Page 1

User Manual

XM-720 Machine Monitor

Catalog Numbers

1440-PK02-05M0, 1440-PK02-05M1, 1440-PK02-05M2

Page 2

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT

Allen-Bradley, Rockwell Software, Rockwell Automation, XM, and TechConnect are trademarks of Rockwell Automation, Inc.

DeviceNet is a trademark of the Open DeviceNet Vendor Association (ODVA).

Microsoft and Windows are registered trademarks of the Microsoft Corporation.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Page 3

Introduction

Installing the XM-720 Machine

Monitor

Table of Contents

Chapter 1

Introducing the XM-720 Machine Monitor . . . . . . . . . . . . . . . . . . . . . . 5

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Selecting a Location for the XM-720 Monitor. . . . . . . . . . . . . . . . 10

Hazardous Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting the XM-720 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cutout Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting the XM-720 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting Wiring for Your Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terminal Block Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting the Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting the Remote Relay Reset Signal . . . . . . . . . . . . . . . . . . 19

Connecting the Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting the Tachometer Signal. . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting the 4-20mA Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the Setpoint Multiplication Switch . . . . . . . . . . . . . . . 30

Front Panel Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Bargraph Meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

BNC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Removing the XM-720 Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . 35

Inserting the XM-720 Terminal Blocks . . . . . . . . . . . . . . . . . . . . . 36

Chapter 3

Configuring the XM-720

3 Publication GMSI10-UM001C-EN-E - June 2011

Installing XM Serial Configuration Utility . . . . . . . . . . . . . . . . . . . . . . 37

Downloading a Pre-Configured Configuration File . . . . . . . . . . . . . . . 39

Files to Use With Your XM-720 Monitor . . . . . . . . . . . . . . . . . . . 39

Download the Configuration File to the XM-120/121/122 . . . . . 41

Editing the XM-720 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Transducer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

gSE Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Alarm Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Relay Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-20mA Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Tachometer Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 4

Table of Contents 4

Specifications

Comparing Connections Between

the 5802 and the XM-720

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Appendix B

Power Supply & Relay Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Signal Conditioner Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Glossary

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Publication GMSI10-UM001C-EN-E - June 2011

Page 5

Chapter

1

Introduction

This chapter provides an overview of the XM-720 Machine Monitor. It also

discusses the components of the monitor.

For information about See page

Introducing the XM-720 Machine Monitor 5

System Description 6

Using this Manual 7

The XM-720 Machine Monitor is referred to as XM-720 or monitor

throughout this manual.

Introducing the XM-720 Machine Monitor

Catalog Number Measures Includes the following XM Modules

1440-PK02-05M0 Standard dynamic vibration XM-120 Dynamic Measurement Module

1440-PK02-05M1 Low frequency dynamic vibration XM-121 Low Frequency Dynamic Measurement Module

1440-PK02-05M2 gSE™ vibration XM-122 gSE Vibration Module

The XM-720 monitor is a 2-channel machine monitor designed for monitoring

the condition of fans, pumps, motors, turbines, gear drives, and other

machines. The XM-720 is designed to be used with accelerometers, velocity

and non-contact sensors. It samples inputs, compares them to threshold

values, performs self-test routines, and provides outputs to bargraph displays,

relays, and LED indicator lights.

There are three variations of the XM-720 Machine Monitor:

Table 1.1 XM-720 Machine Monitor

XM-441 Expansion Relay Module

XM-441 Expansion Relay Module

XM-441 Expansion Relay Module

5 Publication GMSI10-UM001C-EN-E - June 2011

Page 6

6 Introduction

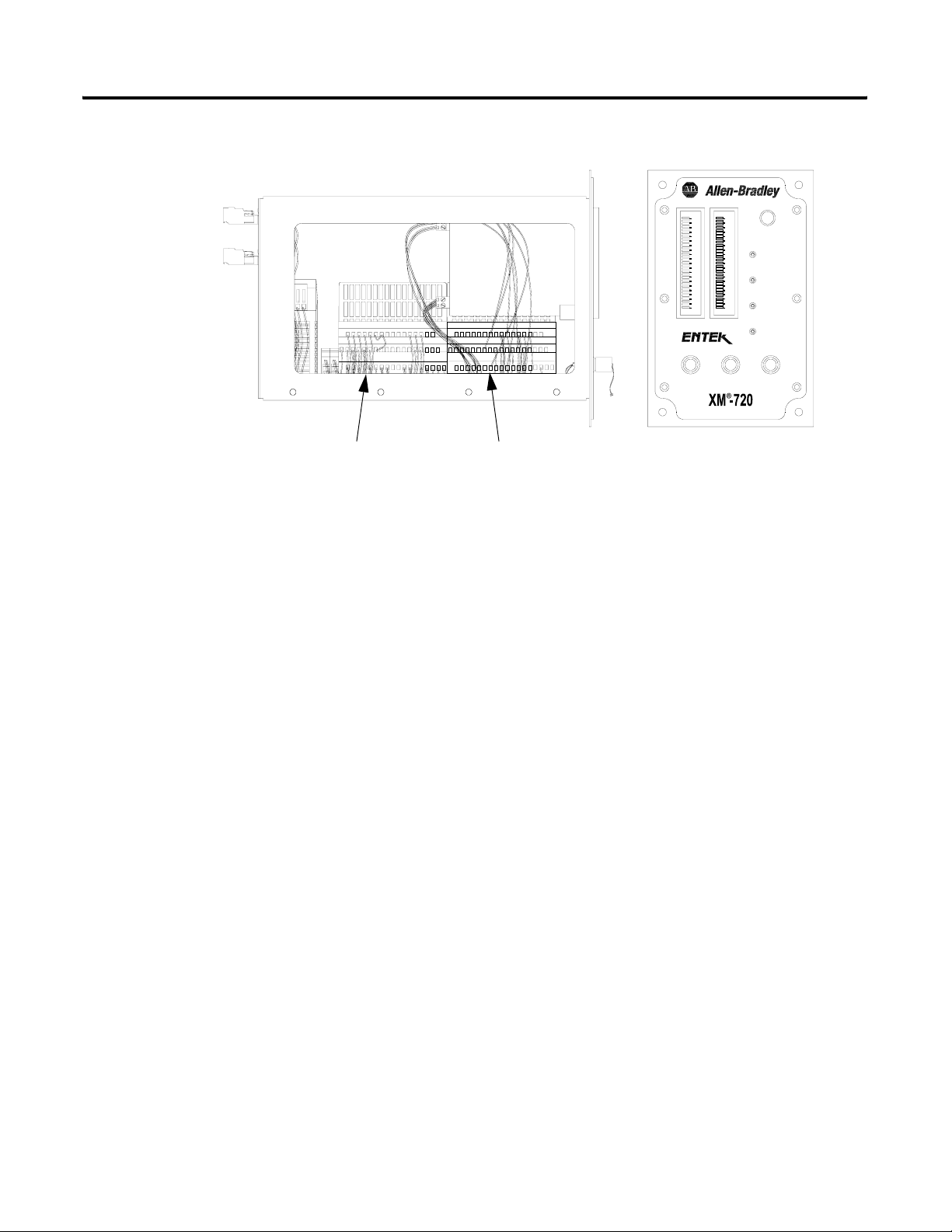

Figure 1.1 XM-720 Front and Side View

123456789100

1617 1819 2021 2223 2425 2627 2829 3031 3233

3435 3637 3839 4041 4243 4445 4647 4849 5051

1112 1314 15

1617 1819 2021 2223 2425 2627 2829 3031 3233

3435 3637 3839 4041 4243 4445 4647 4849 5051

123456789100

XM-120/121/122 module XM-441 module

1112 1314 15

Each monitor offers:

100

100

75

50

25

0

%

Reset

75

Trip

50

Warning

25

Module

0

Fault

%

Xdcr

Fault

Tacho

CH 2CH 1

System Description

• two vibration transducer connections (eddy current probes,

accelerometers, velocity sensors, AC voltage output or DC voltage

output measurement devices)

• one tachometer input signal connection

• remote relay reset connection

• three relays available for module or transducer fault, warning and trip

• isolated 4-20mA per channel into a maximum load of 250 ohm

• three buffered output signals on the front panel BNC connectors

• two front panel digital meters

• four front panel LED indicators (module, transducer, warning, and trip

status)

The concept of machine monitoring is quite simple. During normal operation,

the machine’s "vital signs" remain within relatively narrow ranges. If a

mechanical problem develops, it will be reflected as a change in one or more of

these vital signs. This change will be detected by the XM-720 and cause an

alarm.

The monitoring system consists of a number of transducers connected to the

XM-720. The transducers installed on the machine convert the "vital signs" to

electrical signals that are transmitted to the XM-720 monitor.

Publication GMSI10-UM001C-EN-E - June 2011

The XM-720 accepts the signals from the transducers, processes and measures

the signals, and closes electrical relay contacts if one of the signals increases

too much. The relays can be connected to annunciators or to automatic

machine controls.

Page 7

Introduction 7

Using this Manual

This manual introduces you to the XM-720 Machine Monitor. It is intended

for anyone who installs, configures, or uses the XM-720 monitor.

Document Conventions

There are several document conventions used in this manual, including the

following:

The XM-720 Machine Monitor is referred to as XM-720 or monitor

throughout this manual.

TIP

EXAMPLE

A tip indicates additional information which may be

helpful.

This convention presents an example.

Publication GMSI10-UM001C-EN-E - June 2011

Page 8

8 Introduction

Publication GMSI10-UM001C-EN-E - June 2011

Page 9

Chapter

Installing the XM-720 Machine Monitor

This chapter discusses how to install and wire the XM-720 monitor. It also

describes the front panel of the monitor.

For information about See page

Package Contents 10

Installation Guidelines 10

Mounting the XM-720 Monitor 11

Connecting Wiring for Your Monitor 13

Front Panel Description 31

Removing the XM-720 Terminal Blocks 35

2

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

Industrial environment, in overvoltage Category II applications

(as defined in IEC publication 60664–1), at altitudes up to 2000

meters without derating.

This equipment is supplied as “open type” equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present, and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC publication

60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosures.

9 Publication GMSI10-UM001C-EN-E - June 2011

Page 10

10 Installing the XM-720 Machine Monitor

Package Contents

The XM-720 monitor is shipped with the following items:

• Monitor

Table 2.1 XM-720 Monitor

Cat. No. XM Measurement Module

1440-PK02-05M0 XM-120 Standard Dynamic Vibration Module

1440-PK02-05M1 XM-121 Low Frequency Dynamic Vibration Module

1440-PK02-05M2 XM-122 gSE™ Vibration Module

• USB-style RS-232 serial cable

• XM Documentation and Configuration Utility CD-ROM disk, which

contains the manuals, XM Serial Configuration Utility software,

Hazardous Locations installation drawings, and XM-720 configuration

files.

• Meter caption sheet

• Mounting template sheet

Installation Guidelines

Selecting a Location for the XM-720 Monitor

IMPORTANT

The XM-720 monitor is designed for panel mounting in a control room or

local mounting in an enclosure for ready access to the front panel by operating

personnel. When selecting a location for the monitor, keep in mind that it is a

complex electronic device. It is designed and manufactured to withstand quite

severe environmental conditions, but as with any electronic equipment, it will

give the longest, trouble-free service if treated with care.

The selected location should not subject the monitor to dripping water from

above, or to heat from equipment installed beneath it.

This product is an open type component and shall be

installed in a suitable grounded enclosure accepted by local

authority having jurisdiction.

Publication GMSI10-UM001C-EN-E - June 2011

Page 11

Installing the XM-720 Machine Monitor 11

Hazardous Locations

Due to the proximity of some control rooms to process machinery, the control

room interior may be designated as a hazardous area within the definition of

Article 500 of the (U.S.) National Electrical Code, or similar codes in other

countries.

If the control room is classified as a Division 2 area (N.E.C.), present

interpretation of the code usually permits the operation of electrical equipment

if two conditions are met during normal operation:

1. Arcing or sparking contacts must not be exposed, and

2. No surface temperature may exceed 80% of the ignition temperature (in

°C) of the hazardous gas or vapor.

The XM-720 monitor meets the first requirement since all relay contacts are

hermetically sealed. The second requirement is met if ignition temperature of

the hazardous gas or vapor is above 200°C (392°F).

Mounting the XM-720 Monitor

ATTENTION

See the XM Documentation and Configuration Utility CD

for Hazardous Locations installation drawings. The XM

Documentation and Configuration Utility CD is packaged

with the XM-720.

Wiring

Use solid or stranded wire. All wiring should meet the following specifications:

• 12 to 28 AWG (0.08 to 2.5 mm

• Recommended strip length 8 to 9 millimeters (0.33 inches)

The XM-720 monitor is designed for installation in a wall, panel cutout, or

custom enclosure.

2

)

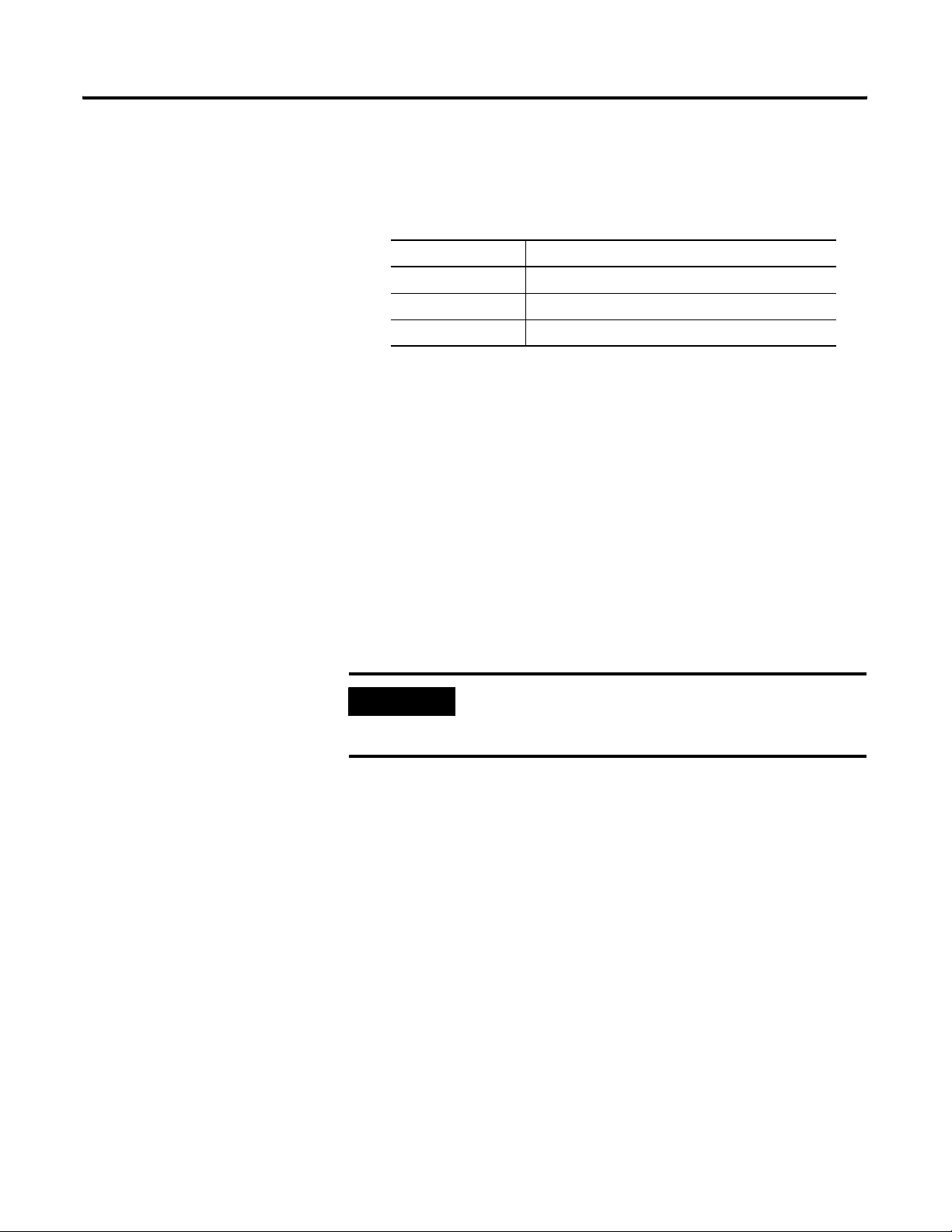

Mounting Dimensions

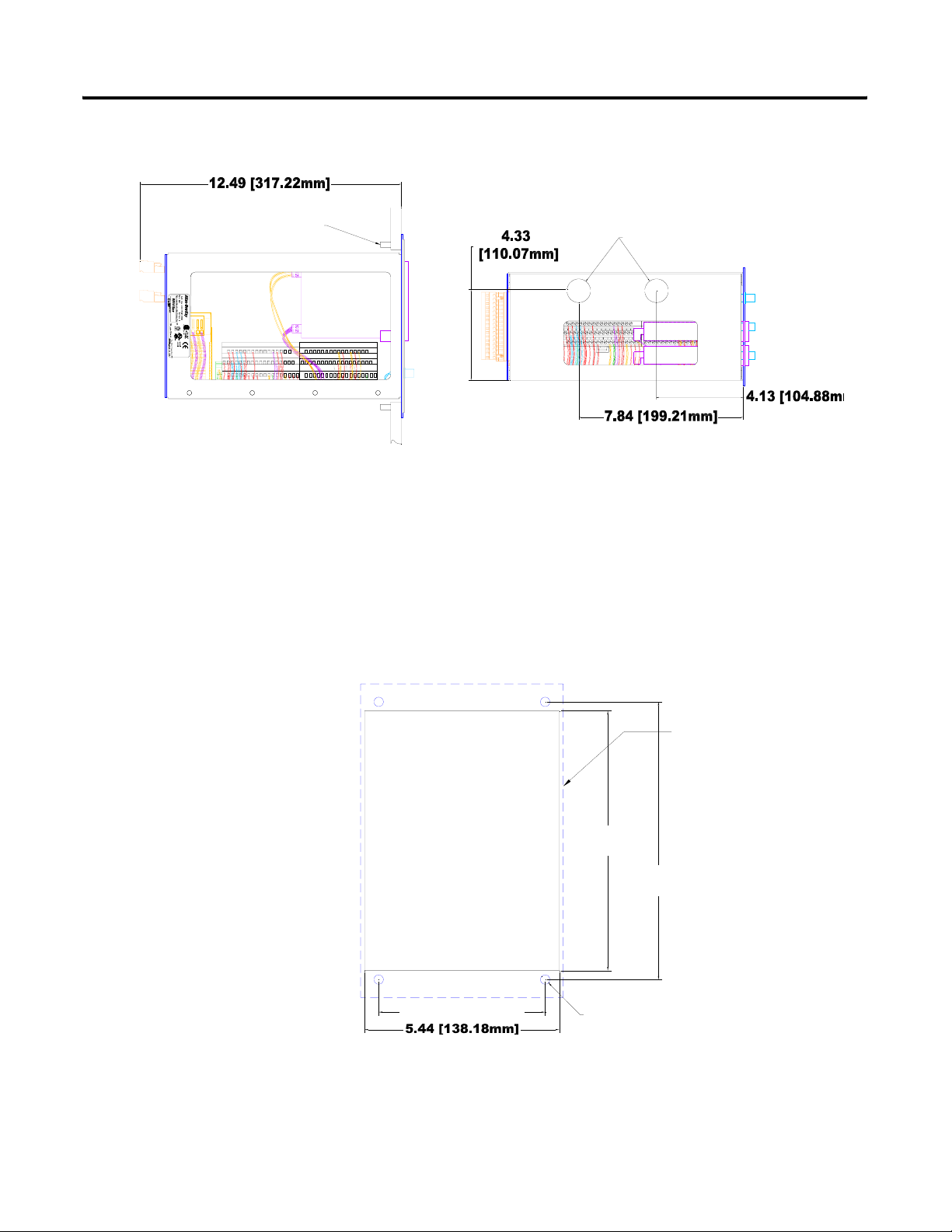

Figure 2.1 shows the dimensions of the XM-720 monitor, as well as the

reduced scale cutout. Use this to make sure you have adequate space to install

your monitor. All measurements are in inches [mm].

Publication GMSI10-UM001C-EN-E - June 2011

Page 12

12 Installing the XM-720 Machine Monitor

Figure 2.1 Mounting Dimensions and Side View

1/4" MOUNTING

SCREWS 4 PLACES

123456789100

16171819 2021 222324 252627 282930 313233

11121314 15 123456789100

34353637 383940 414243 444546 474849 5051

16171819 2021 222324 252627 282930 313233

34353637 383940 414243 444546 474849 5051

KNOCKOUTS FOR 3/4"

CONDUIT FITTINGS

LOCATED IN TOP OF CASE.

11121314 15

Cutout Dimension

Use the full size template shipped with the XM-720 monitor to mark the

cutout dimensions. The figure below shows a reduced scale cutout.

Figure 2.2 Cutout Dimensions

PANEL

CUTOUT

4.650 [118.11mm]

FRONT PANEL

7.25

[184.15mm]

7.75

[196.85mm]

Ø.26

4 PLACES

Publication GMSI10-UM001C-EN-E - June 2011

Page 13

Mounting the XM-720 Monitor

Installing the XM-720 Machine Monitor 13

ATTENTION

• Disconnect all electrical power from the panel before

making cutout.

• Make sure area around the panel cutout is clear.

• Take precautions so that metal cuttings do not enter any

components already installed in panel

• Failure to follow this warning may result in personal

injury or damage to the panel components.

Mount the monitor to the panel using four 1/4 inch mounting screws (not

included in shipment).

IMPORTANT

If you are installing the XM-720 monitor in an existing

cutout, skip to step 2.

1. Cut an opening in the panel and drill four holes for the mounting screws

using the cutout template provided with the XM-720 monitor. Remove

sharp edges or burrs.

2. Slide the XM-720 monitor through the opening.

Connecting Wiring for Your Monitor

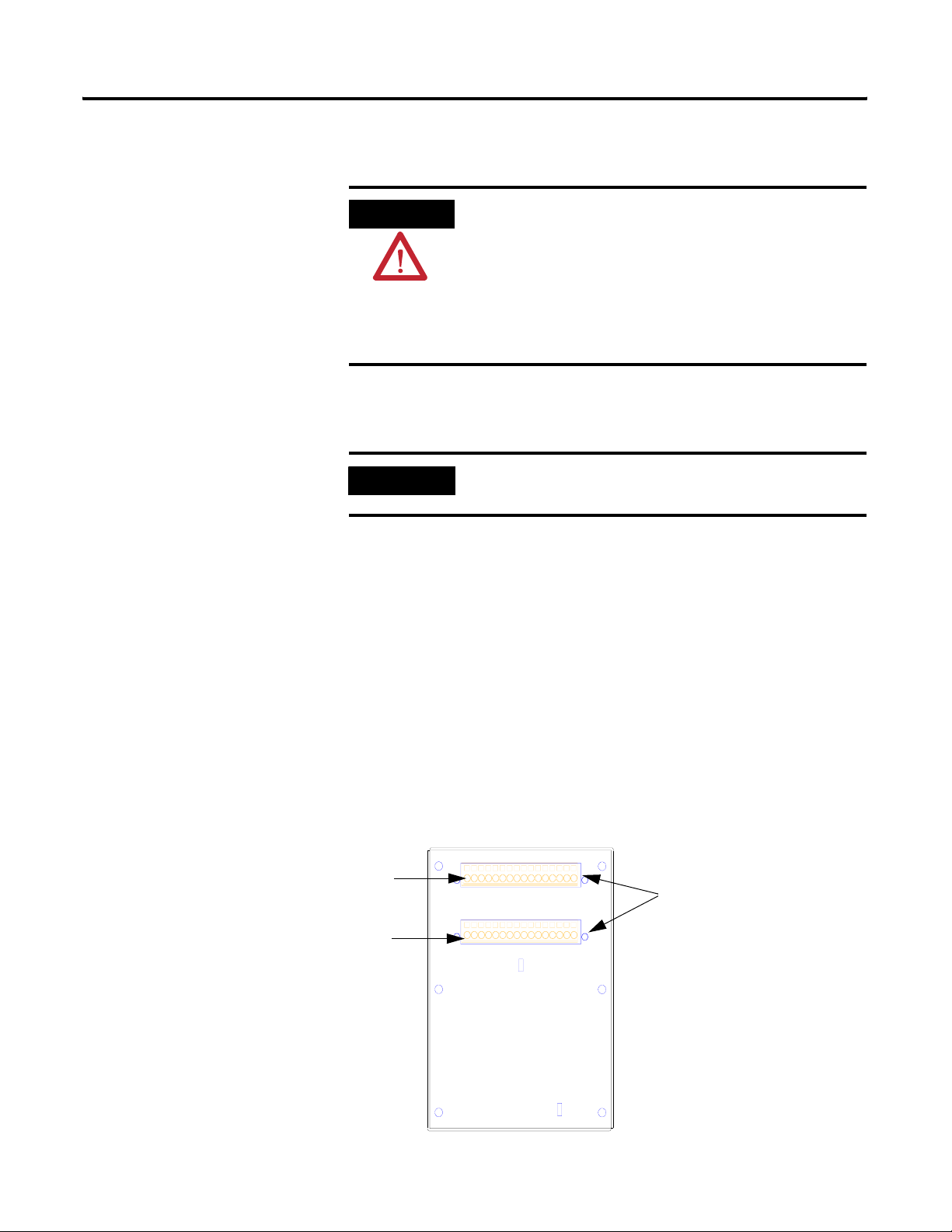

Terminal Block (TB) 1

Terminal Block (TB) 2

3. Install and alternately tighten the mounting screws until the monitor is

held firmly against the panel.

Wiring to the monitor is made through the two-single row, removable terminal

blocks located on the back panel of the XM-720 monitor. See Figure 2.3

Figure 2.3 XM-720 Back Panel

9

78654NLE

25 32313027 28 292621 23 242220191817

16151411 131210

Removable Terminal

Blocks (RTB)

Publication GMSI10-UM001C-EN-E - June 2011

Page 14

14 Installing the XM-720 Machine Monitor

The XM-720 terminal blocks have spring clamp connectors. Follow these

steps to connect wiring to the back panel connectors.

IMPORTANT

The XM-720 terminal plugs are keyed so they will only fit

into the corresponding socket. Be certain that you are

connecting the wires to the correct connectors.

1. Insert a 1/8" [3.5 mm] wide blade-type screwdriver into the slot above

the selected wiring port.

2. Insert the wire into the open terminal while holding the screwdriver up.

3. Remove the drive blade to secure the wire.

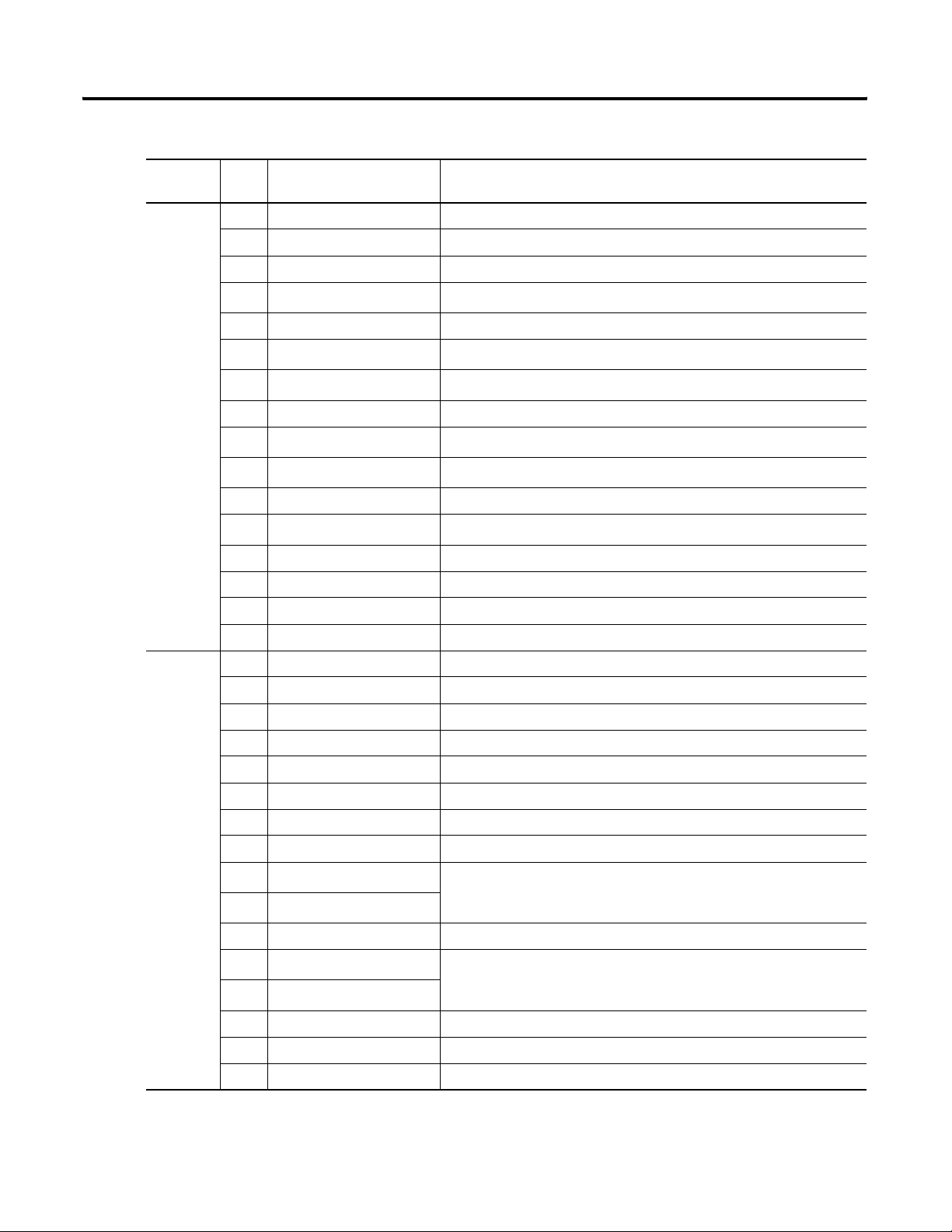

Terminal Block Assignments

The terminal block assignments and descriptions for the XM-720 monitor are

shown in Table 2.2.

WARNING

EXPLOSION HAZARD

Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connections that mate

to this equipment by using screws, sliding latches, threaded

connectors, or other means provided with this product.

Publication GMSI10-UM001C-EN-E - June 2011

Page 15

Terminal

Block

TB1

(top)

Installing the XM-720 Machine Monitor 15

Table 2.2 Terminal Block Assignments

No. Name Description

E AC Earth Ground AC equipment earth ground

L AC Input Line AC power (hot)

N AC Input Neutral AC common (neutral)

4

Fault Relay NC

1

Normally Closed contact for Module/Transducer Fault relay

5 Fault Relay Common Common for Module/Transducer Fault relay

6

7

Fault Relay NO

Warning Relay NO

1

2

Normally Open contact for Module/Transducer Fault relay

Normally Open contact for Warning relay

8 Warning Relay Common Common for Warning relay

9

10

Warning Relay NC

Trip Relay NO

2

2

Normally Closed contact for Warning relay

Normally Open contact for Trip relay

11 Trip Relay Common Common for Trip relay

12

Trip Relay NC

2

Normally Closed contact for Trip relay

13 Reset Relay Switch Switch input to reset internal relays

TB2

(bottom)

14 Switch RTN Switch return for Reset Relay and Setpoint Multiplier switch

15 Setpoint Multiplier Switch Switch input to activate Setpoint Multiplication (active open)

16 24V Common Tachometer 24V power return

17 Xducer 1 (+) Vibration transducer channel 1 connection

18 Xducer 1 (-) Vibration transducer channel 1 connection

19 Chassis GND Connection to chassis ground (channel 1 shield)

20 Xducer 2 (+) Vibration transducer channel 2 connection

21 Xducer 2 (-) Vibration transducer channel 2 connection

22 Chassis GND Connection to chassis ground (channel 2 shield)

23 Xducer +24V Transducer power, positive side; used to power external sensor

24 Xducer -24V Transducer power, negative side; used to power external sensor

25

26

4-20mA 1 (+)

4-20mA 1 (-)

3

3

4-20mA output; channel 1

250 ohm maximum load

27 Chassis GND Connection to chassis ground (4-20mA outputs shield)

28

29

4-20mA 2 (+)

4-20mA 2 (-)

3

3

4-20mA output; channel 2

250 ohm maximum load

30 Tachometer In (+) Tachometer transducer/signal input, positive side

31 Tachometer In (-) Tachometer transducer/signal input, negative side

32 Chassis GND Connection to chassis ground (tachometer shield)

1 It is assumed that the relay is to be configured as failsafe.

2. It is assumed that the relay is to be configure as non-failsafe.

Publication GMSI10-UM001C-EN-E - June 2011

Page 16

16 Installing the XM-720 Machine Monitor

3 4-20mA operation requires a jumper at terminals 25 & 26 (or terminals 28 & 29) if 4-20mA output is not used.

Otherwise the associated meter on front panel will not function properly. Refer to Connecting the 4-20mA

Outputs on page 29 for more information.

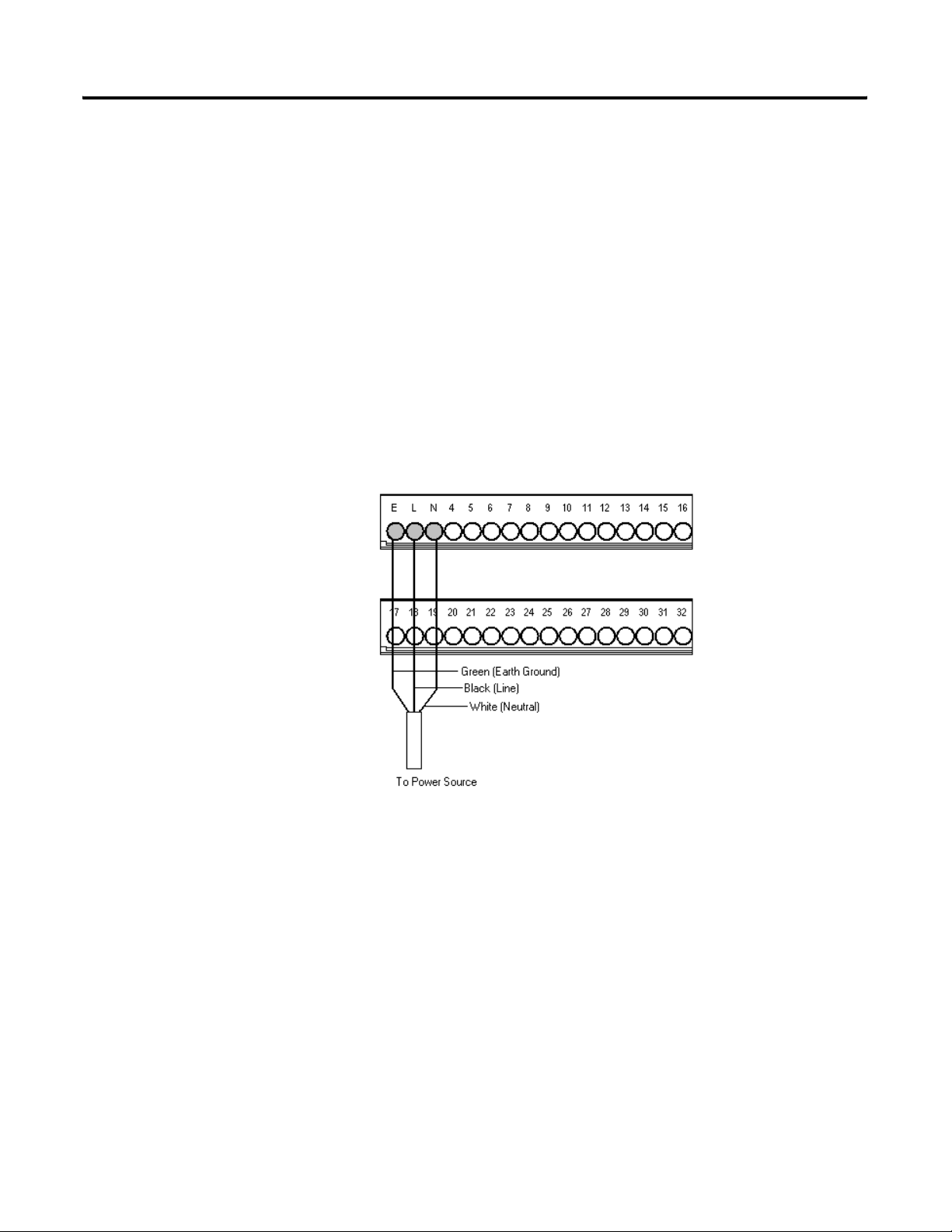

Connecting the Power Supply

The XM-720 monitor accepts inputs from 100-240V ac (47 to 63 Hz). The

internal power supply has internal (not accessible) input fuse. No other

protection is required. In order to meet local requirements, please consult local

codes and regulations for proper installation. Maximum rating of an

overcurrent protective device shall not exceed 15A.

Wire the AC power connections to the back panel as shown in Figure 2.4.

Figure 2.4 Power Supply Connection

Publication GMSI10-UM001C-EN-E - June 2011

Connecting the Relays

The XM-720 monitor has both Normally Open (NO) and Normally Closed

(NC) relay contacts. Normally Open relay contacts close when the control

output is energized. Normally Closed relay contacts open when the control

output is energized.

The alarms associated with the relay and whether the relay is normally

de-energized (non-failsafe) or normally energized (failsafe) depends on the

configuration of the monitor.

Page 17

Installing the XM-720 Machine Monitor 17

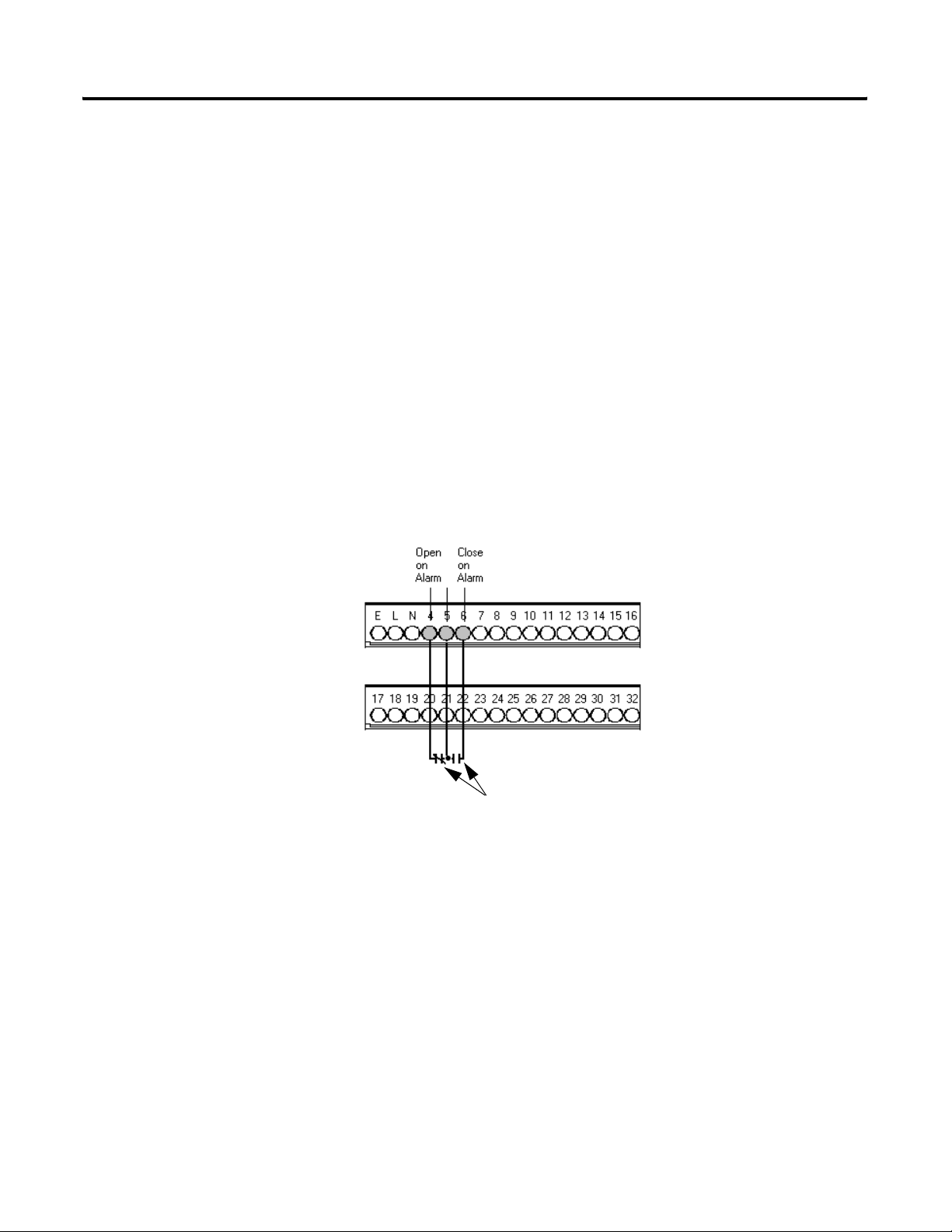

The XM-720 back panel terminal block is equipped with three single-pole,

double-throw relays. Figures 2.5 to 2.7 show the connection for the three

relays.

Module/Transducer Fault Relay

In the provided configuration files, the Fault relay is configured to be a failsafe

relay and is set up to activate if any one of the conditions occurs:

• There is a hardware or firmware failure.

• A transducer fault is detected on the associated transducer.

You can change the alarms associated with this relay as well as the behavior of

the relay using the XM Serial Configuration Utility. Refer to Editing the

XM-720 Parameters on page 44 for more information.

Figure 2.5 shows the on-board relay connection for the Fault relay.

Figure 2.5 Wiring Connection for Fault Relay (Failsafe)

Shown with power on

and no fault

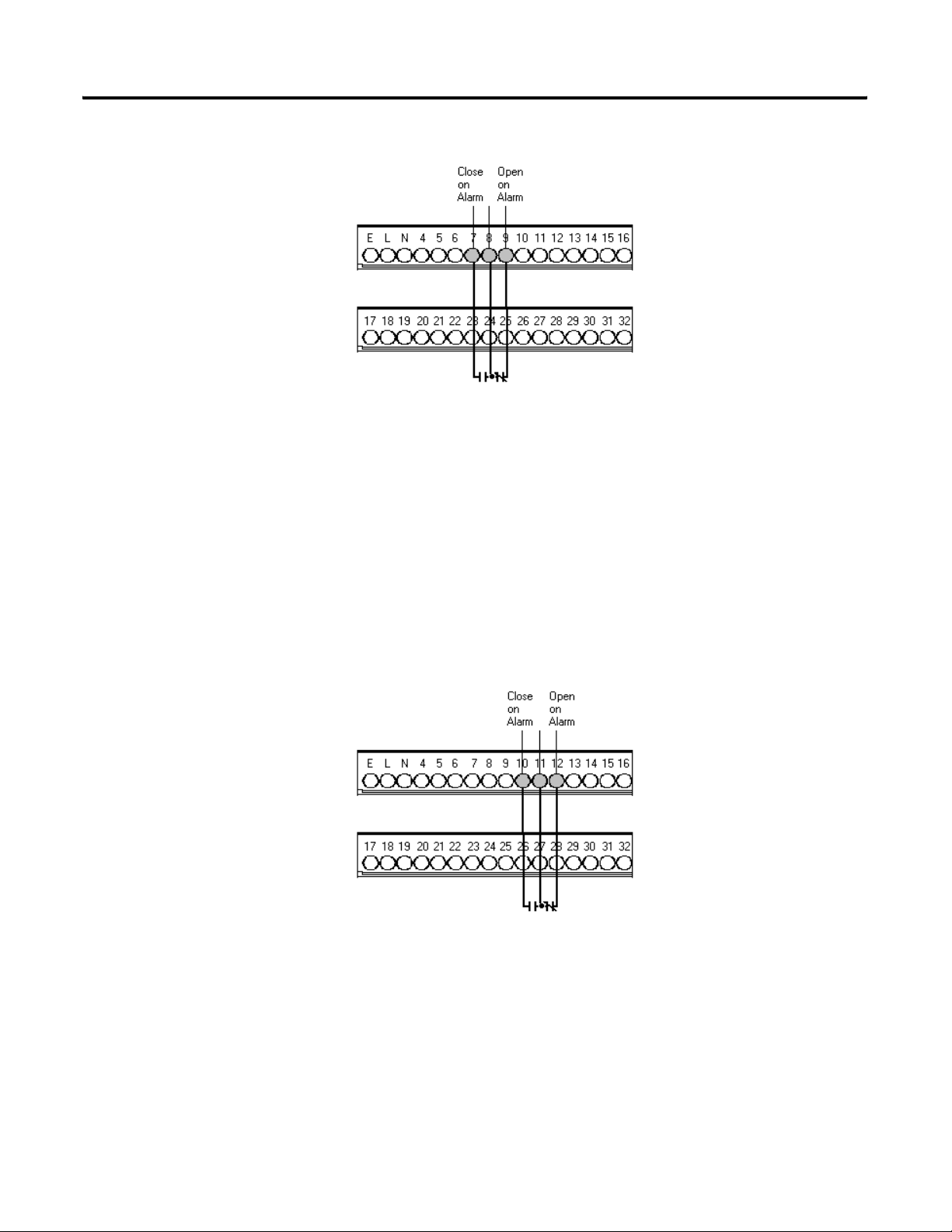

Warning Relay

In the provided configuration files, the Warning relay is configured to activate

when the overall measurement in either channel exceeds the alert threshold

levels (same conditions that activate the Warning LED). This relay is

configured as a non-failsafe relay. Figure 2.6 shows the on-board relay

connection for the Warning relay.

The alert threshold levels and the behavior of the relay can be changed using

the XM Serial Configuration Utility. Refer to Editing the XM-720 Parameters

on page 44.

Publication GMSI10-UM001C-EN-E - June 2011

Page 18

18 Installing the XM-720 Machine Monitor

Figure 2.6 Wiring Connection for Warning Relay (Non-failsafe)

Trip Relay

In the provided configuration files, the Trip relay is configured to activate

when the overall measurement in either channel exceeds the danger threshold

level (same conditions that activate the Trip LED). This relay is also

configured as a non-failsafe relay. Figure 2.7 shows the on-board relay

connection for the Trip relay.

The danger threshold level and the behavior of the relay can be changed using

the XM Serial Configuration Utility. Refer to Editing the XM-720 Parameters

on page 44.

Figure 2.7 Wiring Connection for Trip Relay (Non-failsafe)

Publication GMSI10-UM001C-EN-E - June 2011

Page 19

Installing the XM-720 Machine Monitor 19

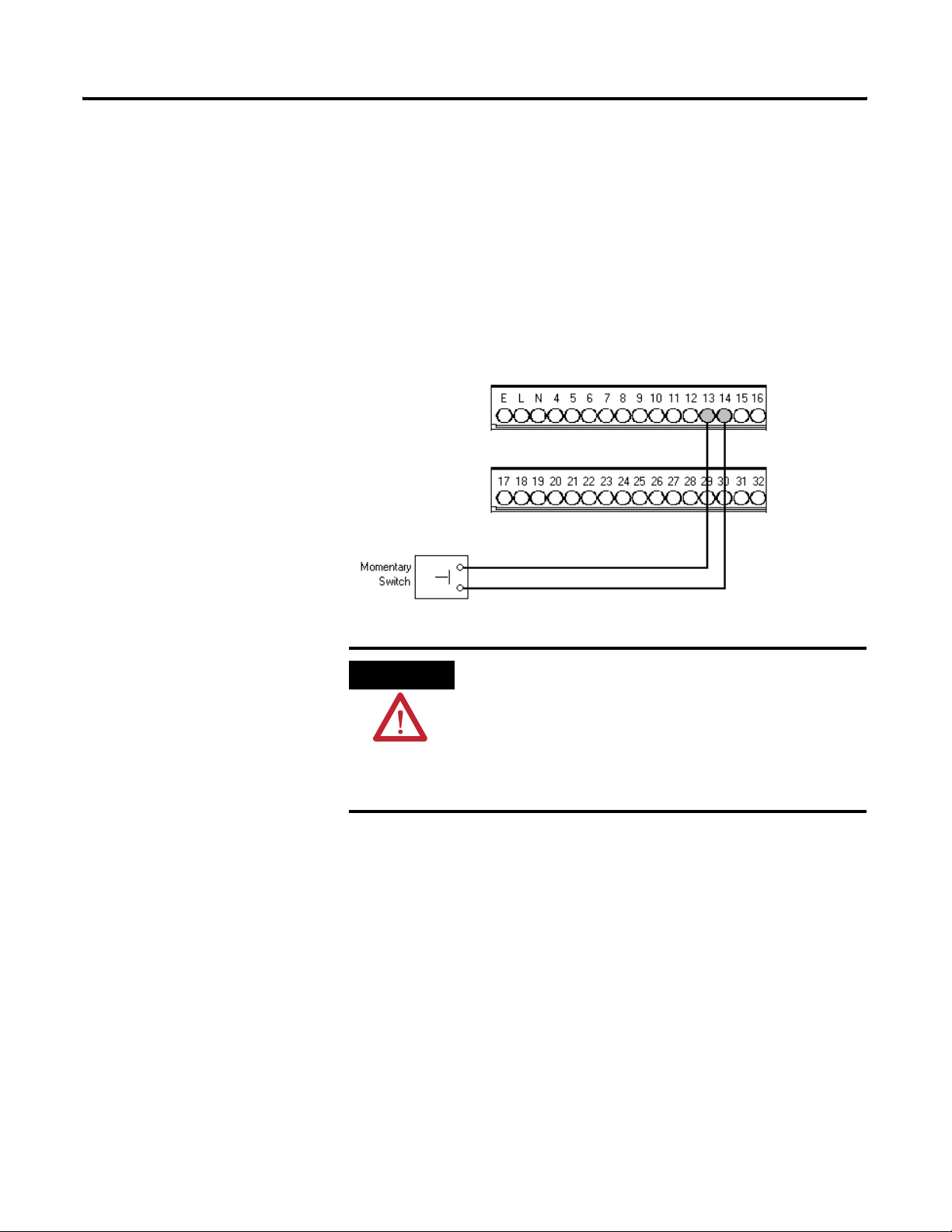

Connecting the Remote Relay Reset Signal

In the provided configuration files, the XM-720 relays are configured to be

latching relays. This means the relays stay activated even when the condition

that caused the alarm has ended. The remote relay reset signal enables you to

reset the XM-720 relays remotely after you have corrected the alarm condition.

Wire the Remote Relay Reset Signal to the XM-720 back panel as shown in

Figure 2.8.

Figure 2.8 Remote Relay Reset Signal Connection

ATTENTION

The switch input power supply must be grounded at a

single point. Connect the Switch Return signal to chassis or

earth ground at either the XM-720 system, the switch, or

other equipment that is wired to this switch. If grounding

at the XM-720 system, connect a jumper between the

Switch RTN terminal and any available Chassis GND

terminal.

Connecting the Transducers

The XM-720 monitor can accept input from any Entek non-contact eddy

current probe, a standard IEPE acclerometer, velocity transducer, AC voltage

output or a DC voltage output measurement device.

Publication GMSI10-UM001C-EN-E - June 2011

Page 20

20 Installing the XM-720 Machine Monitor

The sensitivity, operating range, and power requirements have been predefined

in the provided configuration files. The characteristics of the transducer and

the signal processing performed on the input signals can be changed using the

XM Serial Configuration Utility. Refer to Transducer Parameters on page 44.

IMPORTANT

The 1440-PK02-05M2 (gSE) monitor can measure both

"standard" vibration, similarly to the 1440-PK02-05M0,

and g’s Spike Energy™ (gSE). It can produce the gSE

measurement only with an IEPE accelerometer or

externally powered sensor.

Setting the Buffer Range for the Transducer

The XM-720 provides buffered outputs of all transducer input signals through

the BNC connectors on the front panel.

The voltage operating range of the buffered outputs must be configured to

coincide with the corresponding transducer bias range. This operating range is

configured by placing a jumper from terminal 5 (channel 1) and terminal 22

(channel 2) to terminal 6 (Positive Buffer Bias) or terminal 21 (Buffer -) on the

XM-120/121/122 module, depending on the transducer. The buffered output

operating range is configured independently per channel.

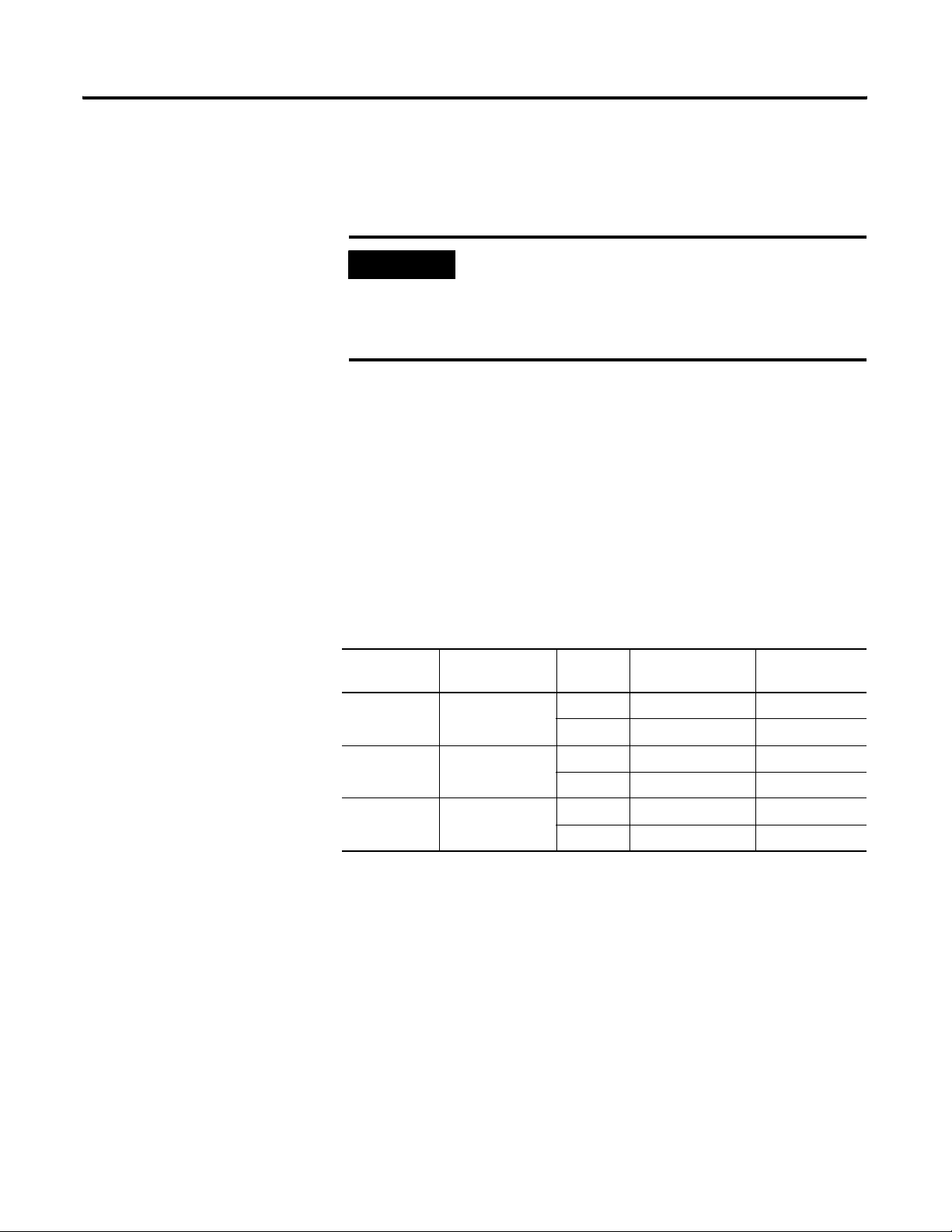

Table 2.3 Configuring Buffered Output Operating Range

Transducer Input Range Channel Connect XM-12x

Terminal

Negative Bias -24 to +9V 1 5 21

222 21

Positive Bias -5 to +24V 1 5 6

To XM-12x

Terminal

Publication GMSI10-UM001C-EN-E - June 2011

222 6

Non-Bias -5 to +9V 1 ---- ----

2 ---- ----

Page 21

Installing the XM-720 Machine Monitor 21

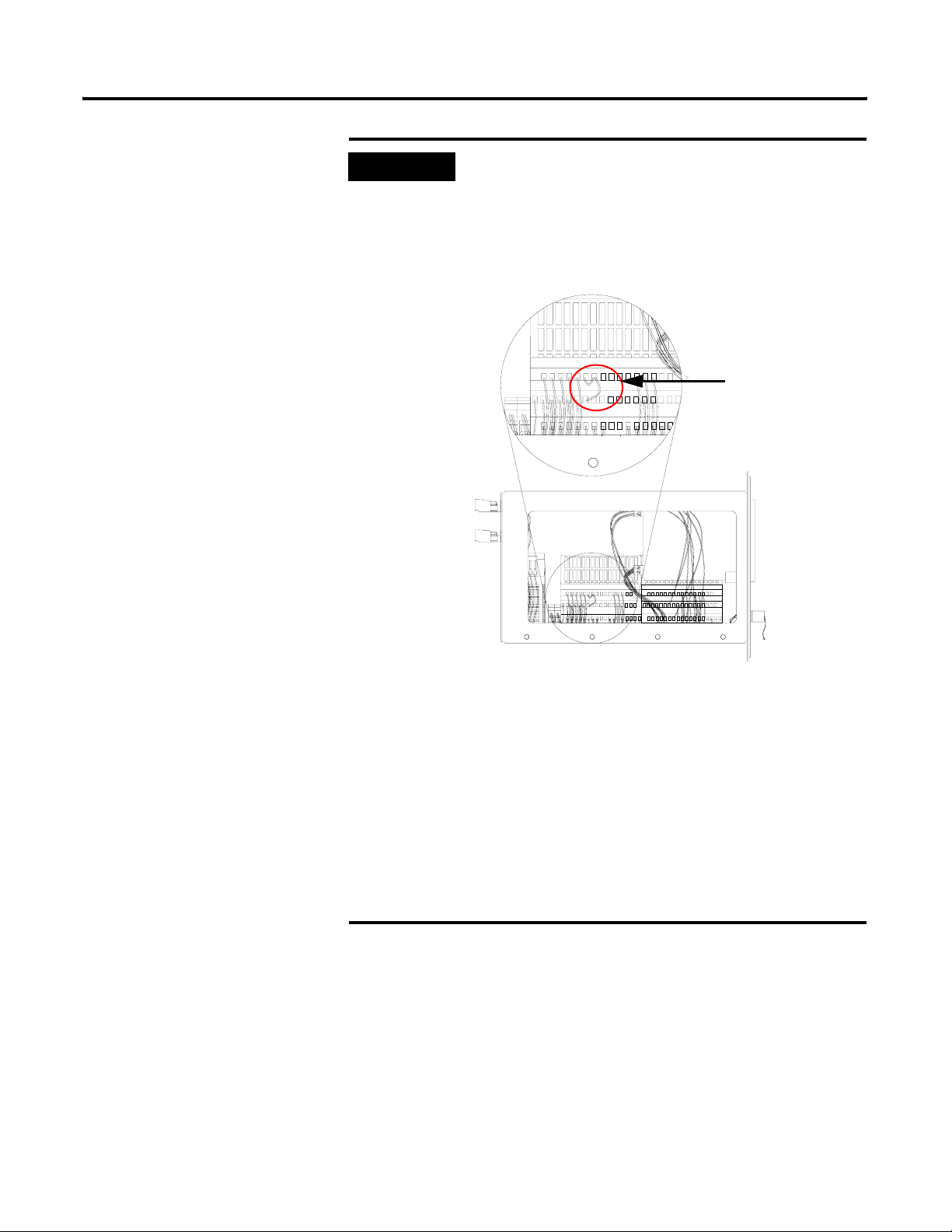

IMPORTANT

By default, both buffered outputs have been wired for a

positive bias transducer (accelerometer and powered

sensor). This means that orange jumper wires have been

supplied on the XM-120/121/122 terminal block between

terminals 5, 6, and 22 (see Figure 2.9).

Figure 2.9 Jumpers for buffer input wiring

123456789100

1617 1819 2021 222324 2526 272829 3031 3233

3435 3637 383940 4142 434445 4647 48495

123456789100

161718 19 2021 2223 2425 2627 2829 3031 323 3

343536 373 839 4041 4243 4445 4647 4849 5051

1112 1314 15

111213 141 5 123456789100

16171819 202122 232425 26272829 30313233

Orange jumpers for

buffer outputs

11121314 15

34353637 383940 41424344 454647 48495051

If the transducer is not a positive bias transducer, follow

these guidelines:

• For a non-contact sensor, remove the orange jumper

between terminals 5 and 6 (terminals 22 and 6 for

channel 2) and install it between terminals 5 and 21

(terminals 22 and 21 for channel 2).

• For a non-bias sensor, such as a velocity sensor, remove

the orange jumper between terminals 5 and 6 (terminals

22 and 6 for channel 2).

Refer to Table 2.3 for details. Refer to the XM Users Guide

for more information about the XM-120/121/122 module.

Publication GMSI10-UM001C-EN-E - June 2011

Page 22

22 Installing the XM-720 Machine Monitor

Connecting an IEPE Accelerometer

The following figure shows the wiring of an IEPE accelerometer to the

XM-720 back panel.

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

You may ground the cable shield at either end of the cable.

Do not ground the shield at both ends. Recommended

practice is to ground the cable shield to one of the Chassis

GND terminals on the XM-720 terminal block and not at

the transducer. Any of the Chassis GND terminals on the

XM-720 terminal block provides a grounding point for the

cable shield.

The internal transducer power supply is providing power to

the IEPE accelerometer.

Using the XM Serial Configuration Utility, make certain the

IEPE Power parameter is enabled

. Refer to Transducer

Parameters on page 44.

A jumper from terminals 5 to 6 on the XM-120/121/122

terminal block is required for channel 1 buffered output. A

jumper from terminals 22 to 6 on XM-120/121/122

terminal block is required for channel 2 buffered output.

Refer to Setting the Buffer Range for the Transducer on

page 20.

Publication GMSI10-UM001C-EN-E - June 2011

Page 23

Figure 2.10 IEPE Accelerometer Wiring

Installing the XM-720 Machine Monitor 23

TYPICAL WIRING FOR IEPE ACCELEROMETER

Pin A - Signal

Pin B - Common

Cable shield not

connected at this end

Pin A - Signal

Pin B - Common

Cable shield not

connected at this end

TO XM-720 BACK PANEL

Channel 1 Input Signal

Signal Common

Shield

Channel 2 Input Signal

Signal Common

Shield

17

18

19

20

21

22

Connecting a Non-Contact Sensor

The figure below show the wiring of a non-contact sensor to the XM-720 back

panel.

IMPORTANT

IMPORTANT

You may ground the cable shield at either end of the cable.

Do not ground the shield at both ends. Recommended

practice is to ground the cable shield to one of the Chassis

GND terminals on the XM-720 terminal block and not at

the transducer. Any of the Chassis GND terminals on the

XM-720 terminal block provides a grounding point for the

cable shield.

The internal transducer power supply is providing power to

the IEPE accelerometer.

Publication GMSI10-UM001C-EN-E - June 2011

Page 24

24 Installing the XM-720 Machine Monitor

IMPORTANT

Using the XM Serial Configuration Utility, make certain the

IEPE Power parameter is disabled

Parameters on page 44.

IMPORTANT

A jumper from terminal 5 to 21 on the XM-120/121/122

terminal block is required for channel 1 buffered output. A

jumper from terminal 22 to 21 on XM-120/121/122

terminal block is required for channel 2 buffered output.

Refer to Setting the Buffer Range for the Transducer on

page 20.

Figure 2.11 Non-Contact Sensor Wiring

TYPICAL WIRING FOR NON-CONTACT SENSOR

TO XM-720 BACK PANEL

-24

SIG

COM

Shield

Floating

. Refer to Transducer

Channel 1 Input Signal

Signal Common

Shield

-24V DC

17

18

19

24

Publication GMSI10-UM001C-EN-E - June 2011

Channel 2 Input Signal

Signal Common

-24

SIG

COM

Shield

Floating

Shield

-24V DC

20

21

22

24

Page 25

Installing the XM-720 Machine Monitor 25

Connecting a Passive Transducer

The figure below shows the wiring of a passive transducer, such as a coil-based

velocity sensor, to the XM-720 back panel.

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

You may ground the cable shield at either end of the cable.

Do not ground the shield at both ends. Recommended

practice is to ground the cable shield to one of the Chassis

GND terminals on the XM-720 terminal block and not at

the transducer. Any of the Chassis GND terminals on the

XM-720 terminal block provides a grounding point for the

cable shield.

The module does not power the sensor. It measures only

the input voltage.

Using the XM Serial Configuration Utility, make certain the

IEPE Power parameter is disabled

. Refer to Transducer

Parameters on page 44.

No jumper is required for buffered outputs on the

XM-120/121/122 terminal block. Remove any jumpers

between terminals 5, 6, 21, and 22 on the

XM-120/121/122 terminal block. Refer to Setting the

Buffer Range for the Transducer on page 20.

Publication GMSI10-UM001C-EN-E - June 2011

Page 26

26 Installing the XM-720 Machine Monitor

Figure 2.12 Velocity Sensor Wirings

TYPICAL WIRING FOR COIL-BASED VELOCITY SENSOR

Pin A - Signal

Pin B - Common

Cable shield not

connected at this end

Pin A - Signal

Pin B - Common

Cable shield not

connected at this end

TO XM-720 BACK PANEL

Channel 1 Input Signal

Signal Common

Shield

Channel 2 Input Signal

Signal Common

Shield

17

18

19

20

21

22

Connecting a Powered Sensor

The figure below shows the wiring of a powered sensor, such as Entek IRD

Model 544 or 580 Vibration Pickup, to the XM-720 back panel.

IMPORTANT

IMPORTANT

You may ground the cable shield at either end of the cable.

Do not ground the shield at both ends. Recommended

practice is to ground the cable shield to one of the Chassis

GND terminals on the XM-720 terminal block and not at

the transducer. Any of the Chassis GND terminals on the

XM-720 terminal block provides a grounding point for the

cable shield.

Using the XM Serial Configuration Utility, make certain the

IEPE Power parameter is disabled

. Refer to Transducer

Parameters on page 44.

Publication GMSI10-UM001C-EN-E - June 2011

Page 27

Installing the XM-720 Machine Monitor 27

+24V DC

Common

Signal

IMPORTANT

A jumper from terminal 5 to 6 on the XM-120/121/122

terminal block is required for channel 1 buffered output. A

jumper from terminal 22 to 6 on XM-120/121/122

terminal block is required for channel 2 buffered output.

Refer to Setting the Buffer Range for the Transducer on

page 20.

Figure 2.13 Powered Sensor Wiring

TYPICAL WIRING FOR ENTEK MODEL 580 VIBRATION PICKUP

Cable shield not

connected at this end

TO XM-720 BACK PANEL

Channel 1 Input Signal

Signal Common

Shield

+24V DC

17

18

19

23

+24V DC

Common

Signal

Channel 2 Input Signal

Signal Common

Shield

+24V DC

20

21

22

23

Publication GMSI10-UM001C-EN-E - June 2011

Page 28

28 Installing the XM-720 Machine Monitor

Connecting the Tachometer Signal

The XM-720 monitor provides a single tachometer input signal. The signal

processing performed on the tachometer signal depends on the configuration

of the module. See the XM Module User Guide for a description of the

tachometer parameters.

IMPORTANT

The tachometer measurement has been disabled in the

provided configuration files. To enable the tachometer

measurement, you must set the Pulses per Revolution

parameter to a non-zero value using the XM Serial

Configuration Utility. Refer to Tachometer Parameters on

page 51 for more information.

Connecting a Magnetic Pickup Tachometer

Figure 2.14 shows the wiring of a magnetic pickup tachometer to the XM-720

back panel.

Figure 2.14 Tachometer Signal Connection

Publication GMSI10-UM001C-EN-E - June 2011

Page 29

Installing the XM-720 Machine Monitor 29

Connecting a Hall Effect Tachometer Sensor

Figure 2.15 shows the wiring of a Hall Effect Tachometer Sensor,

Cat. No. 44393, to the XM-720 back panel.

Figure 2.15 Hall Effect Tachometer Signal Connection

Connecting the 4-20mA Outputs

The XM-720 monitor includes an isolated 4-20mA per channel output into a

maximum load of 250 ohms. In the provided configuration files, the 4-20mA

output signals track the overall measurement, and the Min and Max range is set

according to the type of transducer.

The measurements that the 4-20mA tracks and the signal levels that

correspond to the 4mA and 20mA can be changed using the XM Serial

Configuration Utility. Refer to 4-20mA Output Parameters on page 50 for

details.

Wire the 4-20mA outputs to the XM-720 back panel as shown in Figure 2.16.

Publication GMSI10-UM001C-EN-E - June 2011

Page 30

30 Installing the XM-720 Machine Monitor

Figure 2.16 4-20mA Output Connections

Channel 2 4-20mA output is

not being used. Therefore a

jumper from terminal 28 to

29 is required.

ATTENTION

The 4-20mA outputs must be grounded at a single point.

Connect the 4-20mA Return signal to chassis ground at the

XM-720 end through the 4-20mA (-) terminal. Do not

ground the 4-20mA return elsewhere.

ATTENTION

If a 4-20mA output is not used, a jumper must be wired

between the unused 4-20mA terminals (terminals 25 and

26 for channel 1; terminals 28 and 29 for channel 2),

otherwise the associated meter on the front panel will not

function properly.

Connecting the Setpoint Multiplication Switch

You can configure the XM-720 monitor to multiply the alarm setpoints, or

inhibit the alarms during the start-up period. This can be used to avoid alarm

conditions that may occur during startup, for example, when the monitored

machine passes through a critical speed.

The startup period and the action to take when the setpoint multiplier switch is

closed in predefined in the provided configuration files. These settings can be

changed using the XM Serial Configuration Utility. Refer to Alarm Parameters

on page 46.

Publication GMSI10-UM001C-EN-E - June 2011

Wire the Setpoint Multiplication switch to the XM-720 back panel as shown in

Figure 2.17.

Page 31

Figure 2.17 Setpoint Multiplication Connection

Installing the XM-720 Machine Monitor 31

Front Panel Description

ATTENTION

The switch input power supply must be grounded at a

single point. Connect the Switch Return signal to chassis or

earth ground at either the XM-720 system, the switch, or

other equipment that is wired to this switch. If grounding

at the XM-720 system, place a jumper between the Switch

RTN terminal and any available Chassis GND terminal.

The XM-720 monitor front panel consists of four LEDs, two easy to read

digital meters, three BNC connectors and a Reset Relay switch.

Figure 2.18 XM-720 Front Panel

100

Channel 1 meter

showing overall

measurement

Channel 2 meter

showing overall

measurement

100

75

50

25

0

%

Reset

75

Trip

50

Warning

25

Module

0

Fault

%

Xdcr

Fault

Relay reset switch

LED indicators

Tacho

CH 2CH 1

output of buffered

input signals

Publication GMSI10-UM001C-EN-E - June 2011

BNC connectors for

Page 32

32 Installing the XM-720 Machine Monitor

Bargraph Meters

The XM-720 front panel has two vertical-scale meters, one for each input

channel. Each meter consists of 31 solid-state lamps (light emitting diodes)

arranged one above the other. Scale markings on the window appear at 3%

increments, thus there is one scale mark for each of the thirty lamps.

In the provided configuration files, each meter is configured to continuously

display the overall vibration level. The amplitude of the signal appears as a

continuous bright light next to the one of the thirty scale marks. This

simplified display makes it easy for you to recognize potential problems as the

measured signal amplitude approaches one of the setpoints.

The measurement displayed in the meter, the full scale, and the alarm and trip

(danger) thresholds are configurable using the XM Serial Configuration Utility.

Refer to Chapter 3 for more information about the XM Serial Configuration

Utility.

The XM-720 is shipped with clear self-adhesive caption sheet for customizing

the meter scale. The caption stickers contain the most popular measured units

and ranges. The caption sheet also contains orange and red arrows for labeling

the alert and danger (trip) threshold levels.

Follow these instructions to customize the scaled face plate.

1. Remove the front bezel. To do this, insert a blade-type screwdriver

between the plastic bezel frame and front panel and lift the bezel off.

2. Remove the scaled faceplate. Be careful not to scratch the clear lens.

3. Peel the desired measured units and the orange and red arrows from the

caption sheet and place on the scaled faceplate. Refer to To determine

placement for Alert and Danger Threshold Arrows on page 33 for an

example.

4. Replace the faceplate, lens and bezel.

Publication GMSI10-UM001C-EN-E - June 2011

Page 33

Amplitude Bargraph % 100⁄()4-20mA Max Range value 4-20mA Min Range value–()4-20mA Min Range value+×=

Installing the XM-720 Machine Monitor 33

To determine the signal amplitude on bargraph meter

To determine the signal amplitude in engineering units, use the following

formula:

Measure units/range

sticker

Place the red arrow

sticker on meter to

show danger threshold

level (e.g. 70%).

Place the orange

arrow sticker on meter

to show alert

threshold level (e.g.

50%).

EXAMPLE

meter reading: 40%

4-20mA Min Range value: 0 mils

4-20mA Max Range value: 5 mils

amplitude = (40% / 100) x (5 -0) + 0 = 2 mils

To determine placement for Alert and Danger Threshold Arrows

The caption sheet (included in package) contains red (danger) and orange

(alert) arrows for you to place on the meter to show the alert and danger

threshold levels. Use the following formula to determine placement of the

arrows.

Threshold value 4-20mA Min Range value–()100%×

Threshold %

EXAMPLE

EXAMPLE

----------------------------------------------------------------------------------------------------------------------------------------------

=

4-20mA Max Range value 4-20mA Min Range value–()

Alert Threshold value in configuration: 2.5 g

4-20mA Min Range value in configuration: 0 g

4-20mA Max Range value in configuration: 5 g

Alert threshold % sticker = (2.5 - 0) x 100% / (5 - 0) = 50%

Danger threshold value in configuration: 3.5 g

4-20mA Min Range value in configuration: 0 g

4-20mA Max Range value in configuration: 5 g

Danger threshold % sticker = (3.5 - 0) x 100% / (5 - 0) =

70%

Publication GMSI10-UM001C-EN-E - June 2011

Page 34

34 Installing the XM-720 Machine Monitor

BNC Connectors

The XM-720 front panel provides three BNC connectors directly below the

bargraph meters. There are two connectors (CH1 and CH2) for monitoring

the input signals. And a third BNC connector (TACHO) for phase referencing

or triggering.

WARNING

EXPLOSION HAZARD

Do not use BNC connectors when area is known to be

hazardous. BNC caps must be securely installed on ALL

connectors during normal operation.

LED Indicators

The four LEDs on the front panel of the XM-720 monitor indicate the status

of the monitor. In the provided configuration files, the LEDs are configured to

function as described in Table 2.D. Use this table to help you troubleshoot

your monitor.

IMPORTANT

IMPORTANT

Making a change to the configuration parameters may

possibly change the intended function of the LED.

The Module Fault LED will be illuminated when you first

apply power to the XM-720 monitor because the relay

associated with this LED is not configured for failsafe.

Make sure you configure your XM-720. For information on

how to configure the XM-720, see Chapter 3 on page 37.

Publication GMSI10-UM001C-EN-E - June 2011

Table 2.D LED Description

LED State Indicates

Trip Off Normal condition

On The current overall measurement in either channel is in

excess of the danger level thresholds.

Warning Off Normal condition

On The current overall measurement in either channel is in

excess of either the alert level thresholds or the danger

level thresholds.

Page 35

Table 2.D LED Description

LED State Indicates

Module

Fault

Xdcr Fault Off Normal condition

Off Normal condition

On • A hardware or firmware failure is preventing proper

operation of the device.

• Relay #1 is not configured to be failsafe. Typically

this occurs on new installations, in which the

XM-720 has not been configured. Refer to Chapter 3

on page 37 for information on how to configure the

XM-720.

On The transducer DC bias in either channel is

out-of-range.

Reset Switch

Installing the XM-720 Machine Monitor 35

Removing the XM-720 Terminal Blocks

The XM-720 front panel has an external reset switch located above the LED

indicators (see Figure 2.18). The switch can be used to reset all latched relays

and LEDs on the front panel of the XM-720 monitor. To reset the relays and

LED indicators, press and release the Reset button.

IMPORTANT

The Reset switch resets the relays only if the input is no

longer in alarm or the condition that caused the alarm is no

longer present.

TIP

In the provided configuration files, the XM-720 relays are

configured to be latching relays. This means the relays stay

activated even when the condition that caused the alarm

has ended.

The XM-720 monitor has two removable terminal blocks (RTB) on the back

panel.

Removing the XM-720 Terminal Blocks

WARNING

When you connect or disconnect the RTB with field side

power, an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous

before proceeding.

Publication GMSI10-UM001C-EN-E - June 2011

Page 36

36 Installing the XM-720 Machine Monitor

To remove the XM-720 terminal blocks, grasp the terminal block with your

thumb and forefinger and pull straight out.

Inserting the XM-720 Terminal Blocks

WARNING

When you connect or disconnect the RTB with field side

power, an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous

before proceeding.

IMPORTANT

The XM-720 terminal plugs are keyed so they will only fit

into the corresponding socket.

Insert the terminal block by aligning it and pushing it firmly onto the

connector contacts.

Publication GMSI10-UM001C-EN-E - June 2011

Page 37

Chapter

3

Configuring the XM-720

This chapter provides information to help you configure your XM-720

monitor using the XM Serial Configuration Utility software. Refer to the XM

User Guide for a complete listing and description of the configuration

parameters.

Please refer to the online help and the XM Serial Configuration Utility Getting

Results Guide (publication XMSCU-GR002) for assistance on how to use the

XM Serial Configuration Utility software.

Installing XM Serial Configuration Utility

TIP

For information about See page

Installing XM Serial Configuration Utility 37

Downloading a Pre-Configured Configuration File 39

Editing the XM-720 Parameters 44

The XM Serial Configuration Utility is a 32-bit Windows application program

that allows you to configure and view live data from any XM module.

The XM Serial Configuration Utility runs as a stand-alone program on a

computer connected directly to an XM module through a special cable

(included with the XM-720). The cable connects to the computer’s serial port

and to a mini-connector on the XM-120/121/122 module that is inside the

XM-720 enclosure.

The XM Module User Guides and XM Serial

Configuration Utility Getting Results Guide can be found

on the XM Documentation and Configuration Utility CD,

which is packaged with your XM-720 monitor.

37 Publication GMSI10-UM001C-EN-E - June 2011

Page 38

38 Configuring the XM-720

Figure 3.1 XM Cable Connection

Cable connects to the

mini-connector on top

of the

XM-120/121/122

module.

To install the XM Serial Configuration Utility software, follow these steps.

Note that the Serial Configuration Utility can be accessed only from the

computer on which it is installed.

1. Insert the XM Documentation and Configuration Utility CD-ROM into

the CD-ROM drive.

If autorun is: Then:

enabled The Setup program starts automatically and

the XM Serial Configuration Utility opening

screen appears. Proceed to step 2.

disabled Perform the following steps:

a. Click Start, and then click Run. The Run

dialog appears.

b. In the open field, type x:\autorun,

where x is the letter of the drive

containing the XM Documentation and

Configuration Utility CD-ROM.

c. Click OK. The XM Serial Configuration

Utility opening screen appears.

2. Follow the instructions that appear on the screen to install the XM Serial

Configuration Utility.

When you are finished installing the software and configuring the XM-720

monitor, remove the XM Documentation and Configuration Utility CD-ROM

from the CD-ROM drive. Store it in a safe place.

TIP

Descriptions on how to navigate through the software as

well as the software screens are contained in the online

help. Refer to the Getting Results Guide for additional

assistance.

Publication GMSI10-UM001C-EN-E - June 2011

Page 39

Configuring the XM-720 39

Downloading a Pre-Configured Configuration File

The XM-120/121/122 module (inside the XM-720 enclosure) samples inputs,

compares them to threshold values, and provides outputs to the relays and

front panel meters and LED indicators. It must be configured in order to

properly take measurements and to control the meters and LEDs.

The XM-720 package supplies configuration files (.120, .121, .122) that contain

predefined settings for a standard IEPE accelerometer, and other types of

powered and externally or self powered sensors. Use one of these

configuration files to help you set up your XM-720 monitor.

Files to Use With Your XM-720 Monitor

Tables 3.1 to 3.3 provide a list and description of the configuration files

included on the XM Documentation and Configuration Utility CD.

IMPORTANT

The configuration files provide a base from which to set up

your XM-720 monitor. The provided files are intended only

as an aid to configure the monitor. Please refer to the

manufacturer/OEM recommendations, historical data,

ISO and other industry standards to determine the correct

settings for your machine.

1440PK0205M0 (XM-120) Configuration Files

The XM Serial Configuration Utility uses the .120 file extension for the

XM-120 configuration files (XM-720 Cat. No. 1440PK0205M0).

IMPORTANT

Table 3.1 XM-120 Configuration Files

Configuration File Name Transducer

ACCEL.120 Accelerometer/

ACCEL_to_VEL_metric.120 Accelerometer/

ACCEL_to_VEL_english.120 100 mv/g 6 V 18 V Calculated

DISP_metric.120 Displacement/

DISP_english.120 200 mv/mils -20 V -2 V True pk to pk 7 mils 9 mils 0 - 15 mils

Type /

Measures

Acceleration

Velocity

Displacement

Sensitivity Fault

100 mv/g 6 V 18 V Calculated

100 mv/g 6 V 18 V Calculated

7.87 mv/µm -20 V -2 V True pk to pk 175 µm 225 µm 0 - 375 µm

The configuration files for XM-120 module are located on

the XM Documentation and Configuration Utility CD in

the 1440PK0205M0 Configuration Files folder.

Predefined Parameter Values

Low

Fault

High

Signal

Detection

peak

peak

peak

Alert

Thresholds

2.5 g 3.5 g 0 - 5 g

10 mm/s 15 mm/s 0 - 25 mm/s

0.4 ips 0.6 ips 0 - 1 ips

Danger

Thresholds

4-20 mA

Range

Publication GMSI10-UM001C-EN-E - June 2011

Page 40

40 Configuring the XM-720

Predefined Parameter Values

Configuration File Name Transducer

Type /

Measures

VEL_to_DISP_metric.120 Velocimeter/

Displacement

VEL_to_DISP_english 100 mv/ips 4 V 18 V Calculated

VEL_metric.120 Velocimeter/

Velocity

VEL_english.120 100 mv/ips 4 V 18 V Calculated

Sensitivity Fault

3.937

mv/mm/s

3.937

mv/mm/s

Low

4 V 18 V Calculated

4 V 18 V Calculated

Fault

High

Signal

Detection

peak

peak

peak

peak

1440PK0205M1 (XM-121) Configuration Files

The XM Serial Configuration Utility uses the .121 file extension for the

XM-121 configuration files (XM-720 Cat. No. 1440PK0205M1).

Alert

Thresholds

175 µm 225 µm 0 - 375 µm

7 mils 9 mils 0 - 15 mils

10 mm/s 15 mm/s 0 - 25 mm/s

0.4 ips 0.6 ips 0 - 1 ips

Danger

Thresholds

4-20 mA

Range

IMPORTANT

The configuration files for XM-121 module are located on

the XM Documentation and Configuration Utility CD in

the 1440PK0205M1 Configuration Files folder.

Table 3.2 XM-121 Configuration Files

Predefined Parameter Values

Configuration File Name Transducer

ACCEL.121 Accelerometer/

ACCEL_to_VEL_metric.121 Accelerometer/

ACCEL_to_VEL_english.121 500 mv/g 4 V 18 V Calculated

DISP_metric.121 Displacement/

DISP_english.121 200 mv/mils -20 V -2 V True pk to pk 7 mils 9 mils 0 - 15 mils

VEL_to_DISP_metric.121 Velocimeter/

VEL_to_DISP_english.121 1080 mv/ips 4 V 18 V Calculated

VEL_to_VEL_metric.121 Velocimeter/

VEL_to_VEL_english.121 1080 mv/ips 4 V 18 V Calculated

Type /

Measures

Acceleration

Velocity

Displacement

Displacement

Velocity

Sensitivity Fault

500 mv/g 4 V 18 V Calculated

500 mv/g 4 V 18 V Calculated

7.87 mv/µm -20 V -2 V True pk to pk 175 µm 225 µm 0 -375 µm

42.5

mv/mm/s

42.5

mv/mm/s

Fault

Low

High

4 V 18 V Calculated

4 V 18 V Calculated

Signal

Detection

Peak

Peak

Peak

Peak

Peak

Peak

Peak

Alert

Thresholds

2.5 g 3.5 g 0 - 5 g

10 mm/s 15 mm/s 0 - 25 mm/s

0.4 ips 0.6 ips 0 - 1 ips

175 µm 225 µm 0 - 375 µm

7 mils 9mils 0 - 15 mils

10 mm/s 15 mm/s 0 - 25 mm/s

0.4 ips 0.6 ips 0 - 1 ips

Danger

Thresholds

4-20 mA

Range

Publication GMSI10-UM001C-EN-E - June 2011

Page 41

Configuring the XM-720 41

1440PK0205M2 (XM-122) Configuration Files

The XM Serial Configuration Utility uses the .122 file extension for the

XM-122 configuration files (XM-720 Cat. No 1440PK0205M2).

IMPORTANT

The configuration files for XM-122 module are located on

the XM Documentation and Configuration Utility CD in

the 1440PK0205M2 Configuration Files folder.

Table 3.3 XM-122 Configuration Files

Predefined Parameter Values

Configuration File Name Transducer

Type /

Measures

ACCEL.122 Accelerometer/

Acceleration

ACCEL_to_VEL_metric.122 Accelerometer/

Velocity

ACCEL_to_VEL_english.122 100 mv/g g 4 V 18 V Calculated

Sensitivity Eng.

Units

100 mv/g g 4 V 18 V Calculated

100 mv/g g 4 V 18 V Calculated

1 The XM-122 can only perform gSE measurements with an accelerometer. The gSE measurements are only

available for the channel if Eng. Units is set to "g." Refer to Editing the XM-720 Parameters on page 44 for

details.

1

Fault

Low

Fault

High

Signal

Detection

Peak

Peak

Peak

Alert

Thresholds

2.5 g 3.5 g 0 - 5 g

10 mm/s 15 mm/s 0 - 25 mm/s

0.4 ips 0.6 ips 0 - 1 ips

Danger

Thresholds

4-20 mA

Range

Download the Configuration File to the XM-120/121/122

To use one of the provided configuration files, follow these steps.

1. Make certain the XM Serial Configuration Utility software is installed

onto the computer that will be connected directly to the

XM-120/121/122 module.

2. Insert the XM Documentation and Configuration Utility CD into the

CD-ROM drive of the computer.

Publication GMSI10-UM001C-EN-E - June 2011

Page 42

42 Configuring the XM-720

3. Connect the computer’s serial port to the XM-120/121/122 module’s

mini-connector using the special serial cable that is shipped with the

XM-720 monitor. The mini-connector is accessed from the top or side

of the XM-720 enclsure.

Cable connects to the

mini-connector on top

of the

XM-120/121/122

module.

WARNING

If you connect or disconnect the serial cable with power

applied to the module or the serial device on the other end

of the cable, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before

proceeding.

4. Power up the XM-720 module if you haven’t already done so, and start

the XM Serial Configuration Utility program. Click the Start program,

and then choose Programs > Entek > XM > Serial Config Utility.

TIP

The Configuration Utility defaults to the COM 1

serial port. If you are not using COM 1, select the

correct COM port on the XM Serial Configuration

Utility screen.

When you are connected to an XM module, the XM

Serial Configuration Utility automatically detects the

type of module. The module type appears on the

XM icon, and the connection icon changes to show

the connection.

5. Click the Configure button on the XM Serial Configuration Utility

screen. The Configuration Tool for the connected XM module appears.

Publication GMSI10-UM001C-EN-E - June 2011

Page 43

The name of the configuration file.

Configuring the XM-720 43

Below is an example of the XM-120 Module Configuration Tool.

6. From the File menu, choose Open. The Open dialog appears.

7. Navigate to one of the 1440 Configuration Files directory on the CD.

Select the appropriate configuration file and click Open. Refer to Files

to Use With Your XM-720 Monitor on page 39.

TIP

The name of the configuration file appears at the

bottom of the Configuration Tool.

8. Verify the predefined values and edit if necessary. Refer to Editing the

XM-720 Parameters on page 44.

If you need help, press F1 to display the online help topic for the current

tab or dialog, or refer to Chapter 3 in the XM Module User Guide for a

description of the parameters.

9. When you are finished modifying the configuration parameters, choose

Device > Download to Device to download the configuration to the

connected XM module.

TIP

You can save the XM module configuration to the

computer’s hard drive or other media by choosing

File > Save As. You can also print the configuration

by choosing File > Print.

10. From the File menu, choose Close to close the Configuration Tool

window.

Publication GMSI10-UM001C-EN-E - June 2011

Page 44

44 Configuring the XM-720

Editing the XM-720 Parameters

Once you open one of the provided configuration files, you can modify the

existing parameters so they better meet your requirements.

IMPORTANT

Any configuration parameter changes that you make in the

Configuration Tool do not affect the XM module until you

download them to the module. To download the

configuration parameters to the module, choose Device >

Download to Device. The module begins using the new

parameters immediately after the download.

Transducer Parameters

The Channel tab in the Configuration Tool allows you to change the

characteristics of the transducers you will be using with your XM-720 monitor

as well as the signal processing performed on channel 1 or channel 2. There

are two Channel tabs, one for each channel.

In the provided configuration files, both channels are configured identically.

Refer to Files to Use With Your XM-720 Monitor on page 39 for a list of the

provided configuration files.

Check this checkbox when an

IEPE accelerometer is wired to

the channel. Uncheck this

checkbox when any other type

of transducer is wired to the

channel.

The XM-122 can only perform

gSE measurements with an

accelerometer. gSE

measurements are only

available for this channel if you

select g.

A voltage reading outside this

range constitutes a transducer

fault.

To modify the channel parameters, follow these steps.

1. In the XM Module Configuration Tool, click the appropriate Channel

tab. (Channel 1 is the default tab.) You will see a screen similar to this.

Publication GMSI10-UM001C-EN-E - June 2011

Page 45

Configuring the XM-720 45

2. Enter or select the desired parameters to configure the transducer

sensitivity, operating range, and power requirements.

The signal processing and the measurement parameters affect the data

units of the measurement values, the sampling mode of the

spectrum/waveform data, and any spectral derived measurement.

TIP

Refer to Chapter 3 in the XM Module User Guide

for a detailed description of the configuration

parameters.

TIP

Press F1 to display the online help topic for the

current tab or dialog.

3. When you are finished, choose Device > Download to Device to

download your changes to the XM module.

gSE Parameters

Use the gSE tab in the XM-122 Configuration Tool to define the

characteristics of the gSE signal processing performed on channel 1 and

channel 2. The settings on the gSE tab are independent of the (conventional)

Signal processing and Spectrum/Waveform settings on the Channel 1 and

Channel 2 tabs.

In the provided configuration files, both channels are configured identically.

Refer to Files to Use With Your XM-720 Monitor on page 39 for a list of the

provided configuration files.

TIP

The XM-122 can perform gSE measurements for a channel

only with an accelerometer. The Eng. units must be set to

"g" on the Channel 1 or Channel 2 tabs for gSE

measurements.

Publication GMSI10-UM001C-EN-E - June 2011

Page 46

46 Configuring the XM-720

To modify the gSE parameters, follow these steps.

1. In the XM-122 Configuration Tool, click the gSE tab. You will see a

screen similar to this.

2. Enter or select the desired parameters to configure the gSE

measurement.

TIP

Refer to Chapter 3 in the XM Module User Guide

for a detailed description of the configuration

parameters.

TIP

Press F1 to display the online help topic for the

current tab or dialog.

3. When you are finished, choose Device > Download to Device to

download your changes to the XM module.

Alarm Parameters

Use the Alarm, Relay and 4-20 mA Output tab in the Configuration Tool to

select the type of measurement that is associated with an alarm and to set the

alert and danger threshold values.

In the provided configuration files, alarm number 1 and 2 have been

configured for you. Both alarms are configured identically except that Alarm

Number 1 is set up to monitor Ch 1 overall and Alarm Number 2 is set up to

Publication GMSI10-UM001C-EN-E - June 2011

Page 47

This checkbox must be checked in

order to use the alarm.

The measurement and channel

associated with the alarm.

Configuring the XM-720 47

monitor Ch 2 overall. Refer to Files to Use With Your XM-720 Monitor on

page 39 for list of the provided configuration files.

To modify the alarm parameters, follow these steps.

1. In the XM Configuration Tool, click the Alarm, Relay, and 4-20 mA

tab. You will see a screen similar to this.

Determines on which side of the threshold

values the alert and danger conditions

exist.

The threshold values for the

alert and danger threshold

conditions.

Click to configure the Setpoint Multiplier

switch.

2. Select the Alarm Number that you want to modify or configure.

3. Enter or select the desired parameters to set up the behavior of the

alarm. This includes:

• the measurement that the alarm is monitoring

• the measurement values at which the alarm changes state

• the amount that the measurement must fall before the alarm

condition is cleared (hysteresis)

• the action to take when the setpoint multiplier switch is closed

TIP

Refer to Chapter 3 in the XM Module User Guide

for a detailed description of the configuration

parameters.

TIP

Press F1 to display the online help topic for the

current tab or dialog.

4. When you are finished, choose Device > Download to Device to

download your changes to the XM module.

Publication GMSI10-UM001C-EN-E - June 2011

Page 48

48 Configuring the XM-720

Relay Parameters

Use the Alarm, Relay and 4-20 mA Output tab in the Configuration Tool to

configure the behavior of the relays in the XM-720 monitor.

In the provided configuration files, the relays are configured to function as

described in Table 3.4.

IMPORTANT

Making a change to the relay parameters may possibly

change the intended function of the relay and front panel

LED.

Refer to Files to Use With Your XM-720 Monitor on page 39 for a list of the

provided configuration files.

Table 3.4 Pre-Configured Relay Functionality

Configuration Tool

Relay Number

1 Module Fault N/A Indicates a module fault, such as a hardware or

2 Xducer Fault N/A Indicates transducer DC bias on either channel is

3 N/A Fault Relay Indicates a module fault and/or transducer DC bias is

4 Warning Warning

Front Panel

LED

Back Panel

Connection Intended Function

firmware failure.

Turns on the Module Fault LED on the front panel.

out-of-range.

Turns on the Xducer Fault LED on the front panel.

out-of-range.

Indicates that the overall measurement in either

Relay

channel exceeds either the alert level thresholds or the

danger level thresholds.

Turns on the Warning LED on the front panel.

5 Trip Trip Relay Indicates that the measurement in either channel

Publication GMSI10-UM001C-EN-E - June 2011

exceeds the danger level thresholds.

Turns on the Trip LED on the front panel.

Page 49

To modify the relay parameters, follow these steps.

1. In the Configuration Tool, click the Alarm, Relay, and 4-20 mA tab.

Check the checkbox if the relay must be explicitly

reset. Uncheck the checkbox if the relay is to

reset itself once the alarm condition has passed.

The activation logic must persist for this length of

time before the relay is activated.

The relay activation logic and what

alarm(s) the relay is to monitor.

The alarm conditions that cause the relay to

activate. More than one can be checked.

Configuring the XM-720 49

You will see a screen similar to this.

Check the checkbox if the relay is normally

energized. Uncheck the checkbox if the relay is

normally de-energized.

2. Select the relay Number that you want to modify or configure.

3. Enter or select the desired parameters to set up the behavior of the relay.

This includes:

• the number of seconds after an alarm condition has been exceeded

• the activation logic and the alarm(s) that the relay monitors

• the conditions that will cause the relay to activate (for example,

• whether the relay is latched and failsafe

before the relay activates (activation delay)

module fault, measurement exceeds danger level thresholds)

TIP

Refer to Chapter 3 in the XM Module User Guide

for a detailed description of the configuration

parameters.

TIP

Press F1 to display the online help topic for the

current tab or dialog.

4. When you are finished, choose Device > Download to Device to

download your changes to the XM module.

Publication GMSI10-UM001C-EN-E - June 2011

Page 50

50 Configuring the XM-720

4-20mA Output Parameters

Use the Alarm, Relay and 4-20 mA Output tab in the Configuration Tool to set

up the two 4-20mA output signals as well as the bargraph meter on the front

panel. The parameters are the same for each output.

In the provided configuration files, the 4-20mA output signals are configured

identically except that 4-20 mA Output A is set up to monitor Ch1 overall and

4-20 mA Output B is set up to monitor Ch2 overall. Refer to Files to Use

With Your XM-720 Monitor on page 39 for a list of the provided

configuration files.

IMPORTANT

Changing the 4-20mA output parameters may affect the

operation of the front panel bargraph meters. Refer

to Bargraph Meters on page 32 for more information.

To modify the 4-20mA parameters, follow these steps.

1. In the Configuration Tool, click the Alarm, Relay, and 4-20 mA tab.

You will see a screen similar to this.

This checkbox must be checked to

enable the 4-20mA output.

The measurement and channel that

the 4-20mA output tracks.

The measured value associated with

the 4mA end of the range.

The measured value associated with

the 20mA end of the range.

Publication GMSI10-UM001C-EN-E - June 2011

2. Select the 4-20 mA output (A or B) that you want to modify or

configure.

3. Enter or select the desired parameters to define the characteristics of the

4-20mA output signal. This includes:

• the measurement that the 4-20mA output is tracking

Page 51

Configuring the XM-720 51

• the min and max range of the 4-20mA output signal

TIP

Refer to Chapter 3 in the XM Module User Guide

for a detailed description of the configuration

parameters.

TIP

Press F1 to display the online help topic for the

current tab or dialog.

4. When you are finished, choose Device > Download to Device to

download your changes to the XM module.

Tachometer Parameters

Use the Tachometer tab to enable the tachometer measurement and to define

the characteristics of the tachometer as well as the signal processing that will

be performed on the tachometer signal.

In the provided configuration files, the tachometer measurement has been

disabled (Pulses per Revolution set to zero) to prevent a tachometer fault

when no signal is present. Refer to Files to Use With Your XM-720 Monitor

on page 39 for a list of the provided configuration files.

A voltage reading

outside this range

constitutes a

tachometer fault.

To modify the tachometer parameters, follow these steps.

1. In the Configuration Tool, click the Tachometer tab. You will see a

screen similar to this.

To enable the

tachometer

measurement, enter a

non-zero value.

Check this checkbox

to enable Auto Trigger

mode. Uncheck this to

enable Manual

Trigger mode and

enter Trigger

threshold and

Trigger slope.

Publication GMSI10-UM001C-EN-E - June 2011

Page 52

52 Configuring the XM-720

2. Enter or select the desired parameters to define the characteristics of the

tachometer signal. This includes:

• the minimum and maximum expected DC voltage

• the DC bias time constant

• the number of tachometer signal pulses per revolution of the shaft

• the amount of hysteresis around the trigger threshold

TIP

Refer to Chapter 3 in the XM Module User Guide

for a detailed description of the configuration

parameters.

TIP

Press F1 to display the online help topic for the

current tab or dialog.

3. When you are finished, choose Device > Download to Device to

download your changes to the XM module.

Publication GMSI10-UM001C-EN-E - June 2011

Page 53

Appendix

Specifications

The Appendix lists the technical specifications for the XM-720 Machine

Monitor.

XM-720 Technical Specifications

Product Feature Specification

Communications

Local Configuration

Local configuration is provided through the

serial port connection of the

XM-120/121/122 module. The serial port is