Page 1

User Guide

Firmware Revision 5

XM-441 Expansion Relay Module

Catalog Numbers

1440- REX00-04RD

Page 2

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT

Allen-Bradley, Rockwell Automation, and XM are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Page 3

Safety Approvals

3

The following information applies when operating this

equipment in hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in

Class I Division 2 Groups A, B, C, D, Hazardous Locations and

nonhazardous locations only. Each product is supplied with markings

on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the

most adverse temperature code (lowest "T" number) may be used to

help determine the overall temperature code of the system.

Combinations of equipment in your system arfe subject to

investigation by the local Authority Having Jurisdiction at the time of

installation.

WARNING:

EXPLOSION HAZARD

•Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

•Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

•Substitution of components may impair suitability

for Class I, Division 2.

•If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent

qu'à une utilisation en environnements de Classe I Division 2

Groupes A, B, C, D dangereux et non dangereux. Chaque produit

est livré avec des marquages sur sa plaque d'identification qui

indiquent le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés dans un

système, le code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour déterminer le

code de température global du système. Les combinaisons

d'équipements dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de l'installation.

WARNING:

RISQUE D’EXPLOSION

•Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher l'équipement.

•Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer tous

les connecteurs externes reliés à cet

équipement à l'aide de vis, loquets coulissants,

connecteurs filetés ou autres moyens fournis

avec ce produit.

•La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

•S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

IMPORTANT

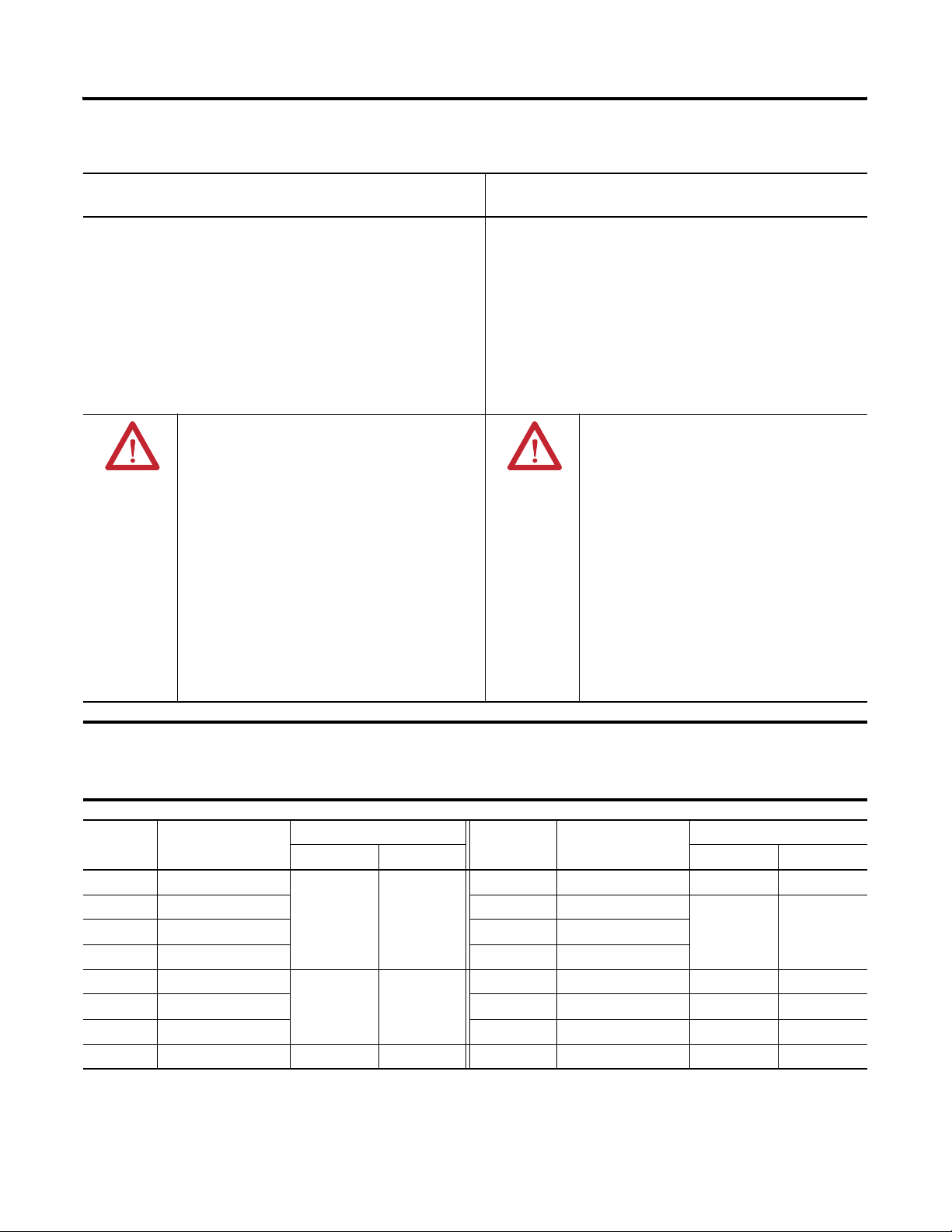

Wiring to or from this device, which enters or leaves the system enclosure, must utilize wiring methods suitable for

Class I, Division 2 Hazardous Locations, as appropriate for the installation in accordance with the product drawings as

indicated in the following table.

Model Catalog Number Haz Location Drawings* Model Catalog Number Haz Location Drawings*

w/o Barriers w/ Barriers w/o Barriers w/ Barriers

XM-120 1440-VST0201RA

XM-121 1440-VLF0201RA XM-360 1440-TPR0600RE

XM-122 1440-VSE0201RA XM-361 1440-TUN0600RE

XM-123 1440-VAD0201RA XM-361 1440-TTC0600RE

XM-160 1440-VDRS0600RH

XM-161 1440-VDRS0606RH XM-441 1440-REX0004RD 48241-HAZ N/A

XM-162 1440-VDRP0600RH XM-442 1440-REX0304RG 48642-HAZ N/A

XM-220 1440-SPD0201RB 48640-HAZ 48641-HAZ

48178-HAZ 48179-HAZ

51263-HAZ 51264-HAZ

XM-320 1440-TPS0201RB 48238-HAZ 48239-HAZ

48295-HAZ 48299-HAZ

XM-440 1440-RMA0004RC 48240-HAZ N/A

* Drawings are available on the included CD

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2010

Page 4

4

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 5

Introduction

Installing the XM-441 Expansion

Relay Module

Table of Contents

Chapter 1

Introducing the XM-441 Expansion Relay Module . . . . . . . . . . . . . . . . 7

XM-441 Module Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2

XM Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting the Terminal Base Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DIN Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Panel/Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting Wiring for Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Terminal Block Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connecting the Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Module Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications

Glossary

Index

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 6

6 Table of Contents

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 7

Chapter

1

Introduction

This chapter provides an overview of the XM-441 Expansion Relay module. It

also discusses the components of the module.

For information about See page

Introducing the XM-441 Expansion Relay Module 7

XM-441 Module Components 8

Using this Manual 8

Introducing the XM-441 Expansion Relay Module

The XM-441 Expansion Relay module provides an additional four relays to

any XM measurement module or to the XM-440 Master Relay module. It is a

member of the Allen-Bradley™ XM

condition monitoring and protection modules that operate both in stand-alone

applications or integrate with Programmable Logic Controllers (PLCs) and

control system networks.

The XM-441 offers four high power relays suitable for use in almost any

protection application. Up to two Relay Expansion modules may be connected

to the XM-440 Master Relay module, providing an additional four or eight

relays.

The XM-441 is not an intelligent XM module. It must be connected to either

an XM measurement module or the XM-440 Master Relay module in order to

function. In addition, it does not consume a node address on the DeviceNet

bus. The XM-441 simply extends the circuitry of its host module.

No direct configuration of the XM-441 is required. Setup of the XM-441

relays is through its host XM measurement or XM-440 Master Relay module.

®

Series, a family of DIN rail mounted

7Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 8

8 Introduction

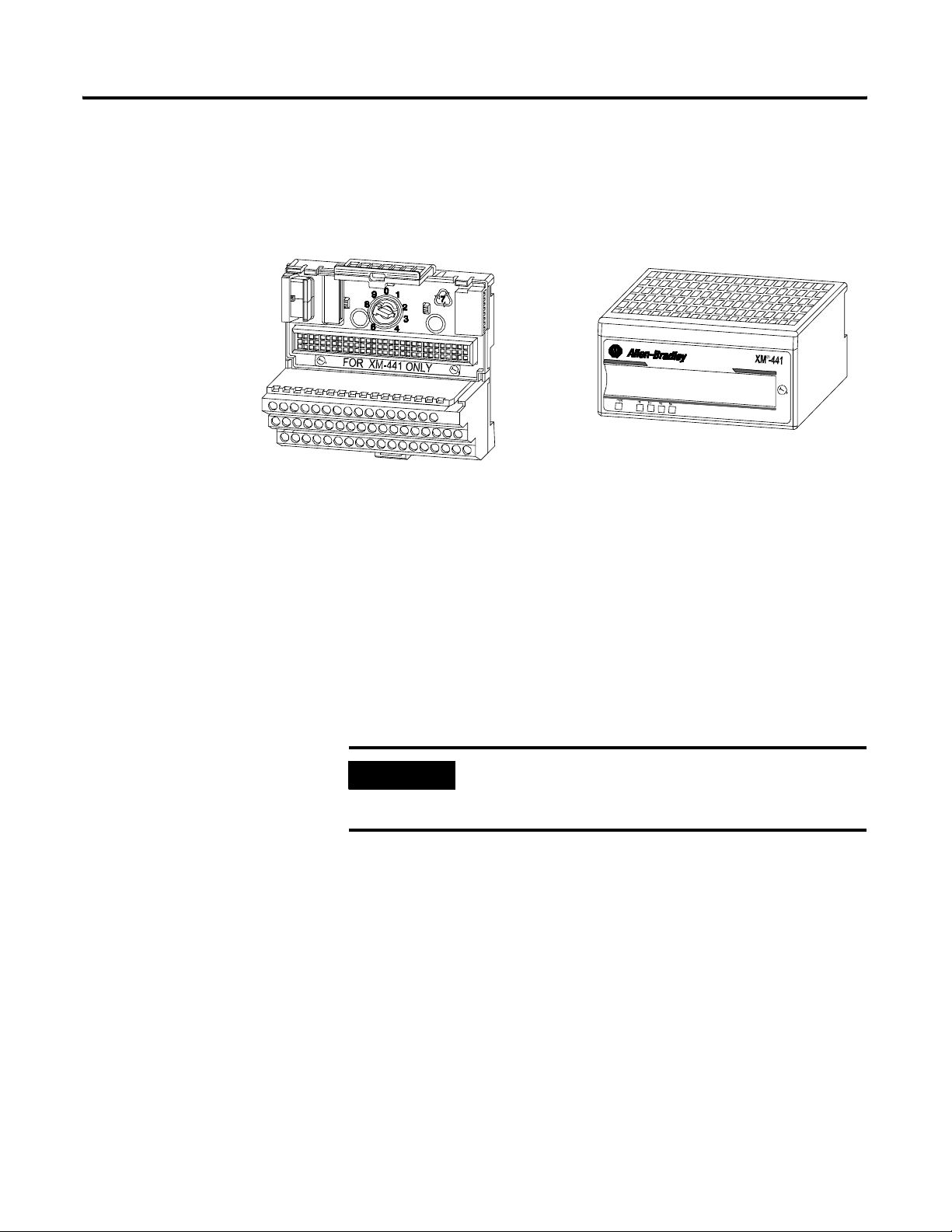

XM-441 Module Components

The XM-441 consists of a terminal base unit and an instrument module. The

XM-441 Expansion Relay Module and the XM-943 Expansion Relay Terminal

Base are shown below.

Figure 1.1 XM-441 Module Components

XM-943 Expansion Relay Module Terminal Base Unit

Cat. No. 1440-TB-D

• XM-943 Expansion Relay Terminal Base Unit - A DIN rail mounted

base unit that provides terminations for all field wiring required by the

XM-441.

1

4

4

0

E

X

P

A

N

S

I

O

N

R

E

L

A

Y

-

R

E

X

0

0

0

-

4

R

D

XM-441 Expansion Relay Module

Cat. No. 1440-REX00-04RD

Using this Manual

• XM-441 Expansion Relay Module - Mounts on the XM-943 terminal

base unit via a keyswitch and a 96-connector. The XM-441 contains four

on-board relays to expand relay capabilities to the XM module to which

it is connected.

IMPORTANT

The host XM module controls the operation of the relays

in the Expansion Relay module. Refer to the manual for the

specific module for configuration information.

This manual introduces you to the XM-441 Relay Expansion module. It is

intended for anyone who installs or uses the XM-441 Relay Expansion

module.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 9

Introduction 9

Organization

To help you navigate through this manual, it is organized in chapters based on

these tasks and topics.

Chapter 1 “Introduction” contains an overview of this manual and the

XM-441 module

Chapter 2 “Installing the XM-441 Expansion Relay Module” describes how to

install, wire, and use the XM-441 module.

Appendix A “Specifications” lists the technical specifications for the XM-441

module.

For definitions of terms used in this Guide, see the Glossary at the end of the

Guide.

Document Conventions

There are several document conventions used in this manual, including the

following:

The XM-441 Expansion Relay module is referred to as XM-441, Expansion

Relay module, device, or module throughout this manual.

TIP

EXAMPLE

A tip indicates additional information which may be

helpful.

This convention presents an example.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 10

10 Introduction

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 11

Chapter

2

Installing the XM-441 Expansion Relay

Module

This chapter discusses how to install and wire the XM-441 Expansion Relay

module. It also describes the module indicators and the basic operations of the

module.

For information about See page

XM Installation Requirements 12

Mounting the Terminal Base Unit 16

Connecting Wiring for Your Module 19

Mounting the Module 25

Module Indicators 26

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

Industrial environment, in overvoltage Category II applications

(as defined in IED publication 60664–1), at altitudes up to 2000

meters without derating.

This equipment is supplied as “open type” equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present, and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC publication

60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosures.

11Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 12

12 Installing the XM-441 Expansion Relay Module

XM Installation Requirements

This section describes wire, power and grounding requirements for an XM

system.

Wiring Requirements

Use solid or stranded wire. All wiring should meet the following requirements:

• 14 to 22 AWG copper conductors without pretreatment; 8 AWG

required for grounding the DIN rail for electromagnetic interference

(emi) purposes

• Recommended strip length 8 millimeters (0.31 inches)

• Minimum insulation rating of 300V

• Soldering the conductor is forbidden

• Wire ferrules can be used with stranded conductors; copper ferrules

recommended

ATTENTION

See the XM Documentation and Configuration Utility CD

for Hazardous Locations installation drawings. The XM

Documentation and Configuration Utility CD is packaged

with the XM modules.

Power Requirements

Before installing your module, calculate the power requirements of all modules

interconnected via their side connectors. The total current draw through the

side connector cannot exceed 3A. Refer to the specifications for the specific

modules for power requirements.

ATTENTION

A separate power connection is necessary if the total

current draw of the interconnecting modules is greater than

3A.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 13

Installing the XM-441 Expansion Relay Module 13

IMPORTANT

Power connections are not made directly to the XM-441

module. Rather power is passed via the side connector

from the Expansion Module's host module. Refer to that

module's User Manual for further details on power

requirements.

Grounding Requirements

Use these grounding requirements to ensure safe electrical operating

circumstances, and to help avoid potential emi and ground noise that can cause

unfavorable operating conditions for your XM system.

DIN Rail Grounding

The XM modules make a chassis ground connection through the DIN rail.

The DIN rail must be connected to a ground bus or grounding electrode

conductor using 8 AWG or 1 inch copper braid. See Figure 2.1.

Use zinc-plated, yellow-chromated steel DIN rail (Allen-Bradley part no.

199-DR1 or 199-DR4) or equivalent to assure proper grounding. Using other

DIN rail materials (e.g. aluminum, plastic, etc.), which can corrode, oxidize, or

are poor conductors can result in improper or intermittent platform

grounding.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 14

14 Installing the XM-441 Expansion Relay Module

Figure 2.1 XM System DIN Rail Grounding

1

Power

Supply

DYNAMIC MEASUREMENT

MASTER RELAY

1440-VST02-01RA

1440-RMA00-04RC

EXPANSION RELAY

EXPANSION RELAY

1440-REX00-04RD

1440-REX00-04RD

DYNAMIC MEASUREMENT

POSITION

1440-VST02-01RA

1440-TSP02-01RB

EXPANSION RELAY

EXPANSION RELAY

1440-REX00-04RD

1440-REX00-04RD

1

Power

Supply

DYNAMIC MEASUREMENT

1440-VST02-01RA

EXPANSION RELAY

1440-REX00-04RD

1 Use 14 AWG wire.

The grounding wire can be connected to the DIN rail using a DIN Rail

Grounding Block (Figure 2.2).

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

DYNAMIC MEASUREMENT

1440-VST02-01RA

EXPANSION RELAY

1440-REX00-04RD

Page 15

Figure 2.2 DIN Rail Grounding Block

Installing the XM-441 Expansion Relay Module 15

Panel/Wall Mount Grounding

The XM modules can also be mounted to a conductive mounting plate that is

grounded. See Figure 2.4. Use the grounding screw hole provided on the

terminal base to connect the mounting plate the Chassis terminals.

Figure 2.3 Grounding Screw on XM Terminal Base

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 16

16 Installing the XM-441 Expansion Relay Module

1

Figure 2.4 Panel/Wall Mount Grounding

Power

Supply

Mounting the Terminal Base Unit

1

Power

Supply

1 Use 14 AWG wire.

The XM family includes several different terminal base units to serve all of the

XM modules. The XM-943 terminal base, Cat. No. 1440-TB-D, is the only

terminal base unit used with the XM-441.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 17

Installing the XM-441 Expansion Relay Module 17

The terminal base can be DIN rail or wall/panel mounted. Refer to the

specific method of mounting below.

ATTENTION

The XM modules make a chassis ground connection

through the DIN rail. Use zinc plated, yellow chromated

steel DIN rail to assure proper grounding. Using other

DIN rail materials (e.g. aluminum, plastic, etc.), which can

corrode, oxidize or are poor conductors can result in

improper or intermittent platform grounding.

You can also mount the terminal base to a grounded

mounting plate. Refer to Panel/Wall Mount Grounding on

page 15.

DIN Rail Mounting

Use the following steps to mount the XM-943 terminal base unit on a DIN rail

(A-B pt no. 199-DR1 or 199-DR4).

IMPORTANT

The XM-943 terminal base unit is mounted to the right of

the XM module to which it is providing additional relays.

1. Position the terminal base on the 35 x 7.5mm DIN rail (A).

Position terminal base at a slight angle and hook over the top of the DIN rail.

2. Make certain the side connector (B) if fully retracted into the base unit.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 18

18 Installing the XM-441 Expansion Relay Module

3. Slide the terminal base unit over tight against the neighboring terminal

base. Make sure the hook on the terminal base slides under the edge of

the adjacent base and the side connector is fully retracted.

4. Rotate the terminal base onto the DIN rail with the top of the rail

hooked under the lip on the rear of the terminal base.

5. Press down on the terminal base unit to lock the terminal base on the

DIN rail. If the terminal base does not lock into place, use a screwdriver

or similar device to open the locking tab, press down on the terminal

base until flush with the DIN rail and release the locking tab to lock the

base in place.

6. Gently push the side connector into the side of the neighboring terminal

base to complete the backplane connection.

7. Repeat the above steps to install another Expansion Relay terminal base

unit. Up to two Expansion Relay modules can be added to each XM-440

Master Relay module.

Panel/Wall Mounting

Installation on a wall or panel consists of:

• laying out the drilling points on the wall or panel

• drilling the pilot holes for the mounting screws

• installing the terminal base units and securing them to the wall or panel

Use the following steps to install the XM-943 terminal base on a wall or panel.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 19

Side Connector

Installing the XM-441 Expansion Relay Module 19

1. Lay out the required points on the wall/panel as shown in the drilling

dimension drawing below.

Connecting Wiring for Your Module

2. Drill the necessary holes for the #6 self-tapping mounting screws.

3. Retract the side connector into the base unit. Make sure it is fully

retracted.

4. Position the terminal base unit up tight against the neighboring terminal

base. Make sure the hook on the terminal base slides under the edge of

the terminal base unit.

5. Gently push the side connector into the side of the neighboring terminal

base to complete the backplane connection.

6. Secure the terminal base to the wall with two #6 self-tapping screws.

7. Repeat the above steps to install another Expansion Relay terminal base

unit. Up to two Expansion Relay modules can be added to each XM-440

Master Relay module.

Wiring to the module is made through the terminal base unit on which the

module mounts. The XM-441 is compatible only with the XM-943 terminal

base unit, Cat. No. 1440-TB-D.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 20

20 Installing the XM-441 Expansion Relay Module

Figure 2.5 XM-942 Terminal Base Unit

XM-943, Cat. No. 1440-TB-D

Terminal Block Assignments

The terminal block assignments and descriptions for the XM-441 module are

shown below.

ATTENTION

The terminal block assignments are different for different

XM modules. The following table applies only to the

XM-441. Refer to the installation instructions for the

specific XM module for its terminal assignments.

WARNING

EXPLOSION HAZARD

Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connections that mate

to this equipment by using screws, sliding latches, threaded

connectors, or other means provided with this product.

Terminal Assignments

No. Name Description

0 No Connection

1 No Connection

2 No Connection

3 Reserved

4 Relay 1 N.O. 2 Relay #1 Normally Open contact 2

5 Relay 1 N.O. 1 Relay #1 Normally Open contact 1

6 Relay 2 N.O. 2 Relay # 2 Normally Open contact 2

7 No Connection

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 21

Installing the XM-441 Expansion Relay Module 21

Terminal Assignments

No. Name Description

8 Relay 2 N.O. 1 Relay # 2 Normally Open contact 1

9 Relay 3 N.O. 2 Relay #3 Normally Open contact 2

10 No Connection

11 Relay 3 N.O. 1 Relay #3 Normally Open contact 1

12 Relay 4 N.O. 2 Relay #4 Normally Open contact 2

13 Relay 4 N.O. 1 Relay #4 Normally Open contact 1

14 No Connection

15 Chassis Connection to DIN rail ground spring or panel mounting hole

16 No Connection

17 No Connection

18 No Connection

19 No Connection

20 Relay 1 Common 2 Relay #1 Common contact 2

21 Relay 1 Common 1 Relay #1 Common contact 1

22 Relay 2 Common 2 Relay #2 Common contact 2

23 No Connection

24 Relay 2 Common 1 Relay #2 Common contact 1

25 Relay 3 Common 2 Relay #3 Common contact 2

26 No Connection

27 Relay 3 Common 1 Relay #3 Common contact 1

28 Relay 4 Common 2 Relay #4 Common contact 2

29 Relay 4 Common 1 Relay #4 Common contact 1

30 No Connection

31 Chassis Connection to DIN rail ground spring or panel mounting hole

32

33

DNet V (+)

CAN_High

1

1

DeviceNet bus power input, positive side (red wire)

DeviceNet bus connection, high differential (white wire)

34 No Connection

35 No Connection

36 No Connection

37 No Connection

38 Relay 1 N.C. 2 Relay #1 Normally Closed contact 2

39 Relay 1 N.C. 1 Relay #1 Normally Closed contact 1

40 Relay 2 N.C. 2 Relay #2 Normally Closed contact 2

41 No Connection

42 Relay 2 N.C. 1 Relay #2 Normally Closed contact 1

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 22

22 Installing the XM-441 Expansion Relay Module

No. Name Description

43 Relay 3 N.C. 2 Relay #3 Normally Closed contact 2

44 No Connection

45 Relay 3 N.C. 1 Relay #3 Normally Closed contact 1

46 Relay 4 N.C. 2 Relay #4 Normally Closed contact 2

47 Relay 4 N.C. 1 Relay #4 Normally Closed contact 1

48 No Connection

49 Chassis Connection to DIN rail ground spring or panel mounting hole

50

51

Terminal Assignments

DNet V (-)

CAN_Low

1 DeviceNet communication is not used by the XM-943 but DeviceNet connections are available on the terminal

base unit and the side connector.

1

1

DeviceNet bus power input, negative side (black wire)

DeviceNet bus connection, low differential (blue wire)

Power Supply

The host XM module provides power, via the side connector, for the XM-441

module.

Connecting the Relays

The XM-441 has both Normally Open (NO) and Normally Closed (NC) relay

contacts. Normally Open relay contacts close when the control output is

energized. Normally Closed relay contacts open when the control output is

energized.

The alarms associated with the relay and whether the relay is normally

de-energized (non-failsafe) or normally energized (failsafe) depends on the

configuration of the module. Refer to the User Guide for the specific module

for a description of the Relay parameters.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 23

Installing the XM-441 Expansion Relay Module 23

There are four double pole double throw relays in the XM-441. All relay

contacts (24 total) are available for wiring at the terminal base unit, as shown in

Table 2.1 on the page 23.

IMPORTANT

All XM relays are double pole. This means that each relay

has two contacts in which each contact operates

independently but identically. The following information

and illustrations show wiring solutions for both contacts;

although, in many applications it may be necessary to wire

only one contact.

IMPORTANT

The NC/NO terminal descriptions (pages 20–22)

correspond to a de-energized (unpowered) relay.

When the relay is configured for non-failsafe operation, the

relay is normally de-energized.

When the relay is configured for failsafe operation, the

relay is normally energized, and the behavior of the NC and

NO terminals is inverted.

Table 2.1 Relay Connections for XM-441

Configured for

Failsafe Operation Relay 1 Terminals Relay 2 Terminals Relay 3 Terminals Relay 4 Terminals

Nonalarm Alarm Wire Contacts Contact 1 Contact 2 Contact 1 Contact 2 Contact 1 Contact 2 Contact 1 Contact 2

Closed Opened COM 21 20 24 22 27 25 29 28

NO 5 4 8 6 11 9 13 12

Opened Closed COM 21 20 24 22 27 25 29 28

NC 39 38 42 40 45 43 47 46

Configured for

Non-failsafe Operation Relay 1 Terminals Relay 2 Terminals Relay 3 Terminals Relay 4 Terminals

Nonalarm Alarm Wire Contacts Contact 1 Contact 2 Contact 1 Contact 2 Contact 1 Contact 2 Contact 1 Contact 2

Closed Opened COM 21 20 24 22 27 25 29 28

NC 39 38 42 40 45 43 47 46

Opened Closed COM 21 20 24 22 27 25 29 28

NO 5 4 8 6 11 9 13 12

Figures 2.6 and 2.7 illustrate the behavior of the NC and NO terminals when

the relay is wired for failsafe, alarm or nonalarm condition or non-failsafe,

alarm or nonalarm condition.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 24

24 Installing the XM-441 Expansion Relay Module

Figure 2.6 Relay Connection - Failsafe, Nonalarm Condition

Non-failsafe, Alarm Condition

Figure 2.7 Relay Connection - Failsafe Alarm Condition

Non-failsafe, Nonalarm Condition

Alternate Relay Wiring

Figures 2.8 and 2.9 show how to wire both ends of a single external indicator

to the XM terminal base for failsafe, nonalarm or alarm condition or

non-failsafe, nonalarm or alarm condition.

Figure 2.8 Relay Connection - Failsafe, Nonalarm Condition

Non-failsafe, Alarm Condition

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 25

Installing the XM-441 Expansion Relay Module 25

Figure 2.9 Relay Connection - Failsafe, Alarm Condition

Non-failsafe, Alarm Condition

Mounting the Module

The XM-441 mounts on the XM-943 terminal base unit, Cat. No. 1440-TB-D.

You should mount the module after you have connected the wiring on the

terminal base unit.

ATTENTION

The XM-441 is compatible only with the XM-943 terminal

base unit. The keyswitch on the terminal base unit should

be at position 3 for the XM-441.

Do not attempt to install XM-441 modules on other

terminal base units.

Do not change the position of the keyswitch after

wiring the terminal base.

ATTENTION

This module is designed so you can remove and insert it

under power. However, when you remove or insert the

module with power applied, I/O attached to the module

can change states due to its input/output signal changing

conditions. Take special care when using this feature.

WARNING

When you insert or remove the module while power is on,

an electrical can occur. This could cause an explosion in

hazardous location installations. Be sure that power is

removed or the area is nonhazardous before proceeding.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 26

26 Installing the XM-441 Expansion Relay Module

1. Make certain the keyswitch (A) on the terminal base unit (C) is at

position 3 as required for the XM-441.

Module Indicators

2. Make certain the side connector (B) is pushed all the way to the left. Yo u

cannot install the module unless the connector is fully extended.

3. Make sure that the pins on the bottom of the module are straight so they

will align properly with the connector in the terminal base unit.

4. Position the module (D) with its alignment bar (E) aligned with the

groove (F) on the terminal base.

5. Press firmly and evenly to seat the module in the terminal base unit. The

module is seated when the latching mechanism (G) is locked into the

module.

6. Repeat the above steps to install the next XM-441 module in its terminal

base.

The XM-441 has a power status indicator (PWR) that is on when power is

applied to the module and an activation status indicator for each relay (four in

all). The indicators are located on top of the module.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 27

Figure 2.10 LED Indicators

Installing the XM-441 Expansion Relay Module 27

Module Indicators

EXPANSION RELAY

1440-REX00-04RD

The following tables describe the states of the LED status indicators.

Power Status Indicator

Color State Description

No color Off No power applied to the module.

Green Solid Power applied to the module.

Relay Indicators (4 in all)

Color State Description

Red Off On-board relay is not activated.

Solid On-board relay is activated.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 28

28 Installing the XM-441 Expansion Relay Module

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 29

Appendix

Specifications

The Appendix lists the technical specifications for the XM-441 module.

XM-441 Technical Specifications

Product Feature Specification

Communications

Communication interface is via the side

connector between the XM-441 and the XM

module mounted directly to the left of the

XM-441.

A

Indicators

Relays

Side Connector

5 LEDs Module Power -green

Number

Contacts

All XM measurement and relay modules

include side connectors that allow

interconnecting adjacent modules, thereby

simplifying the external wiring

requirements.

The interconnect provides primary power,

DeviceNet communication, and the circuits

necessary to support expansion modules,

such as the XM-441 Expansion Relay

module.

NOTE: DeviceNet protocol, which is not used by

the XM-441, and primary power are passed

through the module’s terminal base to modules

connected on either side of the XM-441.

Relay 1 - red

Relay 2 - red

Relay 3 - red

Relay 4 - red

Four relays, two sets of contacts each DPDT (2 Form C)

250V AC, 50/60 Hz, 3 A Resistive

Failsafe

These features are managed/controlled by

the host XM module. Refer to the applicable

XM module’s specification for details on

these features:

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Normally energized (failsafe), or

Normally de-energized (non-failsafe)

Latching

Time Delay

Voting Logic

Reset

Activation

Page 30

30 Specifications

XM-441 Technical Specifications

Product Feature Specification

Power

Module

24V DC

Consumption

Heat Production

Environmental

Operating Temperature

Storage Temperature

Relative Humidity

Physical

Dimensions

Terminal Screw Torque

Approvals

(when product or packaging is marked)

120mA maximum

2.9 Watts (9.9 BTU/hr) maximum

-20 to +65°C (-4 to +149°F)

-40 to +85°C (-40 to +185°F)

95% non-condensing

All printed circuit boards are conformally coated

in accordance with IPC-A-610C,

Height: 3.8in (97mm)

Width: 3.7in (94mm)

Depth: 3.7in (94mm)

7 pound-inches (0.6Nm)

UL UL Listed for Ordinary

Locations

UL UL Listed for Class I, Division 2

Group A, B, C, and D Hazardous

Locations

CSA CSA Certified Process Control

Equipment

CSA CSA Certified Process Control

Equipment for Class I, Division

2 Group A, B, C, and D

Hazardous Locations

EEX* European Union 94/9/EEC ATEX

Directive, compliant with EN

50021; Potentially Explosive

Atmospheres, Protection “n”

CE* European Union 89/336/EEC

C-Tick* Australian

* See the Product Certification link at

www.rockwellautomation.com for

Declarations of Conformity, Certificates and

other certification details.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

EMC Directive

Radiocommunications Act,

compliant with:

AS/NZS 2064, Industrial

Emissions

Page 31

Glossary

alarm

An alarm alerts you to a change in a measurement. For example, an alarm can

notify you when the measured vibration level for a machine exceeds a

pre-defined value.

Automatic Device Replacement (ADR)

A means for replacing a malfunctioning device with a new unit, and having the

device configuration data set automatically. The ADR scanner uploads and

stores a device’s configuration. Upon replacing a malfunctioning device with a

new unit (MAC ID 63), the ADR scanner automatically downloads the

configuration data and sets the MAC ID (node address).

baud rate

The baud rate is the speed at which data is transferred on the DeviceNet

network. The available data rates depend on the type of cable and total cable

length used on the network:

Maximum Cable Length

Cable 125K 250K 500K

Thick Trunk Line 500m (1,640ft.) 250m (820ft.) 100m (328ft.)

Thin Trunk Line 100m (328ft.) 100m (328ft.) 100m (328ft.)

Maximum Drop Length 6m (20ft.) 6m (20ft.) 6m (20ft.)

Cumulative Drop Length 156m (512ft.) 78m (256ft.) 39m (128ft.)

The XM measurement modules’ baud rate is automatically set by the bus

master. You must set the XM-440 Relay module baud rate. You set the

XM-440 Relay Master to 125kb, 250kb, 500kb, or Autobaud if another device

on the network has set the baud rate.

bus off

A bus off condition occurs when an abnormal rate of errors is detected on the

Control Area Network (CAN) bus in a device. The bus-off device cannot

receive or transmit messages on the network. This condition is often caused by

corruption of the network data signals due to noise or baud rate mismatch.

Change of State (COS)

DeviceNet communications method in which the XM module sends data

based on detection of any changed value within the input data (alarm or relay

status).

31Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 32

32 Glossary

current configuration

The current configuration is the most recently loaded set of configuration

parameters in the XM module’s memory. When power is cycled, the current

configuration is loaded with either the saved configuration (in EEPROM) or

the factory defaults (if there is no saved configuration). In addition, the current

configuration contains any configuration changes that have been downloaded

to the module since power was applied.

DeviceNet network

A DeviceNet network uses a producer/consumer Controller Area Network

(CAN) to connect devices (for example, XM modules). A DeviceNet network

can support a maximum of 64 devices. Each device is assigned a unique node

address (MAC ID) and transmits data on the network at the same baud rate.

A cable is used to connect devices on the network. It contains both the signal

and power wires. General information about DeviceNet and the DeviceNet

specification are maintained by the Open DeviceNet Vendor’s Association

(ODVA). ODVA is online at http://www.odva.org.

EEPROM

See NVS (Non-Volatile Storage).

Electronic Data Sheet (EDS) Files

EDS files are simple text files that are used by network configuration tools

such as RSNetWorx for DeviceNet to describe products so that you can easily

commission them on a network. EDS files describe a product device type,

revision, and configurable parameters.

Help window

A window that contains help topics that describe the operation of a program.

These topics may include:

• An explanation of a command.

• A description of the controls in a dialog box or property page.

• Instructions for a task.

• Definition of a term.

MAC ID

See node address.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 33

Glossary 33

master device

A device which controls one or more slave devices. The XM-440 Master Relay

module is a master device.

node address

A DeviceNet network can have as many as 64 devices connected to it. Each

device on the network must have a unique node address between 0 and 63.

Node address 63 is the default used by uncommissioned devices. Node

address is sometimes called “MAC ID.”

NVS (Non-Volatile Storage)

NVS is the permanent memory of an XM module. Modules store parameters

and other information in NVS so that they are not lost when the module loses

power (unless Auto Save is disabled). NVS is sometimes called “EEPROM.”

online help

Online help allows you to get help for your program on the computer screen

by pressing F1. The help that appears in the Help window is context sensitive,

which means that the help is related to what you are currently doing in the

program.

Polled

DeviceNet communications method in which the module sends data in

response to a poll request from a master device.

slave device

A device that receives and responds to messages from a Master device but

does not initiate communication. Slave devices include the XM measurement

modules, such as the XM-120 Dynamic Measurement module and the XM-320

Position module.

virtual relay

A virtual relay is a non-physical relay. It has the same capabilities (monitor

alarms, activation delay, change status) as a physical relay only without any

physical or electrical output. The virtual relay provides additional relay status

inputs to a controller, PLC, and an XM440 Master Relay module (firmware

revision 5.0 and later).

XM configuration

XM configuration is a collection of user-defined parameters for XM modules.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 34

34 Glossary

XM Serial Configuration Utility Software

XM Serial Configuration Utility software is a tool for monitoring and

configuring XM modules. It can be run on computers running Windows 2000

service pack 2, Windows NT service pack 6, or Windows XP operating

systems.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 35

Index

C

components

terminal base XM-943

XM-441 Expansion Relay module 8

connecting wiring 19

relays 22

terminal base XM-943 19

8

D

description

terminal base XM-943

XM-441 module 8

DIN Rail Grounding Block 14

DIN rail grounding requirements 13

document conventions 9

8

G

grounding requirements 13

DIN rail 13

panel/wall mount 15

P

panel/wall mount grounding requirements 15

power requirements 12

Power Status indicator 27

R

relay contacts

normally closed

normally open 22

relay indicators 27

relays, wiring 22

22

S

specifications 29

T

terminal base

mounting on panel/wall

terminal base, mounting on DIN rail 16

terminal block assignment 20

18

I

indicators 26

Power Status 27

Relay 27

installation requirements

grounding

power 12

wiring 12

introduction 7

13

K

keyswitch 25

M

mounting

terminal base unit

terminal base unit on panel/walll 18

XM-441 module 25

16

N

normally closed relay contacts 22

normally open relay contacts 22

W

wiring

to terminal base

wiring connections

22

relays

wiring requirements 12

19

X

XM-441 Expansion Relay Module

components

description 8

grounding requirements 13

indicators 26

introduction 7

mounting 25

power requirements 12

specifications 29

wiring requirements 12

XM-943 terminal base

description

mounting 16

wiring 19

8

8

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 36

36 Index

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011

Page 37

Page 38

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

, available at http://www.rockwellautomation.com/literature/.

Rockwell Automation Publication GMSI10-UM019C-EN-P - June 2011 38

Supersedes Publication GMSI10-UM019B-EN-P - May 2010 Copyright © 2011 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...