Page 1

Installation Instructions

PowerMonitor 5000 Unit Optional Communication Modules

Catalog Numbers

1426-COMM-DNT, 1426-COMM-CNT

About This Publication

Top ic Pa ge

About This Publication 1

Required Tools 1

Important User Information 2

Install a Communication Module 3

Replace a Communication Module 5

Additional Resources 5

This document provides instructions on how to install or replace an optional

communication module on a PowerMonitor™ 5000 unit. These are the available

optional communication modules:

• 1426-COMM-DNT - DeviceNet Optional Communication Module

• 1426-COMM-CNT - ControlNet Optional Communication Module

The communication module installs in the optional communication slot on the

front panel of the PowerMonitor 5000 unit. The installation is the same for all

communication modules regardless of communication type.

Required Tools

Before You Begin

You need the following tools:

• Torx 8 screwdriver

• Small flat-bladed screwdriver

WARNING: Do not connect or disconnect any communication cable with power

applied to this device or any device on the network. An electrical arc can occur

and could cause an explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before proceeding.

ATT EN TI ON : Work in a static free environment and wear a properly grounded

electrostatic discharge (ESD) wristband. Do not touch the communication

module connector or its internal circuitry to avoid ESD.

Page 2

PowerMonitor 5000 Unit Optional Communication Modules

IMPORTANT

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc.,

is prohibited.

available from

) describes some

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

2 Rockwell Automation Publication 1426-IN002A-EN-P - April 2013

Page 3

PowerMonitor 5000 Unit Optional Communication Modules

IMPORTANT

Virtual Wiring

Correction

---- S1

S2

---- S3

S4

---- S com

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

R2 com

---- R2 C

R3 O

---- R3 com

R3 C

Module

status

Network

status

Config Loc

EtherNet/IP

Power

USB

Device

USB

Host

LNK

ACT

I 1

I 2

I 3

I 4

L1

L2

GND

24V

com

V1

V2

V3

VN

VG

C O M M U N I C A T I O N P O R T

PowerMonitor 5000

Commu nication

Port Cover

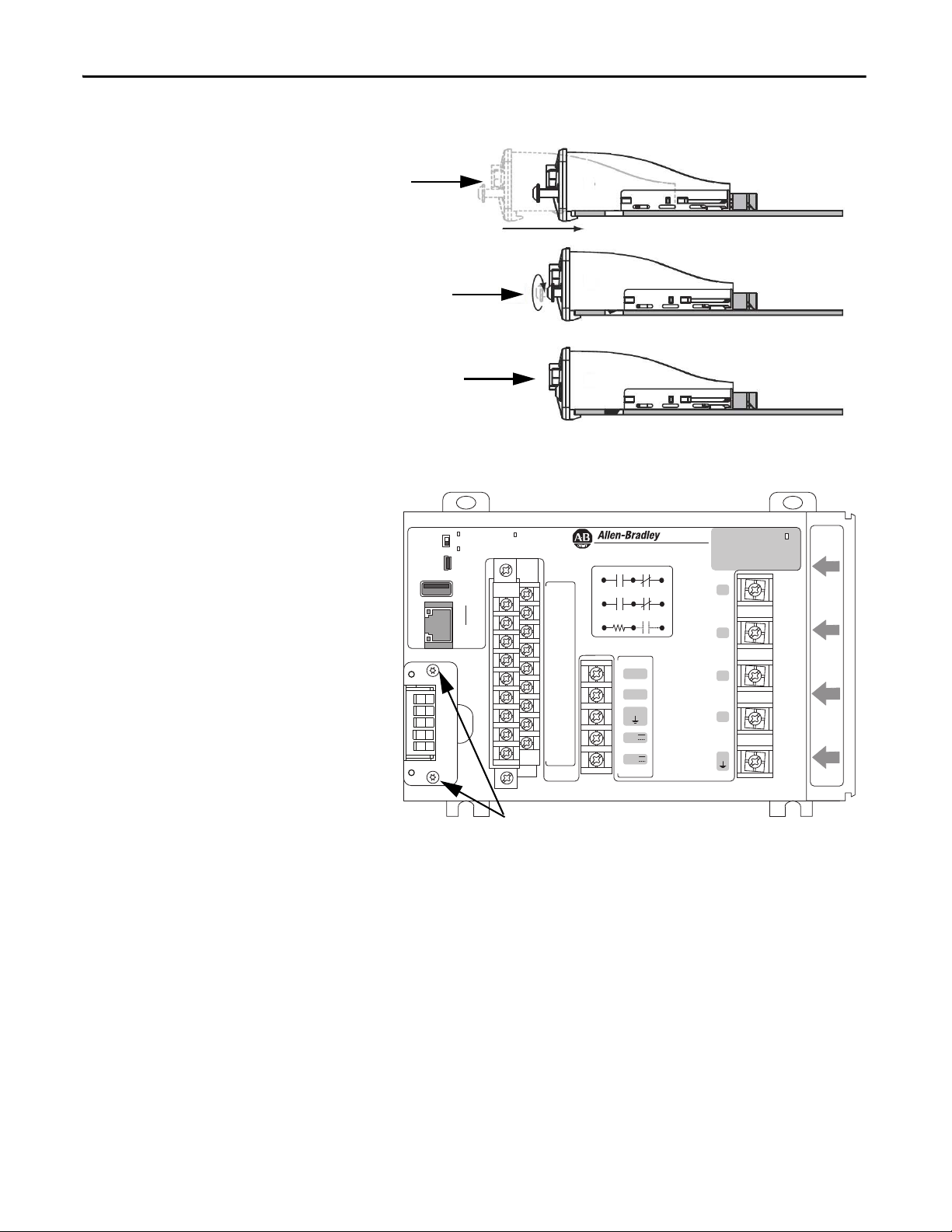

Install a Communication Module

Follow these steps to install a new communication module.

1. Disconnect control and voltage sensing power from the power monitor.

2. Remove the optional communication port cover by prying gently with a

small, flat-bladed screwdriver.

Z

K

Y

Rx com Rx C

Rx O

Internal

S n

24 VDC

Scom

3. Verify that the fastening screws in the communication module are backed

out approximately 4 mm (0.16 in.) and that the fastening cams do not

protrude from the bottom of the module.

4. Carefully slide the communication module flat against the circuit board in

the slot, aligning the tabs along the module’s edges with the guides in the

socket.

When installing the module into the socket, make sure that the

communication module is properly aligned into the socket prior to applying

any force. Rough handling and/or excessive force in combination with

misalignment can cause mechanical damage to the communication module or

the power monitor.

Rockwell Automation Publication 1426-IN002A-EN-P - April 2013 3

Page 4

PowerMonitor 5000 Unit Optional Communication Modules

Step 5 Insert module

Step 6 Tighten to

0.25 N•m

(2.2 lb•in)

Step 7 Module bezel

aligns with the

front panel.

1

DS NS

2345

DeviceNet

Tighten to

0.25 N•m (2.2 lb•in)

5. Gently insert the module into its socket until the module is seated.

6. Tighten the screws with a Torx 8 screwdriver to 0.25 N•m (2.2 lb•in).

Config Loc

LNK

ACT

Module

status

Network

status

USB

Device

USB

Host

EtherNet √IP

Power

PowerMonitor 5000

Z

K

Y

---- S1

S2

---- S3

S4

---- S com

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

R2 com

---- R2 C

R3 O

---- R3 com

R3 C

Rx O

Internal

24 VDC

Rx com Rx C

S n

L1

L2

GND

24V

com

Scom

V1

V2

V3

VN

VG

Virtual Wiring

Correction

7. Check that the module is properly seated.

The rear edge of the module bezel aligns with the front panel of the power

monitor. Tightening the screws engages the fastening cams with holes in

the circuit board, which helps resist efforts to remove the card.

I 1

I 2

I 3

I 4

4 Rockwell Automation Publication 1426-IN002A-EN-P - April 2013

Page 5

PowerMonitor 5000 Unit Optional Communication Modules

Step 2 Use Torx 8

Screwdriver

Step 2 Back out

approximately

4 mm

(0.16 in.)

Step 3 Remove the

communication

module.

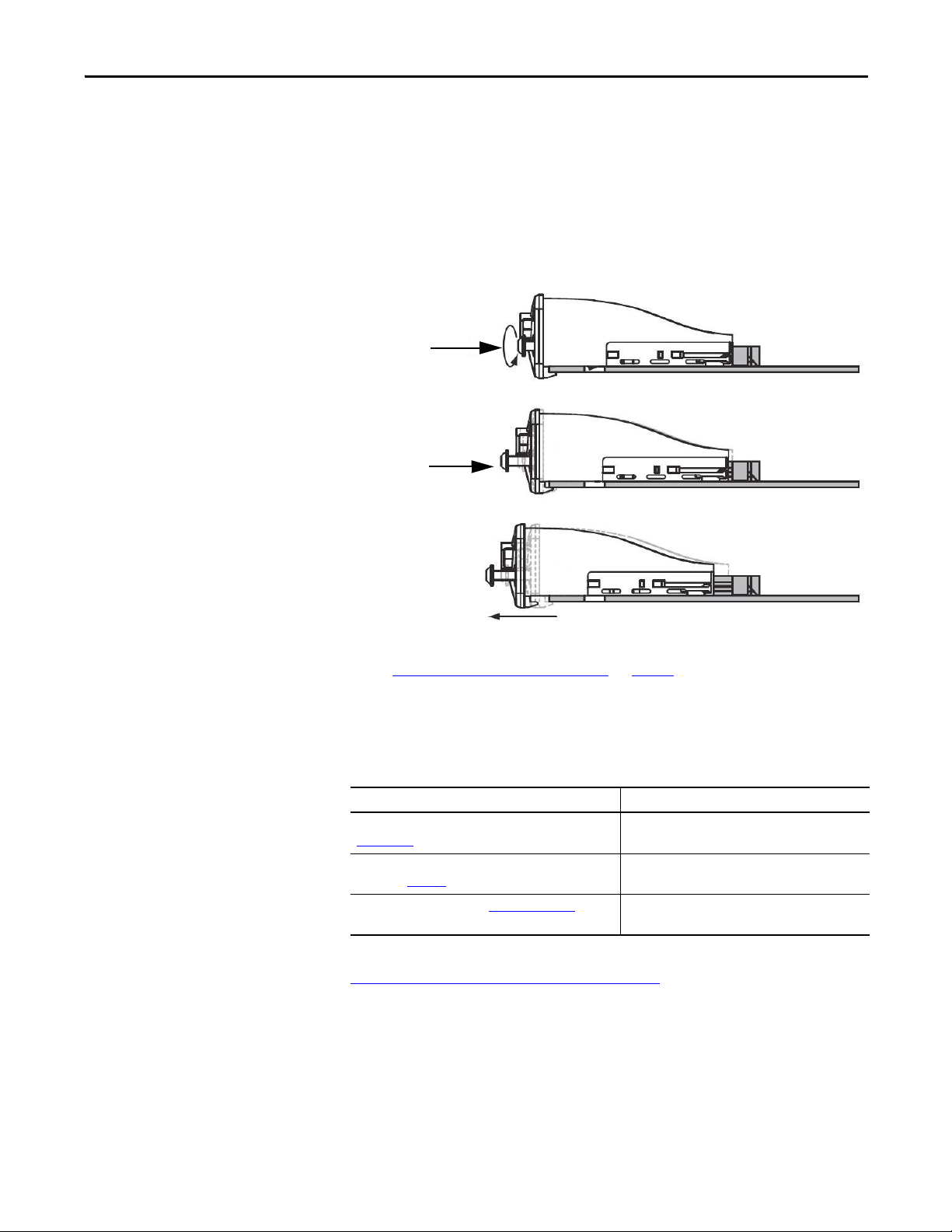

Replace a Communication Module

Follow these steps to replace a communication module.

1. Disconnect control and voltage sensing power from the power monitor.

2. With a Torx 8 screwdriver, back out the fastening screws approximately

4 mm (0.16 in.).

Do not remove the screws.

3. Gently remove the communication module from the power monitor.

Additional Resources

4. Install the new communication module by following steps 3…7 under

Install a Communication Module

on page 3.

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PowerMonitor 5000 Unit User Manual, publication

1426-UM001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com

Provides information on installing, configuring, and

using the PowerMonitor 5000 unit.

Provides general guidelines for installing a Rockwell

Automation® industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1426-IN002A-EN-P - April 2013 5

Page 6

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

code and links to software service packs, and a MySupport feature that you can customize to make the best use of these

tools. You can also visit our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

information, support chat and forums, software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application notes, sample

for FAQs, technical

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

SM

Te c h C o nn e c t

representative, or visit http://www.rockwellautomation.com/support/

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worldwide L ocator

local Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Allen-Bradley, Rockwell Software, Rockwell Automation, PowerMonitor, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Publication 1426-IN002A-EN-P - April 2013

, available at http://www.rockwellautomation.com/literature/.

Copyright © 2013 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...