Page 1

Installation Instruction

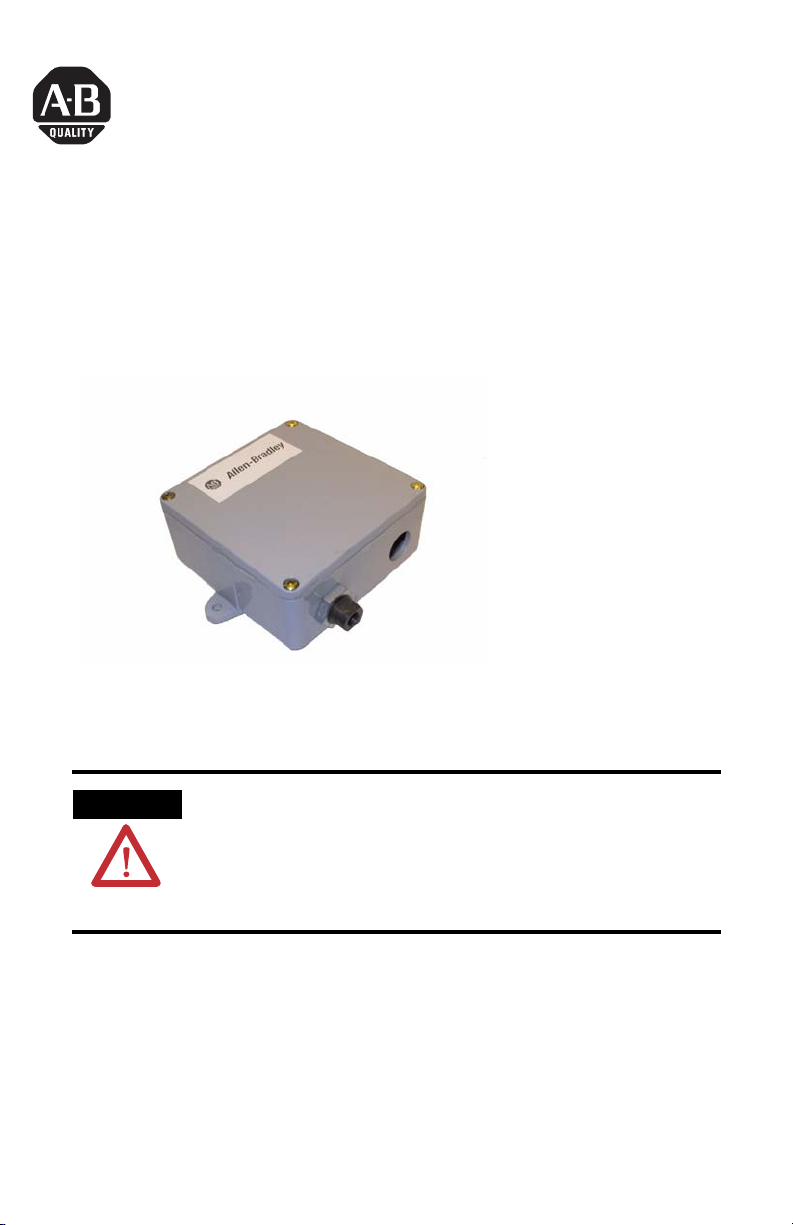

Gauge Liquid/Gas Pressure Transmitter

Catalog Number(s) 1414-CPZ10FSFAA,

1414-IPZ10FSFAA

Explosion Hazard

WARNING

Do not use in an explosive or hazardous environment, with

combustible or flammable gasses, as a safety or emergency stop

device or in any other application where failure of the product

could result in personal injury. Use electrostatic discharge

precautions during installation and do not exceed the device

ratings.

Publication 1414-IN015A-EN-P - October 2005

Page 2

2 Gauge Liquid/Gas Pressure Transmitter

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that dangerous voltage may be present.

Labels may be located on or inside the equipment (e.g., drive or motor) to alert people

that surfaces may be dangerous temperatures.

Publication 1414-IN015A-EN-P - October 2005

Page 3

Gauge Liquid/Gas Pressure Transmitter 3

About the Gauge Liquid/Gas Pressure Transmitter

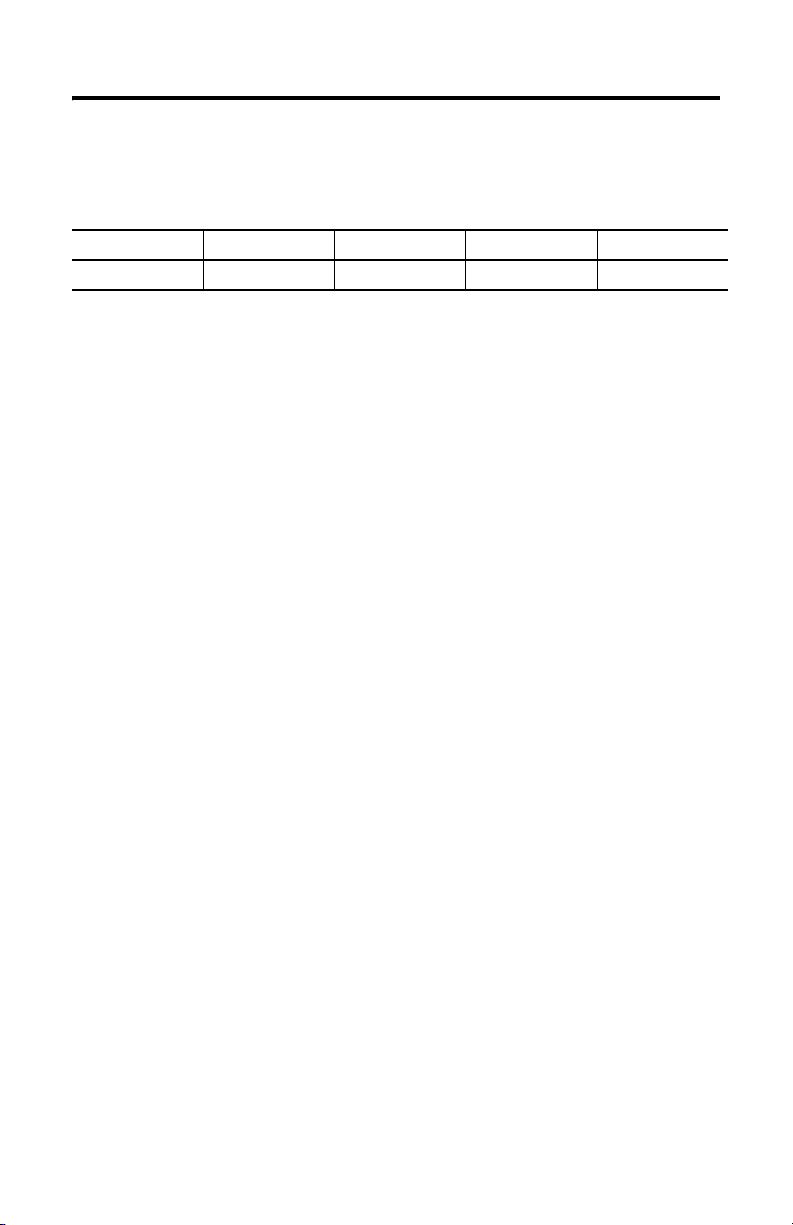

There are four different pressure ranges.

Range 1 2 3 4

Maximum Pressure 100 PSI 50 PSI 20 PSI 10 PSI

Install the Gauge Liquid/Gas Pressure Transmitter

The transmitter mounts on a vertical surface with the pressure ports and cable

entrance on the bottom using the two screw holes on the base of the unit. Ensure

there is enough space around the unit to make the pressure and electrical

connections. Avoid locations with severe vibrations or excessive moisture. The

enclosure has a standard ½” conduit opening and may be installed with either a

conduit coupler or a cable gland type fitting.

Wire and Connect the Gauge Liquid/Gas Pressure Transmitter

Use twisted-pair 18 to 22 AWG shielded wiring for all connections and do not locate

the device wires in the same conduit with wiring used to supply inductive loads

such as motors. Disconnect the power supply before making any connections to

prevent electrical shock or equipment damage. Make all connections in accordance

with national and local electrical codes.

This device is a 3-wire sourcing type transmitter. Connect the positive dc voltage or

the hot side of the ac voltage to the terminal marked PWR. The power supply

common is connected to the terminal marked COM. The device is reverse voltage

protected and will not operate if connected backwards. The analog output signal is

available on the OUT terminal. This signal is jumper selectable for either voltage or

4 to 20 mA output (factory default). In voltage mode, either 0 to 5 or 0 to 10V dc

can also be selected. These options are indicated on the circuit board.

The remote zero feature may be used by wiring a dry-contact (relay only) digital

output to the ZERO terminals. Do not apply voltage to the ZERO terminals.

Plumbing

Use an appropriately rated pressure tubing and arrange it to minimize stress on the

connections. Do not allow material to fall into the pressure ports as contamination

could damage the sensors.

Publication 1414-IN015A-EN-P - October 2005

Page 4

4 Gauge Liquid/Gas Pressure Transmitter

Configure the Gauge Liquid/Gas Pressure Transmitter

As shown on the printed circuit board diagram, push-on jumpers and switches are

used to select the output signal type, the input pressure range and several features.

The device is factory configured to operate in the 4-20 mA output mode but can be

changed to voltage mode by moving the two jumpers from the positions marked

Current to the positions marked Voltage. Always note the current jumper position

first and then move them to the new position. If the jumpers are rotated 90 degrees

and installed incorrectly the product will not work and damage may occur. In

voltage mode the output scale may be changed to either 0-5 or 0-10 Vdc by moving

the single jumper to the 5V or 10V position. The Range and Options switches can

be changed while the unit is operating. However, the output jumpers can only be

changed while the power is removed.

The jumper marked Light is not used. The input pressure range (as shown on the

product label) is set by moving the 4- position slide switch marked RANGE.

Slow damping and analog reverse functions are available by switching the

appropriate DIP switch position to ON.

• Slow Damping

This switch provides an 8-second averaging for surge dampening (normally

it is 4-seconds).

• Output Reverse

This switch reverses the output signal polarity. In reverse mode the analog

output is maximum when the pressure differential is zero and decreases as

pressure increases.

Operation

For normal operation such as 0-100 PSI, the port is used to measure a positive

pressure and 0 PSI = 4 mA and 100 PSI = 20 mA.

Calibration

With the port open to the ambient pressure (or with the port equalized at 0

pressure), press and hold the auto-zero button or provide contact closure on the

ZERO terminals for at least 3 seconds. Release the button or terminals and the

device will calculate and store the new zero point. To protect the unit from

accidental zeroing this feature is enabled only when the detected pressure on the

Publication 1414-IN015A-EN-P - October 2005

Page 5

Gauge Liquid/Gas Pressure Transmitter 5

port is less than 5% of the full range. It is not recommended that the span

calibration be performed in the field unless a high quality calibrator is available.

Optional switch settings. D efault is

Normal (switch set to off).

NO TE: The ra nge and opti ons switc h can be

cha nge d while the unit is pow er e d. Ho weve r,

the output jumpe rs ca n only be cha nge d while

the unit is unpowe red.

Remote zero switch

(optional)

ZERO

ZERO

PWR

OUT

COM

Output, Current or

Voltage.

Commo n is sha red wit h

power s upply

Power in, 24Vac/dc

Commo n is sha red wit h

output

DO NOT CONNECT POWER TO

THE ‘OUT’ TERMINAL AS THE

UNIT WILL BE DAMAGED!

Loop power supply

+ 24 V AC/DC -

Analog Current/

Voltage Input

ANL IN 0 +

ANL IN 0 -

ANL COM

Publication 1414-IN015A-EN-P - October 2005

Page 6

6 Gauge Liquid/Gas Pressure Transmitter

Specifications

Gauge Liquid/Gas Pressure Transmitter Specifications

Specification Value

Media compatibility 17-4 PH stainless steel

Input power 15 … 30 Vdc / 24 Vac nominal

Supply current @ 24 Vdc 35 mA

Output signal 4…20 mA, 0-5 or 0-10 Vdc

Proof pressure Max. 2x F.S. range

Burst pressure Max. 5x F.S. range

Accuracy +/-1 %F.S. (range 4 is +/- 2 %)

Surge damping 4 sec averaging (8 sec for slow)

Long term stability +/-0.25% typical (1 year)

Auto-zero adjust pushbutton and remote input

Sensor operating range -40 … 105 °C (-40 … 220 °F)

Operating environment 0 … 50 °C, 10 … 90 %RH n.c.

Fittings 1/8” NPT female

Enclosure 5” x 5” x 2.25” PVC NEMA 4

Publication 1414-IN015A-EN-P - October 2005

Page 7

Gauge Liquid/Gas Pressure Transmitter 7

All other trademarks are the property of their respective holders, and are hereby acknowledged.

Publication 1414-IN015A-EN-P - October 2005

Page 8

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in

using its products. At http://support.rockwellautomation.com, you can find

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can

also contact a special Customer Support number for initial help in getting your

module up and running:

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning and needs to be returned:

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Publication 1414-IN015A-EN-P - October 2005 PN 40055-245-01(1)

Supersedes Publication XXXX-X.X.X - Month Year Copyright © 2005 Rockwell Autom ation, Inc. All rights reserv ed. Printed in the U.S.A.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Loading...

Loading...