Select to type in a parameter value.

4. Press the Left arrow to save your selection.

Use the descriptions in Spectrogram Plot Parameter Descriptions on

page 37 to help you configure the parameters.

5. When you are finished, press F3 (Display) to display the Spectrogram plot.

See Display the Spectrogram Plot on page 38

36 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

for more information.

Page 37

Run Up/Coast Down Extension Module Chapter 2

Table 9 - Spectrogram Plot Parameter Descriptions

Parameter Name Description Values/Comments

Start Spd (RPM) Sets the start speed of the recorded data for the plot.

This defaults to the Start Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

Stop Spd (RPM) Sets the stop speed of the recorded data for the plot.

This defaults to the Stop Spd value set in the RUCD Setup screen.

See Run Up/Coast Down Setup Parameters on page 18

Spacing Controls the spacing between collected spectra:

•

Δ rpm is a fixed speed change between spectra.

• %

Δ rpm is a percentage speed change between spectra.

•

Δ Time is a fixed time interval between spectra.

•

Δ rpm + Δ Time is a combination of speed and time interval settings. If

speed stops changing then spectra are calculated using the Time

Interval value.

• %

Δ rpm + Δ Time is a combination of speed and time interval

settings. If speed stops changing then spectra are calculated using the

Time Interval value.

Speed Interval (RPM) Sets the speed interval used in calculating FFT spectra.

This parameter not used when Spacing is set to

Δ Time.

.

.

10…3600 rpm

10…3600 rpm

Δ rpm

Δ rpm

%

Δ Time

Δ rpm + Δ Time

Δ rpm + Δ Time

%

Your selection affects the Speed Interval

and Time Interval settings.

1…240 rpm

Time Interval (sec) Sets the time interval used in calculating FFT spectra.

This parameter is not used when Spacing is set to

Display Units Sets the Y-axis units.

The available units depends on the transducer used to collect data.

See Run Up/Coast Down Setup Parameters on page 18.

Detection Sets the signal detection and scaling display for the plot:

• Peak - Measured RMS value multiplied by the square root of two

(1.4142).

• Pk-Pk - Measured RMS value multiplied by two times the square root of

two (2.8284).

• RMS - Root mean squared signal level of the input signal.

Lines The number of lines (bins) of resolution for the FFT spectra. The larger the

number of lines, the better the frequency resolution of the measured data in

the spectra.

Similarly, the higher the number of lines, the longer it takes to display the

spectra in the plot.

X-axis Sets the X-axis frequency units for displaying spectra/FFT data:

• Hz - Displays spectra in Hertz, cycles per second.

• CPM - Displays spectra in cycles per minute.

• Orders - Displays spectra in orders of the operating speed.

Δ RPM and % Δ RPM.

.001…604800 s

RMS

Peak

PkPk

100

200

400

800

1600

3200

6400

12800

Hz

CPM

Orders

Your selection affects the Freq Range and

LF Cutoff parameters.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 37

Page 38

Chapter 2 Run Up/Coast Down Extension Module

TIP

Table 9 - Spectrogram Plot Parameter Descriptions

Parameter Name Description Values/Comments

Freq. Range (EU) The maximum frequency for the measurement.

The frequency range is determined by the X-axis parameter.

10…2000 Hz

600…120000 CPM

.001…166 Orders

LF Cutoff (EU) Sets a low frequency cutoff filter to remove noise from the analysis.

The available options are determined by your X-axis selection.

Display the Spectrogram Plot

When you are done setting up the plot parameters, you can process the spectral

data by pressing F3 (Display) on the RUCD - Spectrogram Setup screen.

The larger the .wav file, the longer it takes to process the data

and display the plot.

Off

21.6 CPM

66 CPM

120 CPM

600 CPM

4200 CPM

.36 Hz

1.1 Hz

2 Hz

10 Hz

70 Hz

Optimize the Spectrogram Plot

Additional parameters display on the screen letting you to control how the

spectra appear in the spectrogram plot.

1. Select a parameter and press the Right arrow to open a list of values.

2. Select or type in a parameter value.

3. Press the Left arrow to save your selection.

Use the descriptions in Spectrogram Plot Setup Parameters on page 39

help you configure the parameters.

4. When you are finished and ready to display data, press F3 (Display) to view

the Spectrogram.

38 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

to

Page 39

Run Up/Coast Down Extension Module Chapter 2

TIP

Frequency and Magnitude

at the Cursor Position

Speed

Cursor

Amplitude Indicator at

Cursor Position

Table 10 - Spectrogram Plot Setup Parameters

Parameter Name Description Values/Comments

Y-axis Sets the Y-axis scaling on the spectrogram plot:

• Linear - The plot grid centers are linearly spaced in Y between the

centers of the first and last grid.

• Log - The plot grid centers are logarithmically spaced in Y between the

centers of the first and last grid.

Z-axis Controls the spacing between the collected spectra:

• RPM- FFTs spaced depending on the rpm at which they were recorded.

• Timestamp- FFTs spaced depending on the time the data was recorded.

• Even Spacing- FFTs spaced evenly along the Z-axis.

Blanking Eliminates the display of data below a certain level on the Y-axis. This

setting helps clarify the presence of machine orders or structural

frequencies.

Linear

Log

RPM

Tim estam p

Even Spacing

0%…25%

View the Spectrogram Plot

After setting up the Spectrogram spectra, press F3 (Display) on the Spectrogram

Display Setup screen.

The Spectrogram plot uses color to indicate the amplitude of the signals. Red

means a higher amplitude and blue means a lower amplitude:

• Use the Up and Down arrows to sequence through the displayed spectra.

• Use the Left and Right arrows to move the cursor on the active spectrum.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 39

Press P to quickly move the cursor to the next significant peak.

Page 40

Chapter 2 Run Up/Coast Down Extension Module

IMPORTANT

Save Run Up/Coast Down Measurements

The Run Up/Coast Down setup parameters and measurements can be saved to a

file which you can recall at a later time. The collected data is saved in the form of

a time waveform (.wav file).

You can save the RUCD setup and measurement anytime the Save function is

displayed on the screen.

Follow these steps to save a RUCD measurement.

1. Do one of the following:

• Press F3 (Save) if you are saving the data from the Setup screen.

• Press F4 (Save) if you are saving the recorded data from a plot screen.

The RUCD - Save Data screen appears.

2. Do one of the following:

• To save the data to an existing file, highlight the file, and press F4 (Save).

Press F2 (Yes) to overwrite the existing file. You can return to the Save

screen without overwriting the file by pressing F3 (No).

• To save the data to a new file, highlight save reading as and press F4

(Save). Enter a file name using the keypad or accept the default file

name (current date timestamp).

3. When the entry is complete, press F4 (OK).

The setup parameters are saved along with the measurement

when you press F4 (Save) on the RUCD - Save Data screen.

4. When you are finished, press F1 (Cancel).

40 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 41

Run Up/Coast Down Extension Module Chapter 2

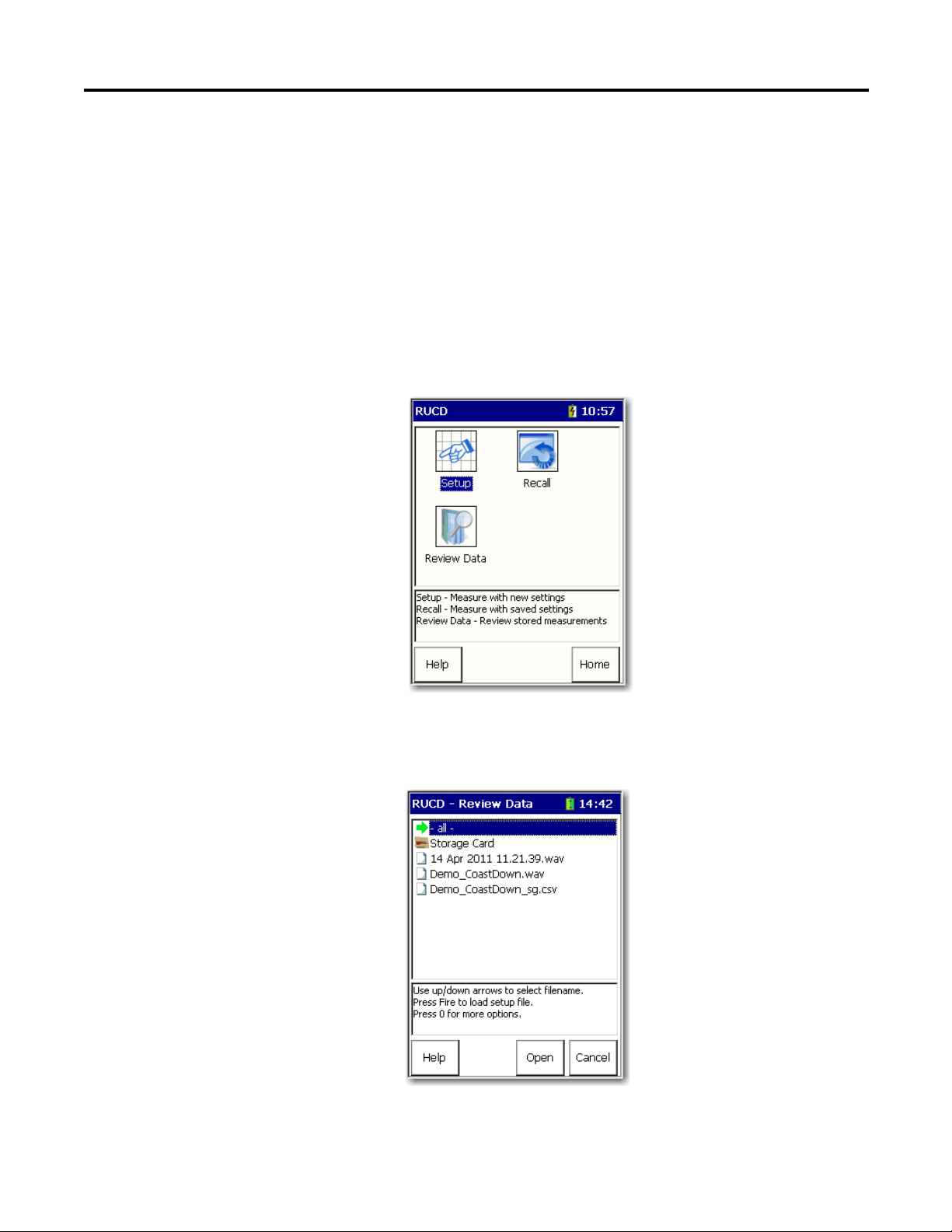

Recall a Setup

You can recall a previously saved setup and use it to collect another measurement.

The setup may have been saved only as a setup, or may have been saved with the

recorded data.

See Save Run Up/Coast Down Measurements on page 40

Follow these steps to recall a setup.

1. Select RUCD on the Main Menu and press Enter.

The RUCD screen appears.

for more information.

2. Select Recall and press Enter.

The RUCD - Load Setup screen appears.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 41

Page 42

Chapter 2 Run Up/Coast Down Extension Module

3. Select the filename that you want recall and press F3 (Open).

The RUCD - Setup screen appears.

You can edit the settings or start collecting data:

• For information on editing the settings, see Set Up Run Up/Coast

Down Measurements on page 17.

• For information on collecting RUCD measurements, see Collect Run

Up/Coast Down Measurements on page 19.

42 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 43

Run Up/Coast Down Extension Module Chapter 2

Review Run Up/Coast Down Measurements

You can review previously saved RUCD measurements with the Dynamix 2500

data collector. The instrument saves the recorded data in the form of a time

waveform (.wav file).

Follow these steps to review an RUCD measurement.

1. Select RUCD on the Main Menu and press Enter.

The RUCD screen appears.

2. Select Review Data and press Enter.

The RUCD - Review Data screen appears.

3. Select the filename that you want review and press F3 (Open).

If you select a .wav file, the RUCD - WAV Setup screen appears. Otherwise

the appropriate plot setup screen appears.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 43

Page 44

Chapter 2 Run Up/Coast Down Extension Module

TIP

The RUCD - WAV Setup screen lets you to setup the .wav file parameters.

The instrument reads the .wav file to determine the

maximum speed present. If the number of pulses per

revolution is not equal to 1, enter the correct value

before processing.

4. Select the parameter and press the Right arrow to open a list of values.

5. Select or type in a parameter value.

6. Press the Left arrow to save your selection.

Use the descriptions in WAV Setup Parameter Descriptions on page 44

help you configure the parameters.

7. When you are finished, press F3 (Start).

The Display Select screen appears letting you select the appropriate plot to

view the recorded time waveform.

Table 11 - WAV Setup Parameter Descriptions

Parameter Name Description Values/Comments

Max M/c Speed The maximum machine speed in the .wav file.This parameter is set to the

Mode The method used in the .wav file to initiate data collection. When in doubt,

Pulses/Rev The number of tachometer signal pulses per revolution of the reference shaft. This value may affect the Max M/c Speed

Start Spd (RPM) The speed used in the .wav file to start collecting data. These parameters are not available if

Stop Spd (RPM) The speed used in the .wav file to stop collecting data.

highest detected m/c speed.

select manual:

• Runup - The data collection starts when the machine speed rises above

Start Spd.

• Coast down -The data collection starts when the machine speed falls

below Stop Spd.

• Manual - Manually start data collection by pressing F4 (Start). No

tachometer signal is required for this mode.

Runup

Coast down

Manual

value.

Mode is set to Manual.

to

44 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 45

Run Up/Coast Down Extension Module Chapter 2

Screen Capturing

Delete Run Up/Coast Down Files

Screens can be saved as a bitmap (.bmp) image to internal memory or to the

Secure Digital (SD) card. Press 0 (Shift) and 7 and follow the instructions.

You can delete a RUCD measurement or setup from the Dynamix 2500 data

collector.

Follow these steps to delete a file.

1. Select RUCD on the Main Menu and press Enter.

The RUCD screen appears.

2. Select Review Data to delete a measurement or Recall Data to delete a

setup and press Enter.

The RUCD - Review Data screen appears.

3. Select the appropriate filename or select all to delete all the files.

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 45

Page 46

Chapter 2 Run Up/Coast Down Extension Module

4. Press 0 (Shift) and F4 (Delete) to delete the selected files.

5. Press F2 (Yes) to delete.

46 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Page 47

Index

B

battery

status icons

battery status icons

Blanking

Bode plot

Bode plot parameters

Detection

Display Units

LF Cutoff 23

Num Traces

Show Overall

Spacing 23

Speed Interval

Start Spd

Stop Spd

Time Interval

Trace Order

Y-axis 23

13

13

34, 39

22

23

23

24

24

23

23

23

23

24

C

collecting data

run up/coast down measurements

configure

bode plot parameters

nyquist plot parameters

run up/coast down parameters

spectrogram plot parameters 37, 39

table parameters

waterfall plot parameters

WAV setup parameters

23

26

28

44

D

Detection 23, 26, 29, 32, 37

Disp. Order

Display Units

34

23, 26, 29, 32, 37

E

Extension Manager 7

F

Freq Range 32, 38

I

install extension module 7

L

LF Cutoff 23, 26, 29, 33, 38

license

extension module

32, 37

Lines

11

31, 34

18

17

M

manage extension modules 12

hide and show

Max Acq Time

Max M/c Speed

Max No Orders

Mode

18, 44

12

19

18, 44

18

N

No. Spectra 34

Num Traces

Nyquist plot

Nyquist plot parameters

Detection

Display Units

LF Cutoff

Num Traces

Spacing 26

Speed Interval

Start Spd

Stop Spd 26

Time Interval

Trace Order

24, 26, 29

25

26

26

26

26

26

26

26

26

P

Pulses/Rev 19, 44

R

Range 18

reviewing data

run up/coast down

RUCD - Bode Plot screen

RUCD - Bode Setup screen

RUCD - Display Select screen

RUCD - Nyquist Plot screen

RUCD - Review Data screen

RUCD - Spectrogram Plot screen

RUCD - Spectrogram Setup screen

RUCD - Table screen

RUCD - Table Setup screen

RUCD - Taking Data screen

RUCD - Waterfall screen

RUCD - Waterfall Setup screen

RUCD - WAV Setup screen

Run Up/Coast Down

Bode plot

Bode plot screen

collecting data

deleting data

Display Select screen

Nyquist plot

Nyquist plot screen

overview

recalling setup

Review Data screen

22

15

43

24

22

21

27

43

30

28

20

34

31

44

15

24

19

45

21

25

27

41

43

39

36

Rockwell Automation Publication 1441-UM006A-EN-P - May 2011 47

Page 48

Index

reviewing data 43

save measurement

save setup 40

setting up

Setup screen

Spectrogram Disp. Setup screen

Spectrogram plot 36

Spectrogram plot screen

Spectrogram Setup screen

Table screen 30

Table Setup screen

Taking Data screen

Waterfall Disp. Setup screen 33

Waterfall plot

Waterfall plot screen

Waterfall Setup screen 31

WAV Setup screen

Run Up/Coast Down Setup parameters

Max Acq Time

Max M/c Speed 18

Max No Orders

Mode

Pulses/Rev 19

Range

Save To

Sens 18

Start Spd

Stop Spd

Transducer 18

17

18

18

19

19

19

40

22

38

39

36

28

20

31

34

44

19

18

S

Save To 19

Sens

18

Show Overall

Spacing

Spectrogram Disp. Setup screen

Spectrogram plot

Spectrogram plot parameters

Blanking

Detection

Display Units

Freq Range

LF Cutoff

Lines

Spacing

Speed Interval

Start Spd

Stop Spd

Time Interval

X-axis

Y-axis

Z-axis 39

Speed Interval

Start Spd

Stop Spd

24

23, 26, 29, 32, 37

38

36

39

37

37

38

38

37

37

37

37

37

37

37

39

23, 26, 29, 32, 37

19, 23, 26, 28, 31, 37, 44

19, 23, 26, 28, 31, 37, 44

Detection

Display Units

LF Cutoff 29

Num Traces

Spacing

Speed Interval

Start Spd 28

Stop Spd

Time Interval

Trace Order 29

Time Interval

Trace Height

Trace Offset

Trace Order

Transducer

29

29

29

29

29

28

29

23, 26, 29, 32, 37

34

34

24, 26, 29

18

U

uninstall extension module 9

W

Waterfall Disp. Setup screen 33

Waterfall plot

Waterfall plot parameters

Blanking

Detection

Disp. Order

Display Units 32

Freq Range

LF Cutoff

Lines 32

No. Spectra

Spacing

Speed Interval 32

Start Spd

Stop Spd

Time Interval

Trace Height

Trace Offset

X-axis

Z-axis

WAV setup parameters

Max M/c Speed

Mode

Pulses/Rev

Start Spd

Stop Spd

31

34

32

34

32

33

34

32

31

31

32

34

34

32

34

44

44

44

44

44

X

X-axis 32, 37

Y

Y-axis 23, 39

T

Table Format 28

Table parameters

48 Rockwell Automation Publication 1441-UM006A-EN-P - May 2011

Z-axis 34, 39

Z

Page 49

Page 50

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Publication 1441-UM006A-EN-P - May 2011 50 Copyright © 2011 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...