Page 1

XM-121 Absolute Shaft Module

User Guide

Firmware Revision 5

1440-VLF02-01RA

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the

Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local Rockwell Automation sales

office or online at http://literature.rockwellautomation.com

wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all

persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in

this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

) describes some important differences between solid state equipment and hard-

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Allen-Bradley, Rockwell Automation, and XM are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Safety Approvals

WARNING

AVERTISSEMENT

IMPORTANT

The following information applies when operating

this equipment in hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable

for use in Class I Division 2 Groups A, B, C, D, Hazardous

Locations and nonhazardous locations only. Each product

is supplied with markings on the rating nameplate

indicating the hazardous location temperature code.

When combining products within a system, the most

adverse temperature code (lowest "T" number) may be

used to help determine the overall temperature code of

the system. Combinations of equipment in your system

arfe subject to investigation by the local Authority Having

Jurisdiction at the time of installation.

EXPLOSION HAZARD -

•Do not disconnect equipment unless power

has been removed or the area is known to be

nonhazardous.

•Do not disconnect connections to this

equipment unless power has been removed

or the area is known to be nonhazardous.

Secure any external connections that mate to

this equipment by using screws, sliding

latches, threaded connectors, or other means

provided with this product.

•Substitution of components may impair

suitability for Class I, Division 2.

•If this product contains batteries, they must

only be changed in an area known to be

nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne

conviennent qu'à une utilisation en environnements de

Classe I Division 2 Groupes A, B, C, D dangereux et non

dangereux. Chaque produit est livré avec des marquages

sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque

plusieurs produits sont combinés dans un système, le

code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour

déterminer le code de température global du système. Les

combinaisons d'équipements dans le système sont

sujettes à inspection par les autorités locales qualifiées

au moment de l'installation.

RISQUE D’EXPLOSION –

•Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher l'équipement.

•Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer

tous les connecteurs externes reliés à cet

équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres

moyens fournis avec ce produit.

•La substitution de composants peut rendre

cet équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

•S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

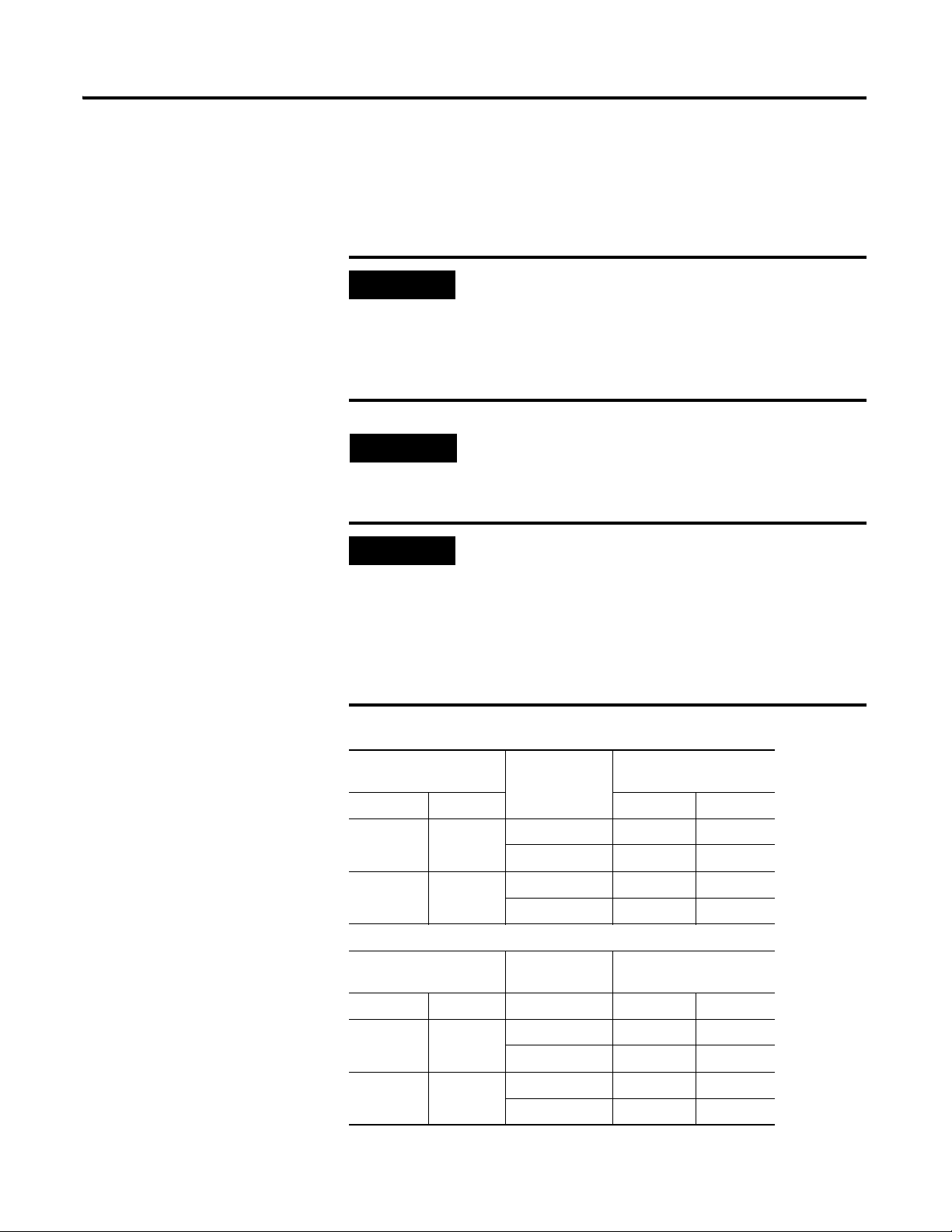

Wiring to or from this device, which enters or leaves the system enclosure, must

utilize wiring methods suitable for Class I, Division 2 Hazardous Locations, as

appropriate for the installation in accordance with the product drawings as

indicated in the following table.

Model Catalog Number Haz Location Drawings* Model Catalog Number Haz Location Drawings*

w/o

Barriers

XM-120 1440-VST0201RA

XM-121 1440-VLF0201RA XM-360 1440-TPR0600RE

XM-122 1440-VSE0201RA XM-361 1440-TUN0600RE

XM-123 1440-VAD0201RA XM-361 1440-TTC0600RE

XM-160 1440-VDRS0600RH

XM-161 1440-VDRS0606RH XM-441 1440-REX0004RD 48241-HAZ N/A

XM-162 1440-VDRP0600RH XM-442 1440-REX0304RG 48642-HAZ N/A

XM-220 1440-SPD0201RB 48640-HAZ 48641-HAZ

48178-HAZ 48179-HAZ

51263-HAZ 51264-HAZ

* Drawings are available on the included CD

w/

Barriers

w/o

Barriers

XM-320 1440-TPS0201RB 48238-HAZ 48239-HAZ

48295-HAZ 48299-HAZ

XM-440 1440-RMA0004RC 48240-HAZ N/A

w/

Barriers

Page 4

Page 5

Introduction

Installing the Absolute Shaft

Module

Table of Contents

Chapter 1

Introducing the Absolute Shaft Module . . . . . . . . . . . . . . . . . . . . . . . . . 1

Absolute Shaft Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2

XM Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting the Terminal Base Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DIN Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Interconnecting Terminal Base Units . . . . . . . . . . . . . . . . . . . . . . . 15

Panel/Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting Wiring for Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Terminal Block Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting the Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting the Tachometer Signal. . . . . . . . . . . . . . . . . . . . . . . . . 24

Connecting the Buffered Outputs . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting the Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting the Remote Relay Reset Signal . . . . . . . . . . . . . . . . . . 31

Connecting the Setpoint Multiplication Switch . . . . . . . . . . . . . . . 32

Connecting the 4-20 mA Outputs . . . . . . . . . . . . . . . . . . . . . . . . . 33

Serial Port Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DeviceNet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mounting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Module Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Powering Up the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Manually Resetting Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing the XM-121 Absolute Shaft Firmware . . . . . . . . . . . . . . . . . 42

Chapter 3

Configuration Parameters

v Publication GMSI10-UM014D-EN-P - May 2010

Channel Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Signal Processing Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Overall Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Waveform Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . 50

Vector Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Speed Measurement Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Tachometer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Tachometer Transducer Parameters . . . . . . . . . . . . . . . . . . . . . . . . 53

Tachometer Signal Processing Parameters . . . . . . . . . . . . . . . . . . . 54

Page 6

Table of Contents vi

Specifications

DeviceNet Information

Alarm Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Relay Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-20 mA Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Triggered Trend Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

SU/CD Trend Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

I/O Data Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Data Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Monitor Data Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Alarm and Relay Status Parameters . . . . . . . . . . . . . . . . . . . . . . . . 71

Device Mode Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Appendix B

Electronic Data Sheets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Changing Operation Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Transition to Program Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Transition to Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

XM Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Invalid Configuration Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Absolute Shaft I/O Message Formats . . . . . . . . . . . . . . . . . . . . . . . . . 85

Poll Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

COS Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Bit-Strobe Message Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

ADR for XM Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

DeviceNet Objects

Publication GMSI10-UM014D-EN-P - May 2010

Appendix C

Identity Object (Class ID 01H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

DeviceNet Object (Class ID 03H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Assembly Object (Class ID 04H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Class Attribute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Assembly Instance Attribute Data Format. . . . . . . . . . . . . . . . . . . 97

Page 7

Table of Contents vii

Connection Object (Class ID 05H). . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Instances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Discrete Input Point Object (Class ID 08H) . . . . . . . . . . . . . . . . . . . 101

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Parameter Object (Class ID 0FH). . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Acknowledge Handler Object (Class ID 2BH) . . . . . . . . . . . . . . . . . 107

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Alarm Object (Class ID 31DH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Channel Object (Class ID 31FH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Auto_Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Device Mode Object (Class ID 320H) . . . . . . . . . . . . . . . . . . . . . . . . 115

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Overall Measurement Object (Class ID 322H) . . . . . . . . . . . . . . . . . 116

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Relay Object (Class ID 323H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Publication GMSI10-UM014D-EN-P - May 2010

Page 8

Table of Contents viii

Spectrum Waveform Measurement Object (Class ID 324H) . . . . . . 121

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Get_Stored_Waveform_Chunk . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Get_Waveform_Chunk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Speed Measurement Object (Class ID 325H). . . . . . . . . . . . . . . . . . . 125

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Tachometer Channel Object (Class ID 326H) . . . . . . . . . . . . . . . . . . 127

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Transducer Object (Class ID 328H) . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Vector Measurement Object (Class ID 329H) . . . . . . . . . . . . . . . . . . 130

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4-20 mA Output Object (Class ID 32AH) . . . . . . . . . . . . . . . . . . . . . 132

Class Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Instances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Instance Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Guidelines for Setting the Full

Scale Value

Glossary

Index

Publication GMSI10-UM014D-EN-P - May 2010

Appendix D

XM-121 Absolute Shaft Full Scale Tables . . . . . . . . . . . . . . . . . . . . . 136

Example on Using Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Page 9

Chapter

IMPORTANT

1

Introduction

This chapter provides an overview of the XM-121 Absolute Shaft module. It

also discusses the components of the module.

For information about See page

Introducing the Absolute Shaft Module 1

Absolute Shaft Module Components 2

Using this Manual 3

This manual only describes how to install and use the

XM-121 Absolute Shaft module. For information about the

low frequency dynamic measurement module, refer to the

XM-120/121 Dynamic Measurement Module User Guide.

Introducing the Absolute Shaft Module

The XM-121 Absolute Shaft module is an XM-121 Low Frequency Dynamic

module with alternative, XM-121A, firmware loaded onto it. The XM-121 is

part of the Allen-Bradley™ XM

condition monitoring and protection modules that operate both in stand-alone

applications or integrate with Programmable Logic Controllers (PLCs) and

control system networks.

Shaft Absolute is the measure of the shaft’s motion relative to free space – its

absolute motion. In the Absolute Shaft module, the Shaft Absolute

measurement is calculated by summing signals of both an eddy current probe,

measuring the motion of the shaft relative to the case, and an Allen-Bradley

9000 series sensor (accelerometer or velocity) measuring the absolute motion

of the case.

In addition to vibration inputs, the Absolute Shaft module accepts one

tachometer input to provide speed measurement and order analysis functions.

It also includes a single on-board relay (expandable to five with an XM-441

module), two 4-20 mA outputs, and a buffered output for each input. The

module can collect data under steady-state and startup/coast-down conditions,

and monitor up to nine alarms making it a complete monitoring system.

®

Series, a family of DIN rail mounted

1 Publication GMSI10-UM014D-EN-P - May 2010

Page 10

2 Introduction

L

F

D

Y

N

A

M

I

C

M

E

A

S

U

R

E

M

E

N

T

1

4

4

0

V

L

F

0

2

0

1

R

A

XM-940 Dynamic Measurement Module Terminal Base Unit

Cat. No. 1440-TB-A

XM-121 Low Frequency Dynamic

Measurement Module

Cat. No. 1440-VLF02-01RA

IMPORTANT

It can operate stand-alone, or it can be deployed on a standard or dedicated

DeviceNet network where it can provide real-time data and status information

to other XM modules, PLCs, distributed control systems (DCS), and

Condition Monitoring Systems.

The Absolute Shaft module can be configured remotely via the DeviceNet

network, or locally using a serial connection to a PC or laptop. Refer to

Chapter 3 for a list of the configuration parameters.

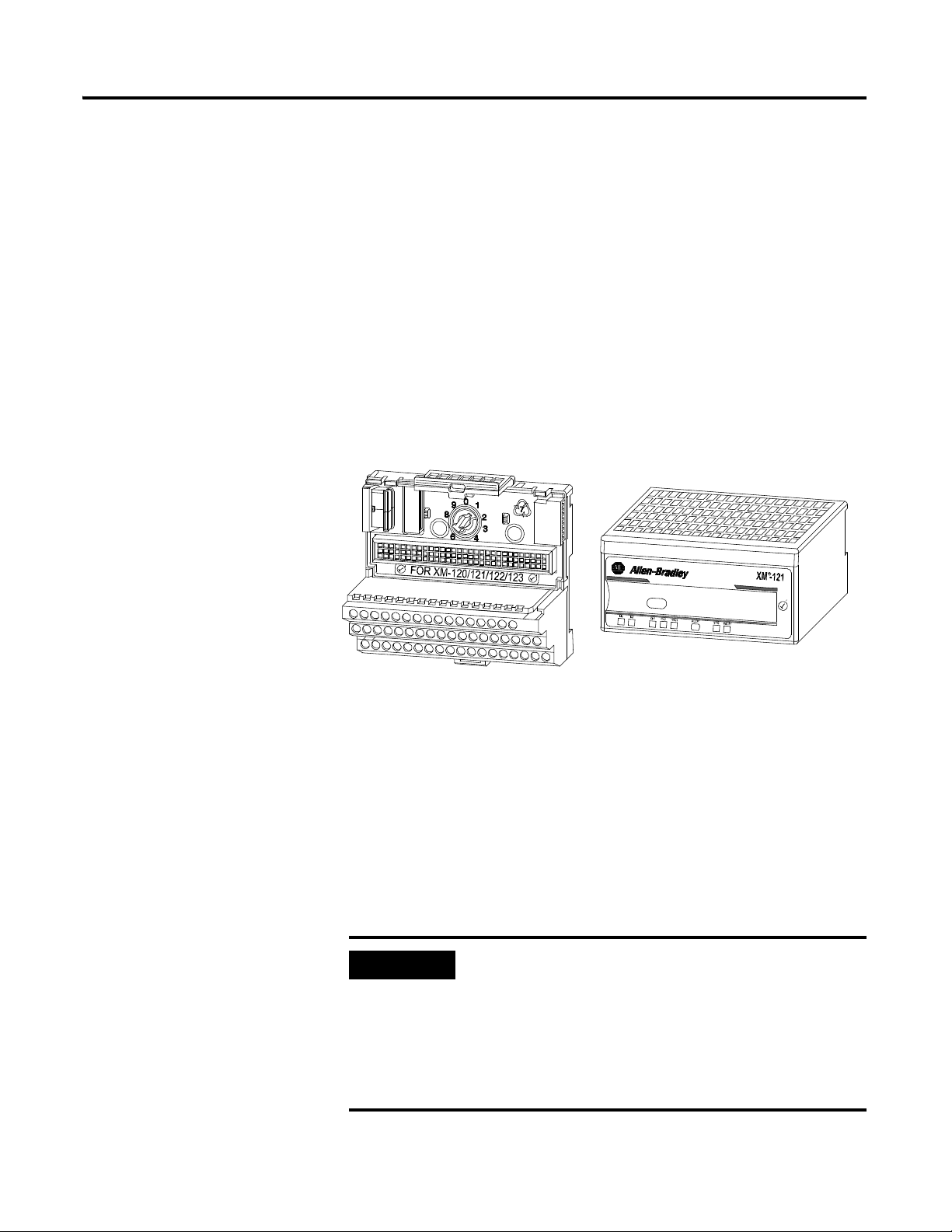

Absolute Shaft Module Components

The Absolute Shaft module consists of a terminal base unit and an instrument

module. The XM-121 Low Frequency Dynamic Measurement Module and the

XM-940 Terminal Base are shown below.

Figure 1.1 Absolute Shaft Module Components

• XM-940 Dynamic Measurement Module Terminal Base - A DIN rail

mounted base unit that provides terminations for all field wiring

required by XM Dynamic Measurement and Absolute Shaft modules.

Publication GMSI10-UM014D-EN-P - May 2010

• XM-121 Low Frequency Dynamic Measurement Module - The XM-121

mounts on the XM-940 terminal base via a keyswitch and a 96-pin

connector. The XM-121 contains the measurement electronics,

processors, relay, and serial interface port for local configuration.

The XM-441 Expansion Relay module may be connected

to the XM-121 module via the XM-940 terminal base.

When connected to the module, the Expansion Relay

module simply “expands” the capability of the XM-121 by

adding four additional epoxy-sealed relays. The module

controls the Expansion Relay module by extending to it the

same logic and functional controls as the on-board relay.

Page 11

Introduction 3

Using this Manual

This manual introduces you to the XM-121 Absolute Shaft module. It is

intended for anyone who installs, configures, or uses the XM-121 Absolute

Shaft module.

Organization

To help you navigate through this manual, it is organized in chapters based on

these tasks and topics.

Chapter 1 "Introduction" contains an overview of this manual and the

XM-121 module.

Chapter 2 "Installing the XM-121 Absolute Shaft Module" describes how to

install, wire, and use the Absolute Shaft module. It also provides instructions

on how to install the Absolute Shaft firmware.

Chapter 3 "Configuration Parameters" provides a complete listing and

description of the Absolute Shaft parameters. The parameters can be viewed

and edited using the XM Serial Configuration Utility software and a personal

computer.

Appendix A "Specifications" lists the technical specifications for the Absolute

Shaft module.

Appendix B "DeviceNet Information" provides information to help you

configure the module over a DeviceNet network.

Appendix C "DeviceNet Objects" provides information on the DeviceNet

objects supported by the XM-121 Absolute Shaft module.

Appendix D "Guidelines for Setting the Full Scale Value" provides guidelines

for determining the optimal Full Scale value in the XM-121 Absolute Shaft

module.

For definitions of terms used in this Guide, see the Glossary at the end of the

Guide.

Document Conventions

There are several document conventions used in this manual, including the

following:

Publication GMSI10-UM014D-EN-P - May 2010

Page 12

4 Introduction

TIP

EXAMPLE

The XM-121 Absolute Shaft module is referred to as XM-121, Absolute Shaft

module, device, or module throughout this manual.

A tip indicates additional information which may be

helpful.

This convention presents an example.

Publication GMSI10-UM014D-EN-P - May 2010

Page 13

Chapter

ATTENTION

2

Installing the Absolute Shaft Module

This chapter discusses how to install and wire the XM-121 Absolute Shaft

module. It also describes the module indicators and the basic operations of the

module, and provides instructions to install the Absolute Shaft firmware.

For information about See page

XM Installation Requirements 6

Mounting the Terminal Base Unit 13

Connecting Wiring for Your Module 17

Mounting the Module 37

Module Indicators 38

Basic Operations 41

Installing the XM-121 Absolute Shaft Firmware 42

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

Industrial environment, in overvoltage Category II applications

(as defined in IED publication 60664–1), at altitudes up to 2000

meters without derating.

This equipment is supplied as “open type” equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present, and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC publication

60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosures.

5 Publication GMSI10-UM014D-EN-P - May 2010

Page 14

6 Installing the Absolute Shaft Module

ATTENTION

ATTENTION

XM Installation Requirements

This section describes wire, power, and grounding requirements for an XM

system.

Wiring Requirements

Use solid or stranded wire. All wiring should meet the following specifications:

• 14 to 22 AWG copper conductors without pretreatment; 8 AWG

required for grounding the DIN rail for electromagnetic interference

(emi) purposes

• Recommended strip length 8 millimeters (0.31 inches)

• Minimum insulation rating of 300 V

• Soldering the conductor is forbidden

• Wire ferrules can be used with stranded conductors; copper ferrules

recommended

See the XM Documentation and Configuration Utility CD

for Hazardous Locations installation drawings. The XM

Documentation and Configuration Utility CD is packaged

with the XM modules.

Power Requirements

Before installing your module, calculate the power requirements of all modules

interconnected via their side connectors. The total current draw through the

side connector cannot exceed 3 A. Refer to the specifications for the specific

modules for power requirements.

A separate power connection is necessary if the total

current draw of the interconnecting modules is greater than

3 A.

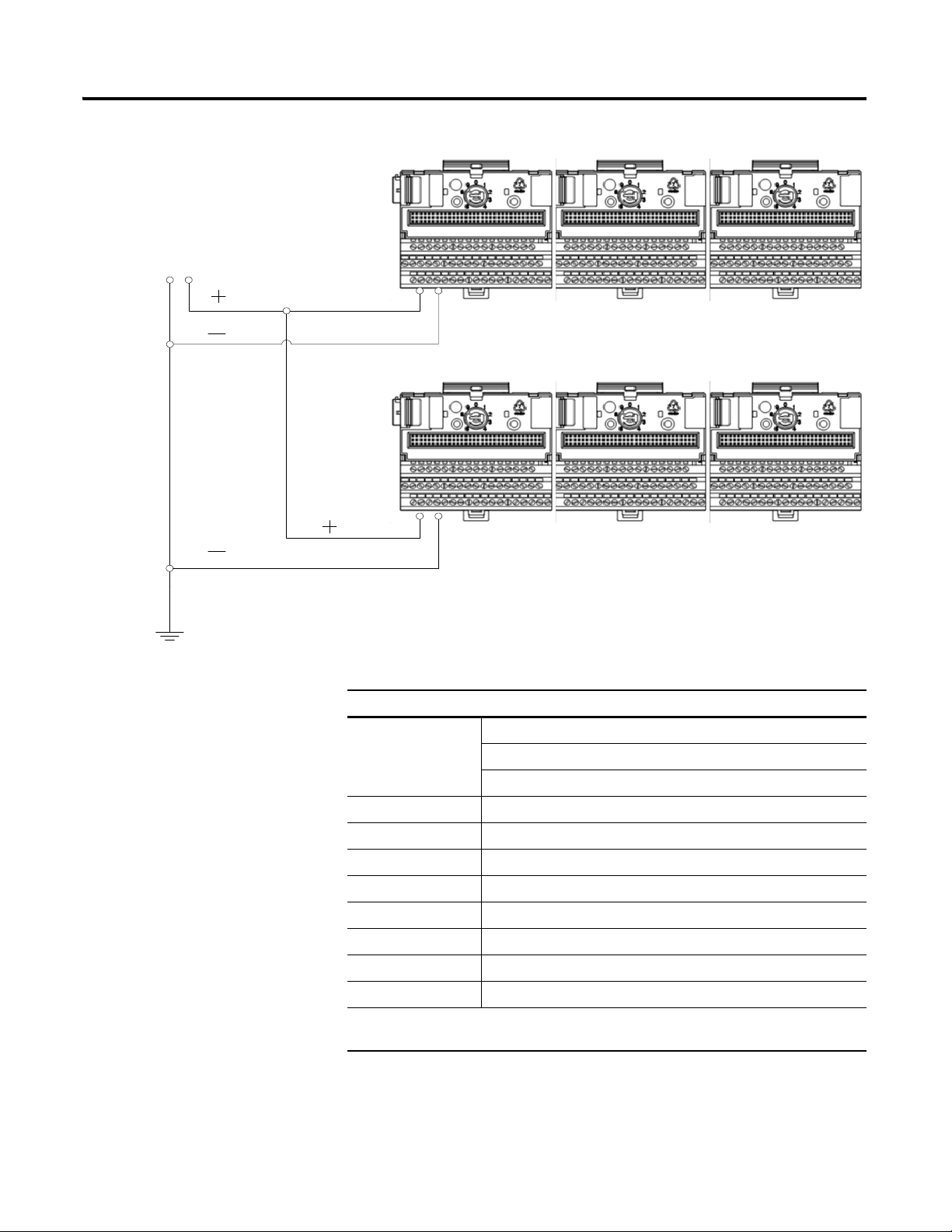

Figure 2.1 is an illustration of wiring modules using separate power

connections.

Publication GMSI10-UM014D-EN-P - May 2010

Page 15

Installing the Absolute Shaft Module 7

Any limited power

source that satisfies

the requirements

specified below

Figure 2.1 XM Modules with Separate Power Connections

Power Supply Requirements

XM Power Supply Requirements

Listed Class 2 rated supply, or

Protection

Fused* ITE Listed SELV supply, or

Fused* ITE Listed PELV supply

Output Voltage 24 Vdc ± 10%

Output Power 100 Watts Maximum (~4A @ 24 Vdc)

Static Regulation ± 2%

Dynamic Regulation ± 3%

Ripple < 100mVpp

Output Noise Per EN50081-1

Overshoot < 3% at turn-on, < 2% at turn-off

Hold-up Time As required (typically 50mS at full rated load)

* When a fused supply is used the fuse must be a 5 amp, listed, fast acting fuse such as

provided by Allen-Bradley part number 1440-5AFUSEKIT

Publication GMSI10-UM014D-EN-P - May 2010

Page 16

8 Installing the Absolute Shaft Module

IMPORTANT

See Application Technique "XM Power Supply Solutions",

publication ICM-AP005A-EN-E, for guidance in

architecting power supplies for XM systems.

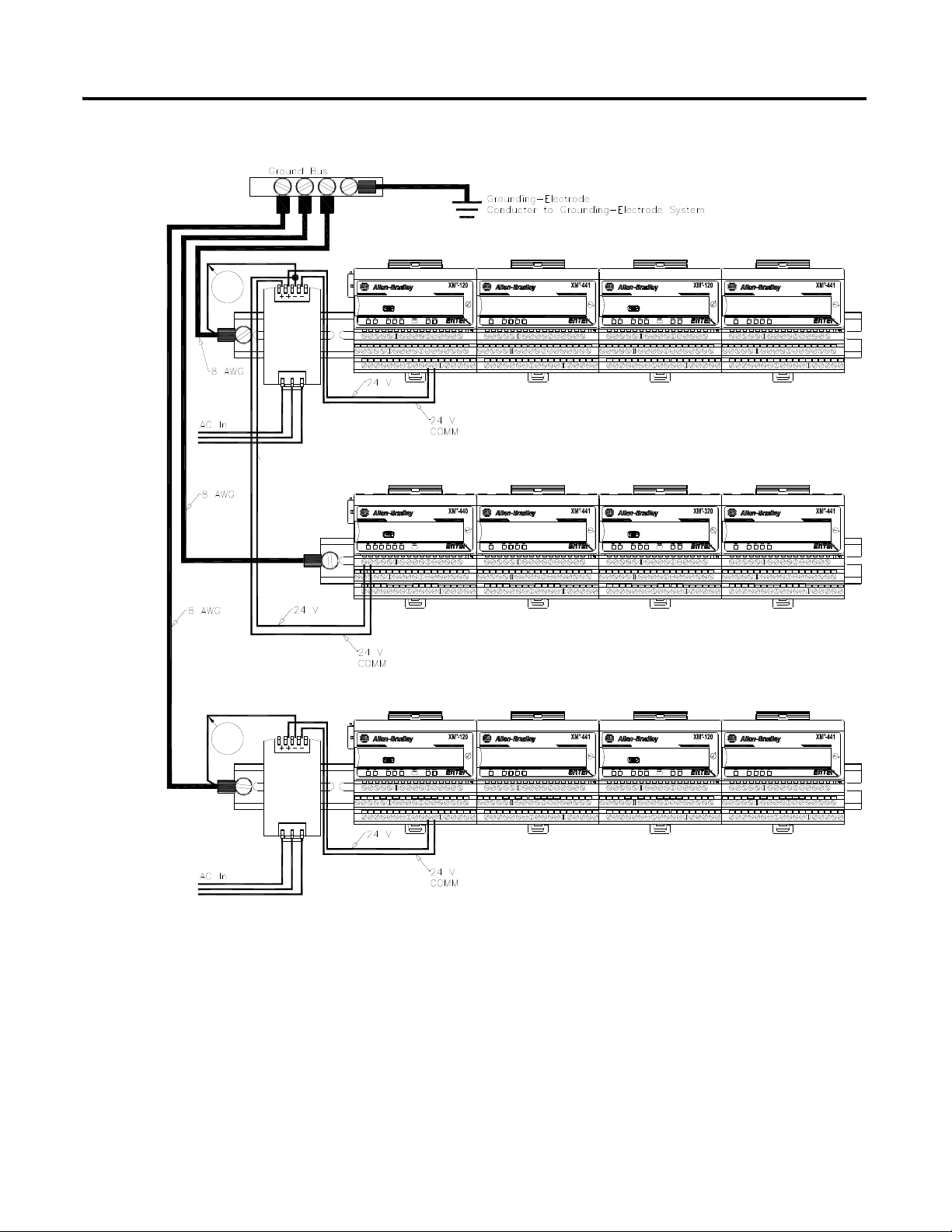

Grounding Requirements

Use these grounding requirements to ensure safe electrical operating

circumstances, and to help avoid potential emi and ground noise that can cause

unfavorable operating conditions for your XM system.

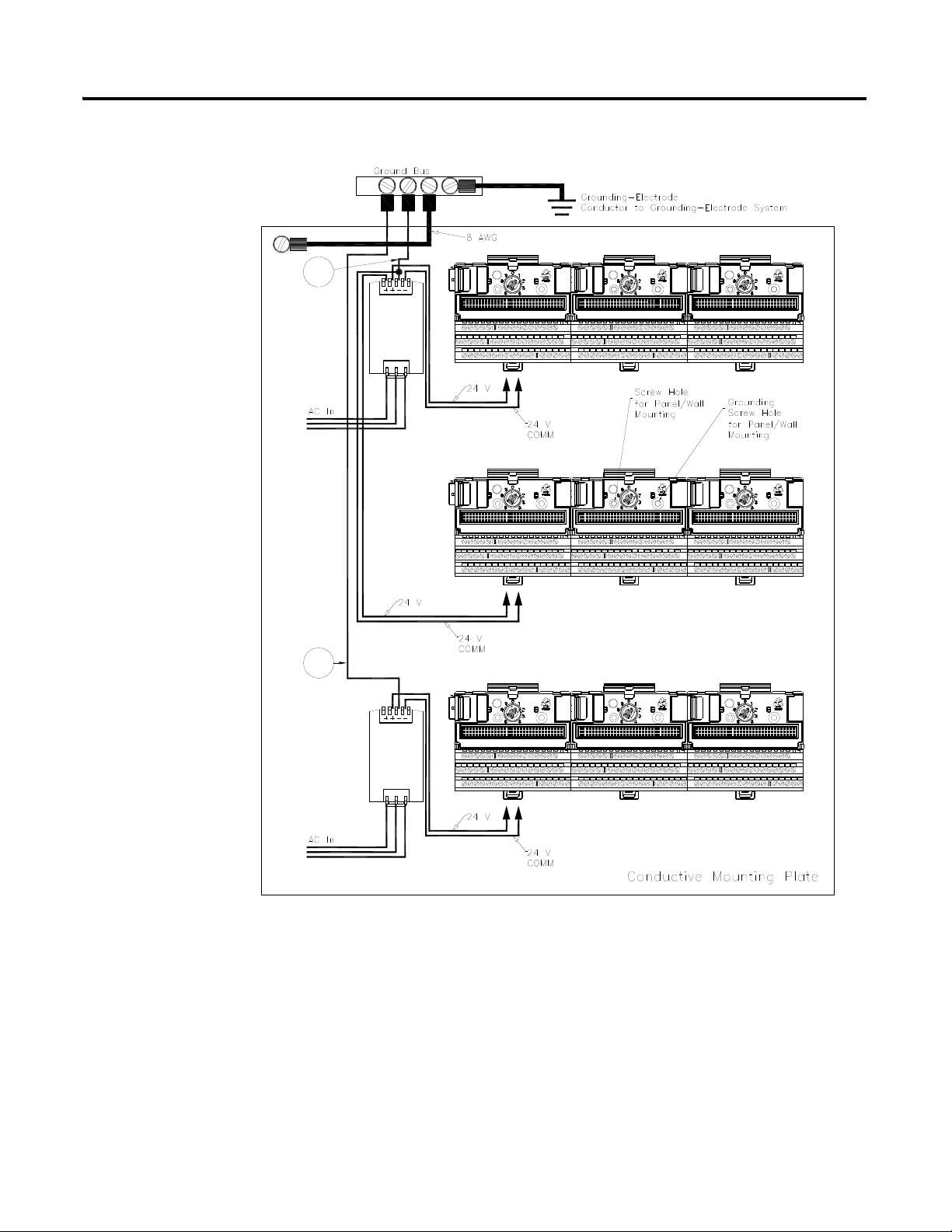

DIN Rail Grounding

The XM modules make a chassis ground connection through the DIN rail.

The DIN rail must be connected to a ground bus or grounding electrode

conductor using 8 AWG or 1 inch copper braid. See Figure 2.2.

Use zinc-plated, yellow-chromated steel DIN rail (Allen-Bradley part no.

199-DR1 or 199-DR4) or equivalent to assure proper grounding. Using other

DIN rail materials (e.g. aluminum, plastic, etc.), which can corrode, oxidize, or

are poor conductors can result in improper or intermittent platform

grounding.

Publication GMSI10-UM014D-EN-P - May 2010

Page 17

Figure 2.2 XM System DIN Rail Grounding

Power

Supply

DYNAMIC MEASUREMENT

1440-VST02-01RA

DYNAMIC MEASUREMENT

1440-VST02-01RA

POSITION

1440-TSP02-01RB

MASTER RELAY

1440-RMA00-04RC

EXPANSION RELAY

1440-REX00-04RD

EXPANSION RELAY

1440-REX00-04RD

EXPANSION RELAY

1440-REX00-04RD

EXPANSION RELAY

1440-REX00-04RD

Power

Supply

DYNAMIC MEASUREMENT

1440-VST02-01RA

DYNAMIC MEASUREMENT

1440-VST02-01RA

EXPANSION RELAY

1440-REX00-04RD

EXPANSION RELAY

1440-REX00-04RD

1

1

Installing the Absolute Shaft Module 9

1 Use 14 AWG wire.

The grounding wire can be connected to the DIN rail using a DIN Rail

Grounding Block (Figure 2.3).

Publication GMSI10-UM014D-EN-P - May 2010

Page 18

10 Installing the Absolute Shaft Module

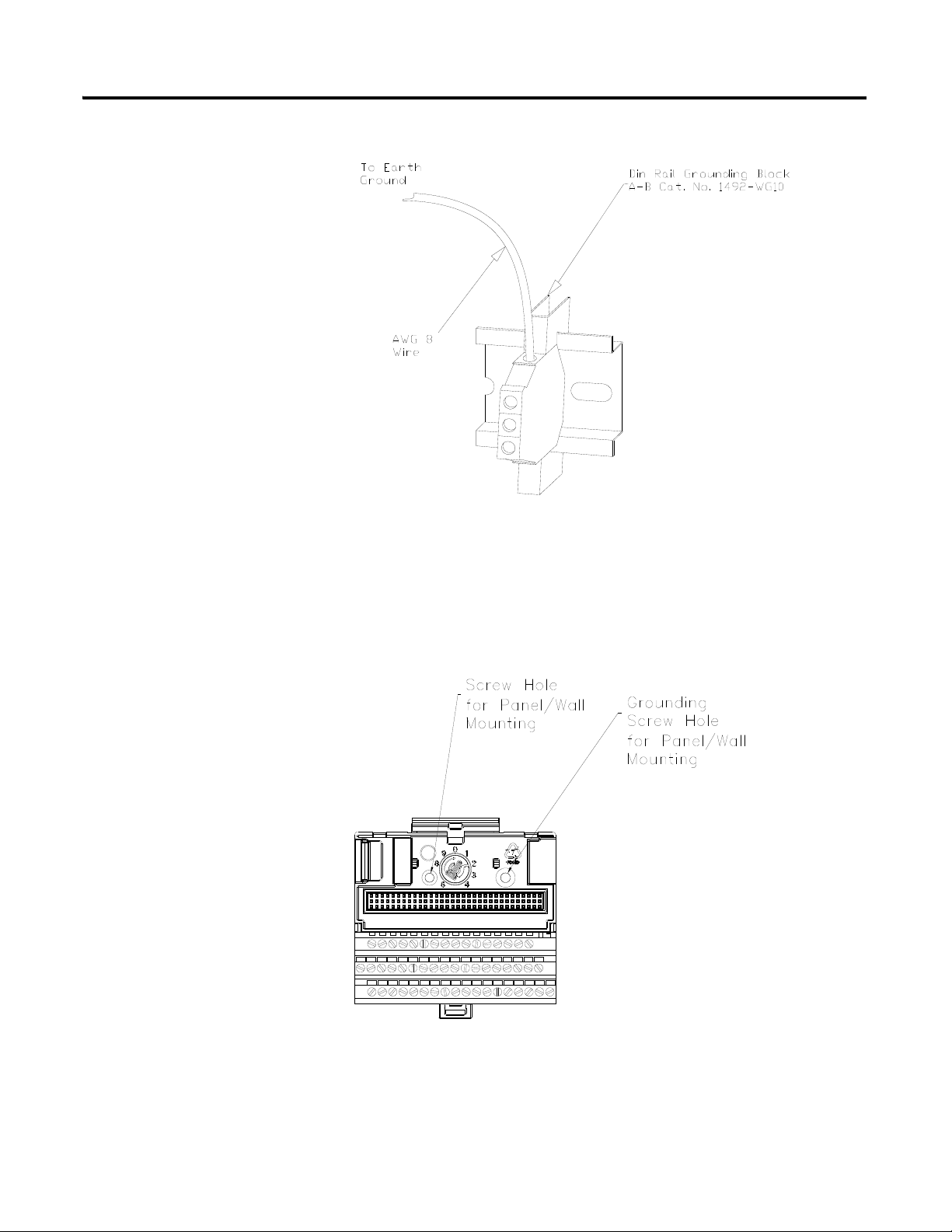

Figure 2.3 DIN Rail Grounding Block

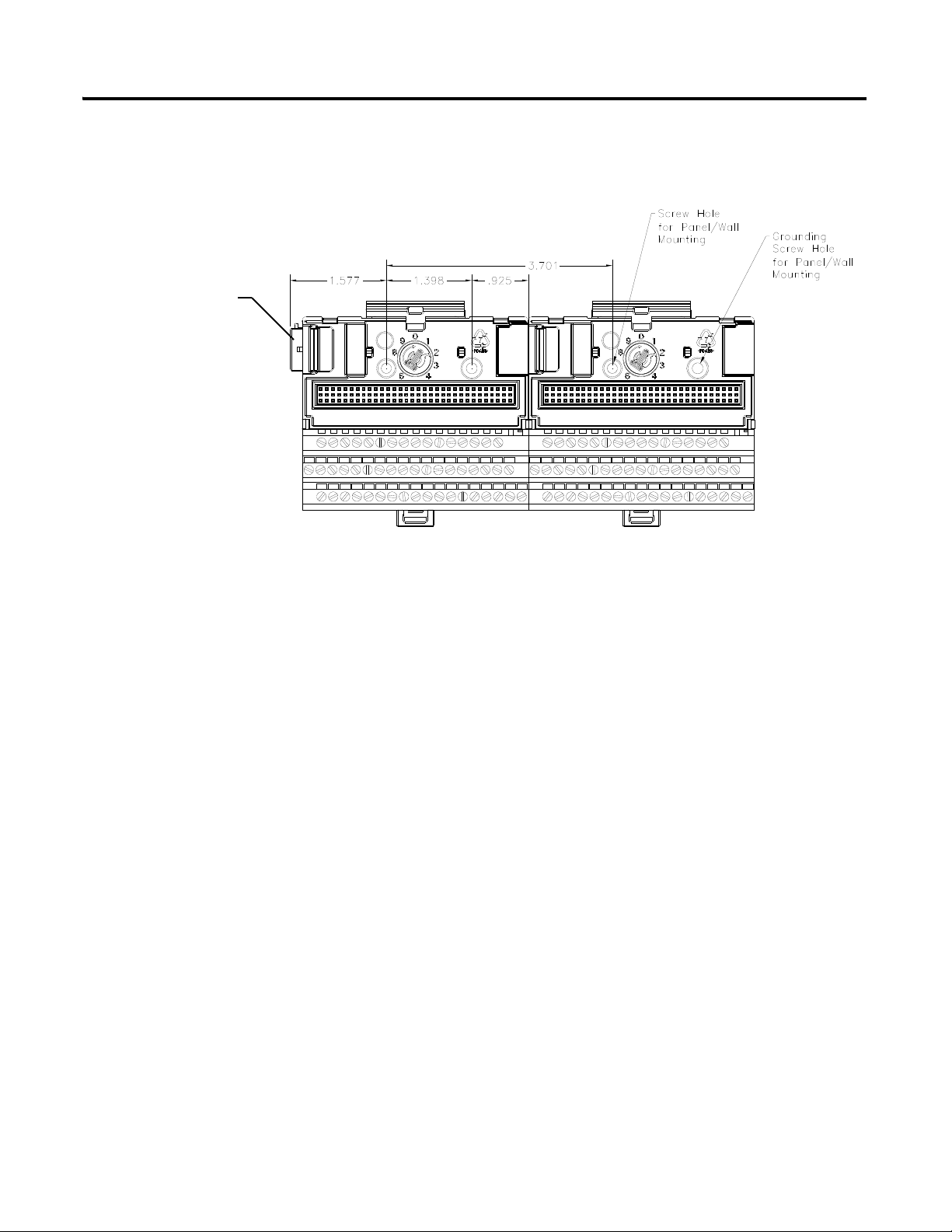

Panel/Wall Mount Grounding

The XM modules can also be mounted to a conductive mounting plate that is

grounded. See Figure 2.5. Use the grounding screw hole provided on the

terminal base to connect the mounting plate the Chassis terminals.

Figure 2.4 Grounding Screw on XM Terminal Base

Publication GMSI10-UM014D-EN-P - May 2010

Page 19

Figure 2.5 Panel/Wall Mount Grounding

Power

Supply

Power

Supply

1

1

Installing the Absolute Shaft Module 11

1 Use 14 AWG wire.

Publication GMSI10-UM014D-EN-P - May 2010

Page 20

12 Installing the Absolute Shaft Module

IMPORTANT

IMPORTANT

24 V Common Grounding

24 V power to the XM modules must be grounded. When two or more power

supplies power the XM system, ground the 24 V Commons at a single point,

such as the ground bus bar.

If it is not possible or practical to ground the -24Vdc

supply, then it is possible for the system to be installed and

operate ungrounded. However, if installed ungrounded

then the system must not be connected to a ground

through any other circuit unless that circuit is isolated

externally. Connecting a floating system to a non-isolated

ground could result in damage to the XM module(s)

and/or any connected device. Also, operating the system

without a ground may result in the system not performing

to the published specifications regards measurement

accuracy and communications speed, distance or reliability.

The 24 V Common and Signal Common terminals are

internally connected. They are isolated from the Chassis

terminals unless they are connected to ground as described

in this section. See Terminal Block Assignments on page 18

for more information.

Transducer Grounding

Make certain the transducers are electrically isolated from earth ground. Cable

shields must be grounded at one end of the cable, and the other end left

floating or not connected. It is recommended that where possible, the cable

shield be grounded at the XM terminal base (Chassis terminal) and not at the

transducer.

DeviceNet Grounding

The DeviceNet network is functionally isolated and must be referenced to

earth ground at a single point. XM modules do not require an external

DeviceNet power supply. Connect DeviceNet V- to earth ground at one of the

XM modules, as shown in Figure 2.6.

Publication GMSI10-UM014D-EN-P - May 2010

Page 21

Installing the Absolute Shaft Module 13

To

Ground

Bus

ATTENTION

Figure 2.6 Grounded DeviceNet V- at XM Module

Use of a separate DeviceNet power supply is not

permitted. See Application Technique "XM Power Supply

Solutions", publication ICM-AP005A-EN-E, for guidance

in using XM with other DeviceNet products.

Mounting the Terminal Base Unit

For more information on the DeviceNet installation, refer to the ODVA

Planning and Installation Manual - DeviceNet Cable System, which is available

on the ODVA web site (http://www.odva.org).

Switch Input Grounding

The Switch Input circuits are functionally isolated from other circuits. It is

recommended that the Switch RTN signal be grounded at a single point.

Connect the Switch RTN signal to the XM terminal base (Chassis terminal) or

directly to the DIN rail, or ground the signal at the switch or other equipment

that is wired to the switch.

The XM family includes several different terminal base units to serve all of the

XM modules. The XM-940 terminal base, Cat. No. 1440-TB-A, is the only

terminal base unit used with the Absolute Shaft module.

Publication GMSI10-UM014D-EN-P - May 2010

Page 22

14 Installing the Absolute Shaft Module

ATTENTION

Position terminal base at a slight angle and hook over the top of the DIN rail.

The terminal base can be DIN rail or wall/panel mounted. Refer to the

specific method of mounting below.

The XM modules make a chassis ground connection

through the DIN rail. Use zinc plated, yellow chromated

steel DIN rail to assure proper grounding. Using other

DIN rail materials (e.g. aluminum, plastic, etc.), which can

corrode, oxidize or are poor conductors can result in

improper or intermittent platform grounding.

You can also mount the terminal base to a grounded

mounting plate. Refer to Panel/Wall Mount Grounding on

page 10.

DIN Rail Mounting

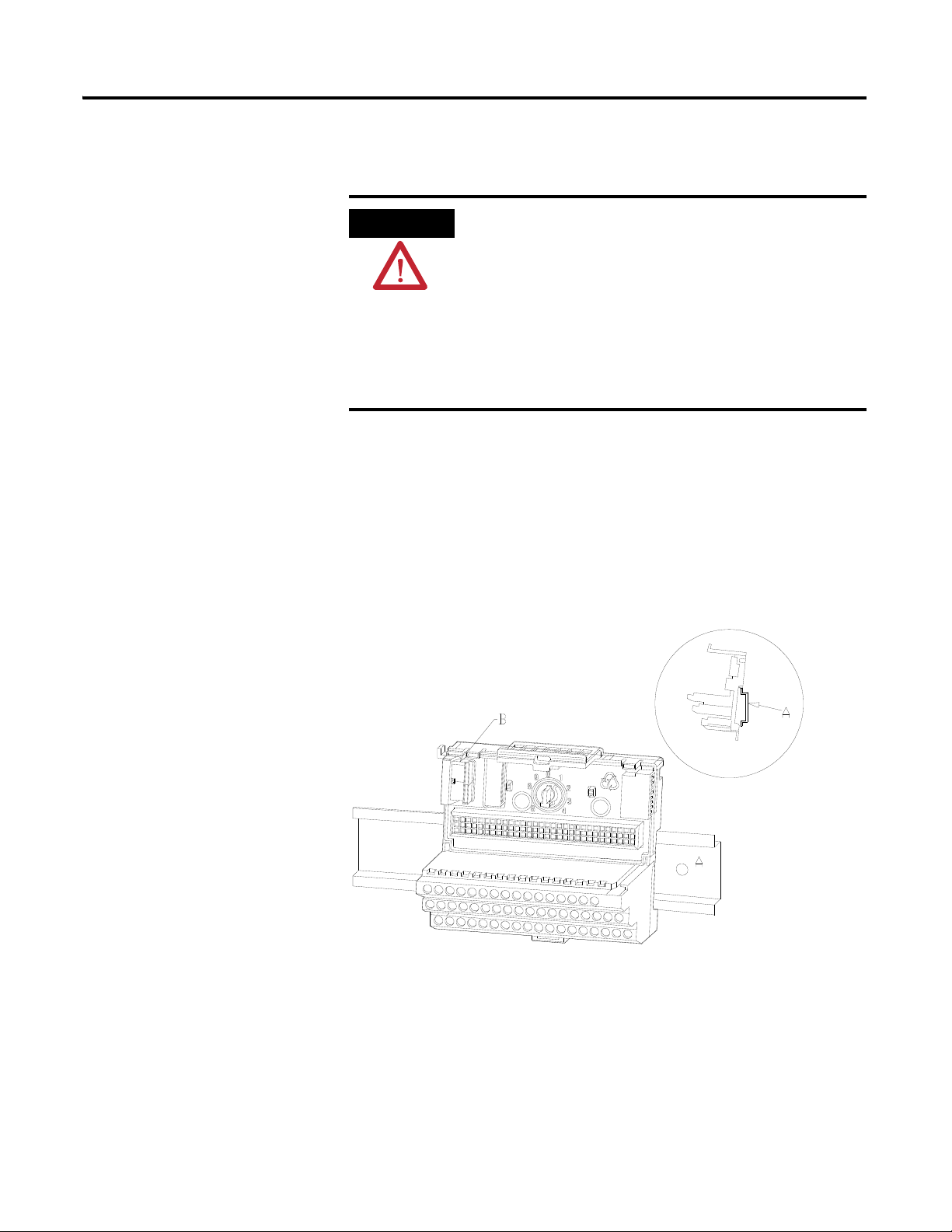

Use the following steps to mount the XM-947 terminal base unit on a DIN rail

(A-B pt no. 199-DR1 or 199-DR4).

1. Position the terminal base on the 35 x 7.5 mm DIN rail (A).

2. Slide the terminal base unit over leaving room for the side

connector (B).

Publication GMSI10-UM014D-EN-P - May 2010

Page 23

Installing the Absolute Shaft Module 15

IMPORTANT

3. Rotate the terminal base onto the DIN rail with the top of the rail

hooked under the lip on the rear of the terminal base.

4. Press down on the terminal base unit to lock the terminal base on the

DIN rail. If the terminal base does not lock into place, use a screwdriver

or similar device to open the locking tab, press down on the terminal

base until flush with the DIN rail and release the locking tab to lock the

base in place.

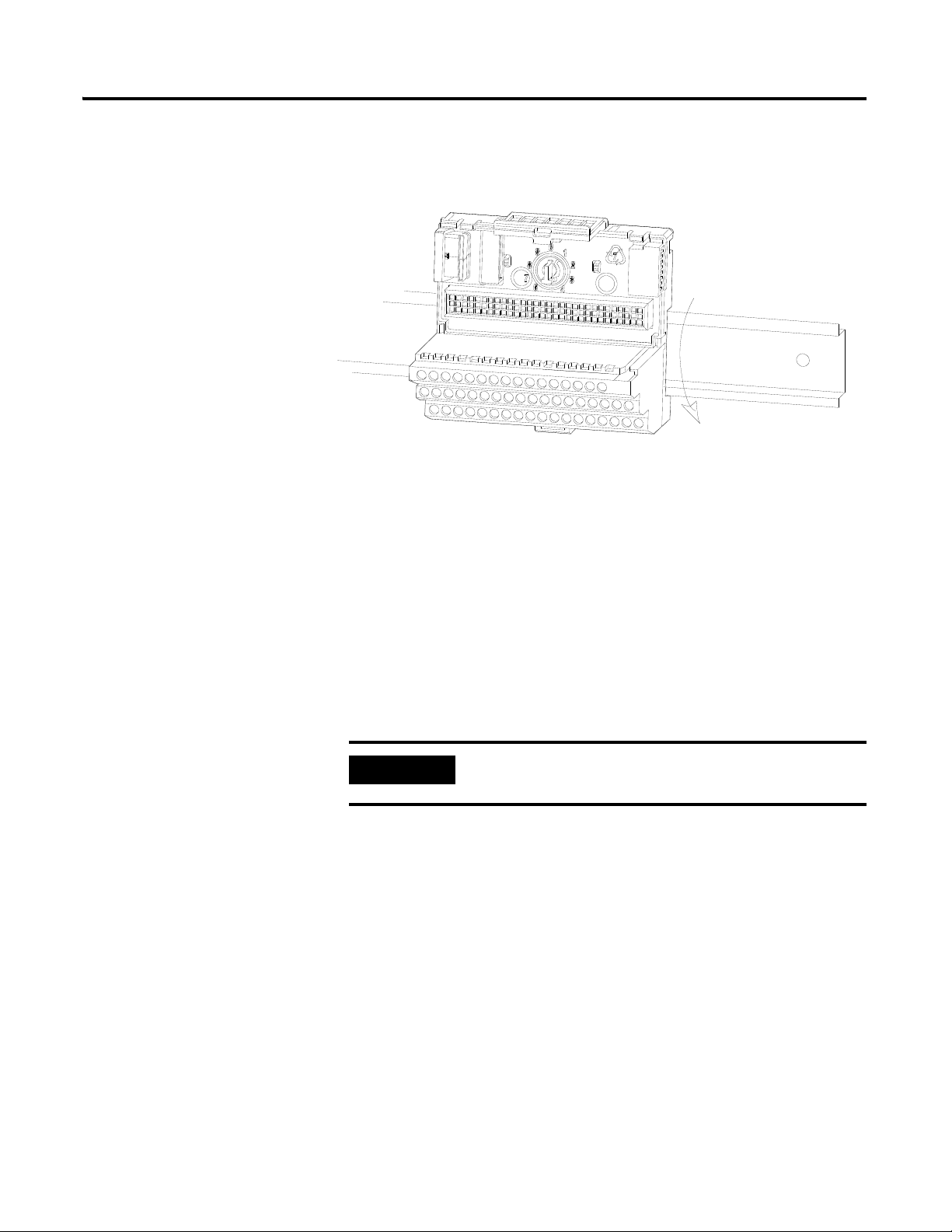

Interconnecting Terminal Base Units

Follow the steps below to install another terminal base unit on the DIN Rail.

Make certain you install the terminal base units in order of

left to right.

1. Position the terminal base on the 35 x 7.5 mm DIN rail (A).

2. Make certain the side connector (B) is fully retracted into the base unit.

3. Slide the terminal base unit over tight against the neighboring terminal

base. Make sure the hook on the terminal base slides under the edge of

the terminal base unit.

4. Press down on the terminal base unit to lock the terminal base on the

DIN rail. If the terminal base does not lock into place, use a screwdriver

or similar device to open the locking tab, press down on the terminal

base until flush with the DIN rail and release the locking tab to lock the

base in place.

Publication GMSI10-UM014D-EN-P - May 2010

Page 24

16 Installing the Absolute Shaft Module

5. Gently push the side connector into the side of the neighboring terminal

base to complete the backplane connection.

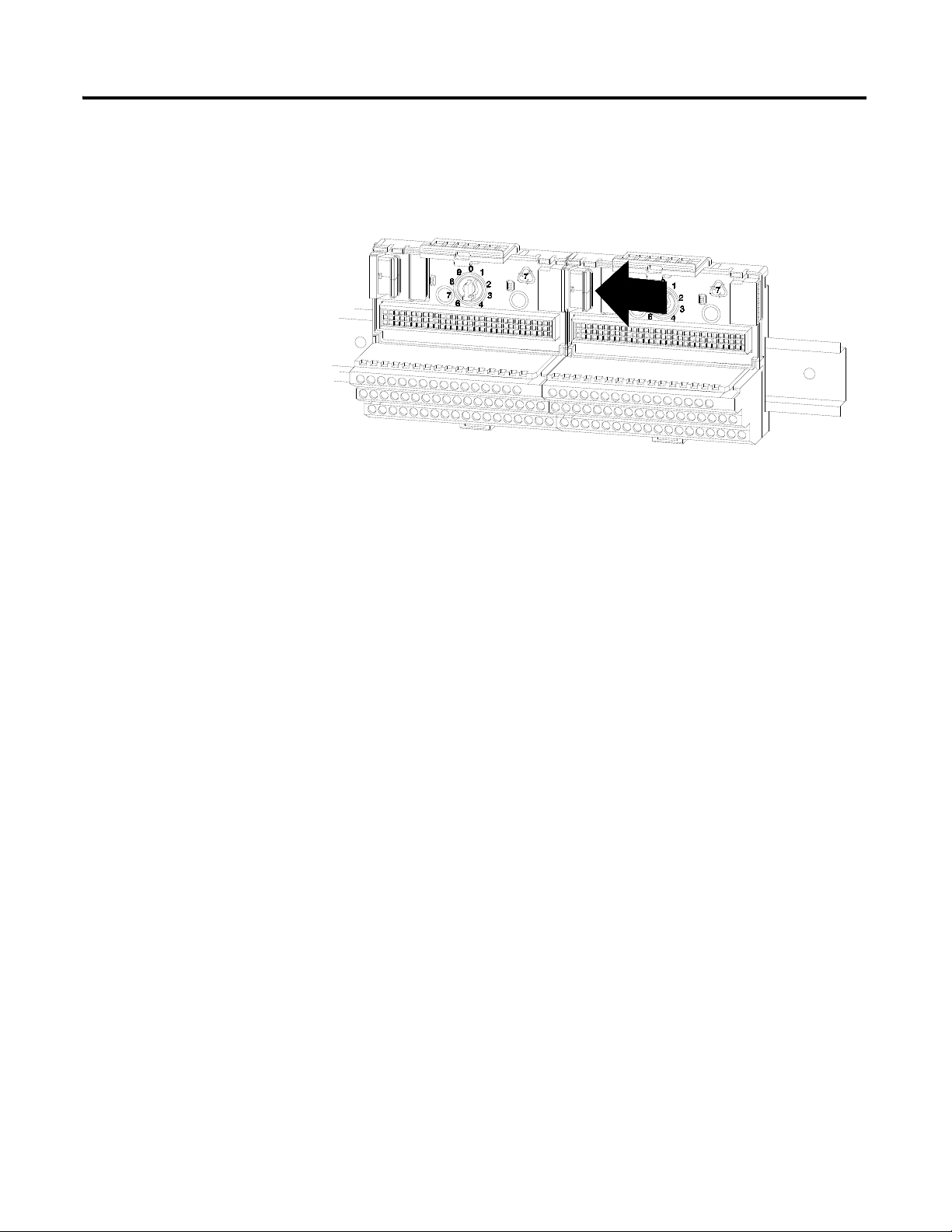

Panel/Wall Mounting

Installation on a wall or panel consists of:

• laying out the drilling points on the wall or panel

• drilling the pilot holes for the mounting screws

• installing the terminal base units and securing them to the wall or panel

Use the following steps to install the terminal base on a wall or panel.

Publication GMSI10-UM014D-EN-P - May 2010

Page 25

Installing the Absolute Shaft Module 17

Side Connector

1. Lay out the required points on the wall/panel as shown in the drilling

dimension drawing below.

Connecting Wiring for Your Module

2. Drill the necessary holes for the #6 self-tapping mounting screws.

3. Secure the terminal base unit using two #6 self-tapping screws.

4. To install another terminal base unit, retract the side connector into the

base unit. Make sure it is fully retracted.

5. Position the terminal base unit up tight against the neighboring terminal

base. Make sure the hook on the terminal base slides under the edge of

the terminal base unit.

6. Gently push the side connector into the side of the neighboring terminal

base to complete the backplane connection.

7. Secure the terminal base to the wall with two #6 self-tapping screws.

Wiring to the module is made through the terminal base unit on which the

module mounts. The XM-121 is compatible only with the XM-940 terminal

base unit, Cat. No. 1440-TB-A.

Publication GMSI10-UM014D-EN-P - May 2010

Page 26

18 Installing the Absolute Shaft Module

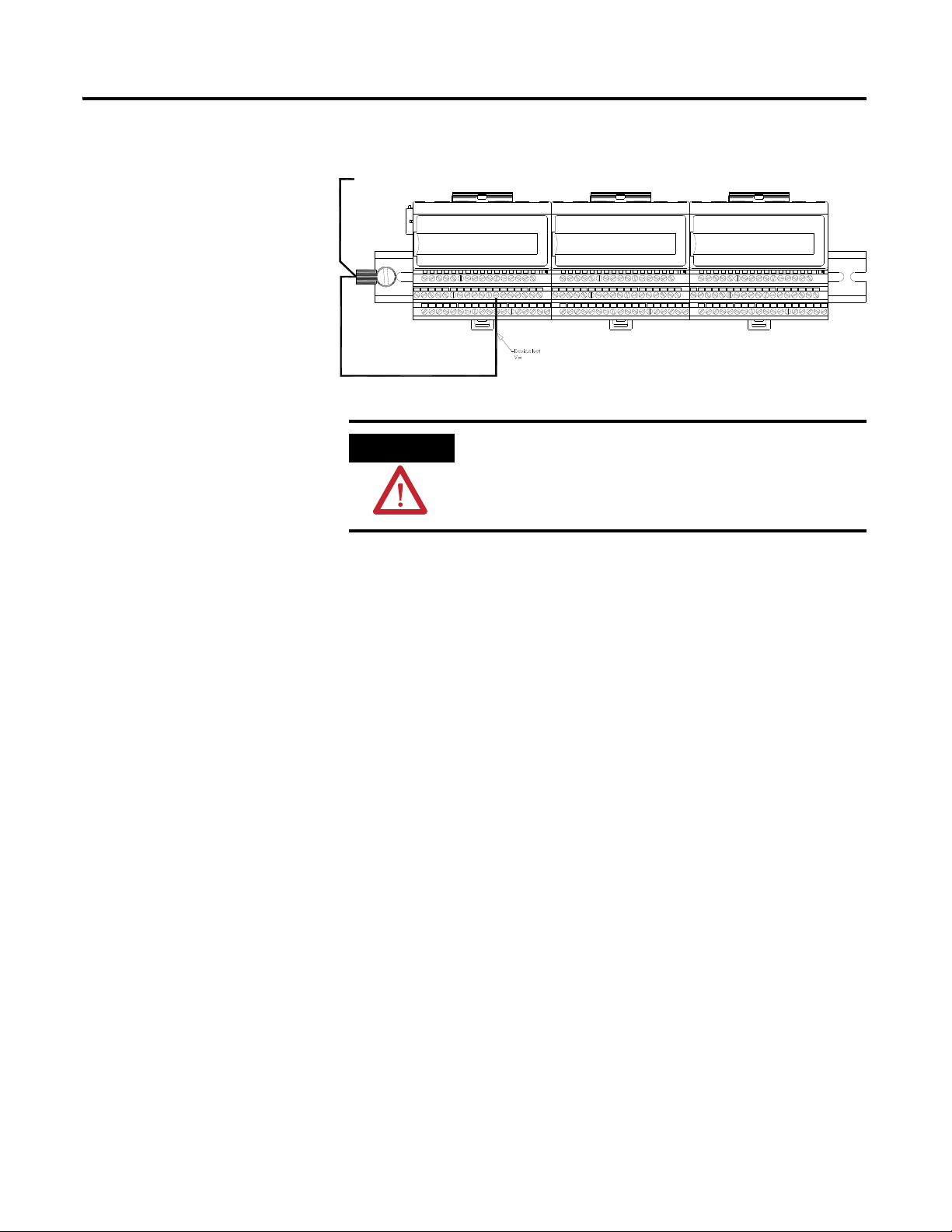

ATTENTION

TIP

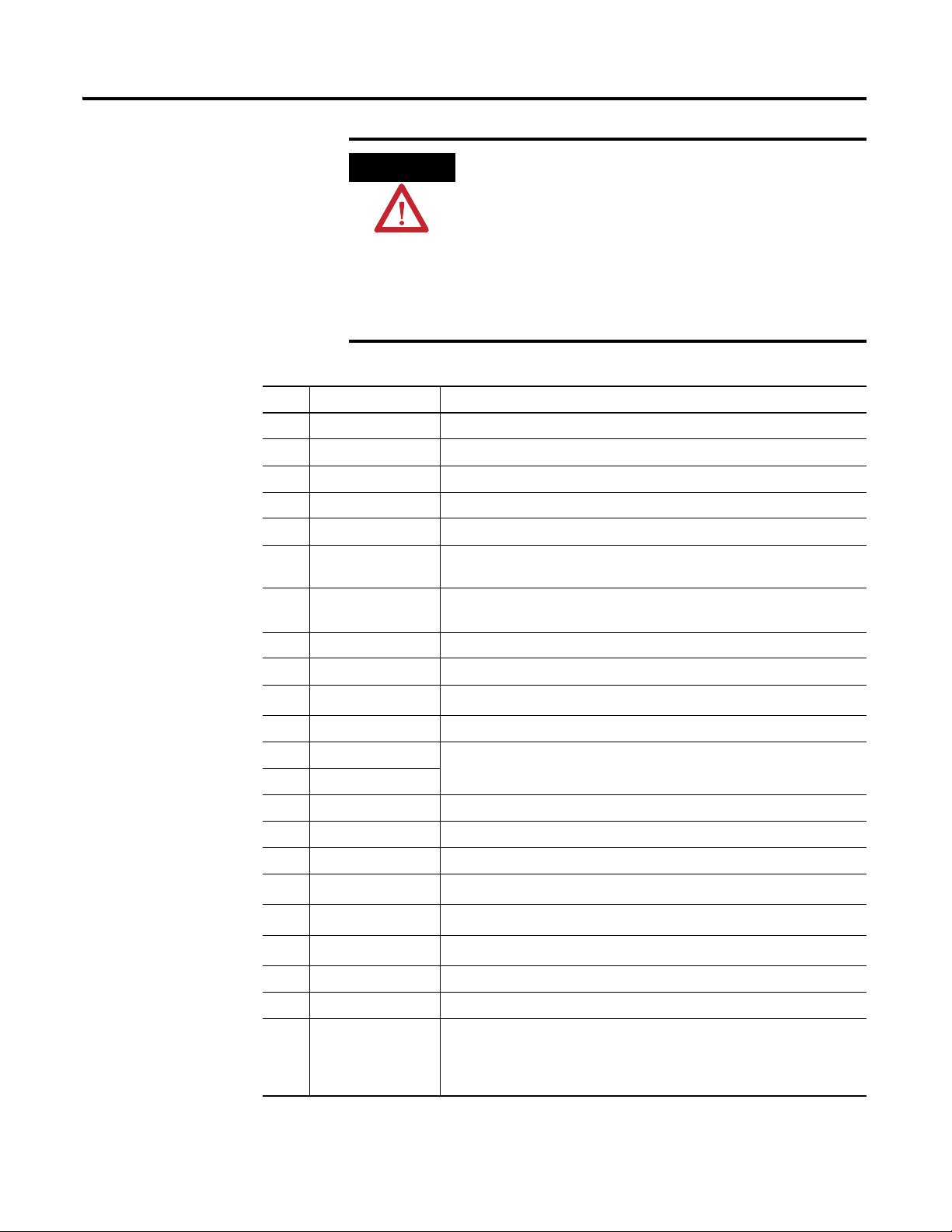

XM-940 (Cat. No. 1440-TB-A)

Revision number

of XM module

Figure 2.7 XM-940 Terminal Base Unit

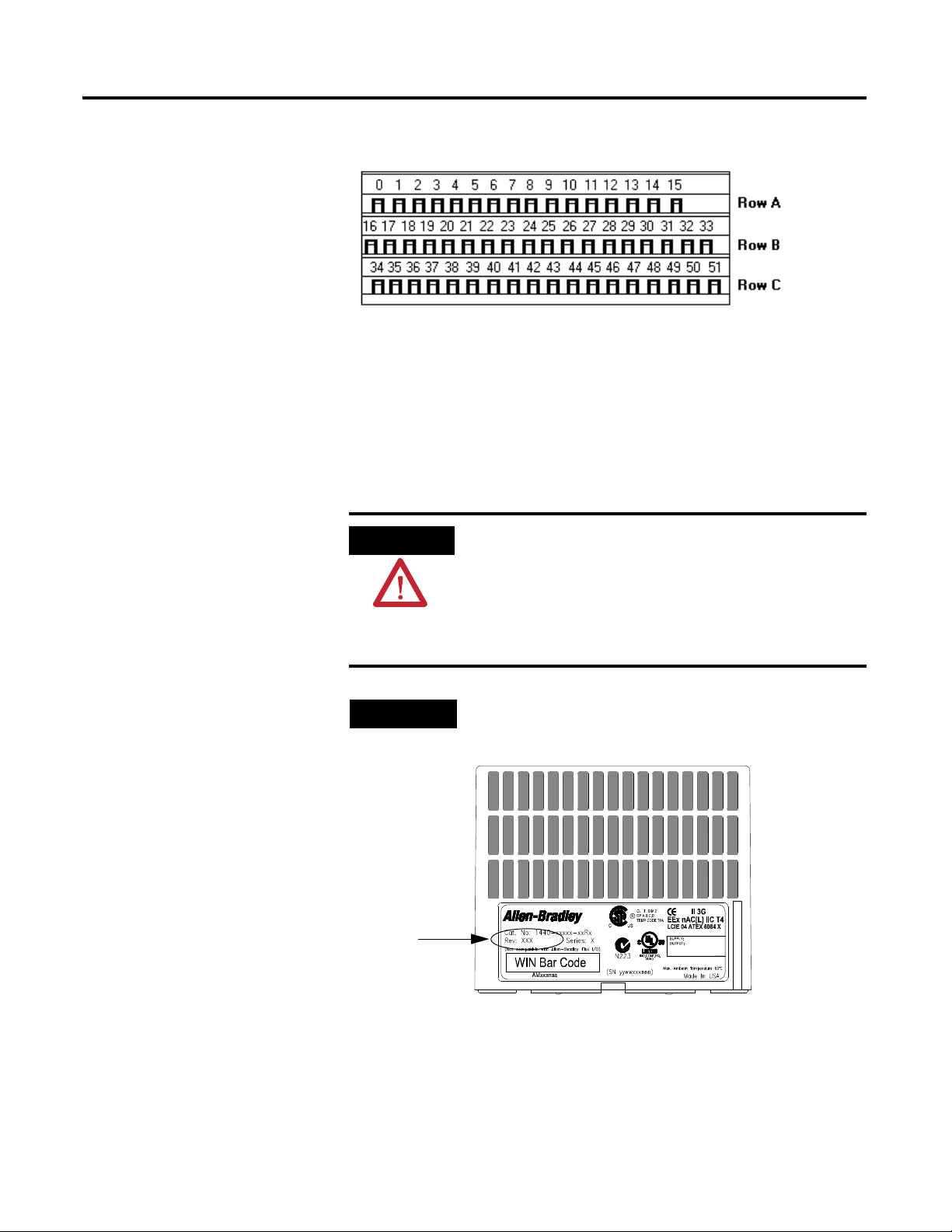

Terminal Block Assignments

The terminal block assignments and descriptions for the Absolute Shaft

module are shown below.

The following table applies only to the XM-121 module

revision B01 (and later). Earlier revisions of the module do

not support the wiring configuration of the Absolute Shaft

module.

Refer to the installation instructions for the specific XM

module for its terminal assignments.

The XM module’s revision number is on the product label

(which is located on the front of the XM module, as shown

below).

Publication GMSI10-UM014D-EN-P - May 2010

Page 27

Installing the Absolute Shaft Module 19

WARNING

EXPLOSION HAZARD

Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connections that mate

to this equipment by using screws, sliding latches, threaded

connectors, or other means provided with this product.

Terminal Block Assignments

No. Name Description

0 Xducer 1 (+) Vibration transducer 1 (shaft relative) connection

1 Xducer 2 (+) Vibration transducer 2 (case absolute) connection

2 Buffer 1 (+) Vibration signal 1 buffered output

3 Buffer 2 (+) Vibration signal 2 buffered output

4 Tach/Signal In (+) Tachometer transducer/signal input, positive side

5 Buffer Power 1 IN Channel 1 buffer power input

Connect to terminal 21 for negative biased transducers

6 Positive Buffer Bias Provides positive (-5 V to +24 V) voltage compliance to buffered outputs

Connect to terminal 22 (CH 2) for positive bias transducers

7 TxD PC serial port, transmit data

8 RxD PC serial port, receive data

9

XRTN

1

Circuit return for TxD and RxD

10 Chassis Connection to DIN rail ground spring or panel mounting hole

11 4-20 mA 1 (+) 4-20 mA output

12 4-20 mA 1 (-)

300 ohm maximum load

13 Chassis Connection to DIN rail ground spring or panel mounting hole

14 Chassis Connection to DIN rail ground spring or panel mounting hole

15 Chassis Connection to DIN rail ground spring or panel mounting hole

16

17

18

Xducer 1 (-)

Xducer 2 (-)

Signal Common

1

1

Vibration transducer 1 connection

Vibration transducer 2 connection

1

Vibration buffered output return

19 TACH Buffer Tachometer transducer/signal output

20 Tachometer (-) Tachometer transducer/signal return, TACH Buffer return

21 Buffer/Xducer Pwr (-) Provides negative (-24 V to +9 V) voltage compliance to buffered outputs

Connect to terminal 5 (CH 1) for negative bias transducers

Transducer power supply output, negative side; used to power external

sensor (40 mA maximum load)

Publication GMSI10-UM014D-EN-P - May 2010

Page 28

20 Installing the Absolute Shaft Module

Terminal Block Assignments

No. Name Description

22 Buffer Power 2 IN Channel 2 buffer power input

23 CAN_High DeviceNet bus connection, high differential (white wire)

24 CAN_Low DeviceNet bus connection, low differential (blue wire)

25 +24 V Out Internally connected to 24 V In 1 (terminal 44)

26 DNet V (+) DeviceNet bus power input, positive side (red wire)

27 DNet V (-) DeviceNet bus power input, negative side (black wire)

28

29 4-2 0mA 2 (+) 4-20 mA output

30 4-20 mA 2 (-)

31 Chassis Connection to DIN rail ground spring or panel mounting hole

32 Chassis Connection to DIN rail ground spring or panel mounting hole

24 V Common

Connect to terminal 6 for positive biased transducers for negative biased

transducers

Used to daisy chain power if XM modules are not plugged into each other

1

Internally connected to 24 V Common (terminals 43 and 45)

Used to daisy chain power if XM modules are not plugged into each other

If power is not present on terminal 44, there is no power on this terminal

300 ohm maximum load

33 Chassis Connection to DIN rail ground spring or panel mounting hole

34 Chassis Connection to DIN rail ground spring or panel mounting hole

35 Chassis Connection to DIN rail ground spring or panel mounting hole

36 Chassis Connection to DIN rail ground spring or panel mounting hole

37 Chassis Connection to DIN rail ground spring or panel mounting hole

38 Chassis Connection to DIN rail ground spring or panel mounting hole

39 SetPtMult Switch input to activate Set Point Multiplication (active closed)

40 Switch RTN Switch return, shared between SetPtMult and Reset Relay

41 Reset Relay Switch input to reset internal relay (active closed)

42 Reserved

43

24 V Common

1

Internally DC-coupled to circuit ground

44 +24 V In Connection to primary external +24 V power supply, positive side

45

24 V Common

1

Connection to external +24 V power supply, negative side (internally

DC-coupled to circuit ground)

46 Relay N.C. 1 Relay Normally Closed contact 1

47 Relay Common 1 Relay Common contact 1

48 Relay N.O. 1 Relay Normally Open contact 1

49 Relay N.O. 2 Relay Normally Open contact 2

50 Relay Common 2 Relay Common contact 2

51 Relay N.C. 2 Relay Normally Closed contact 2

Publication GMSI10-UM014D-EN-P - May 2010

1 Terminals are internally connected and isolated from the Chassis terminals.

Page 29

Installing the Absolute Shaft Module 21

-

24V dc

Power

Supply

+

-

IMPORTANT

IMPORTANT

ATTENTION

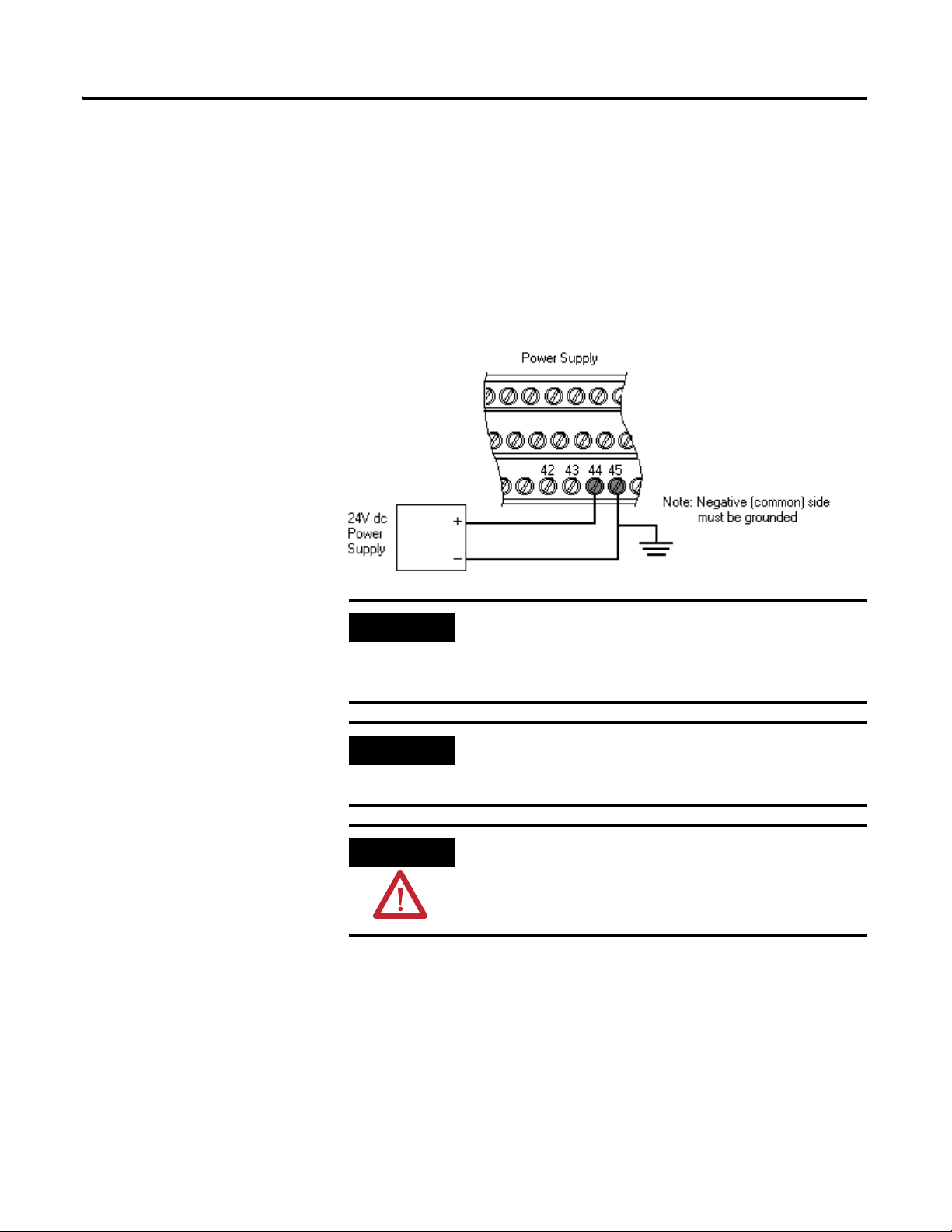

Connecting the Power Supply

Power supplied to the module must be nominally 24 Vdc (±10%) and must be

a Class 2 rated circuit.

Wire the DC-input power supply to the terminal base unit as shown in Figure

2.8.

Figure 2.8 DC Input Power Supply Connections

A Class 2 circuit can be provided by use of an NEC Class 2

rated power supply, or by using a SELV or PELV rated

power supply with a 5 Amp current limiting fuse installed

before the XM module(s).

24Vdc needs to be wired to terminal 44 (+24 V In) to

provide power to the device and other XM modules linked

to the wired terminal base via the side connector.

The power connections are different for different XM

modules. Refer to the installation instructions for your

specific XM module for complete wiring information.

Connecting the Relays

The XM-121 has both Normally Open (NO) and Normally Closed (NC) relay

contacts. Normally Open relay contacts close when the control output is

energized. Normally Closed relay contacts open when the control output is

energized.

Publication GMSI10-UM014D-EN-P - May 2010

Page 30

22 Installing the Absolute Shaft Module

IMPORTANT

TIP

IMPORTANT

The alarms associated with the relay and whether the relay is normally

de-energized (non-failsafe) or normally energized (failsafe) depends on the

configuration of the module. Refer to Relay Parameters on page 59 for details.

Table 2.1 shows the on-board relay connections for the module.

All XM relays are double pole. This means that each relay

has two contacts in which each contact operates

independently but identically. The following table and

illustrations show wiring solutions for both contacts;

although, in many applications it may be necessary to wire

only one contact.

The Expansion Relay module may be connected to the

module to provide additional relays. Refer the XM-441

Expansion Relay Module User’s Guide for wiring details.

The NC/NO terminal descriptions (page 20) correspond

to a de-energized (unpowered) relay.

When the relay is configured for non-failsafe operation, the

relay is normally de-energized.

When the relay is configured for failsafe operation, the

relay is normally energized, and the behavior of the NC and

NO terminals is inverted.

Table 2.1 Relay Connections for XM-121

Configured for

Failsafe Operation Relay 1 Terminals

Nonalarm Alarm Wire Contacts Contact 1 Contact 2

Closed Opened COM 47 50

NO 48 49

Opened Closed COM 47 50

NC 46 51

Configured for

Non-failsafe Operation Relay 1 Terminals

Publication GMSI10-UM014D-EN-P - May 2010

Nonalarm Alarm Wire Contacts Contact 1 Contact 2

Closed Opened COM 47 50

NC 46 51

Opened Closed COM 47 50

NO 48 49

Page 31

Installing the Absolute Shaft Module 23

Figures 2.9 and 2.10 illustrate the behavior of the NC and NO terminals when

the relay is wired for failsafe, alarm or nonalarm condition or non-failsafe,

alarm or nonalarm condition.

Figure 2.9 Relay Connection - Failsafe, Nonalarm Condition

Non-failsafe, Alarm Condition

Figure 2.10 Relay Connection - Failsafe, Alarm Condition

Non-failsafe, Nonalarm Condition

Alternate Relay Wiring

Figures 2.11 and 2.12 show how to wire both ends of a single external

indicator to the XM terminal base for failsafe, nonalarm or alarm condition or

non-failsafe, nonalarm or alarm condition.

Publication GMSI10-UM014D-EN-P - May 2010

Page 32

24 Installing the Absolute Shaft Module

IMPORTANT

Figure 2.11 Relay Connection - Failsafe, Nonalarm Condition

Non-failsafe, Alarm Condition

Figure 2.12 Relay Connection - Failsafe, Alarm Condition

Non-failsafe, Nonalarm Condition

Publication GMSI10-UM014D-EN-P - May 2010

Connecting the Tachometer Signal

The XM-121 provides a single tachometer input signal. The signal processing

performed on the tachometer signal depends on the configuration of the

module. See page 52 for a description of the tachometer parameters.

If you are not using the tachometer input, set the Pulses

per Revolution parameter to zero (0). This will disable the

tachometer measurement and prevent the module from

indicating a tachometer fault (TACH indicator flashing

yellow). A tachometer fault occurs when no signal pulses

are received on the tachometer input signal for a relatively

long period.

Page 33

Installing the Absolute Shaft Module 25

Connecting a Magnetic Pickup Tachometer

Figure 2.13 shows the wiring of a magnetic pickup tachometer to the terminal

base unit.

Figure 2.13 Magnetic Pickup Tachometer Signal Connection

Connecting a Hall Effect Tachometer Sensor

Figure 2.14 shows the wiring of a Hall Effect Tachometer Sensor, Cat. No.

44395, to the terminal base unit.

Figure 2.14 Hall Effect Tachometer Signal Connection

Publication GMSI10-UM014D-EN-P - May 2010

Page 34

26 Installing the Absolute Shaft Module

S

I

G

-

2

4

COM

Signal Common

Tach Input Signal

-24V DC

Shield

S hield Floating

Isolated Sensor Driver

20 21 31

4

18

Connecting a Non-Contact Sensor to the Tachometer Signal

Figure 2.15 shows the wiring of a non-contact sensor to the tachometer input

signal.

Figure 2.15 Non-Contact Sensor to Tachometer Signal Connection

Connecting the Buffered Outputs

The XM-121 provides buffered outputs of all transducer input signals. The

buffered output connections may be used to connect the module to portable

data collectors or other online systems.

Figure 2.16 shows the buffered output connections for the modules.

Publication GMSI10-UM014D-EN-P - May 2010

Page 35

Figure 2.16 Buffered Output Connections

IMPORTANT

Table 2.2 Configuring Buffered Output Operating Range

Transducer Input Range Channel Connect Terminal To Terminal

Negative Bias

1

-24 to +9V 1 5 21

Positive Bias

2

-5 to +24V 2 22 6

Non-Bias

-5 to +9V 2 ---- ----

1 The signal from the non-contact probe must be connected to channel 1 on the terminal base.

2 The signal from the 9000 sensor must be connected to channel 2 on the terminal base.

Applies only to XM-121 module revision B01 (and

later).

The voltage operating range of the buffered outputs must

be configured to coincide with the corresponding

transducer bias range. This operating range is configured by

placing a jumper from terminal 5 (channel 1) and terminal

22 (channel 2) to either terminal 6 (Positive Buffer Bias) or

terminal 21 (Buffer -), depending on the transducer. See

Table 2.2. Note the buffered output operating range is

configured independently per channel.

Installing the Absolute Shaft Module 27

Connecting the Transducers

The Absolute Shaft module can accept input from a non-contact eddy current

probe and a case mounted vibration sensor (accelerometer or velocity sensor).

The signal from a non-contact eddy current probe must be connected to

channel 1. The Absolute Shaft module supports the 5, 8, and 11mm

Allen-Bradley 2100 Series and Bently Nevada 3300 XL Series probes.

Publication GMSI10-UM014D-EN-P - May 2010

Page 36

28 Installing the Absolute Shaft Module

IMPORTANT

ATTENTION

IMPORTANT

The case mounted vibration sensor must be connected to channel 2. The

Absolute Shaft module supports the following Allen-Bradley 9000 series

sensors.

Table 2.3 Supported Allen-Bradley 9000 Series Sensors

Cat. No. Model

EK-43781I 9000A General Purpose Sensor

EK-43808I 9100VO Velocity Output Sensor

EK-43786I 9100CSA General Purpose Sensor

EK-43805I 9100T High Temperature Sensor

Important Considerations

When mounting the vibration sensor and the non-contact eddy current probe,

it is important to note the following:

• The two sensors should be mounted at or adjacent to each machine

bearing.

• The sensors should be mounted in the same geometric plane.

• It is preferable to mount the transducers at the same point on the same

bearing half. This can be done by using a dual mounting housing (such

as the Dual Probe Holder, Cat. No. EK-29000-DPH01). The positions

chosen should be the same at each bearing.

Connecting a Non-Contact Sensor and 9000 Series Sensor

The following figure shows the wiring of a non-contact sensor and a 9000

series sensor to the terminal base unit. The non-contact sensor must be wired

to channel 1 and the 9000 sensor must be wired to channel 2.

The Absolute Shaft module requires the XM-121 module

revision B01 (and later). Earlier revisions of the module do

not support the Absolute Shaft wiring configuration.

You may ground the cable shield at either end of the cable.

Do not ground the shield at both ends. Recommended

practice is to ground the cable shield at the terminal base

and not at the transducer. Any convenient Chassis terminal

may be used (see Terminal Block Assignments on page 18).

The internal transducer power supply is providing power to

the non-contact sensor.

Publication GMSI10-UM014D-EN-P - May 2010

Page 37

Installing the Absolute Shaft Module 29

IMPORTANT

TYPICAL WIRING FOR NON-CONTACT SENSOR AND 9000

SERIES SENSOR TO XM-121 ABSOLUTE SHAFT MODUL E

Shield

Pin A - Signal

Pin B - Common

Cable shield not

connected at this end

0

16

22

6

21

Channel 2 Input Signal

Signal Common

5

37

S

I

G

-

2

4

COM

17

1

Signal Common

Channel 1 Input Signal

-24V DC

13

Shield

S hield Floating

Isolated Sensor Driver

*

*

*Note: Jumpering terminal 5 to terminal 21

configures CH 1 buffer (-24V to +9V)

Jumpering terminal 6 to terminal 22

configures CH 2 buffer (-5V to +24V)

IMPORTANT

Make certain the IEPE Power parameter for channel 2 is

enabled so power is provided to the 9000 sensor. Refer

to Channel Parameters on page 46.

Figure 2.17 Non-Contact Sensor and 9000 Series Sensor Wiring

Connecting Two Non-Contact Sensors and 9000 Series Sensor

The following figure shows the wiring of two non-contact sensors and a 9000

series sensor to the terminal base unit. One non-contact sensor must be wired

to channel 1 and the 9000 sensor must be wired to channel 2. The second

non-contact sensor is wired to the tachometer input signal.

The Absolute Shaft module requires the XM-121 module

revision B01 (and later). Earlier revisions of the module do

not support the Absolute Shaft wiring configuration.

Publication GMSI10-UM014D-EN-P - May 2010

Page 38

30 Installing the Absolute Shaft Module

ATTENTION

IMPORTANT

IMPORTANT

IMPORTANT

TYPICAL WIRING FOR 9000 SERIES SENSOR AND TWO

NON-CONTACT SENSORS TO XM-121 ABSOLUTE SHAFT MODULE

Pin A - Common

Pin B - Signal

Cable shield not

connected at this end

Shield

0

16

Channel 2 Input Signal

Signal Common

S

I

G

-

2

4

COM

S

I

G

-

2

4

COM

17

1

Signal Common

Channel 1 Input Signal

21

22

-24V DC

20

-24V DC

4

Signal Common

Tach Input Signal

36

13

31

Shield

Shield

*

* Note: Jumpering terminal 5 to

terminal 21 configures

CH 1 buffer (-24V to 9V)

18

5

6

*

Jumpering terminal 6 to

terminal 22 configures

CH 2 buffer (-5V to +24V)

You may ground the cable shield at either end of the cable.

Do not ground the shield at both ends. Recommended

practice is to ground the cable shield at the terminal base

and not at the transducer. Any convenient Chassis terminal

may be used (see Terminal Block Assignments on page 18).

The internal transducer power supply is providing power to

the non-contact sensor connected to channel 1.

Make certain the IEPE Power parameter for channel 2 is

enabled so power is provided to the 9000 sensor. Refer

to Channel Parameters on page 46.

Transducer DC bias is monitored on all signals.

Figure 2.18 9000 Series Sensor and Two Non-Contact Sensors

Publication GMSI10-UM014D-EN-P - May 2010

Page 39

Installing the Absolute Shaft Module 31

TIP

TIP

ATTENTION

Connecting the Remote Relay Reset Signal

If you set the module relay to latching and the relay activates, the relay stays

activated even when the condition that caused the alarm has ended. The

remote relay reset signal enables you to reset your module relay remotely after

you have corrected the alarm condition. This includes latched relays in the

Expansion Relay module when it is attached to the XM-121.

If you set a module relay to latching, make sure that any

linked relays, such as relays in an XM-440 Master Relay

Module, are not configured as latching. When both relays

are set to latching, the relay in each module will have to be

independently reset when necessary.

You can discretely reset a relay using the serial or remote

configuration tool.

Wire the Remote Relay Reset Signal to the terminal base unit as shown in

Figure 2.19.

Figure 2.19 Remote Relay Reset Signal Connection

The Switch Input circuits are functionally isolated from

other circuits. It is recommended that the Switch RTN

signal be grounded at a signal point. Connect the Switch

RTN signal to the XM terminal base (Chassis terminal) or

directly to the DIN rail, or ground the signal at the switch

or other equipment that is wired to the switch.

Publication GMSI10-UM014D-EN-P - May 2010

Page 40

32 Installing the Absolute Shaft Module

ATTENTION

A single switch contact can also be shared by multiple XM modules wired in

parallel as shown in Figure 2.20.

The relay reset connections may be different for different

XM modules. Figure 2.20 applies only to the XM-121

module. Refer to the installation instructions for the

module for its terminal assignments.

Figure 2.20 Typical Multiple XM Modules Remote Relay Reset Signal Connection

Connecting the Setpoint Multiplication Switch

You can configure the module to multiply the alarm setpoints, or inhibit the

alarms during the start-up period. This can be used to avoid alarm conditions

that may occur during startup, for example, when the monitored machine

passes through a critical speed.

Wire the Setpoint Multiplication switch to the terminal base unit as shown in

Figure 2.21.

Publication GMSI10-UM014D-EN-P - May 2010

Page 41

Figure 2.21 Setpoint Multiplication Connection

ATTENTION

The Switch Input circuits are functionally isolated from

other circuits. It is recommended that the Switch RTN

signal be grounded at a signal point. Connect the Switch

RTN signal to the XM terminal base (Chassis terminal) or

directly to the DIN rail, or ground the signal at the switch

or other equipment that is wired to the switch.

Installing the Absolute Shaft Module 33

Connecting the 4-20 mA Outputs

The module includes an isolated 4-20 mA per channel output into a maximum

load of 300 ohms. The measurements that the 4-20 mA output tracks and the

signal levels that correspond to the 4 mA and 20 mA are configurable. Refer

to 4-20 mA Output Parameters on page 63 for details.

Wire the 4-20 mA outputs to the terminal base unit as shown in Figure 2.22.

Publication GMSI10-UM014D-EN-P - May 2010

Page 42

34 Installing the Absolute Shaft Module

ATTENTION

-

Figure 2.22 4-20 mA Output Connections

The 4-20 mA outputs are functionally isolated from other

circuits. It is recommended that the outputs be grounded at

a single point. Connect the 4-20 mA (-) to the XM terminal

base (Chassis terminal) or directly to the DIN rail, or

ground the signal at the other equipment in the 4-20 mA

loop.

Serial Port Connection

The XM-121 includes a serial port connection that allows you to connect a PC

to it and configure the module’s parameters. There are two methods of

connecting an external device to the module’s serial port.

• Ter mi nal Bas e Un it - There are three terminals on the terminal base

unit you can use for the serial port connection. They are TxD, RxD, and

RTN (terminals 7, 8, and 9, respectively). If these three terminals are

wired to a DB-9 female connector, then a standard RS-232 serial cable

with 9-pin (DB-9) connectors can be used to connect the module to a

PC (no null modem is required).

The DB-9 connector should be wired to the terminal block as shown.

XM-121 Terminal Base Unit

(Cat. No. 1440-TB-A)

TX Terminal (terminal 7) ---------------------- Pin 2 (RD - receive data)

RX Terminal (terminal 8) ---------------------- Pin 3 (TD - transmit data)

RTN Terminal (terminal 9) --------------------- Pin 5 (SG - signal ground)

DB-9 Female Connector

Publication GMSI10-UM014D-EN-P - May 2010

Page 43

Installing the Absolute Shaft Module 35

mini-connector

WARNING

IMPORTANT

• Mini-Connector - The mini-connector is located on top of the module,

as shown in Figure 2.23.

Figure 2.23 Mini-Connector

A special cable (Cat. No. 1440-SCDB9FXM2) is required for this

connection. The connector that inserts into the PC is a DB-9 female

connector, and the connector that inserts into the module is a USB

Mini-B male connector.

If you connect or disconnect the serial cable with power

applied to the module or the serial device on the other end

of the cable, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before

proceeding.

If 24V Common is not referenced to earth ground, we

recommend you use an RS-232 isolator, such as Phoenix

PSM-ME-RS232/RS232-P (Cat. No. 1440-ISO-232-24), to

protect both the XM module and the computer.

DeviceNet Connection

The XM-121 includes a DeviceNet™ connection that allows the module to

communicate with a programmable controller, DCS, or another XM module.

DeviceNet is an open, global, industry-standard communications network

designed to provide an interface through a single cable from a programmable

controller to a smart device such as the XM-121. As multiple XM modules are

interconnected, DeviceNet also serves as the communication bus and protocol

that efficiently transfers data between the XM modules.

Publication GMSI10-UM014D-EN-P - May 2010

Page 44

36 Installing the Absolute Shaft Module

IMPORTANT

ATTENTION

ATTENTION

ATTENTION

IMPORTANT

Connect the DeviceNet cable to the terminal base unit as shown.

Connect To Terminal

Red Wire DNet V+ 26 (Optional - see note)

White Wire CAN High 23

Bare Wire Shield (Chassis) 10

Blue Wire CAN Low 24

Black Wire DNet V- 27

The DeviceNet power circuit through the XM module

interconnect, which is rated at only 300 mA, is not intended

or designed to power DeviceNet loads. Doing so could

damage the module or terminal base.

To preclude this possibility, even unintentionally, it is

recommended that DeviceNet V+ be left unconnected.

You must ground the DeviceNet shield at only one

location. Connecting the DeviceNet shield to terminal 10

will ground the DeviceNet shield at the XM module. If you

intend to terminate the shield elsewhere, do not connect

the shield to terminal 10.

The DeviceNet network must also be referenced to earth at

only one location. Connect DNet V- to earth or chassis at

one of the XM modules.

The DNet V+ and DNet V- terminals are inputs to the XM

module. Do not attempt to pass DeviceNet power through

the XM terminal base to other non-XM equipment by

connecting to these terminals. Failure to comply may result

in damage to the XM terminal base and/or other

equipment.

Terminate the DeviceNet network and adhere to the

requirements and instructions in the ODVA Planning and

Installation Manual - DeviceNet Cable System, which is

available on the ODVA web site (http://www.odva.org).

Publication GMSI10-UM014D-EN-P - May 2010

The devices are shipped from the factory with the network node address

(MAC ID) set to 63. The network node address is software settable. You can

Page 45

Installing the Absolute Shaft Module 37

IMPORTANT

ATTENTION

ATTENTION

WARNING

IMPORTANT

use the XM Serial Configuration Utility or RSNetWorx™ for DeviceNet

(Version 3.0 or later) to set the network node address. Refer to the appropriate

documentation for details.

The baud rate for the XM-121 is set by way of "baud

detection" (Autobaud) at power-up.

Mounting the Module

The XM-121 mounts on the XM-940 terminal base unit, Cat. No. 1440-TB-A.

We recommend that you mount the module after you have connected the

wiring on the terminal base unit.

The XM-121 module is compatible only with the XM-940

terminal base unit. The keyswitch on the terminal base unit

should be at position 1 for the modules.

Do not attempt to install the XM-121 module on other

terminal base units.

Do not change the position of the keyswitch after

wiring the terminal base.

This module is designed so you can remove and insert it

under power. However, when you remove or insert the

module with power applied, I/O attached to the module

can change states due to its input/output signal changing

conditions. Take special care when using this feature.

When you insert or remove the module while power is on,

an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is

removed or the area is nonhazardous before proceeding.

Install the overlay slide label to protect serial connector and

electronics when the serial port is not in use.

Publication GMSI10-UM014D-EN-P - May 2010

Page 46

38 Installing the Absolute Shaft Module

1. Make certain the keyswitch (A) on the terminal base unit (C) is at

position 1 as required for the module.

Module Indicators

2. Make certain the side connector (B) is pushed all the way to the left. Yo u

cannot install the module unless the connector is fully extended.

3. Make sure that the pins on the bottom of the module are straight so they

will align properly with the connector in the terminal base unit.

4. Position the module (D) with its alignment bar (E) aligned with the

groove (F) on the terminal base.

5. Press firmly and evenly to seat the module in the terminal base unit. The

module is seated when the latching mechanism (G) is locked into the

module.

6. Repeat the above steps to install the next module in its terminal base.

The Absolute Shaft module has seven LED indicators, which include a module

status (MS) indicator, a network status (NS) indicator, a status indicator for

each channel (CH1, CH2, and TACH), an activation indicator for the Setpoint

Multiplier, and a status indicator for the Relay. The LED indicators are located

on top of the module.

Publication GMSI10-UM014D-EN-P - May 2010

Page 47

Installing the Absolute Shaft Module 39

Module Indicators

Figure 2.24 LED Indicators

The following tables describe the states of the LED status indicators.

Module Status (MS) Indicator

Color State Description

No color Off No power applied to the module.

Green Flashing Red Module performing power-up self test.

Flashing

Solid

Module operating in Program Mode

Module operating in Run Mode

Red Flashing • Application firmware is invalid or not loaded.

Download firmware to the module.

• Firmware download is currently in progress.

Solid An unrecoverable fault has occurred. The module may

need to be repaired or replaced.

1

.

2

.

1 Program Mode - Typically this occurs when the module configuration settings are being updated with the XM

Serial Configuration Utility. In Program Mode, the module does not perform its normal functions. The signal

processing/measurement process is stopped, and the status of the alarms is set to the disarm state to prevent

a false alert or danger status.

2 Run Mode - In Run Mode, the module collects measurement data and monitors each vibration measurement

device.

Publication GMSI10-UM014D-EN-P - May 2010

Page 48

40 Installing the Absolute Shaft Module

Network Status (NS) Indicator

Color State Description

No color Off Module is not online.

• Module is autobauding.

• No power applied to the module, look at Module

Status LED.

Green Flashing Module is online (DeviceNet) but no connections are

currently established.

Solid Module is online with connections currently

established.

Red Flashing One or more I/O connections are in the timed-out state.

Solid Failed communications (duplicate MAC ID or Bus-off).

1 Normal condition when the module is not a slave to an XM-440, PLC, or other master device.

1

Channel 1, Channel 2, and Tachometer Status Indicators

Color State Description

No color Off • Normal operation within alarm limits on the channel.

• No power applied to the module, look at Module

Status LED.

Yellow Solid An alert level alarm condition exists on the channel

(and no transducer fault, tachometer fault, or danger

level alarm condition exists).

Flashing Tach

LED

Flashing CH1/2

LED

Red Solid A danger level alarm condition exists on the channel

Flashing A transducer fault condition exists on the channel.

A tachometer fault (no transducer fault) condition

exists on the tachometer channel

A tachometer fault condition exists and the channel’s

alarm speed range is enabled (and no transducer fault

on the channel’s transducer).

(and no transducer fault or tachometer fault condition

exists).

Publication GMSI10-UM014D-EN-P - May 2010

Setpoint Multiplier Indicator

Color State Description

Yellow Off Setpoint multiplier is not in effect.

Solid Setpoint multiplier is in effect.

Page 49

Installing the Absolute Shaft Module 41

Relay Indicator

Color State Description

Red Off On-board relay is not activated.

Solid On-board relay is activated.

Basic Operations

Powering Up the Module

The module performs a self-test at power-up. The self-test includes an LED

test and a device test. During the LED test, the indicators will be turned on

independently and in sequence for approximately 0.25 seconds.

The device test occurs after the LED test. The Module Status (MS) indicator is

used to indicate the status of the device self-test.

MS Indicator State Description

Flashing Red and Green Device self-test is in progress.

Solid Green or Flashing Green Device self-test completed successfully,

and the firmware is valid and running.

Flashing Red Device self-test completed, the hardware is