Page 1

User Manual

Balancing Extension Module for the Dynamix 2500

Data Collector

Catalog Number

1441-DYN25-MBAL

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, Dynamix, Enpac, Emonitor, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Installing Optional Extension

Modules

Balancing Extension Module

Index

Optional Extension Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1

Install Extension Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Uninstall Extension Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Manage Extension Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Extension Module Battery Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2

Balancing Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Plane Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Static-couple Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Set Up the Balancing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Balance Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Single Plane Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Single Plane Balancing Procedure Overview. . . . . . . . . . . . . . . . . . . . . 26

Take the Initial Vibration Measurement. . . . . . . . . . . . . . . . . . . . . . . . 27

Add the Trial Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Enter the Trial Weight Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Estimate the Trial Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Take a Trial Run Weight Measurement . . . . . . . . . . . . . . . . . . . . . . . . 32

Take a Correction Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Perform a Trim Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Add the Correction Weight and Take a Residual Measurement . . 41

Two Plane Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Two Plane Balancing Procedure Overview. . . . . . . . . . . . . . . . . . . . . . 46

How to Set Up a Two-Plane Procedure . . . . . . . . . . . . . . . . . . . . . . . . 46

How to Perform Two-plane Balancing . . . . . . . . . . . . . . . . . . . . . . . . . 50

Move Around in a Balance Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Saving, Loading, and Reviewing Balance Measurements . . . . . . . . . . . . . 61

Save a Balance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Load a Previously Saved Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Review Balancing Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

How to Delete Stored Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 3

Page 4

Table of Contents

Notes:

4 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 5

Preface

This manual describes the Balancing extension module for the Dynamix 2500

data collector. You install the extension module with the Balancing Secure Digital

(SD) card.

Optional Extension

Modules

See Installing Optional Extension Modules on page 7

instructions.

The balancing test determines the amount and location of the heavy spot on a

rotating shaft so that you can balance it with an equal amount of weight in the

opposite direction.

There are three types of measurements in the balancing process:

• Initial Vibration

• Tri al Wei gh t

• Residual Measurements

These are the optional extension modules for the Dynamix 2500 data collector:

• 1441-DYN25-4C, 4-channel Activation

The 4-channel activation lets you take 3- and 4-channel magnitude, time

waveform, spectra, and Offroute measurements.

• 1441-DYN25-MBMP Bump Test

A bump test (or hammer test) determines the natural frequencies of a

machine or a structure.

• 1441-DYN25-MBAL Balancing

for installation

(1)

Balancing application resolves single-plane, two-plane, and static-couple

balances with high precision.

• 1441-DYN25-MFRF Frequency Response Function

The FRF test lets you determine the natural frequencies of a machine as

well as sophisticated information about the frequency response of the

structure being tested.

• 1441-DYN25-MREC Time Recorder

The Time Recorder test uses a the instrument as a data recorder for real-

time data acquisition and analysis.

• 1441-DYN25-MRUC Run Up Coast Down

The RUCD test records and analyzes data from intermittent events and

transient vibration signals from non-steady state machines.

See Additional Resources on page 6

(1) This is an activation license for the Dynamix 2500 data collector.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 5

for a listing of available publications.

Page 6

Preface

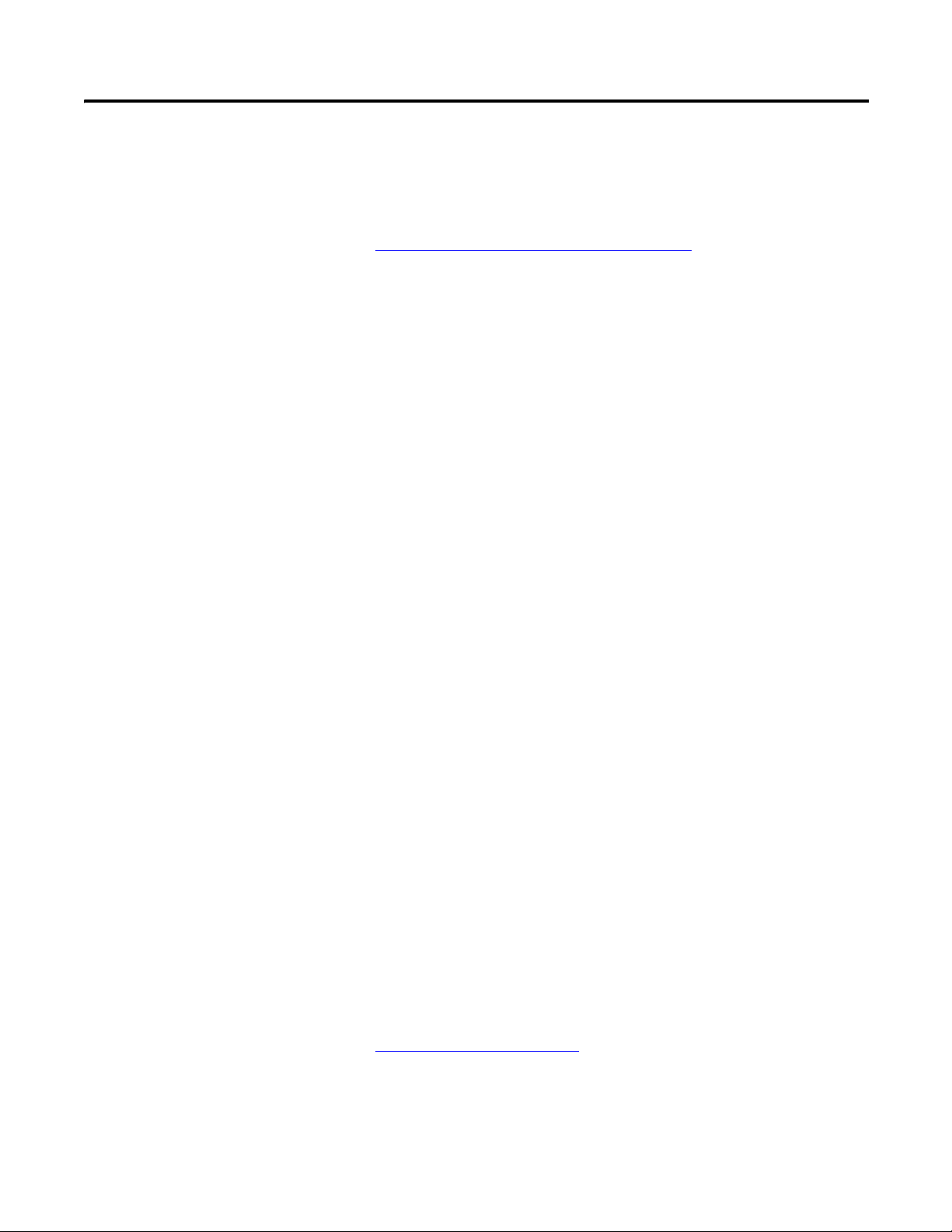

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Dynamix 2500 Data Collector User Manual,

publication 1441-UM001

Bump Test Extension Module for the Dynamix 2500

Data Collector User Manual,

publication 1441-UM002

Frequency Response Function Extension Module

for the Dynamix 2500 Data Collector User Manual,

publication 1441-UM003

Time Recorder Extension Module for the Dynamix

2500 Data Collector User Manual,

publication 1441-UM005

Run Up Coast Down Extension Module for the

Dynamix 2500 Data Collector User Manual,

publication 1441-UM006

Emonitor User’s Guide, publication

EMONTR-UM001

Dynamix 2500 Data Collector Kit Release Notes,

publication 1441-RN001

Dynamix 2500 Data Collector Optional Extension

Modules Release Notes, publication 1441-RN002

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, http://www.ab.com

Describes the Dynamix 2500 data collector

which provides predictive maintenance by

using noise and vibration analysis.

Describes how determine natural (or resonant)

frequencies of a machine or structure.

Describes how to determine the natural

frequencies of a machine or structure by using

modal hammer.

Describes how to use the data collector as a

data recorder for real-time data acquisition,

post processing, and analysis.

Describes how to record and analyze data from

intermittent events and transient vibration

signals from non-steady state machines.

Describes data management for predictive

maintenance services.

Provides information on the latest updates, for

example, firmware, certifications, warnings,

and hardware changes for the data collector.

Provides information on how to install the

Optional Extension Modules on to the Dynamix

2500 data collector.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity,

certificates, and other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

6 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

. To order paper copies of

Page 7

Chapter

IMPORTANT

IMPORTANT

1

Installing Optional Extension Modules

The data collector uses the Extension Manager to install and uninstall extension

modules. These extension modules are licensed and ordered separately from the

basic entry-level product.

Topic Page

Install Extension Modules 7

Uninstall Extension Modules 9

Manage Extension Modules 12

Extension Module Battery Status Indicators 13

Install Extension Modules

The installation Secure Digital (SD) cards that you receive work with any

Dynamix 2500 data collector. Once you have installed an extension module, the

card is locked so that it can only be used with that instrument.

One installation SD card is required for each instrument that needs to

be upgraded.

You can uninstall extension modules if required. When uninstalling an extension

module, you have the option to free up the license so you can install the extension

module on another instrument. This makes the extension module available to be

transferred between units.

When ever you re-run the OS Loader software, you will re-load only the

main OS firmware. The OS loader will backup licence files and data, but

not the optional extension modules. Once you have updated the OS

firmware, insatll the latest version of your optional extension modules.

See the Dynamix 2500 Data Collector User Manual, 1441-UM001

more information.

Follow these instructions to install an extension module.

1. Open the base cover at the bottom of the Dynamix 2500 data collector.

, for

2. Place the extension module SD card contact side-up into the unit until it is

firmly seated in place.

3. Close the base cover.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 7

Page 8

Chapter 3 Installing Optional Extension Modules

Extension Manager

4. Apply power to the data collector.

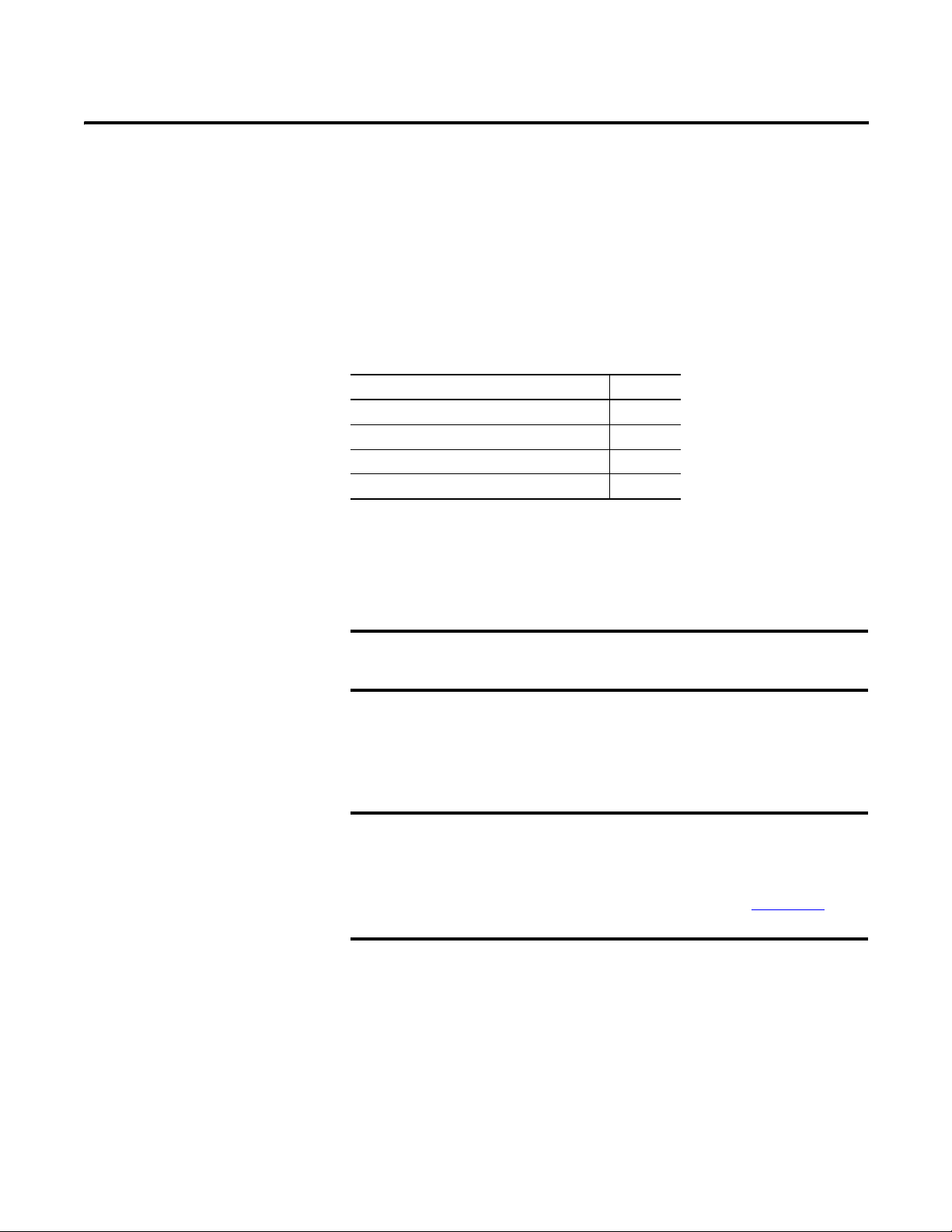

5. From the Main Menu, select Setup Utility and press Enter.

6. Press 0 (Shift) to display the second set of functions.

The Extension Manager function remains on the screen for about three

seconds after releasing 0 (Shift).

7. Press F1 (Extn Mgr).

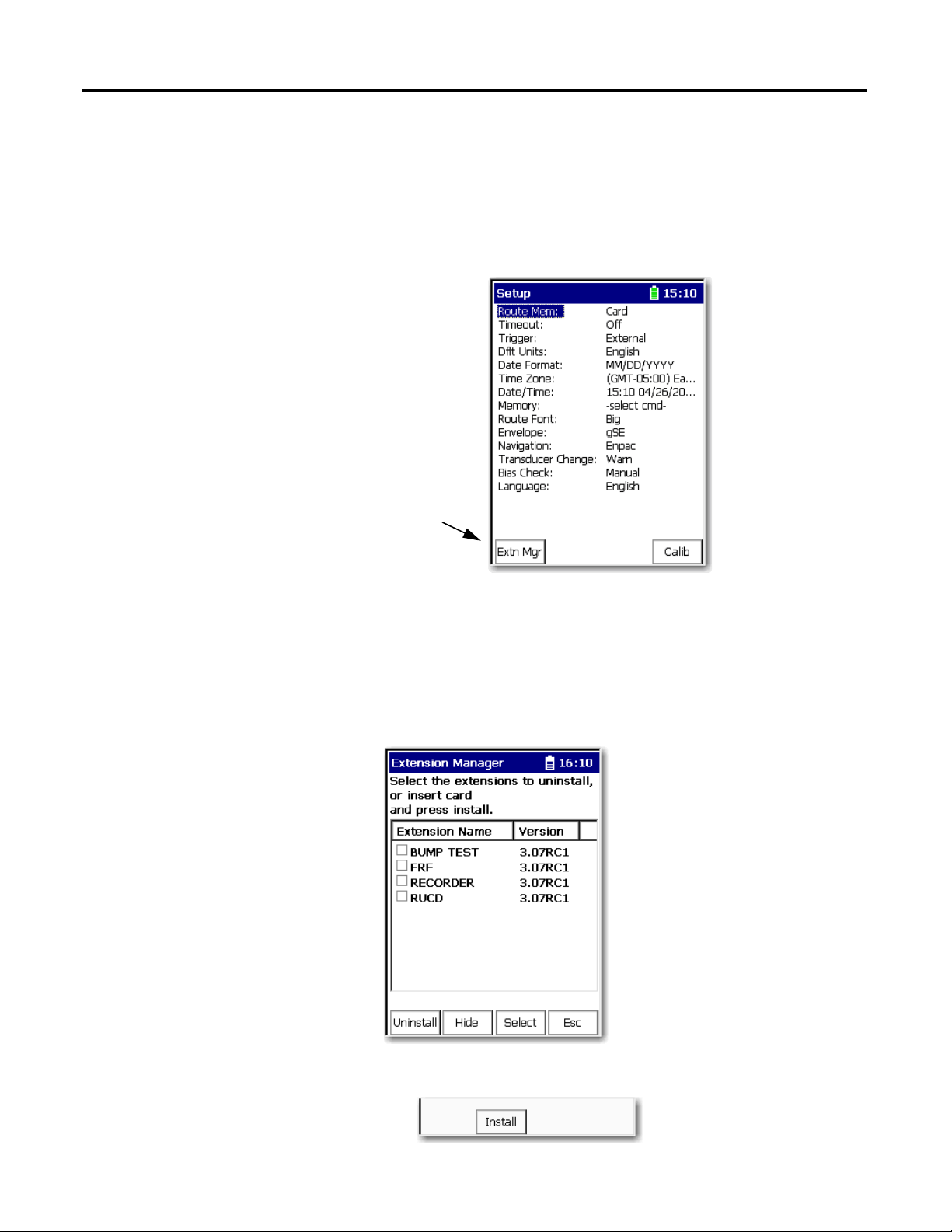

The Extension Manager screen appears showing the current extension

module installations.

8 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

8. Press 0 (Shift) to display the Install Extension function.

9. Press F2 (Install) to install the new extension module.

Page 9

Installing Optional Extension Modules Chapter 3

Extension Manager

When the installation is complete, a confirmation prompt appears.

10. Press F4 (OK).

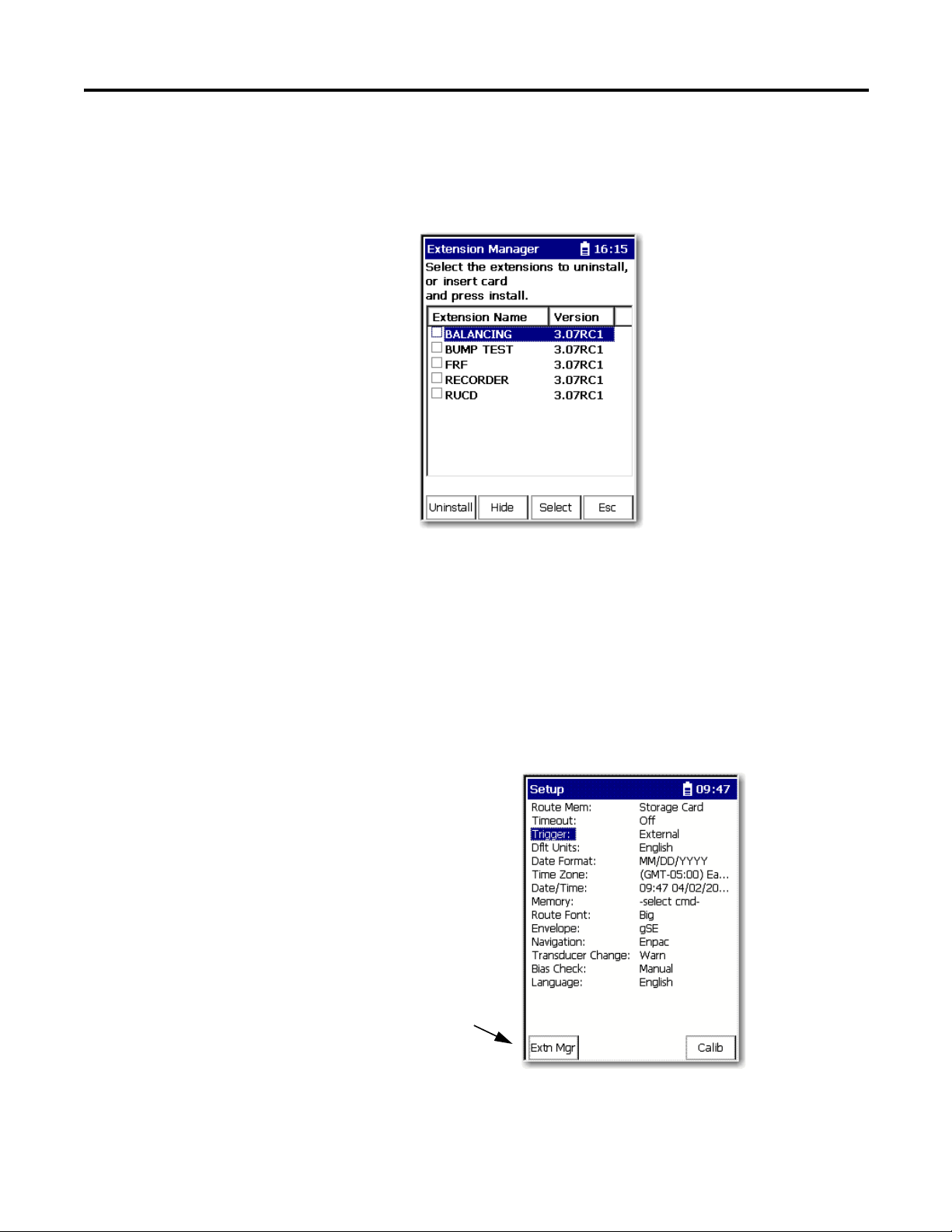

The new extension module appears in the list.

Uninstall Extension

Modules

11. Press F4 (Esc) to exit the Extension Manager screen.

Follow these instructions to uninstall an extension module.

1. Press 0 (Shift) from the Setup Utility screen to display the Extension

Manager function.

The Extension Manager function remains on the screen for about three

seconds after releasing 0 (Shift).

2. Press F1 (Extn Mgr).

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 9

Page 10

Chapter 3 Installing Optional Extension Modules

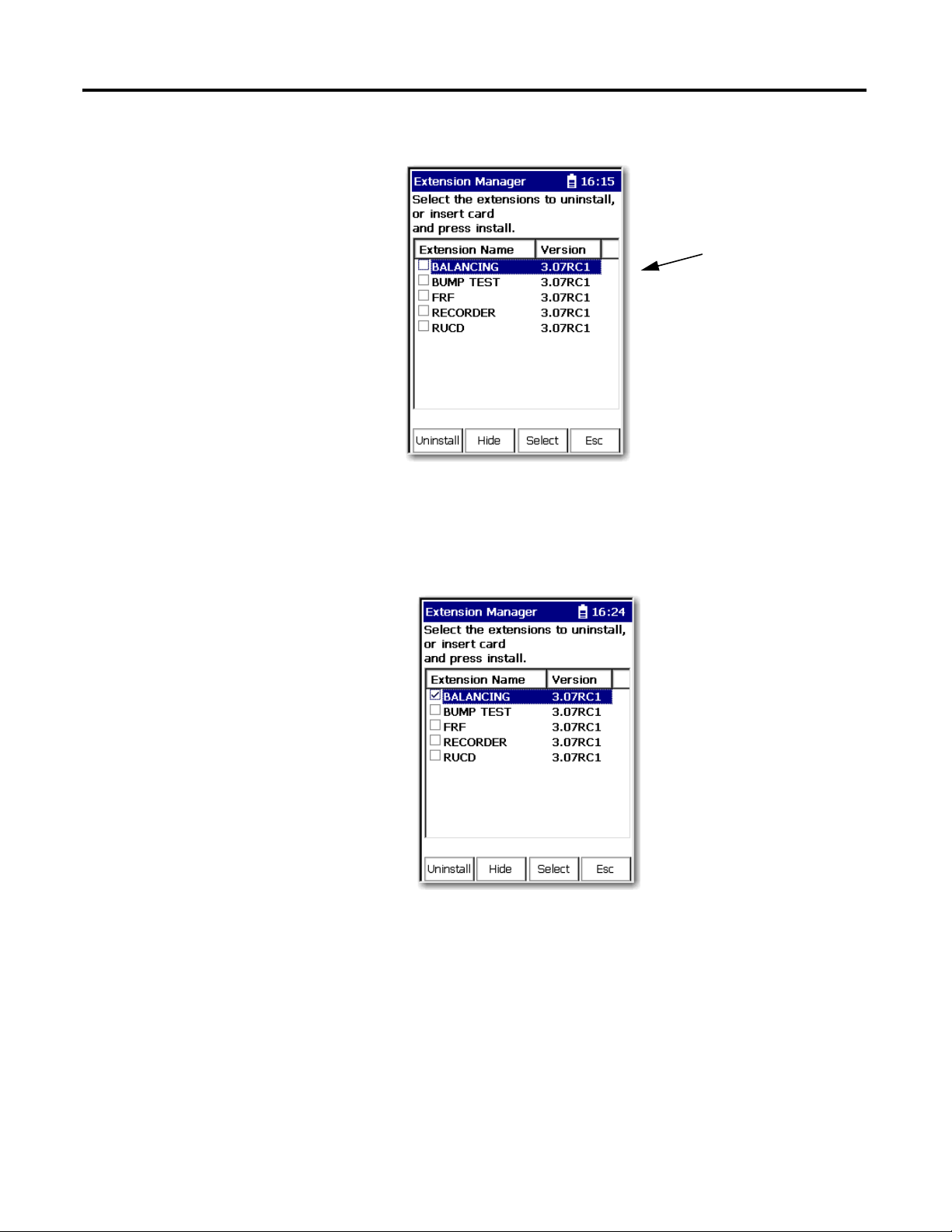

This screen lists the

extension modules

currently installed and the

on the unit.

The Extension Manager screen appears.

3. Select the extension module you want to uninstall and press F3 (Select).

F3 (Select) toggles the selection on and off.

A checkmark appears next to that extension module.

4. Press F1 (Uninstall).

10 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 11

Installing Optional Extension Modules Chapter 3

IMPORTANT

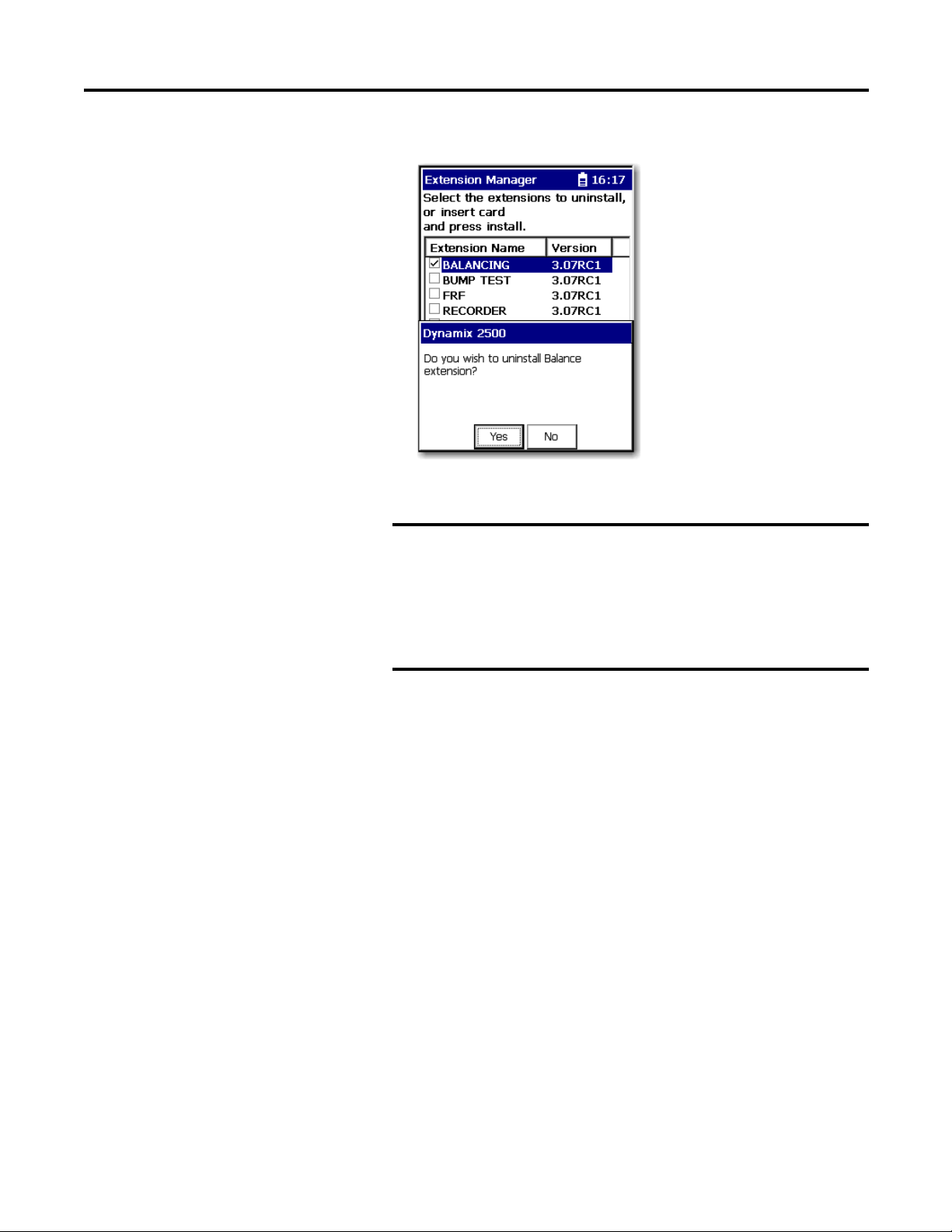

A confirmation message appears.

5. Make sure your installation card is inserted into the instrument.

The extension module is uninstalled and the license on the card is

released so that the card can be used to install the extension

module on another Dynamix 2500 data collector.

If the installation card is not inserted in the instrument and no

card, you are is found or the card does not have the extension

module license for the unit, you are prompted to insert the correct

installation card or continue without freeing the license.

6. Press F2 (Yes) to uninstall the extension module.

7. Press F4 (Esc) to exit the Extension Manager screen.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 11

Page 12

Chapter 3 Installing Optional Extension Modules

IMPORTANT

TIP

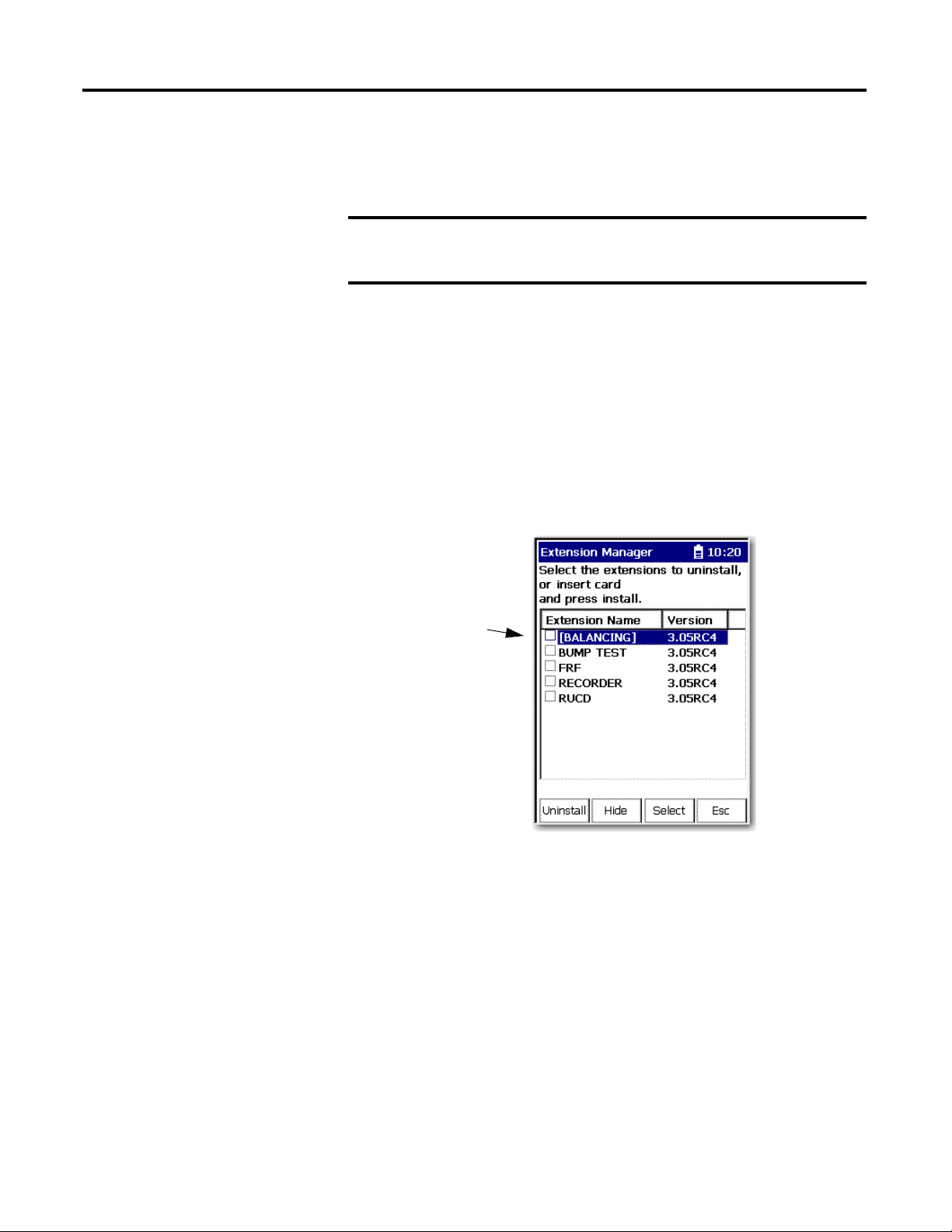

The extension modules that

are hidden are shown in

[square brackets].

Manage Extension

Modules

The Dynamix 2500 data collector lets you to hide installed extension modules

from the Main Menu. You may need to hide an advanced extension module icon

from an inexperienced user, for example, RUCD and FRF.

Once an extension module is hidden, its icon is not represented on the

Main Menu or displayed in the Dynamix 2500 data collector About

screen.

Follow these instructions to hide or show an extension module icon on the Main

Menu.

1. Press 0 (Shift) on the Setup Utility screen to display the Extension

Manager function.

The Extension Manager function should remain on the screen for

approximately three seconds after releasing 0 (Shift).

2. Press F1 (Extn Mgr). The Extension Manager screen appears.

The Extension Manager displays a list of installed extensions module.

12 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

The F2 (Hide) toggles between Hide and Show depending if the selected

extension module is hidden or not.

You have to exit and re-enter the Extension Manager after hiding an

extension module to have the Show function appear.

Page 13

Installing Optional Extension Modules Chapter 3

TIP

3. Select the extension module that you want to hide or show and press F2

(Show/Hide).

If you want to show or hide multiple extension modules

simultaneously, select each extension module and press F3

(Select).

A checkbox appears next to each selected extension module. If

you select multiple extension modules and some are hidden

while others are shown, F2 (Show/Hide) reflects the status of the

selected extension module.

4. Press F4 (Esc) to exit the Extension Manager.

Extension Module Battery

Status Indicators

The battery status icons show the strength of the battery.

Table 1 - Extension Module Battery Icon Descriptions

Battery Icon Meaning

Battery status is good: >30% life remaining.

Battery status is low: >10% life remaining.

Battery status is very low: <10% life remaining.

Battery is charging.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 13

Page 14

Chapter 3 Installing Optional Extension Modules

Notes:

14 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 15

Chapter

2

Balancing Extension Module

The Balancing extension module is an optional module for the Dynamix 2500

data collector. You install the extension module with the Balancing Secure Digital

(SD) storage card.

Topic Page

Balancing Measurements 16

Plane Balancing 16

Static-couple Balancing 18

Set Up the Balancing Parameters 20

Single Plane Balancing 26

Two Plane Balancing 45

Saving, Loading, and Reviewing Balance Measurements 61

Balancing application resolves single-plane, two-plane, and static-couple balances

with high precision. You can use the Dynamix 2500 data collector coupled with a

speed-measuring device such as a strobe light or laser tachometer.

The Dynamix 2500 data collector Balancing extension module provides a simple,

direct method to balance your rotating machinery in one or two planes. You can

use the internal laser tachometer in the data collector or an external laser

tachometer, optical tachometer, or strobescope for measuring phase during the

balance run.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 15

Page 16

Chapter 2 Balancing Extension Module

Balancing Measurements

Balancing is the technique for determining the amount and location of the heavy

spot on a rotating shaft so that you can balance it with an equal amount of weight

in the opposite direction. These methods go through the technique with

stopping points where you start and stop the machine to perform weight addition

or subtraction.

There are three types of measurements in the balancing process:

• Initial Vibration

The initial vibration measurement is taken without any added weights on

the machine. The initial vibration measurement establishes a reference of

how the machine vibrates at each plane without any extra weight added.

This vibration is what will be corrected by the correction weight.

• Tri al Wei gh t

The trial weight measurements are taken with a single trial weight attached

to the machine at one plane or the other. The trial weight measurements

are used to determine how the machine is affected by the added weight.

The ideal trial weight should produce either a 30 % change in amplitude or

a 30

° change in phase.

• Residual Measurements

Plane Balancing

The residual measurements are taken with the correction weight or the

correction weight and trim weights attached to the machine. The

correction weight should cancel out the initial unbalance. A residual

vibration measurement is taken to measure the remaining unbalance. Trim

weights are added to the machine to cancel out the vibration measured

during a residual measurement.

Regardless of whether you are performing a single or two-plane balancing

procedure, all balancing procedures progress through basic runs as you start

(spin) and stop the rotor.

For two-plane procedures, you perform some of the runs twice, once with weights

on correction plane one and again with weights on correction plane two. For

simplicity, the following example describes a single-plane procedure.

These are the steps you need to take to take a single-plane balancing

measurement.

1. Set up balancing equipment and the Balancing parameters.

With the machine stopped, set up the balancing equipment and mark your

tachometer reference point on the rotor or shaft.

See Set Up the Balancing Parameters on page 20

measurement parameters for the balancing run sequence.

16 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

to configure balancing

Page 17

Balancing Extension Module Chapter 2

2. Perform the initial measurement.

a. Start the machine.

b. Take the initial measurement.

The initial measurement provides a starting place for balancing

computations. It records the machine's initial imbalance, 1X vibration

magnitude and phase angle. Later in the procedure, initial measurement

data is automatically compared with trial (weight) measurement data to

calibrate the machine's imbalance.

3. Attach a trial weight.

a. Stop the machine after collecting the initial measurement data.

b. Add a trial weight.

A trial weight is a temporary weight attached to produce a change from

the original unbalance readings (reference run readings). Input the trial

weight amount and placement angle into the data collector.

4. Perform the trial measurement.

a. Start the machine again with the trial weight securely attached.

b. Take trial measurement with the trial weight.

The trial measurement calibrates the machine's unbalance and allows

the data collector to calculate the influence coefficient and permanent

correction weight amount and placement. To allow for accurate

balancing computations, the trial weight should pass the 30/30 rule.

The trial weight should do the following:

• Increase or decrease the 1X vibration amplitude by at least 30 %

• Change the phase angle by at least 30

°

• Be a combination of A and B.

5. Attach the correction weight.

a. Stop the machine.

b. Remove the trial weight

c. Attach the specified correction weight at the specified angle.

6. Perform a correction weight measurement.

a. Start the machine again.

b. Take correction weight measurement.

The correction weight run performs two functions:

• It calculates the amount of residual imbalance with the correction

weight in place to confirm that the machine is now balanced within

tolerances.

• If further balancing is necessary, it automatically applies the

influence coefficient to calculate additional trim weights that can be

added to further balance the machine.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 17

Page 18

Chapter 2 Balancing Extension Module

7. If additional trim weights are necessary to balance the machine within

tolerances, stop the machine and attach the specified trim weights.

a. Stop the machine.

b. Attach the specified trim weights.

c. Take another measurement.

8. Perform a trim measurement.

a. Start the machine.

b. Take a trim measurement to verify the machine is balanced within

tolerances. If not, you can take additional trim measurements.

Static-couple Balancing

With stiffer rotors, a two-plane procedure may reduce the amount of imbalance

to target tolerances. However, with narrow or flexible rotors, more often a

static-couple procedure works best.

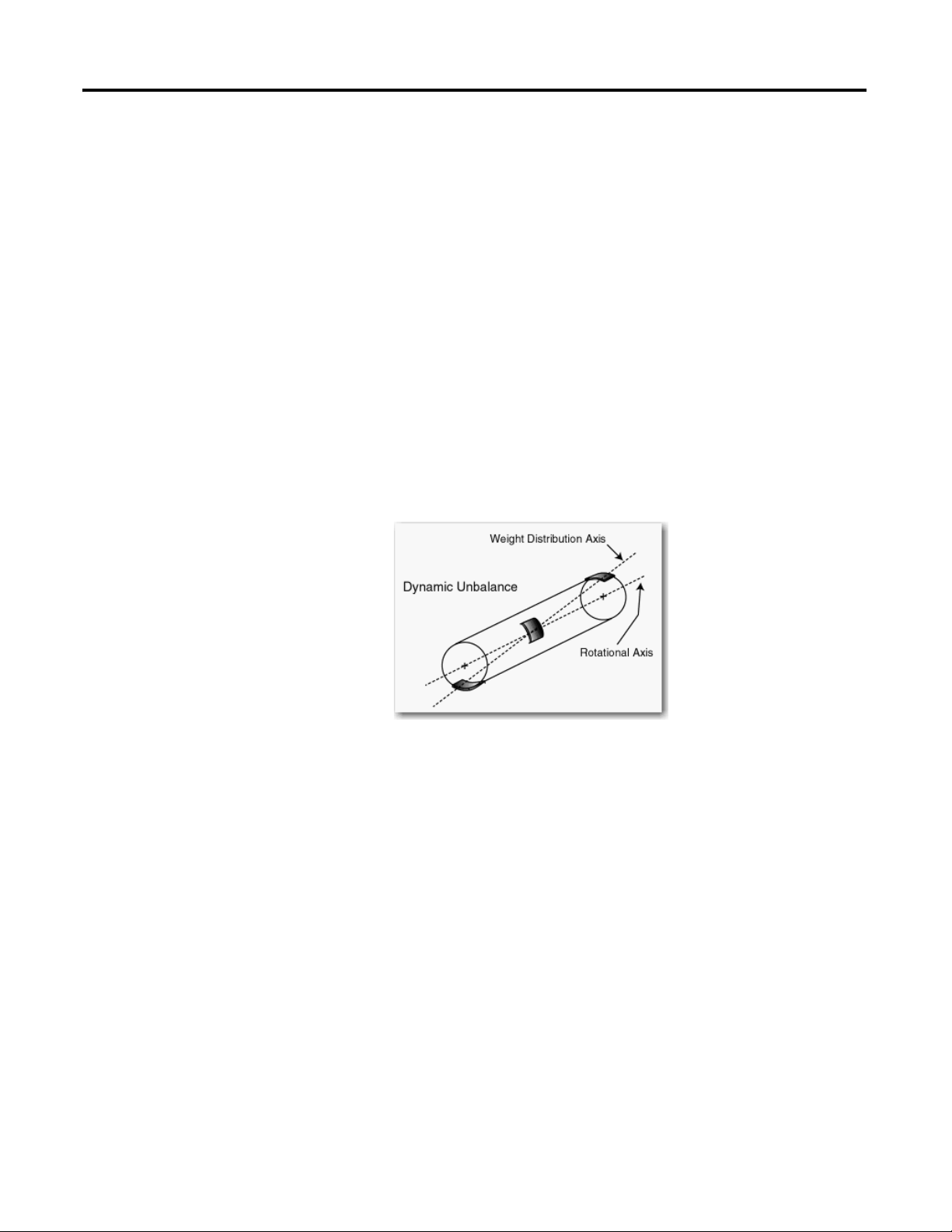

This graphic shows a narrow rotor showing three heavy spots.

The static-couple procedure corrects the static unbalance with weights added to

the center of gravity plane, and corrects the couple unbalance with weights added

to the end planes.

In practice, a static-couple balancing procedure is almost identical to a two-plane

balancing procedure, except that it provides three correction weight solutions

instead of two. One correction weight for each plane, and an additional

correction weight to correct the static unbalance.

Unless you are able to attach weights to the machine’s center of gravity plane, the

static weight is typically split in half and applied to the end planes to correct the

static unbalance.

In as such, on the data collector, the static-couple procedure is identical to the

two-plane procedure except the Correction Weight and Trim Weight screens

show three correction weights for the static-couple procedure:

• One weight for end plane 1

• One weight for end plane 2

18 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 19

Balancing Extension Module Chapter 2

Except for the Solution field, all static-couple balancing parameters are identical

to two plane balancing settings.

If you want to compute three correction weights, select Static-Couple for the

Solution parameter on the Balance - Setup screen.

See Balance Extension Module Parameters on page 22

for more information

about these parameters.

Except for attaching three correction and trim weights instead of two (or four if

you split the static weight), all static-couple balancing run procedures are

identical to the two-plane balancing procedures.

SeeTwo Plane Balancing on page 45

on how to perform a two- plane Procedure

section for details.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 19

Page 20

Chapter 2 Balancing Extension Module

Set Up the Balancing

Parameters

All balancing measurement parameters are set up from Balance Setup screen.

Follow these steps to go to the Balancing extension module.

1. From the Main Menu, select Balancing and press Enter.

The Balance menu displays.

These are the Balance menu options:

• Setup

Access the Balance - Setup screen where you can set up and perform a new

balancing run.

• Recall

Access the Balance - Load Setup screen where you can select a previously

saved balancing run and perform a new run by using the saved settings.

• Review

Review Data screen where you can review previously stored measurements

or resume a previous balance measurement from the last completed run.

20 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 21

Balancing Extension Module Chapter 2

Balance Setup Screen

After setting up your balance measuring equipment and marking your

tachometer reference point, the next step is to configure balancing measurement

parameters for the balancing run sequence.

Follow these steps to setup the Balancing parameters.

1. From the Balance main menu, select Setup and press Enter.

The Balance Setup lets you configure the balance measurement

parameters.

2. Select an option and press the Right arrow to open a list choices.

3. Use the arrow keys to select a parameter.

4. Press the Left arrow to save your selection.

Use the descriptions in Balance Extension Module Parameters

to help you

configure the parameters in the Balance Setup screen.

5. Save the setup or start taking the balancing measurement.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 21

Page 22

Chapter 2 Balancing Extension Module

width

width

width

diameter

diameter

diameter

W/D RATIO 1-PLANE 2-PLANE

Less than 0.5

More than 0.5

but less than 2

More than 2

0 - 1000 RPM

0 - 150 RPM

0 - 100 RPM

Above

1000 RPM

150 - 2000

RPM or above

70% of 1st

critical

Above 100

RPM to 70%

of 1st critical

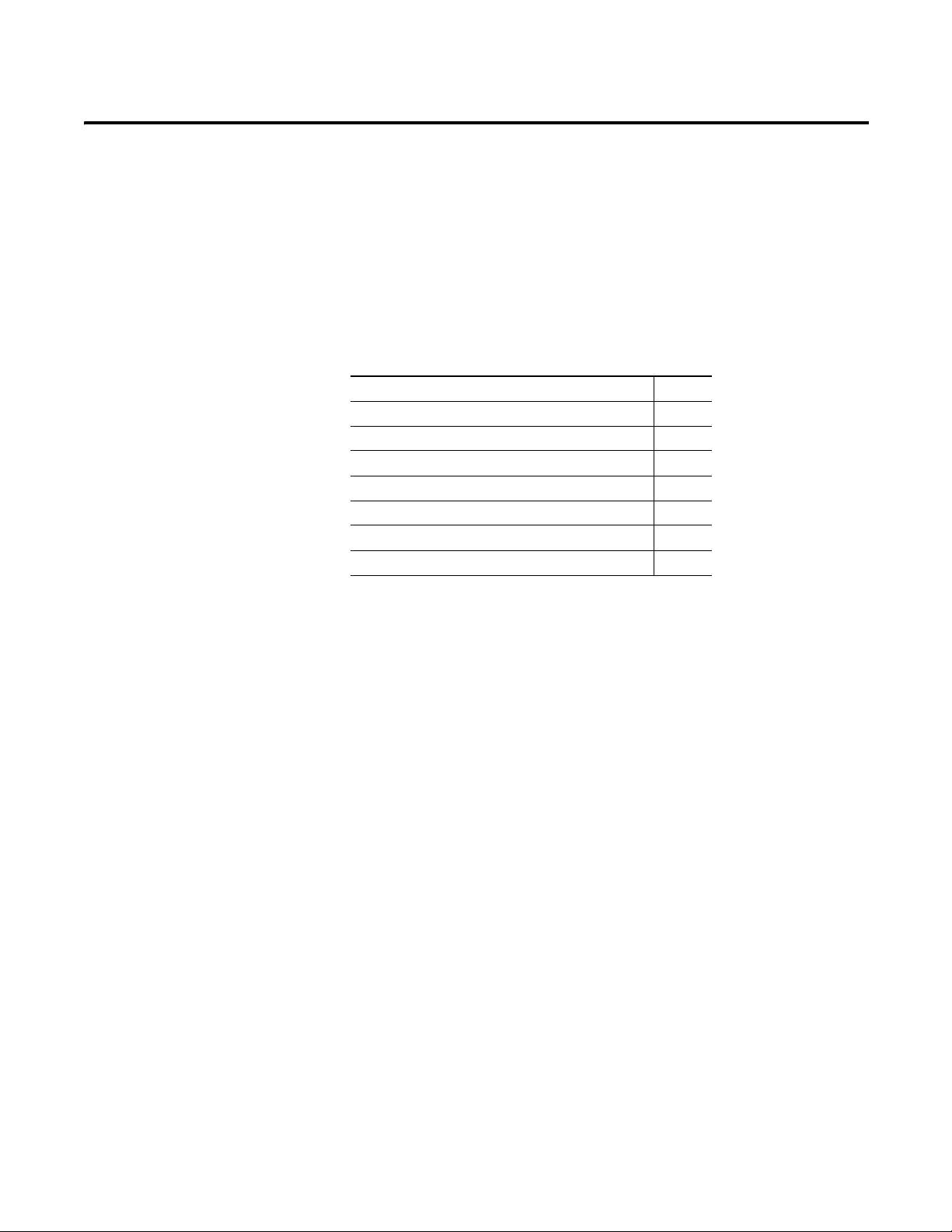

Table 2 - Balance Extension Module Parameters

Parameter Description Value

Num. of Planes Determines whether single-plane or two-plane balancing is

required. A good rule-of-thumb is the rotor’s width-to-diameter

(W/D) ratio. The W/D ratio is the width (excluding shaft length)

of the combine rotors divided by their diameter. The following

chart can be used to help determine whether to use one- or

two-plane balancing.

1

2 (default)

Num. Transducer Determines the number of transducers to be used. Connector A and B

Sensor (transducer) Type Vibration measurement type.

The type of vibration measurement depends on the type of

transducer used, for example, accelerometer, velocity pickup, or

proximity probe. This is required to establish integration

requirements for the FFT calculation.

Typically, accelerometers are used to perform velocity

measurements for field balancing procedures.

A Manual Entry option is available at the end of the list for

Accel (G) (default)

Vel IPS

Vel mm/s

Disp um

Disp mil

Manual Entry

manual balancing data entry, letting you to review and change

balancing run data. If selected, you are prompted to manually

enter the running speed, vibration magnitude, and phase angle

for the balancing runs.

Display Units Specify the unit of measurement for the select transducer type.

EU

The options available in the list vary depending on the

transducer selected.

Weight Units Defines the units used in balancing.

Specify the units of measurement used for your trial, correction,

and trim weights.

g

kg

oz (default)

lb

EU

22 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 23

Balancing Extension Module Chapter 2

Table 2 - Balance Extension Module Parameters

Parameter Description Value

Length Units Specifies the units of measurement used for measuring the

radius of the weight placement (from the shaft center to the

position of the weight).

You can use this information when you have the data collector

to estimate the trial weight for you.

Movement Specify your weight angle placement convention, either With

Rotation or Against Rotation. During a balancing procedure,

when weight angle placements are specified, this setting

determines their direction from the zero reference point.

You place weights on the rotor to balance the machine. The

position of this weight is given in degrees or positions (where

the total number of positions equals the number of blades or

vanes) from the reference notch or mark. You must select

whether you are measuring the angle with or against the

direction of the shaft rotation.

The Movement parameter affects how the angles are

measured. If Movement is set to "With Rotn," angles are

measured from the reference mark, in the direction of the

machine’s normal rotation.

If Movement is set to "Against Rotn," angles are measured from

the reference mark, in the opposite direction of the machine’s

normal rotation.

Trigger Type Sets the trigger source:

• External Analog - An external trigger will be used to trigger

data sampling. You must also set the slope and trigger

level.

• Laser Tach - Enables the internal Laser Tachometer new

firmware and ext modules coming soon check SKF to

confirm this function. should be fixed

Ext trig slope Sets the slope for externally triggering the measurement.

Slope is the direction in which the signal is moving, and is

either positive (rising) or negative (falling) before a trigger is

detected.

This parameter is applicable only when Trigger Type is set to

ext Analog or ext TTL.

Trigger Level Amplitude level for the external trigger the measurement.

Enter the number of volts to eliminate noise, which may cause

false triggering.

This is applicable only for external analog trigger type

measurements.

Vib. Threshold The acceptable imbalance level you are trying to achieve. If the

vibration magnitude is greater than this threshold, the

magnitude bar is colored red when taking a reading. The bar

turns green when the selected level of imbalance is achieved.

Filter Sets the high pass filter to. apply to the measurement.

The high pass filter is useful in removing high vibration, low

frequency signal components, which can dominate the signal.

mm

cm

m

inch (default)

feet

EU

With Rotn

Against Rotn (default)

Ext Analog (default)

Laser Tach

-ve

+ve (default)

volts

2 V (default)

1.00 EU (default)

Off

2 Hz (default)

10 Hz

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 23

Page 24

Chapter 2 Balancing Extension Module

Table 2 - Balance Extension Module Parameters

Parameter Description Value

Detection Selects the type of signal detection and scaling for the

measurement:

• Peak - The data collector measures the dynamic signal

from zero to peak voltage. Use this or the RMS setting for

most acceleration and velocity measurements.

• Pk-Pk - The data collector measures the dynamic signal

from the minimum peak to the maximum peak. Use this

setting for most displacement measurements.

• RMS - The data collector measures the dynamic signal as

the square root of the mean of the square. Use this or Peak

for most acceleration and velocity measurements. Also use

this for voltage measurements.

No. Averages Enter the number of averages (1 to 8) for the measurement. 4 (default)

Solution Select the balancing solution. The parameter is available only

when you are two-plane balancing:

• Dynamic - The correction weights will be calculated for

both planes 1 and 2.

• Static-Couple - The correction weights will be calculated

as a combination of Static and Couple. The Couple balance

weights will be presented as the same weight in both

planes 1 and 2, with a phase angle of 180

° difference. The

Static part of the solution will be calculated at the center

between planes 1 and 2.

Peak: Scaled from RMS as 2

Pk-Pk: Scaled from RMS as 2

RMS: The Root Mean Squared overall

calculated from the FFT or time data.

Defaults to Peak for Accel

Defaults to Vel and Pk-Pk for Disp.

Dynamic (default)

Static-Couple

RMS

2 RMS

24 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 25

Balancing Extension Module Chapter 2

Input Chan The input channel required for the measurement.

Select channel X for single-plane balancing, with the

transducer connected to the data collector’s Connection A.

For two-plane balancing with two transducers, you set one

plane’s transducer as channel X, the other plane’s transducer as

channel Y.

See Two Plane Balancing on page 45

for more information.

X (default) on connector A only

Y, on Connector B

Coupling The type of coupling to be applied to the measurement.

• AC, Acquires the input signal from a buffered output

(external) device. Power is not applied to the transducer.

• ICP, Applies DC to the charge amplified transducer signal

and couples the dynamic signal to the input channel.

AC

ICP

(default)

Sensitivity The sensitivity of the transducer. Sensitivity is set as mV/EU,

where EU is the base engineering unit of the transducer.

Use the keypad to enter the transducer sensitivity in millivolts

(mv) per Engineering Unit (EU). 100 mV/EU is used for most

acceleration transducers, 200 mV/EU for most non-contact

displacement transducers, and 1000 mV/EU if the input is volts

and the scales is to be read directly. The default setting is 100

mV/EU.

0.010 to 1000 mV/EU

A 100 m V/G accelerometer

would be set as 100 m V/EU

Input Range Select the signal input range between Autorange and a fixed

range in transducer units in a 1 - 2 - 5 sequence. The available

fixed values vary depending on the transducer type being used.

If a fixed range is selected and the data collector detects an

over range, it automatically selects the next higher range until

it does not over range.

Autoranging

Type Select the appropriate weight position type,

For a rotor without vanes or blades, set Type to Continuous.

Continuous specifies that weights may be placed at any

placement position on the balance plane.

Fixed is known also as vector splitting. It works with Number of

Positions and Position 1 Offset fields. Fixed specifies that

weights may be placed only at designated positions, for

example, rotors having a specific weight hole pattern, or with a

specific number of fan blades.

Continuous (default)

Fixed

No. of posns Applies to Fixed weight position measurements only.

The first position defaults to 0

°, subsequent positions evenly

spaced.The number of positions refers to the number of rotor

components, such as blades on a fan.

3 to 360

°

Enter 0 (zero) for a rotor without

vanes or blades.

Posn 1 Offset Applies to Fixed weight position measurements only.

Enter the fixed position 1 offset, from zero to 360

°, relative to

the trigger reference.

0 to 360

°

Table 2 - Balance Extension Module Parameters

Parameter Description Value

Plane (x) Sets the plane for which the settings below apply.

Two plane get two sets of the following attributes/parameters

(settings)

1

2

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 25

Page 26

Chapter 2 Balancing Extension Module

Single Plane Balancing

The balancing of a machine in one plane is divided into taking these three

measurements:

• Initial measurement

• Trial weight measurement

• Residual measurement

You must complete the entire procedure until the vibration level has been

reduced enough for your needs.

See Balancing Measurements on page 16

for more information.

Single Plane Balancing Procedure Overview

This is an overview of the steps you need to take when performing a single plane

balancing measurement.

1. Take the Initial Vibration Measurement on page 27

2. Add the Trial Weight on page 28

a. Enter the Trial Weight Manually on page 29

b. Estimate the Trial Weight on page 30

.

.

.

.

3. Take a Trial Run Weight Measurement on page 32

4. Take a Cor rect ion Run on p ag e 35

5. Perform a Trim Run on page 37

6. Combine the Balance Run Weights on page 38

7. Add the Correction Weight and Take a Residual Measurement on page 41

a. Split the Correction Weight on page 42

b. Modify the Radius on page 42

c. Add or Remove Weight on page 42

d. Take the Residual Measurement on page 42

.

.

.

.

.

.

.

.

.

26 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 27

Balancing Extension Module Chapter 2

TIP

IMPORTANT

TIP

Take the Initial Vibration Measurement

The initial vibration measurement is taken without any added weights on the

machine. The initial vibration measurement establishes a reference of how the

machine vibrates at each plane without any extra weight added. This vibration is

what will be corrected by the correction weight.

Skip step 1 if you are using the internal Laser

Tachometer as the trigger source.

1. If you are using an external tachometer, optical tachometer, or strobescope

as the trigger source, then connect the tachometer cable to the POWER/

USB/TRIGGER connector at the top of the data collector.

2. Attach a transducer to the machine to be balanced.

3. Mark the rotor by making a mark on one rotor that will serve as a reference

mark.

It is also possible to use an existing mark on the rotor as the reference mark,

such as a key or keyway.

If the rotor has multiple positions (vanes or fan blades), the

reference mark must be at one of the blade positions.

4. Start the machine and allow it to reach normal running speed.

5. Press Enter to take the initial vibration measurement.

Depending on your setup, the Dynamix 2500 data

collector may ask if the transducer is attached to

plane 1. If the transducer is attached, press F4 (OK).

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 27

Page 28

Chapter 2 Balancing Extension Module

IMPORTANT

TIP

Running Speed

Vibration Magnitude and Phase

Phase Angle and

Magnitude Diagram

The data collection begins as soon as the trigger conditions are satisfied.

The Dynamix 2500 data collector automatically measures the speed,

vibration, and plane. The values are continually updated on the screen.

Note the speed reading at the top of the display. For accurate balancing

results, it is important to maintain the same speed across all balancing

runs.

It is recommended that you save the initial run so that you do not have to

repeat it. Then you can update the saved file with subsequent runs.

6. When the speed, vibration, and phase values are stable, press Enter to

complete the initial vibration measurement.

The results are stored in the Vibration Summary Table.

7. Shut down the machine and continue the balancing procedure.

Anytime during the initial run, you can do the following:

• Press F4 (Esc) to exit the balancing module.

• Press the 0 (Shift) key and F1 (Go to) to simultaneously go back to

a previous step in the balance run.

See Move Around in a Balance Run on page 60

for details.

• Press F2 (Summary) to display the results in the Vibration

Summary Table.

28 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Add the Trial Weight

The Add Trial Weight screen appears when the initial run measurement is

complete.

You can manually enter the trial weight, the angle, and the radius, or you can have

the data collector automatically estimate the trial weight for you.

Page 29

Balancing Extension Module Chapter 2

Enter the Trial Weight Manually

Follow these instructions to manually enter the trial weight you are attaching to

the machine. A negative number can be entered if trial weight is removed, instead

of added. Trial weights are typically attached at 0° (the trigger reference). Unless

you wish the data collector to estimate a trial weight, the Radius entry is not

necessary, so long as you position the trial, correction, and trim weights at the

same radius.

1. On the machine, carefully attach the precise weight at the precise angle and

radius specified.

Balancing results depend greatly on the precision of your measurements

and actions.

2. Use the Up/Down arrows to select the parameters and the Right arrow to

enter trial weight, angle, or radius value by using the numeric key pad.

In the Mass parameter, enter the trial weight. Enter rotor mass supported

in this plane (in the Weight Units specified on the Balance Setup screen).

Use total rotor mass for single plane and 50% of mass for two plane.

3. In the Angle parameter, enter the location (in degrees) of the trial weight

on the rotor.

The trial weight’s Angle placement is typically zero. The angle is measured

from the reference mark in the direction specified in the Movement

parameter in the Balance Setup screen.

See Set Up the Balancing Parameters on page 20

for additional

information.

4. In the Radius parameter, enter the radius of the trial weight.

5. Press OK.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 29

Page 30

Chapter 2 Balancing Extension Module

Trial Weight

.1 rotor mass 9.81 900

radius [speed 2

--------------------------------------------------------------------

=

You are returned to the Add Trial Weight screen where the estimated trial

weight displays in both the Mass and Estimated Mass fields.

Estimate the Trial Weight

At times, you may want the data collector to calculate the trial weight for you.

The Trial Weight Estimate is based on the criteria that the trial run centrifugal

force does not exceed 10% of the bearing shaft load.

The Dynamix 2500 data collector calculates the trial weight (mass), the angle,

and the radius by using the following formula.

Follow these instructions to estimate the trial weight.

1. From the Add Trial Weight screen, enter the trial weight’s Angle placement

(typically zero) and Radius.

2. Press F3 (Estimate).

You are prompted to enter the rotor’s mass support in this plane.

3. Enter rotor mass supported in this plane (in the Weight Units specified on

the Balance Setup screen).

30 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Use total rotor mass for single plane and 50% of mass for two plane.

4. Press F2 (OK).

You are returned to the Add Trial Weight screen where the estimated trial

weight displays in both the Mass and Estimated Mass fields.

Page 31

Balancing Extension Module Chapter 2

TIP

TIP

5. When the speed, vibration, and phase values are stable, press Enter.

The trial weight measurement is complete and the results are stored in the

Vibration Summary Table.

A message appears asking if the trial weight is still attached:

• Press F2 (Yes) if the weight is still attached to the rotor.

• Press F3 (No) if the weight has been removed from the rotor.

It is good practice to remove the trial weight.

6. Shut down the machine.

Anytime during the initial run, you can do the following:

• Press F4 (Esc) to exit the balancing program.

• Press 0 (Shift) and F1 (Go to) simultaneously to go back to a

previous step in the balance run.

See Move Around in a Balance Run on page 60

• Press F2 (Summary) to display the results in the Vibration

Summary Table.

See Review Balancing Measurements on page 63

for details.

for details.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 31

Page 32

Chapter 2 Balancing Extension Module

Take a Trial Run Weight Measurement

The trial weight measurements are taken with a single trial weight attached to the

machine at one plane or the other. The trial weight measurements are used to

determine how the machine is affected by the added weight. The ideal trial

weight should produce either a 30 % change in amplitude or a 30 ° change in

phase.

Follow these instruction to take a trial weight measurement.

1. With the trial weight securely attached to the machine, start the machine

and bring it back up to the same speed used with the initial run.

2. Press Enter to start taking trial weight measuremnt.

The Trial Run 1 screen shows vibration magnitude and phase readings

with the trial weight attached. For accurate balancing efforts, these

readings should satisfy the 30/30 rule. From the reference run, the trial

weight causes a 30% change in magnitude, or a 30 degree change in phase,

or both. The Dynamix 2500 data collector automatically analyzes the data

to determine if the 30/30 rule is being met.

• The Trial Run magnitude is between 70% and 130% of the Initial Run

magnitude, and the Trial Run phase is within ±30 of the Initial Run phase,

the 30/30 rule is not being met, this warning appears:

32 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 33

Balancing Extension Module Chapter 2

• If the Trial Run magnitude is over 200% of the Initial Run magnitude, this

warning appears:

3. In either case, press F2 (Yes) to return to the Add Trial Weight – Plane 1

screen where you can adjust your settings or press F3 (No) to continue with

the current settings.

With the 30/30 rule satisfied, the data collector uses differences between

the reference run readings and trial run readings to compute the influence

coefficient, which it uses to compute the permanent correction weight

solution.

4. If you need to, correct any values.

5. From the Trial Weight Measurement screen, press Enter to proceed.

Before computing the correction weight solution, you are prompted to

indicate whether the trial weight is to remain attached or be removed.

Trial weights are normally temporary, and removed before one final

correction weight is attached. However, sometimes the trial weight must

be permanently attached for safety purposes, and is therefore left on the

machine.

6. Select No, as you typically plan to remove the temporary trial weight (or

select Yes if you plan to leave the trial weight attached).

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 33

Page 34

Chapter 2 Balancing Extension Module

The Correction Weight – Solution screen displays.

7. From the Correction Weight Solution screen, press Enter to begin the

correction run.

The Correction Weight – Solution screen displays fields at the top of the

screen, and the permanent correction weight mass, angle, and radius

balance solution for the field settings.

Parameter Description

Split Mass? Sometimes a weight cannot be placed at the angle specified by balancing

Weight Add/Subtract Specifies whether you are adding or subtracting the correction weight.

Radius Lets you to specify a new weight placement radius. Mass and Angle

Angle (1) / Angle (2) Applicable only if you split weights. Lets you to specify the placement angle

computations. The Split Mass? option automatically splits the specified

weight into two weights positioned at two placement angles around the

original angle.

Mass and Angle settings automatically adjust per your selection. Defaults

to Add.

settings automatically adjust for the new radius. If you split weights, a

radius setting is available for each weight.

for the two weights. Both angles must be specified for weight recalculation.

The data collector recalculates the weight for each position based on the

relative phase between the correction weight and the split weight locations.

8. Stop the machine, remove the temporary trial weight, and securely attach

the permanent correction weight at the precise angle and radius specified.

34 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 35

Balancing Extension Module Chapter 2

If the vibration magnitude is

greater than this threshold, the

magnitude bar is colored red

when taking a reading. The bar

turns green when the selected

level of imbalance is achieved.

Take a Correction Run

The Correction Run screen displays, showing the amount of residual unbalance

with the correction weight attached.

Verify whether the amount of residual unbalance is within specifications for the

machine. If the amount of residual imbalance is within specifications, you can end

the balance measurement, if not, you should proceed with a trim run.

1. Press Enter.

You are prompted whether you wish to perform7 a trim run.

The data collector automatically measures the speed, vibration, and phase.

The values are constantly updated on the screen.

2. If necessary, press Yes to proceed with a trim run.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 35

Page 36

Chapter 2 Balancing Extension Module

The Trim 1 Weight - Solution screen displays the trim weight data (or press

No to end the balance measurement).

3. If Necessary, attach a Trim Weight.

The Trim 1 Weight – Solution screen displays the trim weight mass, angle,

and radius to help balance the residual.

4. Stop the machine and securely attach the permanent trim weight at the

precise angle and radius specified.

36 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 37

Balancing Extension Module Chapter 2

Perform a Trim Run

You can repeat trim runs until you are satisfied that you have the finished the

balancing measurement.

Follow these instructions to perform a Trim Run.

1. With the trim weight securely attached, start the machine and press an

Enter button to perform the trim run.

The Trim Run 1 screen displays the amount of residual unbalance with the

trim weight attached.

2. Verify whether the amount of residual unbalance is within specifications

for the machine.

If the amount of residual unbalance is within specifications, you can end

the balance measurement, if not, you should proceed with another trim

run.

3. Press Enter to proceed.

When you press No to the Trim Residual? prompt, the Vibration Summary

screen automatically displays a summary of your measurement’s balancing data.

The Summary function button is available from all balancing screens.

4. Press F2 (Summary) to display your procedure’s Vibration Summary Table.

The Vibration Summary Table screen displays all magnitude and phase

values for each run performed during your balancing procedure.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 37

Page 38

Chapter 2 Balancing Extension Module

5. Press the F2 (Wts) to display the Weights Summary Table screen.

The Weights Summary screen appears.

The Weights Summary Table screen displays the mass, angle, and radius for your

trial, correction, and trim weights. If the correction or trim weights are split (in

the continuous case) or fixed positions are chosen, then the two sets of correction

weights display sequentially. An asterisk next to a trial weight indicates that the

weight has been removed.

Combine the Balance Run Weights

After your balancing runs, you may want to combine your correction and trim

weights into a single weight.

Follow these steps to access the combine weights screen.

1. From the Weights Summary Table, press F2 (Comb Wt.).

38 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 39

Balancing Extension Module Chapter 2

2. Select the weights you wish to combine and press F3 (Select, this function

also deselects) each weight.

A checkmark appears next to selected weights.

3. After selecting all the weights you wish to combine into one, press F2

(Accept) to compute your combined weight.

You are prompted whether you wish to remove all selected weights and

combine with one weight?

4. Press F2 (Yes) to proceed.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 39

Page 40

Chapter 2 Balancing Extension Module

You are prompted to enter the radius for the combined weight.

5. Enter the combined weight’s placement radius and press F2 (OK).

The Combine Weights screen re-displays, showing the new combined

weight’s mass, angle, and radius.

6. Press F4 (Esc) to return to previous screens.

7. Remove the weights specified for removal, and attach the final combined

weight at the precise angle and radius specified.

40 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 41

Balancing Extension Module Chapter 2

F3 (Memory) take you to

the Save Setup screen if

you want to save your

Solution.

Add the Correction Weight and Take a Residual Measurement

The residual measurements are taken with the correction weight or the correction

weight and trim weights attached to the machine. The correction weight should

cancel out the initial unbalance. A residual vibration measurement is taken to

measure the remaining unbalance. Trim weights are added to the machine to

cancel out the vibration measured during a residual measurement.

The Dynamix 2500 data collector calculates and displays a recommended

balancing weight in the Correction Weight - Solution screen.

You can split the correction weight into two distinct angles, as well as modify the

radius of the correction weight. Additionally, the Dynamix 2500 data collector

calculates the amount of weight that might be removed if weights are already

attached to the rotor.

When you need to save the Correction Weight solution, press F3 (Memory.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 41

Page 42

Chapter 2 Balancing Extension Module

Split the Correction Weight

On many rotors, such as a fan, it is not possible to correct the unbalance at the

angle indicated by a measurement run. The Dynamix 2500 data collector lets the

correction to be split into two components at points where it is possible to add or

remove weight.

Follow these instructions to split the correction weight.

1. Select Split Mass, then press the Right arrow key.

2. Select Yes to split the weight and press the Left arrow key to save your

choice.

The Dynamix 2500 data collector calculates the weight and displays the

new recommendation at the bottom of the screen.

3. To unsplit the correction weight, repeat steps 1 and 2 and select No.

Modify the Radius

Follow these instructions to modify the radius.

1. Select Radius, and press the Right arrow key.

2. Use the key pad to enter a new radius value and press the Enter key to save

your entry.

The data collector calculates the weight and displays the new

recommendation at the bottom the screen.

Add or Remove Weight

Follow these instructions to add or remove weight.

1. Select Weight and press the Right arrow.

2. Select Add or Subtract, and press the Left arrow key to save your choice.

The Dynamix 2500 data collector calculates the weight and displays the

new recommendation at the bottom the screen.

Take the Residual Measurement

Follow these instructions to take a residual measurement.

1. Attach the correction weight to the rotor.

2. Start the machine and let it reach operating speed.

3. Press Enter to take a residual measurement.

42 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 43

Balancing Extension Module Chapter 2

TIP

IMPORTANT

The data collector automatically measures the speed, vibration, and phase.

The values are constantly updated on the screen.

4. When the speed, vibration, and phase values are stable, press Enter.

The residual measurement is complete.

The green status indicator illuminates when the

measurement is complete.

• Amber is waiting for data acquisition

• Red ICP or overrange detection fault.

5. Do one of the following.

• Press F2 (Yes) to trim the residual. The data collector calculates the trim

correction weights and displays the following screen.

You can split the trim weight and modify the radius.

• Press F3 (No) if you do not want to trim the residual.

The Vibration Summary Table appears.

See Split the Correction Weight on page 42

for details.

6. Shut down the machine and attach the trim weight(s) whose weight, angle,

and radius are indicated on the screen.

Do not remove the original correction weight.

7. Start the machine and let it reach operating speed.

8. Press Enter.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 43

Page 44

Chapter 2 Balancing Extension Module

The data collector takes vibration readings, calculates new trim weight(s)

and displays the values.

• If the rotor is still out of balance, repeat adding the trim weight and

taking residual measurements until the rotor is properly balanced.

• If several trim correction runs have been performed (resulting in several

trim weights), values may be combined into one permanent trim

weight.

• If the balance never improves, check to see if you entered the correct

trial weight size and location, or check other factors such as

misalignment or a faulty bearing.

However, if the vibration has been reduced to an acceptable level,

balancing is complete.

9. Save your balancing data, if desired, by pressing F3 (Memory).

See Save a Balance Measurement on page 61

for details.

44 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 45

Balancing Extension Module Chapter 2

Two Plane Balancing

With two-plane balancing, the measurement sequence proceeds in the same

order as with single-plane balancing, except two trial weights and two trial runs

are required to calculate four influence coefficients (only one influence

coefficient exists for single-plane).

The balancing of a machine in two planes is divided into taking these three

measurements:

• Initial measurement

The initial vibration measurement is taken without any added weights on

the machine. The initial vibration measurement establishes a reference of

how the machine vibrates at each plane without any extra weight added.

This vibration is what is corrected by the correction weight.

• Trial weight measurement

The trial weight measurements are taken with a single trial weight attached

to the machine at one plane or the other. The trial weight measurements

are used to determine how the machine is affected by the added weight.

The ideal trial weight should produce either a 30 percent change in

amplitude or a 30 ° change in phase.

• Residual measurement

The residual measurements are taken with the correction weight or the

correction weight and trim weights attached to the machine. The

correction weight should cancel out the initial unbalance. A residual

vibration measurement is taken to measure the remaining unbalance. Trim

weights are added to the machine to cancel out the vibration measured

during a residual measurement.

See Balancing Measurements on page 16

for details about these measurements.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 45

Page 46

Chapter 2 Balancing Extension Module

Two Plane Balancing Procedure Overview

This is an overview of the steps you need to take when performing a two plane

balancing measurement.

1. How to Set Up a Two-Plane Procedure on page 46

2. Set-up Options Specific to Two-plane Balancing on page 47

3. How to Perform Two-plane Balancing on page 50

4. Perform the Initial Runs on page 50

5. Two-plane Balancing with One Transducer on page 51

6. Perform Trial Run 1 on Both Planes on page 53

7. Perform Trial Run 2 on Both Planes on page 54

8. Perform Correction Weight Runs on Both Planes on page 55

9. Perform Trim Runs on both Planes on page 58

.

.

.

.

.

.

.

.

.

How to Set Up a Two-Plane Procedure

Specific differences exist between single and two-plane balancing measurement

field settings. Setup options specific to two-plane procedures are detailed below.

See Single Plane Balancing on page 26

both single and two-plane balancing.

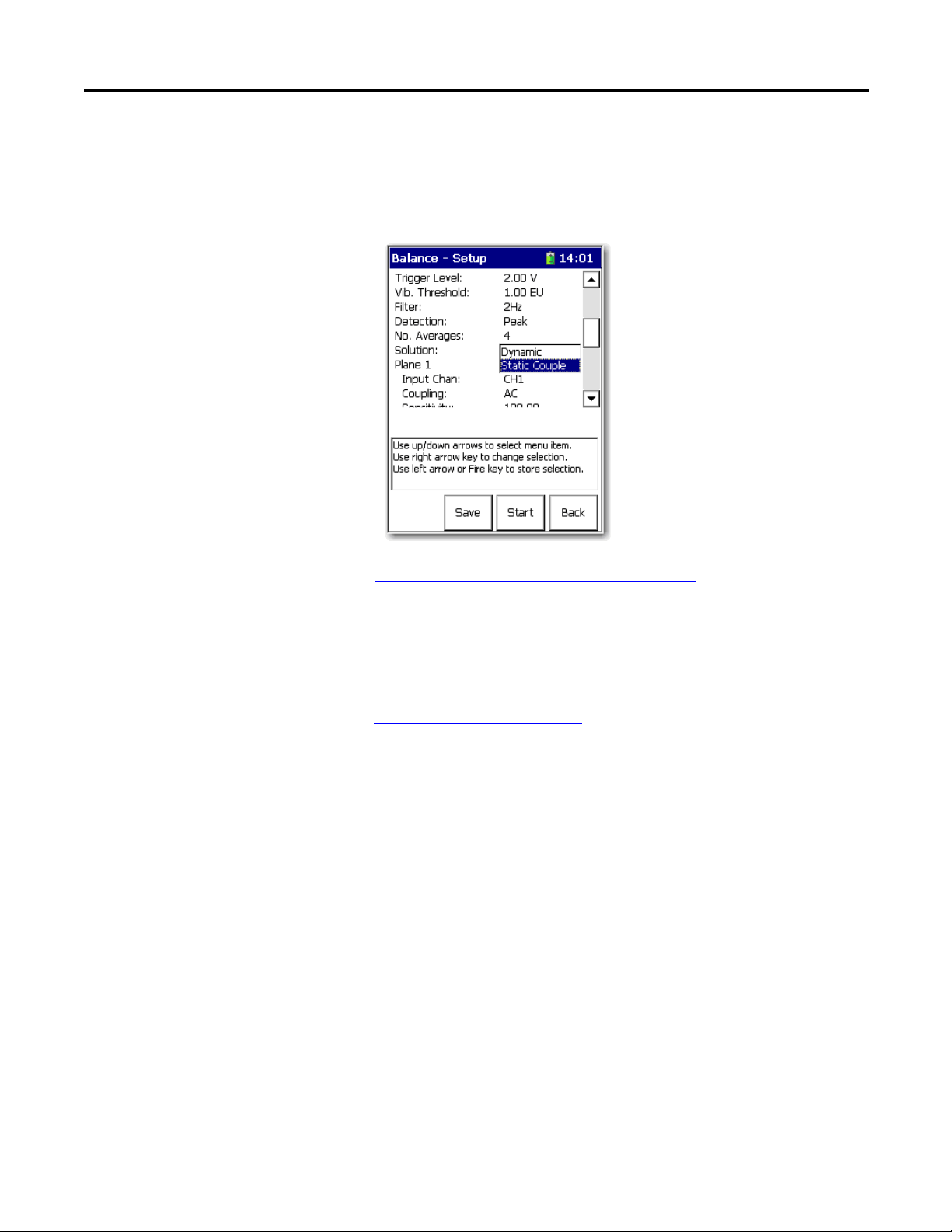

Figure 1 - Balance Setup Screen with 2 Planes Selected.

46 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

section for all other settings that apply to

Page 47

Balancing Extension Module Chapter 2

IMPORTANT

Specific differences exist between single and two-plane balancing measurement

field settings. Setup options specific to two-plane procedures are detailed below.

See Single Plane Balancing on page 26

section for all other settings that apply to

both single and two-plane balancing.

Set-up Options Specific to Two-plane Balancing

Adjust these settings on the Balance Setup screen for a two-plane procedure.

See Balance Extension Module Parameters on page 22

1. Enter 2 for Num. of Planes to specify a two-plane balancing procedure.

Other setup fields may adjust to display options specific to two-plane

balancing.

2. Select whether or not you are using one or two transducers in the Num.

Transducers field.

• Select one if you are moving a single transducer between channel 1 and

channel 2 to collect the measurements.

• Select 2 to affix a transducer to each plane (using Connector A and

Connector 2 on the data collector) and take both measurements

simultaneously.

If using only one transducer, you must also specify the same input

channels for both Plane 1 and Plane 2 sections.

For two transducer balancing, you must also specify X and Y input

channels for Plane 1 and Plane 2 sections.

for descriptions.

3. In the Solutions field, select whether or not you are using a Dynamic or

Static-Couple

• Select Dynamic to compute two correction weight solutions for a

two-plane balancing procedure.

• A Static-Couple option is available for situations where you wish to

compute three correction weights, one to correct the static unbalance,

and two to correct the couple unbalance (static-couple balancing).

See Static-couple Balancing on page 18

for more information about the

Static Couple parameter.

4. Select Plane 1/Plane 2 – When setting up two planes, the Balance - Setup

screen expands to include a section for Plane 2 settings.

• When two-plane balancing with one transducer, the Input Channel,

Coupling, Sensitivity, and Input Range are set on Plane 1 and apply to

both planes.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 47

Page 48

Chapter 2 Balancing Extension Module

5. Use the Input Channel, Coupling, Sensitivity, Input Range, Type, Number

of Positions, and Position 1 Offset fields to set up each balancing plane’s

transducer and weight placement settings for the following balancing

setups.

• One transducer/Two Identical Planes

When two-plane balancing with one transducer (where the balancing

planes are identical), set the Input Channel, Coupling, Sensitivity, and

Input Range on Plane 1. Set the Type, Number of Positions, and

Position 1 Offset fields in the Plane 1 and Plane 2 sections as

appropriate for the one transducer and the identical balancing planes.

• One transducer/Two Differing Planes

When two-plane balancing with one transducer (where balancing plane

weight pattern positions are different for each plane), set up the

transducer (Connector A) and balancing plane one’s weight pattern

settings in the Plane 1 section. Then configure balancing plane two’s

differing weight pattern settings in the Plane 2 section.

• Two tra nsducers

When two-plane balancing with two transducers (regardless of the type

of transducer used for each plane, or whether the two balancing planes

are identical), first set up the first transducer (connector A) and

balancing plane one’s weight pattern settings in the Plane 1 section.

Then set up the second transducer (connector B) and the second

balancing plane’s settings in the Plane 2 section.

Each plane’s weight position radius is specified during the balancing procedure, at

the Add Trial Weight screen.

Complete the following settings in both the Plane 1 and Plane 2 sections.

1. In the Input Channel field, select channel X or channel Y.

For two-plane balancing with one transducer, set the transducer as channel

X in the Plane 1 section. For two-plane balancing with two transducers, set

one plane’s transducer as channel X, the other plane’s transducer as channel

channel Y.

2. Select the type of coupling signal acquired for the transducers.

• AC acquires the input signal from a buffered output (external) device.

• ICP applies DC to the charge amplified transducers signal, and couples

the dynamic signal to the input channel.

48 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

Page 49

Balancing Extension Module Chapter 2

3. In the Sensitivity field, enter the transducers sensitivity in millivolts (mv)

per Engineering Unit (EU).

100 mV/EU is used for most acceleration transducers, 200 mV/EU for

most non-contact displacement transducers, and 1000 mV/EU if the input

is volts and the scales is to be read directly. The default setting is 100 mV/

EU.

4. In the Input Range field, select the signal input range.

The range is between Automatic and a fixed range in transducer units in a

1 - 2 - 5 sequence. The available fixed values vary depending on the

transducer type being used.

5. In the Type field, select the appropriate weight position type.

• Continuous specifies that weights may be placed at any placement

position on the balance plane.

• Fixed (Works with Number of Positions and Position 1 Offset fields.)

specifies that weights may be placed only at designated positions, for

example, rotors having a specific weight hole pattern, or with a specific

number of fan blades.

6. In the No. of posns field, enter the number of weight positions for the

respective plane, from 3…360.

Applies to Fixed weight position measurements only. The first position is

assumed to be at zero degrees, subsequent positions are evenly spaced.

7. In the Position 1 Offset field, enter the fixed position 1 offset for the

respective plane, from 0…360.

Applies to Fixed weight position measurements only.

8. Press F3 (Start) or Enter to begin the two-plane balancing procedure.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 49

Page 50

Chapter 2 Balancing Extension Module

IMPORTANT

How to Perform Two-plane Balancing

After setting up your balance measuring equipment, and setting the data

collector’s balancing measurement parameters, you are ready to perform the

two-plane balancing procedure.

Perform the Initial Runs

The two plane procedure is slightly different, depending on whether you are

using one transducer or two. When using one transducer, Plane 1 and Plane 2

runs are performed sequentially, allowing you to move the transducer between

the planes. When using two transducers, it is assumed the transducer positions

remain fixed and all Plane 1 and 2 runs occur simultaneously.

When you use two transducers with two plane balancing, the measurements are

displayed simultaneously.

Anytime during the initial run, you can do the following:

•Press F4 (Esc) to exit the balancing program.

•Press 0 (Shift) and F1 (Go to) simultaneously to go back to a

previous step in the balance run.

See Move Around in a Balance Run on page 60

•Press F2 (Summary) to display the results in the Vibration

Summary Table.

50 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

for details.

Page 51

Balancing Extension Module Chapter 2

Two-plane Balancing with One Transducer

Follow these steps to begin the two-plane balancing procedure with one

transducer.

1. Start the machine and bring it up to its steady running speed.

2. At the Balance Setup screen, press Enter to begin taking reference run data.

You are prompted to verify the transducer is attached to the bearing

nearest Plane.

3. Verify the transducer on Plane 1 and press OK.

The data collector initiates the initial run measurements for Plane 1. The

Initial Run – Plane 1 screen displays the measurement results.

If two transducers are used for the balancing, both planes appear

simultaneously. You may skip to the next section.

4. Press Enter to proceed.

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 51

Page 52

Chapter 2 Balancing Extension Module

You are prompted to verify the transducer is attached to the bearing

nearest Plane 2.

5. Verify the transducer and Plane 2 and press OK.

The data collector initiates the initial run measurements for Plane 2. The

Initial Run – Plane 2 screen displays the measurement results.

6. From the Initial Run – Plane 2 screen, press Enter.

7. Attach a Trial Weight to Plane 1.

The Add Trial Weight – Plane 1 screen appears.

8. Stop the machine.

9. On the data collector, enter the Mass, Angle and Radius for the trial weight

you are attaching to Plane 1.

• A negative number can be entered if trial weight is removed, instead of

added.

• Trial weights are typically attached at 0°.

• Unless you wish the data collector to estimate a trial weight, the Radius

entry is not necessary, so long as you position the trial, correction, and

trim weights at the same radius.

For more information, see Add the Trial Weight on page 28

52 Rockwell Automation Publication 1441-UM004A-EN-P - May 2011

.

Page 53

Balancing Extension Module Chapter 2

10. On the machine, carefully attach the precise weight at the precise angle and

radius specified.

Balancing results depend greatly on the precision of your measurements

and actions.

Perform Trial Run 1 on Both Planes

1. With the trial weight securely attached to the machine, start the machine

and bring it back up to the same speed used with the reference runs (initial

runs).

2. Press Enter.

You are prompted to verify the transducer is attached to the bearing closest

to Plane 1.

3. Verify your transducer is attached and press the Yes function button.

The Trial Run 1 – Plane 1 screen appears.

If two transducers are used for the balancing, both planes appear

simultaneously. The Trial Run 1 – Plane 1 screen shows vibration

magnitude and phase readings for Plane 1 with the trial weight on Plane 1.

For accurate balancing efforts, these readings should satisfy the 30/30 rule

(from the reference run, the trial weight causes a 30% change in

magnitude, or a 30 ° change in phase, or both).

4. From the Trial Run 1 – Plane 1 screen, press Enter to proceed.

You are prompted to verify the transducer is attached to the bearing

nearest Plane 2.

5. Verify the transducer and press OK.

The Trial Run 1 – Plane 2 screen appears.

The Trial Run 1 – Plane 2 screen shows vibration magnitude and phase

readings for Plane 2 with the trial weight on Plane 1.

6. Press Enter to proceed.

You are prompted if the trial weight is remaining attached to Plane 1.

Trial weights are normally temporary, and removed before one final

correction weight is attached. However, at times the trial weight must be

permanently attached for safety purposes, and is therefore left on the

machine.

Typically, select No, as you typically plan to remove the temporary trial

weight (or select Yes if you plan to leave the trial weight attached).

Rockwell Automation Publication 1441-UM004A-EN-P - May 2011 53

Page 54

Chapter 2 Balancing Extension Module

The Add Trial Weight – Plane 2 screen appears.

For more information, see Add the Trial Weight on page 28

.

7. Attach the Trial Weight to Plane 2.

8. Stop the machine.

9. On the data collector, enter the Mass, Angle and Radius for the trial weight

you are attaching to Plane 2 (typically the same weight used on Plane 1).

A negative number can be entered if trial weight is removed, instead of

added. Trial weights are typically attached at 0°.