Page 1

Installation Instructions

Duct Temperature Transmitter

Catalog Numbers

1414-CTQ03AIDAA, 1414-CTQ03PDDAA, 1414-CTQ03PCDAA,

1414-CTQ03PBDAA, 1414-CTP03PDDAA, 1414-CTP03PCDAA, 1414-CTP03PBDAA,

1414-ITQ03ADDAA, 1414-ITQ03ACDAA, 1414-ITQ03ABDAA, 1414-ITP03ADDAA,

1414-ITP03ACDAA, 1414-ITP03ABDAA, 1414-ITQ02ADDAA, 1414-ITQ02ACDAA,

1414-ITQ02ABDAA, 1414-ITP02ADDAA, 1414-ITP02ACDAA, 1414-ITP02ABDAA

Top ic Pa ge

About the Duct Temperature Transmitter 1

Important User Information 2

Install the Duct Temperature Transmitter 3

Field Calibration 5

Specifications 5

Dimensions 7

About the Duct Temperature Transmitter

This duct temperature transmitter is designed for single point monitoring. It is available with

two probe lengths and enclosures to fit commercial and light-industrial applications. The duct

temperature transmitter provides a 4…20 mA current signal proportional to the sensed

temperature and is loop powered.

The temperature transmitter is designed to convert 1000 ohm RTD signal into an analog output

with ±0.15 °C Class A, ±0.30 °C Class B, and 0.1% FSO accuracy for the board.

Page 2

2 Duct Temperature Transmitter

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.rockwellautomation.com/literature/

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an

explosion in a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

) describes some important differences between solid-state

ATTENTION: Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid

a hazard and recognize the consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to

alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to

alert people that surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the

product.

Publication 1414-IN005B-EN-P - July 2010

Page 3

Duct Temperature Transmitter 3

Install the Duct Temperature Transmitter

The duct type probes monitor a single point temperature within the duct. Follow these steps to

install the duct temperature transmitter.

1. Drill a 6.35 mm (0.25 in.) hole in a straight section of duct away from heating, cooling,

or humidifier elements.

2. Select a probe length that places the sensor well into the duct.

Probes are tip sensitive, this helps to avoid errors due to laminar flow.

3. Install the probe through the hole.

Wire and Connect the Duct Temperature Transmitter

Follow these steps to wire and connect the duct temperature transmitter.

IMPORTANT

1. Disconnect the power supply before making any connections to prevent electrical shock

or equipment damage.

2. Connect the transmitter to the controller using 14…22 AWG wire.

Use shielded cable for the highest noise immunity. The unit comes factory set for

4…20 mA loop powered operation with only the PWR and OUT required. The COM

terminal is used for voltage output types or for AC power.

IMPORTANT

3. Follow the example wiring diagram and make all connections in accordance with

national and local electrical codes.

4. Ensure the controller Analog Input (AI) matches the transmitter output signal type

before power is applied.

The device is reverse voltage protected and will not operate if connected backwards.

Follow specification ratings or inaccurate readings may result.

Follow anti-static precautions to prevent damage to the device.

Do not route signal wires in the same conduit with power cables as signal

degradation may occur.

Operation

1. Allow the product to warm-up for 20 minutes before you attempt to verify accuracy of

the transmitter.

2. Measure the signal by inserting a mA meter in series with the OUT terminal.

The signal should read between 4…20 mA.

Publication 1414-IN005B-EN-P - July 2010

Page 4

4 Duct Temperature Transmitter

3. Calibrate the unit in the field by using precision resistance values equal to the zero and

span of the temperature range.

4. Replace the attached probe with the resistor, then adjust the ZERO and SPAN pots

accordingly to obtain the correct output signal.

5. Repeat the adjustments until both values are correct.

Wiring Digram

Sinking 4…20 mA signal w/excitation from controller

Temp Sensor

CONTROLLER

Power Supply

24V DC

( - ) ( + )

COM

CONTROLLER

PT1000 ohm

NEG

SEN

EXC

24V DCIN

4…20 mA loop signal

4…20 mA signal w/external 24V DC power supply

PT1000 ohm

Temp Sensor

4…20 mA loop signal

IN

OUT

COM

PWR

SPAN

ZERO

NEG

SEN

EXC

PWR

OUT

COM

SPAN

ZERO

Publication 1414-IN005B-EN-P - July 2010

Page 5

Duct Temperature Transmitter 5

Field Calibration

The unit can be calibrated in the field by using precision resistor values equal to the zero and

span of the transmitter temperature range.

1. Disconnect the sensor from the transmitter and connect the resistor that represents the

zero value to the EXC and NEG terminals.

TIP

If the unit uses a three-wire sensor, a jumper must be placed between EXC and

SEN.

2. Adjust the ZERO pot until the desired output is achieved.

3. Connect the resistor that represents the span value to the EXC and NEG terminals.

4. Adjust the SPAN pot until the desired output is achieved.

Repeat these steps until no further adjustment is required.

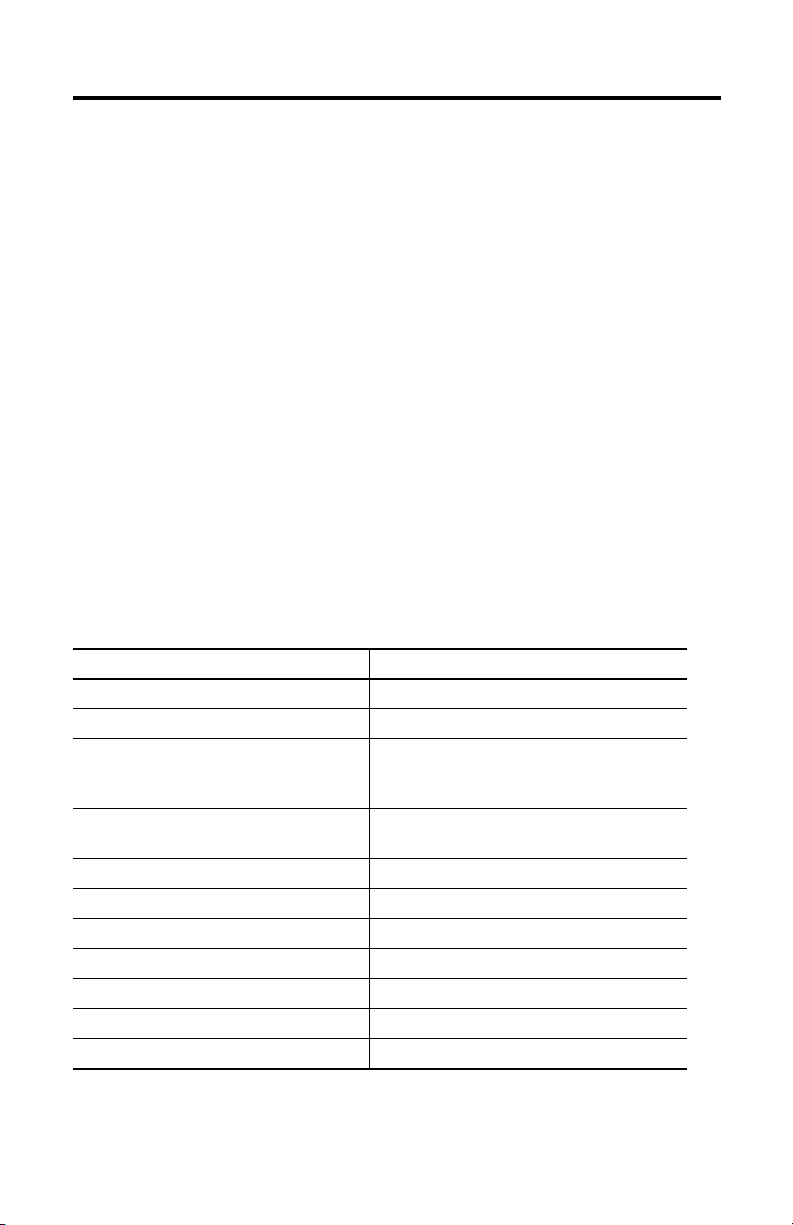

Specifications

Technical Specifications - Duct Temperature Transmitter

Attribute 1414-CTQx, 1414-CTPx, 1414-ITQx, 1414-ITPx

Operating temperature range -20…105 °C (-4…221 °F)

PCB operating temperature range 0…70 °C (32…158 °F)

Sensor types PT1000 Ω Platinum RTD

Enclosures Plastic ABS - UL94-V - NEMA 1

Cable type PVC insulated, parallel bonded

Probe 304 stainless steel with spin welded tip

Output signal 4… 20 mA current loop

Transmitter accuracy ±0.1% of span, including linearity

Power supply 15…35V DC

Consumption Current: 22.5 mA Max. (with open sensor)

Wiring connections Screw terminal block (14…22 AWG)

Commercial and Hybrid: ±0.3% Class B

Industrial: ±0.2% Class A

Aluminum - NEMA 3R

Publication 1414-IN005B-EN-P - July 2010

Page 6

6 Duct Temperature Transmitter

Available Duct Transmitters, 4…20 mA

Description Commercial Hybrid Industrial with

cc-pcb

Plastic Enclosure Aluminum Enclosure

457 mm (18 in.) probe

0…100 °C (32…212 °F)

457 mm (18 in.) probe

0…50 °C (32…122 °F)

457 mm (18 in.) probe

0…35 °C (32…95 °F)

457 mm (18 in.) probe

-50…50 °C (-58…122 °F)

457 mm (18 in.) probe

-50…100 °C (-58…212 °F)

457 mm (18 in.) probe

-50…121 °C (-58…250 °F)

305 mm (18 in.) probe

-6.7…48.9 °C (20…120 °F)

305 mm (12 in.) probe

0…100 °C (32…212 °F)

305 mm (12 in.) probe

0…50 °C (32…122 °F)

305 mm (12 in.) probe

0…35 °C (32…95 °F)

305 mm (12 in.) probe

-50…50 °C (-58…122 °F)

305 mm (12 in.) probe

-6.7…48.9 °C (20…120 °F)

1414-CTQ03PDDAA 1414-ITQ02ADDAA

1414-CTQ03PCDAA 1414-ITQ02ACDAA

1414-CTQ03PBDAA 1414-ITQ02ABDAA

1414-ITQ02WADAA

1414-ITQ02WJDAA

1414-ITQ02WMDAA

1414-CTQ03AIDAA 1414-ITQ02AIDAA

1414-CTP03PDDAA 1414-ITP02ADDAA

1414-CTP03PCDAA 1414-ITP02ACDAA

1414-CTP03PBDAA 1414-ITP02ABDAA

1414-ITP02WADAA

1414-CTP03AIDAA 1414-ITP02AIDAA

Publication 1414-IN005B-EN-P - July 2010

Page 7

Dimensions

Duct Temperature Transmitter 7

Plastic ABS Enclosure (NEMA 1)

Aluminum Enclosure (NEMA 3R)

115.8 mm

114.3 mm

(4.50 in.)

(4.56 in.)

53.9 mm

(2.12 in.)

53.6 mm

(2.11 in.)

Various Lengths

Conduit Holes

Ø 12.7 mm (0.50 in.) (2X)

Conduit Holes

Ø 25. 6 mm (0.85 in.) (2X )

Various Lengths

Stainless Steel Probe

Foam Gasket

Stainless Steel Probe

6.35 mm

(0.25 in.)

72 mm

6.35 mm

(2.85 in.)

(0.25 in.)

84.3mm

(3.32 in.)

Mounting Holes

Ø 5.08 mm (0.2 in.) (2X)

25.4 mm

(1.0 in.)

85 mm

(3.35 in.)

96 mm

(3.78 in.)

Publication 1414-IN005B-EN-P - July 2010

Page 8

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products. At

http://www.rockwellautomation.com/support/

technical and application notes, sample code and links to software service packs, and a MySupport feature that

you can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer

TechConnect support programs. For more information, contact your local distributor or Rockwell Automation

representative, or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's

contained in this manual. You can also contact a special Customer Support number for initial help in getting your

product up and running.

United States or Canada 1.440.646.3434

Outside United States

or Canada

Use the Worldwide Locator

http://www.rockwellautomation.com/support/americas/phone_en.html

your local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these

procedures.

, you can find technical manuals, a knowledge base of FAQs,

.

at

, or contact

United States

Outside United States

Contact your distributor. You must provide a Customer Support case number (call the

phone number above to obtain one) to your distributor to complete the return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to

improve this document, complete this form, publication RA-DU002

http://www.rockwellautomation.com/literature/

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

.

Publication 1414-IN005B-EN-P - July 2010 PN-79834

Supersedes Publication 1414-IN005A-EN-P - October 2005 Copyright © 2010 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

, available at

Loading...

Loading...