Page 1

Installation Instructions

Air Flow Transmitter

Catalog Number 1414-IFZ35FGDAA

Before you Install

In order for the transmitter to operate correctly all the information supplied in this

document must be followed.

IMPORTANT

Transmitter must not be mounted near elbows , damper vanes or

other restrictions that may cause turbulent air flow. Always install

in a straight section of duct.

About the Air Flow Transmitter

The Air Flow Transmitter is an airflow transducer which may be used for control,

monitoring and regulation of airflow speed in fresh air and ventilation units etc.

The transmitter registers airflow speed according to a thermal principle based on

the fact that the cooling action of air increases with airspeed. The action is

measured and converted to a 4 to 20 ma or a 0 to 10V signal corresponding to

airflow speeds from 0.5 to 8 m/s (100 to 1575 ft/min) or 0.5 to 16 m/s (100 to 3150

ft/min).

The micro-processor based electronics provides an output signal that is linear and

corrected for temperature changes. If a standard analog instrument is connected the

airflow speed and temperature can be read remotely.

The transmitter has a separate 0 to 10 Vdc output signal for measurement of the air

temperature 0 to 50ºC (32 to 122°F).

Publication 1414-IN001A-EN-P - October 2005

Page 2

2 Air Flow Transmitter

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that dangerous voltage may be present.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that surfaces may be dangerous temperatures.

Publication 1414-IN001A-EN-P - October 2005

Page 3

Air Flow Transmitter 3

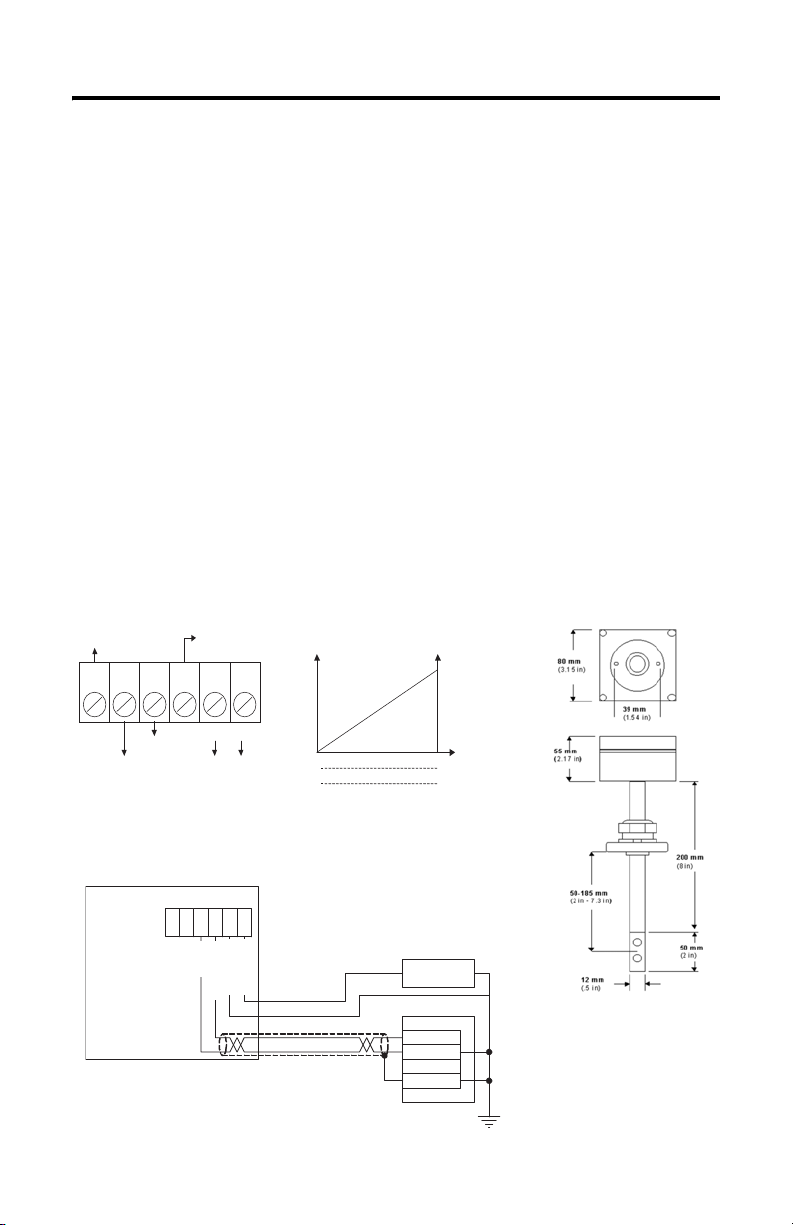

Install Air Flow Transmitter

The transmitter is mounted in such a way that the airflow passes the sensor head.

The power supply cables to the transmitter should be kept separated from high

voltage lines where heavy transients may occur.

The transmitter can be mounted in airflow channels with a diameter or channel

width of 100 to 370 mm (4 in to 15 in)

Wire and Connect Air Flow Transmitter

The length of the cable is not critical. Avoid placing it in parallel with other cables,

which may induce electrical noise on the voltage signal and thus disturb the

function of the transmitter.

The best installation is obtained with a separate cable to the transmitter. It is

recommended to use a shielded cable to the transmitter as this improves immunity

against noise when it is used in light-industrial areas. The shield should be

terminated at the supply point but not terminated at the transmitter.

Wiring Diagram

Tem p 0- 10 VDC

6 5 4 3 2 1

Flow 0-10VDC

GRD

Flow 4-20Ma

- +

24 VAC

16-30 VDC

Wire to a Programmable Controller

Air Flow Transmitter

132

465

- +

Ground

Power

24 VAC,

Flow, 0-1 0 V

Temp 0-10 V

16-30 V DC

Flow, 4-20 mA

Output Signals Scales

mA

20

4

0

0

Loop power supply

Analog Current Input

V ou t( d c)

10

(3150 ft /min)

16 m/s

(1575 ft /min)

8 m/s

+ 24 VDC -

ANL IN 0 +

ANL IN 0 -

ANL COM

Publication 1414-IN001A-EN-P - October 2005

Dimensions

Page 4

Post-installation

The module is delivered with the range set at 0.5 to 8 m/sec (100 to 1575 ft/min). If

jumper SW1 is removed on the printed circuit board, the range 0.5 to 16 m/sec (100

to 3150 ft/min) is obtained.

Maintenance

As the thermal measuring principle is based on the cooling principle of the air, dirt

accumulation on the sensor will reduce the measuring accuracy. If the transmitter is

used in dirty air, the sensor head should be cleaned at suitable intervals.

Specifications

Air Flow Transmitter Specifications

Specification Value

Airflow speed 0.5…8 m/s (100…1575 ft/m, 0.5…16 m/s (100…3150 ft/m)

Standard current signal 4…20 ma (loop resistance < 500Ω)

Standard voltage signal 0…10V (max. 5mA)

Air temperature –10ºC…+60ºC (+14°F…140°F)

Ambient temperature –20ºC…+50ºC (-4°F…+122°F)

AC voltage supply 24V ac ±10% (120 ma)

DC voltage supply 16…30V dc (80 ma)

Absolute accuracy ±5% of full scale

Rise time 20 sec

Time constant 5 sec

Depth of insertion in channel 50…200 mm (2…8 in.)

Dimensions (HxWxD) 80 x 80 x 55 mm(3.15 x 3.15 x 2.17 in)

All other trademarks are the property of their respective holders, and are hereby acknowledged.

Publication 1414-IN001A-EN-P - October 2005 PN 40055-231-01(1)

Supersedes Publication XXXX-X.X.X - Month Year Copyright © 2005 Rockwell Automation, Inc. A ll rights reserved. Printed in t he U.S.A.

Loading...

Loading...