Page 1

User Manual

PowerMonitor 5000 Unit

Catalog Numbers 1426

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, PowerMonitor, FactoryTalk, ControlLogix, SLC, RSLog ix, RSLinx, RSNetWorx, PLC-5, Logix5000, CompactLogix, Studio 500 0, and ControlFLASH are

trademarks of Roc kwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

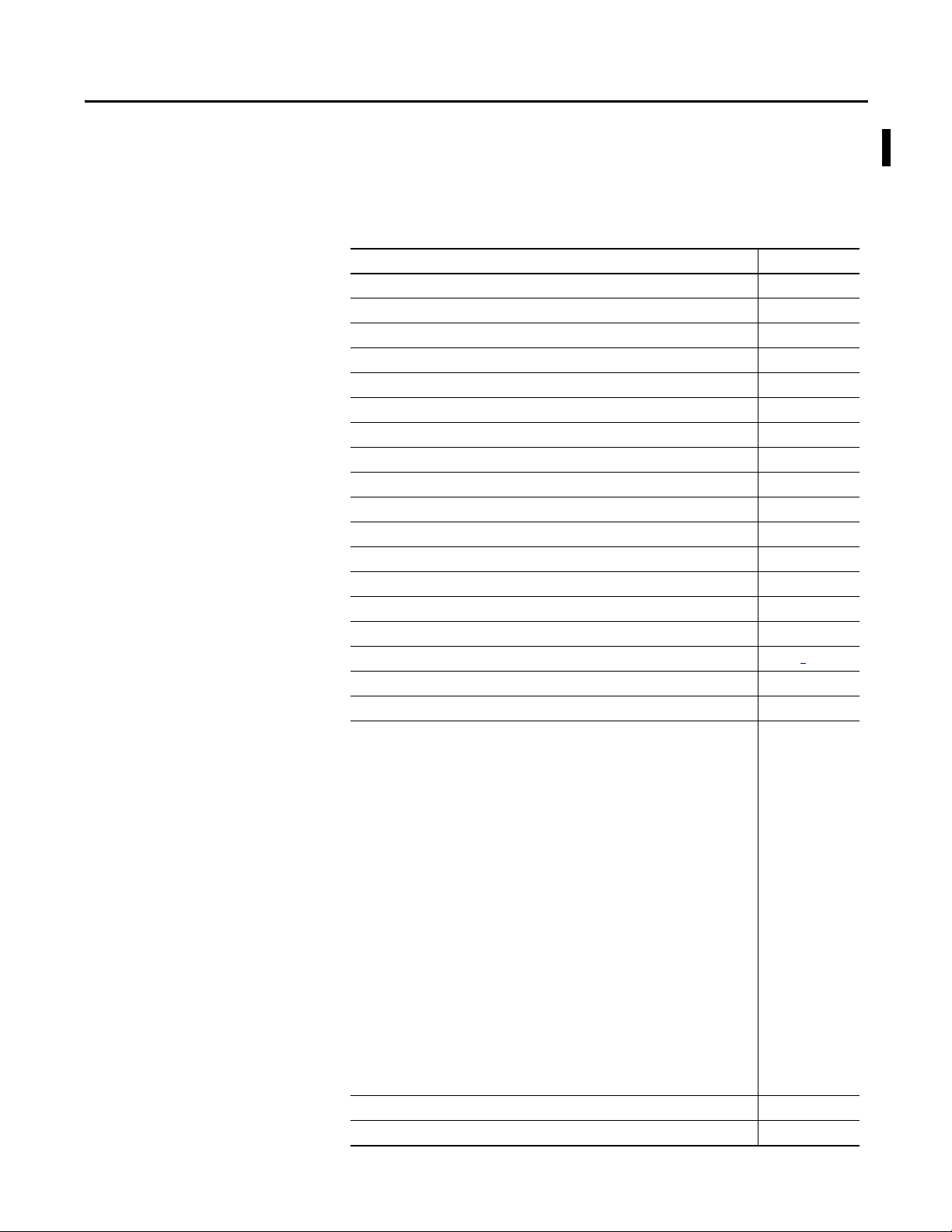

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Added information about the M6 model. Throughout

Added information on connecting to a ControlNet network. 40

Added information on setting up ControlNet network communication. 47

Added information about Power Quality monitoring 74

Updated the Logging Overview section 99

Added information on Waveform Log 105

Added parameters to the Data Log Parameter list 114

Added parameters to the Alarm Codes and Description list 137

Added information about the Power Quality Log 141

Added information about the Trigger Data Log 145

Added information about the Snapshot Log 148

Added information about Setpoint Logic Gates 160

Added parameters to the Setpoint Output Action List 167

Added information about Optional ControlNet Communication 183

Added information about Electronic Data Sheet 184

Added ControlNet netwrok information Chapter 9

Added ControlNet I/O Connection information 208

Added information about Upgrading the PowerMonitor 5000 Model and Communication 223

Added data table information for the following:

• Configuration.Setpoints_11_15 (M6 model)

• Configuration.Setpoints_16_20 (M6 model)

• Configuration.Setpoint_Logic (M6 Model)

• Configuration.TriggerDataLogFile (M6 Model)

• Configuration.TriggerSetpointInfoFile (M6 model)

• Configuration.TriggerData(M6 model)

• Configuration.WaveformFileName (M6 model)

• Status.Option alComm

• Status.IEEE1588 (M6 model)

• Statistics.Setpoint_Output

• Statistics.Logging

• Statistics.Setpoint_Logic (M6 model)

• LoggingResults. TriggerLog_Setpoint_Info_File_Name (M6 model)

• LoggingResults.TriggerLog_FileName (M6 model)

• LoggingResults.TriggerData_Header Data Table (M6 model)

• LoggingResults.TriggerData_Log (M6 model)

• LoggingResults.Power_Quality_Log (M6 model)

• LoggingResults.Snapshot_Log (M6 model)

• LoggingResults.WaveformFileName (M6 model)

• LoggingResults.Waveform_Log (M6 model)

• Power Quali ty.Harm onics _Results (M6 model)

• PowerQuality.IEEE1159_Results (M6 model)

• PowerQuality.Synchro_Phasor_Results

• PowerQuality.IEEE519_ Results (M6 model)

• PowerQuality.Harmonics Results (M6 model)

Removed reserved elements in Table 116 - Status.Alarms Data Table 302

Added information for PowerMonitor 5000 Waveform Capture and Compression (M6 model) Appendix D

Appendix A

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 3

Page 4

Summary of Changes

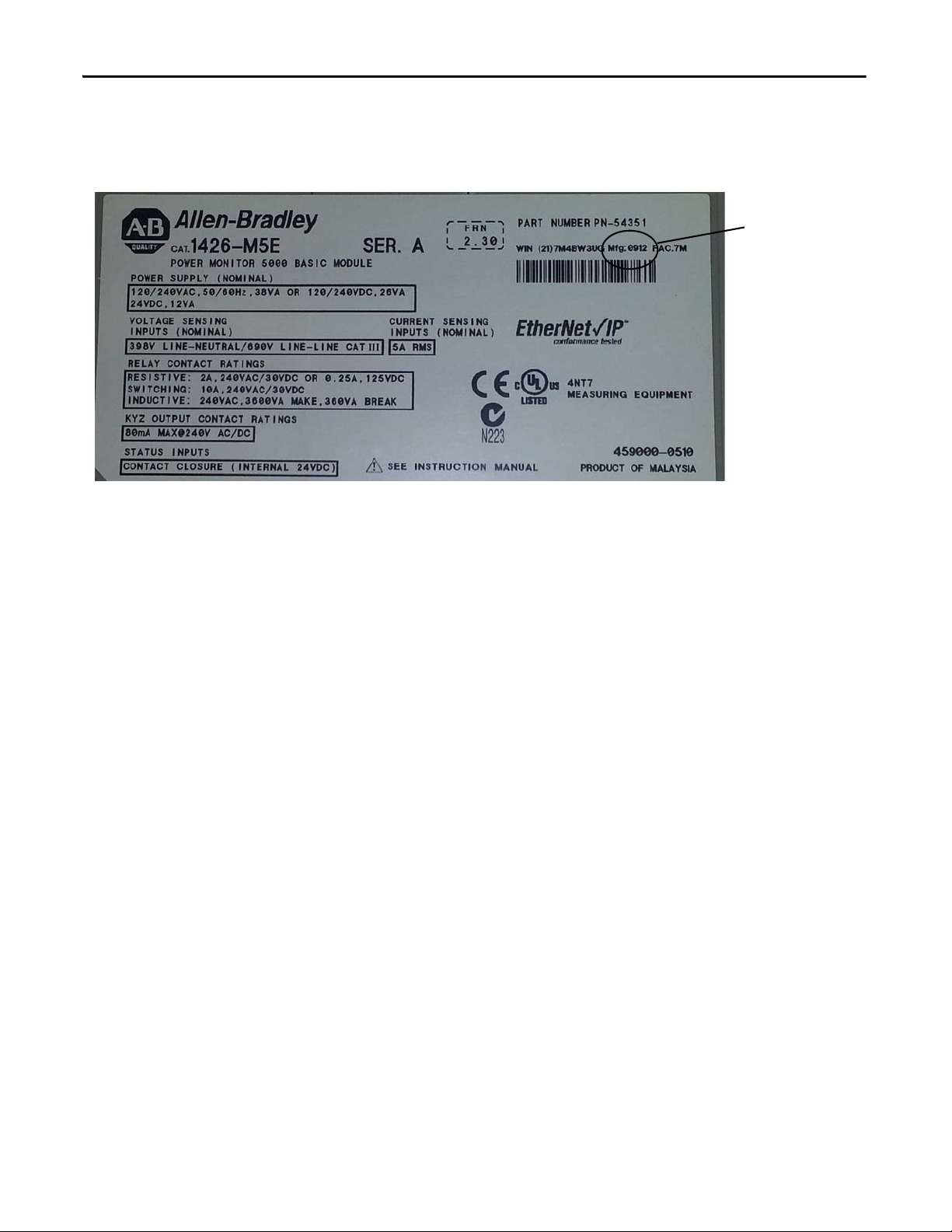

Manufacturing Date Code

on Product Label

For catalog number 1426-M5E (PN-54351) units manufactured from

July 2012…January 2013, the accuracy is Class 0.5 not Class 0.2. All other

characteristics and products are not impacted. The impacted units are those with

manufacturing date codes of 0712, 0812, 0912, 1012, 1112, 1212, and 0113.

4 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 5

Table of Contents

Preface

PowerMonitor 5000 Unit Overview

Install the PowerMonitor 5000 Unit

Setup

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PowerMonitor 5000 Unit Features and Functions . . . . . . . . . . . . . . . . . . 12

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Product Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wire the PowerMonitor 5000 Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connect Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 3

Setup Using the Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setup Using Optional Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setup Using Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Metering

Power Quality Monitoring

Chapter 4

Basic Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Wiring Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Wiring Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Metering Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Energy Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Demand Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Power Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Voltage, Current, Frequency Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Configuration Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 5

Harmonic Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Sag and Swell Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Power Quality Event Classification (M6 model) . . . . . . . . . . . . . . . . . . . . 81

Short Duration RMS Variations (Category 2.0 - Sags, Swells, and

Interruptions) (M6 model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Long Duration RMS Variations (Category 3.0 - Undervoltage,

Overvoltage, Sustained Interruptions) (M6 model) . . . . . . . . . . . . . . . . . 84

Power Quality Event Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Voltage and Current Imbalance (Category 4.0) . . . . . . . . . . . . . . . . . . . . . 87

Waveform Distortion (Category 5.1 - DC Offset, and

5.2 - Harmonics) (M6 model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 5

Page 6

Table of Contents

Logging

Power Frequency Variations (Category 7.0) . . . . . . . . . . . . . . . . . . . . . . . . 89

IEEE 519 Pass/Fail Capability (M6 model) . . . . . . . . . . . . . . . . . . . . . . . . . 90

IEEE 519 Pass/Fail Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

IEEE519_Overall_Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

IEEE-519 Short Term and Long Term Harmonic Results . . . . . . . . . . . 92

Waveform Recording (M6 model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Chapter 6

Logging Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Waveform Log (M6 Model). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Energy Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Data Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Min/Max Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Load Factor Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Time-of-use (TOU) Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Setpoint Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Power Quality Log (M6 model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Trigger Data Log (M6 model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Snapshot Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Logic Functions

Other Functions

Communication

Chapter 7

Relay and KYZ Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Status Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Chapter 8

Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Date and Time Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Network Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

System Error Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Miscellaneous Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Chapter 9

Native Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Optional DeviceNet Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Optional ControlNet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Electronic Data Sheet (EDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

PowerMonitor 5000 Unit Memory Organization . . . . . . . . . . . . . . . . . . 184

Communication Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

EtherNet/IP Object Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

DeviceNet and ControlNet Object Model. . . . . . . . . . . . . . . . . . . . . . . . . 188

Explicit Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Examples: Explicit Message Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

6 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 7

Maintenance

PowerMonitor 5000 Unit Data Tables

Technical Specifications

Table of Contents

SCADA Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Controller Applications: Class 1 Connection. . . . . . . . . . . . . . . . . . . . . . 202

CIP Energy Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Chapter 10

Update the PowerMonitor 5000 Unit Firmware. . . . . . . . . . . . . . . . . . . 221

Upgrading the PowerMonitor 5000 Model and Communication . . . 223

Use the ControlFLASH Utility to Update Firmware . . . . . . . . . . . . . . 223

Appendix A

Summary of Data Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Data Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Information Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Appendix B

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

PowerMonitor 5000 Display Module

Application Summary

PowerMonitor 5000 Waveform

Capture and Compression

(M6 model)

Glossary

Index

Appendix C

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Terminal Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Appendix D

Compression Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 9

Catalog Number Explanation

Preface

1426

Bulletin Number

1426 - PowerMonitor™ 5000

Additional Resources

-M5 E -CNT -A

Model

M5 - Base Power Monitor

M6 - Basic Power Quality Monitor

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PowerMonitor 5000 USB Driver Installation and

Configuration, publication 1426-IN001

PanelView Component HMI Terminals User Manual,

publication 2711C-UM001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and

Native Comms

E - EtherNet/IP

Optional Comms

CNT - ControlNet Port

DNT - DeviceNet Port

[Blank] - No Optional Port

Provides instructions for installing and configuring the

USB driver.

Provides instructions for setup and operation of the

PanelView Component terminal.

Provides general guidelines for installing a Rockwell

Automation® industrial system.

other certification details.

Series

A

You can view or download publications at

http:/www.rockwellautomation.com/literature/

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 9

. To order paper copies of

Page 10

Preface

Notes:

10 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 11

Safety

IMPORTANT

Chapter 1

PowerMonitor 5000 Unit Overview

ATT EN TI ON : Only qualified personnel, following accepted safety procedures,

can install, wire, and service the PowerMonitor 5000 unit and its associated

components. Before beginning any work, disconnect all sources of power and

verify that they are de-energized and locked out. Failure to follow these

instructions can result in personal injury or death, property damage, or

economic loss.

ATT EN TI ON : Never open a current transformer (CT) secondary circuit with

primary current applied. Wiring between the CTs and the PowerMonitor 5000

unit must include a shorting terminal block in the CT secondary circuit. Shorting

the secondary with primary current present allows other connections to be

removed if needed. An open CT secondary with primary current applied

produces a hazardous voltage, which can lead to personal injury, death,

property damage, or economic loss.

Product Description

The PowerMonitor 5000 unit is not designed for nor intended for use as a

circuit protective device. Do not use this equipment in place of a motor

overload relay or circuit protective relay.

The PowerMonitor 5000 unit is the next generation of high-end electric

metering products from Rockwell Automation. This new family of meters

provides advanced technology, new functionality, faster response, and superior

accuracy. The M5 model is the base version and provides an extensive range of

metering functionality. The M6 model expands the metering capabilities of the

M5 with basic power quality monitoring functionality, including harmonics up

to the 63rd, waveforms and logging, and classification of power quality events.

The PowerMonitor 5000 unit communicates power and energy parameters to

controllers, HMI software, and applications such as FactoryTalk

software over the Ethernet network or other optional networks. The

PowerMonitor 5000 unit works with controllers or software applications to

address key customer applications including the following:

• Load profiling – logging power parameters such as real power, apparent

power and demand, for analysis of power usage by loads over time

®

EnergyMetrix

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 11

Page 12

Chapter 1 PowerMonitor 5000 Unit Overview

Virtual Wiring

Correction

---- S1

S2

---- S3

S4

---- S com

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

R2 com

---- R2 C

R3 O

---- R3 com

R3 C

Module

status

Network

status

Cong Lock

EtherNet √

IP

PowerMonitor 5000

Power

USB

Device

USB

Host

LNK

ACT

I 1

I 2

I 3

I 4

L1

L2

GND

24V

com

V1

V2

V3

VN

VG

1

DS NS

2345

DeviceNet

2

1

3

4

5

6

7

8

9

10

12

11

• Cost allocation – reporting actual energy cost by department or process to

integrate energy information into management decisions

• Billing and sub-billing – charging users of energy the actual usage cost

rather than allocating by square footage or other arbitrary methods

• Power system monitoring and control – display and control power flow

and energy utilization

• Demand management – monitoring power usage and controlling loads to

reduce demand costs

• Demand response – controlling and monitoring usage in response to an

energy provider’s instruction to reduce demand

• Power quality - monitoring, measuring, recording, and logging power

system irregularities that can result in malfunctions or damage to

equipment

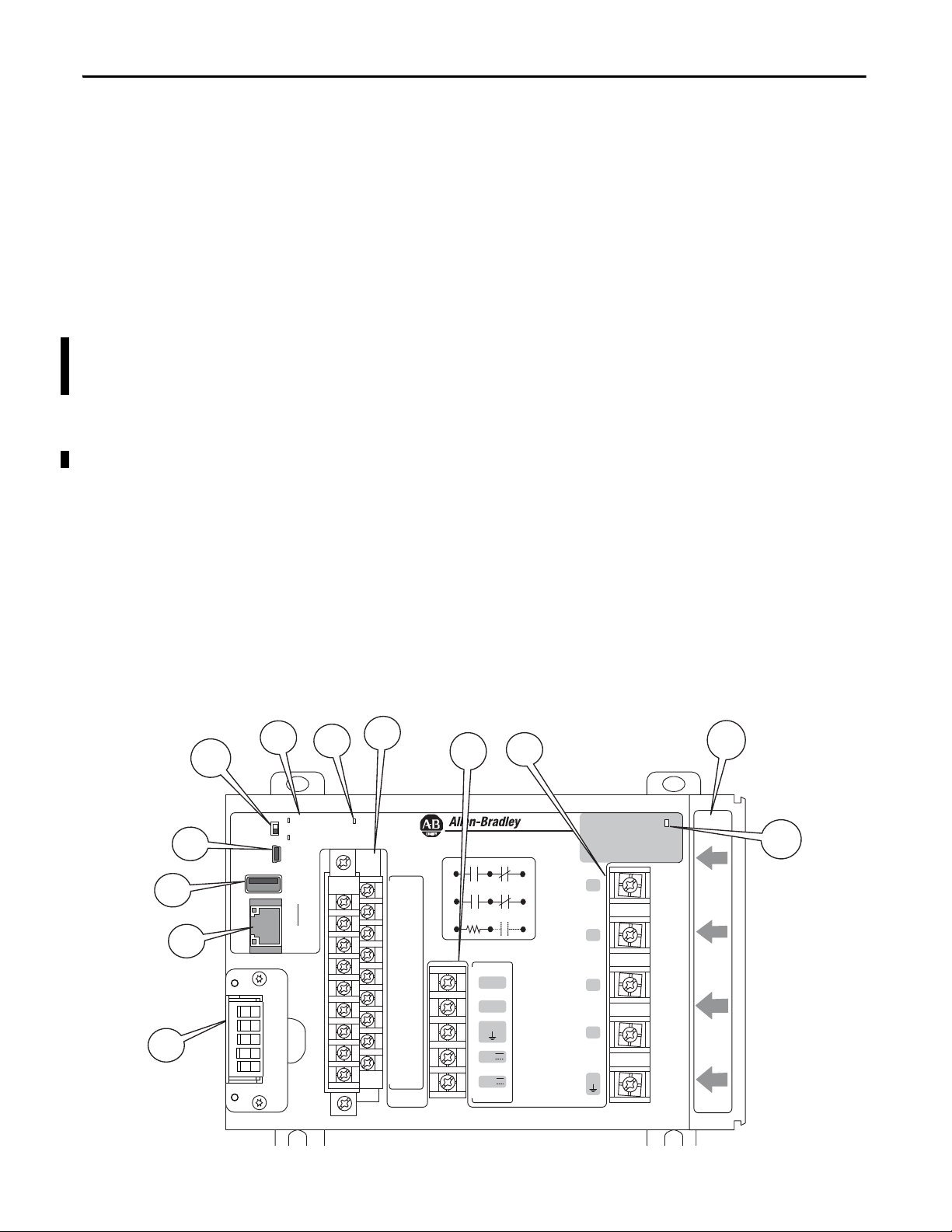

PowerMonitor 5000 Unit Features and Functions

The PowerMonitor 5000 unit connects to your three-phase or split-phase AC

power system directly or through instrument transformers (PTs and CTs). It

converts instantaneous voltage and current values to digital values, and uses the

resulting digital values in calculations of parameters such as voltage, current,

power, and energy.

Features

The PowerMonitor 5000 unit includes a number of hardware features that are

common to all models.

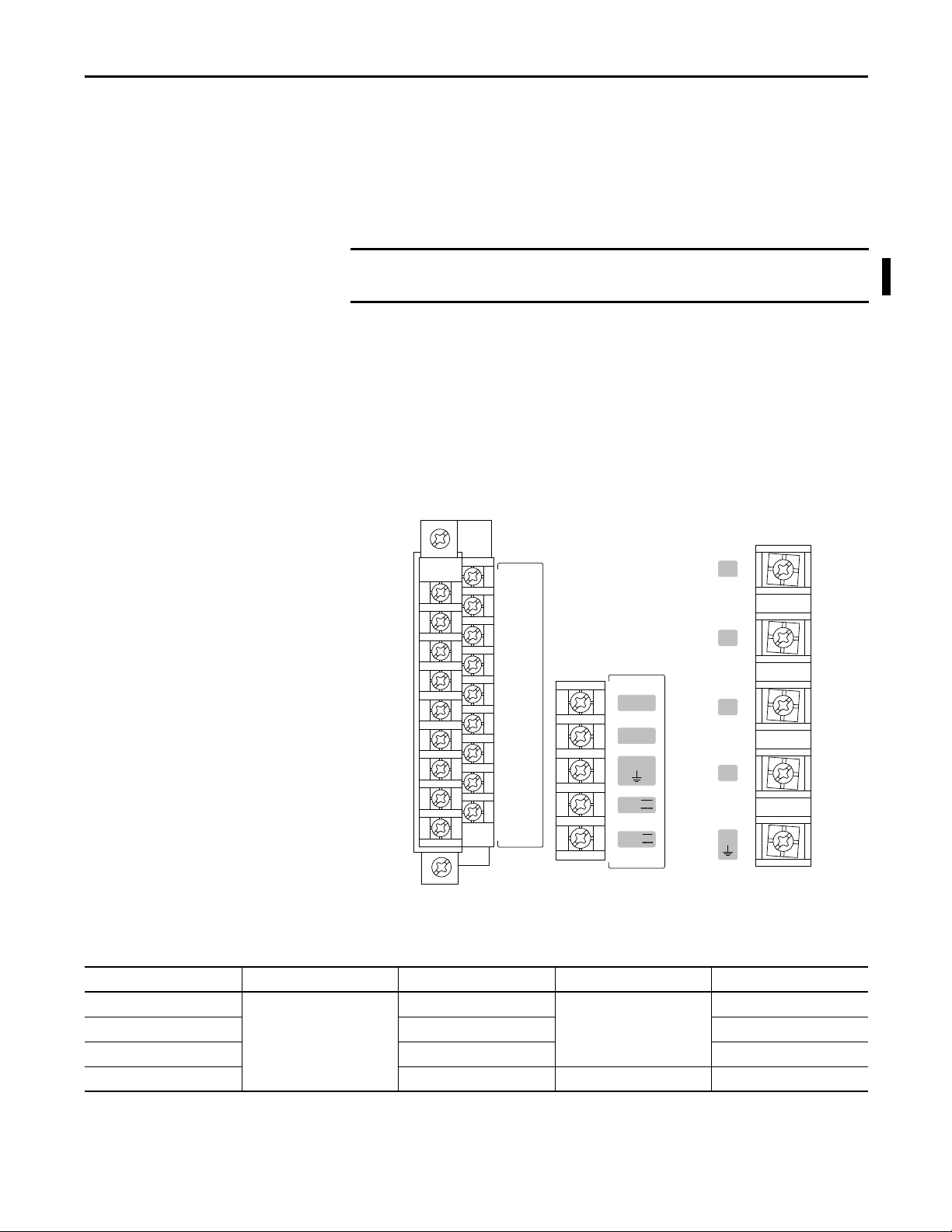

Figure 1 - Hardware Features

12 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Z

K

Y

Rx com Rx C

Rx O

Internal

S n

24 VDC

Scom

Page 13

PowerMonitor 5000 Unit Overview Chapter 1

Table 1 - Hardware Features

Feature Description

1. Ethernet port – standard RJ45 jack with status

indicators

2. Optional communication port DeviceNet and ControlNet networks

3. USB host port USB standard A receptacle. Not used in this model.

4. USB device port The USB device port is a USB Mini-B receptacle that accepts standard USB Mini-B plugs, for connection to a host device,

5. Configuration Lock switch When enabled, this switch prevents changes in configuration that can affect revenue accuracy.

6. Device and Network status indicators • Device status

7. Power • Power stat us

8. Status input, KYZ output, and control relay wiring

terminals

9. Control power and ground wiring terminals • 120…240V AC, 50/60 Hz or 120...240V DC

10.Voltage sensing wiring terminals • Direct connect to up to 690V AC 3-phase line to line

11.Current sensing wiring openings • Nominal input current 5 A

12.Virtual wiring correction indicator Indicates that the sensing voltage and/or current wiring has been modified in the power monitor configuration.

Ethernet port hardware is included on all models. These protocols and functions are supported:

• EtherNet/IP network

• HTML web page for configuration and data access

Ethernet indicators

• LNK indicator

– Solid GREEN: IP link established

– Off: No link established

• ACT indicator

– Flashing YELLOW: Data present on Ethernet port

– Off: No data activity present

• Module Status

– OFF: No control power

– Flashing GREEN/RED: Self-test

– Flashing GREEN: Power monitor has not been configured

– GREEN: Power monitor is running

– Flashing RED: Power monitor has detected a recoverable minor fault

– RED: Power monitor has detected a non-recoverable major fault

• Network Status

– OFF: No control power

– Flashing GREEN/RED: Self-test

– Flashing GREEN: No CIP connection

– Solid GREEN: CIP connection established

– Flashing RED: CIP connection timed out

– Solid RED: Duplicate address detected

such as a notebook computer.

– OFF: No control power

– Flashing GREEN/RED: Self-test

– Flashing GREEN: Power monitor has not been configured

– GREEN: Power monitor is running

– Flashing RED: Power monitor has detected a recoverable minor fault

– RED: Power monitor has detected a non-recoverable major fault

• Network status (Native Ethernet port)

– OFF: No control power

– Flashing GREEN/RED: Self-test

– Flashing GREEN: No CIP connection

– Solid GREEN: CIP connection established

– Flashing RED: CIP connection timed out

– Solid RED: Duplicate IP address detected

– OFF: No control power

– GREEN: Control power is present

• Four internally-powered (24V DC) status inputs

• Status input 2 can be used for demand period synchronization

• KYZ DPDT solid-state relay for signaling use

• Three DPDT control relays

• 24V DC

• Maximum nominal line to ground voltage 690

• Use potential transformers (PTs) for higher voltages

• Neutral voltage and ground voltage connections

• Use current transformers (CTs) to connect to power system

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 13

Page 14

Chapter 1 PowerMonitor 5000 Unit Overview

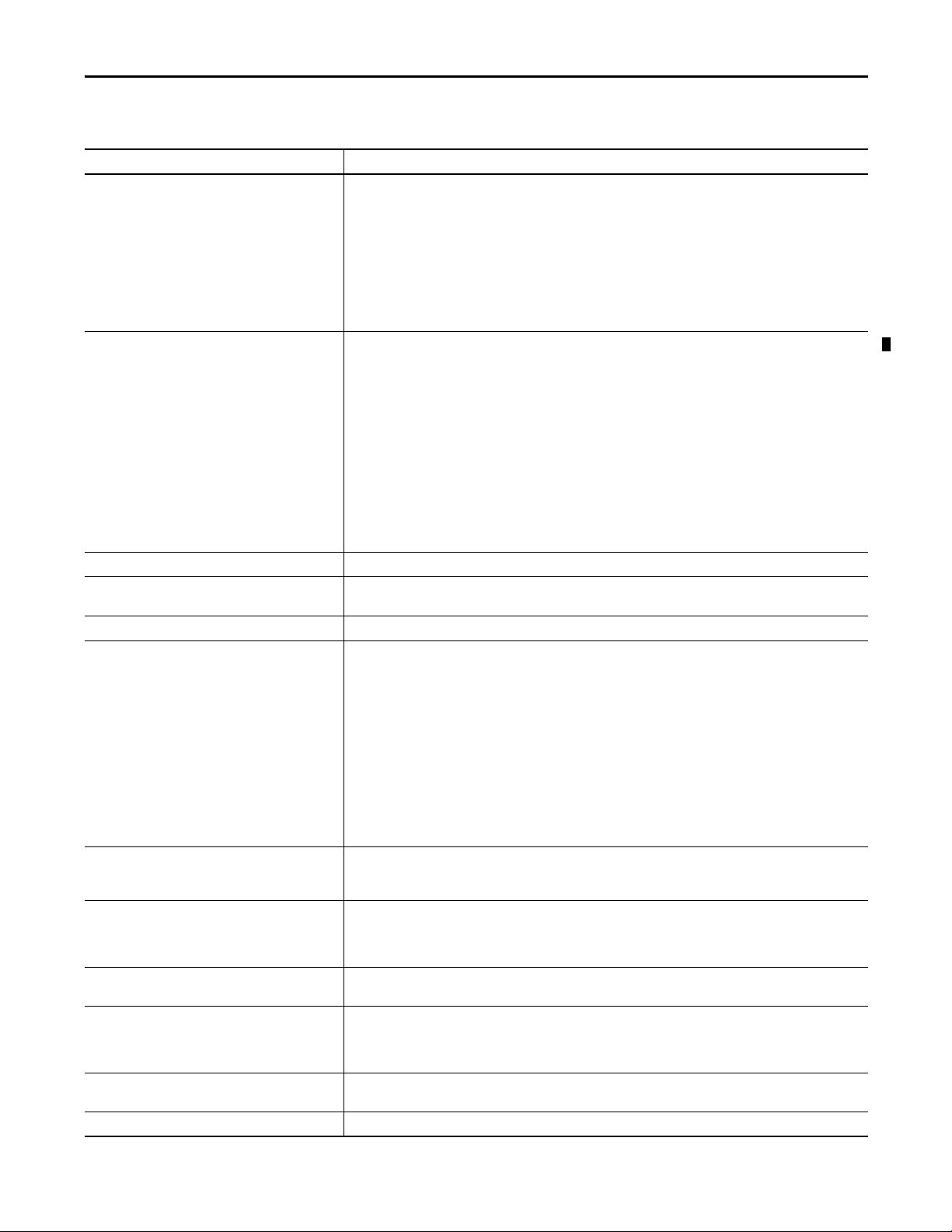

Functionality

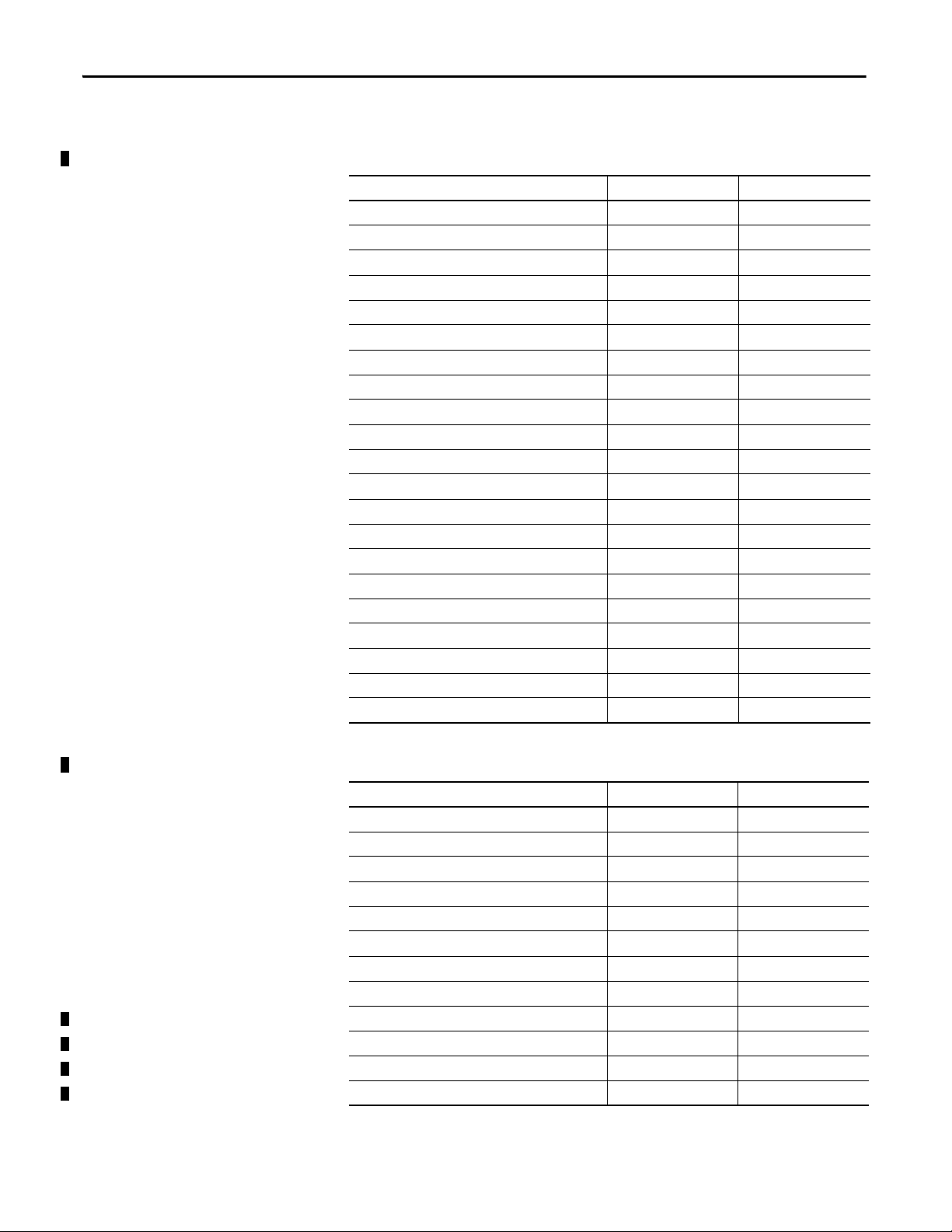

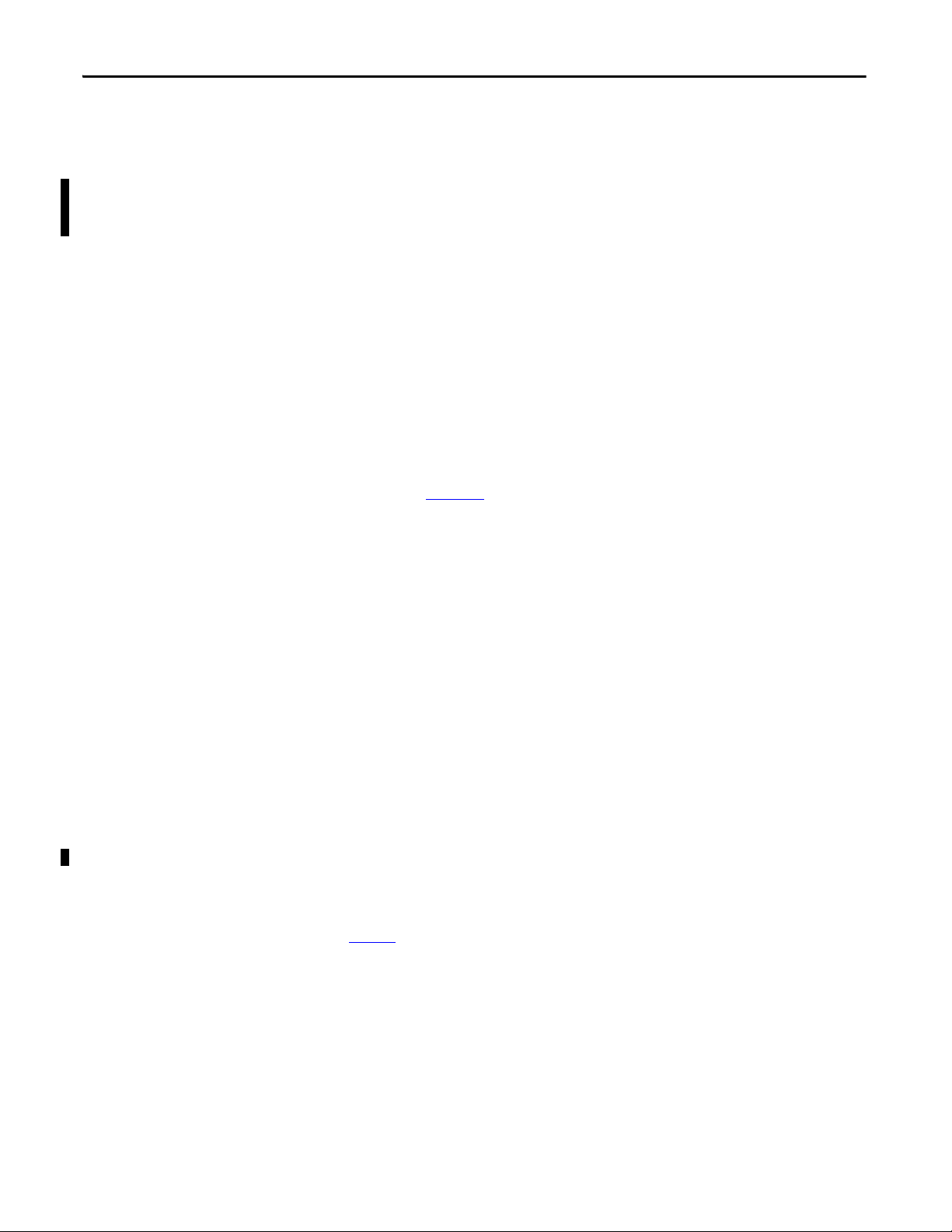

Table 2 - PowerMonitor 5000 Unit Functions

Measured Parameters 1426-M5 1426-M6

Voltage, L-L and L-N • •

Current, per phase and total • •

Frequency, last cycle and average • •

Voltage unbalance • •

Current unba lance • •

Real power, kW • •

Symmetrical Component Analysis • •

Reactive power, kVAR • •

Apparent power, kVA • •

True power factor, per phase and total • •

Displacement power factor, per phase and total • •

Reactive energy, kVARh • •

Real energy, kWh • •

Apparent energy, kVAh • •

Real power demand, kW • •

Reactive power demand, kVAR • •

Apparent power demand, kVA • •

Projected kW demand • •

Projected kVAR demand • •

Projected kVA demand • •

Demand power factor • •

\

Table 3 - Logging Functions

Logging Function 1426-M5 1426-M6

Energy log • •

Data log • •

Min/max log • •

Load factor log • •

Time of use log • •

Event log • •

Setpoint log • •

Alarm log • •

Power Qualit y log •

Waveform log •

Trigger Data log •

Snapshot log •

14 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 15

PowerMonitor 5000 Unit Overview Chapter 1

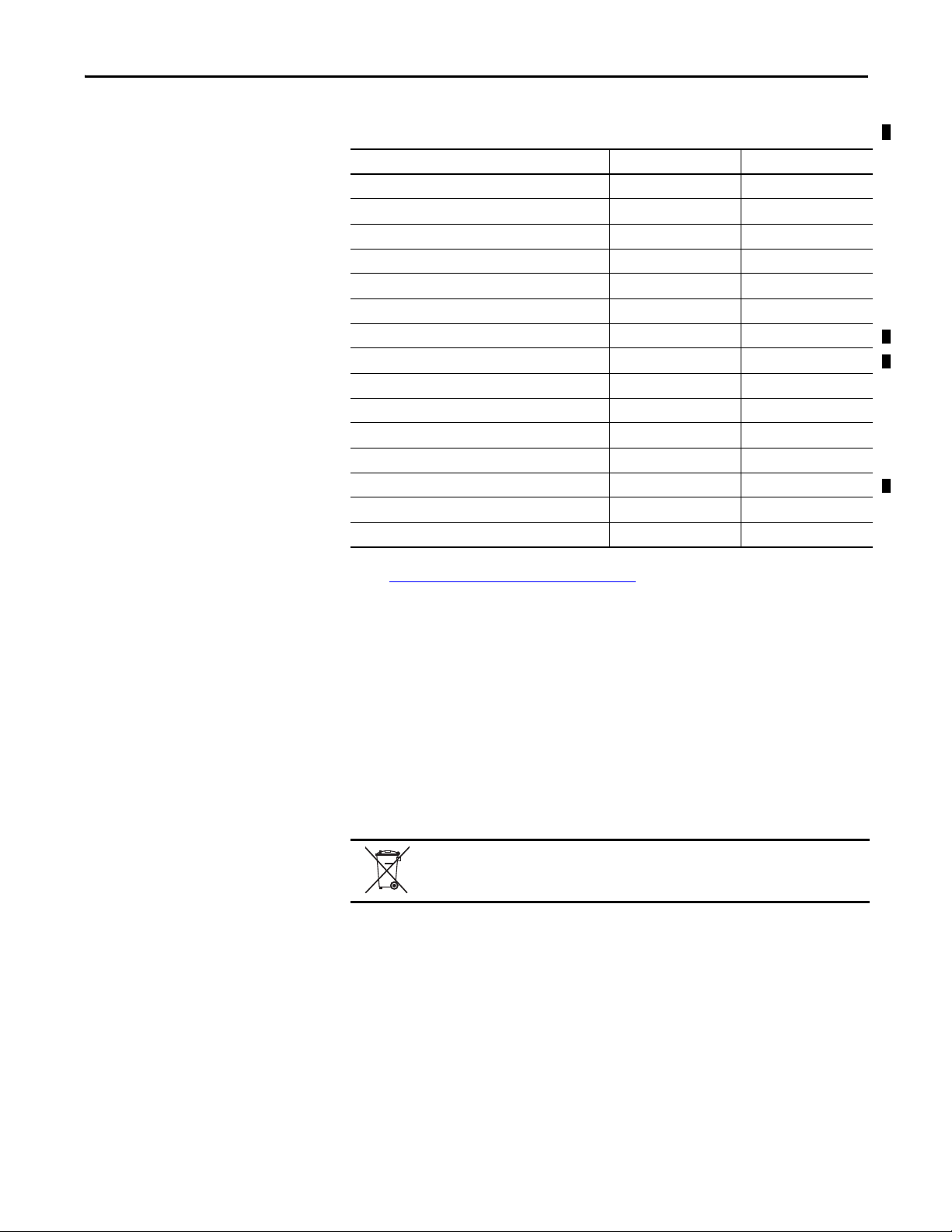

Table 4 - Other Functions

Function 1426-M5 1426-M6

Security • •

Wiring diagnostics • •

Wiring correction • •

Network time synchronization • •

Network demand synchronization • •

Configuration lock • •

IEEE 1588 Precision Time Protocol • •

Waveform synchronization broadcast (WSB) •

Relay (3) and KYZ (1) outputs • •

Status inputs (4) • •

Setpoint programming • •

Sag and swell detection • •

Logical setpoint programming •

Web page • •

CIP energy object • •

Before You Begin

Product Disposal

Refer Power Quality Monitoring on page 73 for a listing of power quality

functions.

Use this document as a guide for installing, wiring, connecting, applying power,

and configuring your power monitor to provide electric power, energy, and power

quality information through your web browser, FactoryTalk EnergyMetrix

software, or other applications. You must already be familiar with AC power and

power metering.

At the end of its life, this equipment must be collected separately from any

unsorted municipal waste.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 15

Page 16

Chapter 1 PowerMonitor 5000 Unit Overview

Notes:

16 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 17

Chapter 2

Install the PowerMonitor 5000 Unit

Only qualified personnel can install, wire, service, and maintain this equipment.

Refer to and follow the safety guidelines and pay attention to all warnings and

notices in these instructions.

ATT EN TI ON : Electrostatic discharge can damage integrated circuits or

semiconductors. Follow these guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist strap grounding device.

• Do not open the module or attempt to service internal components.

• Use a static safe work station, if available.

• Keep the module in its static shield bag when not in use.

Mounting Considerations

Mount the PowerMonitor 5000 unit in a suitable protective enclosure. Select an

enclosure that protects the unit from atmospheric contaminants, such as oil,

water, moisture, dust, corrosive vapors, and other harmful airborne substances.

Make sure the enclosure protects against personal contact with energized circuits.

The ambient temperature within the enclosure must remain within the limits

listed in Appendix B

adequate clearance for ventilation and wiring for the power monitor and other

equipment to be installed within the enclosure.

See PowerMonitor 5000 Unit Dimensions

spacing guidelines for the power monitor.

When installed within a substation or switchgear lineup, we recommend that the

power monitor be mounted within a low-voltage cubicle, isolated from medium

and high-voltage circuits. Be sure that the mounting panel is properly connected

to a low-impedance earth ground.

Mount the enclosure in a position that allows full access to the unit. Install the

unit with the ventilation slots in the bottom and top of the unit unobstructed to

assure adequate free convection cooling of its internal electronic components.

, Technical Specifications. Select an enclosure that provides

on page 18 for dimensions and

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 17

Page 18

Chapter 2 Install the PowerMonitor 5000 Unit

IMPORTANT

Virtual Wiring

Correction

---- S1

S2

---- S3

S4

---- S com

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

R2 com

---- R2 C

R3 O

---- R3 com

R3 C

Module

status

Network

status

Cong Lock

EtherNet/

IP

Power

USB

Device

USB

Host

LNK

ACT

I 1

I 2

I 3

I 4

L1

L2

GND

24V

com

V1

V2

V3

VN

VG

C

O

M M U N I

C

A T I

O

N P

O

R T

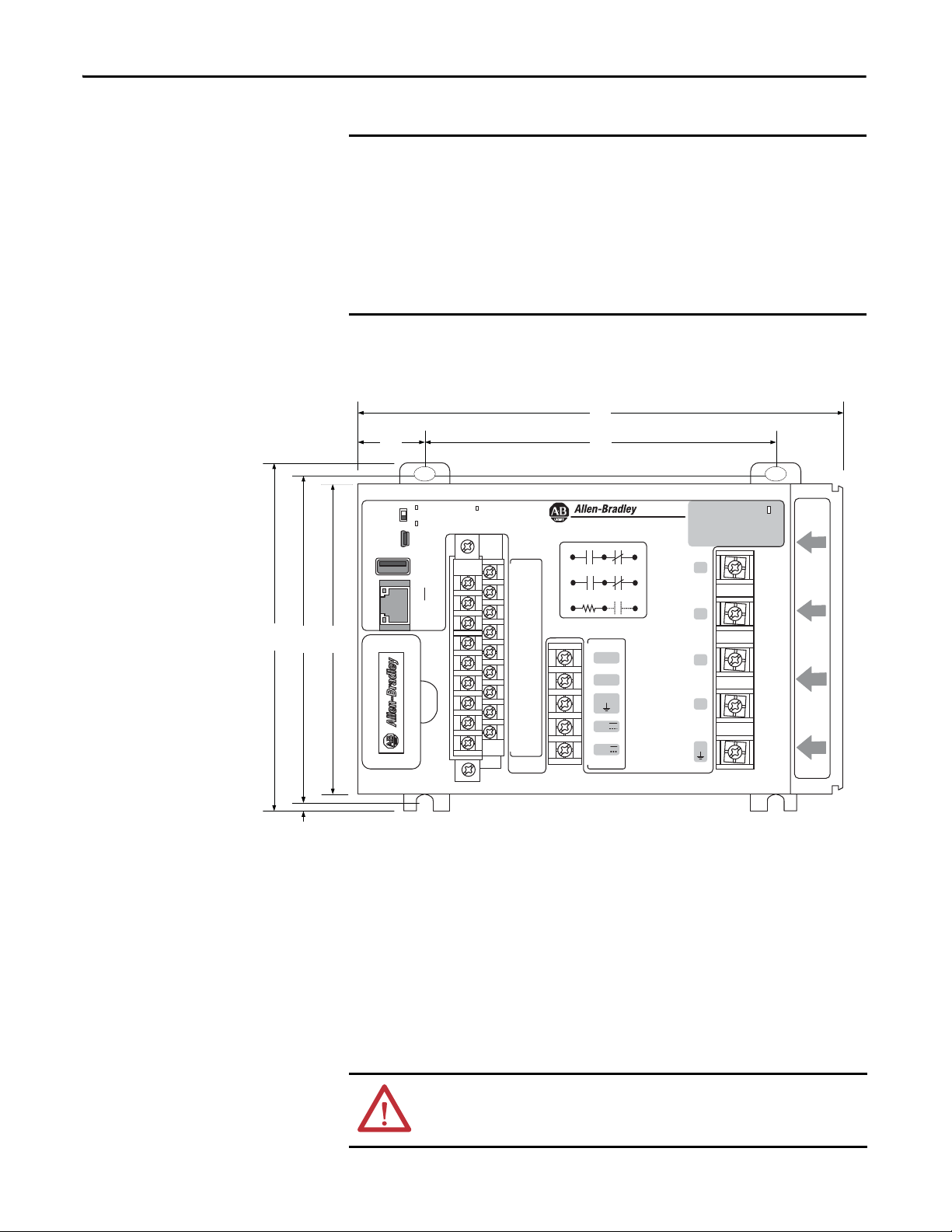

185

7.29

25

1.00

132

5.23

132

5.20

3.3

0.13

124

4.88

118

4.65

PowerMonitor 5000

Mounting Hole Tolerance:

±0.4 mm (0.016 in.)

Dimensions are in mm/in.

Depth: 178/7.0

Use caution not to block the ventilation slots of the power monitor. All wiring,

wire ways, enclosure components, and other obstructions must be a minimum

of 50 mm (2.0 in.) from the top and bottom of the unit to provide ventilation

and electrical isolation. Units can be mounted side-by-side.

Note that access to the USB device port is required for initial configuration of

the power monitor and can be required for eventual administration and

maintenance. Consider safe and convenient access to the power monitor front

panel when planning the installation location.

PowerMonitor 5000 Unit Dimensions

Z

K

Y

Rx com Rx C

Rx O

Internal

S n

24 VDC

Scom

Panel Mounting

Follow these steps for panel mounting a PowerMonitor 5000 unit.

1. Use the power monitor as a template and mark pilot holes on your panel.

2. Drill pilot holes for M4 or #8 screws.

ATT EN TI ON : During mounting of all devices, make sure that all debris (such as

metal chips or wire strands) is kept from falling into the power monitor. Debris

that falls into the module could cause damage when the device is energized.

18 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 19

Install the PowerMonitor 5000 Unit Chapter 2

IMPORTANT

L1

L2

GND

24V

com

V1

V2

V3

VN

VG

---- S 1

S2

---- S 3

S4

---- S c om

S com

---- K

Y

---- Z

R1 O

---- R 1 com

R1 C

---- R 2 O

R2 com

---- R 2 C

R3 O

---- R 3 com

R3 C

3. Use M4 or #8 screws to mount the power monitor to your panel with

1.16 N•m (10 lb•in) of torque.

4. Ground the power monitor on a ground bus with a low-impedance earth

ground connection.

5. Connect the ground bus to a functional earth ground on the panel.

The upper mounting slots are equipped with protective conductor terminals,

that must make metal-to-metal contact with the grounded mounting panel.

Wire the PowerMonitor 5000 Unit

The PowerMonitor 5000 unit is equipped with screw terminals with pressure

plates and finger protection for the control power, I/O wiring, and voltage

connections. The I/O wiring block is removable.

Current sensing conductors are routed through openings in the power monitor

housing.

Figure 2 - Terminal Block Layout

Wiring Category Wire Type Wire Size Range Wires per Terminal Recommended Torque

Control Power Cu - 75 °C (167 °F) 0.25…2.5 mm

Input/Output (I/O) 0.5…0.8 mm2 (20…18 AWG) 0.68 N•m (6 lb•in)

Voltage Sensing 0.75…2.5 mm

Current S ensing 4 mm

Wire Requirements

2

(22…14 AWG) 2 max 1.27 N•m (11.24 lb•in)

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 19

2

(18…14 AWG) 1.50 N•m (13.3 lb•in)

2

max (12 AWG max) 1 max N/A

Page 20

Chapter 2 Install the PowerMonitor 5000 Unit

Grounding

This product is intended to be mounted to a well-grounded mounting surface,

such as a metal panel. The upper mounting slots are equipped with protective

conductor terminals, which must must make metal-to-metal contact with the

mounting panel. In solid-state systems, grounding helps limit the effects of noise

due to electromagnetic interference (EMI).

2

Connect a 2.5 mm

PowerMonitor 5000 unit to the ground bus or other low-impedance earth

ground prior to connecting the control power or any other connections.

You must ground voltage and current sensing circuits to limit the maximum

voltage to ground for safety. Ground CT secondary circuits at either the CT or

the shorting terminal block. All grounds must be made to a common ground bus

or terminal.

Refer to the Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

(14 AWG) wire from the GND terminal of the

, for additional information.

Wiring Accessory Kit

The power monitor accessory kit simplifies the installation of a

PowerMonitor 5000 unit by making all the required installation accessories

available in one catalog number, 1400-PM-ACC. The accessory kit includes

three, 10 A fuses and blocks for protecting voltage sensing wiring, a 1 A fuse and

block for control wiring protection, and an 8-pole shorting terminal block for

CT wiring. Please contact your local Rockwell Automation representative for

more information.

Voltage and Current Sensing Connections

The PowerMonitor 5000 unit is capable of monitoring a variety of three-phase

and split-phase circuits. The voltage sensing connections, current sensing wiring,

and metering mode need to be selected to match the configuration of the circuit

being monitored.

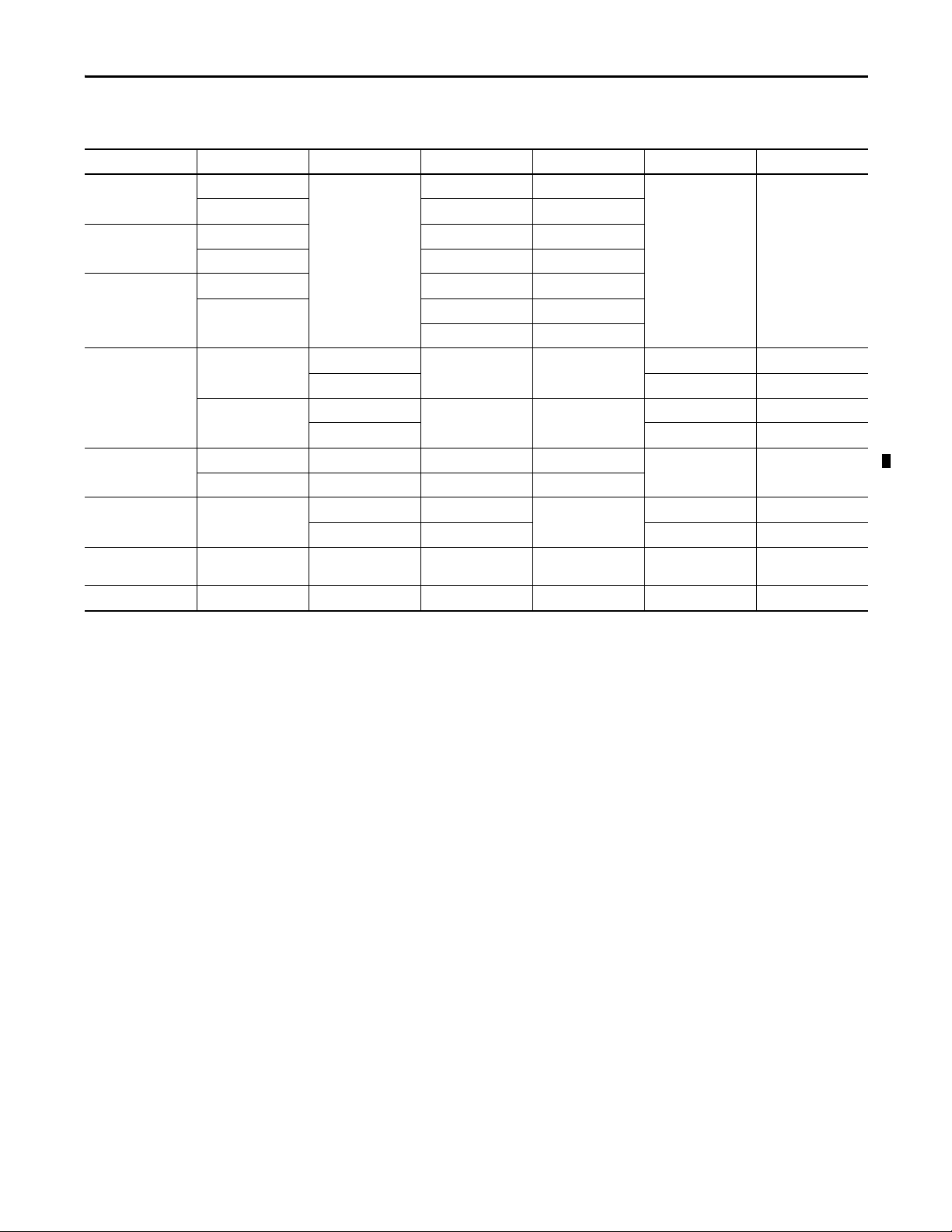

Ta b l e 5

modes.

provides a key to selecting the proper wiring diagrams and metering

20 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 21

Install the PowerMonitor 5000 Unit Chapter 2

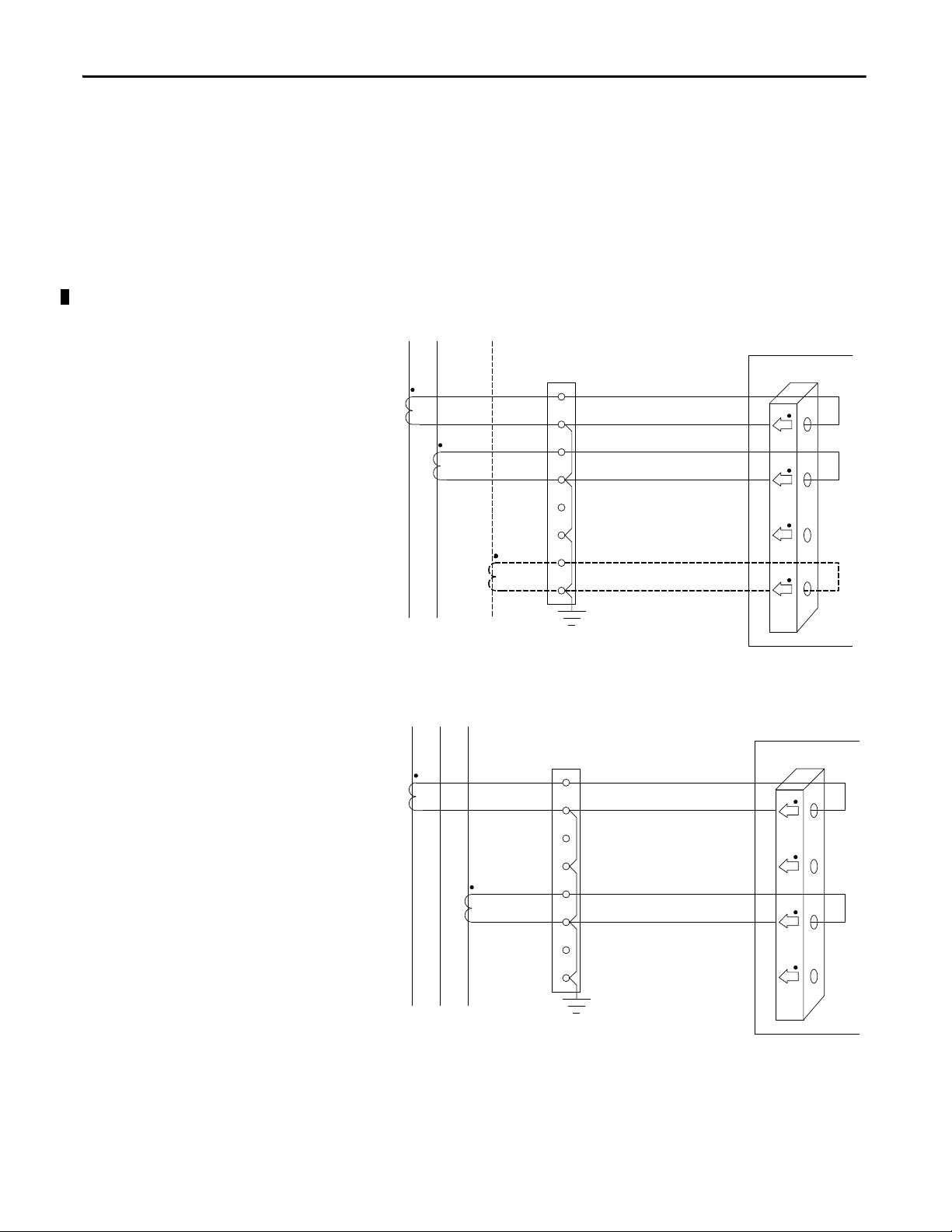

Table 5 - Selecting Wiring Diagrams and Metering Modes

Circuit Type Line - Line Voltage No. of CTs No. of PTs Voltage Sensing Current Sensing Metering_Mode

3-phase, 4-wire Wye ≤690 V 3 - Diagram V1 Diagram I3 Wye

> 690 V 3 Diagram V3

3-phase, 3-wire

grounded Wye

3-phase, 4-wire

impedance grounded

Wye

3-phase, 3-wire Delta

or ungrounded Wye

Split-phase/Single-

(1)

phase

3-phase, 3-wire Delta,

Grounded B Phase

3-phase, 4-wire high-

(2)

leg

(wildcat)

For demo use-----Demo

≤690 V - Diagram V2

> 690 V 3 Diagram V5

≤690 V - Diagram V1

> 690 V 3 L-N Diagram V3

3 L-N, 1 N-G Diagram V4

≤690 V 2 - Diagram V2 Diagram I2 Delta 2 CT

3 Diagram I3 Delta 3 CT

> 690 V 2 2

3 Diagram I3 Open Delta 3 CT

≤690 V 2/1 - Diagram V7 Diagram I1 Split-phase

> 690 V 2/1 2/1 Diagram V8

≤690 V 2 - Diagram V9 Diagram I2 Delta Grd B Ph 2 CT

(2)

3 - Diagram I3 Delta Grd B Ph 3 CT

≤690 V 3 - Diagram V10 Diagram I3 Delta High Leg

(3)

Diagram V6 Diagram I2 Open Delta 2 CT

(1) For true single-phase circuits, connect only V1 to N and wire the CT to I1. Use only the Phase 1 results.

(2) Delta Grounded B Phase and Delta High-Leg are not supported above 690 V L-L. Use the 3-phase, 3-wire Delta circuit type.

(3) 2 PTs used in open-delta configuration.

Voltage Sensing

Circuits rated up to 690V AC line-to-line can be connected directly. Higher

voltages require potential transformers (PTs), also known as voltage transformers

(VTs), to step the voltage down.

Wiring must conform to all applicable codes and standards. In particular, suitable

overcurrent protection must be provided by the user, with current and

interrupting ratings selected to protect the wiring.

Pay particular attention to correct phasing and polarity of voltage connections.

The diagrams use the ‘dot’ convention to indicate transformer polarity. The dot

indicates the H1 and X1 terminals on the high side and low side of the

transformer respectively.

When wiring a PowerMonitor 5000 unit to existing PTs and metering devices,

the voltage sensing terminals of the PowerMonitor 5000 unit must be connected

in parallel with the voltage sensing terminals of the existing metering devices.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 21

Page 22

Chapter 2 Install the PowerMonitor 5000 Unit

Metering_Mode = Wye

V1

V2

VG

V3

VN

PowerMonitor 5000

Fuses (by user)

L1 L2 L3 N

Line

Load

Ground

(1) Fuse in neutral connection is required for impedance grounded systems.

(1)

V1

V2

VG

V3

VN

Metering_Mode = Wye,

Delta 2 CT or Delta 3 CT,

as applicable

PowerMonitor 5000

Fuses (by user)

L1 L2 L3

Line

Load

Ground

The following wiring diagrams indicate typical voltage sensing connections to

various types of power systems.

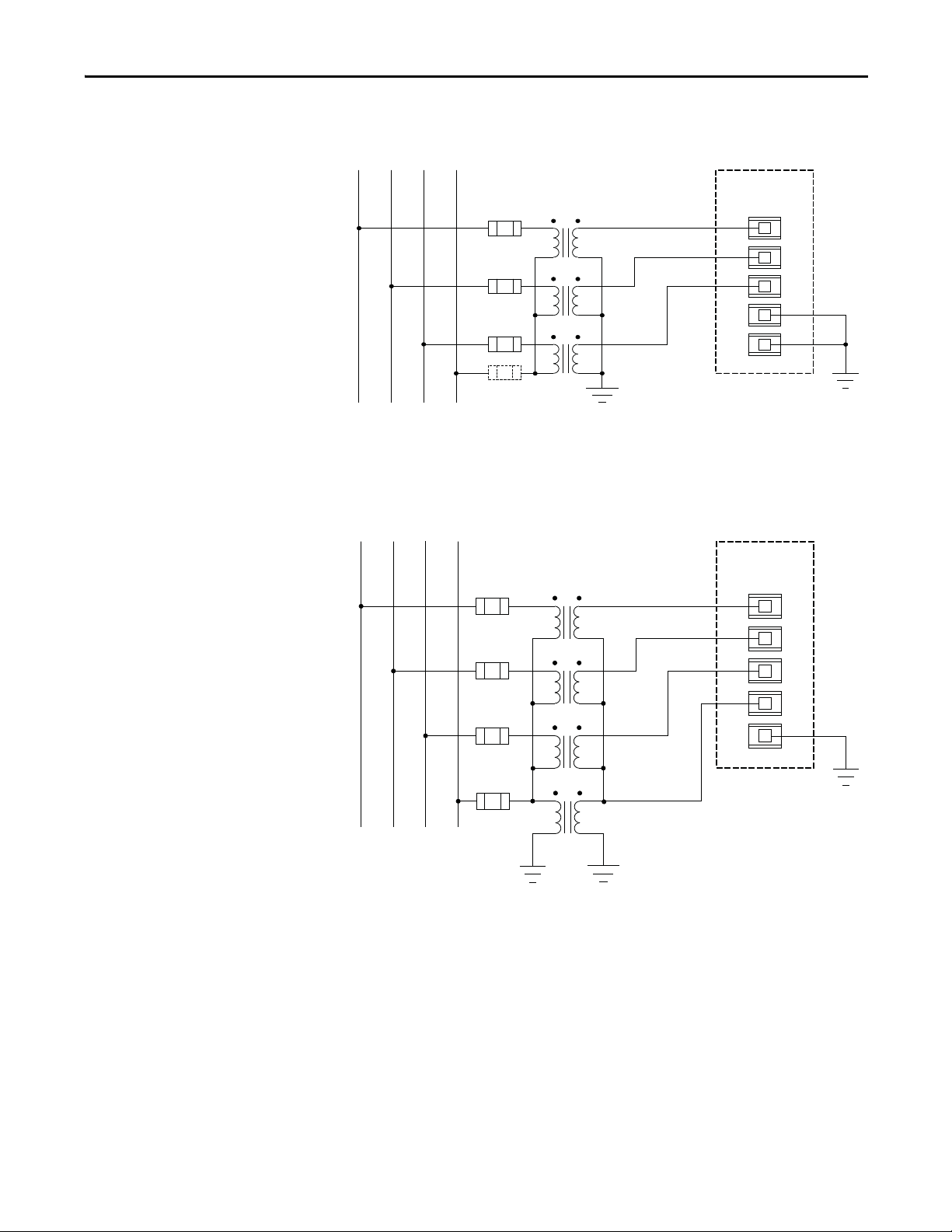

Figure 3 - Diagram V1 - 3-phase, 4-wire Wye, (690V AC line-to-line maximum)

Figure 4 - Diagram V2 - 3-phase, 3-wire Grounded Wye, or 3-phase, 3-wire Delta (690V AC line-toline maximum)

22 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 23

Install the PowerMonitor 5000 Unit Chapter 2

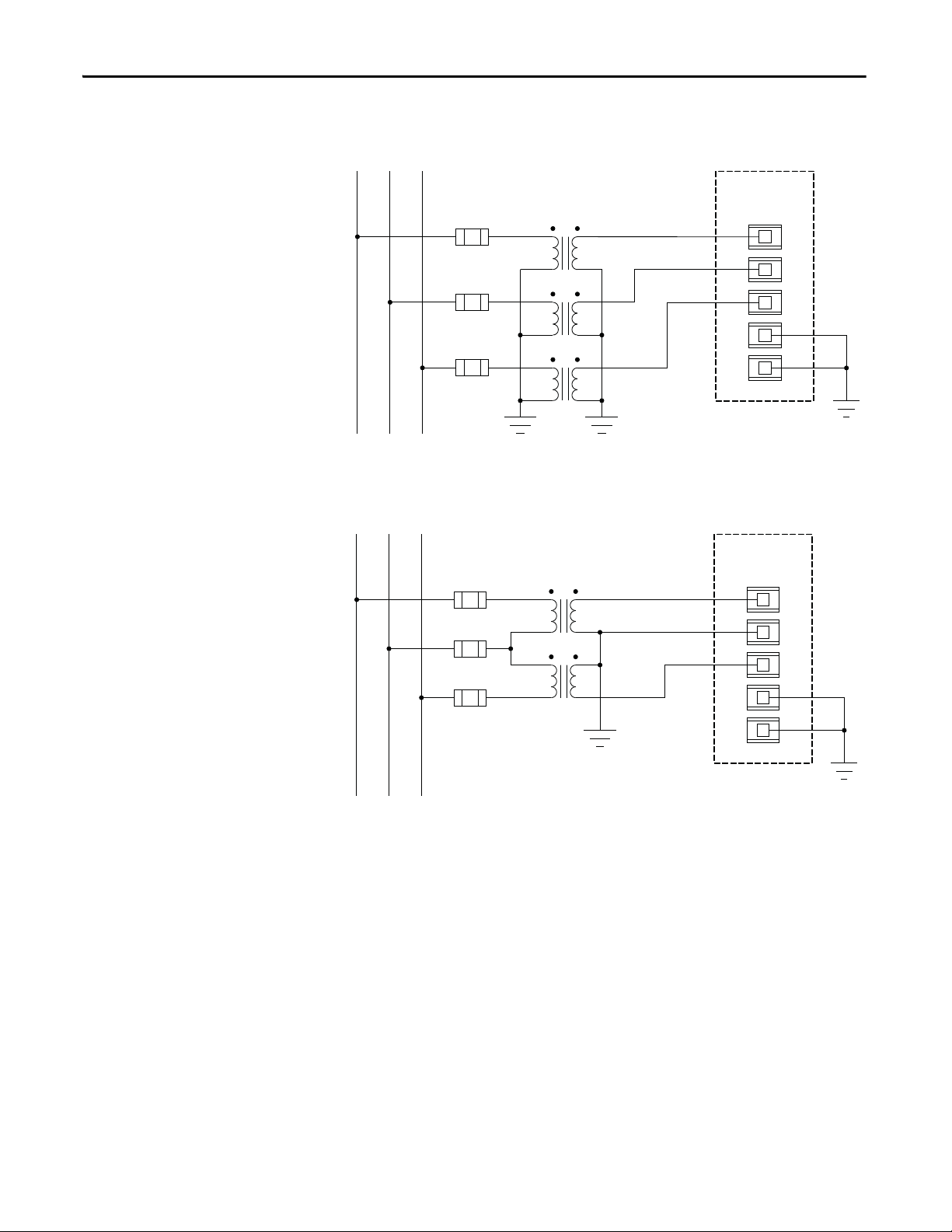

Figure 5 - Diagram V3 - 3-phase, 4-wire Wye or Impedance Grounded Wye with PTs (no neutral PT)

Line

L1 L2 L3 N

Load

(1) Fuse in neutral connection is required for impedance grounded systems.

Metering_Mode = Wye

Fuses (by user)

(1)

PTs (by user)

PowerMonitor 5000

V1

V2

V3

VN

VG

Ground

Ground

Figure 6 - Diagram V4 - 3-phase, 4-wire Impedance Grounded Wye with Line and Neutral PTs

Line

L1 L2 L3 N

Metering_Mode = Wye

Load

Fuses (by user) PTs (by user)

Ground

PowerMonitor 5000

V1

V2

V3

VN

VG

Ground

Ground

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 23

Page 24

Chapter 2 Install the PowerMonitor 5000 Unit

Metering_Mode = Open Delta 2 CT

or Open Delta 3 CT, as applicable

V1

V2

VG

V3

VN

PowerMonitor 5000

Fuses (by user) PTs (by user)

L1 L2 L3

Line

Ground

Ground

Load

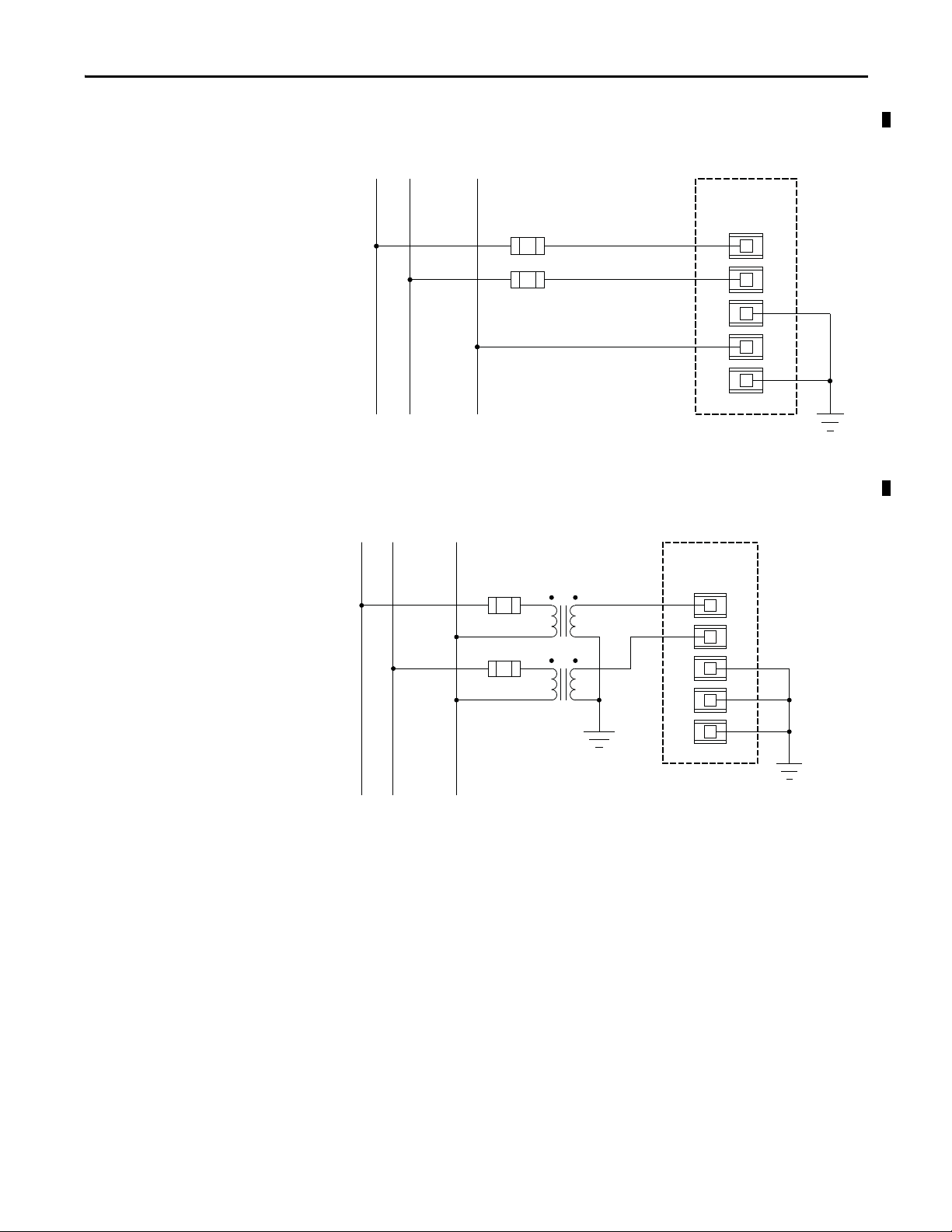

Figure 7 - Diagram V5 -3-phase, 3-wire Grounded Wye with PTs

Line

L1 L2 L3

Metering_Mode = Wye

Fuses (by user) PTs (by user)

Ground GroundLoad

Figure 8 - Diagram V6 - 3-phase, 3-wire Open Delta with Two PTs

PowerMonitor 5000

V1

V2

V3

VN

VG

Ground

24 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 25

Install the PowerMonitor 5000 Unit Chapter 2

Metering_Mode = Split-phase

V1

V2

VG

V3

VN

PowerMonitor 5000

Fuses (by user)

PTs (by user)

L1 L2 N

Line

Ground

Ground

Load

Figure 9 - Diagram V7 - Split-phase (690V AC line-to-line maximum)

Line

L1 L2 L3 N

Metering_Mode = Split-phase

PowerMonitor 5000

Fuses (by user)

Load

Figure 10 - Diagram V8 - Split-phase with PTs

V1

V2

V3

VN

VG

Ground

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 25

Page 26

Chapter 2 Install the PowerMonitor 5000 Unit

(1)

Metering_Mode = Delta High-leg

V1

V2

VG

V3

VN

PowerMonitor 5000

Fuses (by user)

High-leg

Transformer

(by user)

L1 L2 L3 N

N

C

B

A

Ground

Load

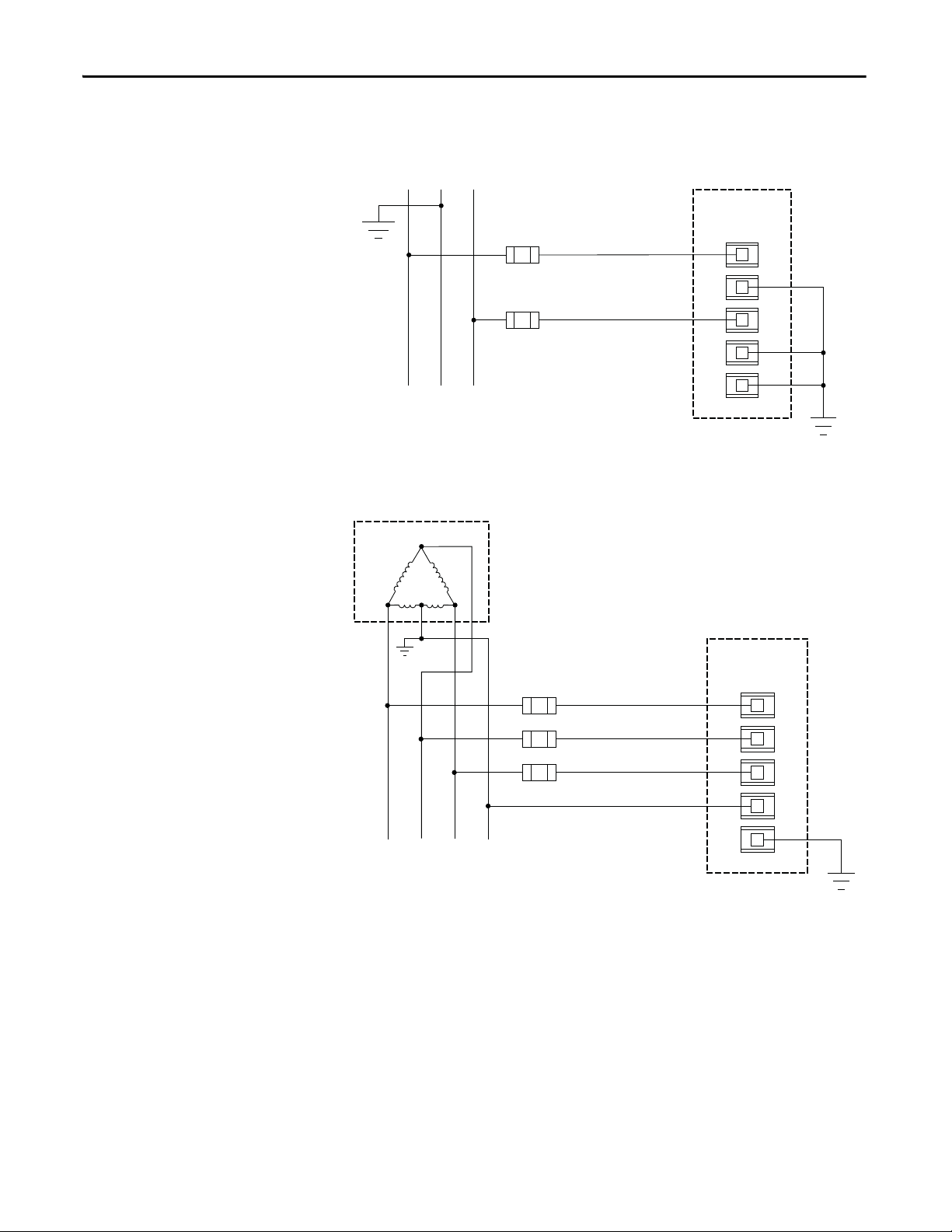

Figure 11 - Diagram V9 - 3-phase, 3-wire Grounded B-phase (690V AC line-to-line maximum)

Metering_Mode = Delta Grd B Ph 2 CT

Line

L1 L2 L3

Distribution

Ground

or Delta Grd B Ph 3 CT, as applicable

Fuses (by user)

PowerMonitor 5000

V1

V2

V3

VN

Load

(1) You can also connect V2 to L2. In this case, omit the connection from V2 to VN.

VG

Ground

Figure 12 - Diagram V10 - 3-phase, 4-wire High-leg Delta (690V AC line-to-line maximum)

26 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 27

Install the PowerMonitor 5000 Unit Chapter 2

IMPORTANT

To s horti ng te rmin al bl ock

and current transformer (CT).

X1

X2

I1

I2

I3

I4

Current Sensing

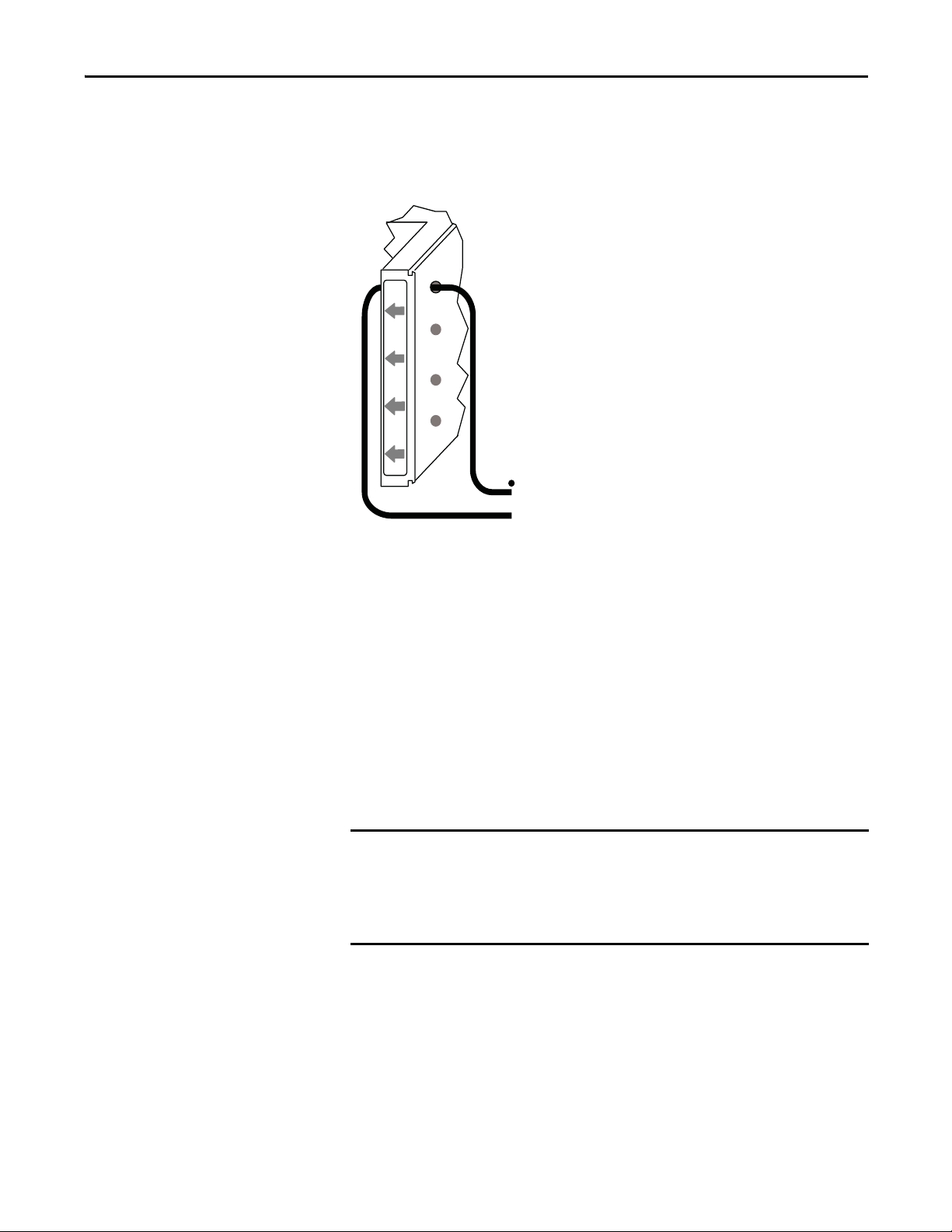

Route the CT secondary wiring through the openings in the

PowerMonitor 5000 unit as shown.

Use a shorting terminal block (included in the 1400-PM-ACC accessory kit),

test block, or shorting switch (by user) for CT wiring to permit safely servicing

connected equipment such as the PowerMonitor 5000 unit without deenergizing the power system.

Use 2.5 mm

PowerMonitor 5000 unit and the shorting block. Use 2.5 mm

2

(14 AWG) or 3.3 mm2 (12 AWG) (maximum) wiring between the

2

(14 AWG) or

larger wire between the shorting block and the CTs, depending on the length of

the circuit. Longer circuits require larger wire so that the wiring burden does not

exceed the CT burden rating and reduce system accuracy. Note that the diameter

of the current sensing wiring openings is 7 mm (0.27 in.).

Ring lugs are recommended for making CT secondary connections. Standard

ring lugs do not pass through the current sensing openings of the

PowerMonitor 5000 unit. We recommend that the installer pass the wire from

the shorting terminal block through the current sensing opening before

crimping on ring lugs.

When wiring a PowerMonitor 5000 unit to existing CTs and metering devices,

current sensing circuits of the PowerMonitor 5000 unit must be wired in series

with the CT secondary and current sensing circuits of the existing metering

devices.

Do not install overcurrent protection or non-shorting disconnecting means in

CT secondary wiring. Connect the current sensing circuit to a low-impedance

earth ground at only one point.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 27

Page 28

Chapter 2 Install the PowerMonitor 5000 Unit

L1 L2

N

(if used)

Line

CTs (by user)

CT1

CT2

CTN

(if used)

Load

Ground

Shorting Terminal

Block (by user)

Metering_Mode = Split-phase

PowerMonitor 5000

I1

I2

I3

I4

X1

X1

X1

X1

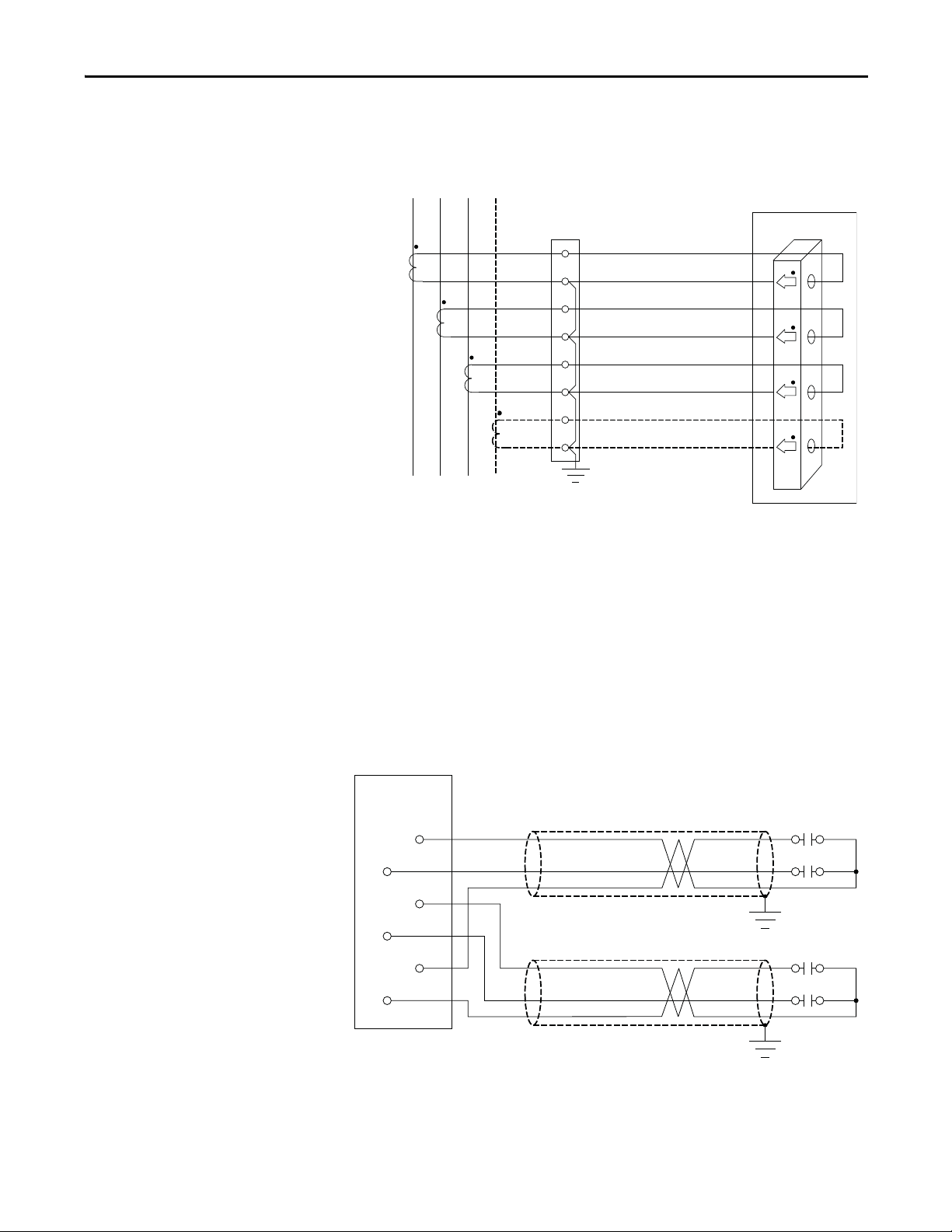

Pay particular attention to the correct phasing and polarity of current sensing

connections. The diagrams use the ‘dot’ convention to indicate transformer

polarity. The dot indicates the H1 and X1 terminals on the primary and

secondary of the CT respectively. Phasing of the CTs must correspond to the

phasing of the voltage sensing connections.

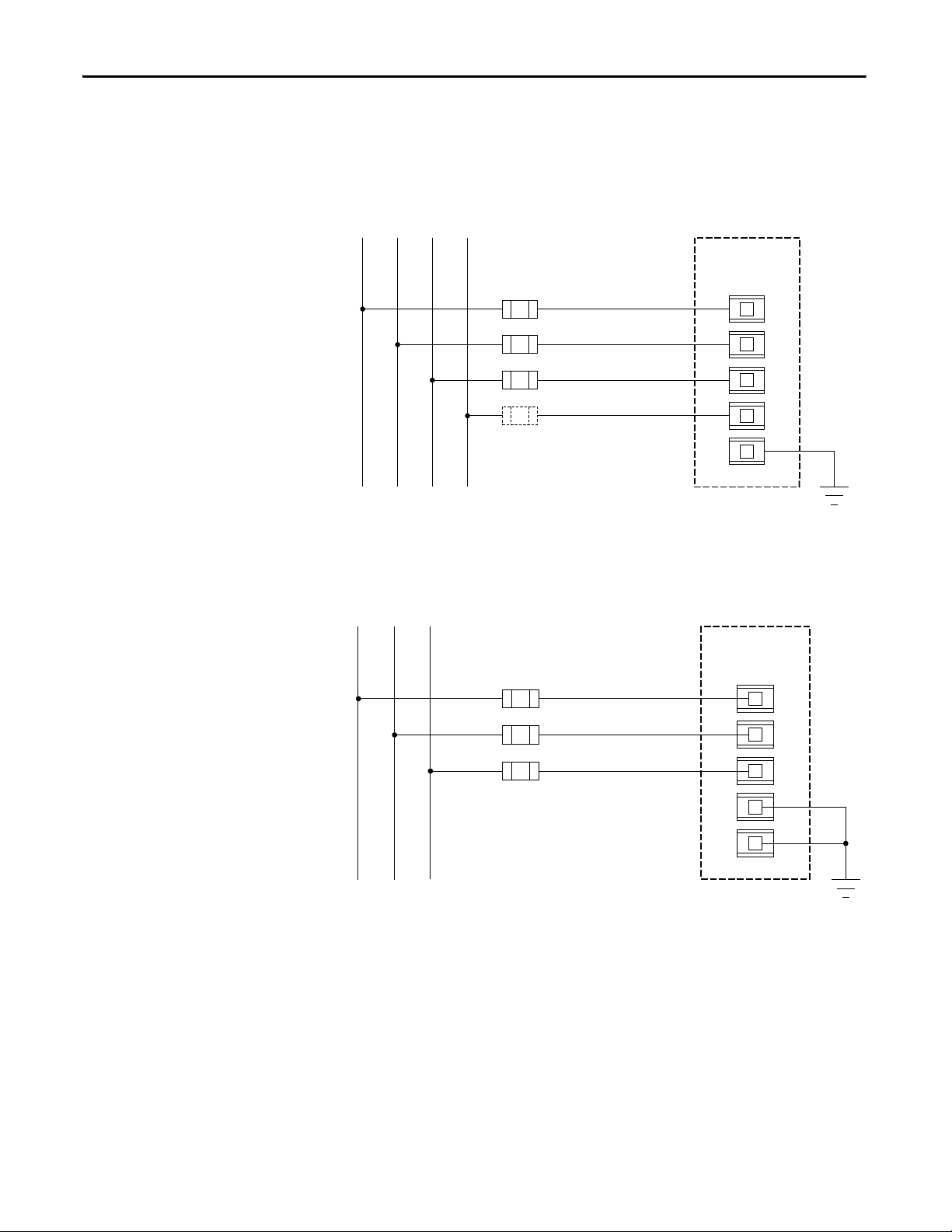

The following wiring diagrams indicate typical current sensing connections to

various types of power systems.

Figure 13 - Diagram I1 - Split-phase, 2 CTs

Figure 14 - Diagram I2 - 3-phase, 3-wire, 2 CTs

Line

L1 L2 L3

CTs (by user)

CT1

CT3

Load

28 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Metering_Mode = Delta 2 CT, Open Delta 2 CT,

Shorting Terminal

Block (by user)

or Delta Grd B Ph 2 CT, as applicable

2 CTs Can Be Used Only

On 3-wire Systems

Ground

PowerMonitor 5000

I1

X1

I2

X1

I3

X1

I4

X1

Page 29

Figure 15 - Diagram I3 - 3-phase, 3- or 4-wire, 3 CTs

S1

S2

S3

S4

Scom

Scom

Ground

Ground

Contact 1

Contact 2

Contact 3

Contact 4

PowerMonitor 5000

Metering_Mode = Wye, Delta 3 CT, Open Delta 3 CT,

Delta Grd B Ph 3 CT, or Delta High-leg, as applicable

N

Shorting Terminal

Block (by user)

CTs (by user)

CT1

Line

L1 L2 L3

(if used)

Install the PowerMonitor 5000 Unit Chapter 2

PowerMonitor 5000

I1

X1

CT2

CT3

Load

CT4

(if

used)

Ground

I2

X1

I3

X1

I4

X1

Status Inputs

Up to four dry (non-powered) contacts can be connected to the

PowerMonitor 5000 unit status inputs. The status input derives 24V DC power

from its internal power supply.

Connect status inputs by using shielded, twisted-pair cable with the shield

connected to the ground bus or other low-impedance earth ground at the contact

end only. The diagram indicates typical status input wiring.

Figure 16 - Status Inputs

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 29

Page 30

Chapter 2 Install the PowerMonitor 5000 Unit

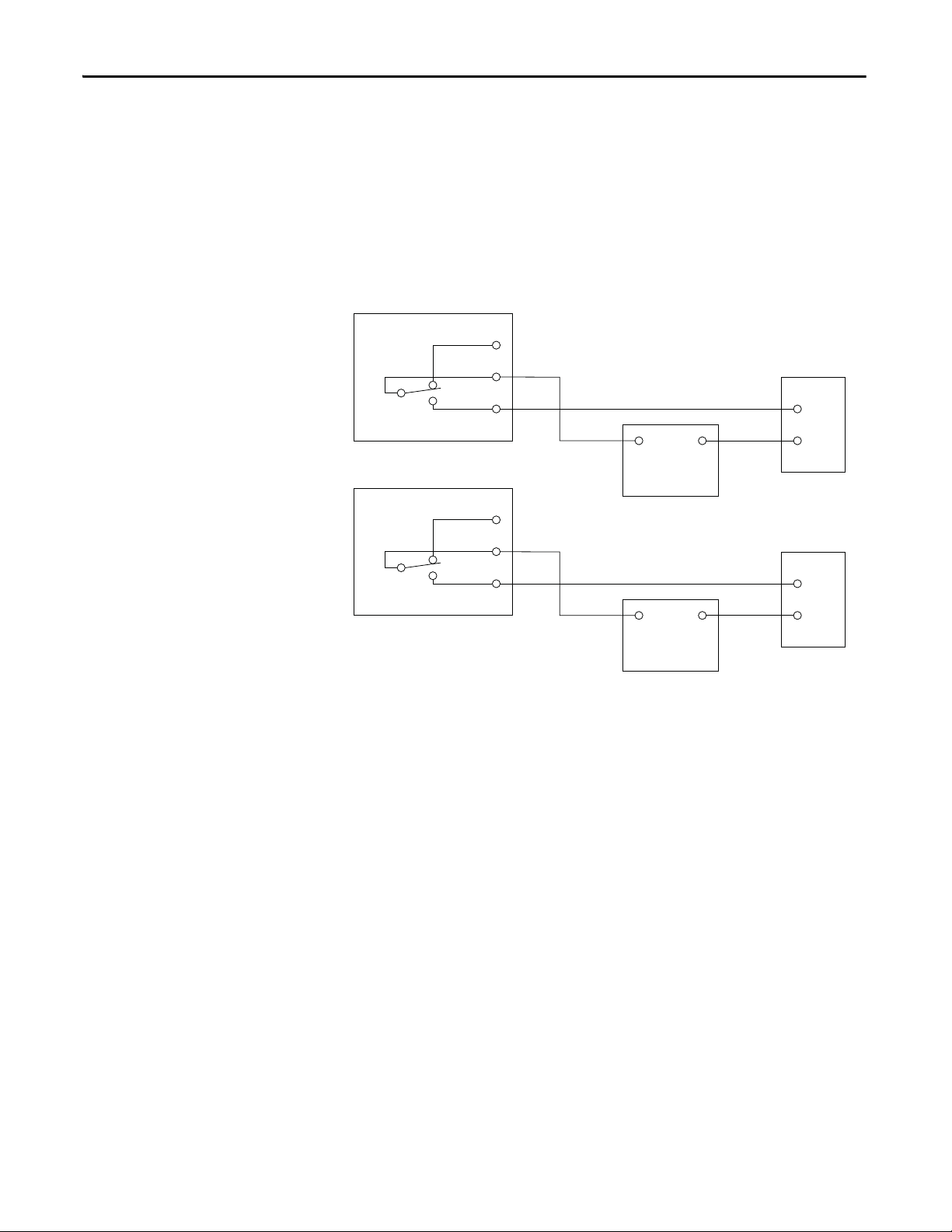

KYZ and Relay Outputs

The KYZ solid-state relay output can be connected to an external pulse

accumulator or controller. Relay outputs can be used for control of loads,

switching of circuit breakers, signaling, and other applications. Wetting voltage

must be provided by the external device or circuit. The KYZ output is designed

for low-current switching. The diagram indicates typical KYZ and relay output

wiring.

Figure 17 - KYZ and Relay Outputs

(N.C.)

(COM)

(N.O.)

PowerMonitor 5000

(equivalent circuit)

(N.C.)

(COM )

(N.O.)

PowerMonitor 5000

(typical for R1, R2, and R3)

Z

K

Y

Rn C

Rn com

Rn O

( + ) ( - )

Wetting Power

Supply

Max 240V AC/DC

(by user)

( + ) ( - )

Wetting Power

Supply

Max 240V AC/DC

(by user)

IN 1

COM

Pulse Accumulator

or Controller

(by user)

T1

T2

Controlled Load

(by user)

30 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 31

Install the PowerMonitor 5000 Unit Chapter 2

* Provided by user.

TIP

Control Power

Connect the PowerMonitor 5000 unit to a source of 120/240V AC (or 24V DC,

shown with dashed lines) control power through a user-provided disconnecting

means, such as a switch or circuit breaker close to the power monitor. Provide

overcurrent protection sized to protect the wiring, for example, a 5 A rated fuse.

Overcurrent protection is included in the 1400-PM-ACC accessory kit. The

PowerMonitor 5000 unit is internally protected. Apply control power only after

all wiring connections are made to the unit.

Figure 18 - Control Power

**

L1

L2

GND

**

24V

com

120/240V AC 50/60 Hz,

or 120/ 240V DC

24V DC

Connect Communication

Ground

This section describes how to connect communication networks.

USB Communication

The USB Device port can be used to set-up a temporary, point-to-point

connection between a personal computer and the PowerMonitor 5000 unit. This

connection is used for configuration, data monitoring, diagnostics, and

maintenance by using the unit's built-in web pages. The USB Device port is a

standard USB Mini-B receptacle. You need to install drivers to enable USB

communication.

To connect your personal computer to the PowerMonitor 5000 unit, use a

standard USB cable with a Type-A and Mini-B male plugs, Allen-Bradley catalog

number 2711C-CBL-UU02 or equivalent.

You can also display the PowerMonitor 5000 web interface by using a

PanelView Plus 6 terminal with a 2711P-RP9_ logic module with extended

features. USB communication drivers are already installed in the logic module.

Refer to Configure the Connection

on page 34 to continue the setup.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 31

Page 32

Chapter 2 Install the PowerMonitor 5000 Unit

Install Drivers

Yo u c an do wn lo ad dr iv er s f ro m

http://www.rockwellautomation.com/compatibility

Follow the steps listed below to install the USB driver.

1. Connect the PowerMonitor 5000 unit to your computer with a USB cable

and apply power to the power monitor.

The computer detects the new device and prompts you to install the driver.

2. Click ‘Yes, this time only’ and click Next.

.

3. Click Install from a list or specific location (Advanced) and click Next.

32 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 33

Install the PowerMonitor 5000 Unit Chapter 2

4. Click Browse and select the folder containing the driver .inf file.

5. Click Next.

Wait while the driver installs.

6. Click Finish when the driver installation is complete.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 33

Page 34

Chapter 2 Install the PowerMonitor 5000 Unit

TIP

Configure the Connection

Follow these steps to configure the connection.

1. From the Windows desktop, choose Start > Settings > Network

Connections.

A new Local Area Connection with a Device Name ‘Remote NDIS based

Device’ was added when you installed the driver.

2. Right-click the connection name and choose Properties.

Setting up a PanelView 6 terminal in Windows CE follows a similar process.

Please refer to the Rockwell Automation Knowledgebase answer ID 115608 or

455067 if you need further details.

34 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 35

Install the PowerMonitor 5000 Unit Chapter 2

3. Select Internet Protocol (TCP/IP) and click Properties.

4. Click Use the following IP address and type in the address

192.168.169.100.

The default subnet mask 255.255.255.0 is correct. The default IP address

of the PowerMonitor 5000 unit is 192.168.169.3.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 35

Page 36

Chapter 2 Install the PowerMonitor 5000 Unit

IMPORTANT

Browse the PowerMonitor 5000 Web Page by Using the USB Connection

Open the Internet Explorer browser on the computer and browse to the url

http://192.168.169.3.

The PowerMonitor 5000 web page displays in your browser.

Your browser must have Allow Scriptlets set to Enable for the

applicable security zone for configuration changes to be made to the

power monitor by using the web page.

By default the security setting of the power monitor's webpage is disabled.

36 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 37

Install the PowerMonitor 5000 Unit Chapter 2

C

O M M U N IC AT I O N P O

R T

C O M M U N I C A T IO N P O R T

Ethernet Switch Uplink to LAN

PowerMonitor 5000 Unit PowerMonitor 5000 Unit

Native Ethernet Communication

The PowerMonitor 5000 unit connects easily to industry-standard Ethernet hubs

and switches by using standard CAT-5 UTP (unshielded twisted-pair) cables

with RJ45 connectors. The table below shows the cable and connector pin

assignments.

Table 6 - Cable and Connector Pin Assignments

Terminal Signal Function

1TX+TX+

2TX-TX-

3RX+RX+

4

5

6RX-RX-

7

8

Typical Ethernet connections are shown in the diagram below.

Figure 19 - Typical Ethernet Connections

Module

Power

status

Cong Lock

Network

status

USB

Device

USB

Host

IP

LNK

EtherNet √

ACT

C

PowerMonitor 5000

Y

---- S1

Rx com Rx C

Rx O

S2

---- S3

Internal

24VDC

S4

---- S com

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

GND

R2 com

---- R2 C

R3 O

24V

---- R3 com

R3 C

com

Virtual Wiring

Correction

Z

K

S n

Scom

L1

L2

I 1

V1

I 2

V2

V3

I 3

VN

VG

I 4

Module

Power

status

Cong Lock

Network

status

USB

Device

USB

Host

---- S1

S2

IP

LNK

ACT

---- S3

S4

---- S com

EtherNet √

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

R2 com

---- R2 C

R3 O

---- R3 com

R3 C

Virtual Wiring

KYZ

S n

L1

L2

GND

Correction

I 1

V1

Scom

I 2

V2

V3

I 3

VN

VG

I 4

PowerMonitor 5000

Rx com Rx C

Rx O

Internal

24VDC

24V

com

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 37

Page 38

Chapter 2 Install the PowerMonitor 5000 Unit

IMPORTANT

Optional DeviceNet Network Communication

An optional DeviceNet port can be factory-installed in PowerMonitor 5000

units with a catalog number ending in -DNT, and can also be purchased from

Rockwell Automation and installed by the user.

ATT EN TI ON : Power must be removed from the power monitor before inserting

or removing an optional communication card. Inserting or removing an

optional communication card under power can damage the card or the power

monitor.

For information on installing the optional communication card, see the

PowerMonitor 5000 Optional Communication Modules Installation

Instructions, publication 1426-IN002

For detailed DeviceNet system installation information, including cable lengths,

the placement of terminating resistors, power supplies, and other media

components, refer to the DeviceNet Cable System Planning and Installation

Manual, publication DNET-UM072

.

.

Install suitable terminating resistors at the ends of the DeviceNet cable.

You must install and wire a suitable 24V DC power supply to the V+ and Vconductors in the DeviceNet cable. The power monitor consumes less than

50 mA from the DeviceNet 24V DC supply.

Configuration options for optional DeviceNet communication include the node

address (MAC ID) and data rate. Defaults are node 63 and 125 Kbps.

Table 7 - DeviceNet Terminal Block Wiring Connections

Terminal Signal Function Color

1 COM (V-) Common Black

2 CAN_L Signal Low Blue

3 SHIELD Shield Uninsulated

4 CAN_H Signal High White

5 VDC+ (V+) Power Supply Red

38 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 39

121 Ω

Terminating

Resistor

(See Note 2)

121 Ω

Terminating

Resistor

(see Note 2)

Personal Computer With

1784-PCDPCMCIA Interface Card

Or

1770-KFD Interface Box

Or

SLC™ Controller With

1747-SDN Scanner

1) Example network protrayed.

For detailed DeviceNet

installations, including

cable requirements, refer to

the DeviceNet Cable System

Planning and Installation Manual,

publication DNET-UM072.

2) Terminating resistors

must be connected

to each end of the

DeviceNet network. Omit the

terminating resistors

if the devices are already

equipped with internal

terminating resistors.

V-

V+

CAN_L

SHLD

CAN_H

V-

V+

CAN_L

SHLD

CAN_H

V-

V+

CAN_L

SHLD

CAN_H

V-

V+

CAN_L

SHLD

CAN_H

+

-

DeviceNet

24V DC

Power Supply

Or Other DeviceNet

Scanner Devices

Or

ControlLogix® Controller

With 1756-DNB Scanner

Virtual Wiring

Correction

---- S1

S2

---- S3

S4

---- S com

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

R2 com

---- R2 C

R3 O

---- R3 com

R3 C

Module

status

Network

status

Cong Lock

EtherNet √

IP

PowerMonitor 5000

Power

USB

Device

USB

Host

LNK

ACT

I 1

I 2

I 3

I 4

L1

L2

GND

24V

com

Rx O

V1

V2

V3

VN

VG

1

DS NS

2345

DeviceNet

12345

Internal

24VDC

Y

K

Rx com Rx C

S n

Install the PowerMonitor 5000 Unit Chapter 2

Figure 20 - Connecting a Powermonitor 5000 Unit to Other DeviceNet Devices

Z

Scom

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 39

Page 40

Chapter 2 Install the PowerMonitor 5000 Unit

Optional ControlNet Communications

An optional ControlNet port can be factory-installed in PowerMonitor 5000

units with a catalog number ending in -CNT, and can also be purchased from

Rockwell Automation and installed by the user.

ATT EN TI ON : Power must be removed from the power monitor before inserting

or removing an optional communication card. Inserting or removing an

optional communication card under power may damage the card or the power

monitor.

For information on installing the optional communication card, see the

PowerMonitor 5000 Optional Communication Modules Installation

Instructions, publication 1426-IN002

A ControlNet media installation includes trunk cable, taps and terminators, and

can include optional redundant media. For detailed ControlNet system

installation information, refer to the ControlNet Coax Media Planning and

Installation Guide, publication CNET-IN002

Configuration User Manual, publication CNET-UM001

.

, and the ControlNet Network

.

This diagram shows a simple ControlNet network installation using redundant

media.

Module

Power

status

Cong Lock

Network

status

USB

Device

USB

Host

IP

LNK

EtherNet √

ACT

MS

ControlNet

AB

---- S1

S2

---- S3

S4

---- S com

S com

---- K

Y

---- Z

R1 O

---- R1 com

R1 C

---- R2 O

R2 com

---- R2 C

R3 O

---- R3 com

R3 C

Y

Rx O

Internal

24VDC

PowerMonitor 5000

K

Rx com Rx C

S n

L1

L2

GND

24V

com

Virtual Wiring

Correction

Z

V1

Scom

V2

V3

VN

VG

I 1

I 2

I 3

I 4

40 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 41

Chapter 3

Setup

Although the PowerMonitor 5000 unit ships from the factory with default

settings, you need to configure it for your particular requirements. The

PowerMonitor 5000 unit provides a built-in Web interface for monitoring and

configuration through its native Ethernet communication port and its USB

device port. You perform initial configuration by using the power monitor's builtin USB Web interface. Once initial setup is complete, you can continue

configuring the PowerMonitor 5000 unit by using its USB or network Web

interface, by using optional software, or by communicating with the power

monitor's data table.

This section describes how to use the USB and Ethernet Web interface for setup.

You can find information on configuring various functions of the

PowerMonitor 5000 unit in the following chapters:

• Chapter 4

• Chapter 5

• Chapter 6 Logging

• Chapter 7 Logic Functions

• Chapter 8 Other Functions

, Metering.

Power Quality Monitoring

Setup Using the Web Interface

If you are using optional software, such as FactoryTalk EnergyMetrix software,

please refer to publication

FTALK-UM001,

refer to the Communication

For initial setup, connect a personal computer to the PowerMonitor 5000 unit by

using a USB cable. Refer to USB Communication

Initial setup is usually performed by using the USB Web interface and initial

security setup can be performed only by using the USB Web interface.

for information. If you are using data communication for setup,

on page 181 for information.

on page 31.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 41

Page 42

Chapter 3 Setup

Open the Internet Explorer browser and browse to http://192.168.169.3. The

PowerMonitor 5000 home page displays in your browser as shown below. The

home page displays general information about the PowerMonitor 5000 unit. You

can navigate by clicking folders and pages from the tree on the left.

Initial setup by using the USB Web interface includes at least the following

configuration steps:

• Basic Metering - this aligns the power monitor metering functionality with

the properties of the circuit to which it connects

• Native Ethernet Network Communication - this permits access to the unit

for data monitoring and setup through an Ethernet network

• Optional Communication - this permits access to the unit for data

monitoring and setup through an optional communication card

• Date and Time - this sets the unit's internal clock so that time stamps in

logged data are correct

• Security (if desired) - enabling and configuring security guards against

unauthorized changes to the power monitor configuration

Once initial setup has been completed, including configuration of the Ethernet

IP address, you can also access the Web interface from a computer connected

through a network to the PowerMonitor 5000 unit’s native Ethernet port. Open

the Internet Explorer browser and browse to the IP address of the unit.

42 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 43

Setup Chapter 3

Obtaining Access to the Configuration Pages

The PowerMonitor 5000 unit initially has security disabled by default. If your

power monitor's security is disabled, you can continue setting up the unit without

logging in.

If Security is Enabled

If security is enabled, the web page header displays ‘Logged in as:’ and a Log in

link.

If security is enabled, you need to log in as an administrator to configure setup

parameters. If not logged in as an administrator, you can view, but not change,

configuration parameters. If you need to log in, click the Log in link.

The USB connection has a special administrator account. Follow these steps to

log in with this account.

1. Type in the user name usbadmin.

2. Type in the password usbadmin.

3. Click Log In.

A dialog box reports the result.

To log in from the network Web interface, select a previously configured

administrator account user name and password. The PowerMonitor 5000 unit

does not permit logging in with the USB administrator login from the network.

You remain logged in until you log out or until 30 minutes have passed since

configuration changes have been applied.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 43

Page 44

Chapter 3 Setup

How to Set Up the PowerMonitor 5000 Unit

From any power monitor web page, click the Configuration folder. A list of

available configuration pages is displayed in the tree. The steps for entering,

editing, and applying configuration parameters are similar for each configuration

page. The configuration parameters and their properties are described nin the

following chapters:

• Chapter 4

• Chapter 5

• Chapter 6 Logging

• Chapter 7 Logic Functions

• Chapter 8 Other Functions

The configuration pages contain text boxes for entering parameter values, pulldown menus for selecting enumerated parameter values, and an Apply Changes

button for committing changes to the power monitor. The power monitor

checks that parameter values are within their valid range before applying them. A

dialog box appears to report the success or reason for failure of an attempt to

apply new parameters.

, Metering.

Power Quality Monitoring

Basic Metering Setup

Follow these steps to configure the basic metering parameters.

1. Click the Metering_Basic page under the open Configuration folder.

This page displays the existing basic metering configuration of the power

monitor, including the metering mode, PT (VT) and CT ratios, nominal

voltage and frequency, and demand.

You can select other configuration pages by clicking the desired page in the

tree, or by clicking the corresponding tab in the page.

2. To change the basic metering setup, enter the desired values into the text

boxes, scroll down, and click Apply Changes.

A dialog box appears to report the result of the setup change.

44 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 45

Setup Chapter 3

EXAMPLE

This Metering_Basic page illustrates the setup for a 480V, 3-phase system with 1000:5 current transformer

(CT) ratios on all phases and the neutral.

Native Ethernet Communication Setup

Choose the Configuration folder and choose the CommunicationsNative page.

The PowerMonitor 5000 unit is set up by default to obtain an IP address

automatically from a DHCP (Dynamic Host Configuration Protocol) server. If

your power monitor is on a network served by a DHCP server, and the power

monitor is connected to the network, it has probably already been assigned an IP

address.

We recommend that each power monitor be assigned a static, or fixed, IP address,

because DHCP addresses can change from time to time, resulting in loss of

communication with client applications. Obtain a fixed IP address, subnet mask,

default gateway, and other network setup parameters from your network

administrator. Another option can be to set up the power monitor as a reserved

client in the DHCP server.

Refer to Communication

setup parameters.

on page 181 for more information on communication

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 45

Page 46

Chapter 3 Setup

EXAMPLE

IMPORTANT

This example explains how to change from a DHCP-assigned to a static IP address.

The initial network configuration is shown below. The IP address assigned is 192.168.200.8. The network

administrator has provided a range of static IP addresses in the same subnet, beginning with

192.168.200.100. In this case, the default gateway and DNS servers remain the same for static or DHCPobtained addresses (verify if this is true in your case with your network administrator).

To change to the new address, from the IP_Address_Obtain pull-down menu choose Static, type in the new

IP address, and click Apply Changes.

You can change the network configuration from the USB or network web

pages. If you change the IP address from the network Web interface, you need

to browse to the new IP address to re-establish communication.

46 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 47

Setup Chapter 3

IMPORTANT

Optional DeviceNet Communication Setup

Choose the Configuration folder and choose the OptionalComm page, which

lets you set the address and communication rate to operate in your system. The

range for DeviceNet_Address is 0…63 (default). The selections for

DeviceNet_Baudrate are the following:

• 0 = 125 Kbps (default)

• 1 = 250 Kbps

• 2 = 500 Kbps

• 3 = Autobaud

Refer to Optional DeviceNet Communication

on page 182 for more

information on optional DeviceNet communication parameters.

You can also set up or change the DeviceNet port parameters by using

RSNetWorx for DeviceNet software or similar utilities.

Optional ControlNet Communication Setup

Choose the Configuration folder and then choose the OptionalComm page. The

ControlNet address is the only configurable parameter. The default is 255.

Set Up Date and Time

Follow these steps to set the date and time.

1. Choose the Configuration folder and choose the DateTime page.

2. Enter the year, month, day, hour, and minute into the corresponding input

fields and click Apply Changes.

If your power monitor is set up for time synchronization with either a

SNTP or IEEE 1588 PTP server, the time is already set.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 47

Page 48

Chapter 3 Setup

Set Up Initial Security

If you choose to enable security on the power monitor, you must perform the

initial security setup by using the USB Web interface.

1. In the USB web page, choose the Security folder and then the Security

page.

2. From the Security Defaults pull-down menu, choose Enable Security.

3. Accept the prompt regarding enabling security and accept the prompt to

reload the web pages.

4. Log in with user name usbadmin and password usbadmin.

5. Accept the prompt that the login was successful.

6. To add a network administrator, click AddNew.

48 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 49

Setup Chapter 3

7. Enter a username and password for a network administrator.

The username and password can be any string up to 32 characters in

length. This example sets a username of admin with a password of admin.

Make a note of the new network administrator login for future use and

keep it in a secure location.

Now that the network administrator user has been created, you can continue

setting up the PowerMonitor 5000 unit by using the USB web page or by

connecting through the native EtherNet/IP port and using the network Web

interface. This includes the ability to configure additional users, administrators,

and application security accounts. Only one administrator class user can be

logged in at a time. Be sure to log out when finished editing the unit

configuration.

To utilize security with optional communication, set up an application class

account by using the USB or Ethernet web page. Security cannot be configured

by using optional communications. DeviceNet communication uses application

class security, which requires a client application to write the username and

password by using explicit messaging before writing configuration and

commands or reading logged data.

Test Security

To test the network administrator login, follow these steps.

1. Browse to the network address of the PowerMonitor 5000 unit.

2. Click Log in from the page header and enter the user name and password

just created and click Log In.

Rockwell Automation Publication 1426-UM001F-EN-P - November 2013 49

Page 50

Chapter 3 Setup

Note that only the USB Web interface can be used to enable, disable, or reset

security. If security accounts are lost or forgotten, you need to connect to the

USB Web interface and log in with the usbadmin account to create new network

security accounts.

Setting Up Remaining Functions of the PowerMonitor 5000 Unit

The remaining functions are set up in the same way as the examples discussed in

this section. This manual lists configuration parameters and options for basic

metering, communication, and other functions and features of the

PowerMonitor 5000 unit in these chapters:

• Metering

• Power Quality Monitoring on page 73

• Logging on page 99

• Logic Functions on page 151

• Other Functions on page 171

on page 51

Setup Using Optional Software

Setup Using Communication

FactoryTalk EnergyMetrix software, with the RT option, provides a

configuration interface for the PowerMonitor 5000 unit, including the ability to

upload, edit, download, and back up the unit configuration on a server. Please

refer to the FactoryTalk EnergyMetrix User Manual, publication

FTALK-UM001

PowerMonitor 5000 unit by using FactoryTalk EnergyMetrix software. Contact

your local Rockwell Automation sales office or Allen-Bradley distributor, or visit

http://www.software.rockwell.com

packages.

Refer to Communication on page 181 for detailed information on unit setup by

using communication with a programmable controller or custom software

application.

, or online help topics for information on configuring the

for more information on available software

50 Rockwell Automation Publication 1426-UM001F-EN-P - November 2013

Page 51

Chapter 4

Metering

Top ic Pag e

Basic Metering 51

Wiring Diagnostics 53